DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1931 of 2895

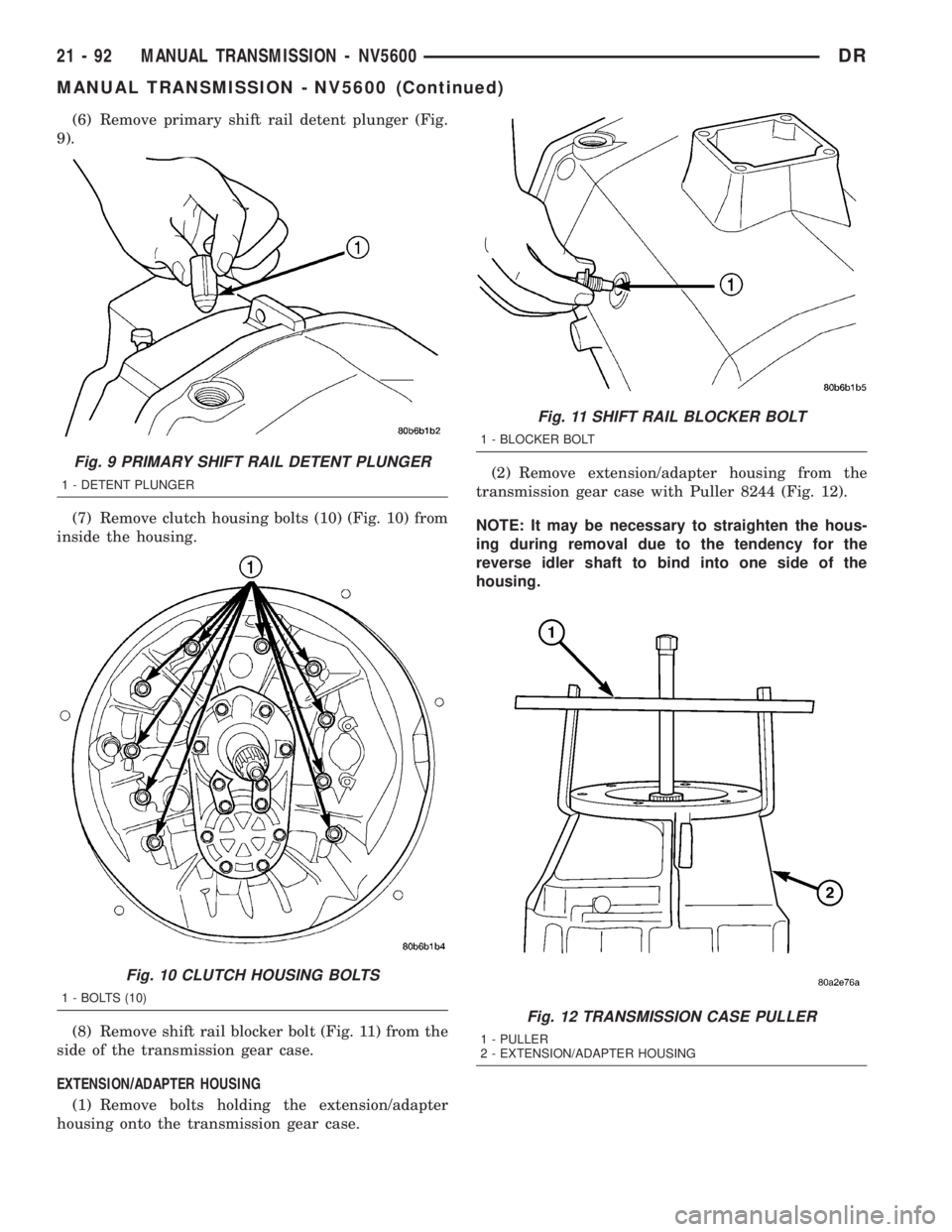

(6) Remove primary shift rail detent plunger (Fig.

9).

(7) Remove clutch housing bolts (10) (Fig. 10) from

inside the housing.

(8) Remove shift rail blocker bolt (Fig. 11) from the

side of the transmission gear case.

EXTENSION/ADAPTER HOUSING

(1) Remove bolts holding the extension/adapter

housing onto the transmission gear case.(2) Remove extension/adapter housing from the

transmission gear case with Puller 8244 (Fig. 12).

NOTE: It may be necessary to straighten the hous-

ing during removal due to the tendency for the

reverse idler shaft to bind into one side of the

housing.

Fig. 9 PRIMARY SHIFT RAIL DETENT PLUNGER

1 - DETENT PLUNGER

Fig. 10 CLUTCH HOUSING BOLTS

1 - BOLTS (10)

