Engine system DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1309 of 2895

REAR MOUNT

REMOVAL

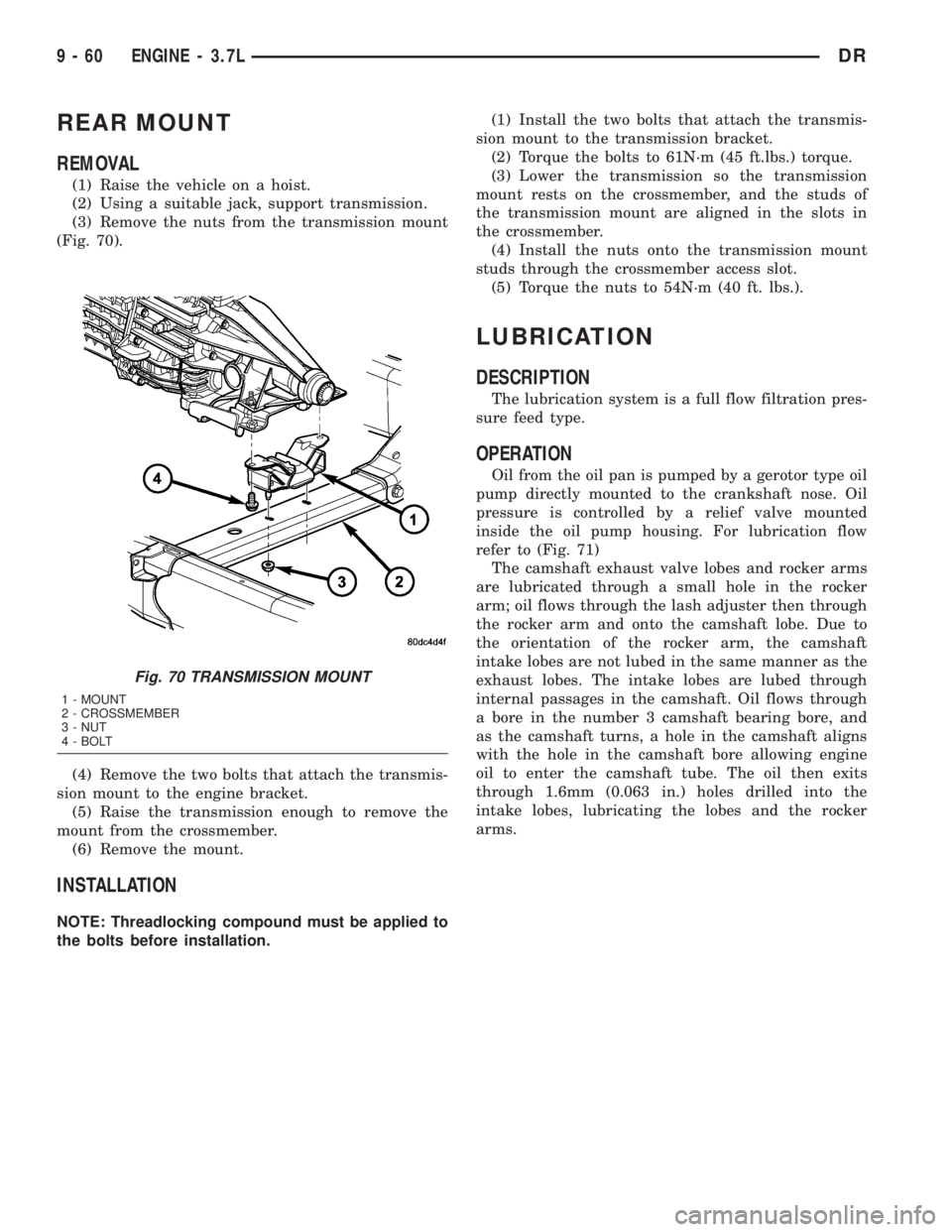

(1) Raise the vehicle on a hoist.

(2) Using a suitable jack, support transmission.

(3) Remove the nuts from the transmission mount

(Fig. 70).

(4) Remove the two bolts that attach the transmis-

sion mount to the engine bracket.

(5) Raise the transmission enough to remove the

mount from the crossmember.

(6) Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to

the bolts before installation.(1) Install the two bolts that attach the transmis-

sion mount to the transmission bracket.

(2) Torque the bolts to 61N´m (45 ft.lbs.) torque.

(3) Lower the transmission so the transmission

mount rests on the crossmember, and the studs of

the transmission mount are aligned in the slots in

the crossmember.

(4) Install the nuts onto the transmission mount

studs through the crossmember access slot.

(5) Torque the nuts to 54N´m (40 ft. lbs.).

LUBRICATION

DESCRIPTION

The lubrication system is a full flow filtration pres-

sure feed type.

OPERATION

Oil from the oil pan is pumped by a gerotor type oil

pump directly mounted to the crankshaft nose. Oil

pressure is controlled by a relief valve mounted

inside the oil pump housing. For lubrication flow

refer to (Fig. 71)

The camshaft exhaust valve lobes and rocker arms

are lubricated through a small hole in the rocker

arm; oil flows through the lash adjuster then through

the rocker arm and onto the camshaft lobe. Due to

the orientation of the rocker arm, the camshaft

intake lobes are not lubed in the same manner as the

exhaust lobes. The intake lobes are lubed through

internal passages in the camshaft. Oil flows through

a bore in the number 3 camshaft bearing bore, and

as the camshaft turns, a hole in the camshaft aligns

with the hole in the camshaft bore allowing engine

oil to enter the camshaft tube. The oil then exits

through 1.6mm (0.063 in.) holes drilled into the

intake lobes, lubricating the lobes and the rocker

arms.

Fig. 70 TRANSMISSION MOUNT

1 - MOUNT

2 - CROSSMEMBER

3 - NUT

4 - BOLT

9 - 60 ENGINE - 3.7LDR

Page 1321 of 2895

(2) Spray a small stream of water (spray bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.(8) D

isconnect left and right radio suppressor straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system. Refer to FUEL SYSTEM.

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level. Refer to COOLING SYSTEM.

(15) Remove the heater hoses from the engine

front cover and the heater core.

(16) Unclip and remove heater hoses and tubes

from intake manifold.

(17) Remove coolant temperature sensor. Refer to

FUEL SYSTEM.

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence.

(19) Remove intake manifold.

