DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1691 of 2895

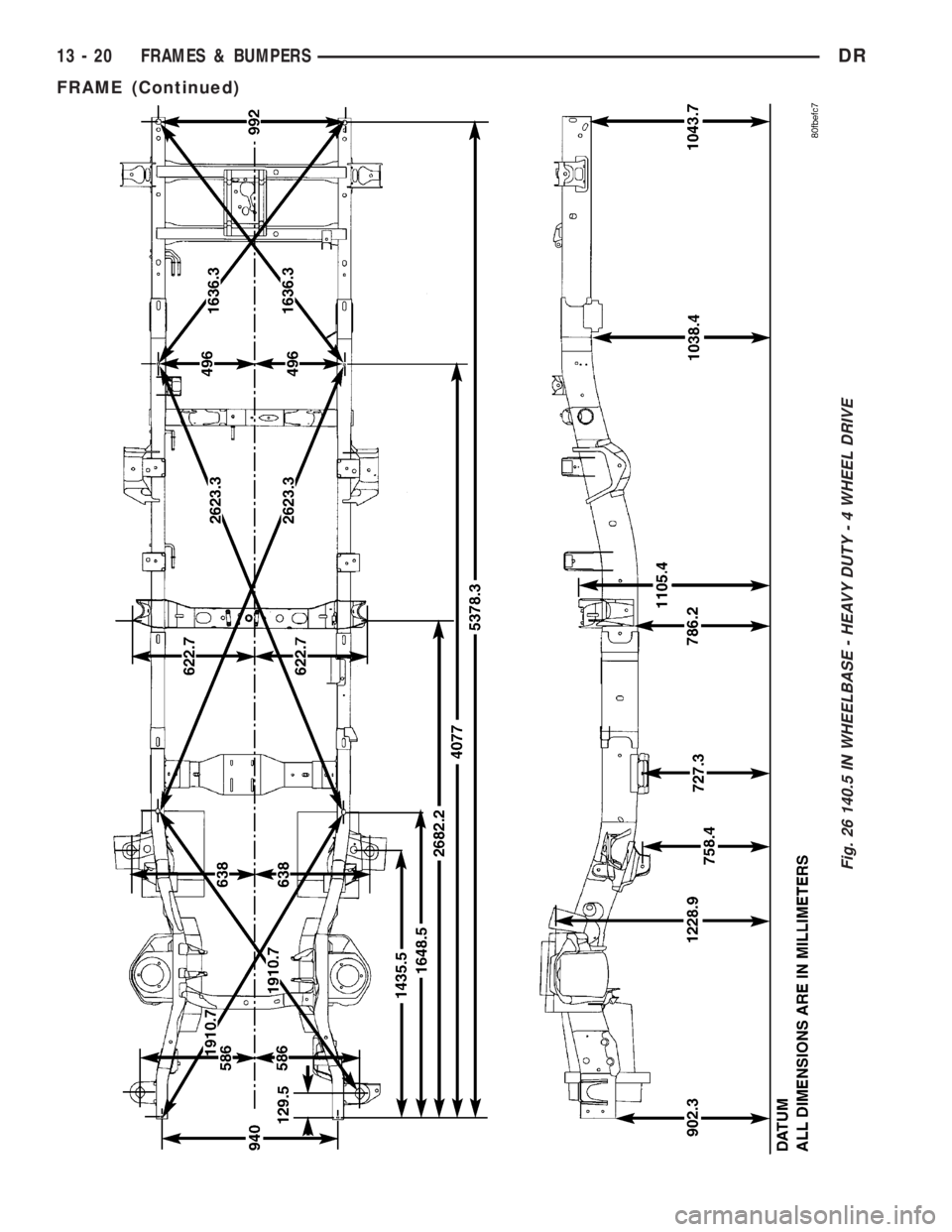

Fig. 26 140.5 IN WHEELBASE - HEAVY DUTY - 4 WHEEL DRIVE

