DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1901 of 2895

(8) Install reverse idler gear in case (Fig. 69).

(9) Install idler gear rear thrust washer between

idler gear and case boss (Fig. 69).

(10) Align idler gear bearings and thrust washers

with a drift.

(11) Install reverse idler shaft with notched end of

shaft facing countershaft (Fig. 70).

(12) Lift countershaft upward and position wood

block between front of shaft and case (Fig. 71).

(13) Install rear bearing cone on countershaft with

Installer C-4040 (Fig. 72).

(14) Remove wood block from under countershaft

and lower countershaft front bearing into front bear-

ing cup.(15) Lubricate countershaft rear bearing cup and

cone with petroleum jelly.

(16) Install countershaft rear bearing cup in gear

case and over rear bearing (Fig. 73). Tap cup into

place with plastic mallet if necessary.

(17) Install countershaft rear bearing plate (Fig.

74).

NOTE: Verify plate is seated in notch in reverse

idler shaft before tightening bearing plate bolts.

Fig. 69 IDLER GEAR

1 - REAR THRUST WASHER

2 - REVERSE IDLER GEAR

3 - FRONT THRUST WASHER

Fig. 70 REVERSE IDLER SHAFT

1 - COUNTERSHAFT

2 - SHAFT NOTCH

3 - REVERSE IDLER SHAFT

Fig. 71 SUPPORTING COUNTERSHAFT

1 - COUNTERSHAFT

2 - WOOD BLOCK

Fig. 72 COUNTERSHAFT REAR BEARING

1 - INSTALLER

2 - REAR BEARING

3 - COUNTERSHAFT

21 - 62 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1902 of 2895

(18) Apply Mopar silicone adhesive/sealer or equiv-

alent to flange and lip of new cap. Installnewfront

bearing cap in gear case (Fig. 75) with Handle

C-4171 and Installer C-3972-A.

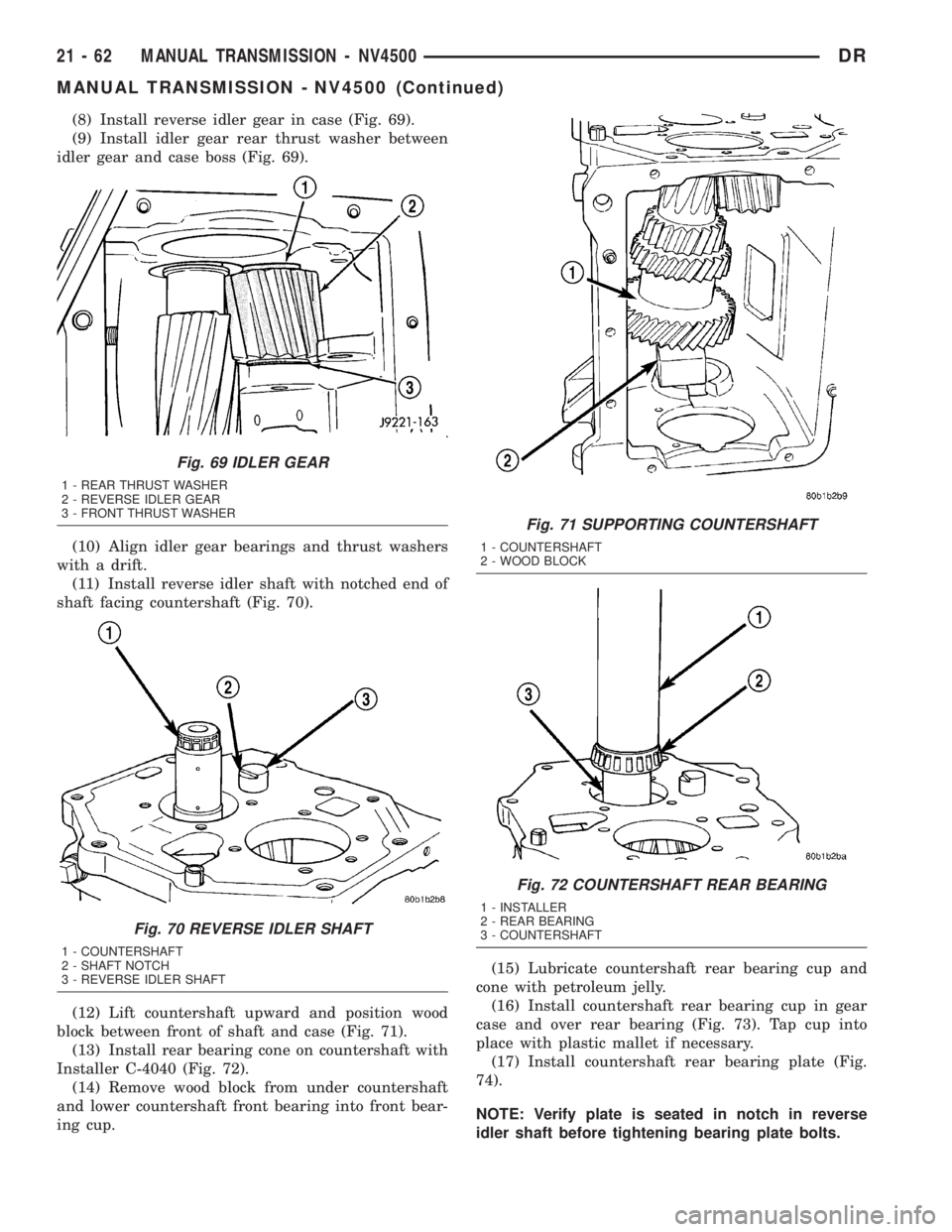

COUNTERSHAFT END PLAY

(1) Rotate countershaft 4-5 times to seat bearings.

(2) Mount dial indicator on case. Then position

indicator plunger on end of countershaft and zero

dial indicator (Fig. 76).

(3) Raise countershaft with screwdriver and note

end play reading on dial indicator. End play should

be 0.051 - 0.15 mm (0.002 - 0.006 in.).

(4) Remove countershaft rear bearing plate.

(5) Install a end play shim that will provide mini-

mum countershaft end play. Position shim on rear

bearing cup (Fig. 77).

Fig. 73 COUNTERSHAFT REAR BEARING CUP

1 - COUNTERSHAFT REAR BEARING CUP

Fig. 74 COUNTERSHAFT REAR BEARING PLATE

1 - COUNTERSHAFT

2 - REAR BEARING PLATE

3 - IDLER SHAFT

Fig. 75 COUNTERSHAFT FRONT BEARING CAP

1 - FRONT BEARING CAP

Fig. 76 MEASURING COUNTERSHAFT END PLAY

1 - DIAL INDICATOR

2 - COUNTER SHAFT

3 - INDICATOR MOUNTING ARM AND BASE

Fig. 77 COUNTERSHAFT END PLAY SHIM

1 - REAR BEARING CUP

2 - END PLAY SHIM (SELECTIVE)

DRMANUAL TRANSMISSION - NV4500 21 - 63

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1903 of 2895

(6) Install countershaft rear bearing plate (Fig.

