DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1721 of 2895

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................24

INSTALLATION.........................24

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................25

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................29

INSTALLATION.........................30

FUEL INJECTOR

DESCRIPTION.........................32

OPERATION

OPERATION - FUEL INJECTOR..........32

OPERATION - PCM OUTPUT............32

REMOVAL.............................32

INSTALLATION.........................33

FUEL PUMP RELAY

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................34INSTALLATION.........................35

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................38

MAP SENSOR

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................42

OXYGEN SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................44

INSTALLATION.........................45

THROTTLE BODY

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................47

THROTTLE CONTROL CABLE

REMOVAL.............................49

INSTALLATION.........................51

THROTTLE POSITION SENSOR

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................53

INSTALLATION.........................54

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

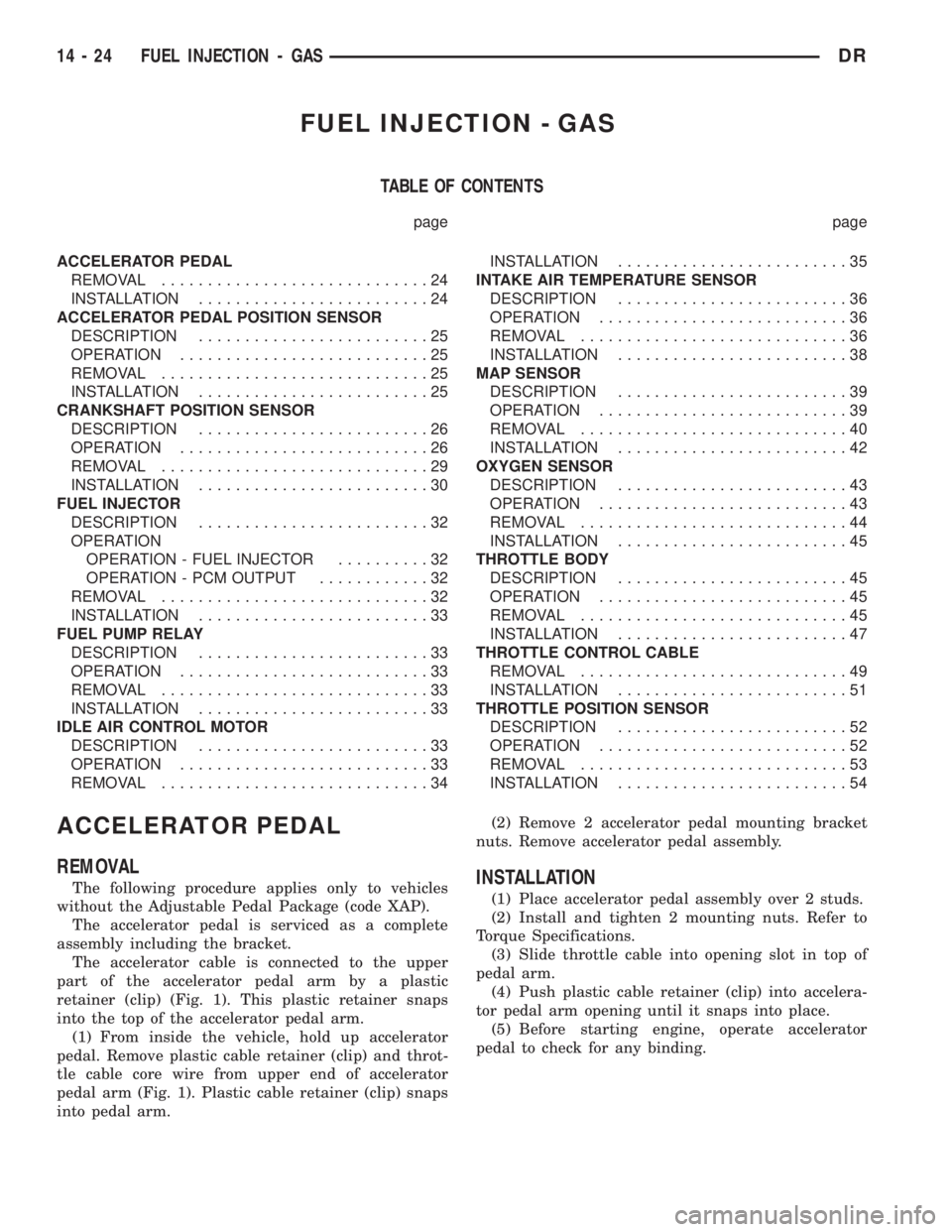

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

14 - 24 FUEL INJECTION - GASDR

Page 1722 of 2895

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

The Accelerator Pedal Position Sensor (APPS)

assembly is located under the vehicle battery tray. A

cable connects the assembly to the accelerator pedal.

A plastic cover with a movable door is used to cover

the assembly.

The APPS is used only with the 5.7L V-8 engine.

OPERATION

The Accelerator Pedal Position Sensor (APPS) is a

linear potentiometer. It provides the Powertrain Con-

trol Module (PCM) with a DC voltage signal propor-

tional to the angle, or position of the accelerator

pedal. The APPS signal is translated (along with

other sensors) to place the throttle plate (within the

throttle body) to a pre-determined position.

A mechanical cable is used between the accelerator

pedal and the APPS assembly. Although a cable is

used between the pedal and APPS, a mechanical

cable is not used at the throttle body. Throttle plate

position is electrically determined.

