ECU DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 204 of 2895

(10) Remove lifting device from axle and lower the

vehicle.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. Compensation for pinion depth variance is

achieved with a select shim. The shim is located

between the rear pinion bearing and the pinion gear

head.

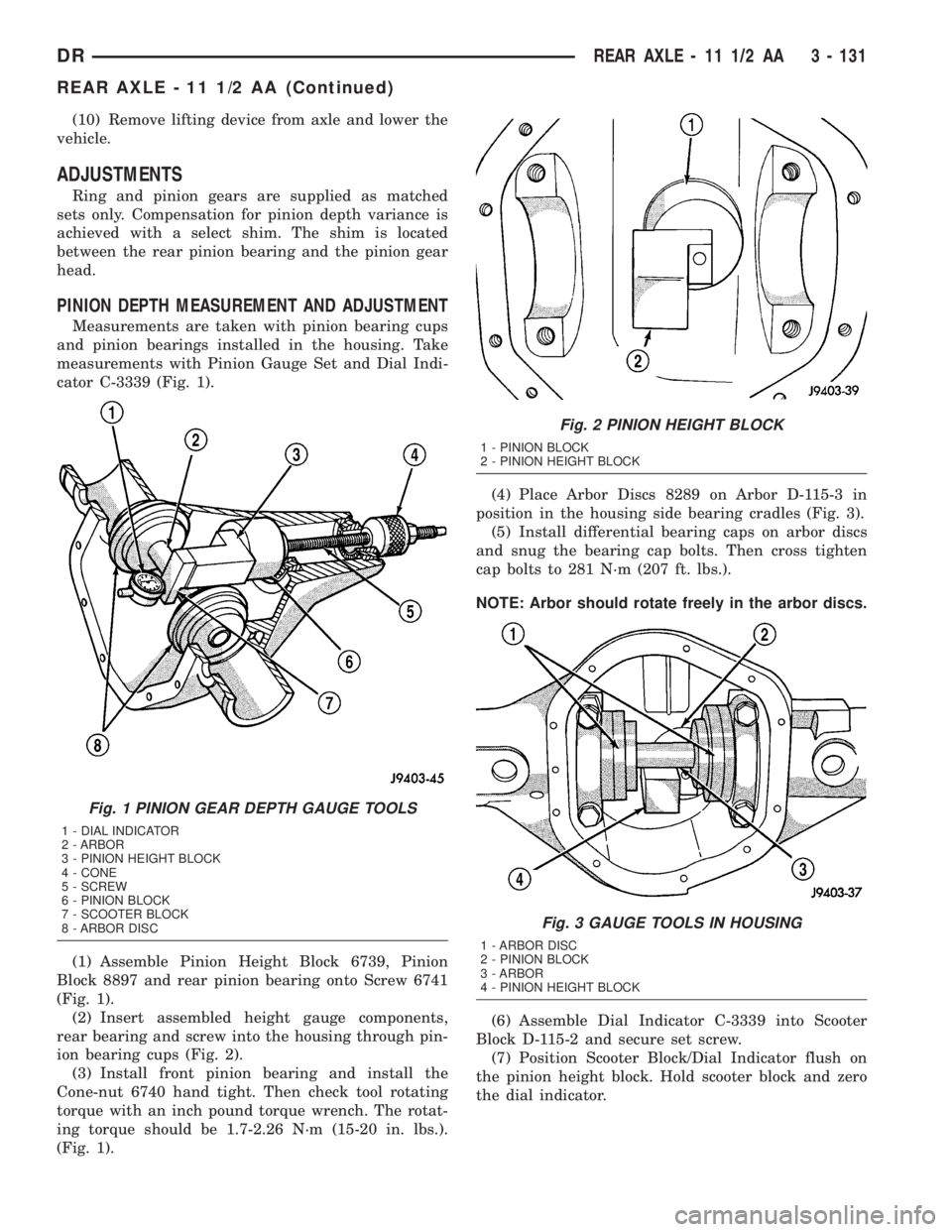

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 1).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8897 and rear pinion bearing onto Screw 6741

(Fig. 1).

