run flat DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2400 of 2895

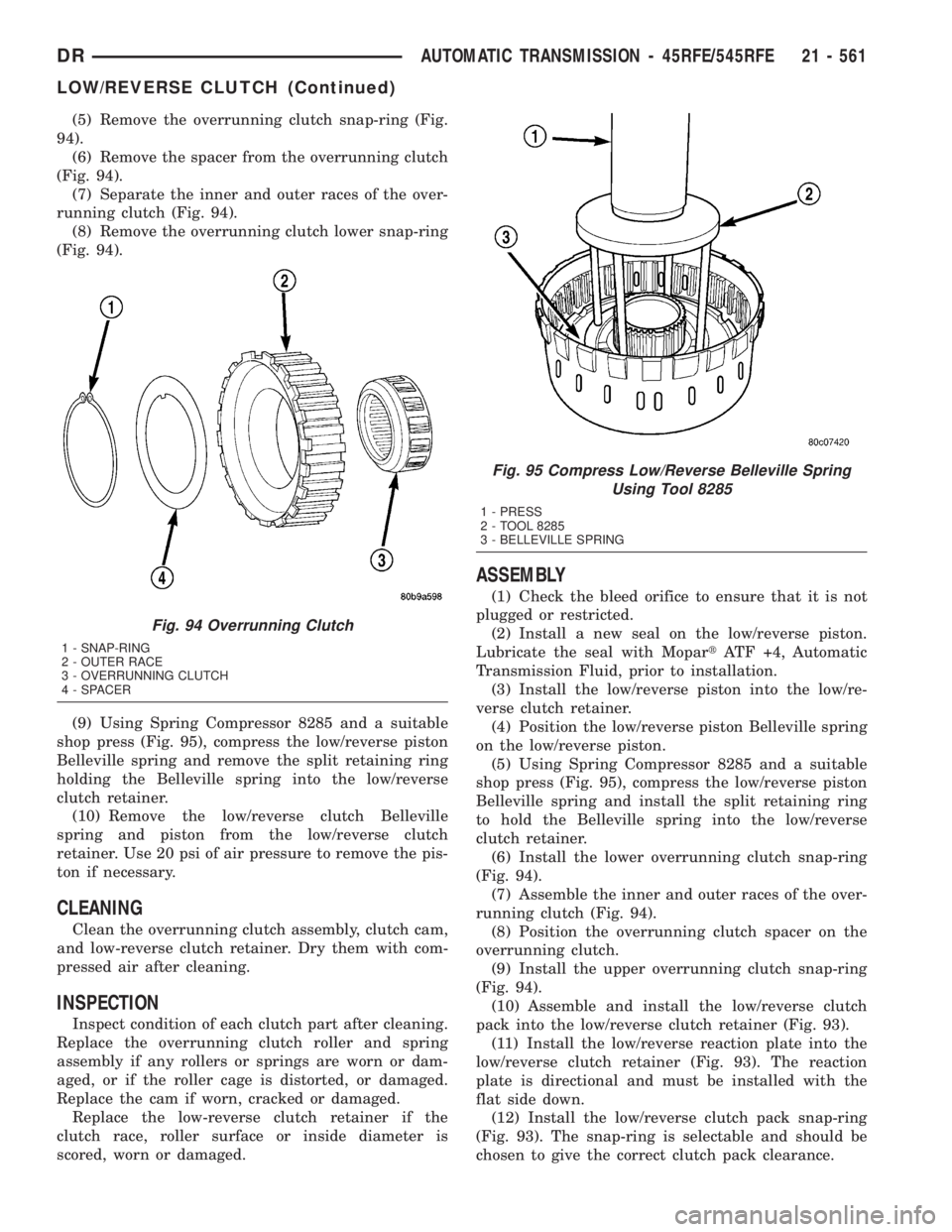

(5) Remove the overrunning clutch snap-ring (Fig.

94).

(6) Remove the spacer from the overrunning clutch

(Fig. 94).

(7) Separate the inner and outer races of the over-

running clutch (Fig. 94).

(8) Remove the overrunning clutch lower snap-ring

(Fig. 94).