REMOVAL

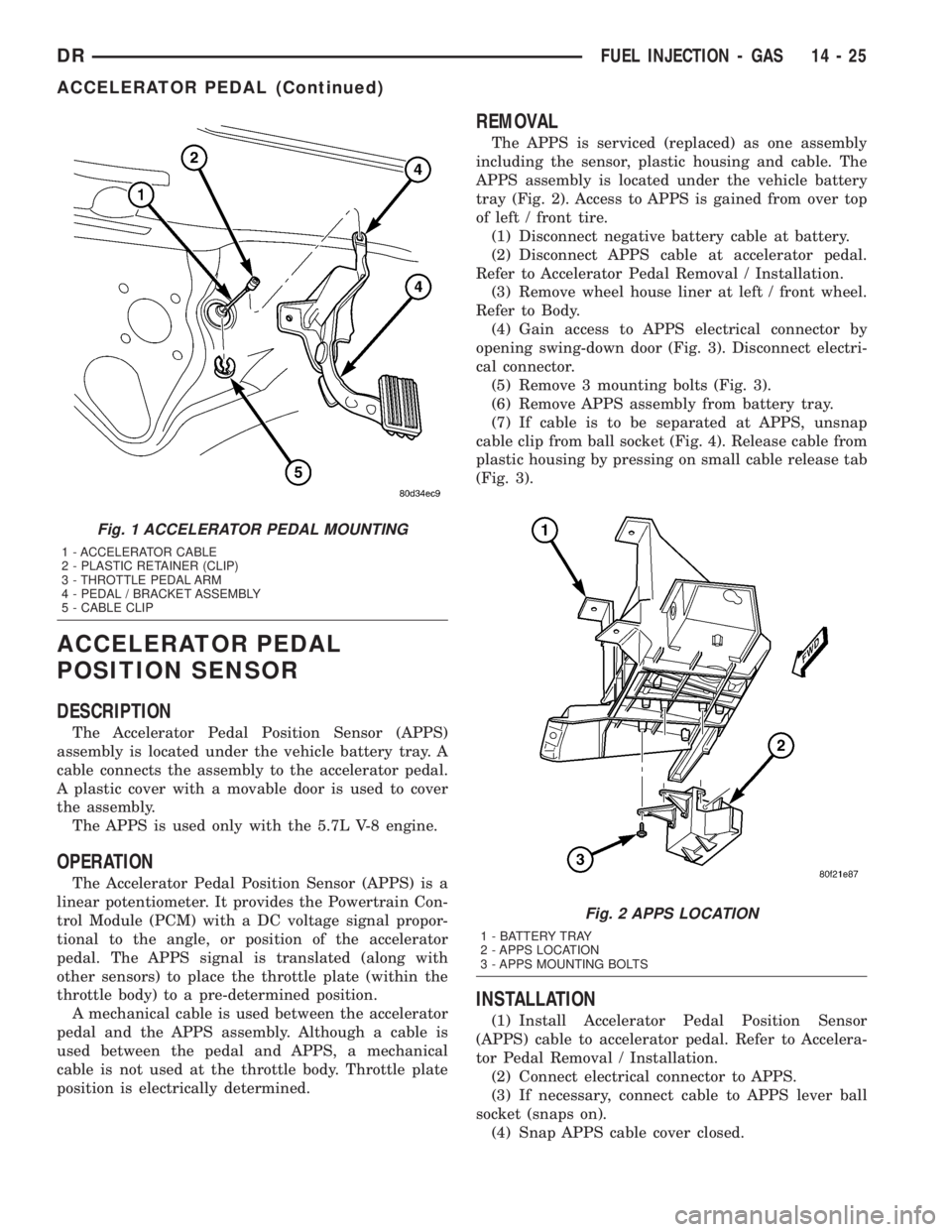

The APPS is serviced (replaced) as one assembly

including the sensor, plastic housing and cable. The

APPS assembly is located under the vehicle battery

tray (Fig. 2). Access to APPS is gained from over top

of left / front tire.

(1) Disconnect negative battery cable at battery.

(2) Disconnect APPS cable at accelerator pedal.

Refer to Accelerator Pedal Removal / Installation.

(3) Remove wheel house liner at left / front wheel.

Refer to Body.