Fig. 11 SHIFT RAIL BLOCKER BOLT

1 - BLOCKER BOLT

Fig. 12 TRANSMISSION CASE PULLER

1 - PULLER

2 - EXTENSION/ADAPTER HOUSING

21 - 92 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1932 of 2895

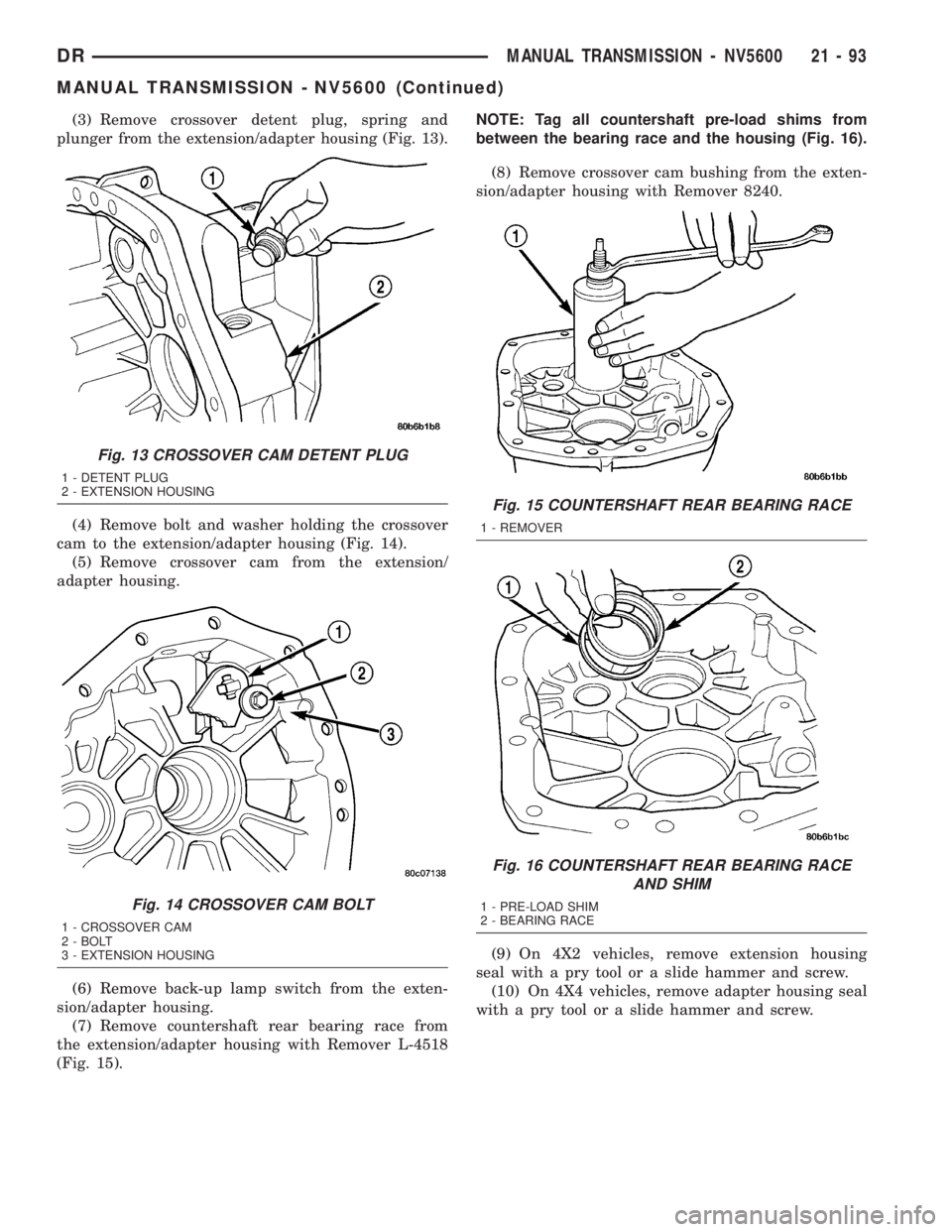

(3) Remove crossover detent plug, spring and

plunger from the extension/adapter housing (Fig. 13).

(4) Remove bolt and washer holding the crossover

cam to the extension/adapter housing (Fig. 14).

(5) Remove crossover cam from the extension/

adapter housing.

(6) Remove back-up lamp switch from the exten-

sion/adapter housing.

(7) Remove countershaft rear bearing race from

the extension/adapter housing with Remover L-4518

(Fig. 15).NOTE: Tag all countershaft pre-load shims from

between the bearing race and the housing (Fig. 16).

(8) Remove crossover cam bushing from the exten-

sion/adapter housing with Remover 8240.

(9) On 4X2 vehicles, remove extension housing

seal with a pry tool or a slide hammer and screw.

(10) On 4X4 vehicles, remove adapter housing seal

with a pry tool or a slide hammer and screw.

