ECU DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 90 of 2895

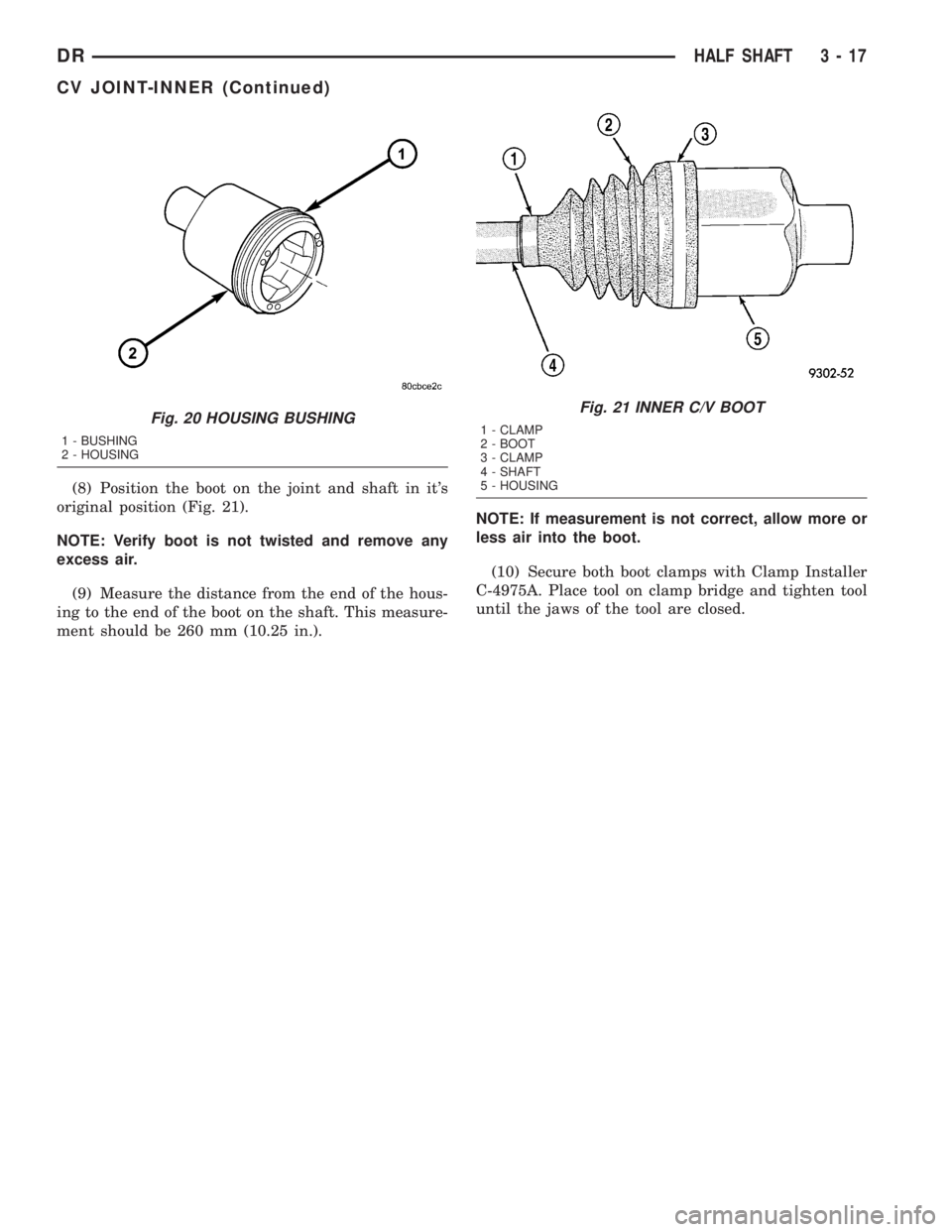

(8) Position the boot on the joint and shaft in it's

original position (Fig. 21).

NOTE: Verify boot is not twisted and remove any

excess air.

(9) Measure the distance from the end of the hous-

ing to the end of the boot on the shaft. This measure-

ment should be 260 mm (10.25 in.).NOTE: If measurement is not correct, allow more or

less air into the boot.

(10) Secure both boot clamps with Clamp Installer

C-4975A. Place tool on clamp bridge and tighten tool

until the jaws of the tool are closed.

Fig. 20 HOUSING BUSHING

1 - BUSHING

2 - HOUSING

Fig. 21 INNER C/V BOOT

1 - CLAMP

2 - BOOT

3 - CLAMP

4 - SHAFT

5 - HOUSING

DRHALF SHAFT 3 - 17

CV JOINT-INNER (Continued)