13 - 20 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1692 of 2895

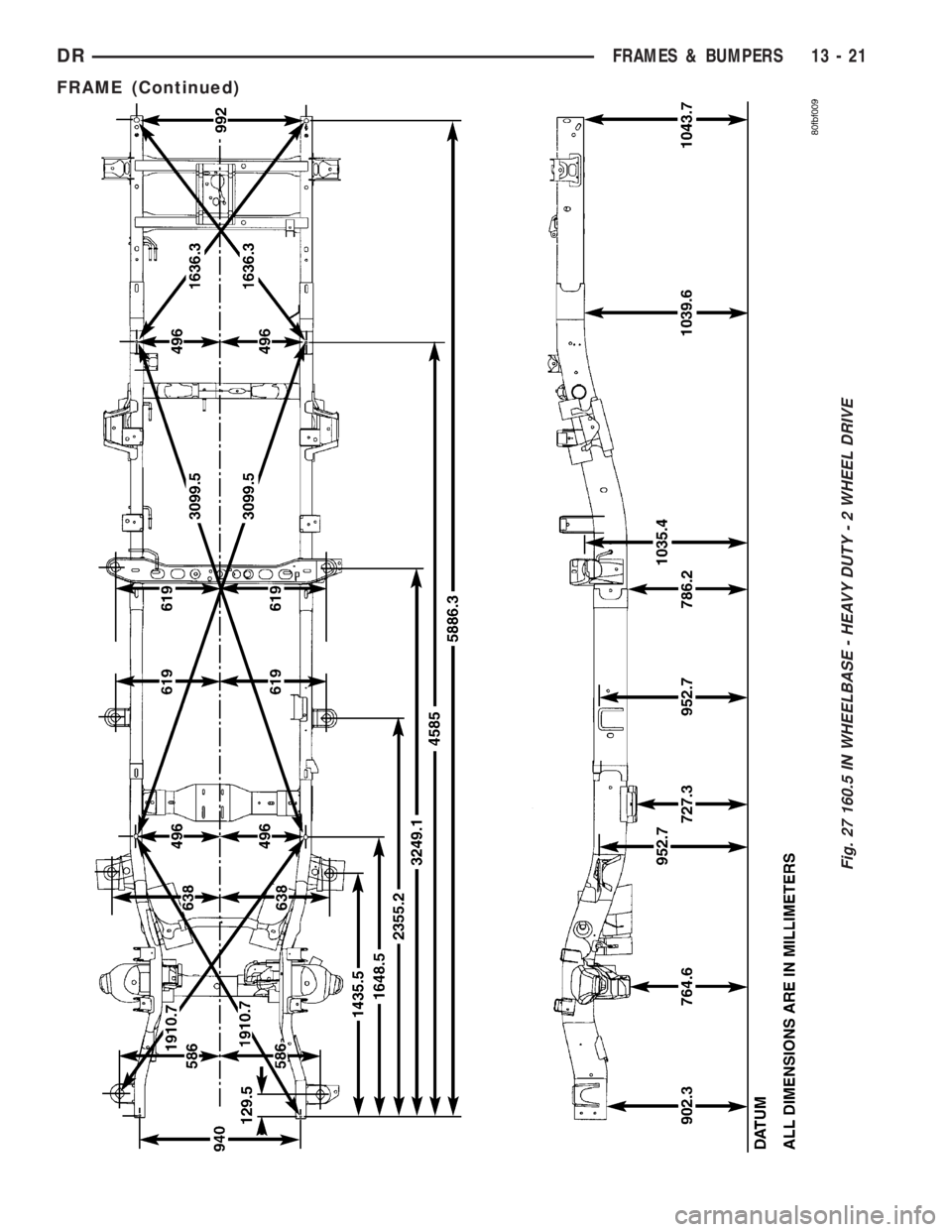

Fig. 27 160.5 IN WHEELBASE - HEAVY DUTY - 2 WHEEL DRIVE

DRFRAMES & BUMPERS 13 - 21

FRAME (Continued)