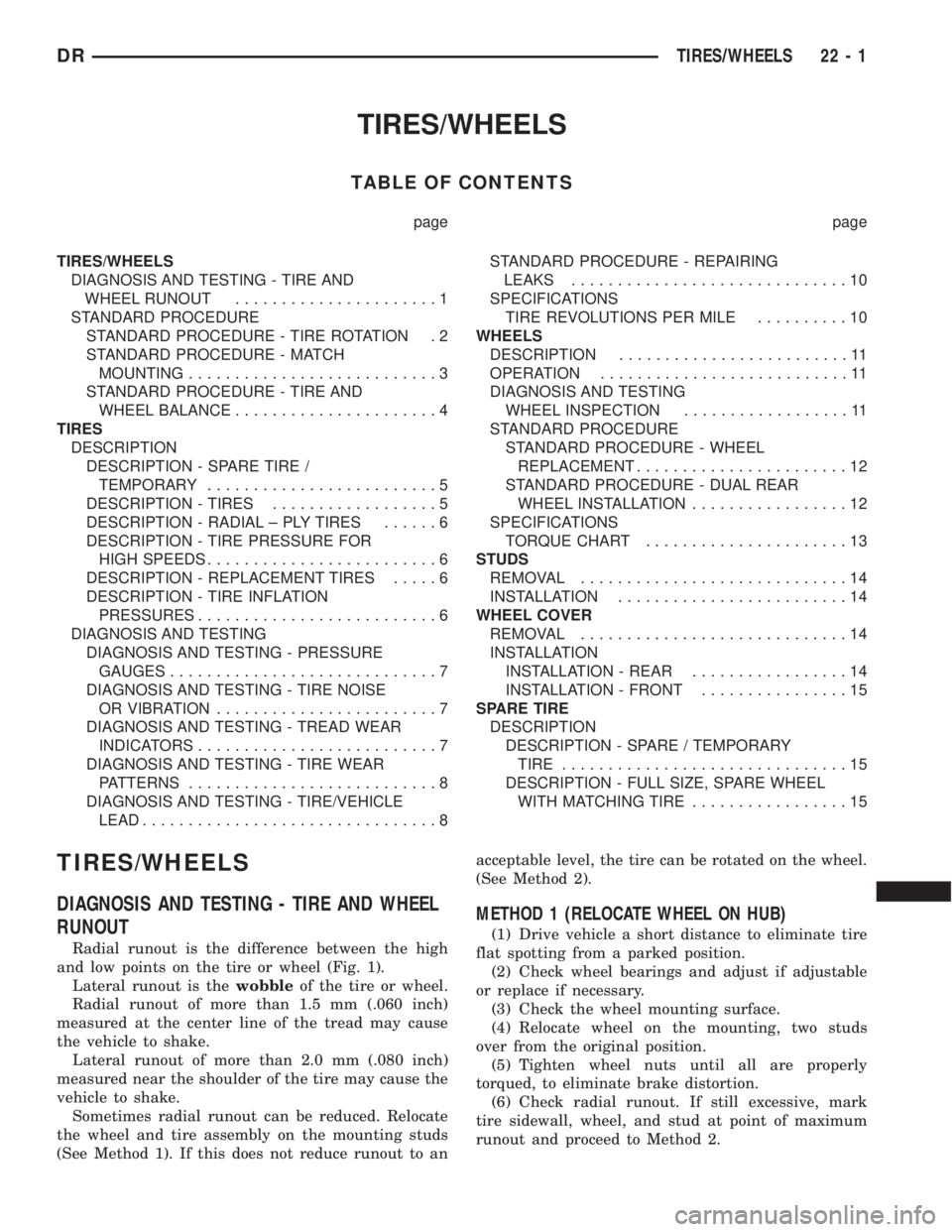

(9) Using Spring Compressor 8285 and a suitable

shop press (Fig. 95), compress the low/reverse piston

Belleville spring and remove the split retaining ring

holding the Belleville spring into the low/reverse

clutch retainer.

(10) Remove the low/reverse clutch Belleville

spring and piston from the low/reverse clutch

retainer. Use 20 psi of air pressure to remove the pis-

ton if necessary.

CLEANING

Clean the overrunning clutch assembly, clutch cam,

and low-reverse clutch retainer. Dry them with com-

pressed air after cleaning.

INSPECTION

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring

assembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse clutch retainer if the

clutch race, roller surface or inside diameter is

scored, worn or damaged.

ASSEMBLY

(1) Check the bleed orifice to ensure that it is not

plugged or restricted.

(2) Install a new seal on the low/reverse piston.

Lubricate the seal with MopartATF +4, Automatic

Transmission Fluid, prior to installation.