Fig. 13 CROSSOVER CAM DETENT PLUG

1 - DETENT PLUG

2 - EXTENSION HOUSING

Fig. 14 CROSSOVER CAM BOLT

1 - CROSSOVER CAM

2 - BOLT

3 - EXTENSION HOUSING

Fig. 15 COUNTERSHAFT REAR BEARING RACE

1 - REMOVER

Fig. 16 COUNTERSHAFT REAR BEARING RACE

AND SHIM

1 - PRE-LOAD SHIM

2 - BEARING RACE

DRMANUAL TRANSMISSION - NV5600 21 - 93

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1933 of 2895

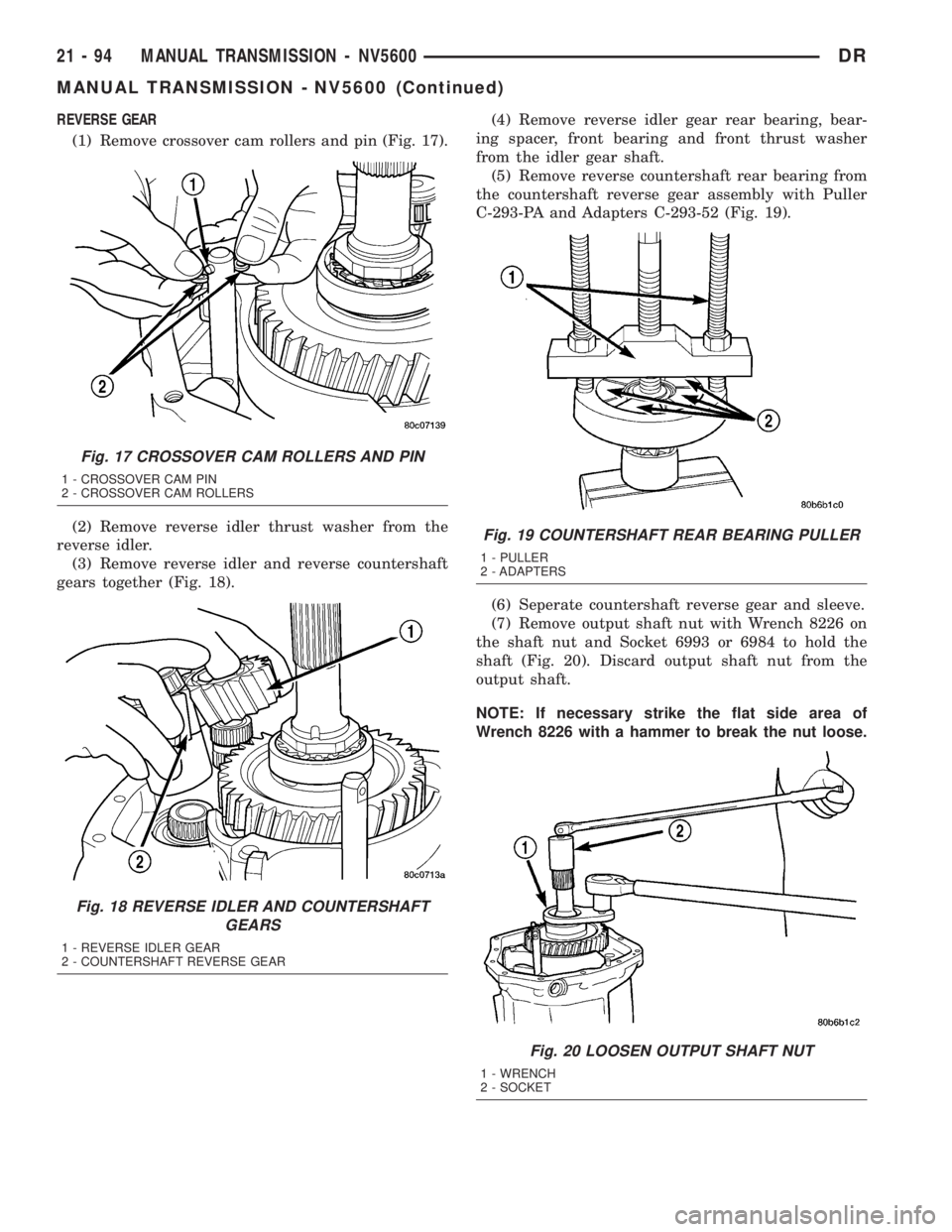

REVERSE GEAR

(1) Remove crossover cam rollers and pin (Fig. 17).

(2) Remove reverse idler thrust washer from the

reverse idler.

(3) Remove reverse idler and reverse countershaft

gears together (Fig. 18).(4) Remove reverse idler gear rear bearing, bear-

ing spacer, front bearing and front thrust washer

from the idler gear shaft.

(5) Remove reverse countershaft rear bearing from

the countershaft reverse gear assembly with Puller

C-293-PA and Adapters C-293-52 (Fig. 19).

(6) Seperate countershaft reverse gear and sleeve.

(7) Remove output shaft nut with Wrench 8226 on

the shaft nut and Socket 6993 or 6984 to hold the

shaft (Fig. 20). Discard output shaft nut from the

output shaft.

NOTE: If necessary strike the flat side area of

Wrench 8226 with a hammer to break the nut loose.

Fig. 17 CROSSOVER CAM ROLLERS AND PIN

1 - CROSSOVER CAM PIN

2 - CROSSOVER CAM ROLLERS

Fig. 18 REVERSE IDLER AND COUNTERSHAFT

GEARS

1 - REVERSE IDLER GEAR

2 - COUNTERSHAFT REVERSE GEAR

Fig. 19 COUNTERSHAFT REAR BEARING PULLER

1 - PULLER

2 - ADAPTERS

Fig. 20 LOOSEN OUTPUT SHAFT NUT

1 - WRENCH

2 - SOCKET

21 - 94 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1934 of 2895

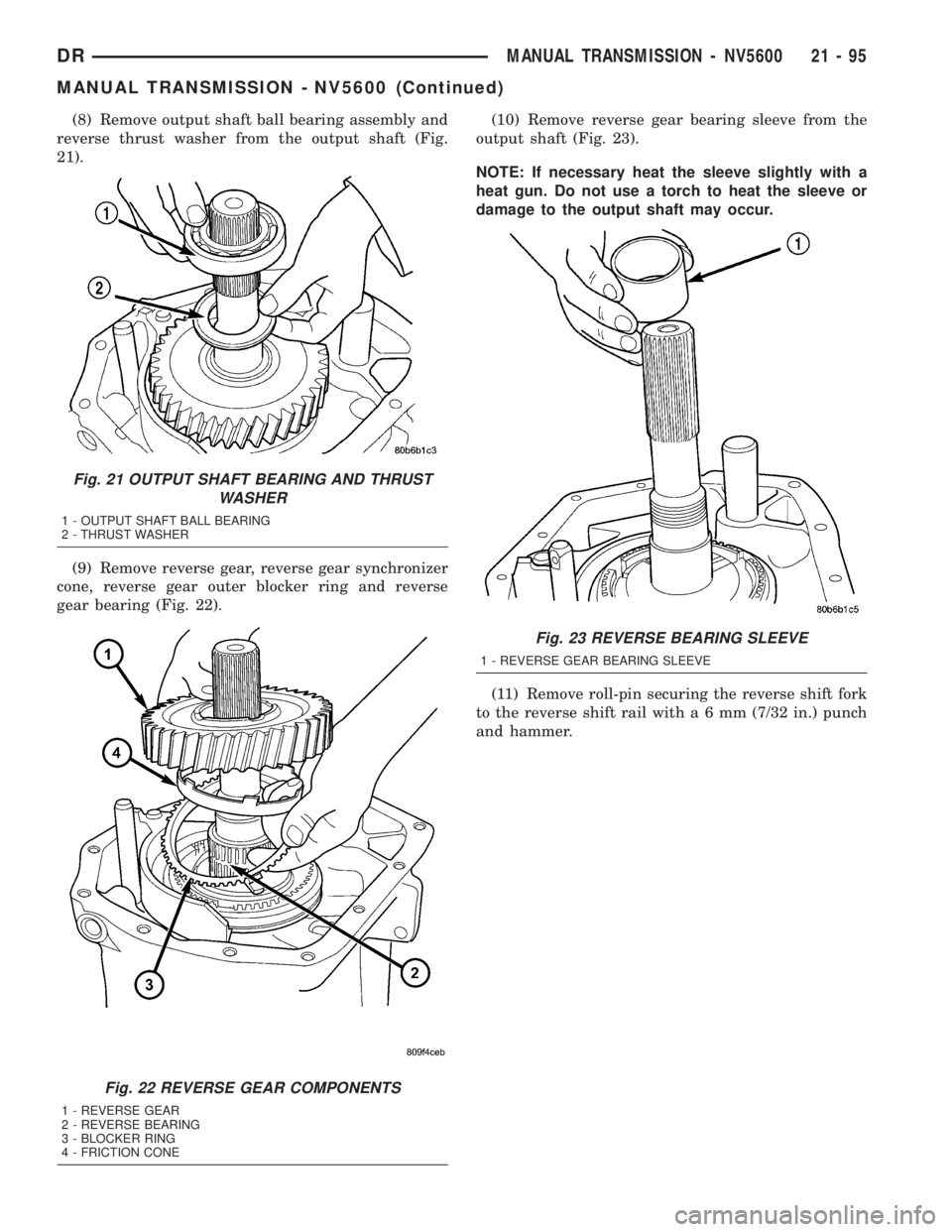

(8) Remove output shaft ball bearing assembly and

reverse thrust washer from the output shaft (Fig.