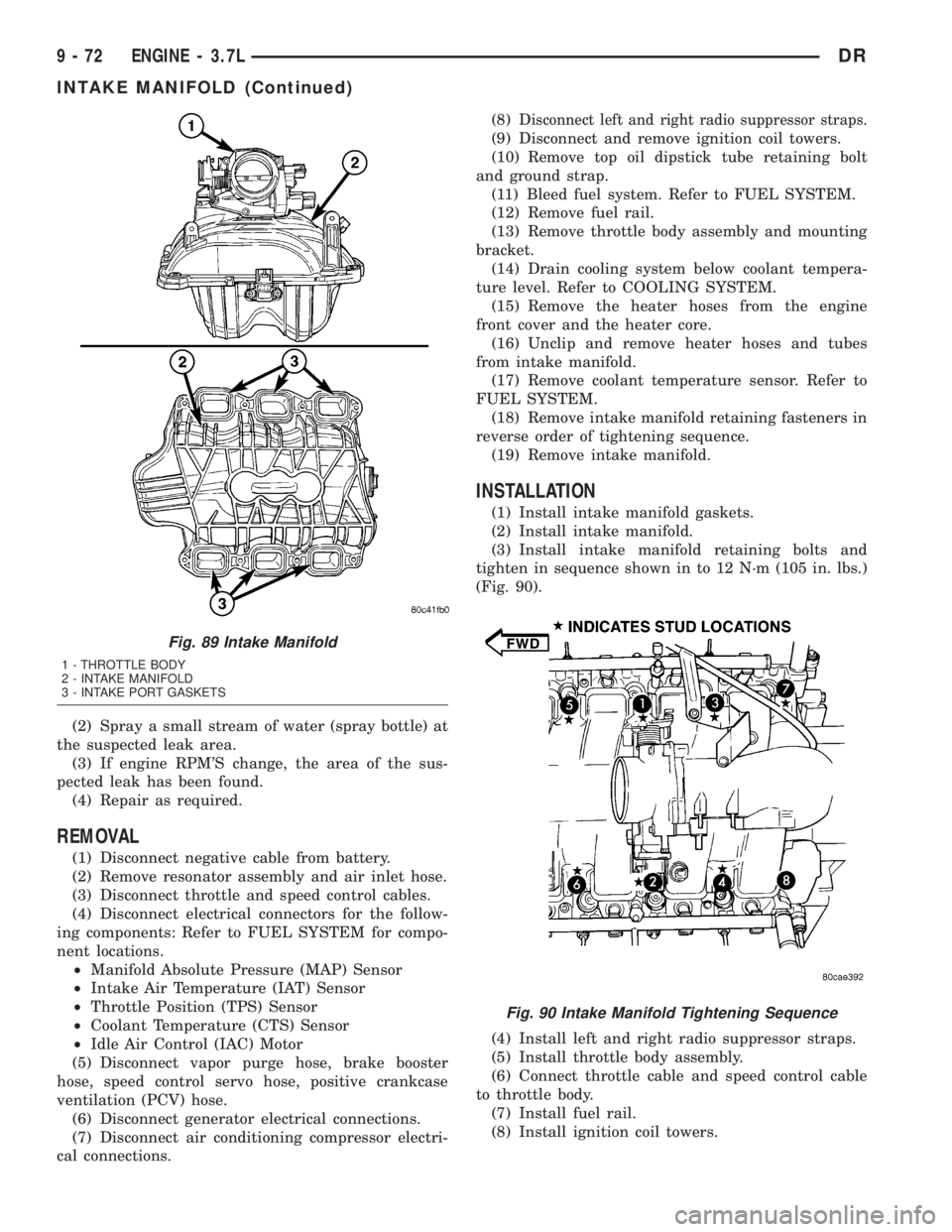

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in to 12 N´m (105 in. lbs.)

(Fig. 90).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Connect throttle cable and speed control cable

to throttle body.

(7) Install fuel rail.

(8) Install ignition coil towers.

Fig. 89 Intake Manifold

1 - THROTTLE BODY

2 - INTAKE MANIFOLD

3 - INTAKE PORT GASKETS

Fig. 90 Intake Manifold Tightening Sequence

9 - 72 ENGINE - 3.7LDR

INTAKE MANIFOLD (Continued)

Page 1322 of 2895

(9) Position and install heater hoses and tubes

onto intake manifold.

(10) Install the heater hoses to the heater core and

engine front cover.

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Connect generator electrical connections.

(14) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(15) Fill cooling system.

(16) Install resonator assembly and air inlet hose.

(17) Connect negative cable to battery.

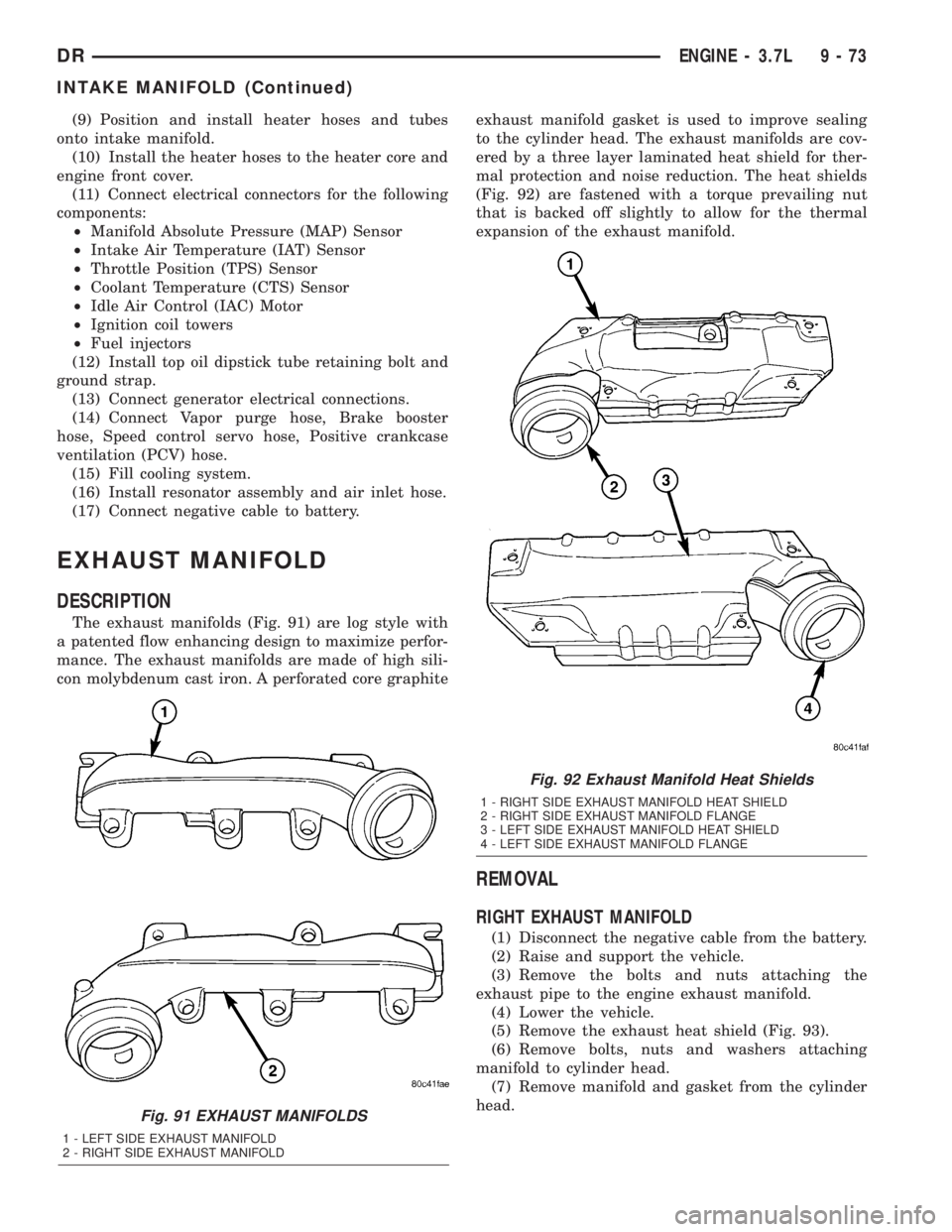

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds (Fig. 91) are log style with