Page 1693 of 2895

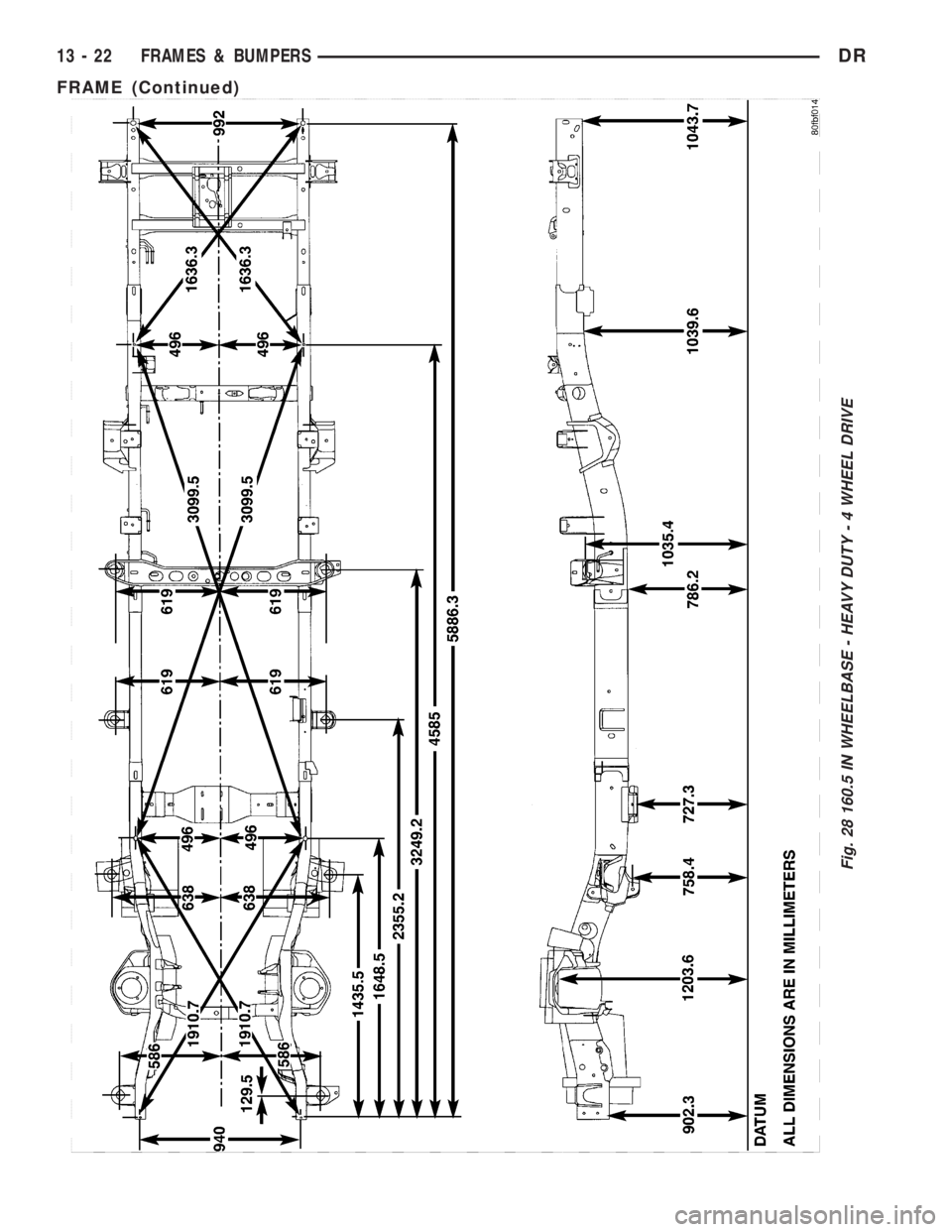

Fig. 28 160.5 IN WHEELBASE - HEAVY DUTY - 4 WHEEL DRIVE

13 - 22 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1694 of 2895

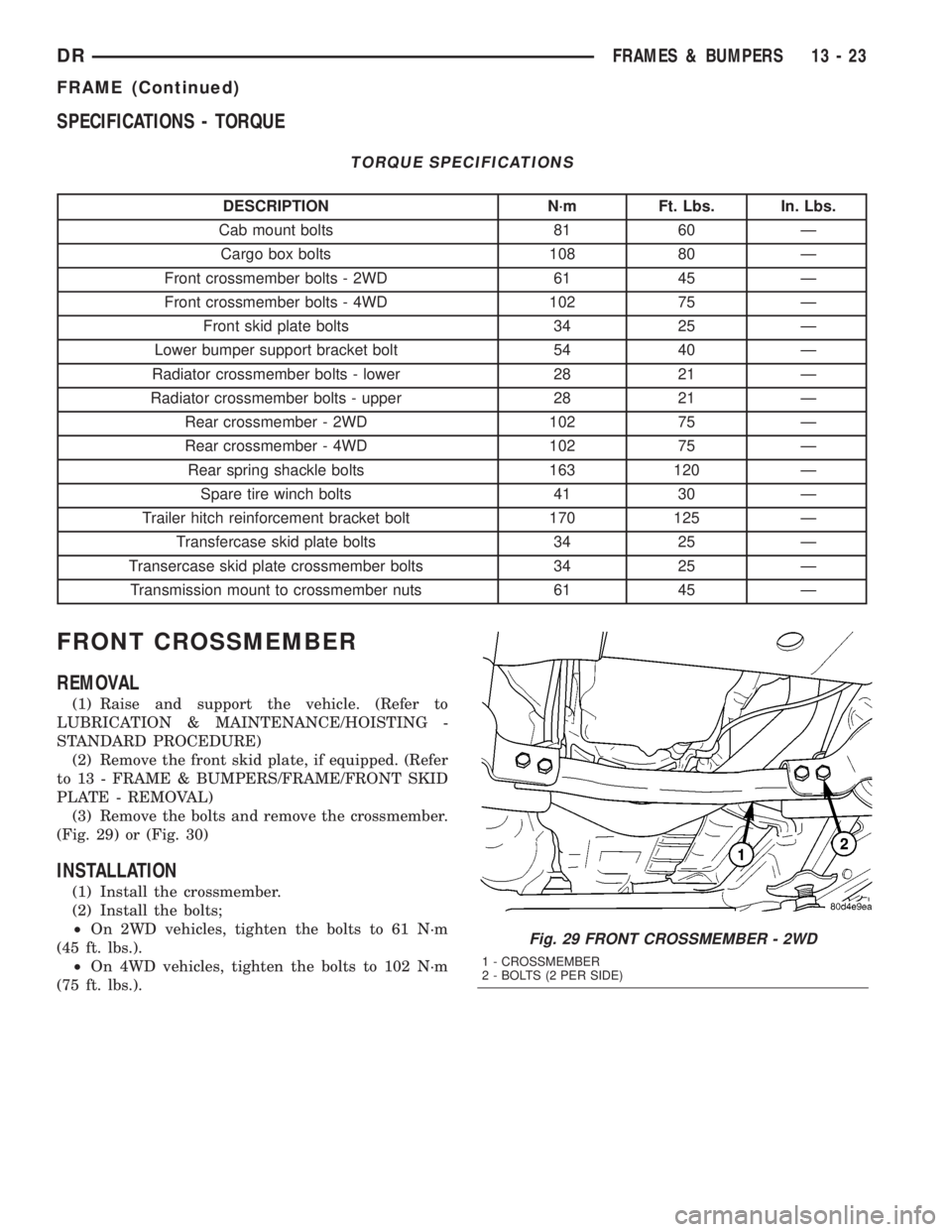

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Cab mount bolts 81 60 Ð

Cargo box bolts 108 80 Ð

Front crossmember bolts - 2WD 61 45 Ð

Front crossmember bolts - 4WD 102 75 Ð

Front skid plate bolts 34 25 Ð

Lower bumper support bracket bolt 54 40 Ð

Radiator crossmember bolts - lower 28 21 Ð

Radiator crossmember bolts - upper 28 21 Ð

Rear crossmember - 2WD 102 75 Ð

Rear crossmember - 4WD 102 75 Ð

Rear spring shackle bolts 163 120 Ð

Spare tire winch bolts 41 30 Ð

Trailer hitch reinforcement bracket bolt 170 125 Ð