(3) Install the low/reverse piston into the low/re-

verse clutch retainer.

(4) Position the low/reverse piston Belleville spring

on the low/reverse piston.

(5) Using Spring Compressor 8285 and a suitable

shop press (Fig. 95), compress the low/reverse piston

Belleville spring and install the split retaining ring

to hold the Belleville spring into the low/reverse

clutch retainer.

(6) Install the lower overrunning clutch snap-ring

(Fig. 94).

(7) Assemble the inner and outer races of the over-

running clutch (Fig. 94).

(8) Position the overrunning clutch spacer on the

overrunning clutch.

(9) Install the upper overrunning clutch snap-ring

(Fig. 94).

(10) Assemble and install the low/reverse clutch

pack into the low/reverse clutch retainer (Fig. 93).

(11) Install the low/reverse reaction plate into the

low/reverse clutch retainer (Fig. 93). The reaction

plate is directional and must be installed with the

flat side down.

(12) Install the low/reverse clutch pack snap-ring

(Fig. 93). The snap-ring is selectable and should be

chosen to give the correct clutch pack clearance.

Fig. 94 Overrunning Clutch

1 - SNAP-RING

2 - OUTER RACE

3 - OVERRUNNING CLUTCH

4 - SPACER

Fig. 95 Compress Low/Reverse Belleville Spring

Using Tool 8285

1 - PRESS

2 - TOOL 8285

3 - BELLEVILLE SPRING

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 561

LOW/REVERSE CLUTCH (Continued)

Page 2560 of 2895

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE ROTATION . 2

STANDARD PROCEDURE - MATCH

MOUNTING...........................3

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................4

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE /

TEMPORARY.........................5

DESCRIPTION - TIRES..................5

DESCRIPTION - RADIAL ± PLY TIRES......6

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEEDS.........................6

DESCRIPTION - REPLACEMENT TIRES.....6

DESCRIPTION - TIRE INFLATION

PRESSURES..........................6

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES.............................7

DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................7

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................7

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................8

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD................................8STANDARD PROCEDURE - REPAIRING