74).

NOTE: Verify plate is seated in reverse idler shaft

notch and end play shims are still in position

before installing bolts.

(7) Apply 1-2 drops Mopar Loc N' Seal or equiva-

lent to threads of rear bearing plate bolts. Then

install and tighten bearing plate bolts to 23 N´m (200

in. lbs.).

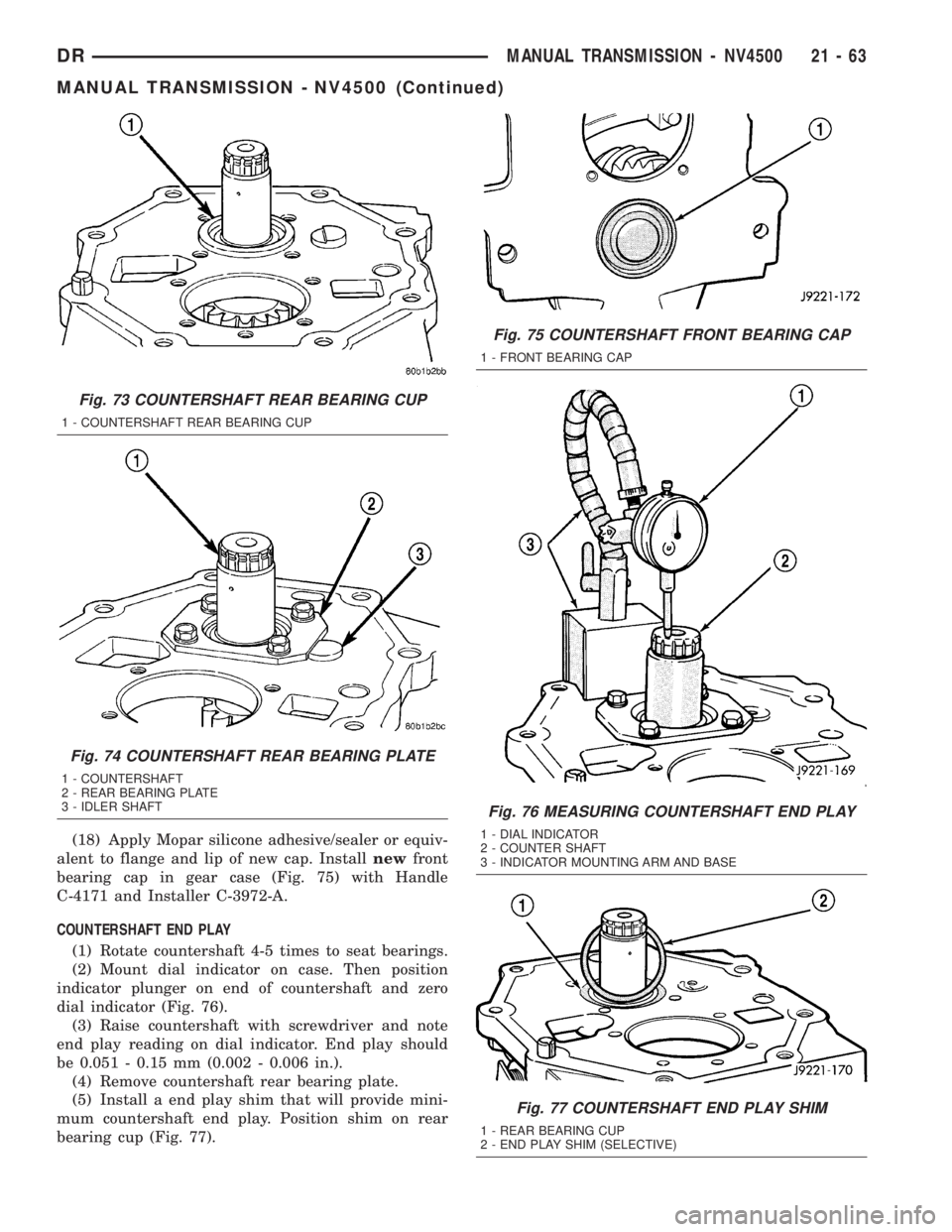

SHIFT LUG AND RAIL

(1) Lubricate shift lug and rail with CastroltSyn-

torq or equivalent.

(2) Insert shift lug rail part way into case.

(3) Install shift lug on rail.

(4) Position shift rail so roll pin notches are

toward outside of case (Fig. 78).

(5) Install roll pin that secures lug to rail (Fig. 78).

MAINSHAFT AND GEARTRAIN

CAUTION: The reverse, 1-2 and 3-4 synchro compo-

nents can be assembled and installed incorrectly.

Follow assembly procedures for component identi-

fication and location.

Lubricate mainshaft bearing surfaces and all bear-

ing assemblies with CastroltSyntorq or with petro-

leum jelly.

(1) Install first snap ring in rear most groove of

mainshaft hub (Fig. 79). This snap ring locates first

gear clutch gear on shaft.NOTE: Four of these snap rings are used to secure

various components on the mainshaft 1-2 synchro

hub. The snap rings are all the same size and are

interchangeable.

(2) Install first gear clutch cone on mainshaft 1-2

synchro hub with recessed side of cone facing front

(Fig. 80). Verify cone is seated against snap ring on

hub.

Fig. 78 SHIFT LUG AND RAIL

1 - NOTCHES (FOR 5TH GEAR SHIFT FORK ROLL PINS)