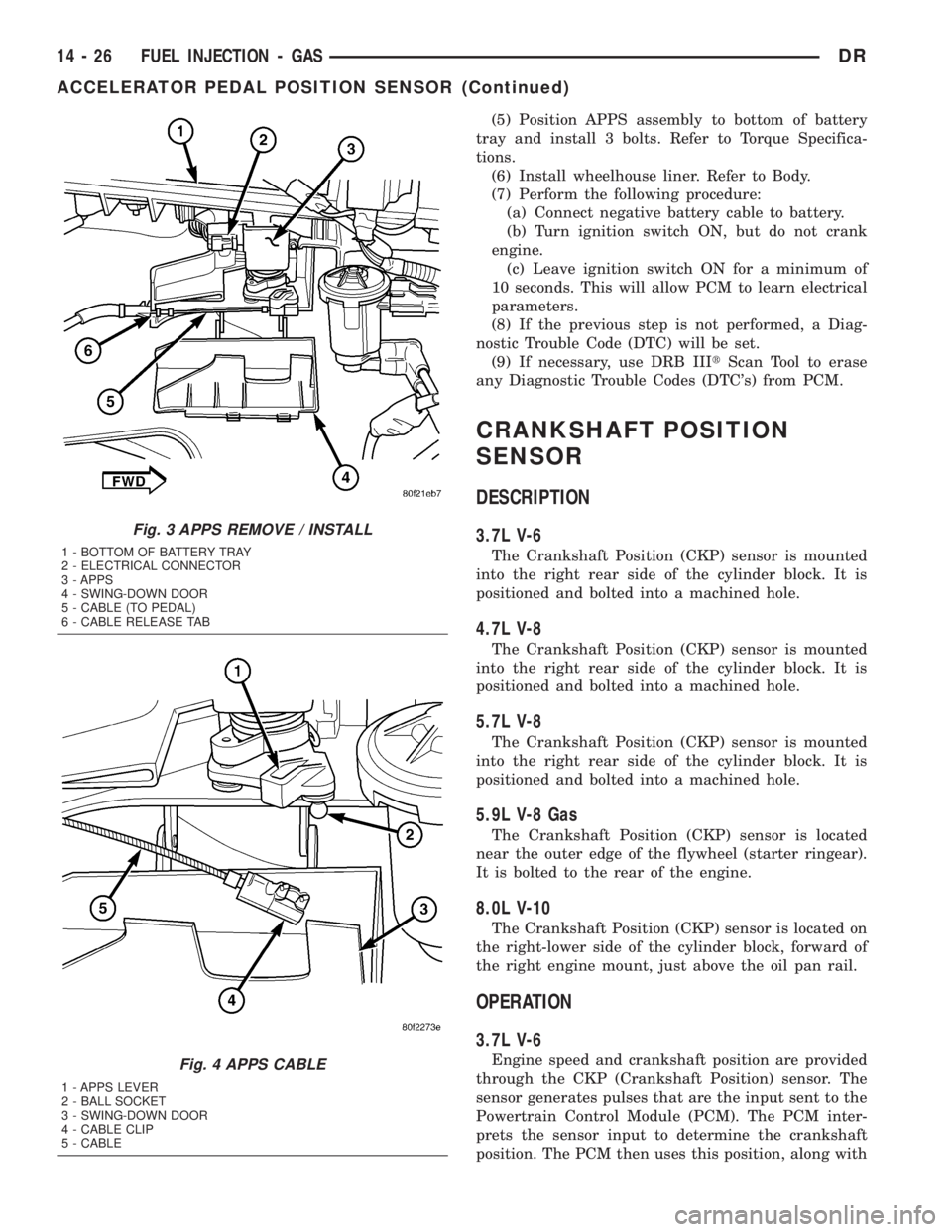

(4) Gain access to APPS electrical connector by

opening swing-down door (Fig. 3). Disconnect electri-

cal connector.

(5) Remove 3 mounting bolts (Fig. 3).

(6) Remove APPS assembly from battery tray.

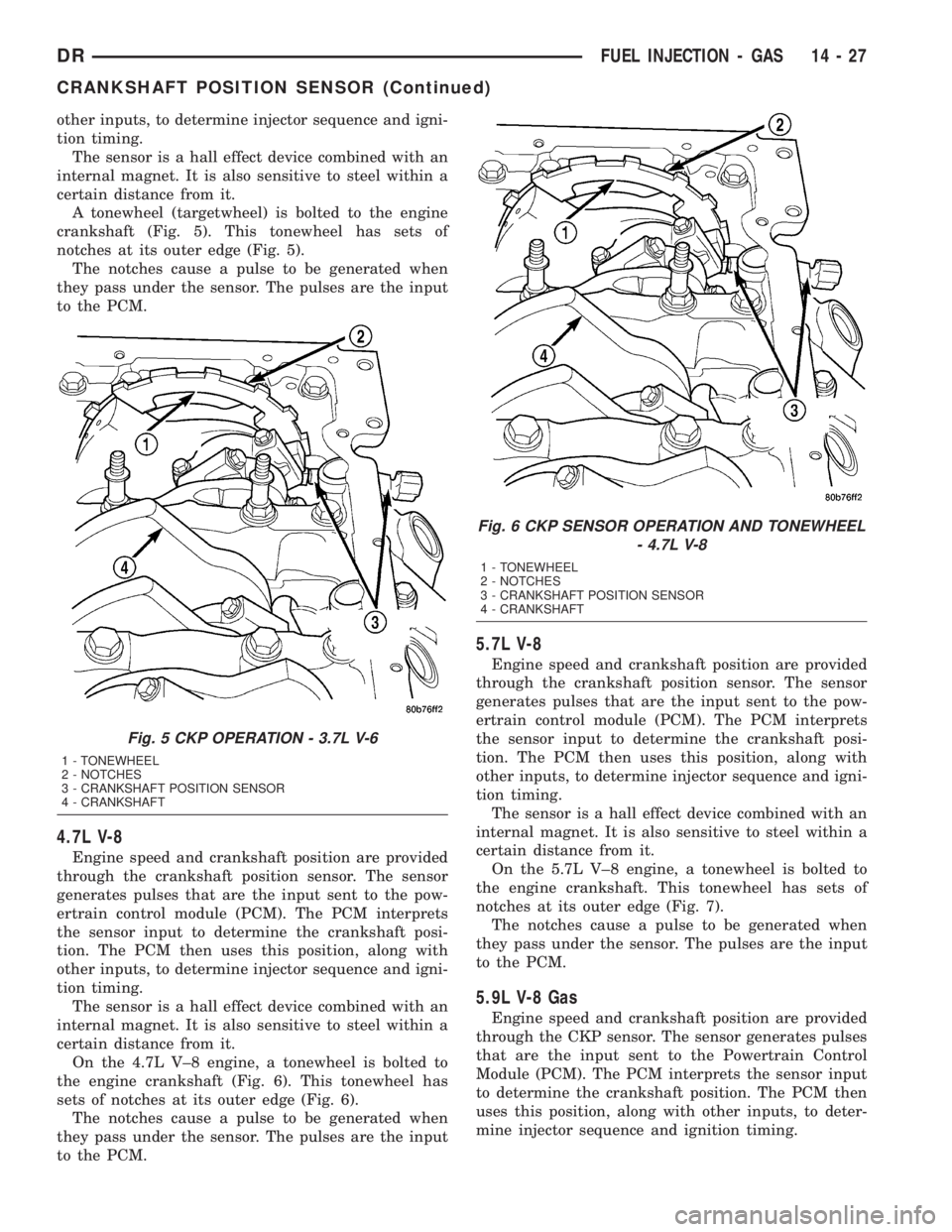

(7) If cable is to be separated at APPS, unsnap

cable clip from ball socket (Fig. 4). Release cable from

plastic housing by pressing on small cable release tab

(Fig. 3).

INSTALLATION

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

Fig. 1 ACCELERATOR PEDAL MOUNTING

1 - ACCELERATOR CABLE

2 - PLASTIC RETAINER (CLIP)

3 - THROTTLE PEDAL ARM

4 - PEDAL / BRACKET ASSEMBLY

5 - CABLE CLIP

Fig. 2 APPS LOCATION

1 - BATTERY TRAY

2 - APPS LOCATION

3 - APPS MOUNTING BOLTS

DRFUEL INJECTION - GAS 14 - 25

ACCELERATOR PEDAL (Continued)

Page 1723 of 2895

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.9L V-8 Gas

The Crankshaft Position (CKP) sensor is located

near the outer edge of the flywheel (starter ringear).

It is bolted to the rear of the engine.