LEAKS..............................10

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE..........10

WHEELS

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING

WHEEL INSPECTION..................11

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................12

STANDARD PROCEDURE - DUAL REAR

WHEEL INSTALLATION.................12

SPECIFICATIONS

TORQUE CHART......................13

STUDS

REMOVAL.............................14

INSTALLATION.........................14

WHEEL COVER

REMOVAL.............................14

INSTALLATION

INSTALLATION - REAR.................14

INSTALLATION - FRONT................15

SPARE TIRE

DESCRIPTION

DESCRIPTION - SPARE / TEMPORARY

TIRE...............................15

DESCRIPTION - FULL SIZE, SPARE WHEEL

WITH MATCHING TIRE.................15

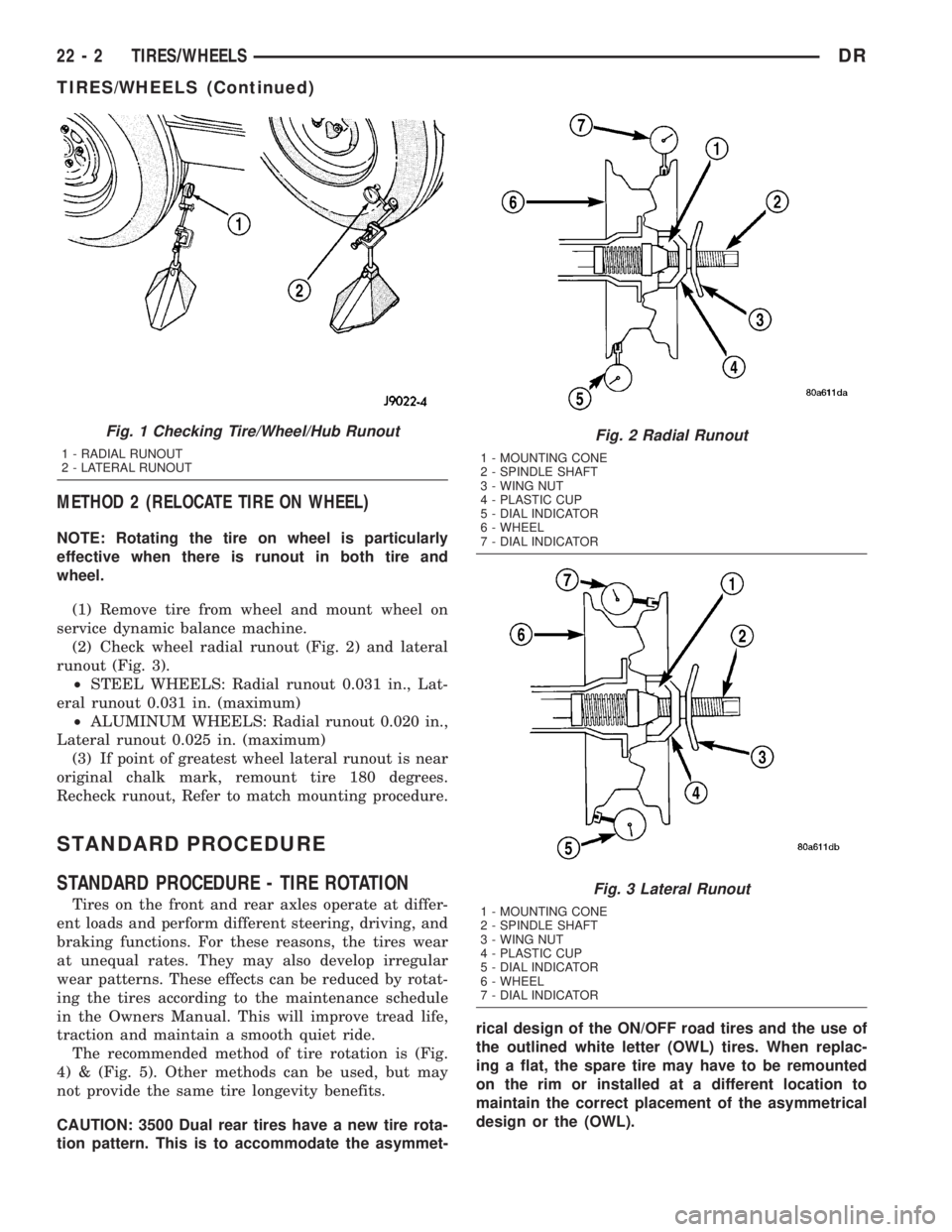

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to anacceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

DRTIRES/WHEELS 22 - 1

Page 2561 of 2895

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

²STEEL WHEELS: Radial runout 0.031 in., Lat-

eral runout 0.031 in. (maximum)

²ALUMINUM WHEELS: Radial runout 0.020 in.,

Lateral runout 0.025 in. (maximum)

(3) If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees.

Recheck runout, Refer to match mounting procedure.

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE ROTATION

Tires on the front and rear axles operate at differ-

ent loads and perform different steering, driving, and

braking functions. For these reasons, the tires wear

at unequal rates. They may also develop irregular

wear patterns. These effects can be reduced by rotat-

ing the tires according to the maintenance schedule

in the Owners Manual. This will improve tread life,

traction and maintain a smooth quiet ride.

The recommended method of tire rotation is (Fig.

4) & (Fig. 5). Other methods can be used, but may

not provide the same tire longevity benefits.

CAUTION: 3500 Dual rear tires have a new tire rota-

tion pattern. This is to accommodate the asymmet-rical design of the ON/OFF road tires and the use of

the outlined white letter (OWL) tires. When replac-

ing a flat, the spare tire may have to be remounted

on the rim or installed at a different location to

maintain the correct placement of the asymmetrical

design or the (OWL).

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

22 - 2 TIRES/WHEELSDR

TIRES/WHEELS (Continued)

