Speed sensor DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2327 of 2895

AUTOMATIC TRANSMISSION - 45RFE/545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 45RFE/545RFE

DESCRIPTION........................489

OPERATION..........................490

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................491

DIAGNOSIS AND TESTING - PRELIMINARY. . 491

DIAGNOSIS AND TESTING - ROAD

TESTING...........................491

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................493

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....494

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................495

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................495

REMOVAL............................495

DISASSEMBLY........................497

CLEANING...........................502

INSPECTION.........................503

ASSEMBLY...........................503

INSTALLATION........................510

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............513

SPECIFICATIONS

TRANSMISSION.....................534

SPECIAL TOOLS

RFE TRANSMISSION.................535

4C RETAINER/BULKHEAD

DISASSEMBLY........................538

ASSEMBLY...........................538

ADAPTER HOUSING SEAL

REMOVAL............................539

INSTALLATION........................539

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................540

OPERATION..........................540

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......540

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................540

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............541

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................541DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................541

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................542

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............542

STANDARD PROCEDURE - TRANSMISSION

FILL...............................544

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................544

REMOVAL............................544

INSTALLATION........................545

ADJUSTMENTS

GEARSHIFT CABLE..................546

HOLDING CLUTCHES

DESCRIPTION........................546

OPERATION..........................546

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................549

OPERATION..........................549

DISASSEMBLY........................550

ASSEMBLY...........................552

INPUT SPEED SENSOR

DESCRIPTION........................558

OPERATION..........................558

REMOVAL............................559

INSTALLATION........................559

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................559

OPERATION..........................559

REMOVAL............................559

INSTALLATION........................560

LOW/REVERSE CLUTCH

DISASSEMBLY........................560

CLEANING...........................561

INSPECTION.........................561

ASSEMBLY...........................561

OIL PUMP

DESCRIPTION........................562

OPERATION..........................562

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................563

DISASSEMBLY........................564

CLEANING...........................566

INSPECTION.........................566

ASSEMBLY...........................566

21 - 488 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2328 of 2895

OIL PUMP FRONT SEAL

REMOVAL............................567

INSTALLATION........................567

OUTPUT SPEED SENSOR

DESCRIPTION........................567

OPERATION..........................567

REMOVAL............................567

INSTALLATION........................567

OVERDRIVE SWITCH

DESCRIPTION........................568

OPERATION..........................568

REMOVAL............................568

INSTALLATION........................569

PISTONS

DESCRIPTION........................569

OPERATION..........................569

PLANETARY GEARTRAIN

DESCRIPTION........................571

OPERATION..........................571

DISASSEMBLY........................573

CLEANING...........................573

INSPECTION.........................573

ASSEMBLY...........................573

SHIFT MECHANISM

DESCRIPTION........................574

OPERATION..........................574

SOLENOID SWITCH VALVE

DESCRIPTION........................574

OPERATION..........................574

SOLENOIDS

DESCRIPTION........................574OPERATION..........................575

TORQUE CONVERTER

DESCRIPTION........................575

OPERATION..........................579

REMOVAL............................580

INSTALLATION........................580

TRANSMISSION CONTROL RELAY

DESCRIPTION........................581

OPERATION..........................581

TRANSMISSION RANGE SENSOR

DESCRIPTION........................581

OPERATION..........................581

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................582

OPERATION..........................582

REMOVAL............................583

INSTALLATION........................583

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................583

OPERATION..........................583

VALVE BODY

DESCRIPTION........................584

OPERATION..........................585

REMOVAL............................585

DISASSEMBLY........................586

CLEANING...........................588

INSPECTION.........................588

ASSEMBLY...........................590

INSTALLATION........................590

AUTOMATIC TRANSMISSION -

45RFE/545RFE

DESCRIPTION

The 45RFE/545RFE automatic transmissions is a

sophisticated, multi-range, electronically controlled

transmission which combines optimized gear ratios

for responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range.

