Radio DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 374 of 2895

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

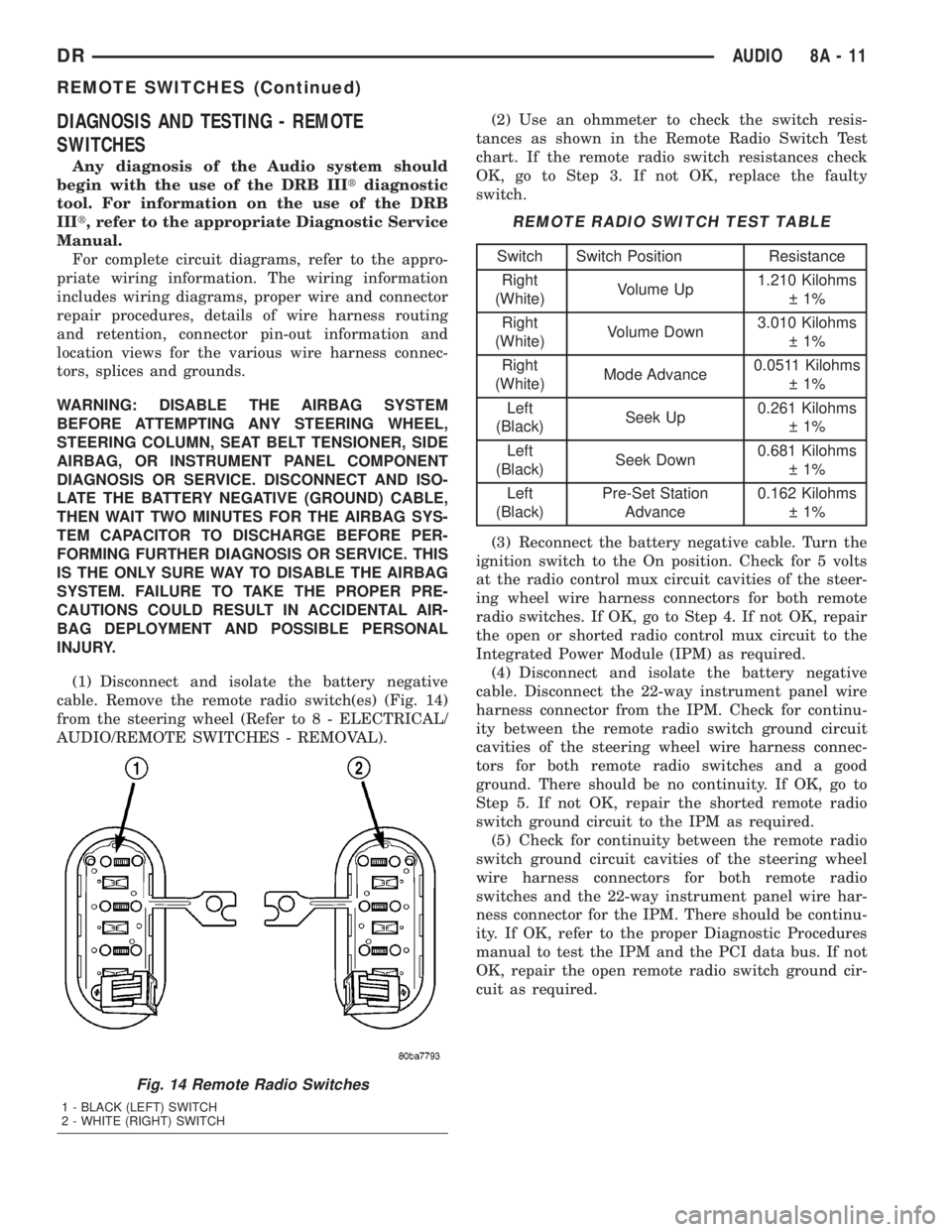

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 14)

from the steering wheel (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

REMOTE RADIO SWITCH TEST TABLE

Switch Switch Position Resistance

Right

(White)Volume Up1.210 Kilohms

1%

Right

(White)Volume Down3.010 Kilohms

1%

Right

(White)Mode Advance0.0511 Kilohms

1%

Left

(Black)Seek Up0.261 Kilohms

1%

Left

(Black)Seek Down0.681 Kilohms

1%

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

1%

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Integrated Power Module (IPM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the IPM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the IPM as required.

(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the IPM. There should be continu-

ity. If OK, refer to the proper Diagnostic Procedures

manual to test the IPM and the PCI data bus. If not

OK, repair the open remote radio switch ground cir-

cuit as required.

Fig. 14 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

DRAUDIO 8A - 11

REMOTE SWITCHES (Continued)

Page 375 of 2895

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver airbag from the vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(3) Remove the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch(es).