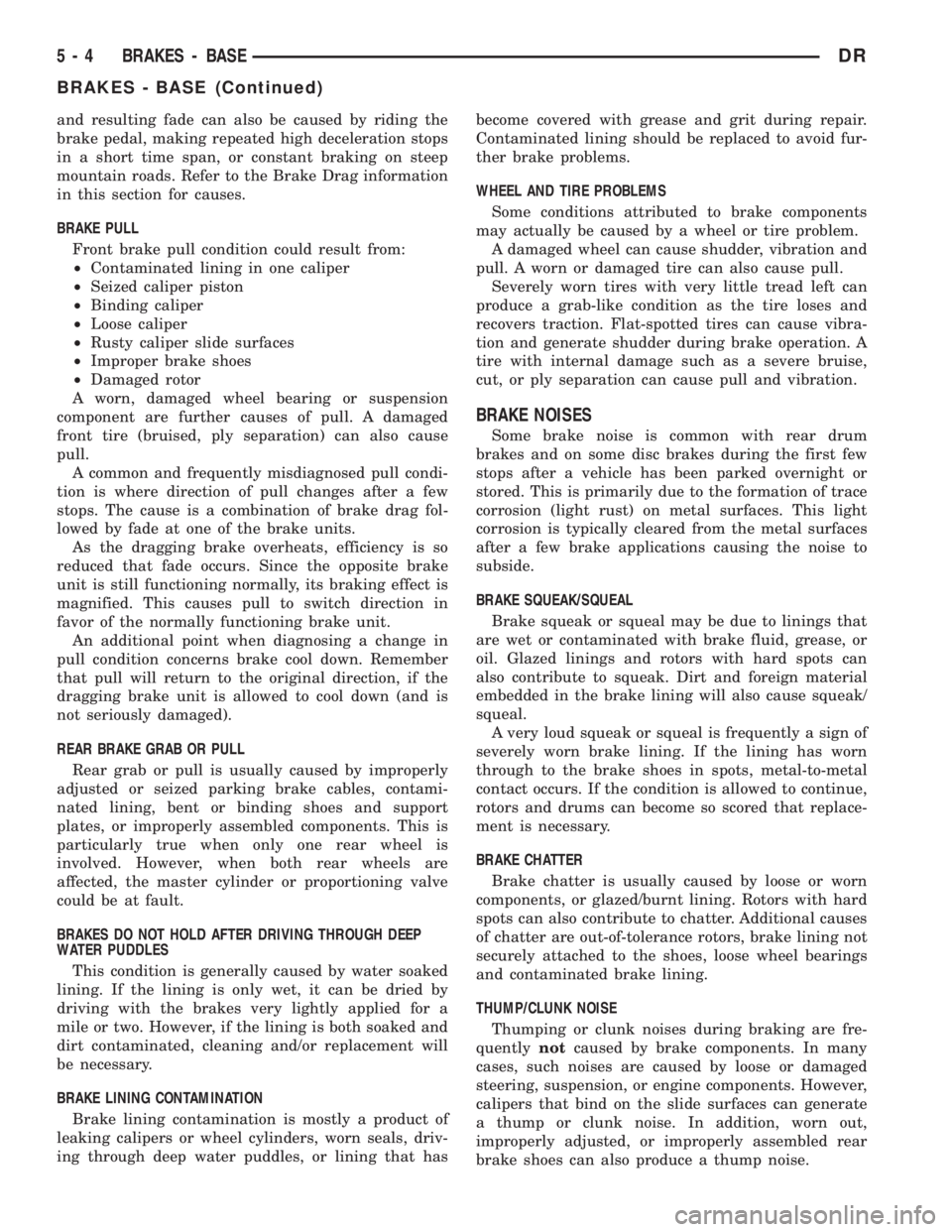

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 2).

(3) Install front pinion bearing and install the

Cone-nut 6740 hand tight. Then check tool rotating

torque with an inch pound torque wrench. The rotat-

ing torque should be 1.7-2.26 N´m (15-20 in. lbs.).

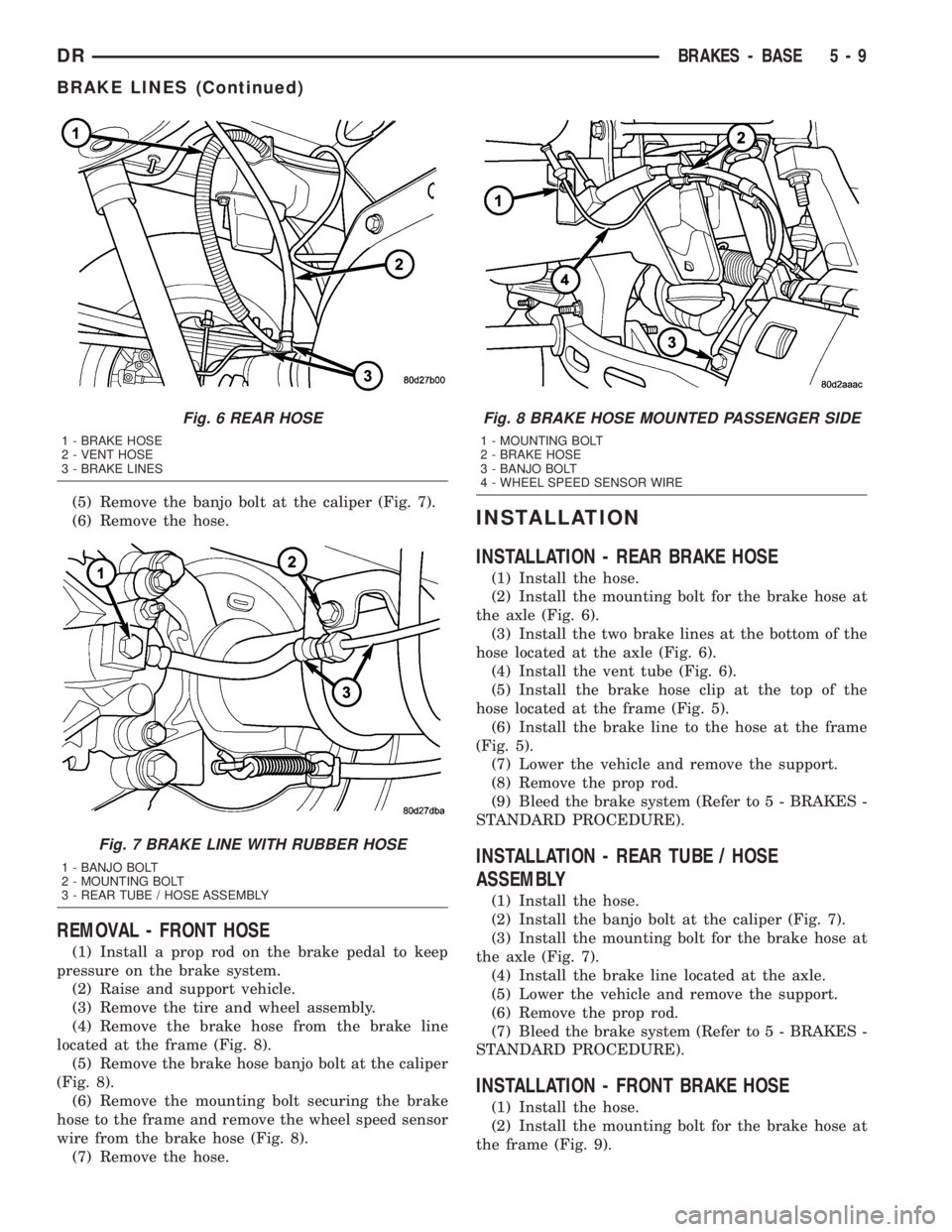

(Fig. 1).(4) Place Arbor Discs 8289 on Arbor D-115-3 in

position in the housing side bearing cradles (Fig. 3).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 281 N´m (207 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor discs.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

Fig. 1 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 2 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 3 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

DRREAR AXLE - 11 1/2 AA 3 - 131

REAR AXLE - 11 1/2 AA (Continued)

Page 231 of 2895

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake shoes

²Damaged rotor

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE GRAB OR PULL

Rear grab or pull is usually caused by improperly

adjusted or seized parking brake cables, contami-

nated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is

involved. However, when both rear wheels are

affected, the master cylinder or proportioning valve

could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or wheel cylinders, worn seals, driv-

ing through deep water puddles, or lining that hasbecome covered with grease and grit during repair.

Contaminated lining should be replaced to avoid fur-

ther brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors and drums can become so scored that replace-

ment is necessary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brake shoes can also produce a thump noise.

5 - 4 BRAKES - BASEDR

BRAKES - BASE (Continued)

Page 236 of 2895

(5) Remove the banjo bolt at the caliper (Fig. 7).

(6) Remove the hose.

REMOVAL - FRONT HOSE

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove the tire and wheel assembly.