8.0L V-10

The Crankshaft Position (CKP) sensor is located on

the right-lower side of the cylinder block, forward of

the right engine mount, just above the oil pan rail.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

14 - 26 FUEL INJECTION - GASDR

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1724 of 2895

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

A tonewheel (targetwheel) is bolted to the engine

crankshaft (Fig. 5). This tonewheel has sets of

notches at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

4.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 4.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft (Fig. 6). This tonewheel has

sets of notches at its outer edge (Fig. 6).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

5.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

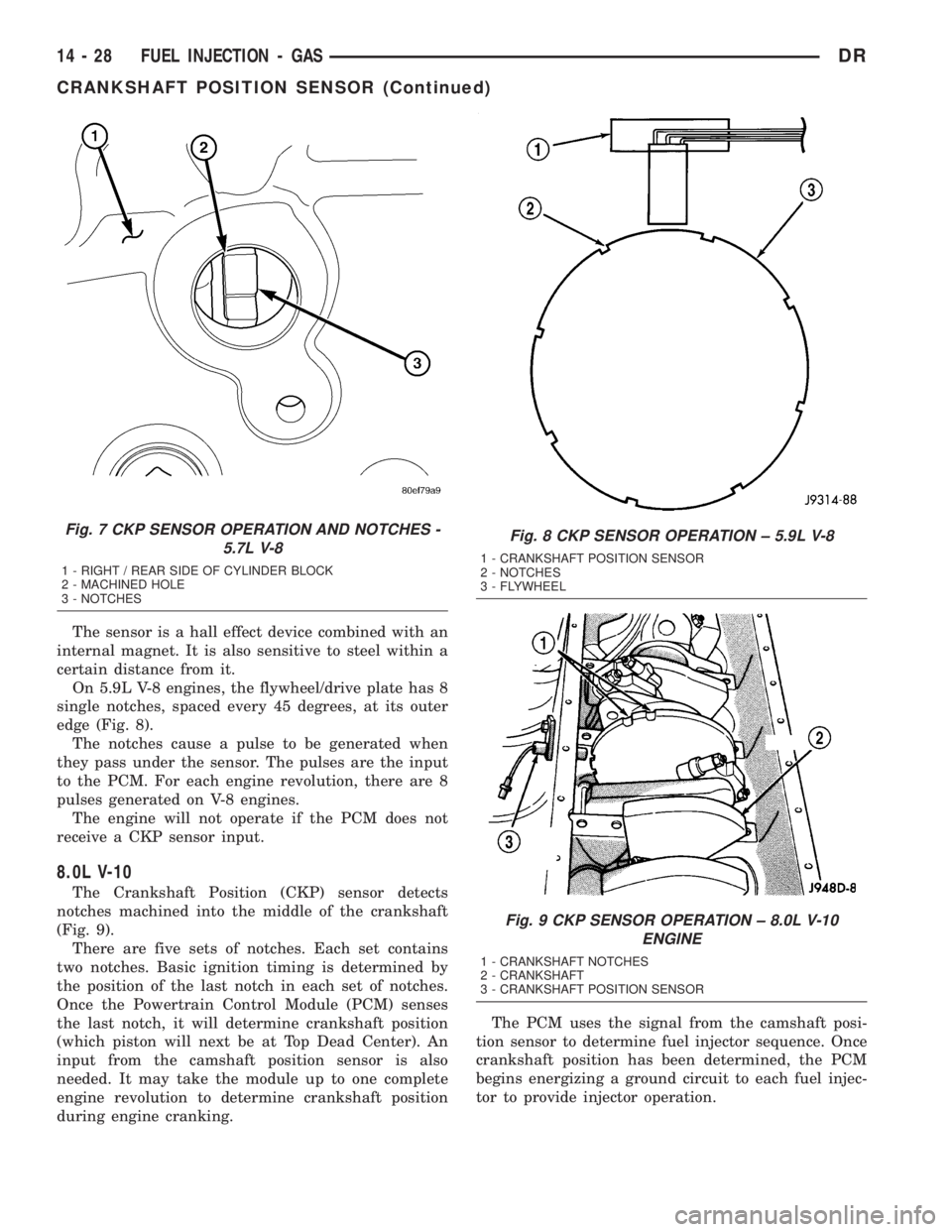

On the 5.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft. This tonewheel has sets of

notches at its outer edge (Fig. 7).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