Transfercase skid plate bolts 34 25 Ð

Transercase skid plate crossmember bolts 34 25 Ð

Transmission mount to crossmember nuts 61 45 Ð

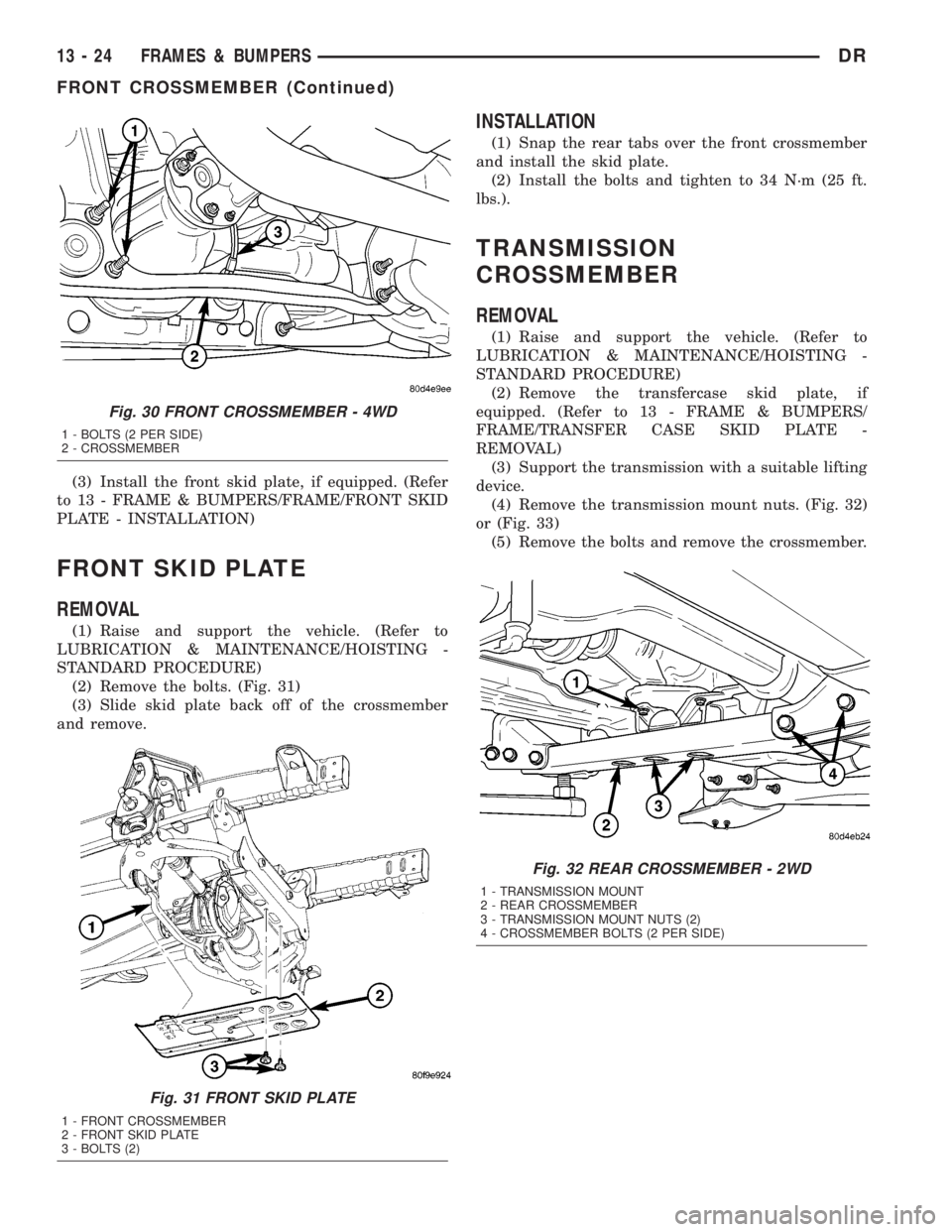

FRONT CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - REMOVAL)

(3) Remove the bolts and remove the crossmember.

(Fig. 29) or (Fig. 30)

INSTALLATION

(1) Install the crossmember.

(2) Install the bolts;

²On 2WD vehicles, tighten the bolts to 61 N´m

(45 ft. lbs.).

²On 4WD vehicles, tighten the bolts to 102 N´m

(75 ft. lbs.).

Fig. 29 FRONT CROSSMEMBER - 2WD

1 - CROSSMEMBER

2 - BOLTS (2 PER SIDE)

DRFRAMES & BUMPERS 13 - 23

FRAME (Continued)

Page 1695 of 2895

(3) Install the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - INSTALLATION)