The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

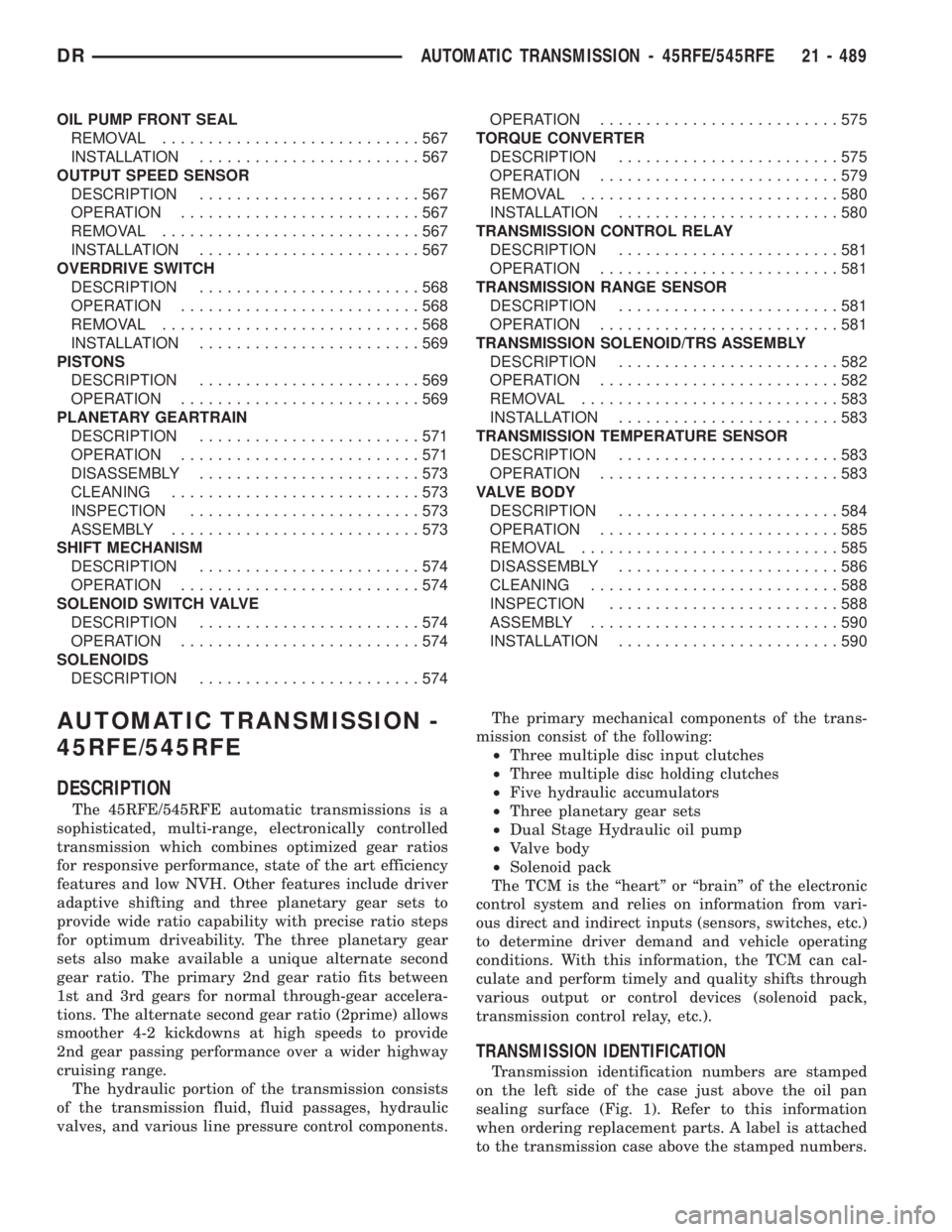

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 489

Page 2329 of 2895

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS

The 45RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

Reverse.............................3.00:1

GEAR RATIOS

The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse.............................3.00:1

OPERATION

The 45RFE/545RFE offers full electronic control of

all automatic up and downshifts, and features real-

time adaptive closed-loop shift and pressure control.

Electronic shift and torque converter clutch controls

help protect the transmission from damage due to

high temperatures, which can occur under severe

operating conditions. By altering shift schedules, line

pressure, and converter clutch control, these controls

reduce heat generation and increase transmission

cooling.

To help reduce efficiency-robbing parasitic losses,

the transmissions includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 45RFE/545RFE pump-pressure

control system monitors input torque and adjusts the

pump pressure accordingly. The primary stage of the

pump works continuously; the second stage is

bypassed when demand is low. The control system

also monitors input and output speed and, if incipi-

ent clutch slip is observed, the pressure control sole-

noid duty cycle is varied, increasing pressure in

proportion to demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 45RFE/545RFE is packaged in

a one-piece die-cast aluminum case. To reduce NVH,

the case has high lateral, vertical and torsional stiff-

ness. It is also designed to maximize the benefit of

the structural dust cover that connects the bottom of

the bell housing to the engine bedplate, enhancing

overall power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRBtscan tool.

Fig. 1 Transmission Part And Serial Number

Location

1 - IDENTIFICATION NUMBERS (STAMPED)

21 - 490 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2335 of 2895

(9) Disconnect and lower or remove any necessary

exhaust components.

(10) Remove the starter motor.