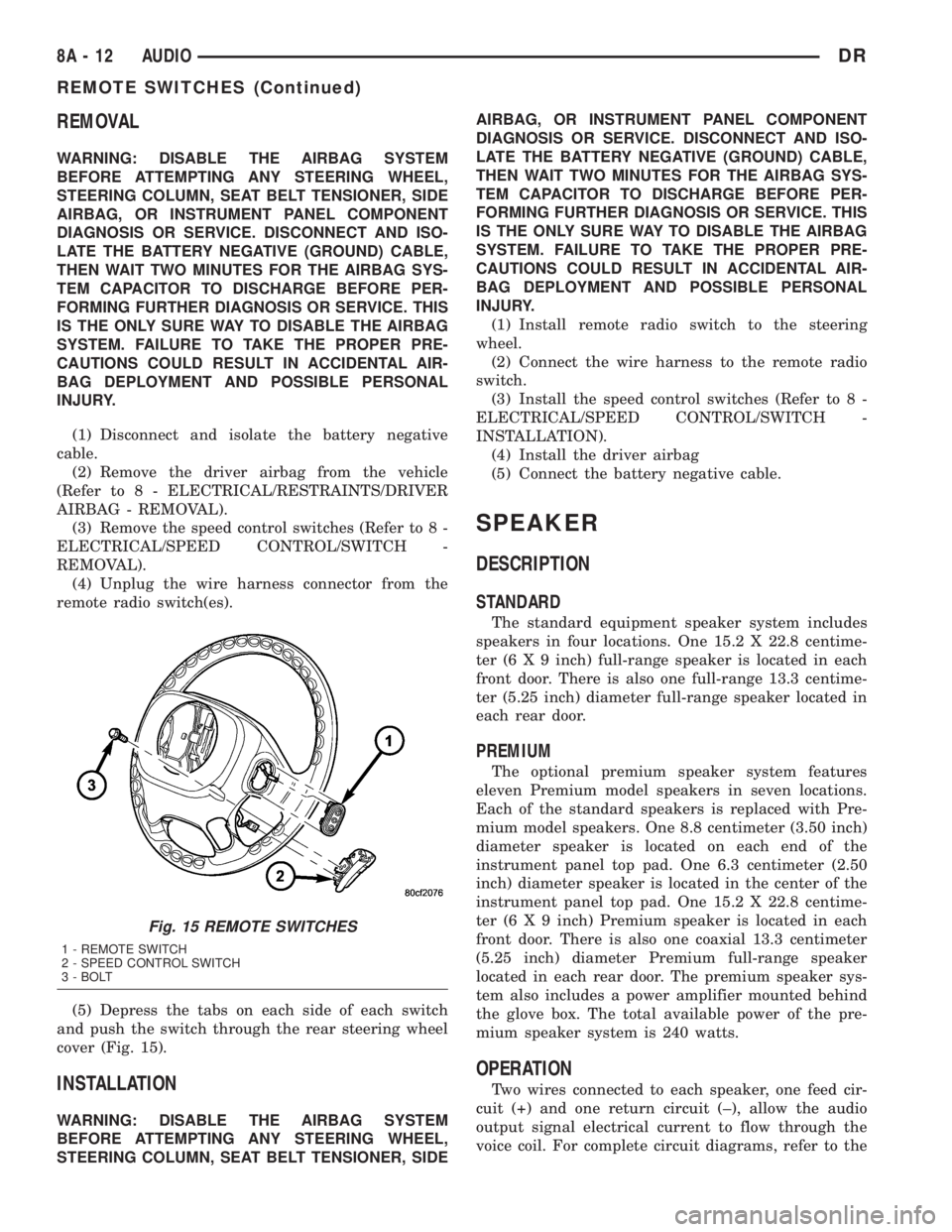

(5) Depress the tabs on each side of each switch

and push the switch through the rear steering wheel

cover (Fig. 15).

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDEAIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Connect the wire harness to the remote radio

switch.

(3) Install the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

INSTALLATION).

(4) Install the driver airbag

(5) Connect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in four locations. One 15.2 X 22.8 centime-

ter (6 X 9 inch) full-range speaker is located in each

front door. There is also one full-range 13.3 centime-

ter (5.25 inch) diameter full-range speaker located in

each rear door.

PREMIUM

The optional premium speaker system features

eleven Premium model speakers in seven locations.

Each of the standard speakers is replaced with Pre-

mium model speakers. One 8.8 centimeter (3.50 inch)

diameter speaker is located on each end of the

instrument panel top pad. One 6.3 centimeter (2.50

inch) diameter speaker is located in the center of the

instrument panel top pad. One 15.2 X 22.8 centime-

ter (6 X 9 inch) Premium speaker is located in each

front door. There is also one coaxial 13.3 centimeter

(5.25 inch) diameter Premium full-range speaker

located in each rear door. The premium speaker sys-

tem also includes a power amplifier mounted behind

the glove box. The total available power of the pre-

mium speaker system is 240 watts.

OPERATION

Two wires connected to each speaker, one feed cir-

cuit (+) and one return circuit (±), allow the audio

output signal electrical current to flow through the

voice coil. For complete circuit diagrams, refer to the

Fig. 15 REMOTE SWITCHES

1 - REMOTE SWITCH

2 - SPEED CONTROL SWITCH

3 - BOLT

8A - 12 AUDIODR

REMOTE SWITCHES (Continued)

Page 376 of 2895

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

and/or amplifier may result.

(1) If all speakers are inoperative, check the fuses

in the Integrated Power Module (IPM). If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

IPM. If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negativecable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 5.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(6) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector or if equipped, the amplifier