(4) Remove the brake hose from the brake line

located at the frame (Fig. 8).

(5) Remove the brake hose banjo bolt at the caliper

(Fig. 8).

(6) Remove the mounting bolt securing the brake

hose to the frame and remove the wheel speed sensor

wire from the brake hose (Fig. 8).

(7) Remove the hose.

INSTALLATION

INSTALLATION - REAR BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the brake hose at

the axle (Fig. 6).

(3) Install the two brake lines at the bottom of the

hose located at the axle (Fig. 6).

(4) Install the vent tube (Fig. 6).

(5) Install the brake hose clip at the top of the

hose located at the frame (Fig. 5).

(6) Install the brake line to the hose at the frame

(Fig. 5).

(7) Lower the vehicle and remove the support.

(8) Remove the prop rod.

(9) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

INSTALLATION - REAR TUBE / HOSE

ASSEMBLY

(1) Install the hose.

(2) Install the banjo bolt at the caliper (Fig. 7).

(3) Install the mounting bolt for the brake hose at

the axle (Fig. 7).

(4) Install the brake line located at the axle.

(5) Lower the vehicle and remove the support.

(6) Remove the prop rod.

(7) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

INSTALLATION - FRONT BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the brake hose at

the frame (Fig. 9).

Fig. 6 REAR HOSE

1 - BRAKE HOSE

2 - VENT HOSE

3 - BRAKE LINES

Fig. 7 BRAKE LINE WITH RUBBER HOSE

1 - BANJO BOLT

2 - MOUNTING BOLT

3 - REAR TUBE / HOSE ASSEMBLY

Fig. 8 BRAKE HOSE MOUNTED PASSENGER SIDE

1 - MOUNTING BOLT

2 - BRAKE HOSE

3 - BANJO BOLT

4 - WHEEL SPEED SENSOR WIRE

DRBRAKES - BASE 5 - 9

BRAKE LINES (Continued)

Page 239 of 2895

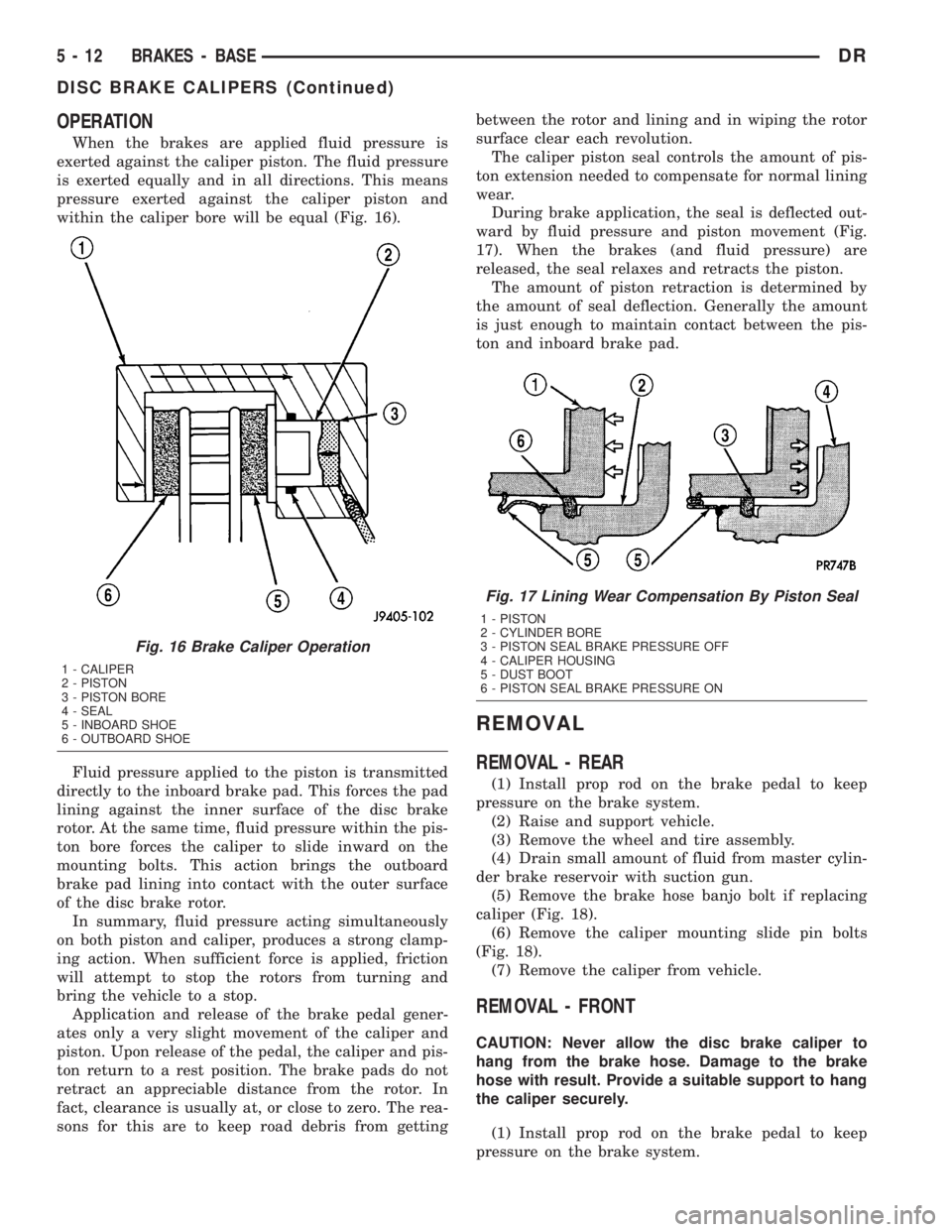

OPERATION

When the brakes are applied fluid pressure is

exerted against the caliper piston. The fluid pressure

is exerted equally and in all directions. This means

pressure exerted against the caliper piston and

within the caliper bore will be equal (Fig. 16).

Fluid pressure applied to the piston is transmitted

directly to the inboard brake pad. This forces the pad

lining against the inner surface of the disc brake

rotor. At the same time, fluid pressure within the pis-

ton bore forces the caliper to slide inward on the

mounting bolts. This action brings the outboard

brake pad lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake pads do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from gettingbetween the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig.

17). When the brakes (and fluid pressure) are

released, the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amount

is just enough to maintain contact between the pis-

ton and inboard brake pad.

REMOVAL

REMOVAL - REAR

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove the wheel and tire assembly.