(11) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

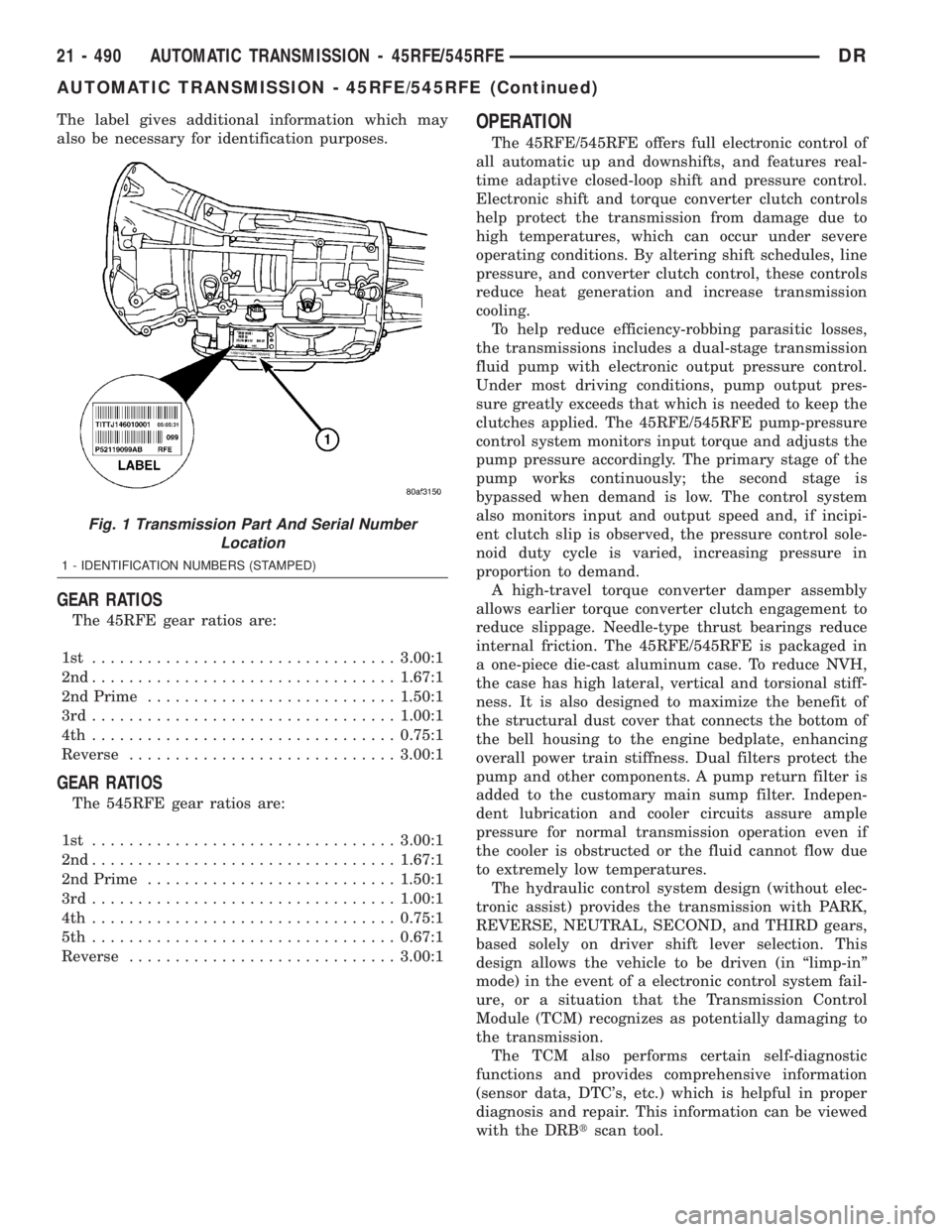

(12) Disengage the output speed sensor connector

from the output speed sensor (Fig. 9).

(13) Disengage the input speed sensor connector

from the input speed sensor (Fig. 10).(14) Disengage the transmission solenoid/TRS

assembly connector from the transmission solenoid/

TRS assembly (Fig. 11).

(15) Disengage the line pressure sensor connector

from the line pressure sensor (Fig. 12).

Fig. 9 Disconnect Output Speed Sensor

1 - TRANSMISSION

2 - OUTPUT SPEED SENSOR

Fig. 10 Disconnect Input Speed Sensor

1 - TRANSMISSION

2 - INPUT SPEED SENSOR

Fig. 11 Disconnect Transmission Solenoid/TRS

Assembly

1 - TRANSMISSION

2 - TRANSMISSION SOLENOID/TRS ASSEMBLY

Fig. 12 Disconnect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

21 - 496 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2336 of 2895

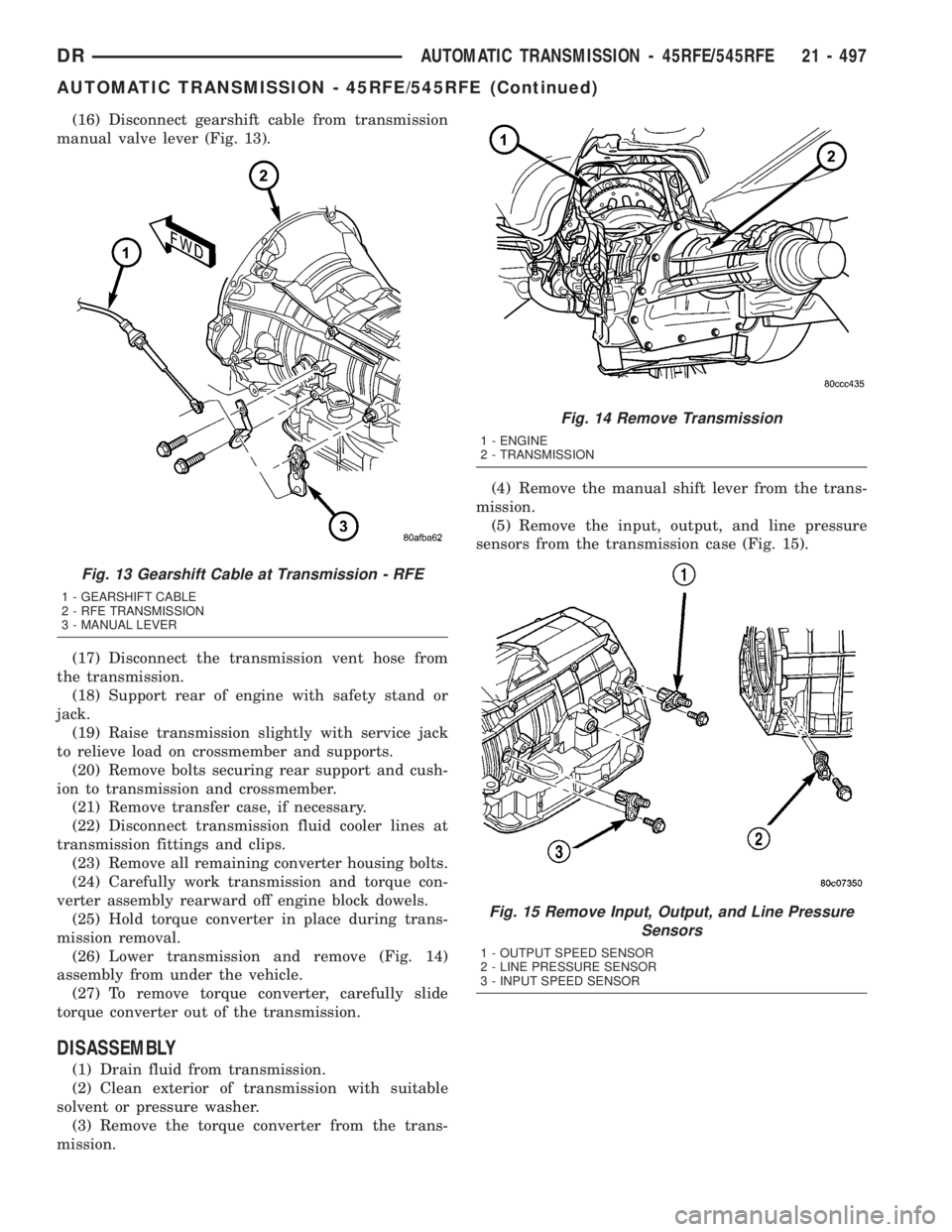

(16) Disconnect gearshift cable from transmission

manual valve lever (Fig. 13).