21).

(9) Remove reverse gear, reverse gear synchronizer

cone, reverse gear outer blocker ring and reverse

gear bearing (Fig. 22).(10) Remove reverse gear bearing sleeve from the

output shaft (Fig. 23).

NOTE: If necessary heat the sleeve slightly with a

heat gun. Do not use a torch to heat the sleeve or

damage to the output shaft may occur.

(11) Remove roll-pin securing the reverse shift fork

to the reverse shift rail witha6mm(7/32 in.) punch

and hammer.

Fig. 21 OUTPUT SHAFT BEARING AND THRUST

WASHER

1 - OUTPUT SHAFT BALL BEARING

2 - THRUST WASHER

Fig. 22 REVERSE GEAR COMPONENTS

1 - REVERSE GEAR

2 - REVERSE BEARING

3 - BLOCKER RING

4 - FRICTION CONE

Fig. 23 REVERSE BEARING SLEEVE

1 - REVERSE GEAR BEARING SLEEVE

DRMANUAL TRANSMISSION - NV5600 21 - 95

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1935 of 2895

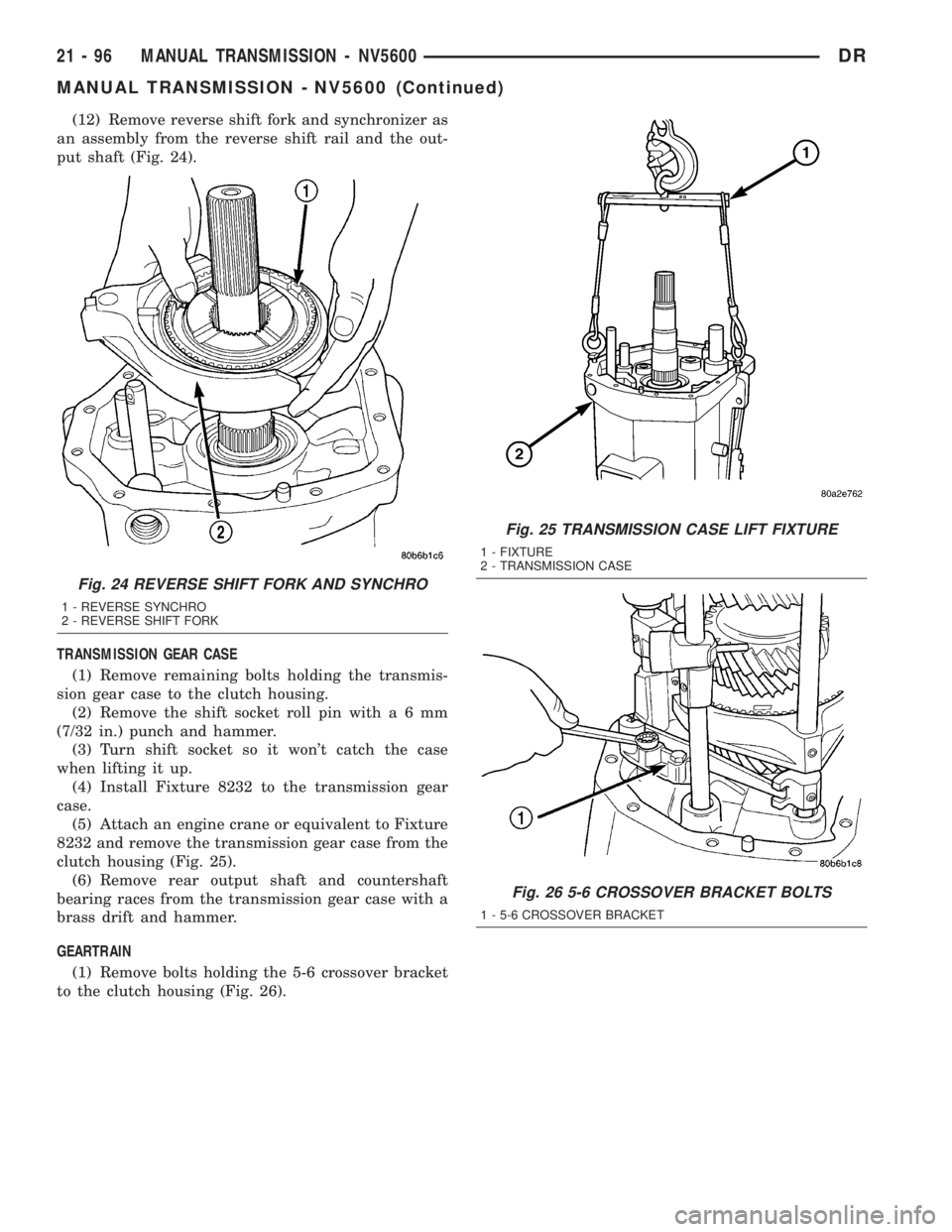

(12) Remove reverse shift fork and synchronizer as

an assembly from the reverse shift rail and the out-

put shaft (Fig. 24).