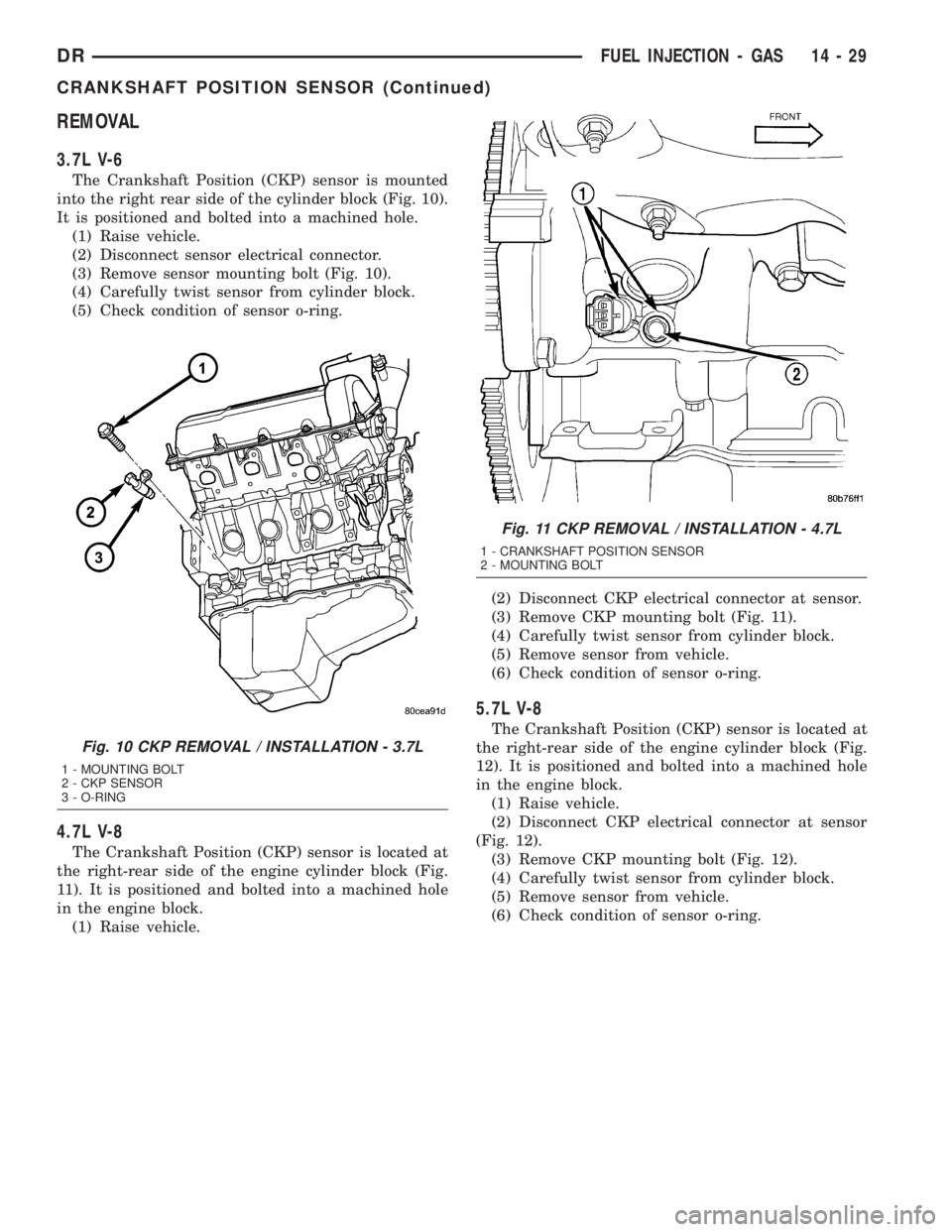

5.9L V-8 Gas

Engine speed and crankshaft position are provided

through the CKP sensor. The sensor generates pulses

that are the input sent to the Powertrain Control

Module (PCM). The PCM interprets the sensor input

to determine the crankshaft position. The PCM then

uses this position, along with other inputs, to deter-

mine injector sequence and ignition timing.

Fig. 5 CKP OPERATION - 3.7L V-6

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

Fig. 6 CKP SENSOR OPERATION AND TONEWHEEL

- 4.7L V-8

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

DRFUEL INJECTION - GAS 14 - 27

CRANKSHAFT POSITION SENSOR (Continued)

Page 1725 of 2895

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On 5.9L V-8 engines, the flywheel/drive plate has 8

single notches, spaced every 45 degrees, at its outer

edge (Fig. 8).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM. For each engine revolution, there are 8

pulses generated on V-8 engines.

The engine will not operate if the PCM does not

receive a CKP sensor input.

8.0L V-10

The Crankshaft Position (CKP) sensor detects

notches machined into the middle of the crankshaft

(Fig. 9).

There are five sets of notches. Each set contains

two notches. Basic ignition timing is determined by

the position of the last notch in each set of notches.

Once the Powertrain Control Module (PCM) senses

the last notch, it will determine crankshaft position

(which piston will next be at Top Dead Center). An

input from the camshaft position sensor is also

needed. It may take the module up to one complete

engine revolution to determine crankshaft position

during engine cranking.The PCM uses the signal from the camshaft posi-

tion sensor to determine fuel injector sequence. Once

crankshaft position has been determined, the PCM

begins energizing a ground circuit to each fuel injec-

tor to provide injector operation.

Fig. 7 CKP SENSOR OPERATION AND NOTCHES -

5.7L V-8

1 - RIGHT / REAR SIDE OF CYLINDER BLOCK

2 - MACHINED HOLE

3 - NOTCHES

Fig. 8 CKP SENSOR OPERATION ± 5.9L V-8

1 - CRANKSHAFT POSITION SENSOR

2 - NOTCHES

3 - FLYWHEEL

Fig. 9 CKP SENSOR OPERATION ± 8.0L V-10

ENGINE

1 - CRANKSHAFT NOTCHES

2 - CRANKSHAFT

3 - CRANKSHAFT POSITION SENSOR

14 - 28 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1726 of 2895

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block (Fig. 10).

It is positioned and bolted into a machined hole.

(1) Raise vehicle.

(2) Disconnect sensor electrical connector.

(3) Remove sensor mounting bolt (Fig. 10).

(4) Carefully twist sensor from cylinder block.

(5) Check condition of sensor o-ring.

4.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

11). It is positioned and bolted into a machined hole

in the engine block.

(1) Raise vehicle.(2) Disconnect CKP electrical connector at sensor.

(3) Remove CKP mounting bolt (Fig. 11).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