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

REMOVAL

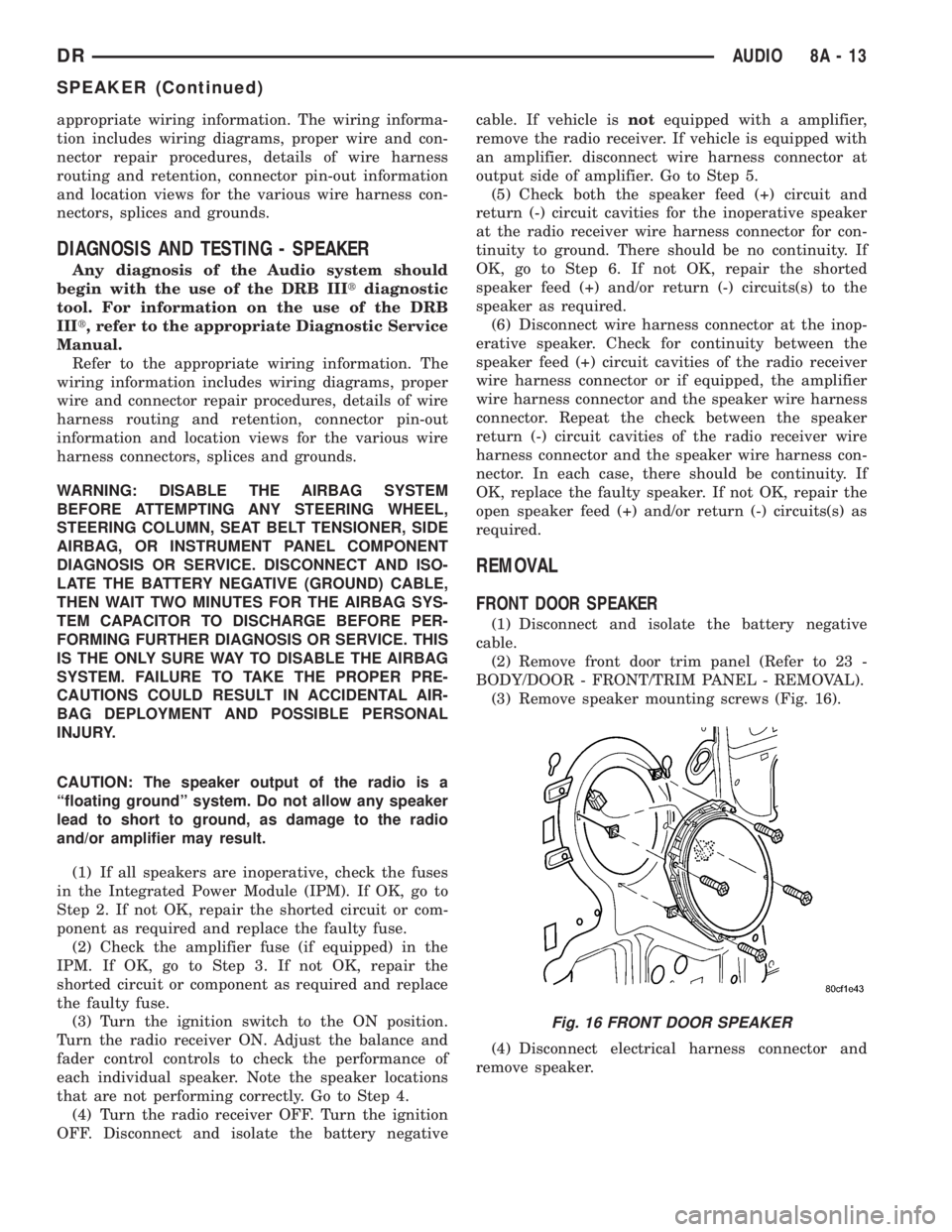

FRONT DOOR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove front door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove speaker mounting screws (Fig. 16).

(4) Disconnect electrical harness connector and

remove speaker.

Fig. 16 FRONT DOOR SPEAKER

DRAUDIO 8A - 13

SPEAKER (Continued)

Page 394 of 2895

(2) Tighten bolts. Refer to torque specifications.

(3) Check pin connectors in the PCM and the three

32±way connectors (four 38±way connectors if

equipped with NGC) for corrosion or damage. Also,

the pin heights in connectors should all be same.

Repair as necessary before installing connectors.

(4) Install three 32±way connectors (four 38±way

connectors if equipped with NGC).

(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install negative battery cable.

(7) Use the DRB scan tool to reprogram new PCM

with vehicles original Vehicle Identification Number

(VIN) and original vehicle mileage.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a cen-

tral processing unit, which includes the Sentry Key

Immobilizer System (SKIS) program logic. The SKIS

programming enables the SKIM to program and

retain in memory the codes of at least two, but no

more than eight electronically coded Sentry Key

transponders. The SKIS programming also enables

the SKIM to communicate over the Programmable

Communication Interface (PCI) bus network with the

Powertrain Control Module (PCM), and/or the

DRBIIItscan tool.

OPERATION

The SKIM transmits and receives RF signals

through a tuned antenna enclosed within a molded

plastic ring that is integral to the SKIM housing.

When the SKIM is properly installed on the steering

column, the antenna ring is oriented around the igni-

tion lock cylinder housing. This antenna ring must be

located within eight millimeters (0.31 inches) of the

Sentry Key in order to ensure proper RF communica-

tion between the SKIM and the Sentry Key tran-

sponder.

For added system security, each SKIM is pro-

grammed with a unique ªSecret Keyº code and a

security code. The SKIM keeps the ªSecret Keyº code

in memory. The SKIM also sends the ªSecret Keyº

code to each of the programmed Sentry Key tran-

sponders. The security code is used by the assembly

plant to access the SKIS for initialization, or by the

dealer technician to access the system for service.

The SKIM also stores in its memory the Vehicle

Identification Number (VIN), which it learns through

a PCI bus message from the PCM during initializa-

tion.The SKIM and the PCM both use software that

includes a rolling code algorithm strategy, which

helps to reduce the possibility of unauthorized SKIS

disarming. The rolling code algorithm ensures secu-

rity by preventing an override of the SKIS through

the unauthorized substitution of the SKIM or the

PCM. However, the use of this strategy also means

that replacement of either the SKIM or the PCM

units will require a system initialization procedure to

restore system operation.

When the ignition switch is turned to the ON or

START positions, the SKIM transmits an RF signal

to excite the Sentry Key transponder. The SKIM then

listens for a return RF signal from the transponder

of the Sentry Key that is inserted in the ignition lock

cylinder. If the SKIM receives an RF signal with

valid ªSecret Keyº and transponder identification

codes, the SKIM sends a ªvalid keyº message to the

PCM over the PCI bus. If the SKIM receives an

invalid RF signal or no response, it sends ªinvalid

keyº messages to the PCM. The PCM will enable or

disable engine operation based upon the status of the

SKIM messages.

The SKIM also sends messages to the Instrument

Cluster which controls the VTSS indicator LED. The

SKIM sends messages to the Instrument Cluster to

turn the LED on for about three seconds when the

ignition switch is turned to the ON position as a bulb

test. After completion of the bulb test, the SKIM

sends bus messages to keep the LED off for a dura-

tion of about one second. Then the SKIM sends mes-

sages to turn the LED on or off based upon the

results of the SKIS self-tests. If the VTSS indicator

LED comes on and stays on after the bulb test, it

indicates that the SKIM has detected a system mal-

function and/or that the SKIS has become inopera-

tive.

If the SKIM detects an invalid key when the igni-

tion switch is turned to the ON position, it sends

messages to flash the VTSS indicator LED. The

SKIM can also send messages to flash the LED as an

indication to the customer that the SKIS has been

placed in it's ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this section for more information on

the ªCustomer Learnº programming mode.

For diagnosis or initialization of the SKIM and the

PCM, a DRBIIItscan tool and the proper Powertrain

Diagnostic Procedures manual are required. The

SKIM cannot be repaired and, if faulty or damaged,

the unit must be replaced.

DRELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

Page 416 of 2895

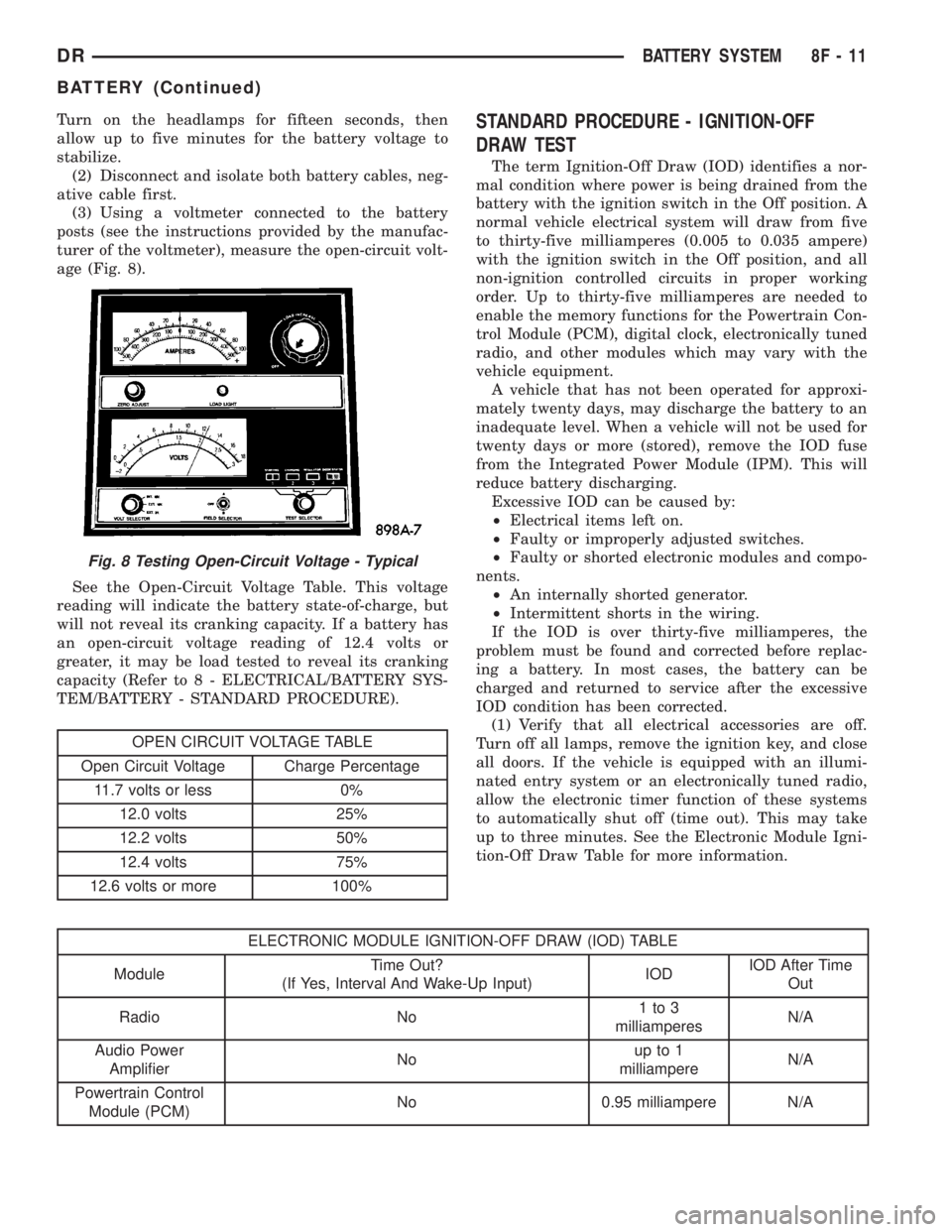

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 8).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Integrated Power Module (IPM). This will

reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes. See the Electronic Module Igni-

tion-Off Draw Table for more information.

ELECTRONIC MODULE IGNITION-OFF DRAW (IOD) TABLE

ModuleTime Out?

(If Yes, Interval And Wake-Up Input)IODIOD After Time

Out

Radio No1to3

milliamperesN/A

Audio Power

AmplifierNoup to 1

milliampereN/A

Powertrain Control

Module (PCM)No 0.95 milliampere N/A

Fig. 8 Testing Open-Circuit Voltage - Typical

DRBATTERY SYSTEM 8F - 11

BATTERY (Continued)

Page 448 of 2895

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................3

OPERATION............................4

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM.............................4

HEATED SEAT ELEMENT

DESCRIPTION..........................5

OPERATION............................6

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT............................6

REMOVAL.............................6

INSTALLATION..........................6

HEATED SEAT SENSOR

DESCRIPTION..........................7OPERATION............................7

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR.............................7

REMOVAL.............................7

HEATED SEAT SWITCH

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH.............................8

REMOVAL.............................9

INSTALLATION..........................9

HEATED SEAT SYSTEM

DESCRIPTION

Individually controlled, electrically heated front

seats are available as a factory-installed option on

some DR models. Vehicles with this option can be

visually identified by the leather trim seats and two

separate heated seat switches mounted in the lower

center of the instrument panel. The heated seat sys-

tem allows the front seat driver and passenger to

select from two different levels of electrical seat heat-

ing, or no seat heating to suit their individual com-

fort requirements. The heated seat system for this

vehicle includes the following major components,

which are described in further detail later in this sec-

tion:

²Heated Seat Switches- Two heated seat

switches are used per vehicle. One switch is used for

each front seat. The switches are mounted in the

instrument panel, below the radio (Fig. 1). Each

switch also includes two Light-Emitting Diode (LED)

indicator lamps and an incandescent back lighting

bulb.

²Heated Seat Module- also referred to as the

Seat Heat Interface Module (SHIM), this module con-

tains the solid state electronic control and diagnostic

logic circuitry for the heated seat system. One heated

seat module is used per vehicle and is mounted

under the drivers front seat cushion (Fig. 1). Refer to

the Electronic Control Modules section of the service

manual for additional heated seat module informa-

tion.²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle. One element is used for

each front seat back and one element and sensor

assembly is used for each front seat cushion (Fig. 1).

The heating elements are integral to the individual

front seat and seat back cushions and cannot be

removed once installed at the factory. Replacement

seat heating elements are available, without having

to replace the entire seat cushion or trim cover. Refer

to the detailed procedure later in this section.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle. One heated seat tempera-

ture sensor is used for each front seat cushion. The

sensors are integral to the individual front seat cush-

ion heating elements (Fig. 1) and cannot be removed

once installed at the factory. Replacement seat heat-

ing elements with the sensors are available, without

having to replace the entire seat cushion or trim

cover. Refer to the detailed procedure later in this

section.