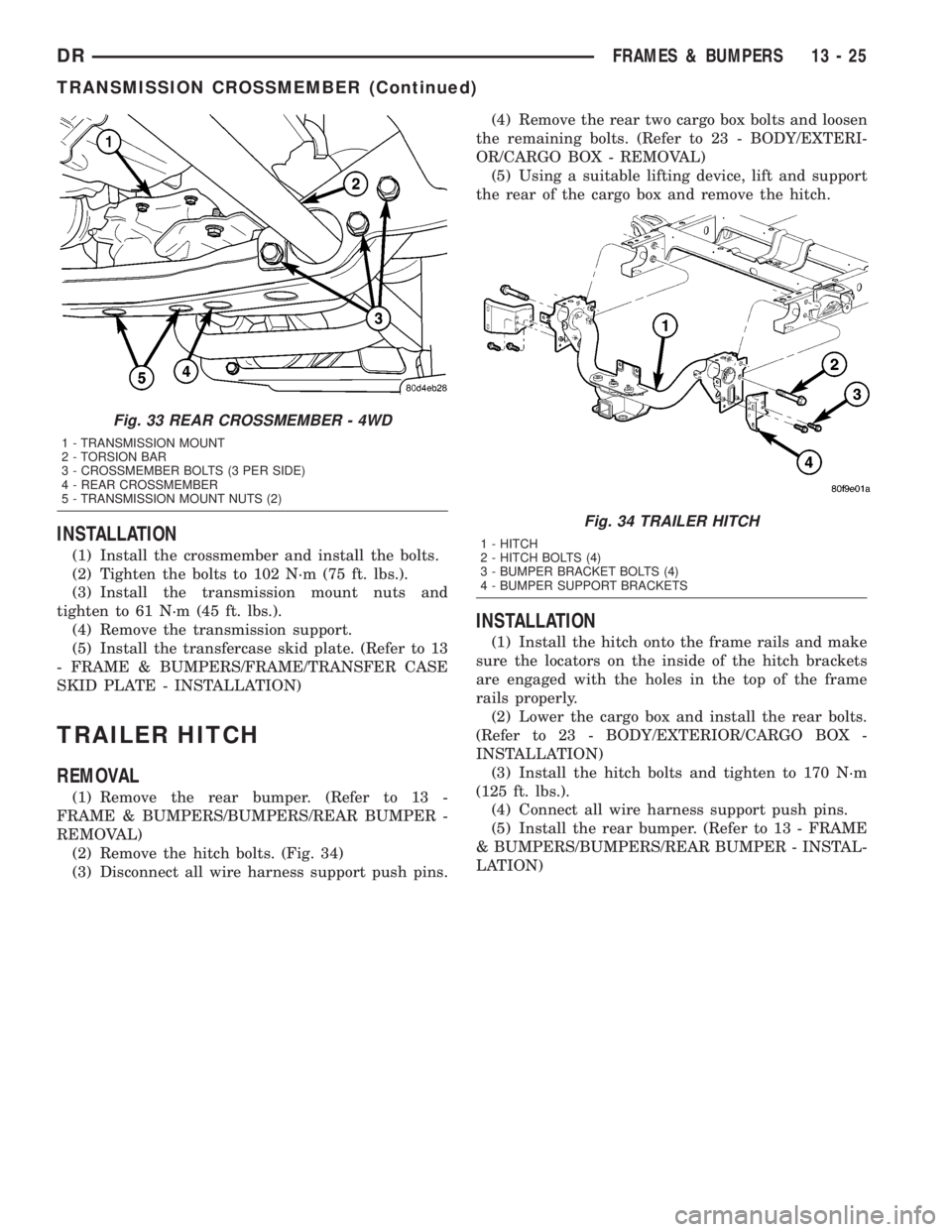

FRONT SKID PLATE

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the bolts. (Fig. 31)

(3) Slide skid plate back off of the crossmember

and remove.

INSTALLATION

(1) Snap the rear tabs over the front crossmember

and install the skid plate.

(2) Install the bolts and tighten to 34 N´m (25 ft.

lbs.).

TRANSMISSION

CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the transfercase skid plate, if

equipped. (Refer to 13 - FRAME & BUMPERS/

FRAME/TRANSFER CASE SKID PLATE -

REMOVAL)

(3) Support the transmission with a suitable lifting

device.

(4) Remove the transmission mount nuts. (Fig. 32)

or (Fig. 33)

(5) Remove the bolts and remove the crossmember.

Fig. 30 FRONT CROSSMEMBER - 4WD

1 - BOLTS (2 PER SIDE)

2 - CROSSMEMBER

Fig. 31 FRONT SKID PLATE

1 - FRONT CROSSMEMBER

2 - FRONT SKID PLATE

3 - BOLTS (2)

Fig. 32 REAR CROSSMEMBER - 2WD

1 - TRANSMISSION MOUNT

2 - REAR CROSSMEMBER

3 - TRANSMISSION MOUNT NUTS (2)

4 - CROSSMEMBER BOLTS (2 PER SIDE)

13 - 24 FRAMES & BUMPERSDR

FRONT CROSSMEMBER (Continued)