(4) Drain small amount of fluid from master cylin-

der brake reservoir with suction gun.

(5) Remove the brake hose banjo bolt if replacing

caliper (Fig. 18).

(6) Remove the caliper mounting slide pin bolts

(Fig. 18).

(7) Remove the caliper from vehicle.

REMOVAL - FRONT

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose with result. Provide a suitable support to hang

the caliper securely.

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

Fig. 16 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

Fig. 17 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 12 BRAKES - BASEDR

DISC BRAKE CALIPERS (Continued)

Page 243 of 2895

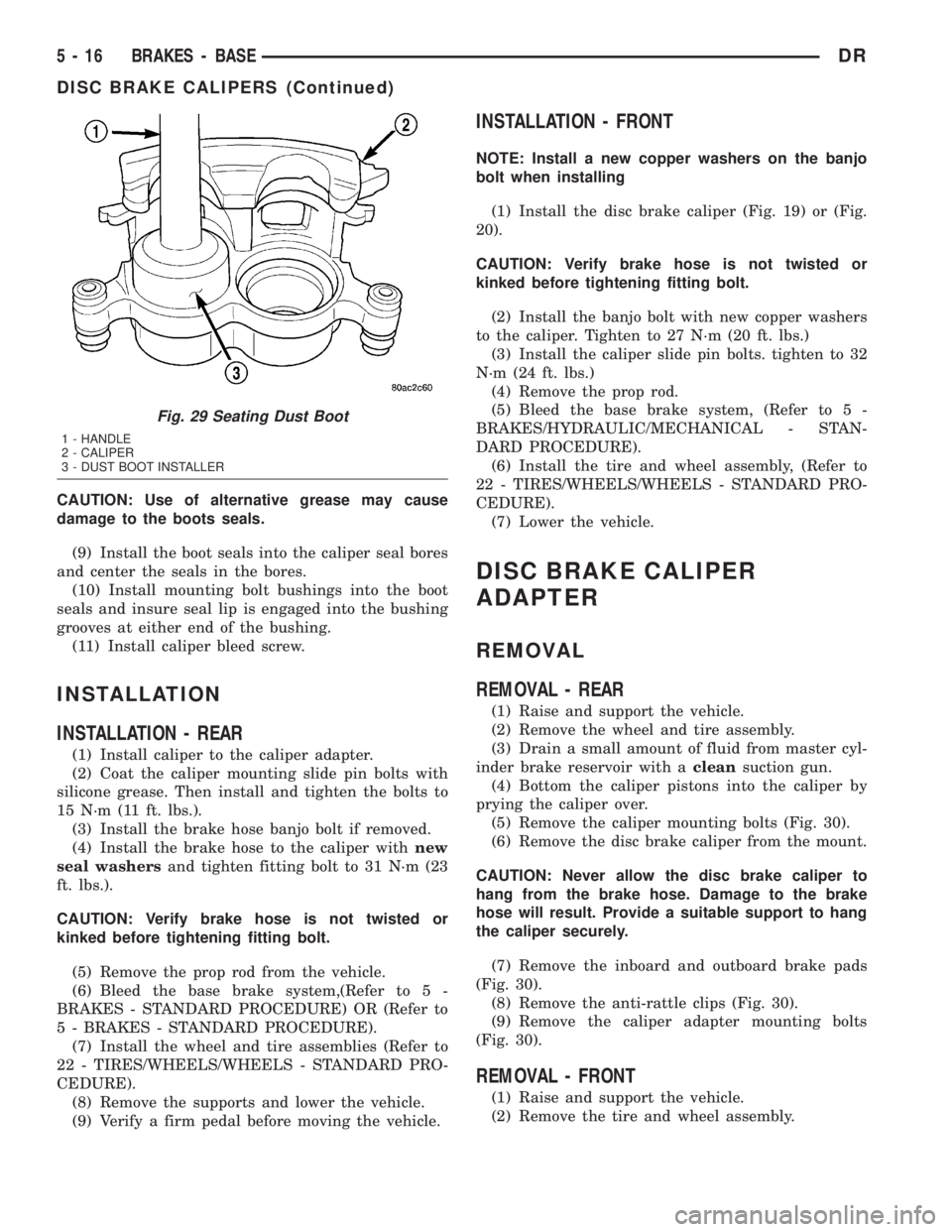

CAUTION: Use of alternative grease may cause

damage to the boots seals.

(9) Install the boot seals into the caliper seal bores

and center the seals in the bores.

(10) Install mounting bolt bushings into the boot

seals and insure seal lip is engaged into the bushing

grooves at either end of the bushing.

(11) Install caliper bleed screw.

INSTALLATION

INSTALLATION - REAR

(1) Install caliper to the caliper adapter.

(2) Coat the caliper mounting slide pin bolts with

silicone grease. Then install and tighten the bolts to

15 N´m (11 ft. lbs.).

(3) Install the brake hose banjo bolt if removed.

(4) Install the brake hose to the caliper withnew

seal washersand tighten fitting bolt to 31 N´m (23

ft. lbs.).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(5) Remove the prop rod from the vehicle.

(6) Bleed the base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(7) Install the wheel and tire assemblies (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

INSTALLATION - FRONT

NOTE: Install a new copper washers on the banjo

bolt when installing

(1) Install the disc brake caliper (Fig. 19) or (Fig.

20).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(2) Install the banjo bolt with new copper washers

to the caliper. Tighten to 27 N´m (20 ft. lbs.)

(3) Install the caliper slide pin bolts. tighten to 32

N´m (24 ft. lbs.)

(4) Remove the prop rod.

(5) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

DISC BRAKE CALIPER

ADAPTER

REMOVAL

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Drain a small amount of fluid from master cyl-

inder brake reservoir with acleansuction gun.

(4) Bottom the caliper pistons into the caliper by

prying the caliper over.