a patented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high sili-

con molybdenum cast iron. A perforated core graphiteexhaust manifold gasket is used to improve sealing

to the cylinder head. The exhaust manifolds are cov-

ered by a three layer laminated heat shield for ther-

mal protection and noise reduction. The heat shields

(Fig. 92) are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

RIGHT EXHAUST MANIFOLD

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shield (Fig. 93).

(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold and gasket from the cylinder

head.

Fig. 91 EXHAUST MANIFOLDS

1 - LEFT SIDE EXHAUST MANIFOLD

2 - RIGHT SIDE EXHAUST MANIFOLD

Fig. 92 Exhaust Manifold Heat Shields

1 - RIGHT SIDE EXHAUST MANIFOLD HEAT SHIELD

2 - RIGHT SIDE EXHAUST MANIFOLD FLANGE

3 - LEFT SIDE EXHAUST MANIFOLD HEAT SHIELD

4 - LEFT SIDE EXHAUST MANIFOLD FLANGE

DRENGINE - 3.7L 9 - 73

INTAKE MANIFOLD (Continued)

Page 1324 of 2895

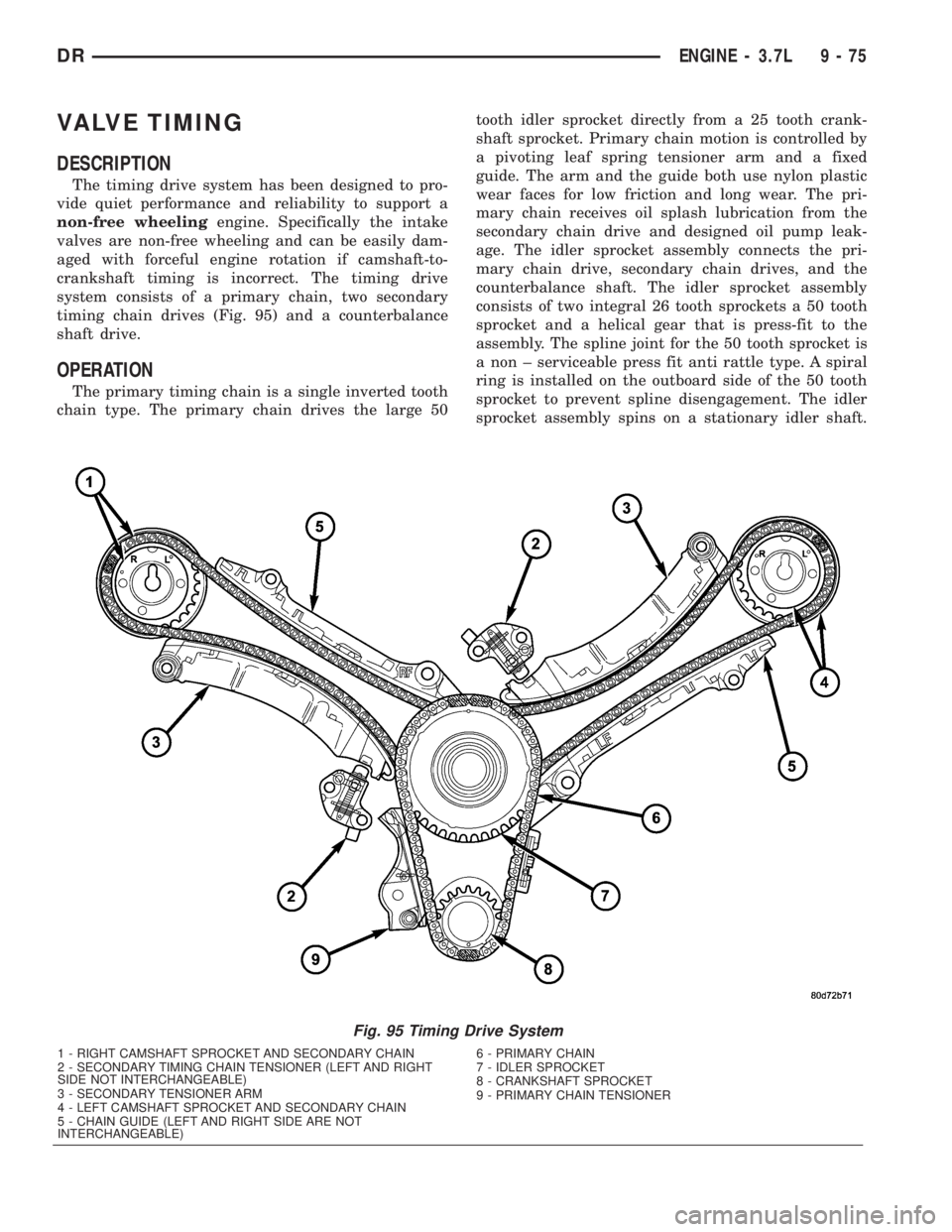

VALVE TIMING

DESCRIPTION

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

non-free wheelingengine. Specifically the intake

valves are non-free wheeling and can be easily dam-

aged with forceful engine rotation if camshaft-to-

crankshaft timing is incorrect. The timing drive

system consists of a primary chain, two secondary

timing chain drives (Fig. 95) and a counterbalance

shaft drive.

OPERATION

The primary timing chain is a single inverted tooth

chain type. The primary chain drives the large 50tooth idler sprocket directly from a 25 tooth crank-

shaft sprocket. Primary chain motion is controlled by

a pivoting leaf spring tensioner arm and a fixed

guide. The arm and the guide both use nylon plastic

wear faces for low friction and long wear. The pri-

mary chain receives oil splash lubrication from the

secondary chain drive and designed oil pump leak-

age. The idler sprocket assembly connects the pri-

mary chain drive, secondary chain drives, and the

counterbalance shaft. The idler sprocket assembly

consists of two integral 26 tooth sprockets a 50 tooth

sprocket and a helical gear that is press-fit to the

assembly. The spline joint for the 50 tooth sprocket is

a non ± serviceable press fit anti rattle type. A spiral

ring is installed on the outboard side of the 50 tooth

sprocket to prevent spline disengagement. The idler

sprocket assembly spins on a stationary idler shaft.