Page 97 of 2895

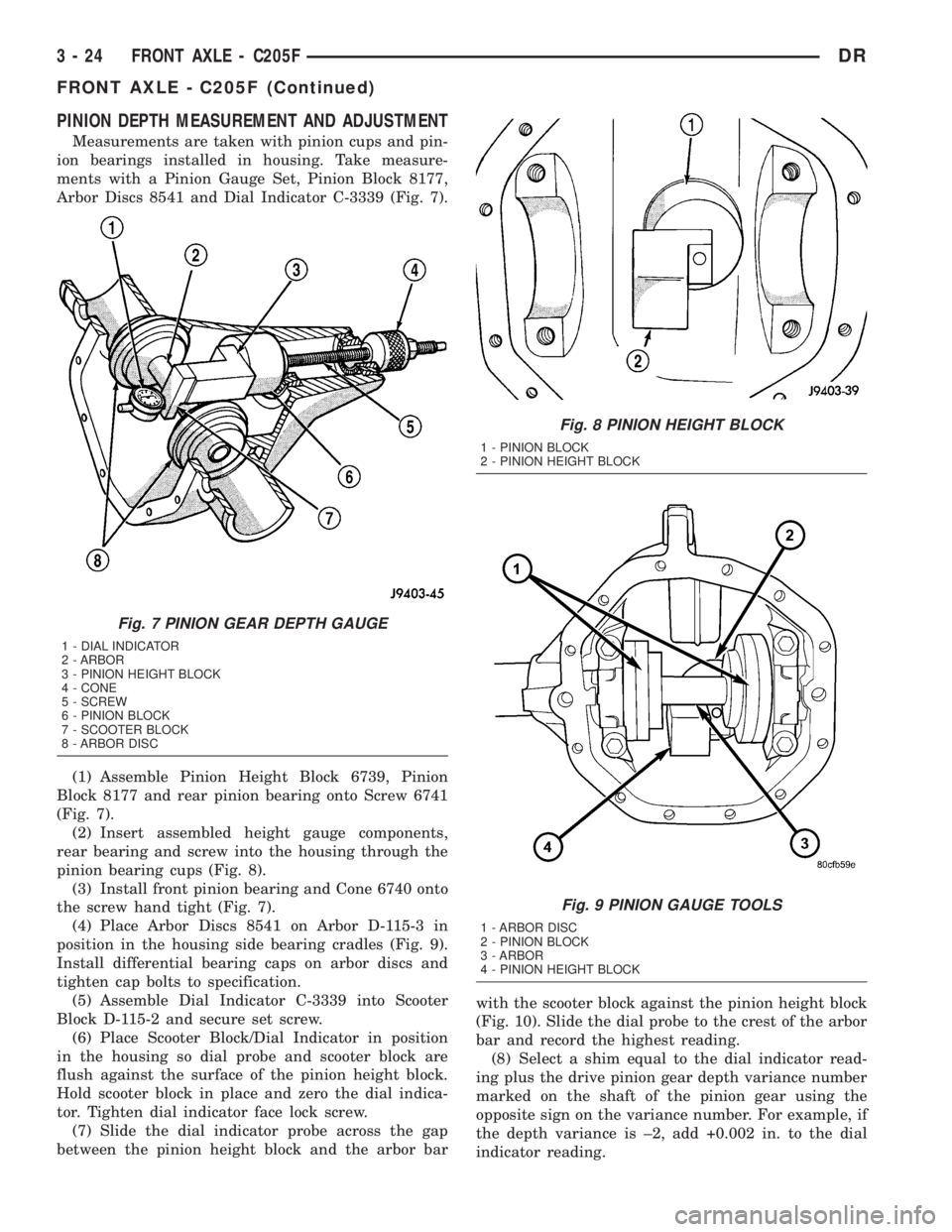

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion cups and pin-

ion bearings installed in housing. Take measure-

ments with a Pinion Gauge Set, Pinion Block 8177,

Arbor Discs 8541 and Dial Indicator C-3339 (Fig. 7).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8177 and rear pinion bearing onto Screw 6741

(Fig. 7).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through the

pinion bearing cups (Fig. 8).

(3) Install front pinion bearing and Cone 6740 onto

the screw hand tight (Fig. 7).

(4) Place Arbor Discs 8541 on Arbor D-115-3 in

position in the housing side bearing cradles (Fig. 9).

Install differential bearing caps on arbor discs and

tighten cap bolts to specification.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in the housing so dial probe and scooter block are

flush against the surface of the pinion height block.

Hold scooter block in place and zero the dial indica-

tor. Tighten dial indicator face lock screw.

(7) Slide the dial indicator probe across the gap

between the pinion height block and the arbor barwith the scooter block against the pinion height block

(Fig. 10). Slide the dial probe to the crest of the arbor

bar and record the highest reading.

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

marked on the shaft of the pinion gear using the

opposite sign on the variance number. For example, if

the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

Fig. 7 PINION GEAR DEPTH GAUGE

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 8 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 9 PINION GAUGE TOOLS