Page 1696 of 2895

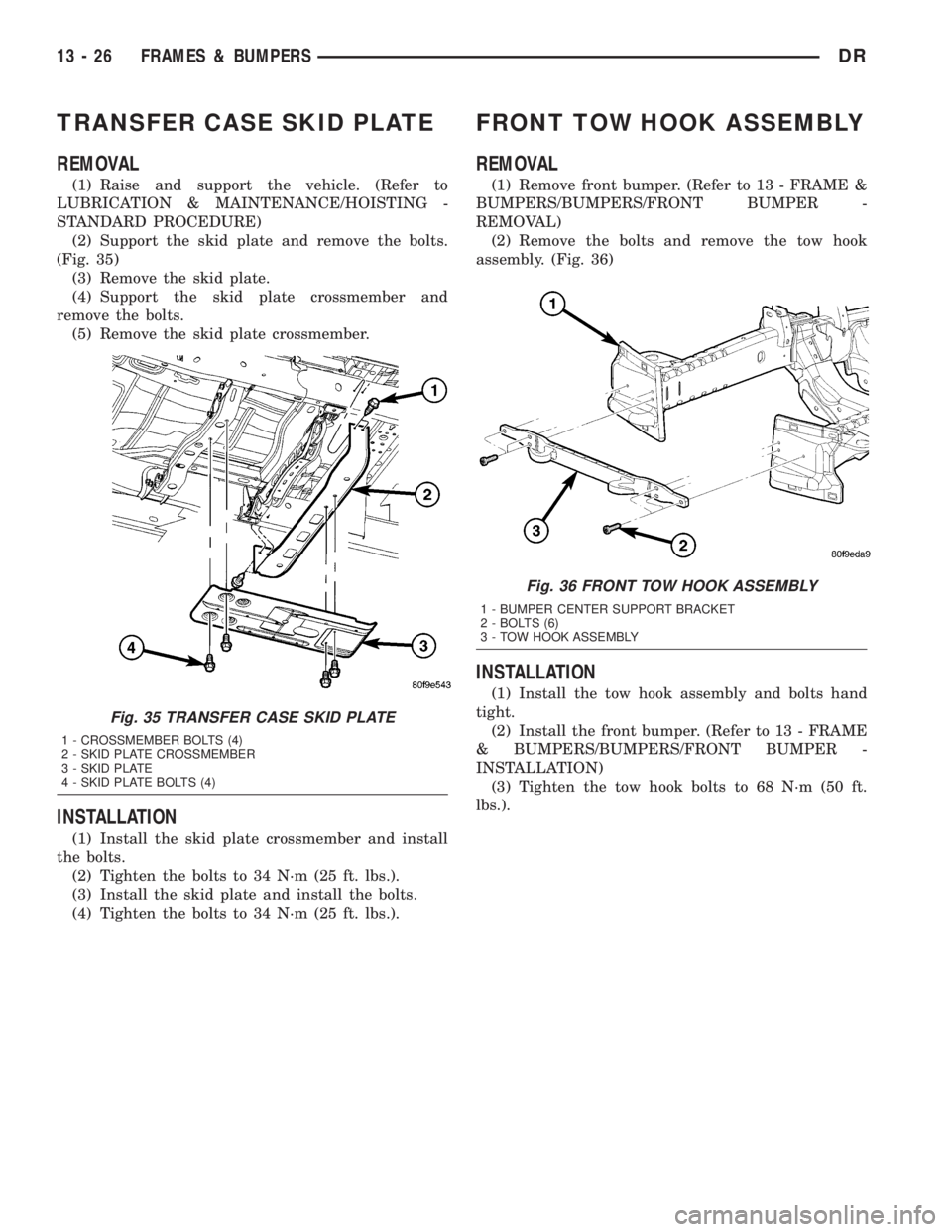

INSTALLATION

(1) Install the crossmember and install the bolts.

(2) Tighten the bolts to 102 N´m (75 ft. lbs.).

(3) Install the transmission mount nuts and

tighten to 61 N´m (45 ft. lbs.).

(4) Remove the transmission support.

(5) Install the transfercase skid plate. (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

TRAILER HITCH

REMOVAL

(1) Remove the rear bumper. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/REAR BUMPER -

REMOVAL)

(2) Remove the hitch bolts. (Fig. 34)

(3) Disconnect all wire harness support push pins.(4) Remove the rear two cargo box bolts and loosen

the remaining bolts. (Refer to 23 - BODY/EXTERI-

OR/CARGO BOX - REMOVAL)

(5) Using a suitable lifting device, lift and support

the rear of the cargo box and remove the hitch.

INSTALLATION

(1) Install the hitch onto the frame rails and make

sure the locators on the inside of the hitch brackets

are engaged with the holes in the top of the frame

rails properly.

(2) Lower the cargo box and install the rear bolts.

(Refer to 23 - BODY/EXTERIOR/CARGO BOX -

INSTALLATION)

(3) Install the hitch bolts and tighten to 170 N´m

(125 ft. lbs.).

(4) Connect all wire harness support push pins.

(5) Install the rear bumper. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/REAR BUMPER - INSTAL-

LATION)

Fig. 33 REAR CROSSMEMBER - 4WD

1 - TRANSMISSION MOUNT

2 - TORSION BAR

3 - CROSSMEMBER BOLTS (3 PER SIDE)

4 - REAR CROSSMEMBER

5 - TRANSMISSION MOUNT NUTS (2)

Fig. 34 TRAILER HITCH

1 - HITCH

2 - HITCH BOLTS (4)

3 - BUMPER BRACKET BOLTS (4)

4 - BUMPER SUPPORT BRACKETS

DRFRAMES & BUMPERS 13 - 25

TRANSMISSION CROSSMEMBER (Continued)

Page 1697 of 2895

TRANSFER CASE SKID PLATE

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Support the skid plate and remove the bolts.

(Fig. 35)

(3) Remove the skid plate.

(4) Support the skid plate crossmember and

remove the bolts.

(5) Remove the skid plate crossmember.

INSTALLATION

(1) Install the skid plate crossmember and install

the bolts.

(2) Tighten the bolts to 34 N´m (25 ft. lbs.).

(3) Install the skid plate and install the bolts.

(4) Tighten the bolts to 34 N´m (25 ft. lbs.).

FRONT TOW HOOK ASSEMBLY

REMOVAL

(1) Remove front bumper. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/FRONT BUMPER -

REMOVAL)

(2) Remove the bolts and remove the tow hook

assembly. (Fig. 36)

INSTALLATION

(1) Install the tow hook assembly and bolts hand

tight.

(2) Install the front bumper. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT BUMPER -

INSTALLATION)

(3) Tighten the tow hook bolts to 68 N´m (50 ft.

lbs.).