Fig. 95 Timing Drive System

1 - RIGHT CAMSHAFT SPROCKET AND SECONDARY CHAIN

2 - SECONDARY TIMING CHAIN TENSIONER (LEFT AND RIGHT

SIDE NOT INTERCHANGEABLE)

3 - SECONDARY TENSIONER ARM

4 - LEFT CAMSHAFT SPROCKET AND SECONDARY CHAIN

5 - CHAIN GUIDE (LEFT AND RIGHT SIDE ARE NOT

INTERCHANGEABLE)6 - PRIMARY CHAIN

7 - IDLER SPROCKET

8 - CRANKSHAFT SPROCKET

9 - PRIMARY CHAIN TENSIONER

DRENGINE - 3.7L 9 - 75

Page 1325 of 2895

The idler shaft is a light press-fit into the cylinder

block. A large washer on the idler shaft bolt and the

rear flange of the idler shaft are used to control

sprocket thrust movement. Pressurized oil is routed

through the center of the idler shaft to provide lubri-

cation for the two bushings used in the idler sprocket

assembly.

There are two secondary drive chains, both are

roller type, one to drive the camshaft in each SOHC

cylinder head. There are no shaft speed changes in

the secondary chain drive system. Each secondary

chain drives a 26 tooth cam sprocket directly from

the 26 tooth sprocket on the idler sprocket assembly.

A fixed chain guide and a hydraulic oil damped ten-

sioner are used to maintain tension in each second-

ary chain system. The hydraulic tensioners for the

secondary chain systems are fed pressurized oil from

oil reservoir pockets in the block. Each tensioner

incorporates a controlled leak path through a device

known as a vent disc located in the nose of the piston

to manage chain loads. Each tensioner also has a

mechanical ratchet system that limits chain slack if

the tensioner piston bleeds down after engine shut

down. The tensioner arms and guides also utilize

nylon wear faces for low friction and long wear. The

secondary timing chains receive lubrication from a

small orifice in the tensioners. This orifice is pro-

tected from clogging by a fine mesh screen which is

located on the back of the hydraulic tensioners.

STANDARD PROCEDURE

MEASURING TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

(1) Remove the timing chain cover. Refer to Timing

Chain Cover in this section for procedure.

(2) To determine if the secondary timing chains

are worn, rotate the engine clockwise until maximum

tensioner piston extension is obtained. Measure the

distance between the secondary timing chain ten-

sioner housing and the step ledge on the piston. The

measurement at point (A) must be less than 15mm

(.5906 inches).

(3) If the measurement exceeds the specification

the secondary timing chains are worn and require

replacement. Refer to Timing Chain and Sprockets in

this section for procedure.

SERVICE PROCEDURE - TIMING VERIFICATION

CAUTION: The 3.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

NOTE: The blue link plates on the chains and the

dots on the camshaft drive sprockets may not line

up during the timing verification procedure. The

blue link plates are lined up with the sprocket dots

only when re-timing the complete timing drive.

Once the timing drive is rotated blue link-to-dot

alignment is no longer valid.

Engine base timing can be verified by the following

procedure:

(1) Remove the cylinder head covers. Refer to the

procedure in this section.

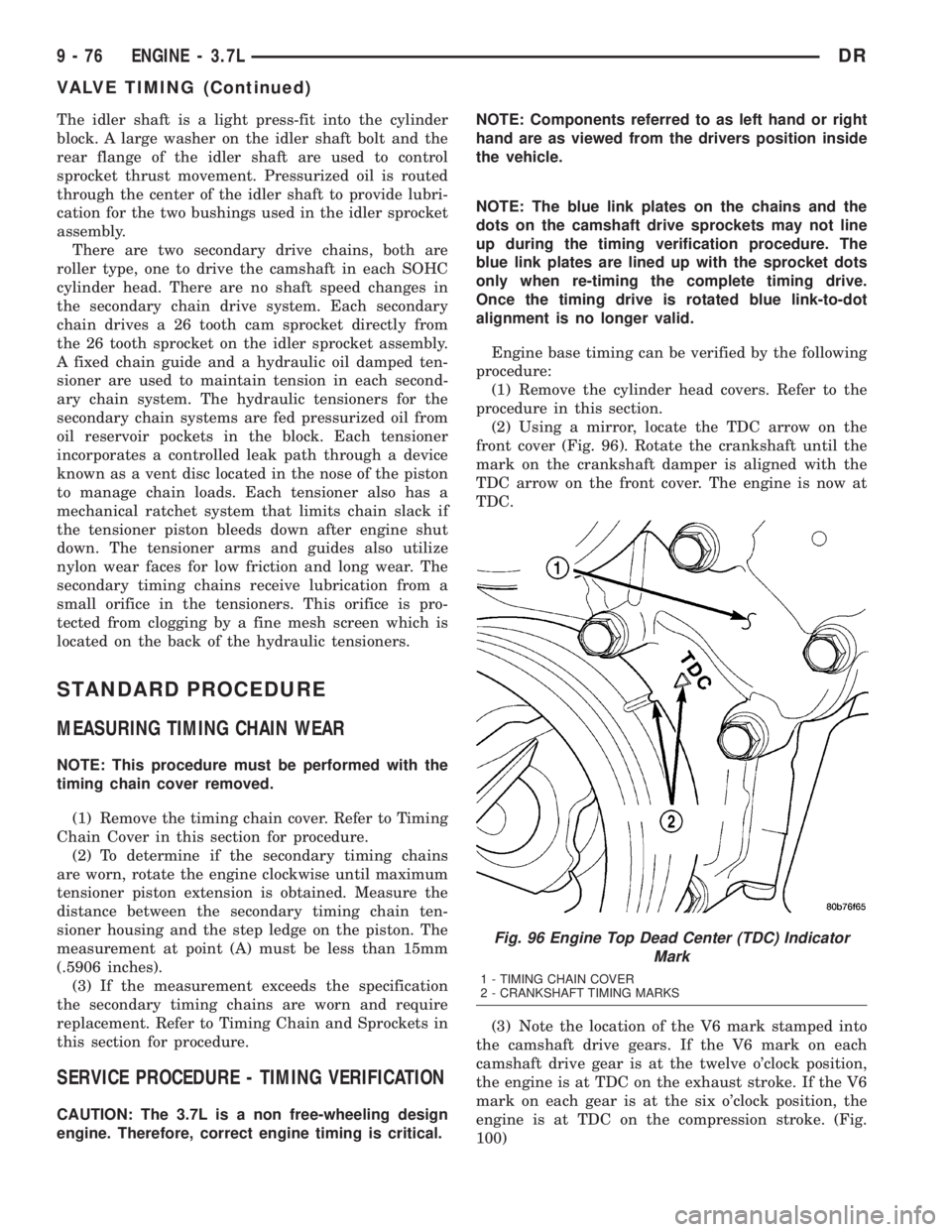

(2) Using a mirror, locate the TDC arrow on the

front cover (Fig. 96). Rotate the crankshaft until the

mark on the crankshaft damper is aligned with the

TDC arrow on the front cover. The engine is now at

TDC.