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

3 - 24 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 121 of 2895

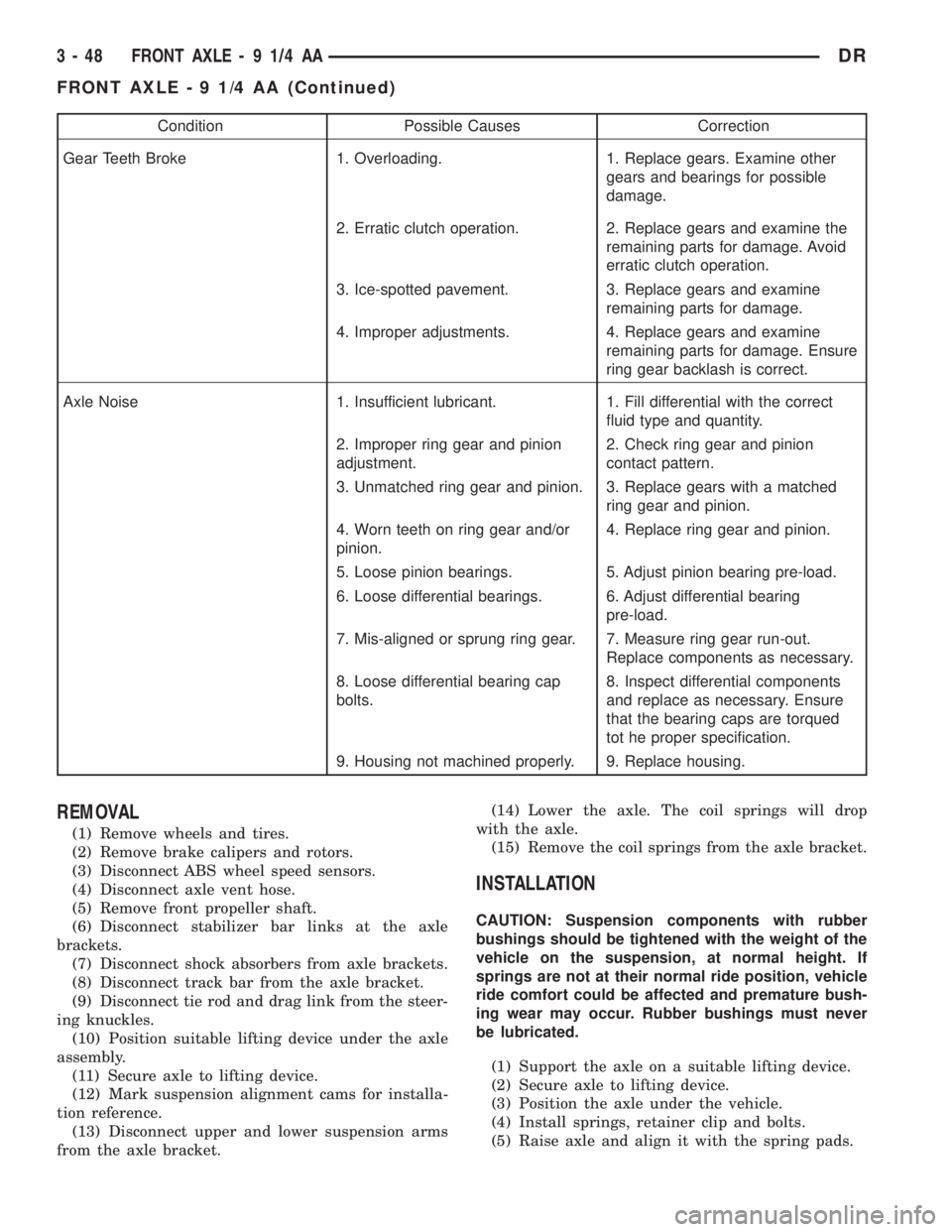

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Remove wheels and tires.

(2) Remove brake calipers and rotors.

(3) Disconnect ABS wheel speed sensors.

(4) Disconnect axle vent hose.

(5) Remove front propeller shaft.

(6) Disconnect stabilizer bar links at the axle

brackets.

(7) Disconnect shock absorbers from axle brackets.

(8) Disconnect track bar from the axle bracket.

(9) Disconnect tie rod and drag link from the steer-

ing knuckles.

(10) Position suitable lifting device under the axle

assembly.

(11) Secure axle to lifting device.

(12) Mark suspension alignment cams for installa-

tion reference.

(13) Disconnect upper and lower suspension arms

from the axle bracket.(14) Lower the axle. The coil springs will drop

with the axle.

(15) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the weight of the

vehicle on the suspension, at normal height. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur. Rubber bushings must never

be lubricated.

(1) Support the axle on a suitable lifting device.

(2) Secure axle to lifting device.

(3) Position the axle under the vehicle.

(4) Install springs, retainer clip and bolts.

(5) Raise axle and align it with the spring pads.