Fig. 35 TRANSFER CASE SKID PLATE

1 - CROSSMEMBER BOLTS (4)

2 - SKID PLATE CROSSMEMBER

3 - SKID PLATE

4 - SKID PLATE BOLTS (4)

Fig. 36 FRONT TOW HOOK ASSEMBLY

1 - BUMPER CENTER SUPPORT BRACKET

2 - BOLTS (6)

3 - TOW HOOK ASSEMBLY

13 - 26 FRAMES & BUMPERSDR

Page 1698 of 2895

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS....................1

FUEL INJECTION - GAS...................24FUEL DELIVERY - DIESEL.................56

FUEL INJECTION - DIESEL................79

FUEL DELIVERY - GAS

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS

DESCRIPTION..........................1

OPERATION............................2

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE...................2

SPECIFICATIONS

FUEL SYSTEM PRESSURE..............3

TORQUE - FUEL SYSTEM...............3

SPECIAL TOOLS

FUEL SYSTEM........................5

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION..........................6

OPERATION............................6

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................8

FUEL LINES

DESCRIPTION..........................8

QUICK CONNECT FITTING

DESCRIPTION..........................8

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS............................8FUEL PUMP

DESCRIPTION.........................12

OPERATION...........................12

FUEL PUMP MODULE

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................13

FUEL RAIL

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................18

FUEL TANK

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL- EXCEPT DIESEL..............20

INSTALLATION - EXCEPT DIESEL..........22

INLET FILTER

REMOVAL.............................23

INSTALLATION.........................23

FUEL DELIVERY - GAS

DESCRIPTION

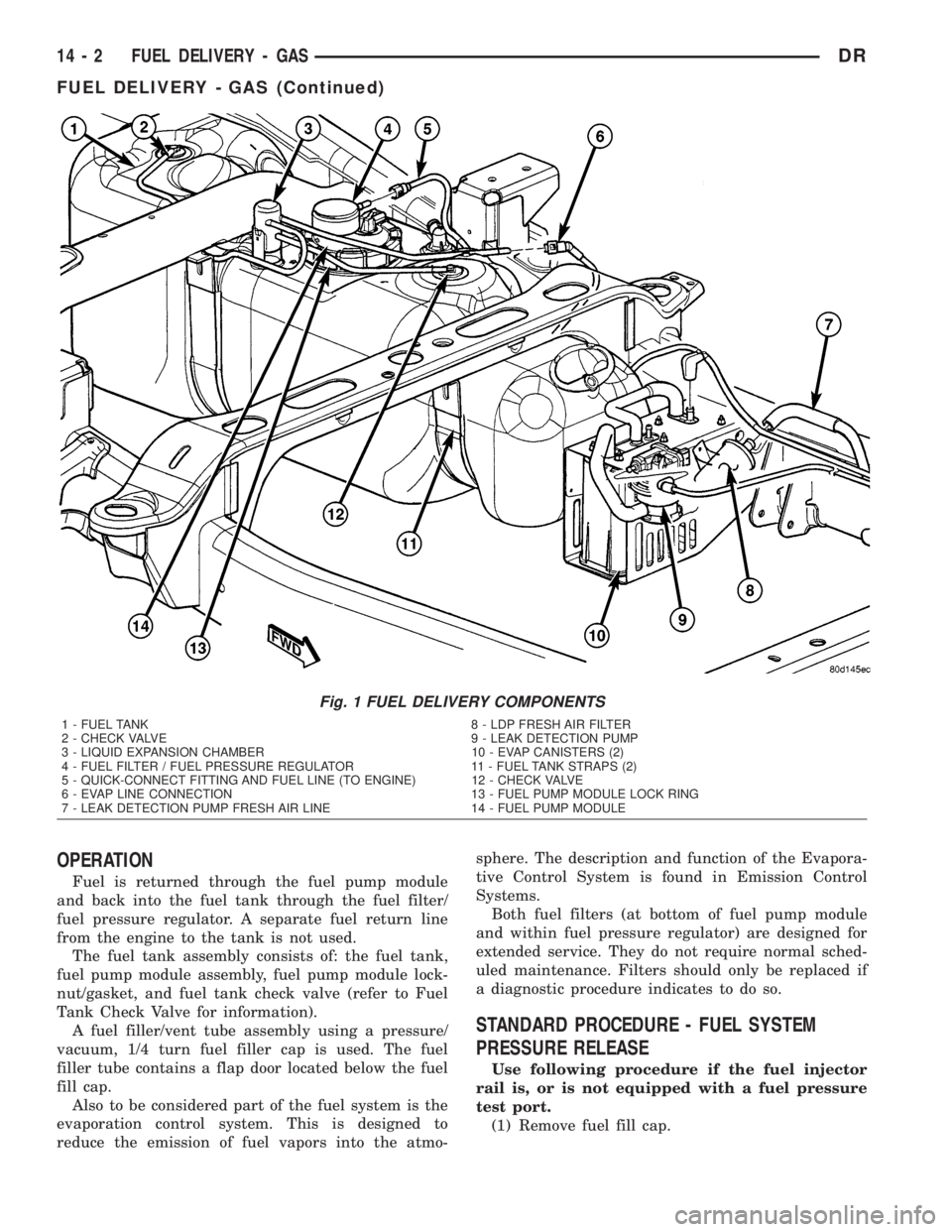

The fuel delivery system consists of:

²a fuel pump module containing the electric fuel

pump, fuel filter/fuel pressure regulator, fuel gauge

sending unit (fuel level sensor) and a secondary fuel

filter located at the bottom of the pump module

²fuel tubes/lines/hoses

²a combination fuel filter/fuel pressure regulator²quick-connect fittings

²fuel injector rail

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

Certain fuel delivery components can be found in

(Fig. 1).

DRFUEL SYSTEM 14 - 1

Page 1699 of 2895

OPERATION

Fuel is returned through the fuel pump module

and back into the fuel tank through the fuel filter/

fuel pressure regulator. A separate fuel return line

from the engine to the tank is not used.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module lock-

nut/gasket, and fuel tank check valve (refer to Fuel

Tank Check Valve for information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-sphere. The description and function of the Evapora-

tive Control System is found in Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE

Use following procedure if the fuel injector

rail is, or is not equipped with a fuel pressure

test port.