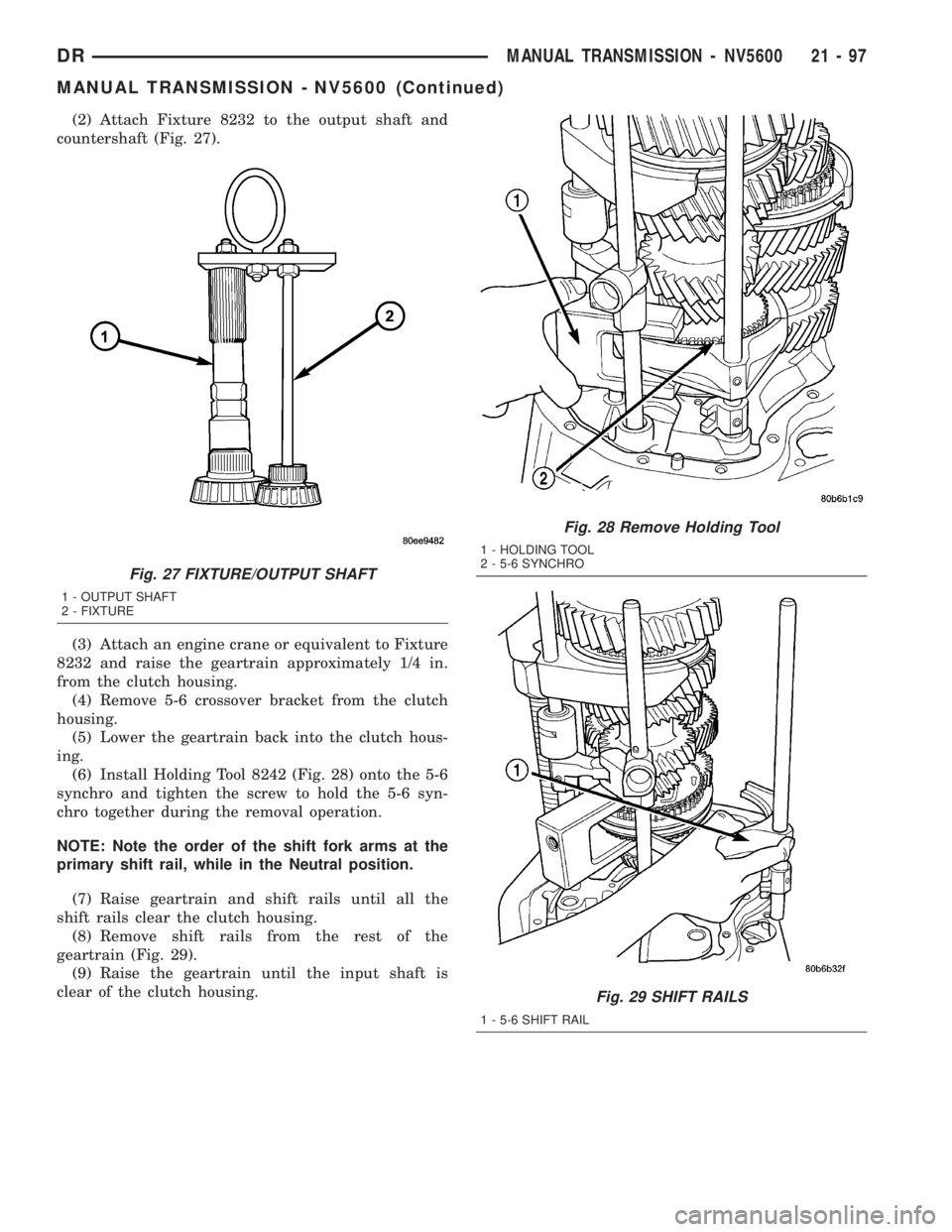

TRANSMISSION GEAR CASE

(1) Remove remaining bolts holding the transmis-

sion gear case to the clutch housing.

(2) Remove the shift socket roll pin witha6mm

(7/32 in.) punch and hammer.

(3) Turn shift socket so it won't catch the case

when lifting it up.

(4) Install Fixture 8232 to the transmission gear

case.

(5) Attach an engine crane or equivalent to Fixture

8232 and remove the transmission gear case from the

clutch housing (Fig. 25).

(6) Remove rear output shaft and countershaft

bearing races from the transmission gear case with a

brass drift and hammer.

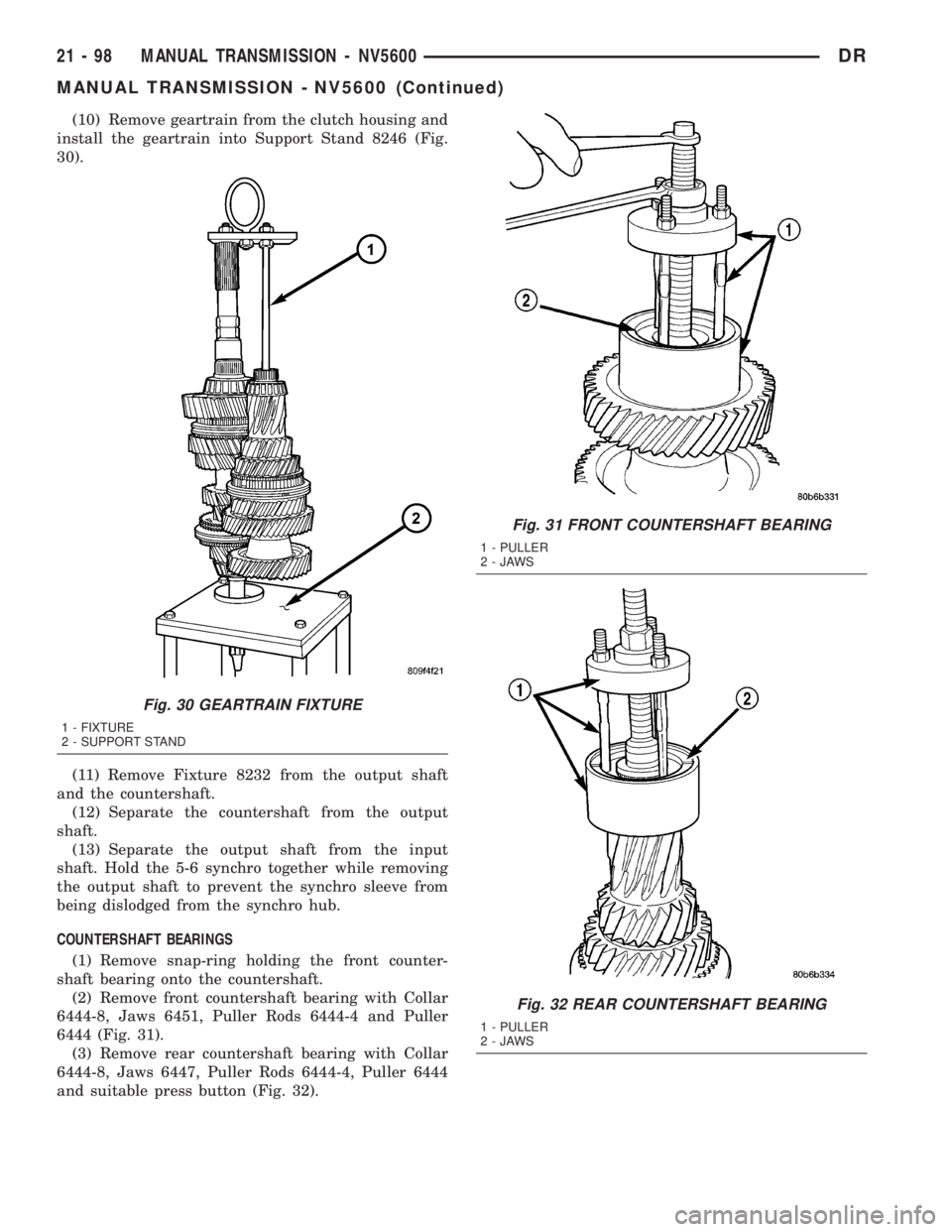

GEARTRAIN

(1) Remove bolts holding the 5-6 crossover bracket

to the clutch housing (Fig. 26).