3 - 48 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 123 of 2895

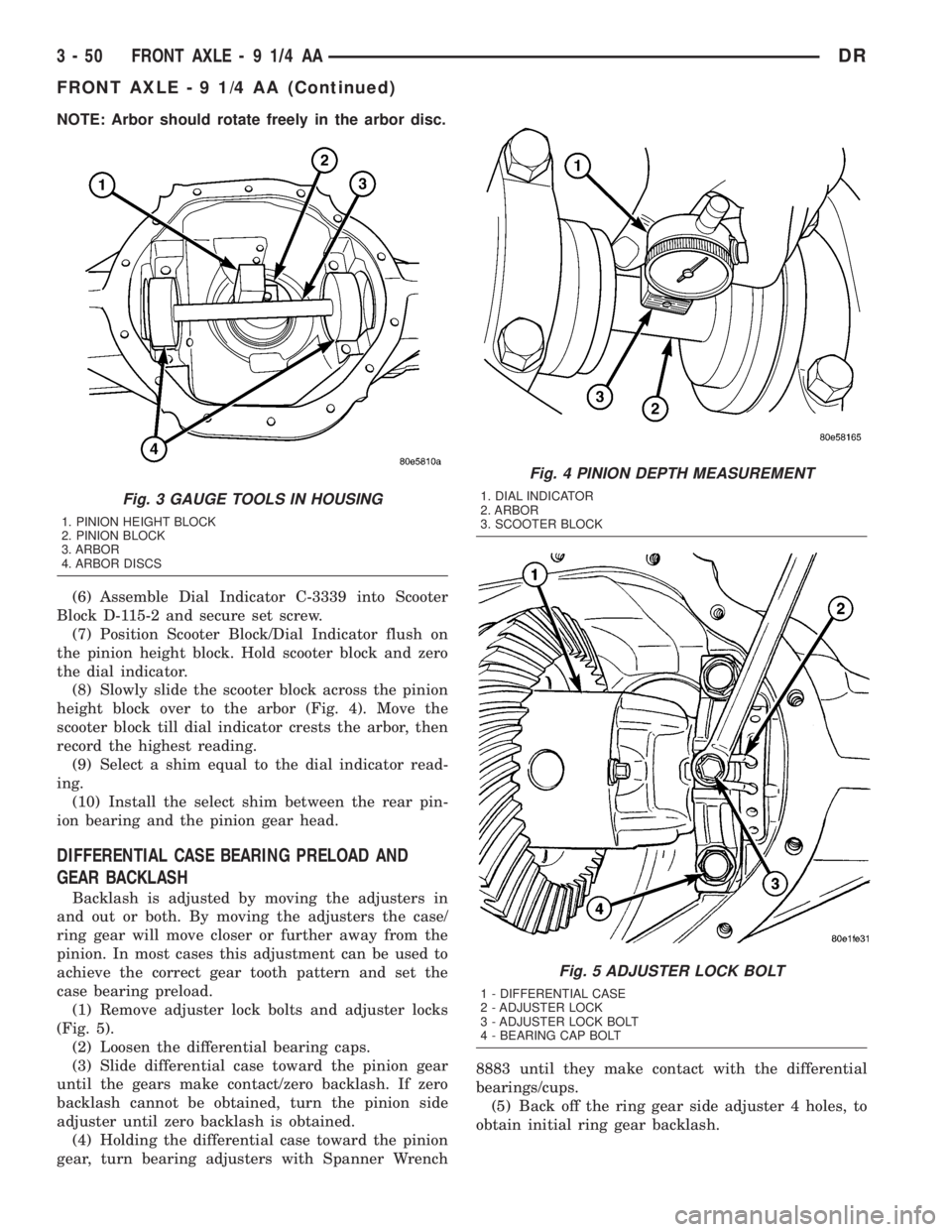

NOTE: Arbor should rotate freely in the arbor disc.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 4). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 5).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench8883 until they make contact with the differential

bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 3 GAUGE TOOLS IN HOUSING

1. PINION HEIGHT BLOCK

2. PINION BLOCK

3. ARBOR

4. ARBOR DISCS

Fig. 4 PINION DEPTH MEASUREMENT

1. DIAL INDICATOR

2. ARBOR

3. SCOOTER BLOCK

Fig. 5 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 50 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 147 of 2895

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers and rotors.

(9) Remove axle vent hose.

(10) Mark propeller shaft and companion flange

for installation alignment reference.

(11) Remove propeller shaft.

(12) Remove shock absorbers from axle.

(13) Remove U-bolets from axle.

(14) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Install brake rotors and calipers.

(7) Connect brake hose to the axle junction block.

(8) Install axle vent hose.

(9) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(10) Install the wheels and tires.

(11) Fill differential to specifications.

(12) Remove lifting device from axle and lower the

vehicle.