(3) Note the location of the V6 mark stamped into

the camshaft drive gears. If the V6 mark on each

camshaft drive gear is at the twelve o'clock position,

the engine is at TDC on the exhaust stroke. If the V6

mark on each gear is at the six o'clock position, the

engine is at TDC on the compression stroke. (Fig.

100)

Fig. 96 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 76 ENGINE - 3.7LDR

VALVE TIMING (Continued)

Page 1329 of 2895

CAUTION: Use care when removing the idler shaft,

Do not strike the radiator cooling fins with the slide

hammer.

(4) Using Special Tool 8517 Slide Hammer, remove

the idler shaft.

INSTALLATION

(1) Thoroughly clean the idler shaft bore.

(2) Position the idler shaft in the bore.

NOTE: The two lubrication holes in the idler shaft

do not require any special alignment.

NOTE: Before using the retaining bolt to install the

idler shaft, coat the threads and the pilot on the

idler shaft, with clean engine oil.

(3) Using the primary idler sprocket retaining bolt

and washer, carefully draw the idler shaft into the

bore until fully seated.

(4) Coat the idler shaft with clean engine oil.

(5) Install the timing chains and sprockets. Refer

to procedure in this section.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove electric cooling fan and fan shroud

assembly.

(4) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(5) Disconnect both heater hoses at timing cover.

(6) Disconnect lower radiator hose at engine.

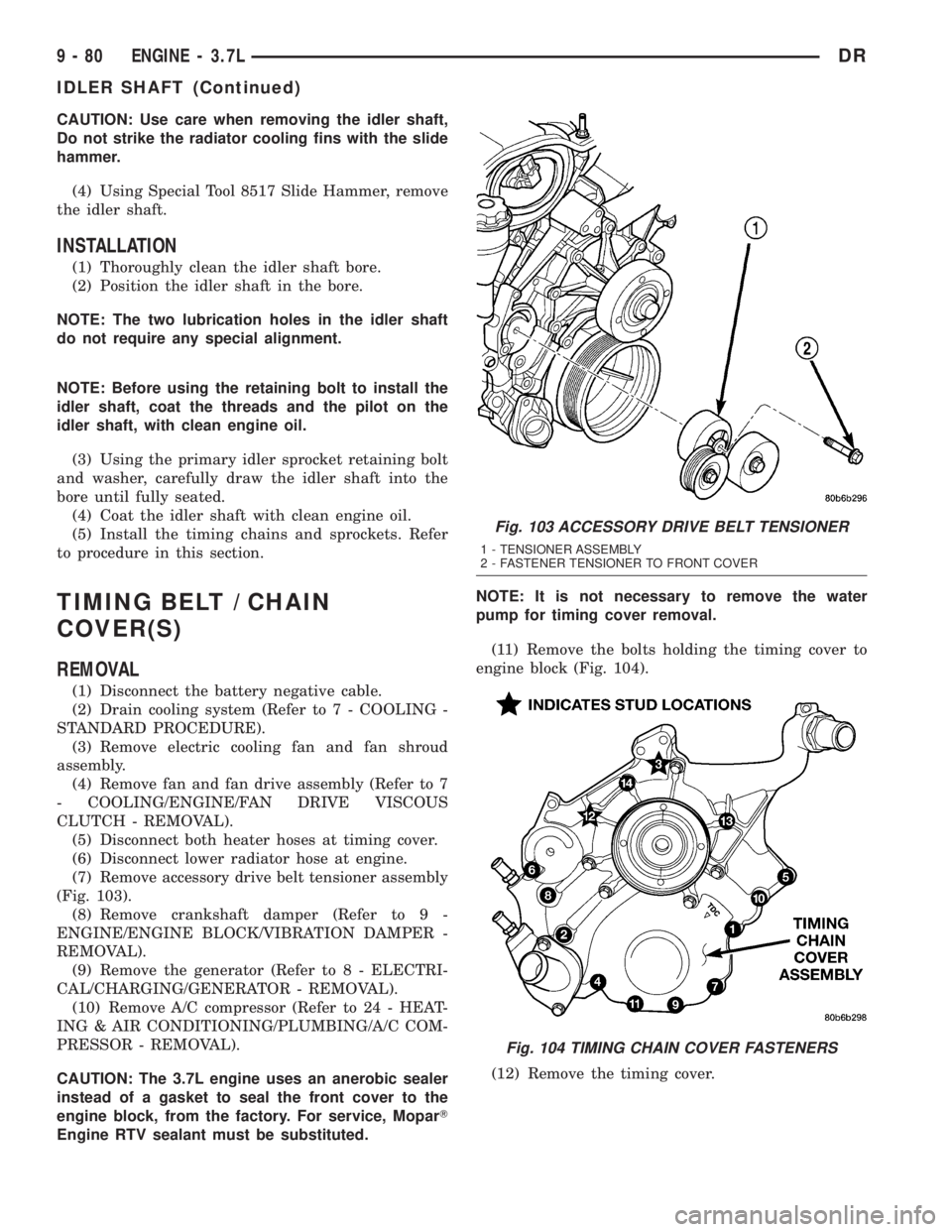

(7) Remove accessory drive belt tensioner assembly

(Fig. 103).

(8) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(9) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(10) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

CAUTION: The 3.7L engine uses an anerobic sealer

instead of a gasket to seal the front cover to the

engine block, from the factory. For service, MoparT

Engine RTV sealant must be substituted.NOTE: It is not necessary to remove the water

pump for timing cover removal.

(11) Remove the bolts holding the timing cover to

engine block (Fig. 104).

(12) Remove the timing cover.

Fig. 103 ACCESSORY DRIVE BELT TENSIONER

1 - TENSIONER ASSEMBLY

2 - FASTENER TENSIONER TO FRONT COVER

Fig. 104 TIMING CHAIN COVER FASTENERS

9 - 80 ENGINE - 3.7LDR

IDLER SHAFT (Continued)

Page 1330 of 2895

INSTALLATION

CAUTION: Do not use oil based liquids to clean tim-

ing cover or block surfaces. Use only rubbing alco-

hol, along with plastic or wooden scrapers. Use no

wire brushes or abrasive wheels or metal scrapers,

or damage to surfaces could result.