Following are general descriptions and operations

of the major components in the heated seat system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the heated seat system. Refer toWiringfor the

location of complete heated seat system wiring dia-

grams.

DRHEATED SEAT SYSTEM 8G - 3

Page 476 of 2895

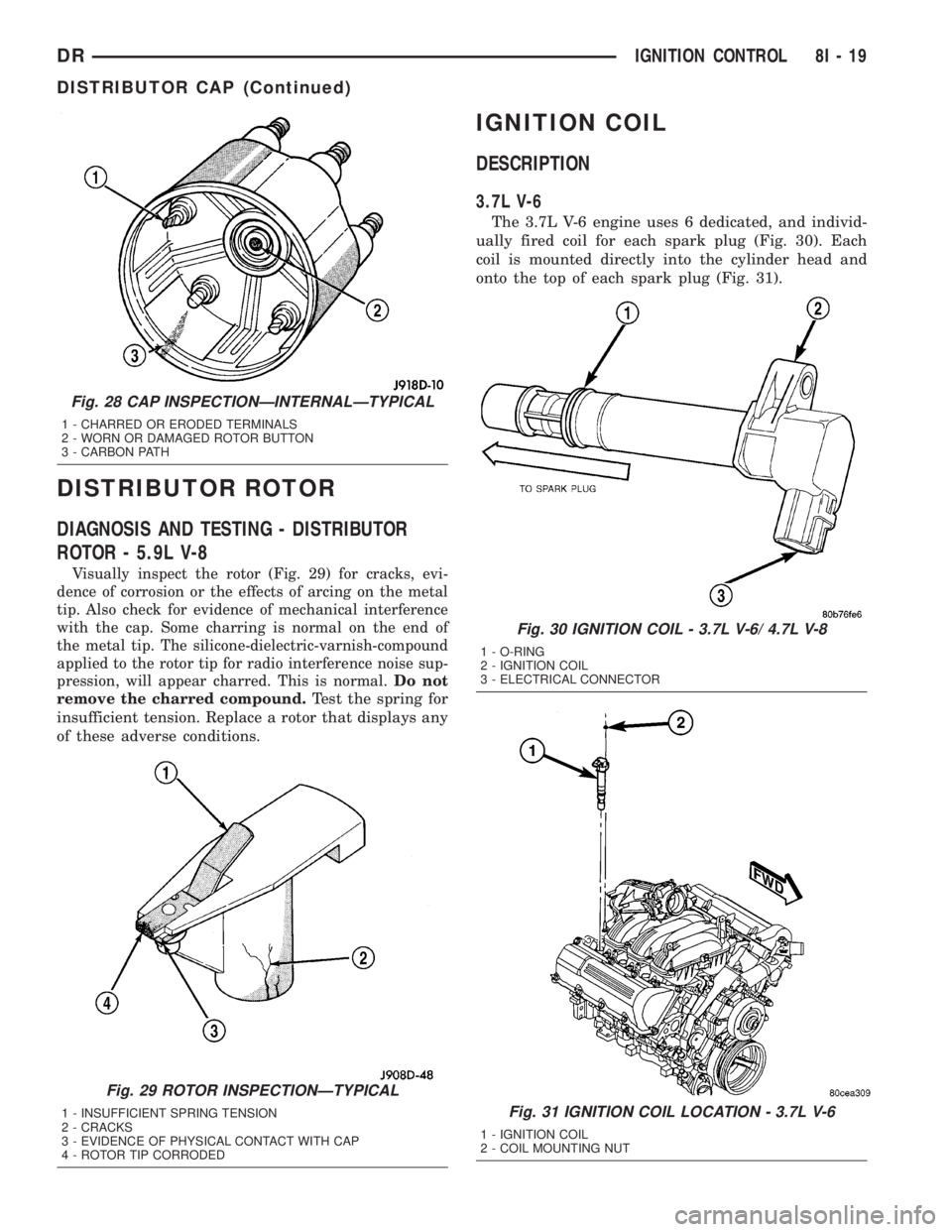

DISTRIBUTOR ROTOR

DIAGNOSIS AND TESTING - DISTRIBUTOR

ROTOR - 5.9L V-8

Visually inspect the rotor (Fig. 29) for cracks, evi-

dence of corrosion or the effects of arcing on the metal

tip. Also check for evidence of mechanical interference

with the cap. Some charring is normal on the end of

the metal tip. The silicone-dielectric-varnish-compound

applied to the rotor tip for radio interference noise sup-

pression, will appear charred. This is normal.Do not

remove the charred compound.

Test the spring for

insufficient tension. Replace a rotor that displays any

of these adverse conditions.

IGNITION COIL

DESCRIPTION

3.7L V-6

The 3.7L V-6 engine uses 6 dedicated, and individ-

ually fired coil for each spark plug (Fig. 30). Each

coil is mounted directly into the cylinder head and

onto the top of each spark plug (Fig. 31).

Fig. 28 CAP INSPECTIONÐINTERNALÐTYPICAL

1 - CHARRED OR ERODED TERMINALS

2 - WORN OR DAMAGED ROTOR BUTTON

3 - CARBON PATH

Fig. 29 ROTOR INSPECTIONÐTYPICAL

1 - INSUFFICIENT SPRING TENSION

2 - CRACKS

3 - EVIDENCE OF PHYSICAL CONTACT WITH CAP

4 - ROTOR TIP CORRODED

Fig. 30 IGNITION COIL - 3.7L V-6/ 4.7L V-8

1 - O-RING

2 - IGNITION COIL

3 - ELECTRICAL CONNECTOR

Fig. 31 IGNITION COIL LOCATION - 3.7L V-6

1 - IGNITION COIL

2 - COIL MOUNTING NUT

DRIGNITION CONTROL 8I - 19

DISTRIBUTOR CAP (Continued)