2 - LUG RAIL

3 - ROLL PIN HOLE

4 - SHIFT LUG

Fig. 79 FIRST GEAR BEARING AND SNAP RING

1 - SNAP RING

2 - FIRST GEAR BEARING

3 - MAINSHAFT SYNCHRO HUB

Fig. 80 FIRST GEAR CLUTCH CONE

1 - MAINSHAFT 1-2 SYNCHRO HUB

2 - FIRST GEAR CLUTCH CONE

21 - 64 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1904 of 2895

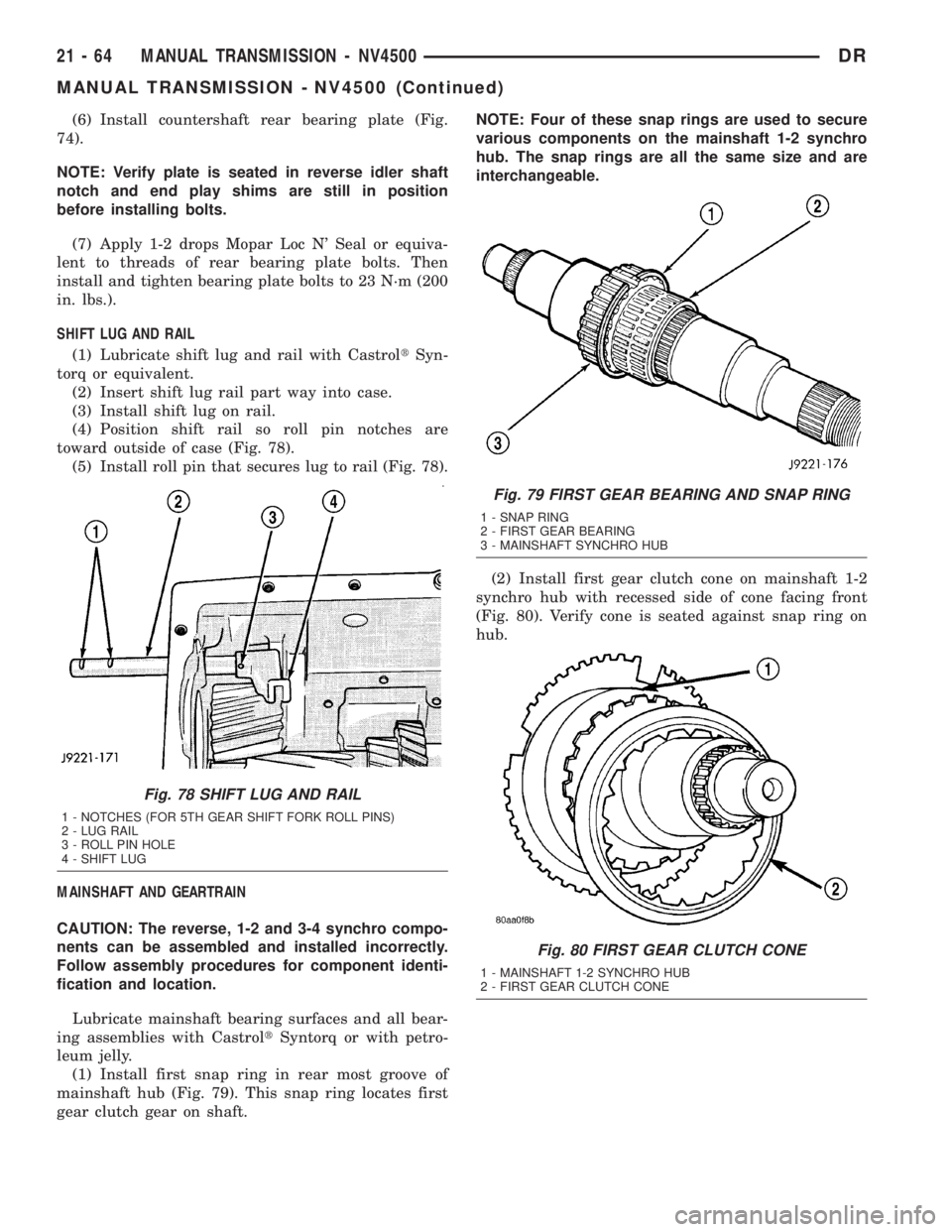

(3) Install snap ring on mainshaft 1-2 synchro hub

to secure clutch cone (Fig. 81). Verify snap ring is

seated in hub groove and against clutch cone.

(4) Support mainshaft in upright position to install

remaining gears, snap rings and synchro compo-

nents. Shaft can be supported in gear case or hole

can be cut in workbench to support shaft.

(5) If 1-2 synchro hub and sleeve were disassem-

bled for service, reassemble hub, sleeve, struts and

springs as follows:

(a) Align and install sleeve on hub. Rotate sleeve

until it slides onto hub. Sleeve only fits one way

and will easily slide onto hub when long slot in

sleeve, aligns with long shoulder on hub (Fig. 82).

(b) Place wood blocks under hub that will raise

hub about 3.5 cm (1.375 in.) above surface of work-

bench. Then allow sleeve to drop down on hub (Fig.

83).

(c) Install springs and struts in hub (Fig. 83).

Use lots of petroleum jelly to hold them in place.

Then compress struts with your fingers and move

sleeve upward until struts are started in sleeve.

Verify that struts are engaged in sleeve before pro-

ceeding.

(d) Turn synchro assembly upright. Then move

sleeve into neutral position on hub and work struts

into sleeve at same time. Be sure struts are seated

and springs are not displaced during assembly.

Fig. 81 FIRST GEAR CLUTCH CONE SNAP RING

1 - FIRST GEAR CLUTCH CONE

2 - MAINSHAFT 1-2 SYNCHRO HUB

3 - CLUTCH CONE SNAP RING

Fig. 82 1-2 SYNCHRO SLEEVE ON HUB

1 - ALIGN WIDE SLOT IN SLEEVE WITH WIDE SPLINE OF HUB

2 - 1-2 SLEEVE AND HUB

Fig. 83 1-2 SYNCHRO STRUTS AND SPRINGS

1 - WOOD BLOCKS

2 - HUB

3 - SLEEVE

4 - STRUTS AND SPRINGS (4 EACH)