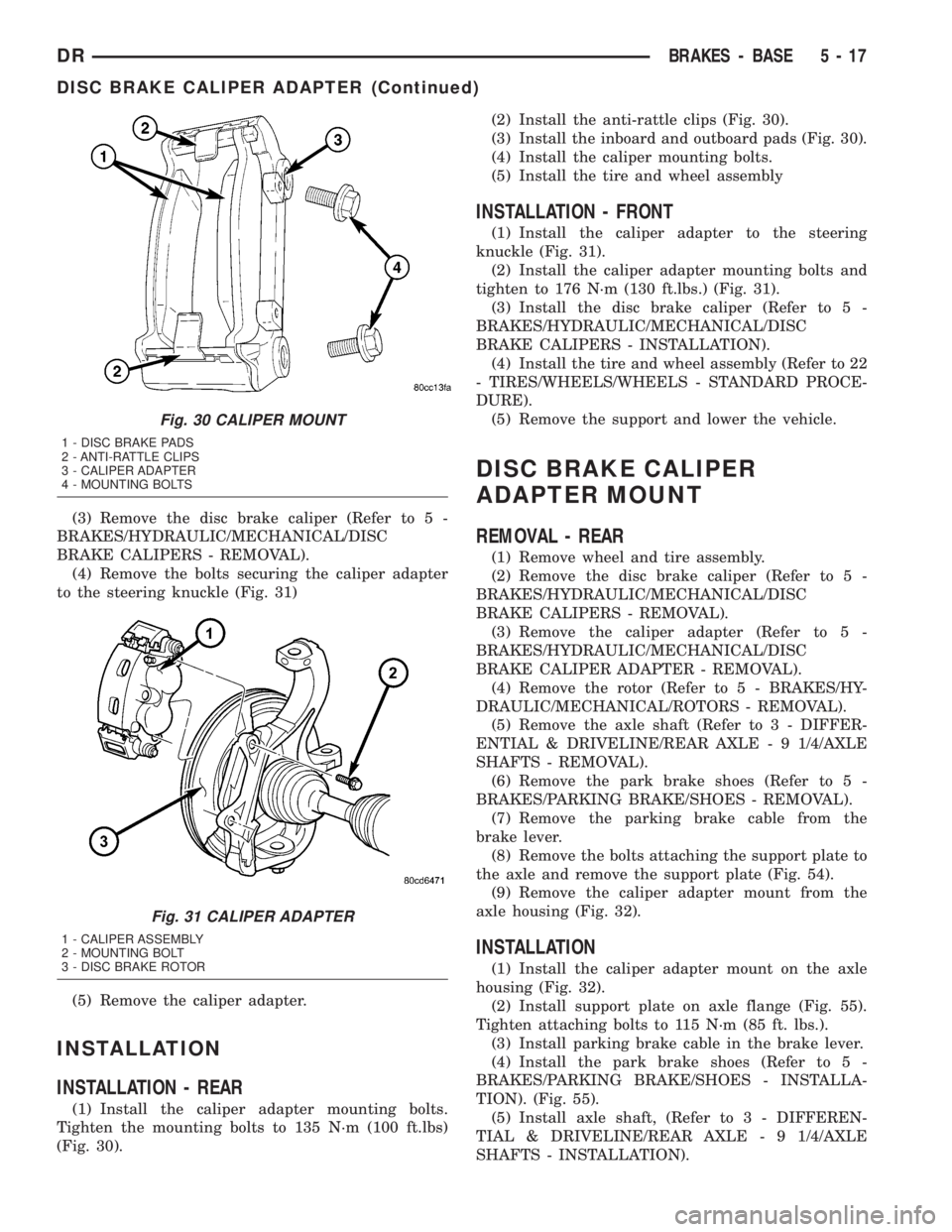

(5) Remove the caliper mounting bolts (Fig. 30).

(6) Remove the disc brake caliper from the mount.

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(7) Remove the inboard and outboard brake pads

(Fig. 30).

(8) Remove the anti-rattle clips (Fig. 30).

(9) Remove the caliper adapter mounting bolts

(Fig. 30).

REMOVAL - FRONT

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

Fig. 29 Seating Dust Boot

1 - HANDLE

2 - CALIPER

3 - DUST BOOT INSTALLER

5 - 16 BRAKES - BASEDR

DISC BRAKE CALIPERS (Continued)

Page 244 of 2895

(3) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the bolts securing the caliper adapter

to the steering knuckle (Fig. 31)

(5) Remove the caliper adapter.

INSTALLATION

INSTALLATION - REAR

(1) Install the caliper adapter mounting bolts.

Tighten the mounting bolts to 135 N´m (100 ft.lbs)

(Fig. 30).(2) Install the anti-rattle clips (Fig. 30).

(3) Install the inboard and outboard pads (Fig. 30).

(4) Install the caliper mounting bolts.

(5) Install the tire and wheel assembly

INSTALLATION - FRONT

(1) Install the caliper adapter to the steering

knuckle (Fig. 31).

(2) Install the caliper adapter mounting bolts and

tighten to 176 N´m (130 ft.lbs.) (Fig. 31).

(3) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(4) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(5) Remove the support and lower the vehicle.

DISC BRAKE CALIPER

ADAPTER MOUNT

REMOVAL - REAR

(1) Remove wheel and tire assembly.

(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 54).

(9) Remove the caliper adapter mount from the

axle housing (Fig. 32).

INSTALLATION

(1) Install the caliper adapter mount on the axle

housing (Fig. 32).

(2) Install support plate on axle flange (Fig. 55).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(3) Install parking brake cable in the brake lever.

(4) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 55).

(5) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

Fig. 30 CALIPER MOUNT

1 - DISC BRAKE PADS

2 - ANTI-RATTLE CLIPS

3 - CALIPER ADAPTER

4 - MOUNTING BOLTS

Fig. 31 CALIPER ADAPTER

1 - CALIPER ASSEMBLY

2 - MOUNTING BOLT

3 - DISC BRAKE ROTOR

DRBRAKES - BASE 5 - 17

DISC BRAKE CALIPER ADAPTER (Continued)

Page 252 of 2895

(2) Install the one mounting bolt for the adjustable

pedal motor (Fig. 46).

(3) Clip the cable fasteners to the support.

(4) Reconnect the electrical connector.

(5) Reconnect the adjustable pedal cables to the

brake and accelerator pedals.

(6) Install the new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(7) Install the kneeblocker (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(8) Reconnect the negative battery cable.

(9) Check for proper operation of the pedals.

POWER BRAKE BOOSTER

DESCRIPTION

All models use a tandem diaphragm, power brake

booster.

NOTE: The power brake booster is not a repairable

component. The booster must be replaced as an

assembly if diagnosis indicates a malfunction has

occurred.

OPERATION

The booster unit consists of a single housing

divided into two by a tandem diaphragm. The outer

edge of the diaphragm is secured to the housing. The

booster push rod, which connects the booster to the

brake pedal and master cylinder, is attached to the

center of the diaphragm. A check valve is used in the

booster outlet connected to the engine intake mani-

fold. Power assist is generated by utilizing a combi-

nation of vacuum and atmospheric pressure to boost

brake assist.