Page 2567 of 2895

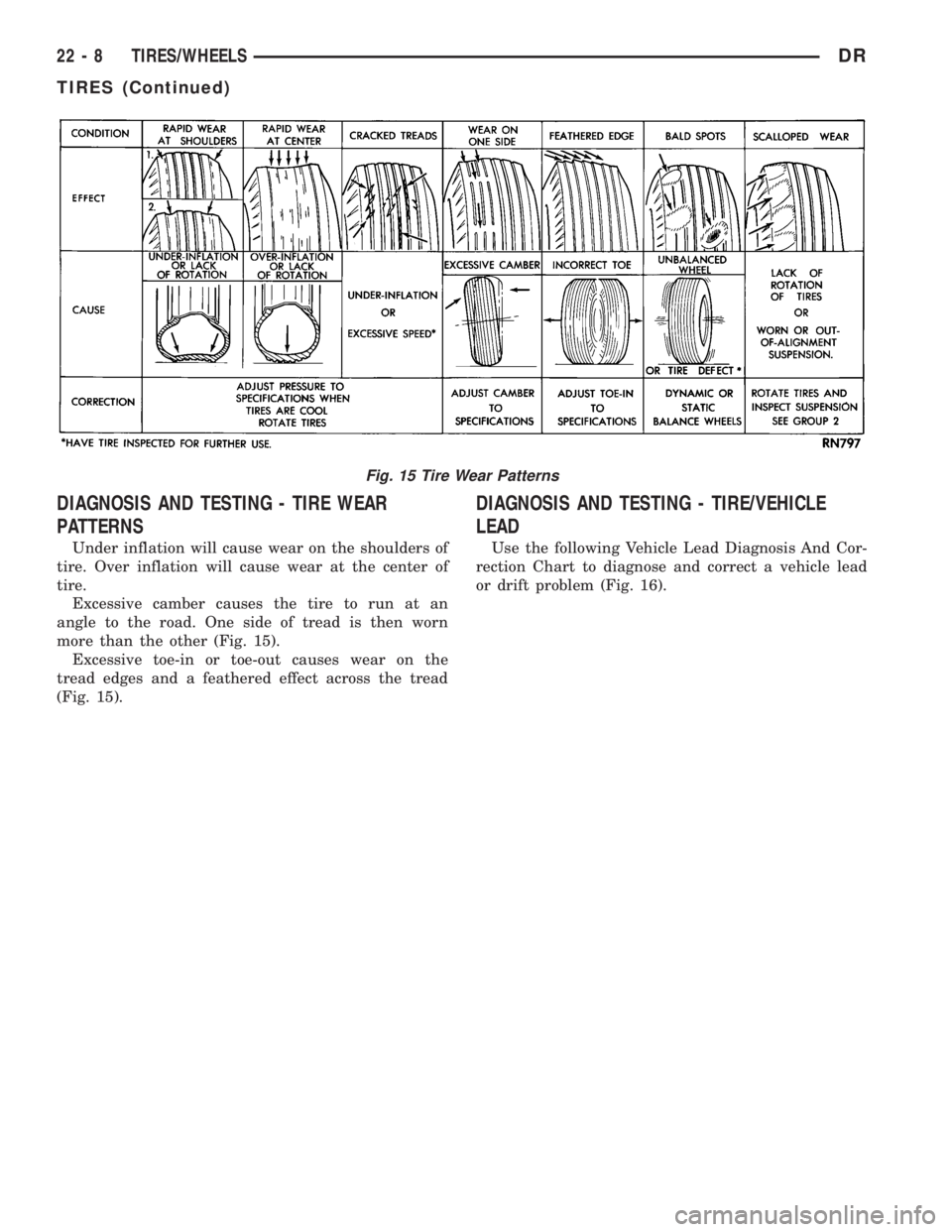

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 15).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 15).

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD

Use the following Vehicle Lead Diagnosis And Cor-

rection Chart to diagnose and correct a vehicle lead

or drift problem (Fig. 16).

Fig. 15 Tire Wear Patterns

22 - 8 TIRES/WHEELSDR

TIRES (Continued)