Fig. 24 REVERSE SHIFT FORK AND SYNCHRO

1 - REVERSE SYNCHRO

2 - REVERSE SHIFT FORK

Fig. 25 TRANSMISSION CASE LIFT FIXTURE

1 - FIXTURE

2 - TRANSMISSION CASE

Fig. 26 5-6 CROSSOVER BRACKET BOLTS

1 - 5-6 CROSSOVER BRACKET

21 - 96 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1936 of 2895

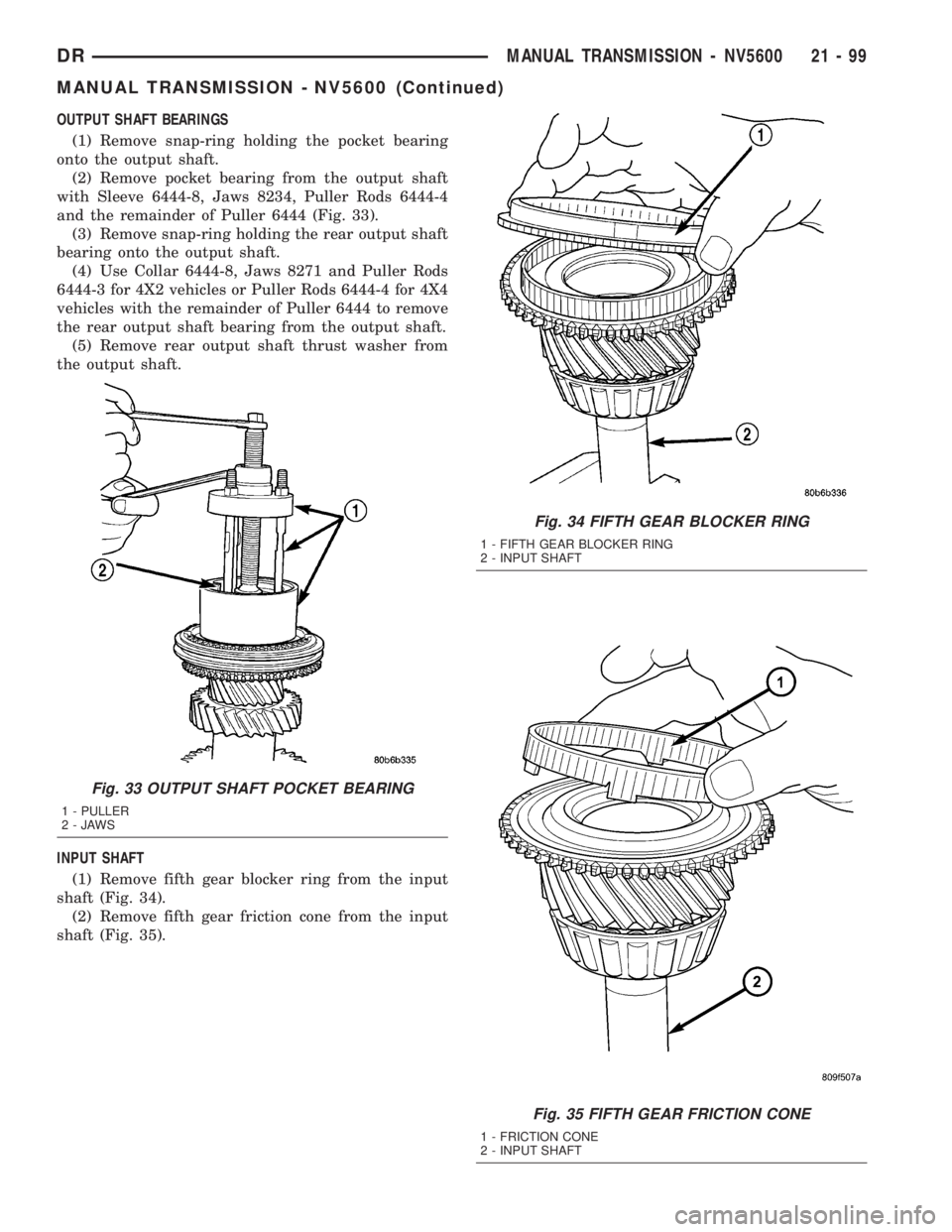

(2) Attach Fixture 8232 to the output shaft and

countershaft (Fig. 27).

(3) Attach an engine crane or equivalent to Fixture

8232 and raise the geartrain approximately 1/4 in.

from the clutch housing.

(4) Remove 5-6 crossover bracket from the clutch

housing.

(5) Lower the geartrain back into the clutch hous-

ing.

(6) Install Holding Tool 8242 (Fig. 28) onto the 5-6

synchro and tighten the screw to hold the 5-6 syn-

chro together during the removal operation.

NOTE: Note the order of the shift fork arms at the

primary shift rail, while in the Neutral position.

(7) Raise geartrain and shift rails until all the

shift rails clear the clutch housing.

(8) Remove shift rails from the rest of the

geartrain (Fig. 29).

(9) Raise the geartrain until the input shaft is

clear of the clutch housing.

Fig. 27 FIXTURE/OUTPUT SHAFT

1 - OUTPUT SHAFT

2 - FIXTURE

Fig. 28 Remove Holding Tool

1 - HOLDING TOOL

2 - 5-6 SYNCHRO

Fig. 29 SHIFT RAILS

1 - 5-6 SHIFT RAIL

DRMANUAL TRANSMISSION - NV5600 21 - 97

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1937 of 2895

(10) Remove geartrain from the clutch housing and

install the geartrain into Support Stand 8246 (Fig.

30).

(11) Remove Fixture 8232 from the output shaft

and the countershaft.