DRMANUAL TRANSMISSION - NV4500 21 - 65

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1905 of 2895

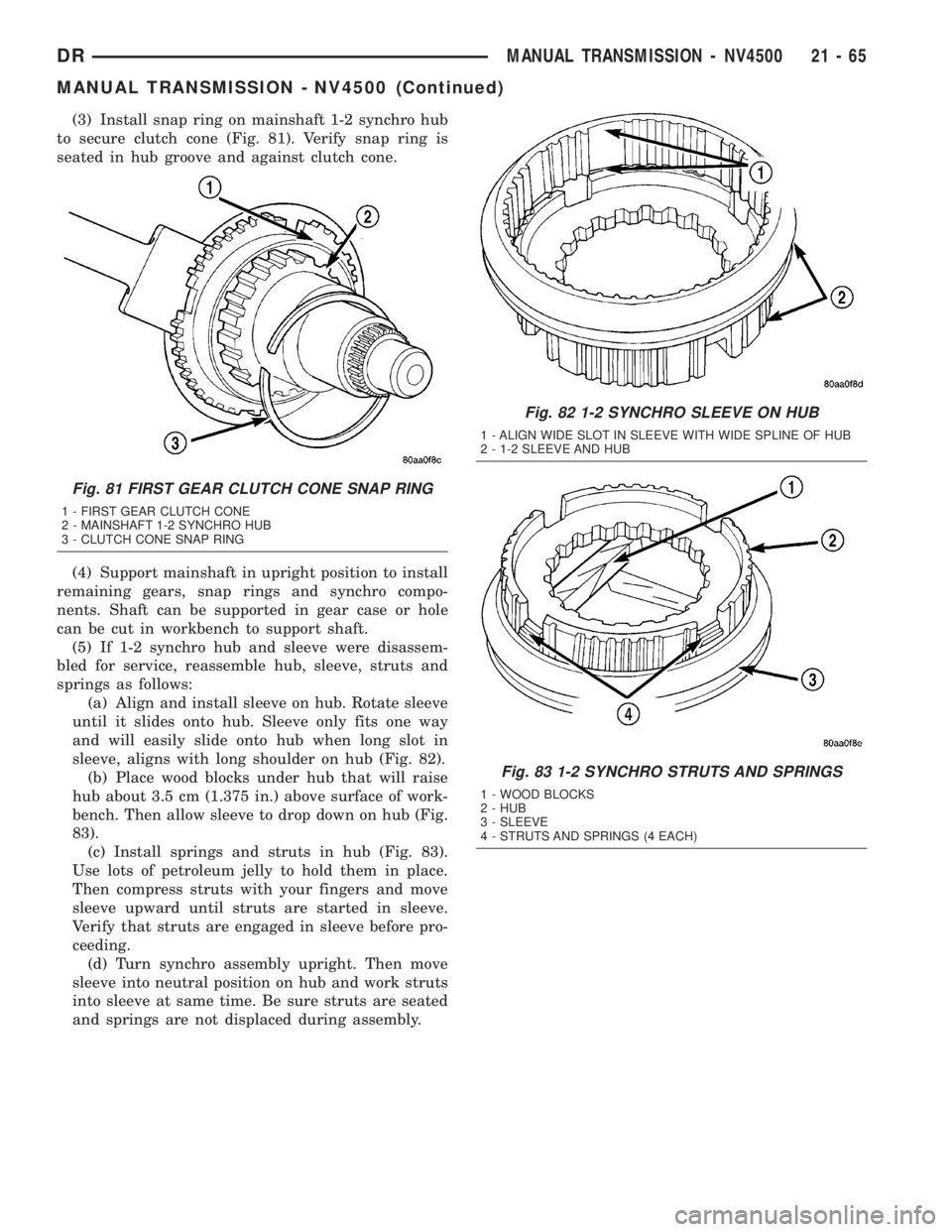

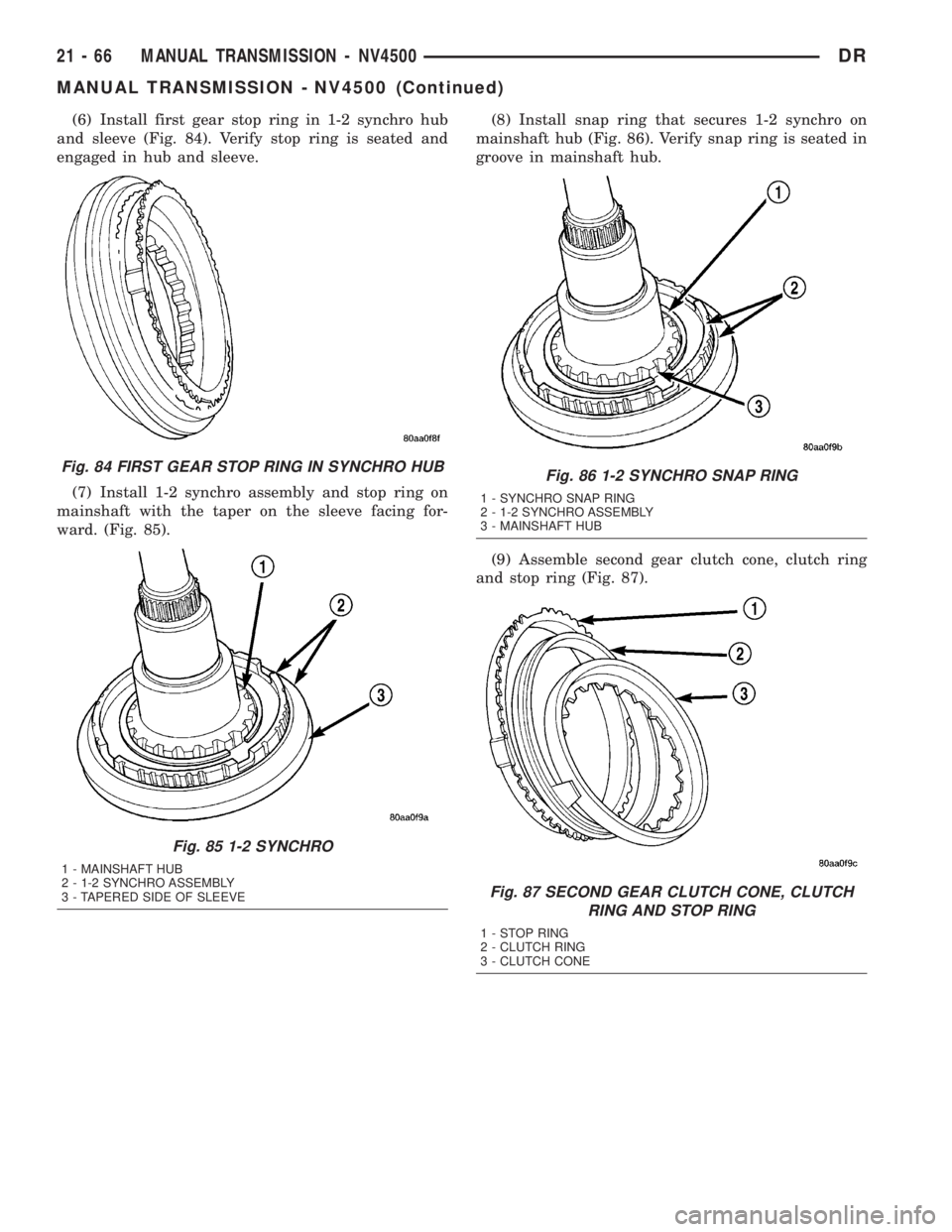

(6) Install first gear stop ring in 1-2 synchro hub

and sleeve (Fig. 84). Verify stop ring is seated and

engaged in hub and sleeve.