(17) Disconnect the transmission vent hose from

the transmission.

(18) Support rear of engine with safety stand or

jack.

(19) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(20) Remove bolts securing rear support and cush-

ion to transmission and crossmember.

(21) Remove transfer case, if necessary.

(22) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(23) Remove all remaining converter housing bolts.

(24) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(25) Hold torque converter in place during trans-

mission removal.

(26) Lower transmission and remove (Fig. 14)

assembly from under the vehicle.

(27) To remove torque converter, carefully slide

torque converter out of the transmission.

DISASSEMBLY

(1) Drain fluid from transmission.

(2) Clean exterior of transmission with suitable

solvent or pressure washer.

(3) Remove the torque converter from the trans-

mission.(4) Remove the manual shift lever from the trans-

mission.

(5) Remove the input, output, and line pressure

sensors from the transmission case (Fig. 15).

Fig. 13 Gearshift Cable at Transmission - RFE

1 - GEARSHIFT CABLE

2 - RFE TRANSMISSION

3 - MANUAL LEVER

Fig. 14 Remove Transmission

1 - ENGINE

2 - TRANSMISSION

Fig. 15 Remove Input, Output, and Line Pressure

Sensors

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 497

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2346 of 2895

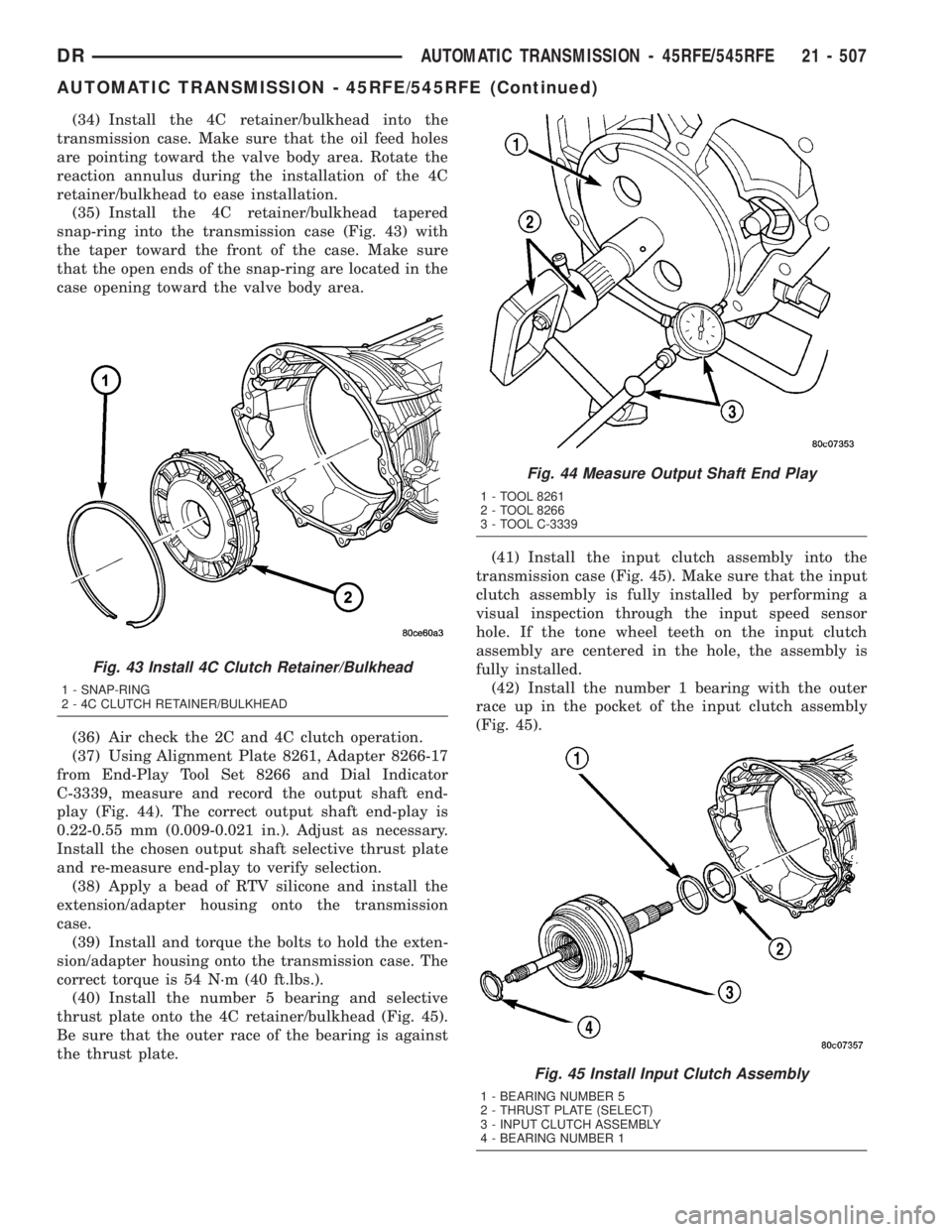

(34) Install the 4C retainer/bulkhead into the

transmission case. Make sure that the oil feed holes

are pointing toward the valve body area. Rotate the

reaction annulus during the installation of the 4C

retainer/bulkhead to ease installation.