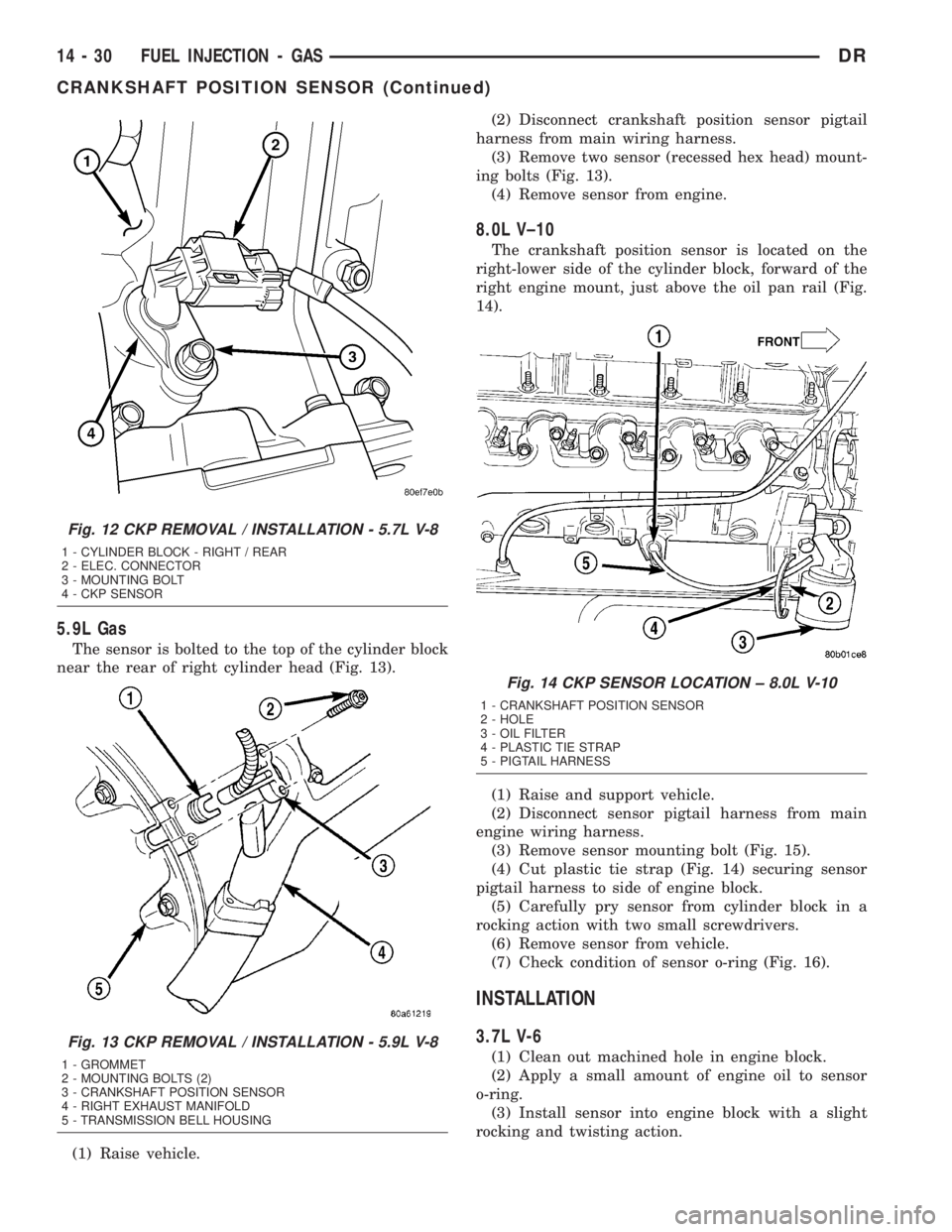

5.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

12). It is positioned and bolted into a machined hole

in the engine block.

(1) Raise vehicle.

(2) Disconnect CKP electrical connector at sensor

(Fig. 12).

(3) Remove CKP mounting bolt (Fig. 12).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

Fig. 10 CKP REMOVAL / INSTALLATION - 3.7L

1 - MOUNTING BOLT

2 - CKP SENSOR

3 - O-RING

Fig. 11 CKP REMOVAL / INSTALLATION - 4.7L

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

DRFUEL INJECTION - GAS 14 - 29

CRANKSHAFT POSITION SENSOR (Continued)

Page 1727 of 2895

5.9L Gas

The sensor is bolted to the top of the cylinder block

near the rear of right cylinder head (Fig. 13).

(1) Raise vehicle.(2) Disconnect crankshaft position sensor pigtail

harness from main wiring harness.

(3) Remove two sensor (recessed hex head) mount-

ing bolts (Fig. 13).

(4) Remove sensor from engine.

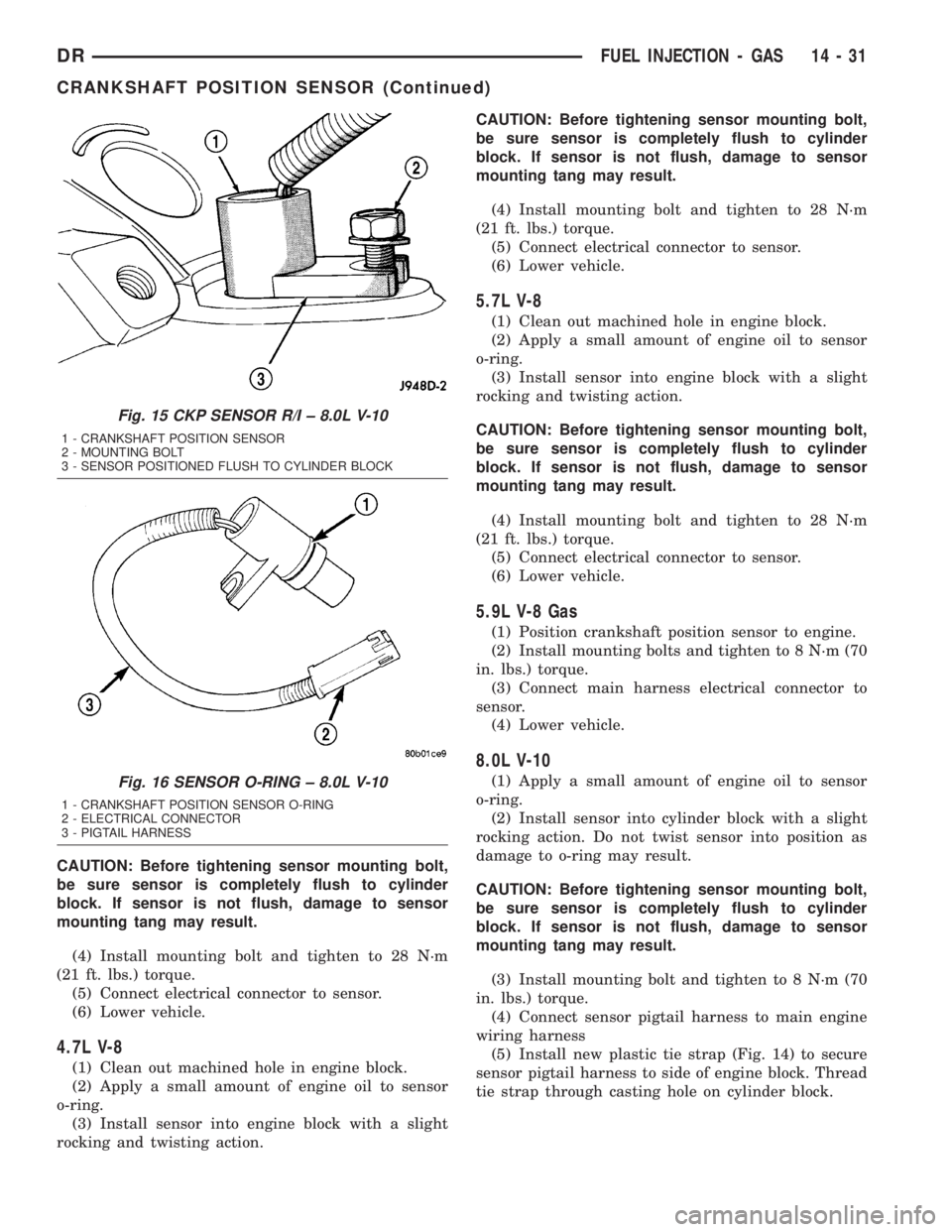

8.0L V±10

The crankshaft position sensor is located on the

right-lower side of the cylinder block, forward of the

right engine mount, just above the oil pan rail (Fig.