ADJUSTMENTS

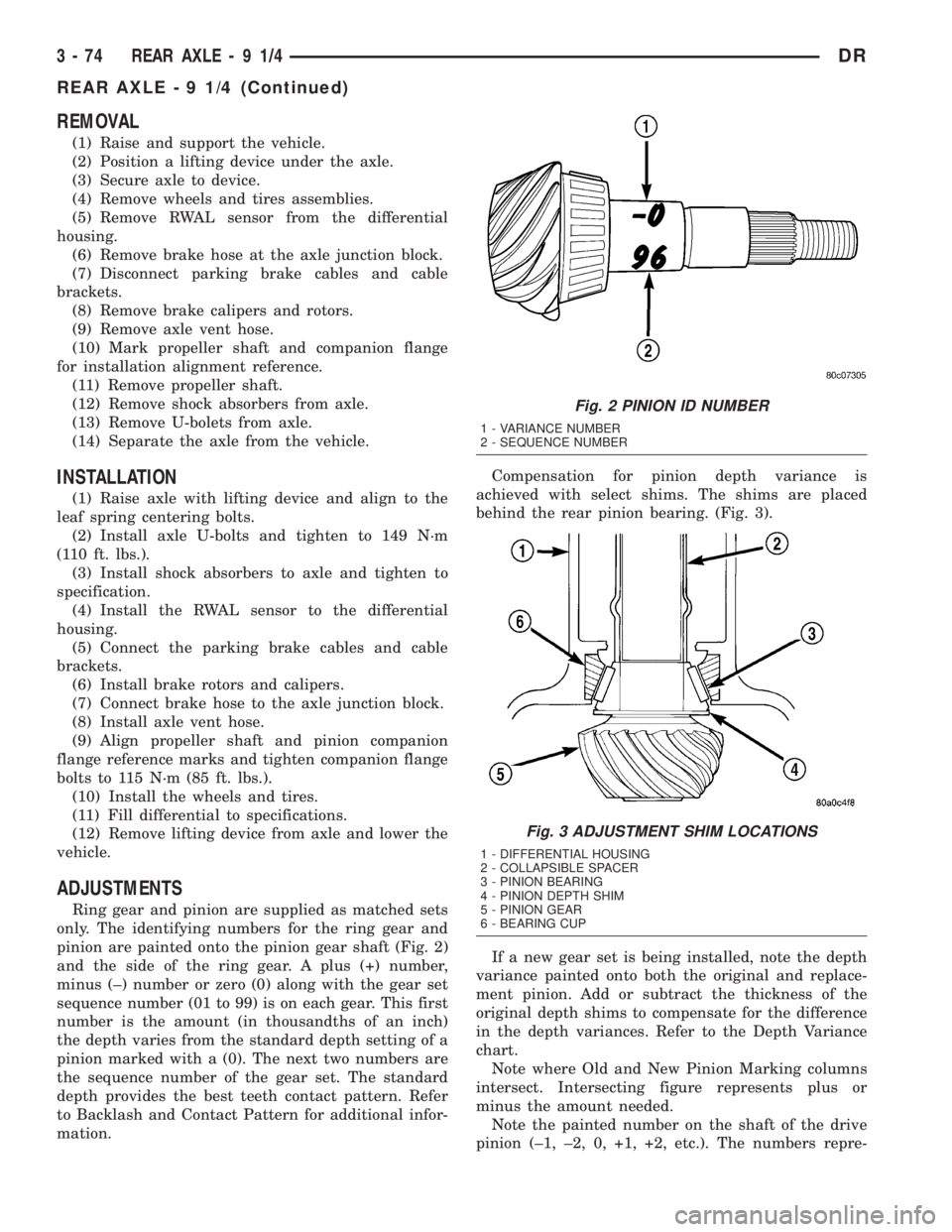

Ring gear and pinion are supplied as matched sets

only. The identifying numbers for the ring gear and

pinion are painted onto the pinion gear shaft (Fig. 2)

and the side of the ring gear. A plus (+) number,

minus (±) number or zero (0) along with the gear set

sequence number (01 to 99) is on each gear. This first

number is the amount (in thousandths of an inch)