(35) Install the 4C retainer/bulkhead tapered

snap-ring into the transmission case (Fig. 43) with

the taper toward the front of the case. Make sure

that the open ends of the snap-ring are located in the

case opening toward the valve body area.

(36) Air check the 2C and 4C clutch operation.

(37) Using Alignment Plate 8261, Adapter 8266-17

from End-Play Tool Set 8266 and Dial Indicator

C-3339, measure and record the output shaft end-

play (Fig. 44). The correct output shaft end-play is

0.22-0.55 mm (0.009-0.021 in.). Adjust as necessary.

Install the chosen output shaft selective thrust plate

and re-measure end-play to verify selection.

(38) Apply a bead of RTV silicone and install the

extension/adapter housing onto the transmission

case.

(39) Install and torque the bolts to hold the exten-

sion/adapter housing onto the transmission case. The

correct torque is 54 N´m (40 ft.lbs.).

(40) Install the number 5 bearing and selective

thrust plate onto the 4C retainer/bulkhead (Fig. 45).

Be sure that the outer race of the bearing is against

the thrust plate.(41) Install the input clutch assembly into the

transmission case (Fig. 45). Make sure that the input

clutch assembly is fully installed by performing a

visual inspection through the input speed sensor

hole. If the tone wheel teeth on the input clutch

assembly are centered in the hole, the assembly is

fully installed.

(42) Install the number 1 bearing with the outer

race up in the pocket of the input clutch assembly

(Fig. 45).

Fig. 43 Install 4C Clutch Retainer/Bulkhead

1 - SNAP-RING

2 - 4C CLUTCH RETAINER/BULKHEAD

Fig. 44 Measure Output Shaft End Play

1 - TOOL 8261

2 - TOOL 8266

3 - TOOL C-3339

Fig. 45 Install Input Clutch Assembly

1 - BEARING NUMBER 5

2 - THRUST PLATE (SELECT)

3 - INPUT CLUTCH ASSEMBLY

4 - BEARING NUMBER 1

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 507

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2348 of 2895

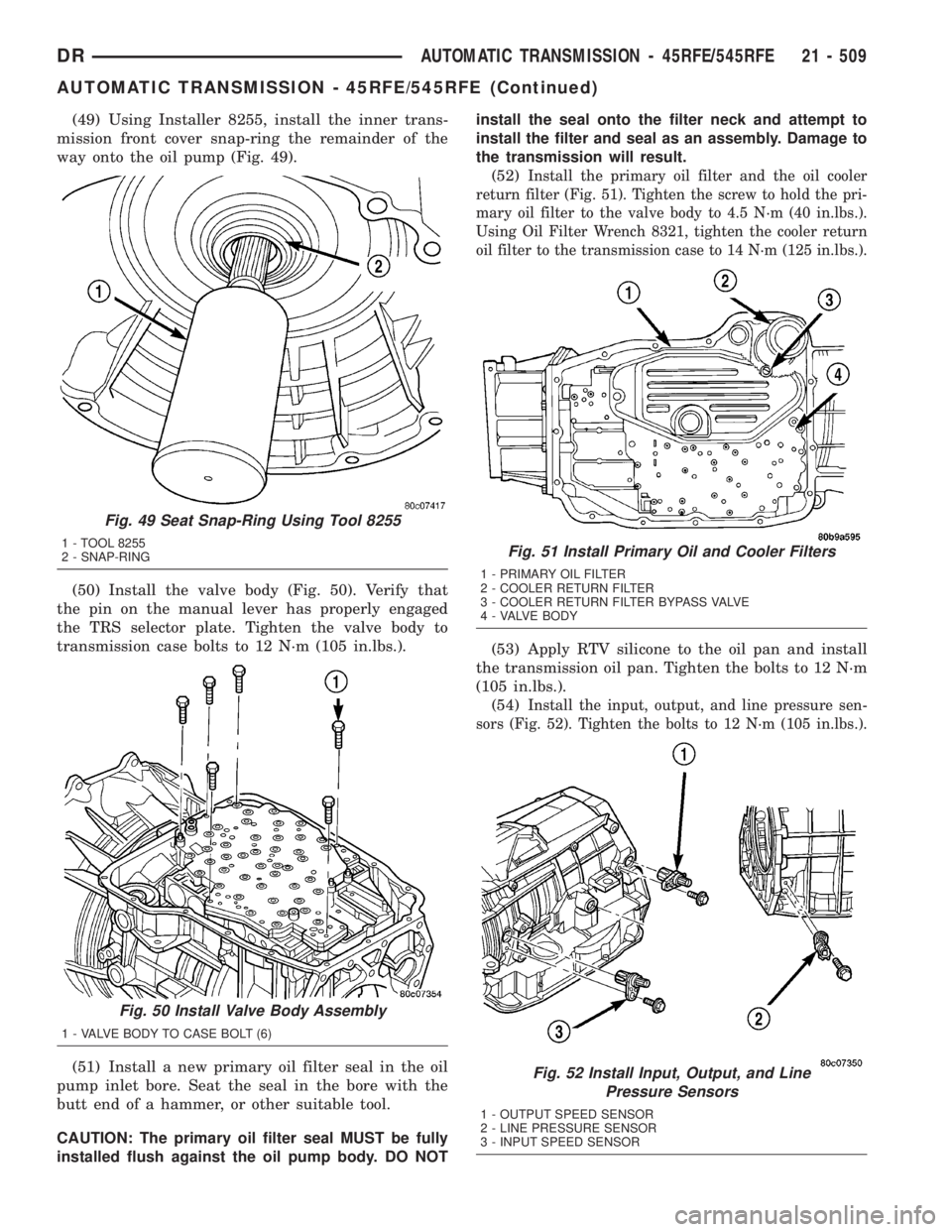

(49) Using Installer 8255, install the inner trans-

mission front cover snap-ring the remainder of the

way onto the oil pump (Fig. 49).