(1) Remove fuel fill cap.

Fig. 1 FUEL DELIVERY COMPONENTS

1 - FUEL TANK 8 - LDP FRESH AIR FILTER

2 - CHECK VALVE 9 - LEAK DETECTION PUMP

3 - LIQUID EXPANSION CHAMBER 10 - EVAP CANISTERS (2)

4 - FUEL FILTER / FUEL PRESSURE REGULATOR 11 - FUEL TANK STRAPS (2)

5 - QUICK-CONNECT FITTING AND FUEL LINE (TO ENGINE) 12 - CHECK VALVE

6 - EVAP LINE CONNECTION 13 - FUEL PUMP MODULE LOCK RING

7 - LEAK DETECTION PUMP FRESH AIR LINE 14 - FUEL PUMP MODULE

14 - 2 FUEL DELIVERY - GASDR

FUEL DELIVERY - GAS (Continued)

Page 1700 of 2895

(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

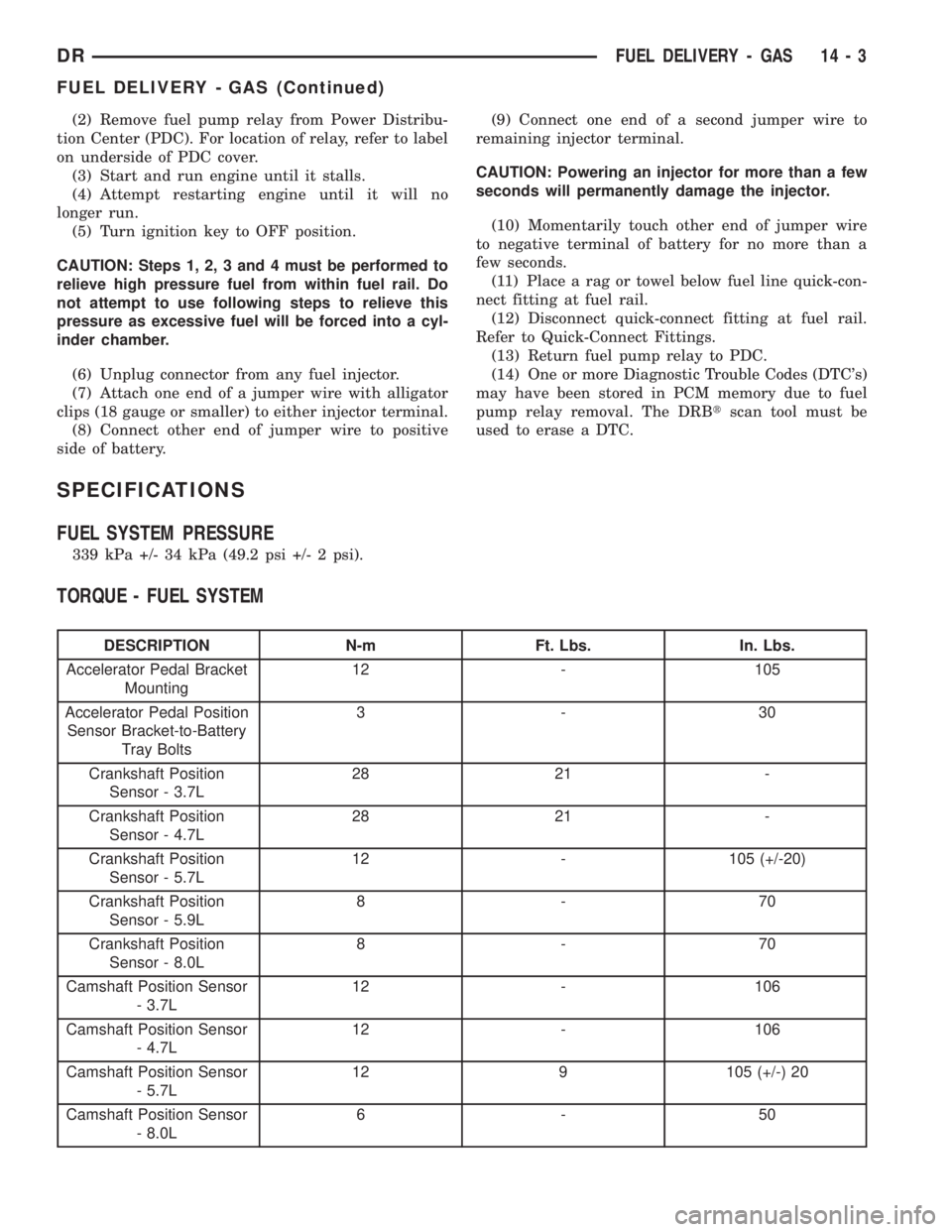

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa +/- 34 kPa (49.2 psi +/- 2 psi).

TORQUE - FUEL SYSTEM

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting12 - 105

Accelerator Pedal Position

Sensor Bracket-to-Battery

Tray Bolts3-30

Crankshaft Position

Sensor - 3.7L28 21 -

Crankshaft Position

Sensor - 4.7L28 21 -

Crankshaft Position

Sensor - 5.7L12 - 105 (+/-20)

Crankshaft Position

Sensor - 5.9L8-70

Crankshaft Position

Sensor - 8.0L8-70

Camshaft Position Sensor

- 3.7L12 - 106

Camshaft Position Sensor

- 4.7L12 - 106

Camshaft Position Sensor

- 5.7L12 9 105 (+/-) 20

Camshaft Position Sensor

- 8.0L6-50

DRFUEL DELIVERY - GAS 14 - 3

FUEL DELIVERY - GAS (Continued)