the depth varies from the standard depth setting of a

pinion marked with a (0). The next two numbers are

the sequence number of the gear set. The standard

depth provides the best teeth contact pattern. Refer

to Backlash and Contact Pattern for additional infor-

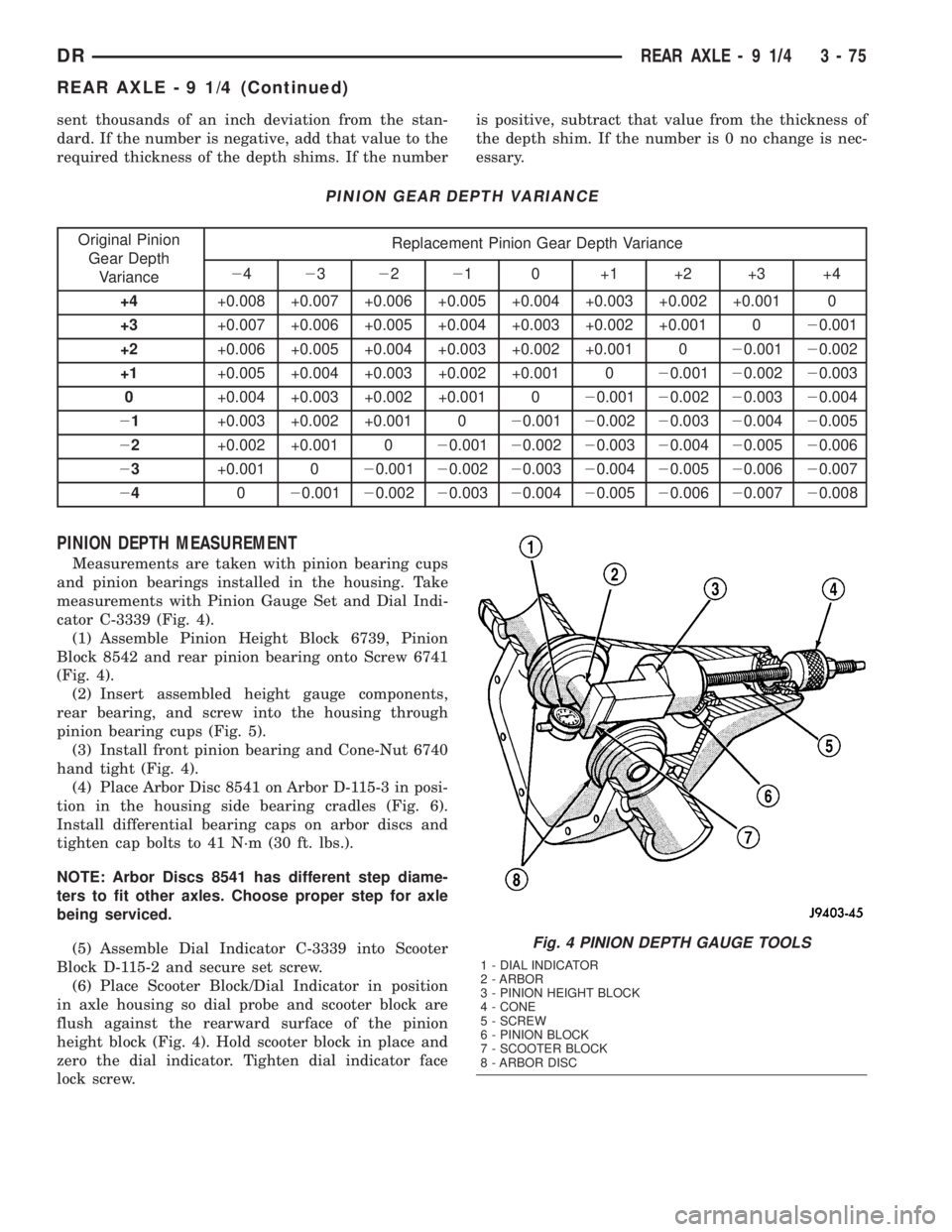

mation.Compensation for pinion depth variance is

achieved with select shims. The shims are placed

behind the rear pinion bearing. (Fig. 3).

If a new gear set is being installed, note the depth

variance painted onto both the original and replace-

ment pinion. Add or subtract the thickness of the

original depth shims to compensate for the difference

in the depth variances. Refer to the Depth Variance

chart.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus the amount needed.

Note the painted number on the shaft of the drive

pinion (±1, ±2, 0, +1, +2, etc.). The numbers repre-

Fig. 2 PINION ID NUMBER

1 - VARIANCE NUMBER

2 - SEQUENCE NUMBER

Fig. 3 ADJUSTMENT SHIM LOCATIONS

1 - DIFFERENTIAL HOUSING

2 - COLLAPSIBLE SPACER

3 - PINION BEARING

4 - PINION DEPTH SHIM

5 - PINION GEAR

6 - BEARING CUP

3 - 74 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 148 of 2895

sent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to the

required thickness of the depth shims. If the numberis positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

PINION DEPTH MEASUREMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 4).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8542 and rear pinion bearing onto Screw 6741

(Fig. 4).

(2) Insert assembled height gauge components,

rear bearing, and screw into the housing through

pinion bearing cups (Fig. 5).

(3) Install front pinion bearing and Cone-Nut 6740

hand tight (Fig. 4).

(4) Place Arbor Disc 8541 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 6).

Install differential bearing caps on arbor discs and

tighten cap bolts to 41 N´m (30 ft. lbs.).

NOTE: Arbor Discs 8541 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in axle housing so dial probe and scooter block are

flush against the rearward surface of the pinion

height block (Fig. 4). Hold scooter block in place and

zero the dial indicator. Tighten dial indicator face

lock screw.

Fig. 4 PINION DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

DRREAR AXLE - 9 1/4 3 - 75

REAR AXLE - 9 1/4 (Continued)