(50) Install the valve body (Fig. 50). Verify that

the pin on the manual lever has properly engaged

the TRS selector plate. Tighten the valve body to

transmission case bolts to 12 N´m (105 in.lbs.).

(51) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOTinstall the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(52)

Install the primary oil filter and the oil cooler

return filter (Fig. 51). Tighten the screw to hold the pri-

mary oil filter to the valve body to 4.5 N´m (40 in.lbs.).

Using Oil Filter Wrench 8321, tighten the cooler return

oil filter to the transmission case to 14 N´m (125 in.lbs.).

(53) Apply RTV silicone to the oil pan and install

the transmission oil pan. Tighten the bolts to 12 N´m

(105 in.lbs.).

(54)

Install the input, output, and line pressure sen-

sors (Fig. 52). Tighten the bolts to 12 N´m (105 in.lbs.).

Fig. 49 Seat Snap-Ring Using Tool 8255

1 - TOOL 8255

2 - SNAP-RING

Fig. 50 Install Valve Body Assembly

1 - VALVE BODY TO CASE BOLT (6)

Fig. 51 Install Primary Oil and Cooler Filters

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

Fig. 52 Install Input, Output, and Line

Pressure Sensors

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 509

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2350 of 2895

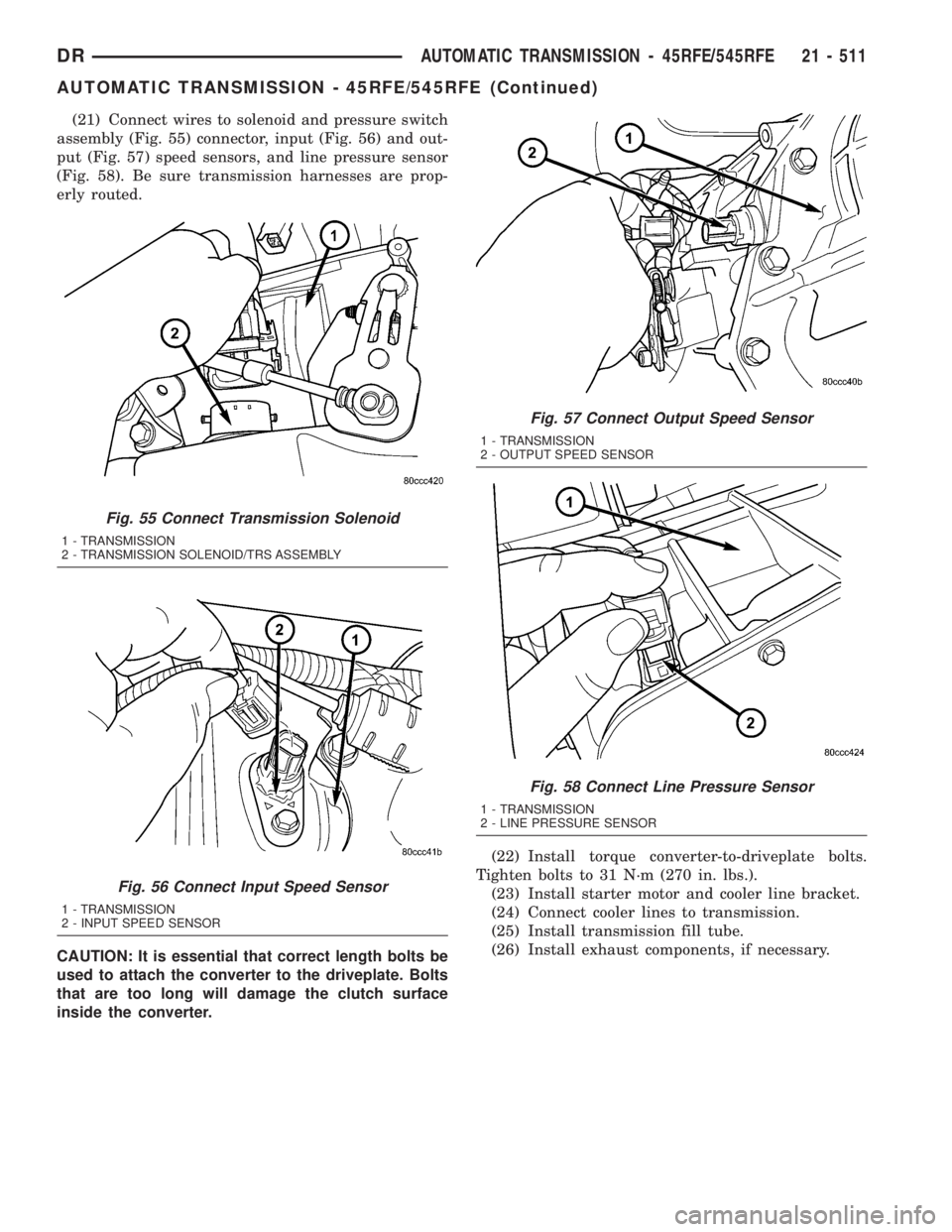

(21) Connect wires to solenoid and pressure switch

assembly (Fig. 55) connector, input (Fig. 56) and out-

put (Fig. 57) speed sensors, and line pressure sensor

(Fig. 58). Be sure transmission harnesses are prop-

erly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.(22) Install torque converter-to-driveplate bolts.