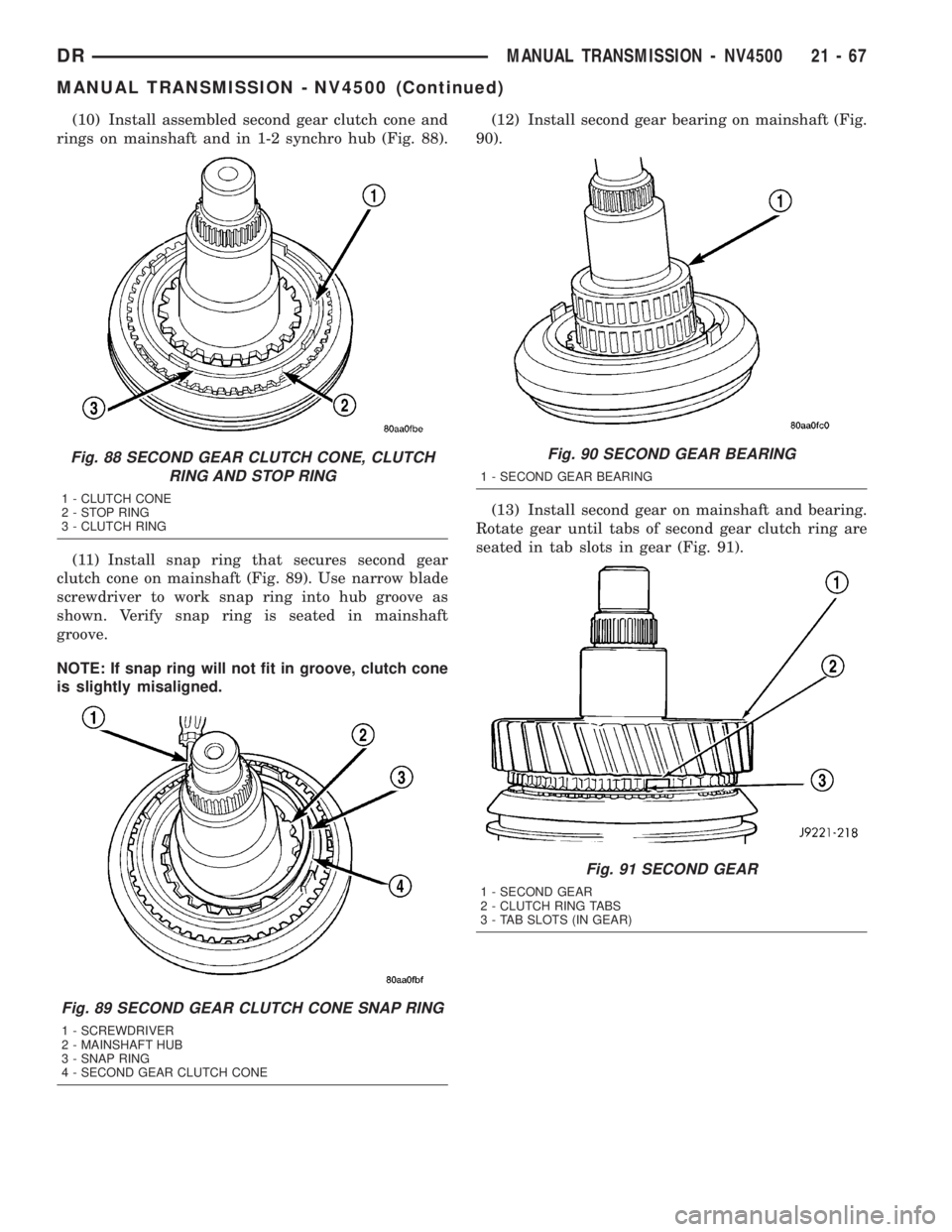

(7) Install 1-2 synchro assembly and stop ring on

mainshaft with the taper on the sleeve facing for-

ward. (Fig. 85).(8) Install snap ring that secures 1-2 synchro on

mainshaft hub (Fig. 86). Verify snap ring is seated in

groove in mainshaft hub.

(9) Assemble second gear clutch cone, clutch ring

and stop ring (Fig. 87).

Fig. 84 FIRST GEAR STOP RING IN SYNCHRO HUB

Fig. 85 1-2 SYNCHRO

1 - MAINSHAFT HUB

2 - 1-2 SYNCHRO ASSEMBLY

3 - TAPERED SIDE OF SLEEVE

Fig. 86 1-2 SYNCHRO SNAP RING

1 - SYNCHRO SNAP RING

2 - 1-2 SYNCHRO ASSEMBLY

3 - MAINSHAFT HUB

Fig. 87 SECOND GEAR CLUTCH CONE, CLUTCH

RING AND STOP RING

1 - STOP RING

2 - CLUTCH RING

3 - CLUTCH CONE

21 - 66 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1906 of 2895

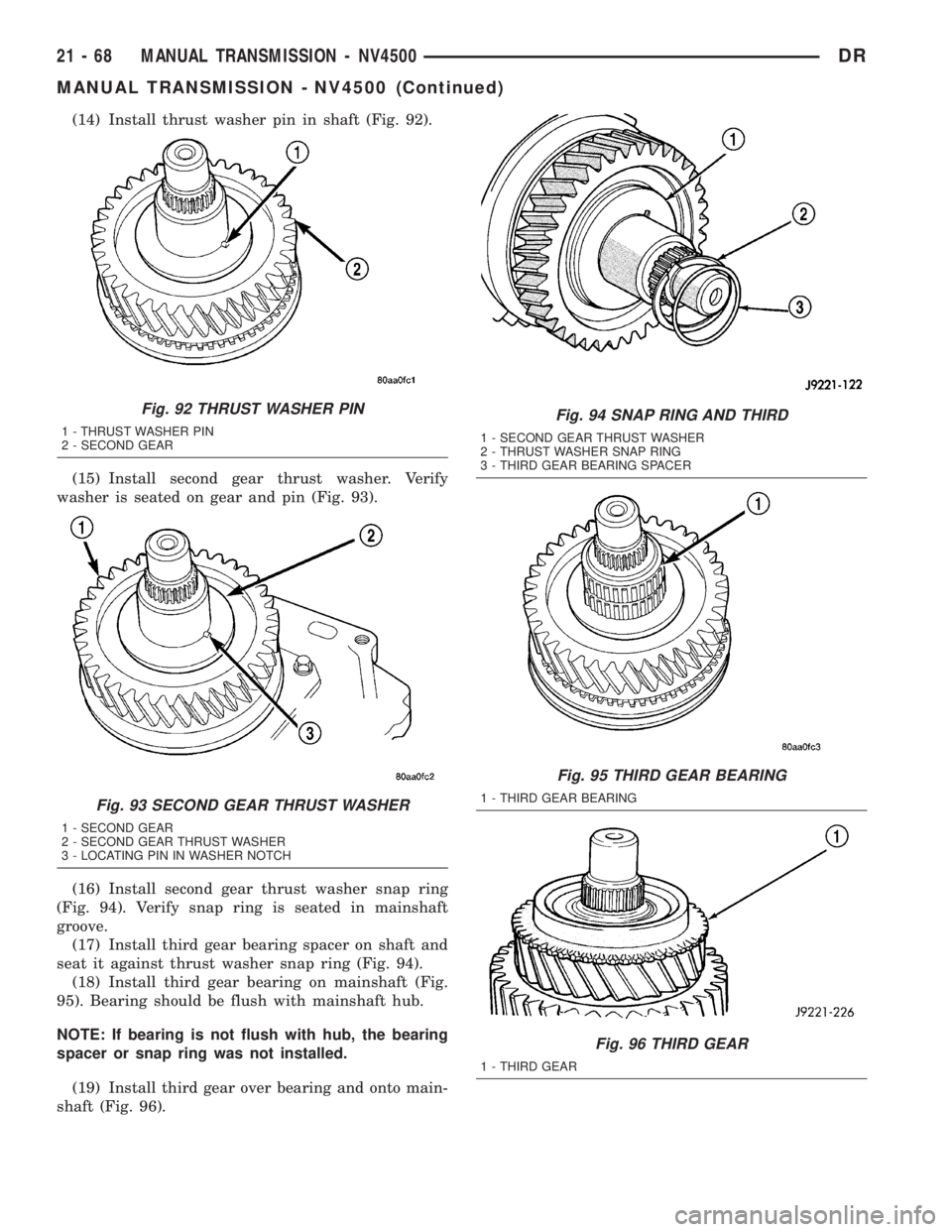

(10) Install assembled second gear clutch cone and

rings on mainshaft and in 1-2 synchro hub (Fig. 88).