(12) Separate the countershaft from the output

shaft.

(13) Separate the output shaft from the input

shaft. Hold the 5-6 synchro together while removing

the output shaft to prevent the synchro sleeve from

being dislodged from the synchro hub.

COUNTERSHAFT BEARINGS

(1) Remove snap-ring holding the front counter-

shaft bearing onto the countershaft.

(2) Remove front countershaft bearing with Collar

6444-8, Jaws 6451, Puller Rods 6444-4 and Puller

6444 (Fig. 31).

(3) Remove rear countershaft bearing with Collar

6444-8, Jaws 6447, Puller Rods 6444-4, Puller 6444

and suitable press button (Fig. 32).

Fig. 30 GEARTRAIN FIXTURE

1 - FIXTURE

2 - SUPPORT STAND

Fig. 31 FRONT COUNTERSHAFT BEARING

1 - PULLER

2-JAWS

Fig. 32 REAR COUNTERSHAFT BEARING

1 - PULLER

2-JAWS

21 - 98 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1938 of 2895

OUTPUT SHAFT BEARINGS

(1) Remove snap-ring holding the pocket bearing

onto the output shaft.

(2) Remove pocket bearing from the output shaft

with Sleeve 6444-8, Jaws 8234, Puller Rods 6444-4

and the remainder of Puller 6444 (Fig. 33).

(3) Remove snap-ring holding the rear output shaft

bearing onto the output shaft.

(4) Use Collar 6444-8, Jaws 8271 and Puller Rods

6444-3 for 4X2 vehicles or Puller Rods 6444-4 for 4X4

vehicles with the remainder of Puller 6444 to remove

the rear output shaft bearing from the output shaft.

(5) Remove rear output shaft thrust washer from

the output shaft.

INPUT SHAFT

(1) Remove fifth gear blocker ring from the input

shaft (Fig. 34).

(2) Remove fifth gear friction cone from the input

shaft (Fig. 35).

Fig. 33 OUTPUT SHAFT POCKET BEARING

1 - PULLER

2-JAWS

Fig. 34 FIFTH GEAR BLOCKER RING

1 - FIFTH GEAR BLOCKER RING

2 - INPUT SHAFT

Fig. 35 FIFTH GEAR FRICTION CONE

1 - FRICTION CONE

2 - INPUT SHAFT

DRMANUAL TRANSMISSION - NV5600 21 - 99

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1939 of 2895

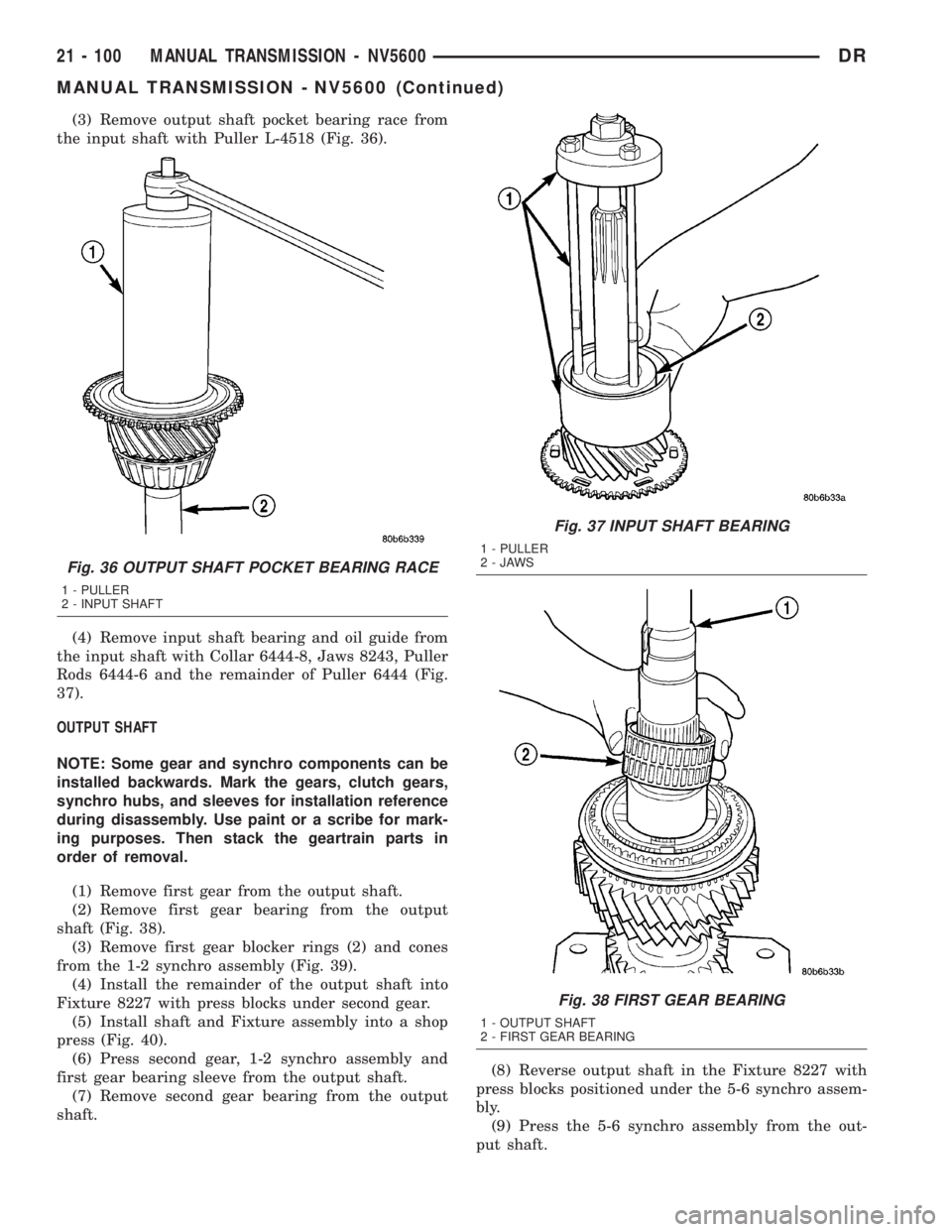

(3) Remove output shaft pocket bearing race from

the input shaft with Puller L-4518 (Fig. 36).