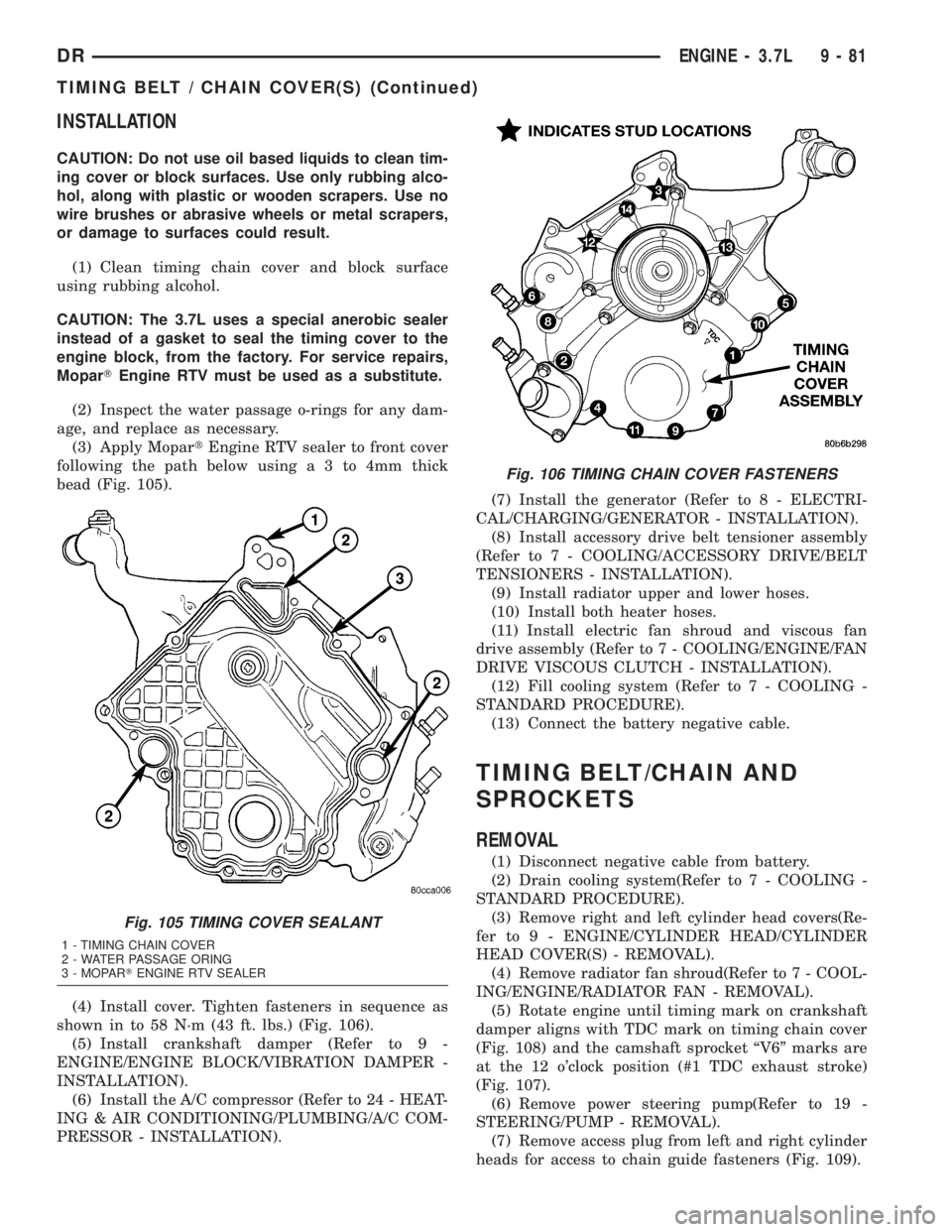

(1) Clean timing chain cover and block surface

using rubbing alcohol.

CAUTION: The 3.7L uses a special anerobic sealer

instead of a gasket to seal the timing cover to the

engine block, from the factory. For service repairs,

MoparTEngine RTV must be used as a substitute.

(2) Inspect the water passage o-rings for any dam-

age, and replace as necessary.

(3) Apply MopartEngine RTV sealer to front cover

following the path below usinga3to4mmthick

bead (Fig. 105).

(4) Install cover. Tighten fasteners in sequence as

shown in to 58 N´m (43 ft. lbs.) (Fig. 106).

(5) Install crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(6) Install the A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).(7) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION).

(8) Install accessory drive belt tensioner assembly

(Refer to 7 - COOLING/ACCESSORY DRIVE/BELT

TENSIONERS - INSTALLATION).

(9) Install radiator upper and lower hoses.

(10) Install both heater hoses.

(11) Install electric fan shroud and viscous fan

drive assembly (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH - INSTALLATION).

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect the battery negative cable.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove right and left cylinder head covers(Re-

fer to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(4) Remove radiator fan shroud(Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 108) and the camshaft sprocket ªV6º marks are

at the 12 o'clock position (#1 TDC exhaust stroke)

(Fig. 107).

(6) Remove power steering pump(Refer to 19 -

STEERING/PUMP - REMOVAL).

(7) Remove access plug from left and right cylinder

heads for access to chain guide fasteners (Fig. 109).