REMOVAL

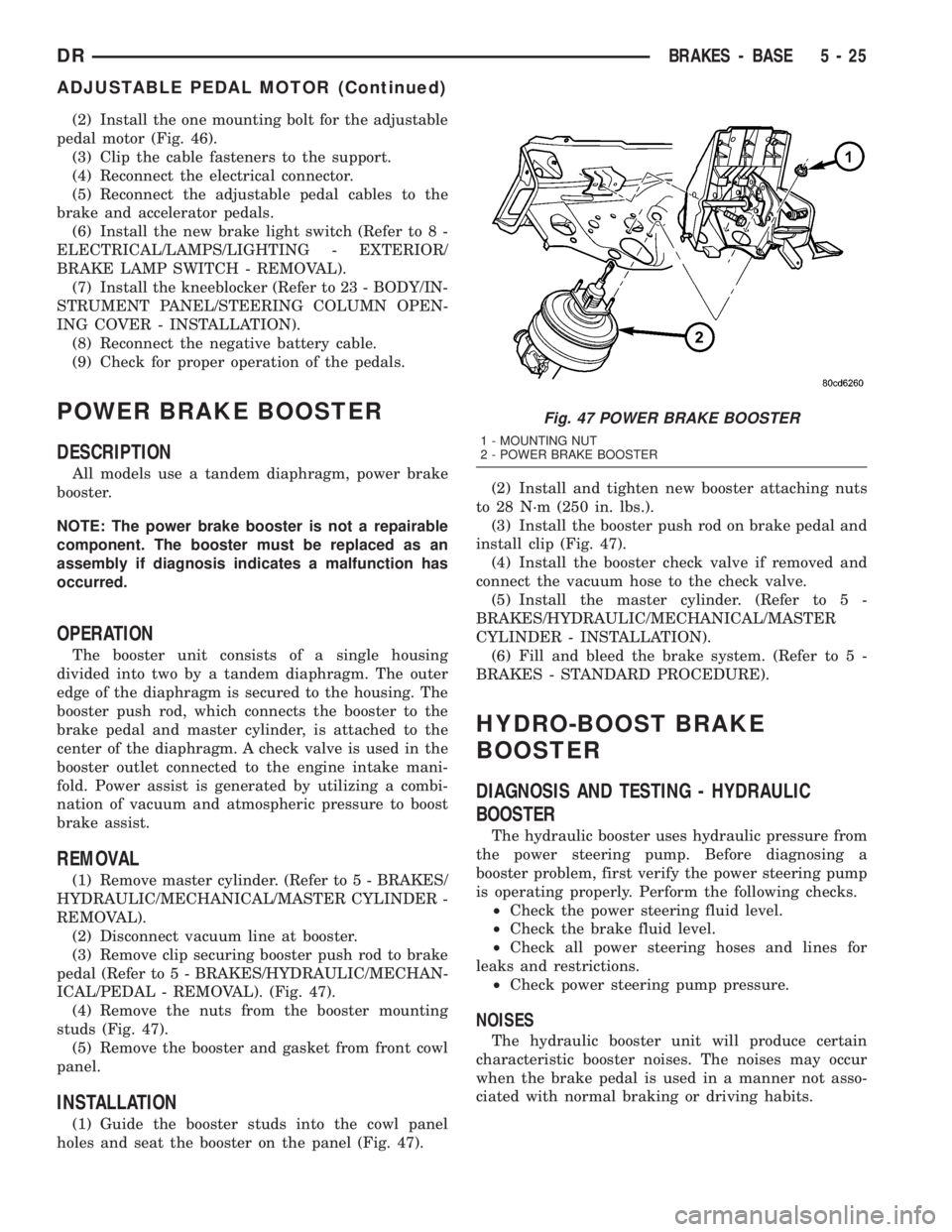

(1) Remove master cylinder. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/MASTER CYLINDER -

REMOVAL).

(2) Disconnect vacuum line at booster.

(3) Remove clip securing booster push rod to brake

pedal (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL). (Fig. 47).

(4) Remove the nuts from the booster mounting

studs (Fig. 47).

(5) Remove the booster and gasket from front cowl

panel.

INSTALLATION

(1) Guide the booster studs into the cowl panel

holes and seat the booster on the panel (Fig. 47).(2) Install and tighten new booster attaching nuts

to 28 N´m (250 in. lbs.).

(3) Install the booster push rod on brake pedal and

install clip (Fig. 47).

(4) Install the booster check valve if removed and

connect the vacuum hose to the check valve.

(5) Install the master cylinder. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - INSTALLATION).

(6) Fill and bleed the brake system. (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

HYDRO-BOOST BRAKE

BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER

The hydraulic booster uses hydraulic pressure from

the power steering pump. Before diagnosing a

booster problem, first verify the power steering pump

is operating properly. Perform the following checks.

²Check the power steering fluid level.

²Check the brake fluid level.

²Check all power steering hoses and lines for

leaks and restrictions.

²Check power steering pump pressure.

NOISES

The hydraulic booster unit will produce certain

characteristic booster noises. The noises may occur

when the brake pedal is used in a manner not asso-

ciated with normal braking or driving habits.

Fig. 47 POWER BRAKE BOOSTER

1 - MOUNTING NUT

2 - POWER BRAKE BOOSTER

DRBRAKES - BASE 5 - 25

ADJUSTABLE PEDAL MOTOR (Continued)