(11) Install snap ring that secures second gear

clutch cone on mainshaft (Fig. 89). Use narrow blade

screwdriver to work snap ring into hub groove as

shown. Verify snap ring is seated in mainshaft

groove.

NOTE: If snap ring will not fit in groove, clutch cone

is slightly misaligned.(12) Install second gear bearing on mainshaft (Fig.

90).

(13) Install second gear on mainshaft and bearing.

Rotate gear until tabs of second gear clutch ring are

seated in tab slots in gear (Fig. 91).

Fig. 88 SECOND GEAR CLUTCH CONE, CLUTCH

RING AND STOP RING

1 - CLUTCH CONE

2 - STOP RING

3 - CLUTCH RING

Fig. 89 SECOND GEAR CLUTCH CONE SNAP RING

1 - SCREWDRIVER

2 - MAINSHAFT HUB

3 - SNAP RING

4 - SECOND GEAR CLUTCH CONE

Fig. 90 SECOND GEAR BEARING

1 - SECOND GEAR BEARING

Fig. 91 SECOND GEAR

1 - SECOND GEAR

2 - CLUTCH RING TABS

3 - TAB SLOTS (IN GEAR)

DRMANUAL TRANSMISSION - NV4500 21 - 67

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1907 of 2895

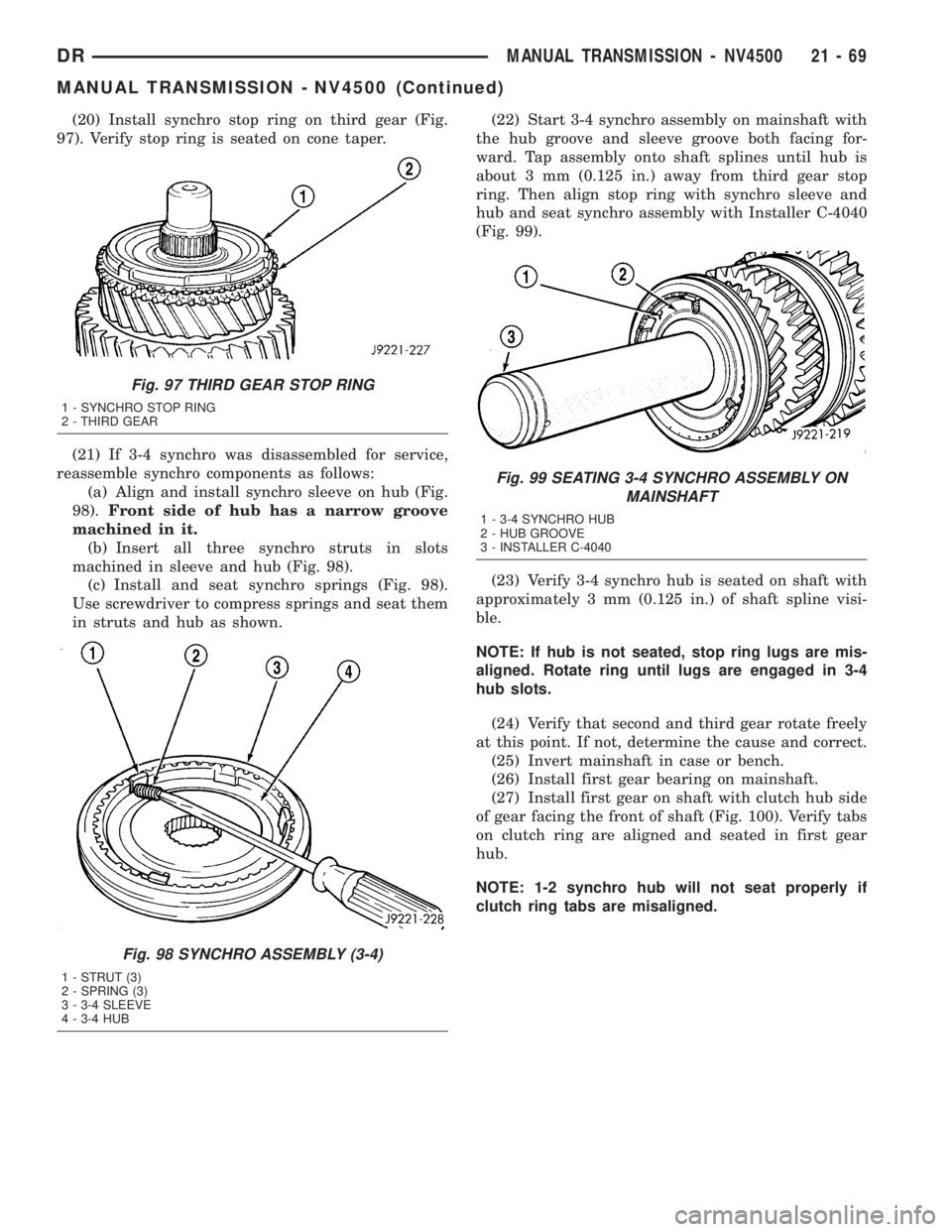

(14) Install thrust washer pin in shaft (Fig. 92).

(15) Install second gear thrust washer. Verify

washer is seated on gear and pin (Fig. 93).

(16) Install second gear thrust washer snap ring

(Fig. 94). Verify snap ring is seated in mainshaft

groove.

(17) Install third gear bearing spacer on shaft and

seat it against thrust washer snap ring (Fig. 94).

(18) Install third gear bearing on mainshaft (Fig.

95). Bearing should be flush with mainshaft hub.

NOTE: If bearing is not flush with hub, the bearing

spacer or snap ring was not installed.

(19) Install third gear over bearing and onto main-

shaft (Fig. 96).

Fig. 92 THRUST WASHER PIN

1 - THRUST WASHER PIN

2 - SECOND GEAR

Fig. 93 SECOND GEAR THRUST WASHER

1 - SECOND GEAR

2 - SECOND GEAR THRUST WASHER

3 - LOCATING PIN IN WASHER NOTCH

Fig. 94 SNAP RING AND THIRD

1 - SECOND GEAR THRUST WASHER

2 - THRUST WASHER SNAP RING

3 - THIRD GEAR BEARING SPACER

Fig. 95 THIRD GEAR BEARING

1 - THIRD GEAR BEARING

Fig. 96 THIRD GEAR

1 - THIRD GEAR

21 - 68 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1908 of 2895

(20) Install synchro stop ring on third gear (Fig.