Page 165 of 2895

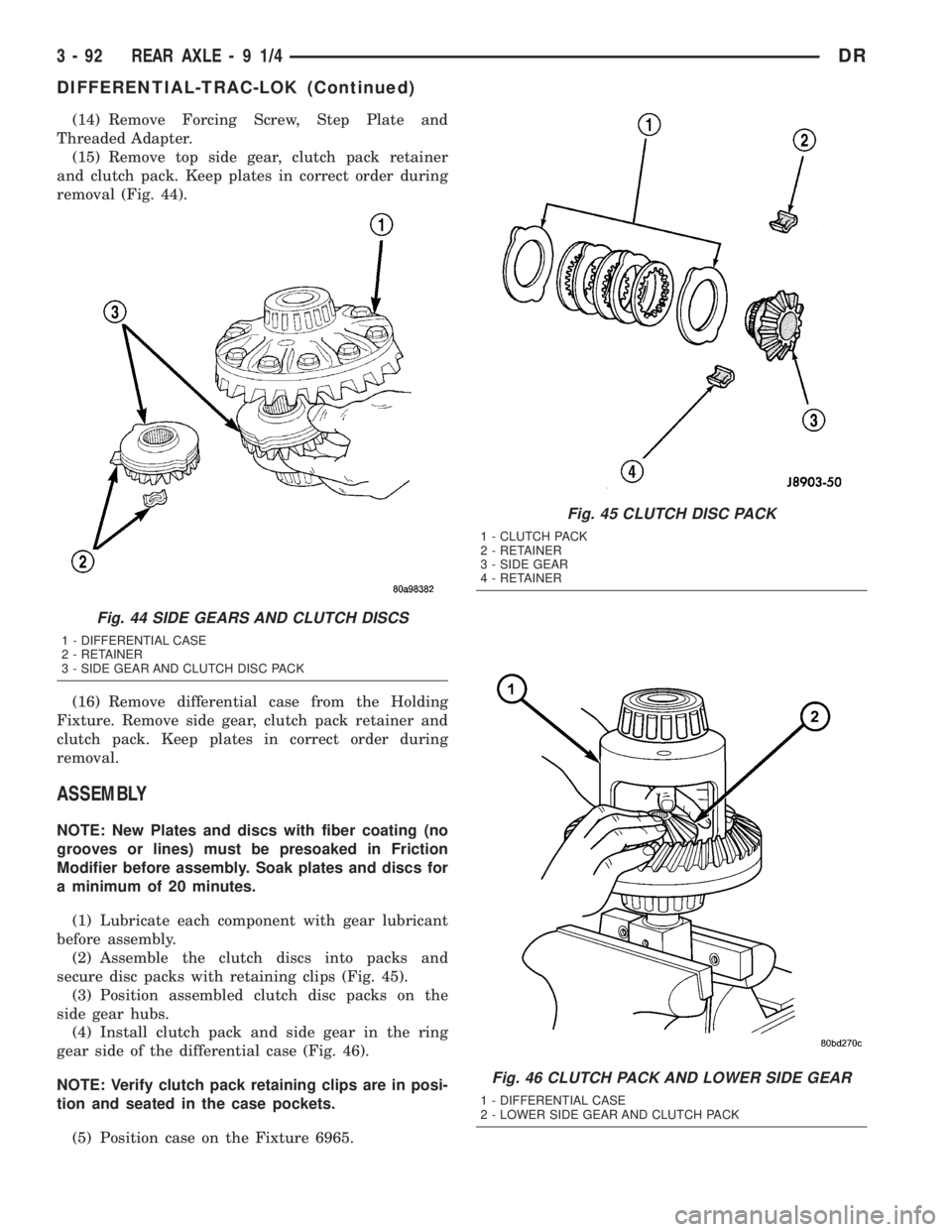

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in correct order during

removal (Fig. 44).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in correct order during

removal.

ASSEMBLY

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

(1) Lubricate each component with gear lubricant

before assembly.

(2) Assemble the clutch discs into packs and

secure disc packs with retaining clips (Fig. 45).

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 46).

NOTE: Verify clutch pack retaining clips are in posi-

tion and seated in the case pockets.

(5) Position case on the Fixture 6965.

Fig. 44 SIDE GEARS AND CLUTCH DISCS

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 45 CLUTCH DISC PACK

1 - CLUTCH PACK

2 - RETAINER

3 - SIDE GEAR

4 - RETAINER

Fig. 46 CLUTCH PACK AND LOWER SIDE GEAR

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH PACK

3 - 92 REAR AXLE-91/4DR

DIFFERENTIAL-TRAC-LOK (Continued)

Page 176 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers and rotors.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolts from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Install brake calipers.

(7) Connect brake hose to the axle junction block

and axle vent hose.

(8) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(9) Install the wheels and tires.

DRREAR AXLE - 10 1/2 AA 3 - 103

REAR AXLE - 10 1/2 AA (Continued)

Page 177 of 2895

(10) Fill differential to specifications.

(11) Remove lifting device from axle and lower the

vehicle.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. Compensation for pinion depth variance is

achieved with a select shim. The shim is located

between the rear pinion bearing and the pinion gear

head.