Tighten bolts to 31 N´m (270 in. lbs.).

(23) Install starter motor and cooler line bracket.

(24) Connect cooler lines to transmission.

(25) Install transmission fill tube.

(26) Install exhaust components, if necessary.

Fig. 55 Connect Transmission Solenoid

1 - TRANSMISSION

2 - TRANSMISSION SOLENOID/TRS ASSEMBLY

Fig. 56 Connect Input Speed Sensor

1 - TRANSMISSION

2 - INPUT SPEED SENSOR

Fig. 57 Connect Output Speed Sensor

1 - TRANSMISSION

2 - OUTPUT SPEED SENSOR

Fig. 58 Connect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 511

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2373 of 2895

SPECIFICATIONS

TRANSMISSION

GENERAL

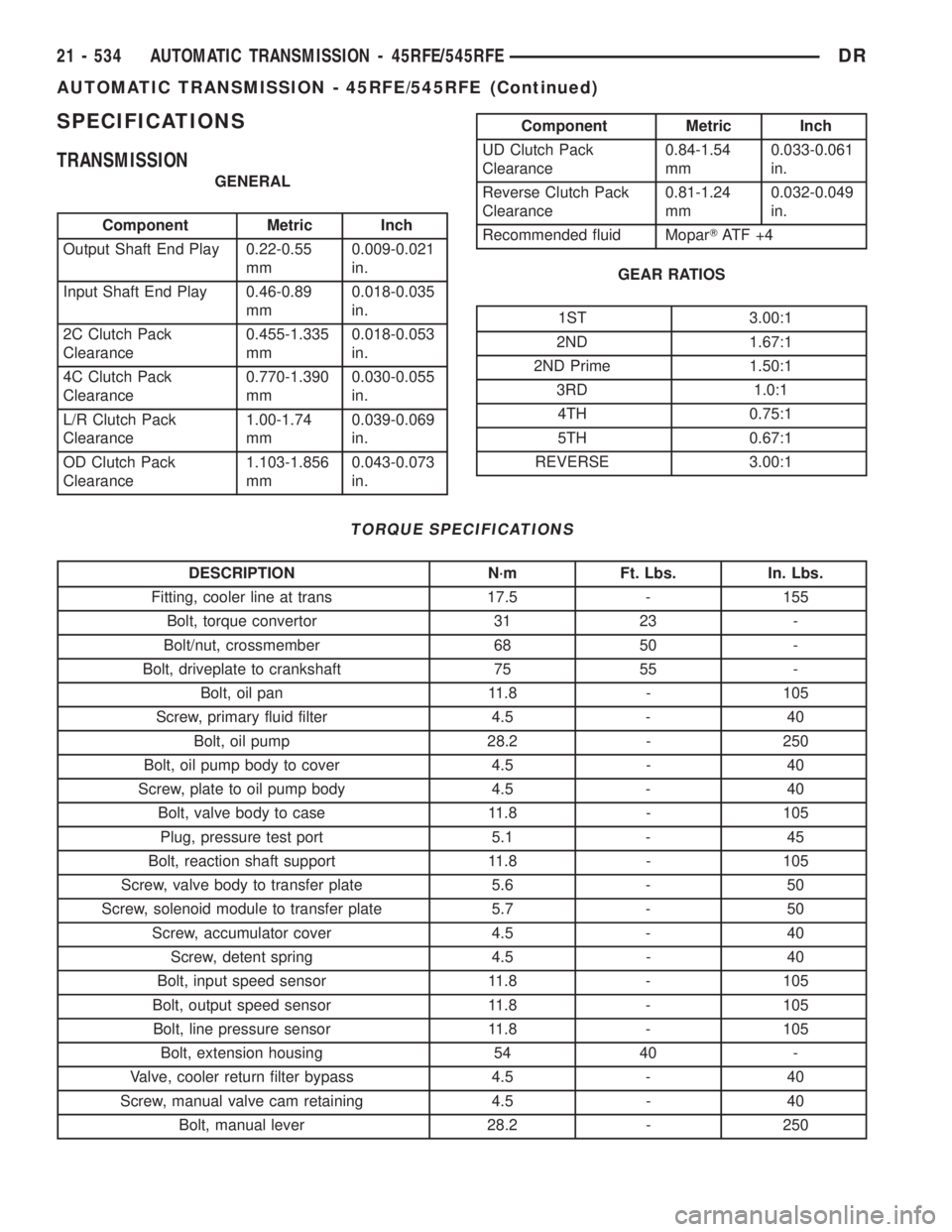

Component Metric Inch

Output Shaft End Play 0.22-0.55

mm0.009-0.021

in.

Input Shaft End Play 0.46-0.89

mm0.018-0.035

in.

2C Clutch Pack

Clearance0.455-1.335

mm0.018-0.053

in.

4C Clutch Pack

Clearance0.770-1.390

mm0.030-0.055

in.

L/R Clutch Pack

Clearance1.00-1.74

mm0.039-0.069

in.

OD Clutch Pack

Clearance1.103-1.856

mm0.043-0.073

in.

Component Metric Inch

UD Clutch Pack

Clearance0.84-1.54

mm0.033-0.061

in.

Reverse Clutch Pack

Clearance0.81-1.24

mm0.032-0.049

in.