Fig. 105 TIMING COVER SEALANT

1 - TIMING CHAIN COVER

2 - WATER PASSAGE ORING

3 - MOPARTENGINE RTV SEALER

Fig. 106 TIMING CHAIN COVER FASTENERS

DRENGINE - 3.7L 9 - 81

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1335 of 2895

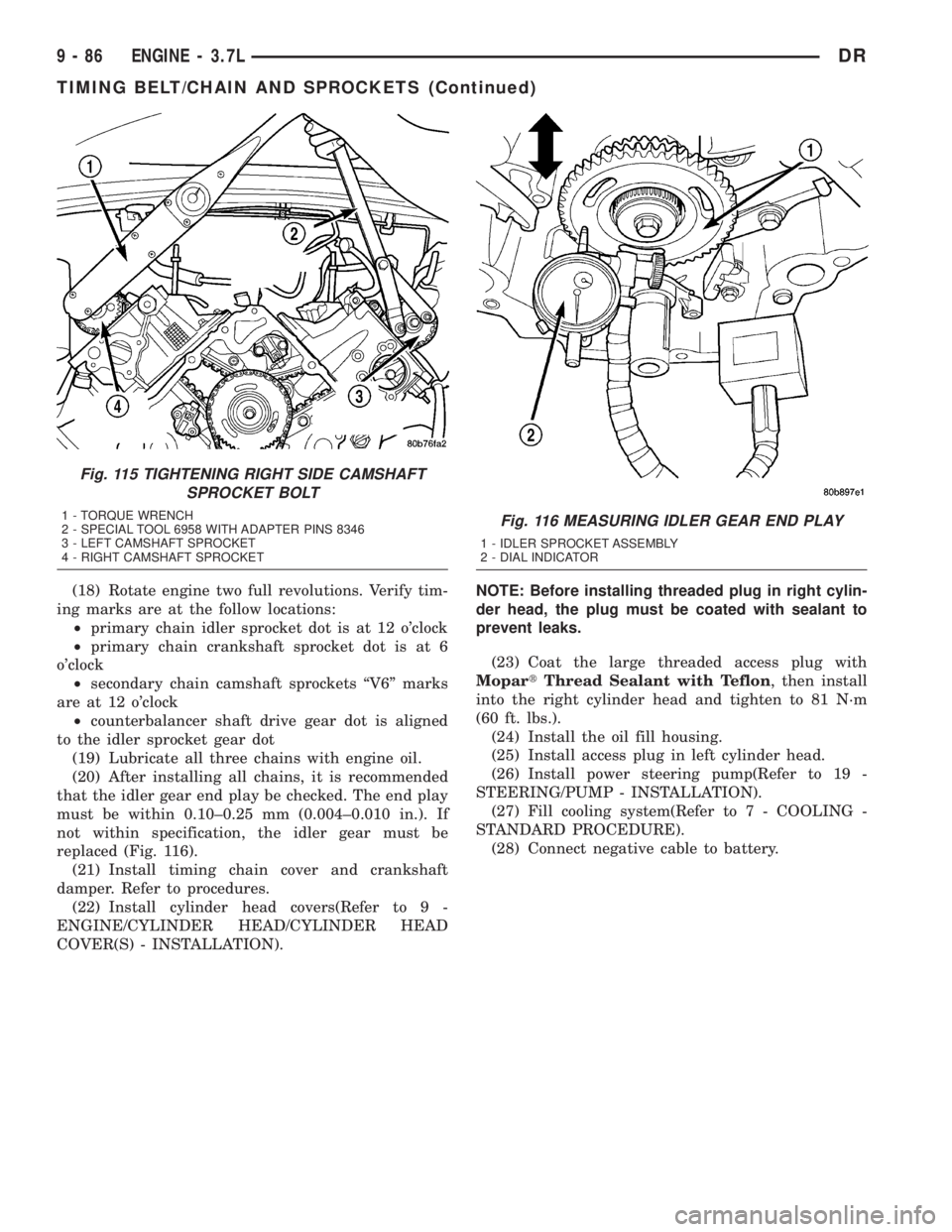

(18) Rotate engine two full revolutions. Verify tim-

ing marks are at the follow locations:

²primary chain idler sprocket dot is at 12 o'clock

²primary chain crankshaft sprocket dot is at 6

o'clock

²secondary chain camshaft sprockets ªV6º marks

are at 12 o'clock

²counterbalancer shaft drive gear dot is aligned

to the idler sprocket gear dot

(19) Lubricate all three chains with engine oil.

(20) After installing all chains, it is recommended

that the idler gear end play be checked. The end play

must be within 0.10±0.25 mm (0.004±0.010 in.). If

not within specification, the idler gear must be

replaced (Fig. 116).

(21) Install timing chain cover and crankshaft

damper. Refer to procedures.

(22) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.

(23) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.).

(24) Install the oil fill housing.

(25) Install access plug in left cylinder head.

(26) Install power steering pump(Refer to 19 -

STEERING/PUMP - INSTALLATION).

(27) Fill cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(28) Connect negative cable to battery.

Fig. 115 TIGHTENING RIGHT SIDE CAMSHAFT

SPROCKET BOLT

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKETFig. 116 MEASURING IDLER GEAR END PLAY

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

9 - 86 ENGINE - 3.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1337 of 2895

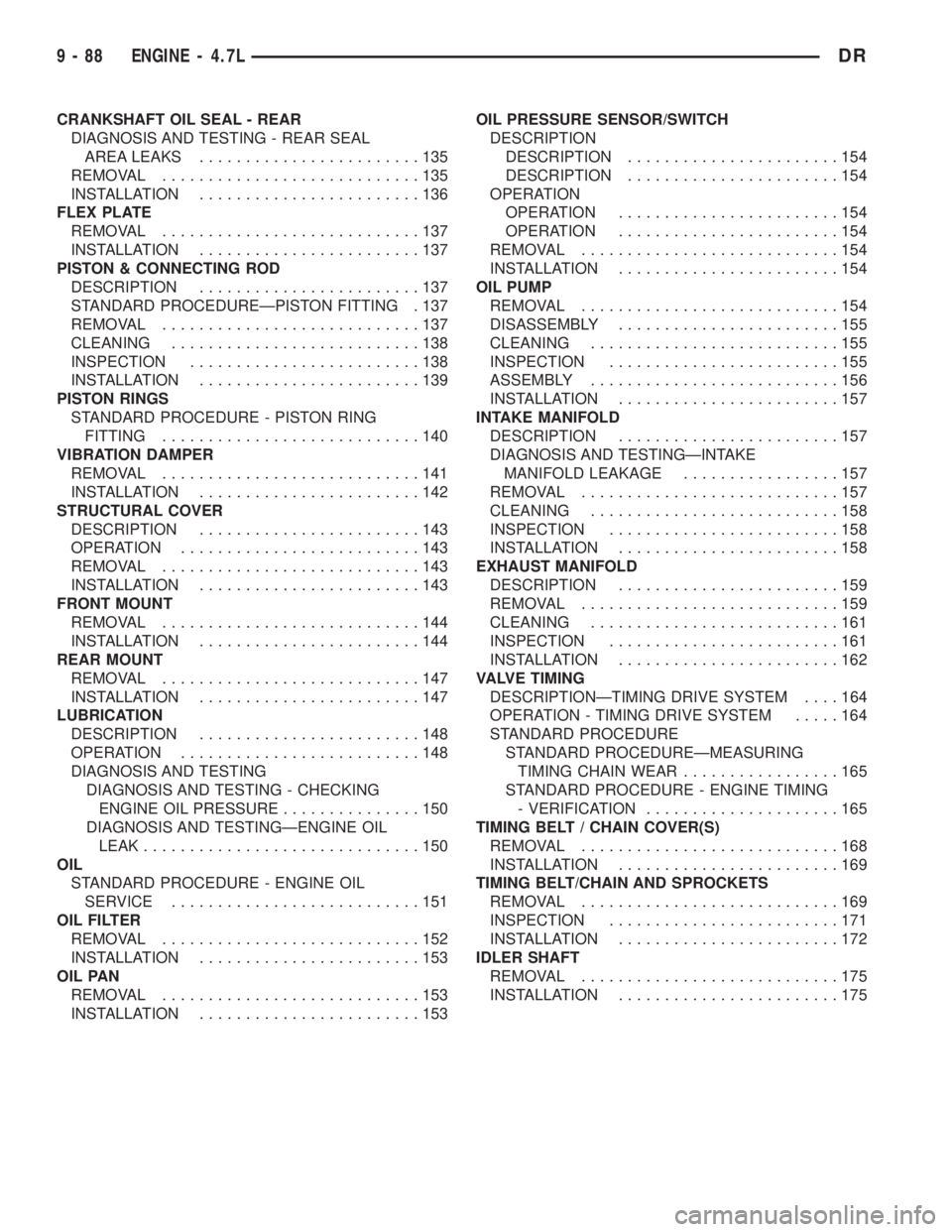

CRANKSHAFT OIL SEAL - REAR

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS........................135