Page 265 of 2895

RELEASE HANDLE

REMOVAL

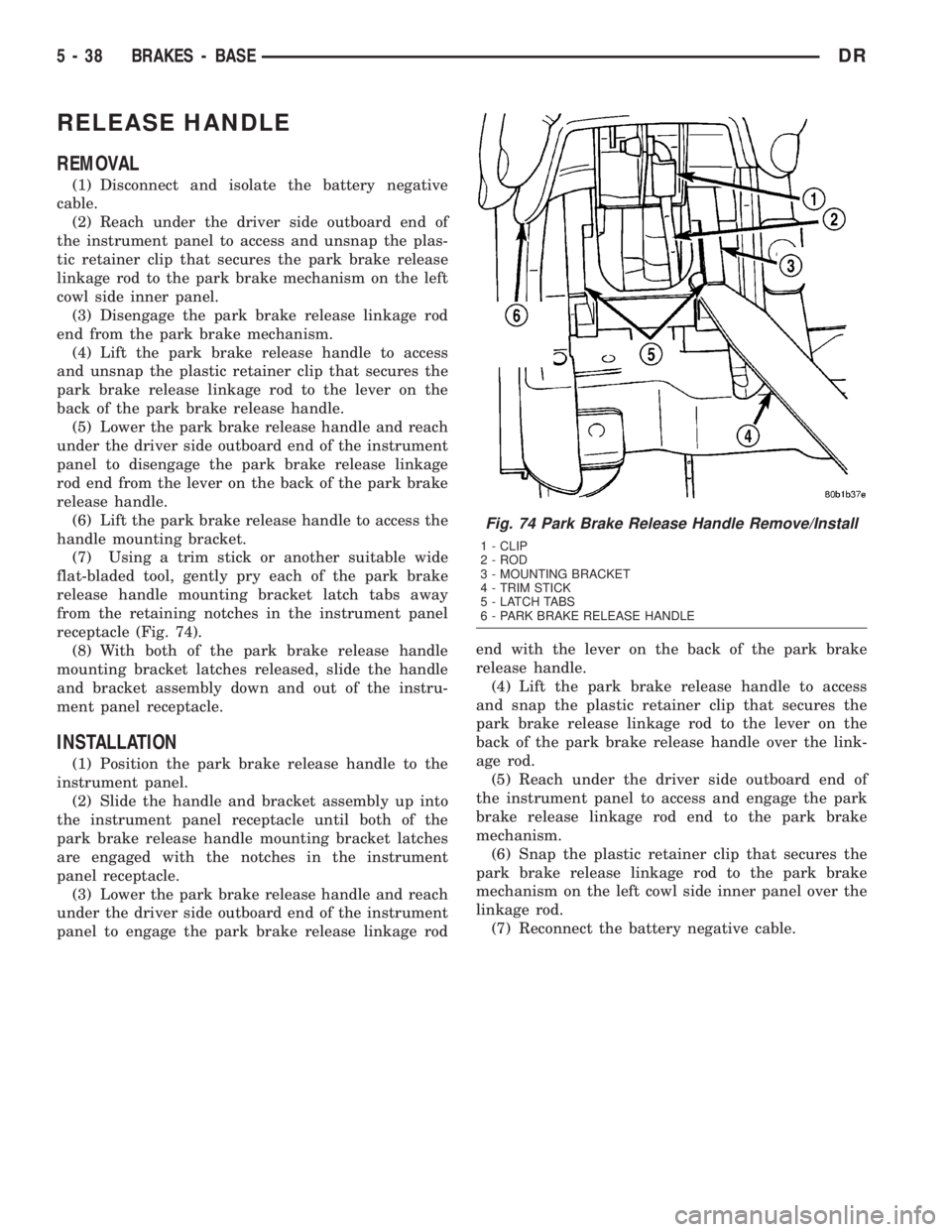

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the driver side outboard end of

the instrument panel to access and unsnap the plas-

tic retainer clip that secures the park brake release

linkage rod to the park brake mechanism on the left

cowl side inner panel.

(3) Disengage the park brake release linkage rod

end from the park brake mechanism.

(4) Lift the park brake release handle to access

and unsnap the plastic retainer clip that secures the

park brake release linkage rod to the lever on the

back of the park brake release handle.

(5) Lower the park brake release handle and reach

under the driver side outboard end of the instrument

panel to disengage the park brake release linkage

rod end from the lever on the back of the park brake

release handle.

(6) Lift the park brake release handle to access the

handle mounting bracket.

(7) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each of the park brake

release handle mounting bracket latch tabs away

from the retaining notches in the instrument panel

receptacle (Fig. 74).

(8) With both of the park brake release handle

mounting bracket latches released, slide the handle

and bracket assembly down and out of the instru-

ment panel receptacle.

INSTALLATION

(1) Position the park brake release handle to the

instrument panel.

(2) Slide the handle and bracket assembly up into

the instrument panel receptacle until both of the

park brake release handle mounting bracket latches

are engaged with the notches in the instrument

panel receptacle.

(3) Lower the park brake release handle and reach

under the driver side outboard end of the instrument

panel to engage the park brake release linkage rodend with the lever on the back of the park brake

release handle.

(4) Lift the park brake release handle to access

and snap the plastic retainer clip that secures the

park brake release linkage rod to the lever on the

back of the park brake release handle over the link-

age rod.

(5) Reach under the driver side outboard end of

the instrument panel to access and engage the park

brake release linkage rod end to the park brake

mechanism.

(6) Snap the plastic retainer clip that secures the

park brake release linkage rod to the park brake

mechanism on the left cowl side inner panel over the

linkage rod.

(7) Reconnect the battery negative cable.

Fig. 74 Park Brake Release Handle Remove/Install

1 - CLIP

2 - ROD

3 - MOUNTING BRACKET

4 - TRIM STICK

5 - LATCH TABS

6 - PARK BRAKE RELEASE HANDLE

5 - 38 BRAKES - BASEDR

Page 270 of 2895

INSTALLATION

(1) Connect the harness to the sensor.Be sure

the seal is securely in place between the sensor

and the wiring connector.

(2) Install the O-ring on the sensor (if removed).

(3) Insert the sensor in the differential housing.

(4) Install the sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (200 in. lbs.).

(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower the vehicle.

TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the Antilock Brake system. For test proce-

dures refer to the Chassis Diagnostic Manual.

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING

Vehicles equipped with ABS use electronic variable

brake proportioning (EVBP) to balance front-to-rear

braking. The EVBP is used in place of a rear propor-

tioning valve. The EVBP system uses the ABS sys-

tem to control the slip of the rear wheels in partial

braking range. The braking force of the rear wheels

is controlled electronically by using the inlet and out-

let valves located in the integrated control unit

(ICU).

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

EVBP is able to decrease, hold and increase rear

brake pressure without activating full ABS control.

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supplyfrom the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump provides the fluid volume needed and is oper-

ated by a DC type motor. The motor is controlled by

the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

NOTE: The three modes mentioned below do occur

but not necessarily in the order listed everytime.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

DRBRAKES - ABS 5 - 43

REAR WHEEL SPEED SENSOR (Continued)

Page 271 of 2895

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

PRESSURE HOLD

Both solenoid valves are closed in the pressure

hold cycle but only the inlet valve is energized. Fluid

apply pressure in the control channel is maintained

at a constant rate. The CAB maintains the hold cycle

until sensor inputs indicate a pressure change is nec-

essary.