(4) Remove input shaft bearing and oil guide from

the input shaft with Collar 6444-8, Jaws 8243, Puller

Rods 6444-6 and the remainder of Puller 6444 (Fig.

37).

OUTPUT SHAFT

NOTE: Some gear and synchro components can be

installed backwards. Mark the gears, clutch gears,

synchro hubs, and sleeves for installation reference

during disassembly. Use paint or a scribe for mark-

ing purposes. Then stack the geartrain parts in

order of removal.

(1) Remove first gear from the output shaft.

(2) Remove first gear bearing from the output

shaft (Fig. 38).

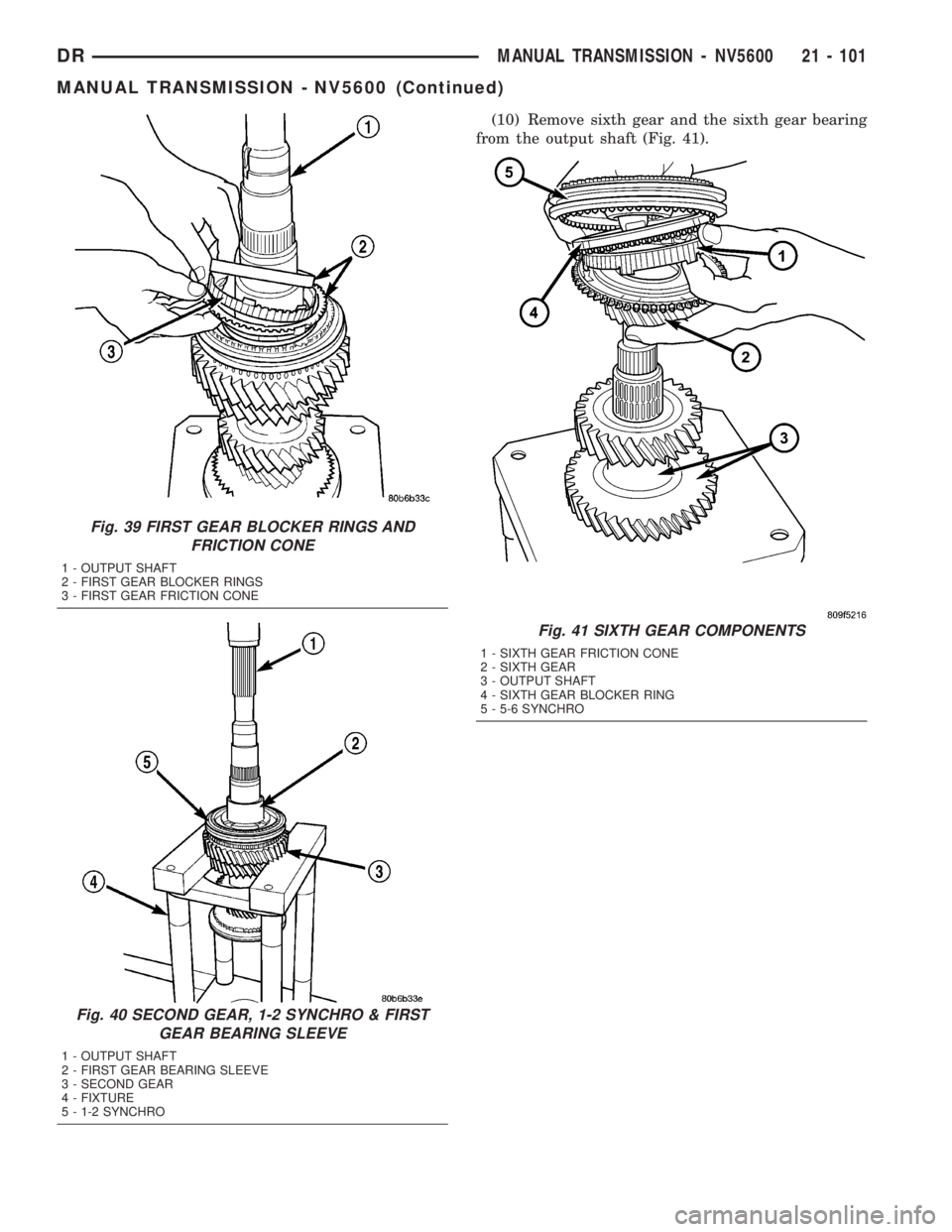

(3) Remove first gear blocker rings (2) and cones

from the 1-2 synchro assembly (Fig. 39).

(4) Install the remainder of the output shaft into

Fixture 8227 with press blocks under second gear.

(5) Install shaft and Fixture assembly into a shop

press (Fig. 40).

(6) Press second gear, 1-2 synchro assembly and

first gear bearing sleeve from the output shaft.

(7) Remove second gear bearing from the output

shaft.(8) Reverse output shaft in the Fixture 8227 with

press blocks positioned under the 5-6 synchro assem-

bly.

(9) Press the 5-6 synchro assembly from the out-

put shaft.

Fig. 36 OUTPUT SHAFT POCKET BEARING RACE

1 - PULLER

2 - INPUT SHAFT

Fig. 37 INPUT SHAFT BEARING

1 - PULLER

2-JAWS

Fig. 38 FIRST GEAR BEARING

1 - OUTPUT SHAFT

2 - FIRST GEAR BEARING

21 - 100 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1940 of 2895

(10) Remove sixth gear and the sixth gear bearing

from the output shaft (Fig. 41).

Fig. 39 FIRST GEAR BLOCKER RINGS AND

FRICTION CONE

1 - OUTPUT SHAFT

2 - FIRST GEAR BLOCKER RINGS

3 - FIRST GEAR FRICTION CONE

Fig. 40 SECOND GEAR, 1-2 SYNCHRO & FIRST

GEAR BEARING SLEEVE

1 - OUTPUT SHAFT

2 - FIRST GEAR BEARING SLEEVE

3 - SECOND GEAR

4 - FIXTURE

5 - 1-2 SYNCHRO

Fig. 41 SIXTH GEAR COMPONENTS

1 - SIXTH GEAR FRICTION CONE

2 - SIXTH GEAR

3 - OUTPUT SHAFT

4 - SIXTH GEAR BLOCKER RING

5 - 5-6 SYNCHRO

DRMANUAL TRANSMISSION - NV5600 21 - 101

MANUAL TRANSMISSION - NV5600 (Continued)