Page 489 of 2895

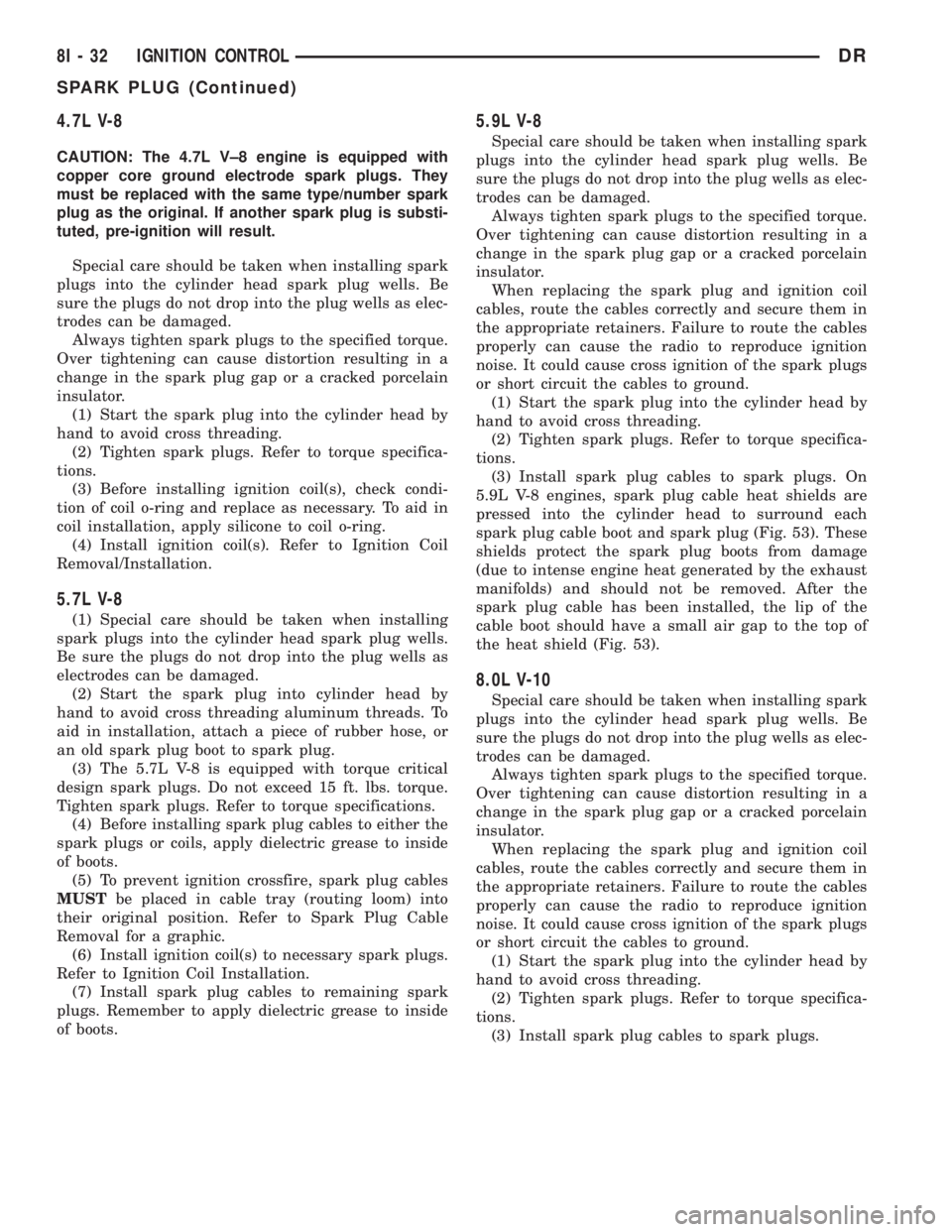

4.7L V-8

CAUTION: The 4.7L V±8 engine is equipped with

copper core ground electrode spark plugs. They

must be replaced with the same type/number spark

plug as the original. If another spark plug is substi-

tuted, pre-ignition will result.

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs. Refer to torque specifica-

tions.

(3) Before installing ignition coil(s), check condi-

tion of coil o-ring and replace as necessary. To aid in

coil installation, apply silicone to coil o-ring.

(4) Install ignition coil(s). Refer to Ignition Coil

Removal/Installation.

5.7L V-8

(1) Special care should be taken when installing

spark plugs into the cylinder head spark plug wells.

Be sure the plugs do not drop into the plug wells as

electrodes can be damaged.

(2) Start the spark plug into cylinder head by

hand to avoid cross threading aluminum threads. To

aid in installation, attach a piece of rubber hose, or

an old spark plug boot to spark plug.

(3) The 5.7L V-8 is equipped with torque critical

design spark plugs. Do not exceed 15 ft. lbs. torque.

Tighten spark plugs. Refer to torque specifications.

(4) Before installing spark plug cables to either the

spark plugs or coils, apply dielectric grease to inside

of boots.

(5) To prevent ignition crossfire, spark plug cables

MUSTbe placed in cable tray (routing loom) into

their original position. Refer to Spark Plug Cable

Removal for a graphic.

(6) Install ignition coil(s) to necessary spark plugs.

Refer to Ignition Coil Installation.

(7) Install spark plug cables to remaining spark

plugs. Remember to apply dielectric grease to inside

of boots.

5.9L V-8

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

When replacing the spark plug and ignition coil

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs. Refer to torque specifica-

tions.

(3) Install spark plug cables to spark plugs. On

5.9L V-8 engines, spark plug cable heat shields are

pressed into the cylinder head to surround each

spark plug cable boot and spark plug (Fig. 53). These

shields protect the spark plug boots from damage

(due to intense engine heat generated by the exhaust

manifolds) and should not be removed. After the

spark plug cable has been installed, the lip of the

cable boot should have a small air gap to the top of

the heat shield (Fig. 53).

8.0L V-10

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

When replacing the spark plug and ignition coil

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs. Refer to torque specifica-

tions.

(3) Install spark plug cables to spark plugs.