PRESSURE INCREASE

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle. The pres-

sure increase cycle is used to reapply thew brakes.

This cycle controls re-application of fluid apply pres-

sure.

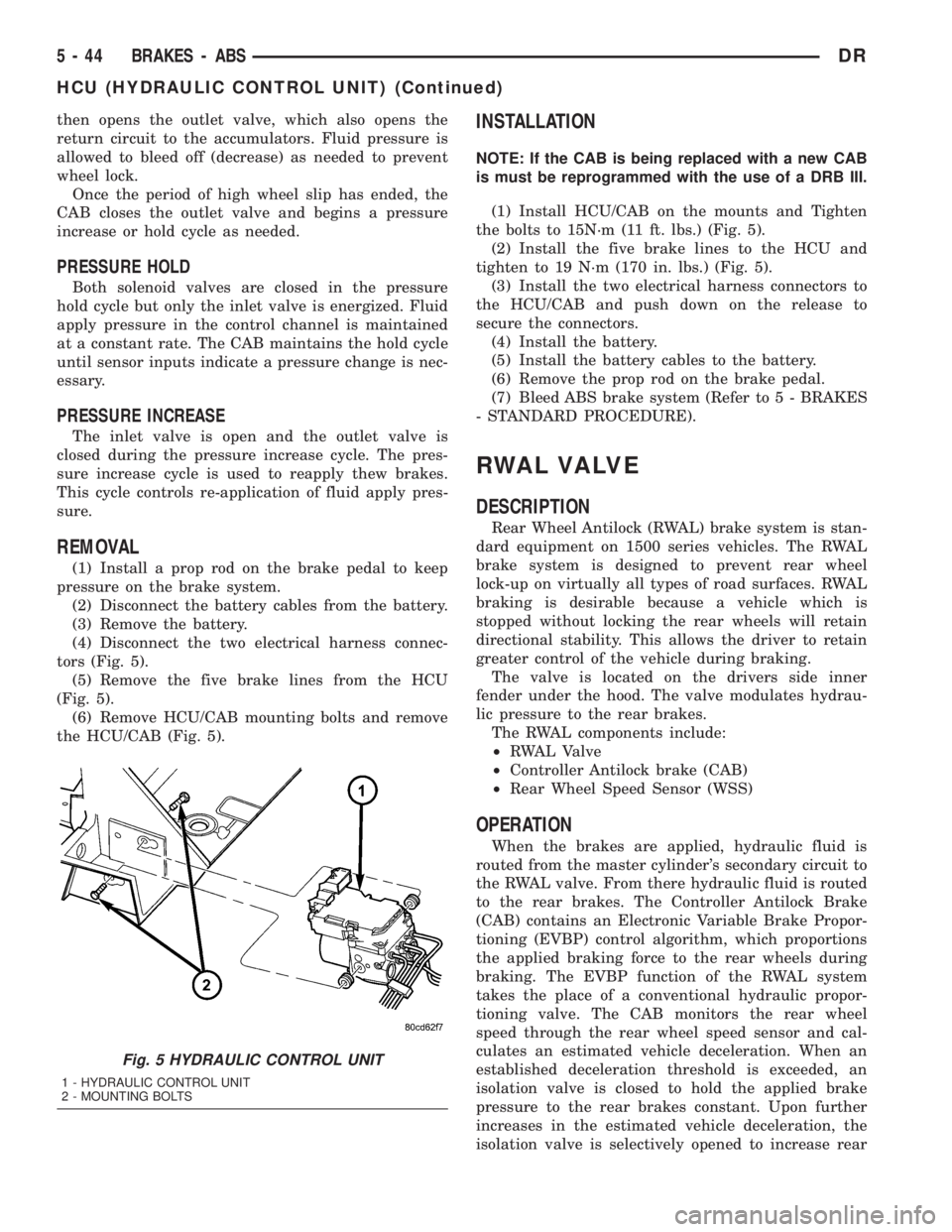

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery.

(3) Remove the battery.

(4) Disconnect the two electrical harness connec-

tors (Fig. 5).

(5) Remove the five brake lines from the HCU

(Fig. 5).

(6) Remove HCU/CAB mounting bolts and remove

the HCU/CAB (Fig. 5).

INSTALLATION

NOTE: If the CAB is being replaced with a new CAB

is must be reprogrammed with the use of a DRB III.

(1) Install HCU/CAB on the mounts and Tighten

the bolts to 15N´m (11 ft. lbs.) (Fig. 5).

(2) Install the five brake lines to the HCU and

tighten to 19 N´m (170 in. lbs.) (Fig. 5).

(3) Install the two electrical harness connectors to

the HCU/CAB and push down on the release to

secure the connectors.

(4) Install the battery.

(5) Install the battery cables to the battery.

(6) Remove the prop rod on the brake pedal.

(7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

RWAL VALVE

DESCRIPTION

Rear Wheel Antilock (RWAL) brake system is stan-

dard equipment on 1500 series vehicles. The RWAL

brake system is designed to prevent rear wheel

lock-up on virtually all types of road surfaces. RWAL

braking is desirable because a vehicle which is

stopped without locking the rear wheels will retain

directional stability. This allows the driver to retain

greater control of the vehicle during braking.

The valve is located on the drivers side inner

fender under the hood. The valve modulates hydrau-

lic pressure to the rear brakes.

The RWAL components include:

²RWAL Valve

²Controller Antilock brake (CAB)

²Rear Wheel Speed Sensor (WSS)

OPERATION

When the brakes are applied, hydraulic fluid is

routed from the master cylinder's secondary circuit to

the RWAL valve. From there hydraulic fluid is routed

to the rear brakes. The Controller Antilock Brake

(CAB) contains an Electronic Variable Brake Propor-

tioning (EVBP) control algorithm, which proportions

the applied braking force to the rear wheels during

braking. The EVBP function of the RWAL system

takes the place of a conventional hydraulic propor-

tioning valve. The CAB monitors the rear wheel

speed through the rear wheel speed sensor and cal-

culates an estimated vehicle deceleration. When an

established deceleration threshold is exceeded, an

isolation valve is closed to hold the applied brake

pressure to the rear brakes constant. Upon further

increases in the estimated vehicle deceleration, the

isolation valve is selectively opened to increase rear

Fig. 5 HYDRAULIC CONTROL UNIT

1 - HYDRAULIC CONTROL UNIT

2 - MOUNTING BOLTS

5 - 44 BRAKES - ABSDR

HCU (HYDRAULIC CONTROL UNIT) (Continued)