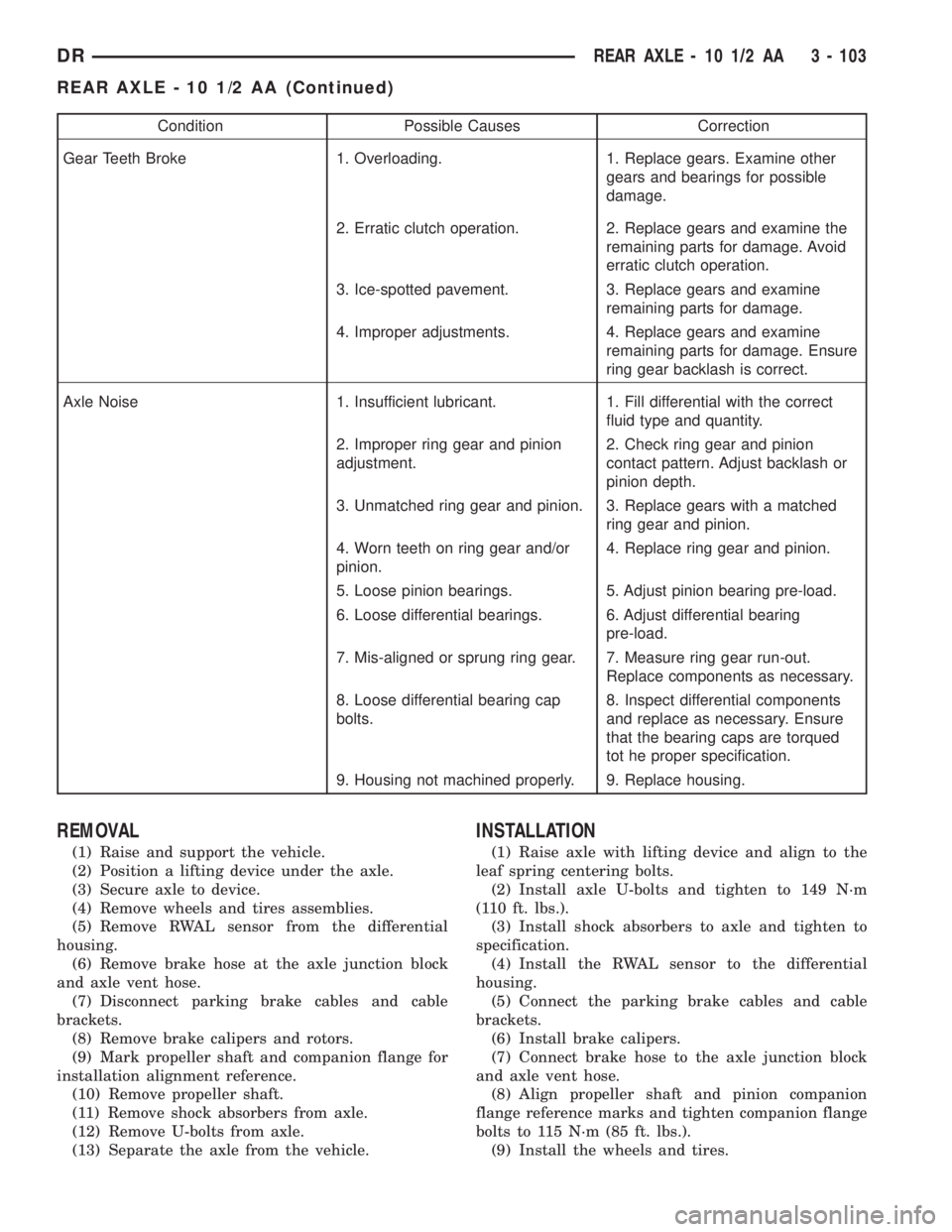

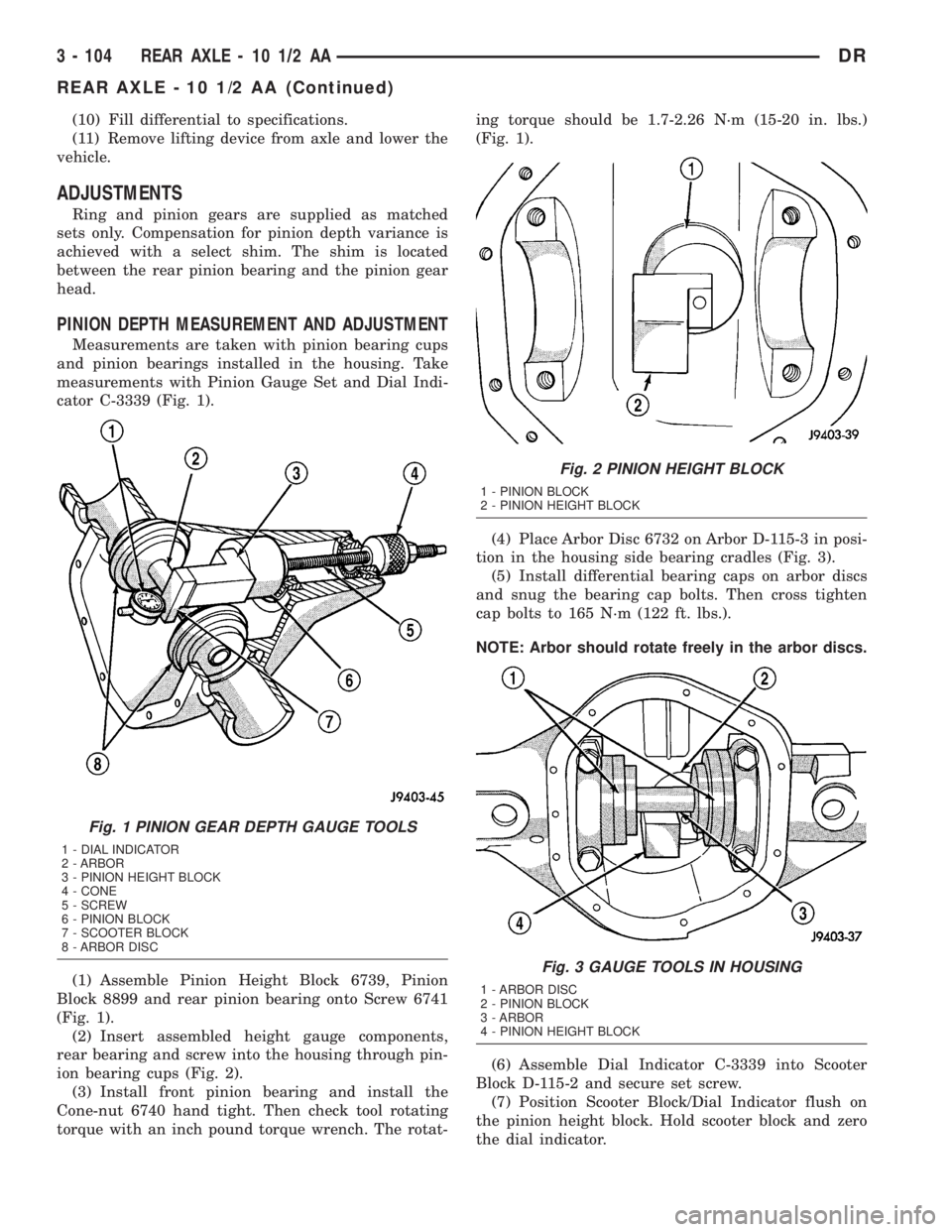

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 1).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8899 and rear pinion bearing onto Screw 6741

(Fig. 1).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 2).

(3) Install front pinion bearing and install the

Cone-nut 6740 hand tight. Then check tool rotating

torque with an inch pound torque wrench. The rotat-ing torque should be 1.7-2.26 N´m (15-20 in. lbs.)

(Fig. 1).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 3).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 165 N´m (122 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor discs.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

Fig. 1 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 2 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 3 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

3 - 104 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 203 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolets from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Connect brake hose to the axle junction block

and axle vent hose.

(7) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(8) Install the wheels and tires.

(9) Fill differential to specifications.

3 - 130 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)