8I - 32 IGNITION CONTROLDR

SPARK PLUG (Continued)

Page 490 of 2895

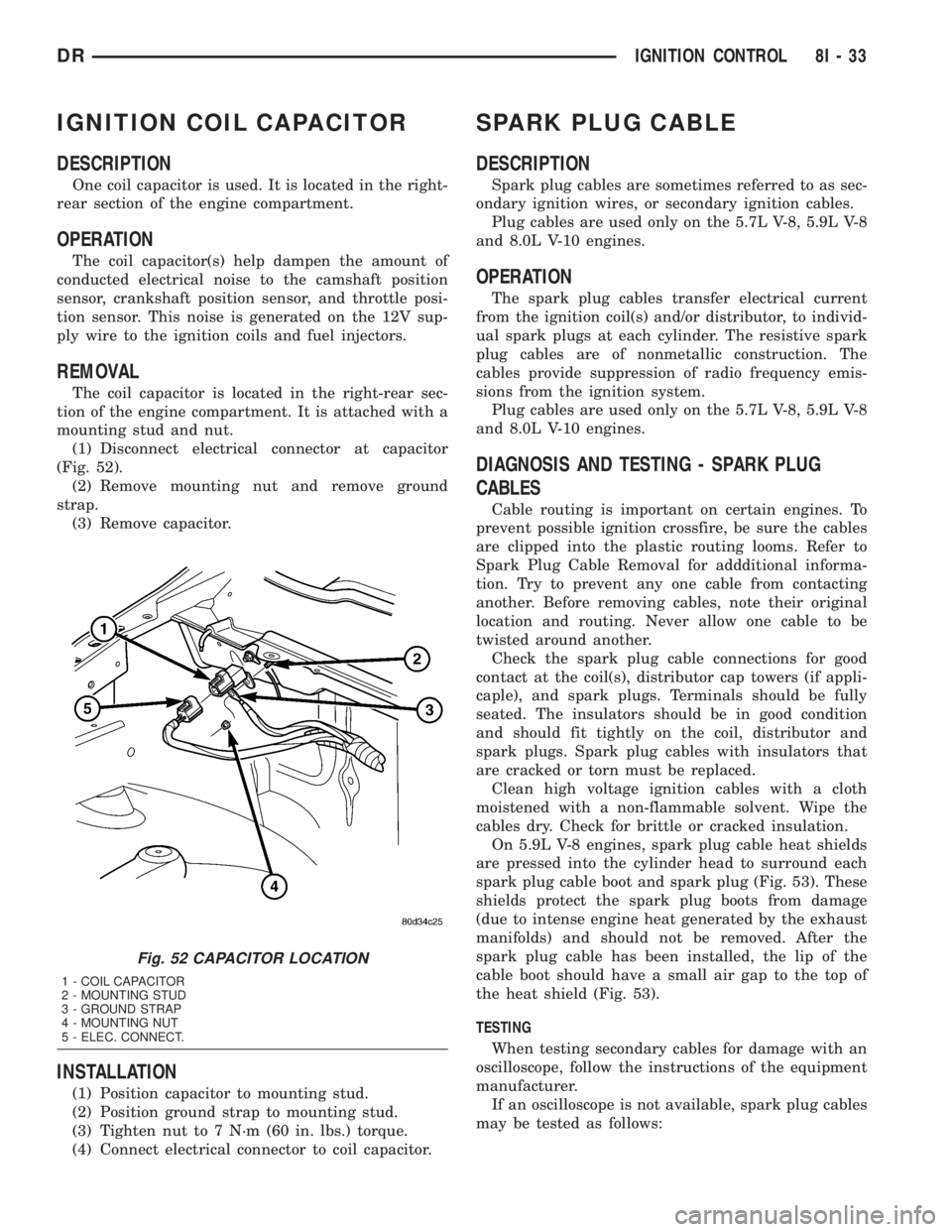

IGNITION COIL CAPACITOR

DESCRIPTION

One coil capacitor is used. It is located in the right-

rear section of the engine compartment.

OPERATION

The coil capacitor(s) help dampen the amount of

conducted electrical noise to the camshaft position

sensor, crankshaft position sensor, and throttle posi-

tion sensor. This noise is generated on the 12V sup-

ply wire to the ignition coils and fuel injectors.

REMOVAL

The coil capacitor is located in the right-rear sec-

tion of the engine compartment. It is attached with a

mounting stud and nut.

(1) Disconnect electrical connector at capacitor

(Fig. 52).

(2) Remove mounting nut and remove ground

strap.

(3) Remove capacitor.

INSTALLATION

(1) Position capacitor to mounting stud.

(2) Position ground strap to mounting stud.

(3) Tighten nut to 7 N´m (60 in. lbs.) torque.

(4) Connect electrical connector to coil capacitor.

SPARK PLUG CABLE

DESCRIPTION

Spark plug cables are sometimes referred to as sec-

ondary ignition wires, or secondary ignition cables.

Plug cables are used only on the 5.7L V-8, 5.9L V-8

and 8.0L V-10 engines.

OPERATION

The spark plug cables transfer electrical current

from the ignition coil(s) and/or distributor, to individ-

ual spark plugs at each cylinder. The resistive spark

plug cables are of nonmetallic construction. The

cables provide suppression of radio frequency emis-

sions from the ignition system.

Plug cables are used only on the 5.7L V-8, 5.9L V-8

and 8.0L V-10 engines.

DIAGNOSIS AND TESTING - SPARK PLUG

CABLES

Cable routing is important on certain engines. To

prevent possible ignition crossfire, be sure the cables

are clipped into the plastic routing looms. Refer to

Spark Plug Cable Removal for addditional informa-

tion. Try to prevent any one cable from contacting

another. Before removing cables, note their original

location and routing. Never allow one cable to be

twisted around another.

Check the spark plug cable connections for good

contact at the coil(s), distributor cap towers (if appli-

caple), and spark plugs. Terminals should be fully

seated. The insulators should be in good condition

and should fit tightly on the coil, distributor and

spark plugs. Spark plug cables with insulators that

are cracked or torn must be replaced.

Clean high voltage ignition cables with a cloth

moistened with a non-flammable solvent. Wipe the

cables dry. Check for brittle or cracked insulation.

On 5.9L V-8 engines, spark plug cable heat shields

are pressed into the cylinder head to surround each

spark plug cable boot and spark plug (Fig. 53). These

shields protect the spark plug boots from damage

(due to intense engine heat generated by the exhaust

manifolds) and should not be removed. After the

spark plug cable has been installed, the lip of the

cable boot should have a small air gap to the top of

the heat shield (Fig. 53).

TESTING

When testing secondary cables for damage with an

oscilloscope, follow the instructions of the equipment

manufacturer.

If an oscilloscope is not available, spark plug cables

may be tested as follows:

Fig. 52 CAPACITOR LOCATION

1 - COIL CAPACITOR

2 - MOUNTING STUD

3 - GROUND STRAP

4 - MOUNTING NUT

5 - ELEC. CONNECT.