14).

(1) Raise and support vehicle.

(2) Disconnect sensor pigtail harness from main

engine wiring harness.

(3) Remove sensor mounting bolt (Fig. 15).

(4) Cut plastic tie strap (Fig. 14) securing sensor

pigtail harness to side of engine block.

(5) Carefully pry sensor from cylinder block in a

rocking action with two small screwdrivers.

(6) Remove sensor from vehicle.

(7) Check condition of sensor o-ring (Fig. 16).

INSTALLATION

3.7L V-6

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

Fig. 12 CKP REMOVAL / INSTALLATION - 5.7L V-8

1 - CYLINDER BLOCK - RIGHT / REAR

2 - ELEC. CONNECTOR

3 - MOUNTING BOLT

4 - CKP SENSOR

Fig. 13 CKP REMOVAL / INSTALLATION - 5.9L V-8

1 - GROMMET

2 - MOUNTING BOLTS (2)

3 - CRANKSHAFT POSITION SENSOR

4 - RIGHT EXHAUST MANIFOLD

5 - TRANSMISSION BELL HOUSING

Fig. 14 CKP SENSOR LOCATION ± 8.0L V-10

1 - CRANKSHAFT POSITION SENSOR

2 - HOLE

3 - OIL FILTER

4 - PLASTIC TIE STRAP

5 - PIGTAIL HARNESS

14 - 30 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1728 of 2895

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

4.7L V-8

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

5.7L V-8

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Lower vehicle.

5.9L V-8 Gas

(1) Position crankshaft position sensor to engine.

(2) Install mounting bolts and tighten to 8 N´m (70

in. lbs.) torque.

(3) Connect main harness electrical connector to

sensor.

(4) Lower vehicle.

8.0L V-10

(1) Apply a small amount of engine oil to sensor

o-ring.

(2) Install sensor into cylinder block with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(3) Install mounting bolt and tighten to 8 N´m (70

in. lbs.) torque.

(4) Connect sensor pigtail harness to main engine

wiring harness

(5) Install new plastic tie strap (Fig. 14) to secure

sensor pigtail harness to side of engine block. Thread

tie strap through casting hole on cylinder block.

Fig. 15 CKP SENSOR R/I ± 8.0L V-10

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

3 - SENSOR POSITIONED FLUSH TO CYLINDER BLOCK

Fig. 16 SENSOR O-RING ± 8.0L V-10

1 - CRANKSHAFT POSITION SENSOR O-RING

2 - ELECTRICAL CONNECTOR

3 - PIGTAIL HARNESS

DRFUEL INJECTION - GAS 14 - 31

CRANKSHAFT POSITION SENSOR (Continued)