97). Verify stop ring is seated on cone taper.

(21) If 3-4 synchro was disassembled for service,

reassemble synchro components as follows:

(a) Align and install synchro sleeve on hub (Fig.

98).Front side of hub has a narrow groove

machined in it.

(b) Insert all three synchro struts in slots

machined in sleeve and hub (Fig. 98).

(c) Install and seat synchro springs (Fig. 98).

Use screwdriver to compress springs and seat them

in struts and hub as shown.(22) Start 3-4 synchro assembly on mainshaft with

the hub groove and sleeve groove both facing for-

ward. Tap assembly onto shaft splines until hub is

about 3 mm (0.125 in.) away from third gear stop

ring. Then align stop ring with synchro sleeve and

hub and seat synchro assembly with Installer C-4040

(Fig. 99).

(23) Verify 3-4 synchro hub is seated on shaft with

approximately 3 mm (0.125 in.) of shaft spline visi-

ble.

NOTE: If hub is not seated, stop ring lugs are mis-

aligned. Rotate ring until lugs are engaged in 3-4

hub slots.

(24) Verify that second and third gear rotate freely

at this point. If not, determine the cause and correct.

(25) Invert mainshaft in case or bench.

(26) Install first gear bearing on mainshaft.

(27) Install first gear on shaft with clutch hub side

of gear facing the front of shaft (Fig. 100). Verify tabs

on clutch ring are aligned and seated in first gear

hub.

NOTE: 1-2 synchro hub will not seat properly if

clutch ring tabs are misaligned.

Fig. 97 THIRD GEAR STOP RING

1 - SYNCHRO STOP RING

2 - THIRD GEAR

Fig. 98 SYNCHRO ASSEMBLY (3-4)

1 - STRUT (3)

2 - SPRING (3)

3 - 3-4 SLEEVE

4 - 3-4 HUB

Fig. 99 SEATING 3-4 SYNCHRO ASSEMBLY ON

MAINSHAFT

1 - 3-4 SYNCHRO HUB

2 - HUB GROOVE

3 - INSTALLER C-4040

DRMANUAL TRANSMISSION - NV4500 21 - 69

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1909 of 2895

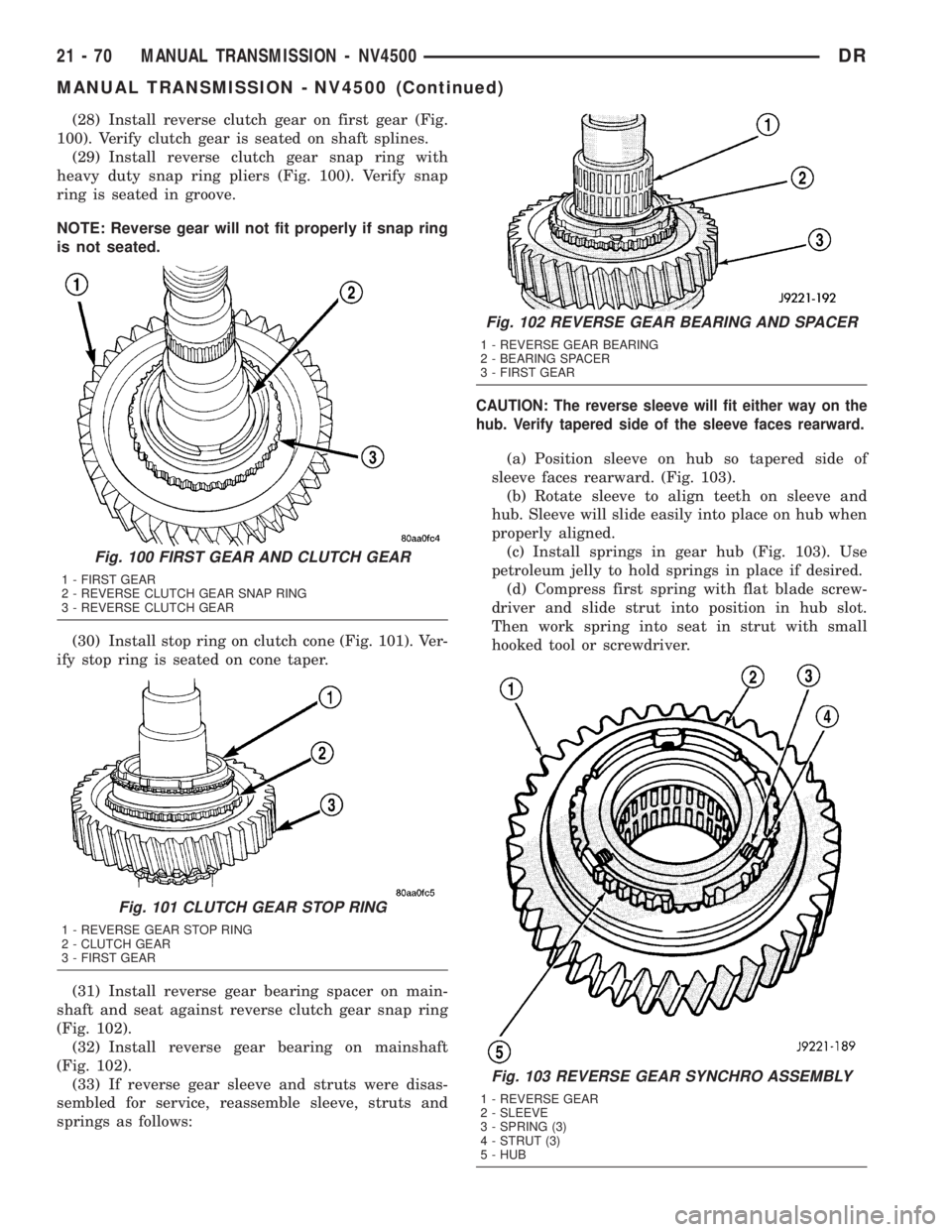

(28) Install reverse clutch gear on first gear (Fig.

100). Verify clutch gear is seated on shaft splines.

(29) Install reverse clutch gear snap ring with

heavy duty snap ring pliers (Fig. 100). Verify snap

ring is seated in groove.

NOTE: Reverse gear will not fit properly if snap ring

is not seated.

(30) Install stop ring on clutch cone (Fig. 101). Ver-

ify stop ring is seated on cone taper.

(31) Install reverse gear bearing spacer on main-

shaft and seat against reverse clutch gear snap ring

(Fig. 102).

(32) Install reverse gear bearing on mainshaft

(Fig. 102).

(33) If reverse gear sleeve and struts were disas-

sembled for service, reassemble sleeve, struts and

springs as follows:

CAUTION: The reverse sleeve will fit either way on the

hub. Verify tapered side of the sleeve faces rearward.