REMOVAL............................135

INSTALLATION........................136

FLEX PLATE

REMOVAL............................137

INSTALLATION........................137

PISTON & CONNECTING ROD

DESCRIPTION........................137

STANDARD PROCEDUREÐPISTON FITTING . 137

REMOVAL............................137

CLEANING...........................138

INSPECTION.........................138

INSTALLATION........................139

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING............................140

VIBRATION DAMPER

REMOVAL............................141

INSTALLATION........................142

STRUCTURAL COVER

DESCRIPTION........................143

OPERATION..........................143

REMOVAL............................143

INSTALLATION........................143

FRONT MOUNT

REMOVAL............................144

INSTALLATION........................144

REAR MOUNT

REMOVAL............................147

INSTALLATION........................147

LUBRICATION

DESCRIPTION........................148

OPERATION..........................148

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE...............150

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAK..............................150

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE...........................151

OIL FILTER

REMOVAL............................152

INSTALLATION........................153

OIL PAN

REMOVAL............................153

INSTALLATION........................153OIL PRESSURE SENSOR/SWITCH

DESCRIPTION

DESCRIPTION.......................154

DESCRIPTION.......................154

OPERATION

OPERATION........................154

OPERATION........................154

REMOVAL............................154

INSTALLATION........................154

OIL PUMP

REMOVAL............................154

DISASSEMBLY........................155

CLEANING...........................155

INSPECTION.........................155

ASSEMBLY...........................156

INSTALLATION........................157

INTAKE MANIFOLD

DESCRIPTION........................157

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE.................157

REMOVAL............................157

CLEANING...........................158

INSPECTION.........................158

INSTALLATION........................158

EXHAUST MANIFOLD

DESCRIPTION........................159

REMOVAL............................159

CLEANING...........................161

INSPECTION.........................161

INSTALLATION........................162

VALVE TIMING

DESCRIPTIONÐTIMING DRIVE SYSTEM....164

OPERATION - TIMING DRIVE SYSTEM.....164

STANDARD PROCEDURE

STANDARD PROCEDUREÐMEASURING

TIMING CHAIN WEAR.................165

STANDARD PROCEDURE - ENGINE TIMING

- VERIFICATION.....................165

TIMING BELT / CHAIN COVER(S)

REMOVAL............................168

INSTALLATION........................169

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL............................169

INSPECTION.........................171

INSTALLATION........................172

IDLER SHAFT

REMOVAL............................175

INSTALLATION........................175

9 - 88 ENGINE - 4.7LDR

Page 1338 of 2895

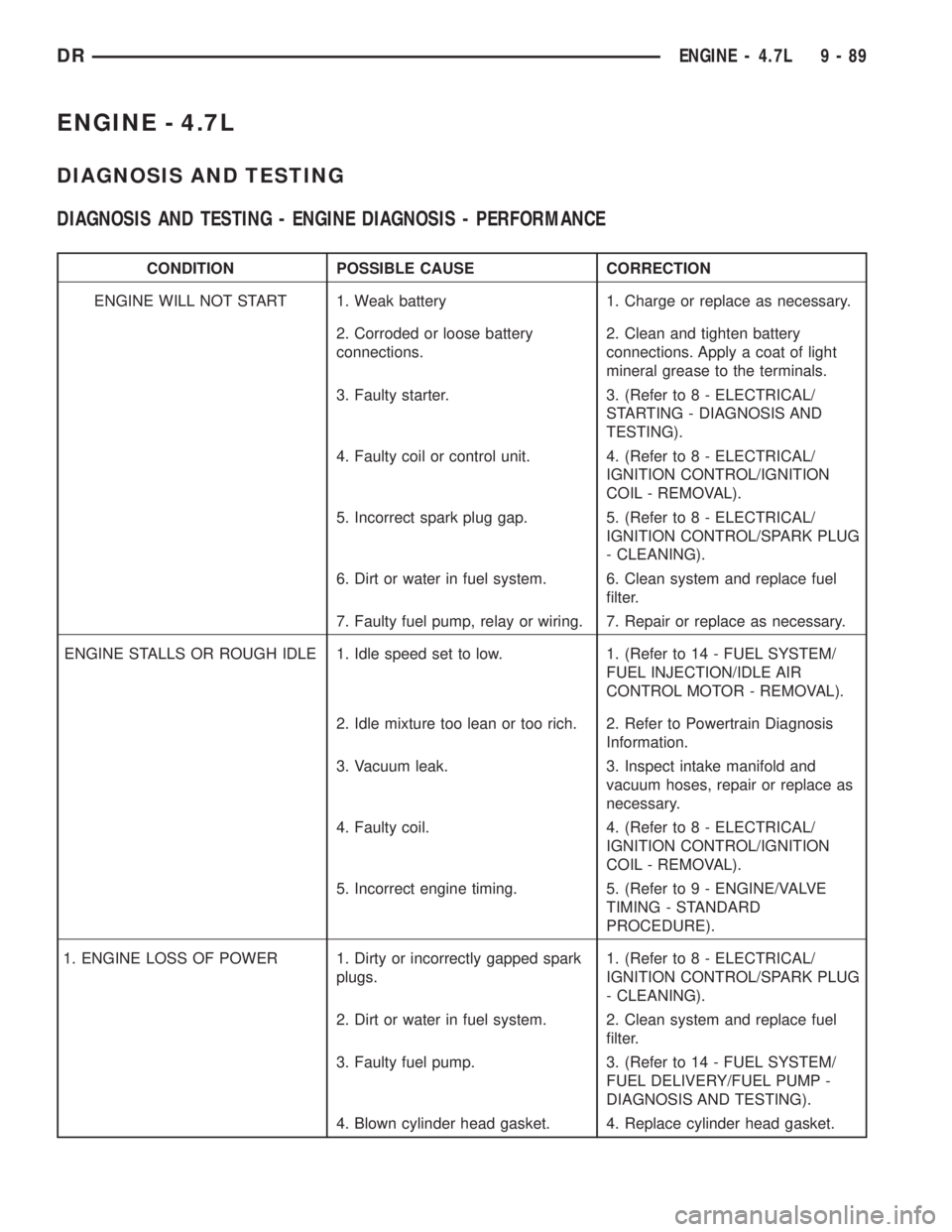

ENGINE - 4.7L

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

6. Dirt or water in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump, relay or wiring. 7. Repair or replace as necessary.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/IDLE AIR

CONTROL MOTOR - REMOVAL).

2. Idle mixture too lean or too rich. 2. Refer to Powertrain Diagnosis

Information.

3. Vacuum leak. 3. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect engine timing. 5. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD

PROCEDURE).

1. ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped spark

plugs.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

2. Dirt or water in fuel system. 2. Clean system and replace fuel

filter.

3. Faulty fuel pump. 3. (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

4. Blown cylinder head gasket. 4. Replace cylinder head gasket.

DRENGINE - 4.7L 9 - 89