Page 1729 of 2895

FUEL INJECTOR

DESCRIPTION

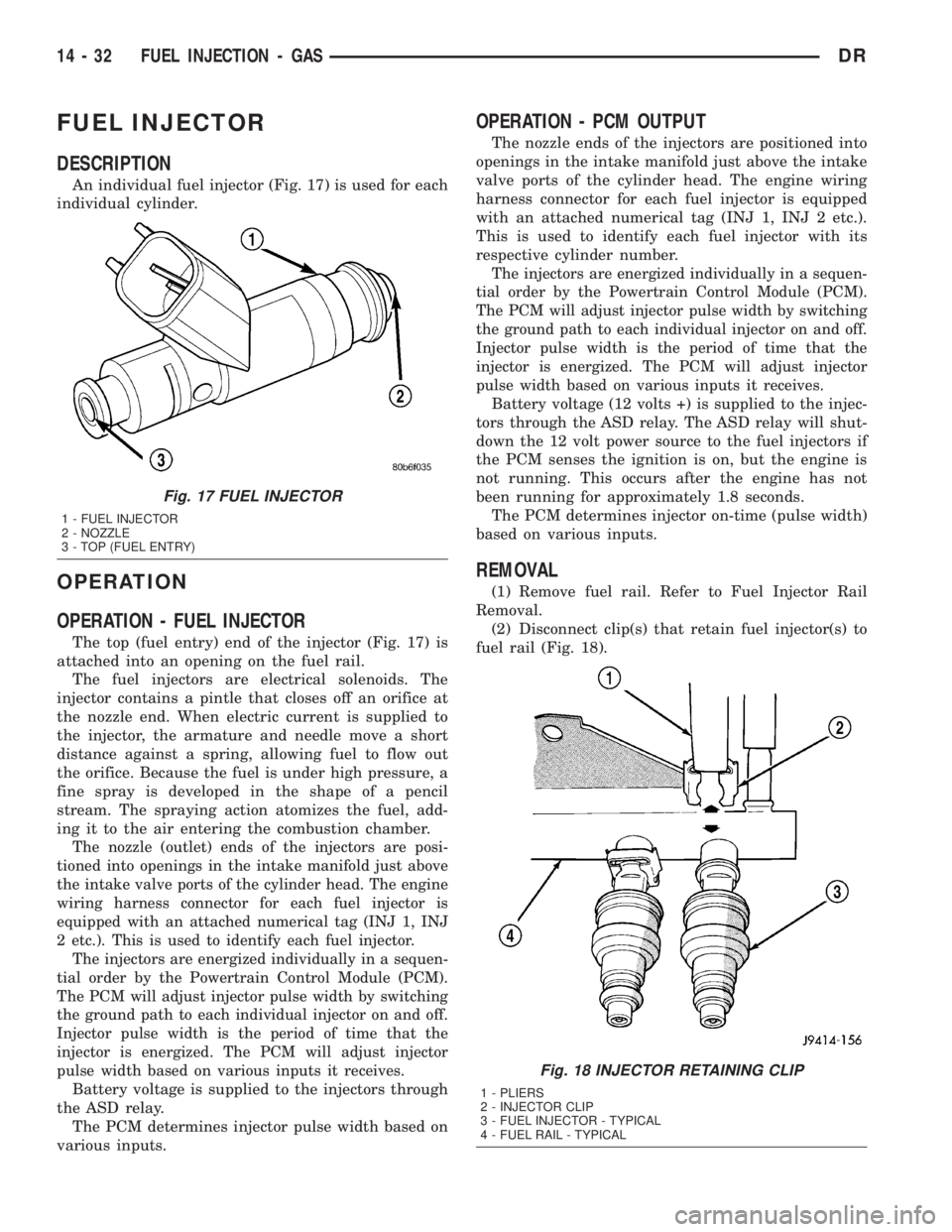

An individual fuel injector (Fig. 17) is used for each

individual cylinder.

OPERATION

OPERATION - FUEL INJECTOR

The top (fuel entry) end of the injector (Fig. 17) is

attached into an opening on the fuel rail.

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just above

the intake valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is

equipped with an attached numerical tag (INJ 1, INJ

2 etc.). This is used to identify each fuel injector.

The injectors are energized individually in a sequen-

tial order by the Powertrain Control Module (PCM).

The PCM will adjust injector pulse width by switching

the ground path to each individual injector on and off.

Injector pulse width is the period of time that the

injector is energized. The PCM will adjust injector

pulse width based on various inputs it receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a sequen-

tial order by the Powertrain Control Module (PCM).

The PCM will adjust injector pulse width by switching

the ground path to each individual injector on and off.

Injector pulse width is the period of time that the

injector is energized. The PCM will adjust injector

pulse width based on various inputs it receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

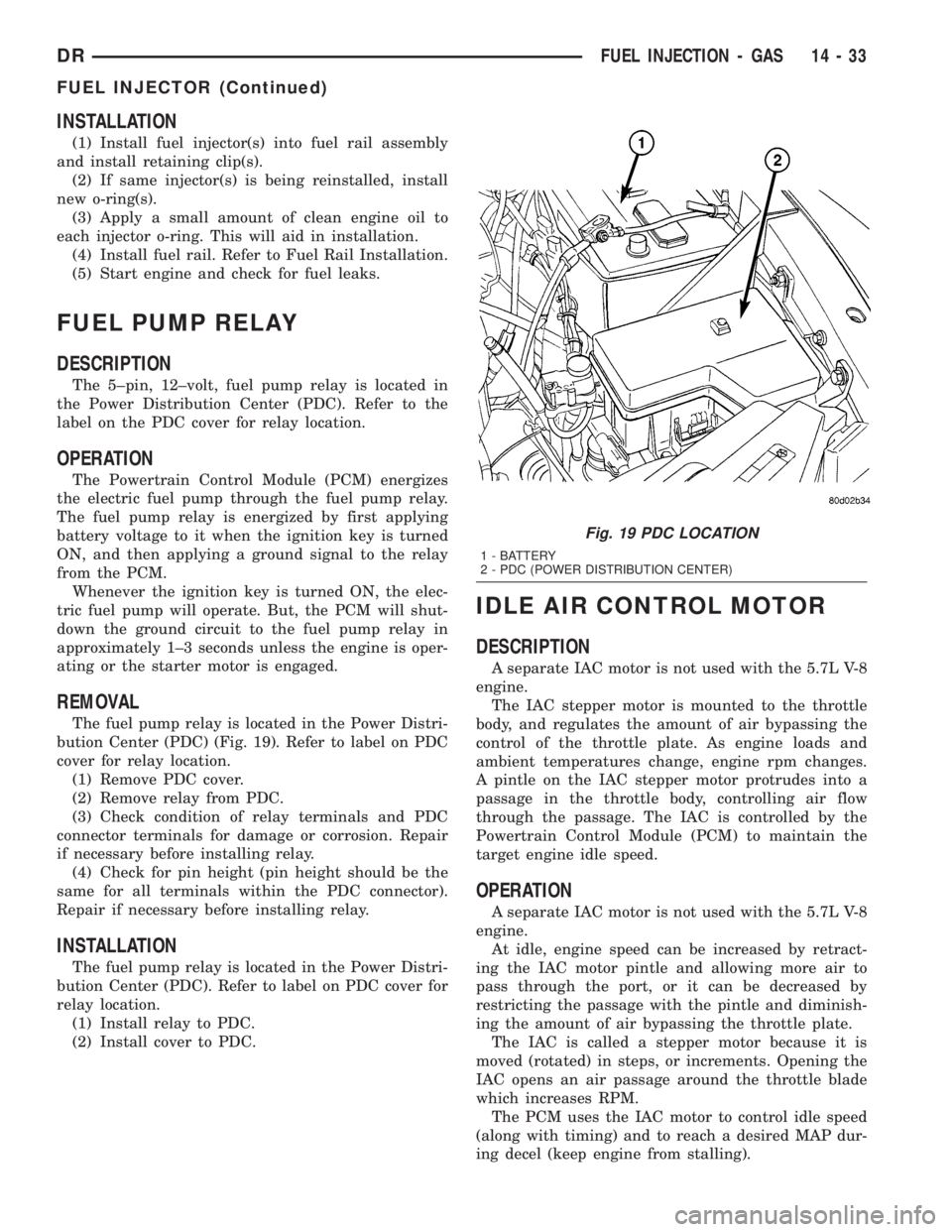

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 18).

Fig. 17 FUEL INJECTOR

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

Fig. 18 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

14 - 32 FUEL INJECTION - GASDR

Page 1730 of 2895

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).

(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 19). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC). Refer to label on PDC cover for

relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

A separate IAC motor is not used with the 5.7L V-8

engine.

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

A separate IAC motor is not used with the 5.7L V-8

engine.

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

Fig. 19 PDC LOCATION

1 - BATTERY

2 - PDC (POWER DISTRIBUTION CENTER)

DRFUEL INJECTION - GAS 14 - 33

FUEL INJECTOR (Continued)