DRIGNITION CONTROL 8I - 33

Page 492 of 2895

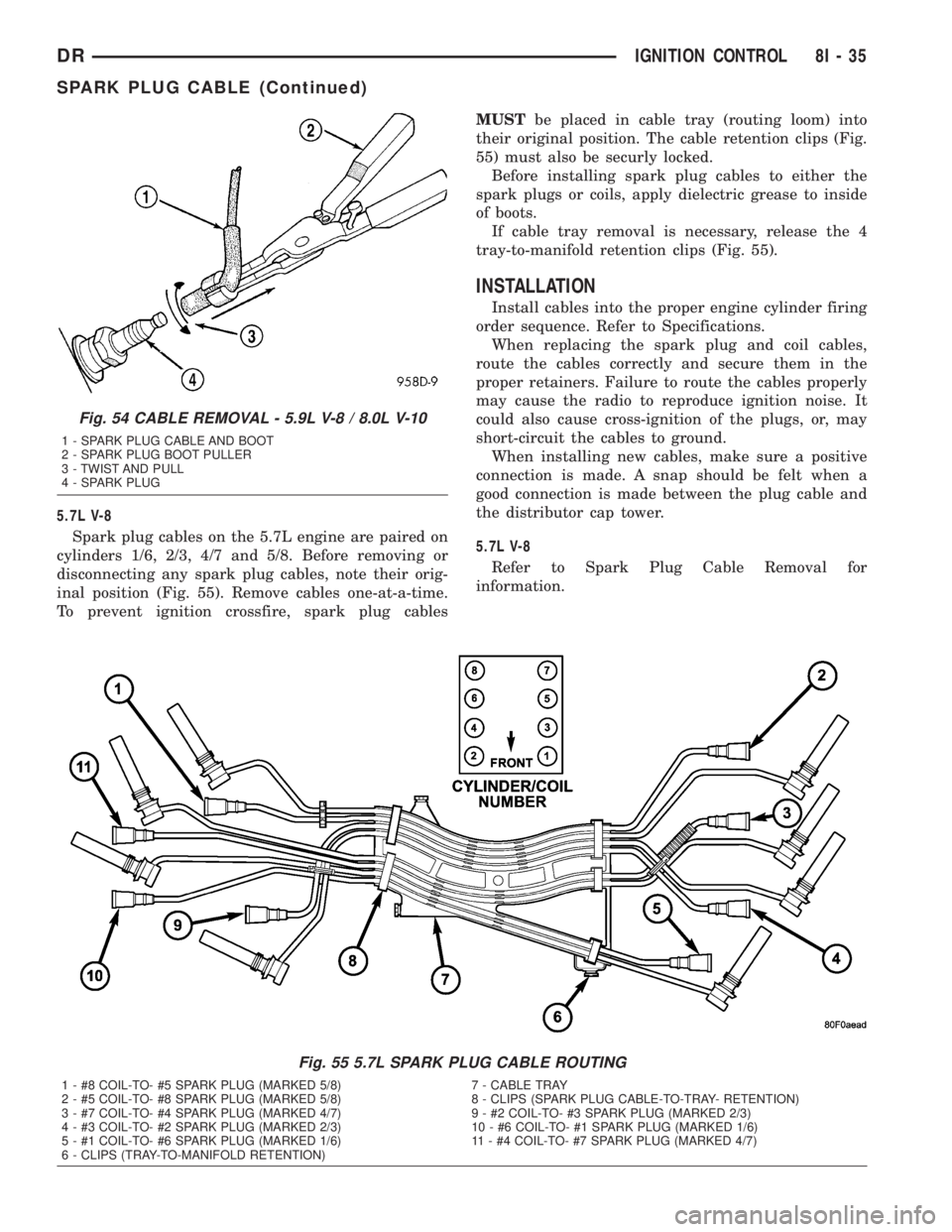

5.7L V-8

Spark plug cables on the 5.7L engine are paired on

cylinders 1/6, 2/3, 4/7 and 5/8. Before removing or

disconnecting any spark plug cables, note their orig-

inal position (Fig. 55). Remove cables one-at-a-time.

To prevent ignition crossfire, spark plug cablesMUSTbe placed in cable tray (routing loom) into

their original position. The cable retention clips (Fig.

55) must also be securly locked.

Before installing spark plug cables to either the

spark plugs or coils, apply dielectric grease to inside

of boots.

If cable tray removal is necessary, release the 4

tray-to-manifold retention clips (Fig. 55).

INSTALLATION

Install cables into the proper engine cylinder firing

order sequence. Refer to Specifications.

When replacing the spark plug and coil cables,

route the cables correctly and secure them in the

proper retainers. Failure to route the cables properly

may cause the radio to reproduce ignition noise. It

could also cause cross-ignition of the plugs, or, may

short-circuit the cables to ground.

When installing new cables, make sure a positive

connection is made. A snap should be felt when a

good connection is made between the plug cable and

the distributor cap tower.

5.7L V-8

Refer to Spark Plug Cable Removal for

information.

Fig. 55 5.7L SPARK PLUG CABLE ROUTING

1 - #8 COIL-TO- #5 SPARK PLUG (MARKED 5/8) 7 - CABLE TRAY

2 - #5 COIL-TO- #8 SPARK PLUG (MARKED 5/8) 8 - CLIPS (SPARK PLUG CABLE-TO-TRAY- RETENTION)

3 - #7 COIL-TO- #4 SPARK PLUG (MARKED 4/7) 9 - #2 COIL-TO- #3 SPARK PLUG (MARKED 2/3)

4 - #3 COIL-TO- #2 SPARK PLUG (MARKED 2/3) 10 - #6 COIL-TO- #1 SPARK PLUG (MARKED 1/6)

5 - #1 COIL-TO- #6 SPARK PLUG (MARKED 1/6) 11 - #4 COIL-TO- #7 SPARK PLUG (MARKED 4/7)

6 - CLIPS (TRAY-TO-MANIFOLD RETENTION)

Fig. 54 CABLE REMOVAL - 5.9L V-8 / 8.0L V-10

1 - SPARK PLUG CABLE AND BOOT

2 - SPARK PLUG BOOT PULLER

3 - TWIST AND PULL

4 - SPARK PLUG

DRIGNITION CONTROL 8I - 35

SPARK PLUG CABLE (Continued)