Recommended fluid MoparTAT F + 4

GEAR RATIOS

1ST 3.00:1

2ND 1.67:1

2ND Prime 1.50:1

3RD 1.0:1

4TH 0.75:1

5TH 0.67:1

REVERSE 3.00:1

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fitting, cooler line at trans 17.5 - 155

Bolt, torque convertor 31 23 -

Bolt/nut, crossmember 68 50 -

Bolt, driveplate to crankshaft 75 55 -

Bolt, oil pan 11.8 - 105

Screw, primary fluid filter 4.5 - 40

Bolt, oil pump 28.2 - 250

Bolt, oil pump body to cover 4.5 - 40

Screw, plate to oil pump body 4.5 - 40

Bolt, valve body to case 11.8 - 105

Plug, pressure test port 5.1 - 45

Bolt, reaction shaft support 11.8 - 105

Screw, valve body to transfer plate 5.6 - 50

Screw, solenoid module to transfer plate 5.7 - 50

Screw, accumulator cover 4.5 - 40

Screw, detent spring 4.5 - 40

Bolt, input speed sensor 11.8 - 105

Bolt, output speed sensor 11.8 - 105

Bolt, line pressure sensor 11.8 - 105

Bolt, extension housing 54 40 -

Valve, cooler return filter bypass 4.5 - 40

Screw, manual valve cam retaining 4.5 - 40

Bolt, manual lever 28.2 - 250

21 - 534 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2381 of 2895

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should be replaced whenever

a failure generates sludge and debris. This is neces-

sary because normal converter flushing procedures

will not remove all contaminants.

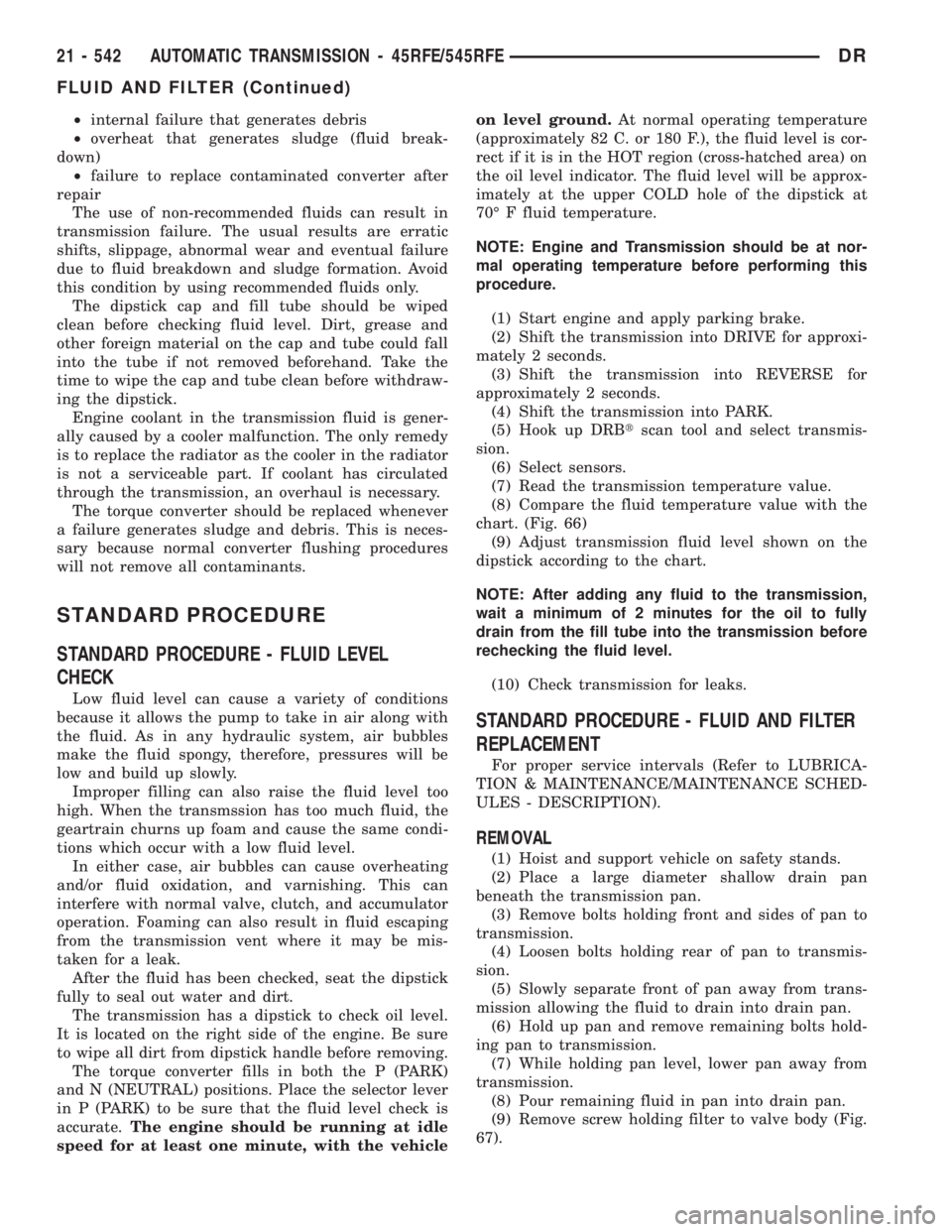

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicleon level ground.At normal operating temperature

(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5) Hook up DRBtscan tool and select transmis-

sion.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

chart. (Fig. 66)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4) Loosen bolts holding rear of pan to transmis-

sion.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

(9) Remove screw holding filter to valve body (Fig.

67).

21 - 542 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

FLUID AND FILTER (Continued)