(a) Position sleeve on hub so tapered side of

sleeve faces rearward. (Fig. 103).

(b) Rotate sleeve to align teeth on sleeve and

hub. Sleeve will slide easily into place on hub when

properly aligned.

(c) Install springs in gear hub (Fig. 103). Use

petroleum jelly to hold springs in place if desired.

(d) Compress first spring with flat blade screw-

driver and slide strut into position in hub slot.

Then work spring into seat in strut with small

hooked tool or screwdriver.

Fig. 103 REVERSE GEAR SYNCHRO ASSEMBLY

1 - REVERSE GEAR

2 - SLEEVE

3 - SPRING (3)

4 - STRUT (3)

5 - HUB

Fig. 100 FIRST GEAR AND CLUTCH GEAR

1 - FIRST GEAR

2 - REVERSE CLUTCH GEAR SNAP RING

3 - REVERSE CLUTCH GEAR

Fig. 101 CLUTCH GEAR STOP RING

1 - REVERSE GEAR STOP RING

2 - CLUTCH GEAR

3 - FIRST GEAR

Fig. 102 REVERSE GEAR BEARING AND SPACER

1 - REVERSE GEAR BEARING

2 - BEARING SPACER

3 - FIRST GEAR

21 - 70 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1910 of 2895

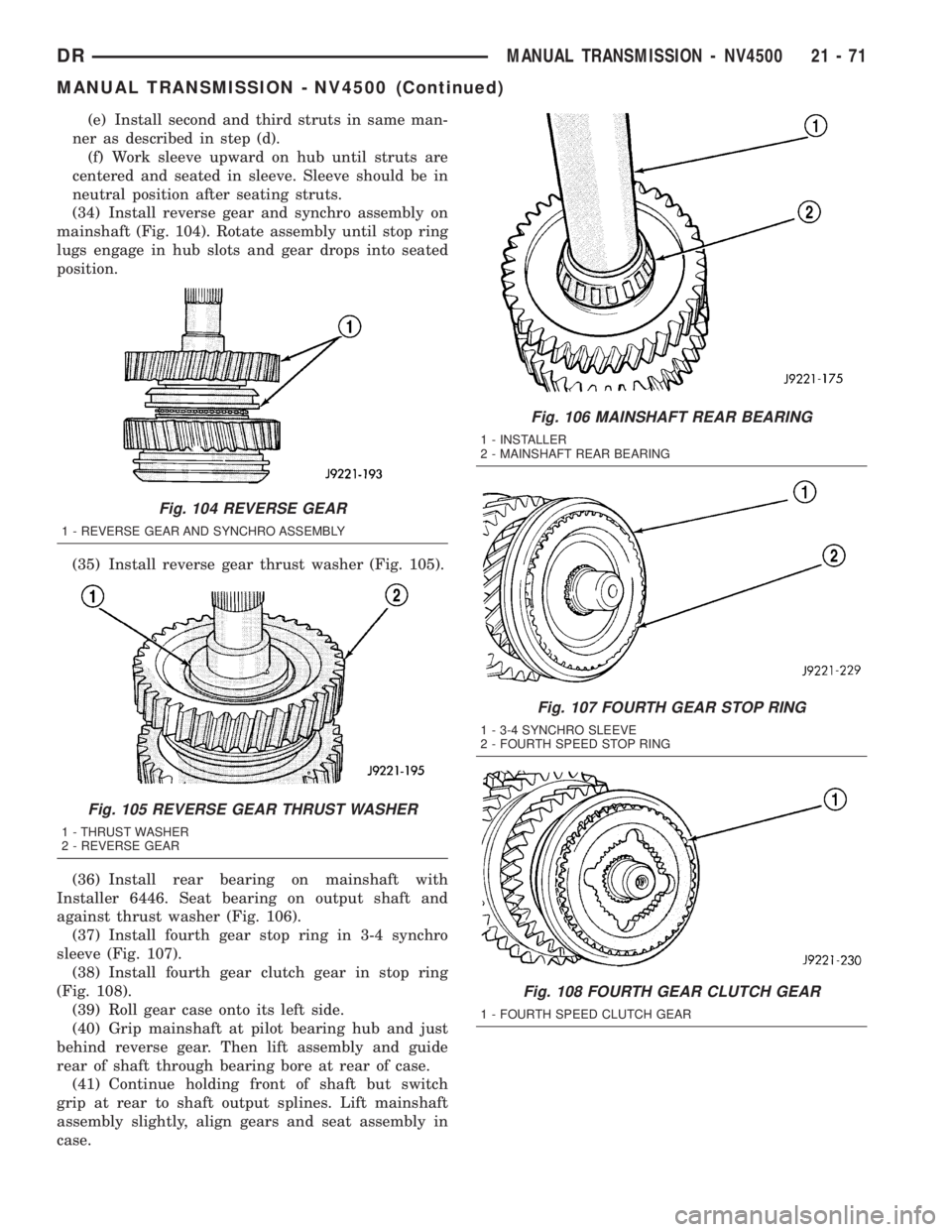

(e) Install second and third struts in same man-

ner as described in step (d).

(f) Work sleeve upward on hub until struts are

centered and seated in sleeve. Sleeve should be in

neutral position after seating struts.

(34) Install reverse gear and synchro assembly on

mainshaft (Fig. 104). Rotate assembly until stop ring

lugs engage in hub slots and gear drops into seated

position.

(35) Install reverse gear thrust washer (Fig. 105).

(36) Install rear bearing on mainshaft with

Installer 6446. Seat bearing on output shaft and

against thrust washer (Fig. 106).

(37) Install fourth gear stop ring in 3-4 synchro

sleeve (Fig. 107).

(38) Install fourth gear clutch gear in stop ring

(Fig. 108).

(39) Roll gear case onto its left side.

(40) Grip mainshaft at pilot bearing hub and just

behind reverse gear. Then lift assembly and guide

rear of shaft through bearing bore at rear of case.

(41) Continue holding front of shaft but switch

grip at rear to shaft output splines. Lift mainshaft

assembly slightly, align gears and seat assembly in

case.

Fig. 104 REVERSE GEAR

1 - REVERSE GEAR AND SYNCHRO ASSEMBLY

Fig. 105 REVERSE GEAR THRUST WASHER

1 - THRUST WASHER

2 - REVERSE GEAR

Fig. 106 MAINSHAFT REAR BEARING

1 - INSTALLER

2 - MAINSHAFT REAR BEARING

Fig. 107 FOURTH GEAR STOP RING

1 - 3-4 SYNCHRO SLEEVE

2 - FOURTH SPEED STOP RING

Fig. 108 FOURTH GEAR CLUTCH GEAR

1 - FOURTH SPEED CLUTCH GEAR

DRMANUAL TRANSMISSION - NV4500 21 - 71

MANUAL TRANSMISSION - NV4500 (Continued)