Page 2570 of 2895

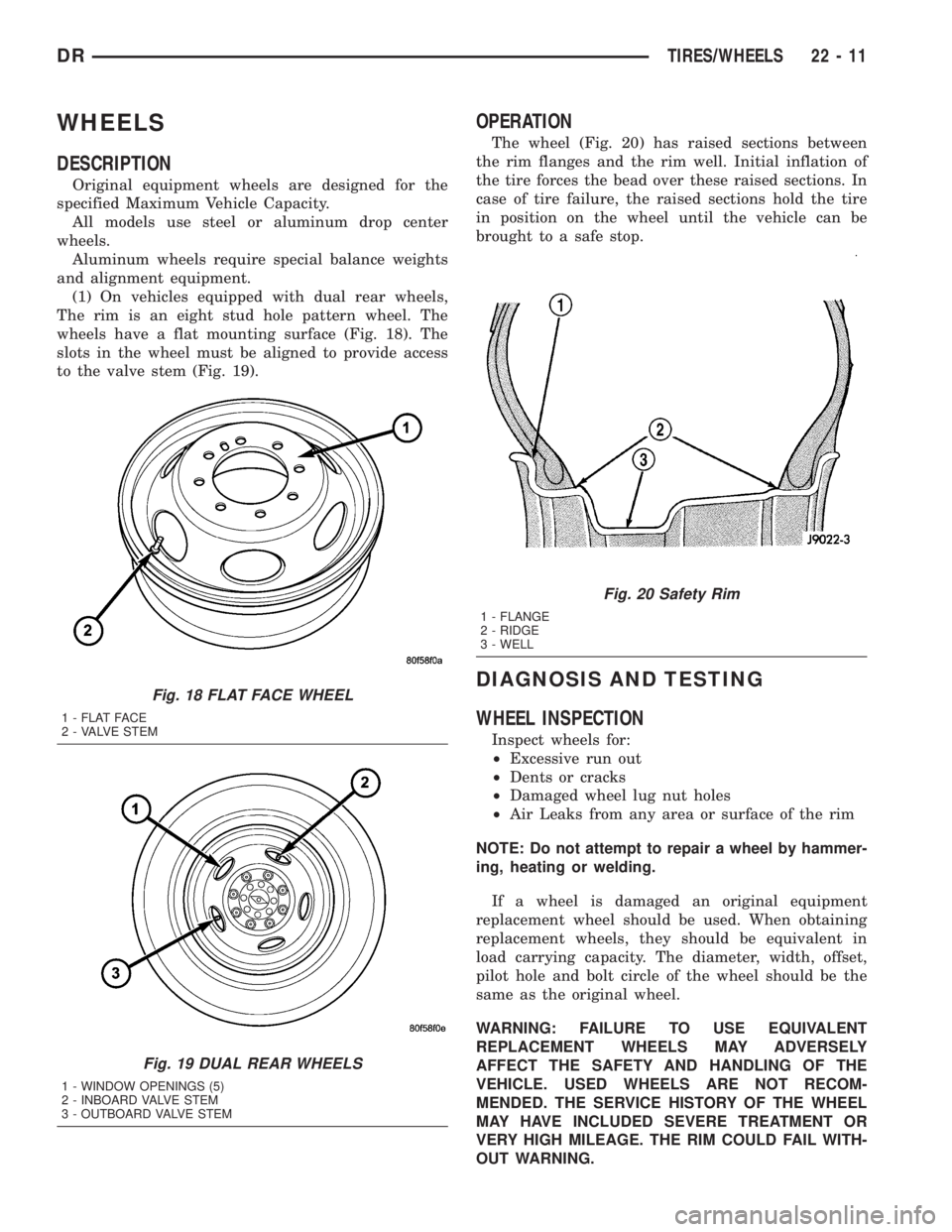

WHEELS

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or aluminum drop center

wheels.

Aluminum wheels require special balance weights

and alignment equipment.

(1) On vehicles equipped with dual rear wheels,

The rim is an eight stud hole pattern wheel. The

wheels have a flat mounting surface (Fig. 18). The

slots in the wheel must be aligned to provide access

to the valve stem (Fig. 19).

OPERATION

The wheel (Fig. 20) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

Fig. 18 FLAT FACE WHEEL

1 - FLAT FACE

2 - VALVE STEM

Fig. 19 DUAL REAR WHEELS

1 - WINDOW OPENINGS (5)

2 - INBOARD VALVE STEM

3 - OUTBOARD VALVE STEM

Fig. 20 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

DRTIRES/WHEELS 22 - 11

Page 2889 of 2895

TACHOMETER - DESCRIPTION..........8J-37

TACHOMETER - OPERATION............8J-37

TAIL LAMP - INSTALLATION............8L-21

TAIL LAMP - REMOVAL................8L-21

TAIL LAMP UNIT - INSTALLATION.......8L-21

TAIL LAMP UNIT - REMOVAL...........8L-21

TAILGATE - INSTALLATION.............23-17

TAILGATE - REMOVAL.................23-17

TAILPIPE - 5.9L DIESEL - INSPECTION....11-9

TAILPIPE - 5.9L DIESEL - INSTALLATION . . . 11-9

TAILPIPE - 5.9L DIESEL - REMOVAL......11-9

TAILPIPE - INSPECTION...............11-10

TAILPIPE - INSTALLATION..............11-10

TAILPIPE - REMOVAL.................11-10

TANK - DESCRIPTION, FUEL............14-20

TANK - OPERATION, FUEL..............14-20

TANK MODULE - DESCRIPTION, FUEL....14-75

TANK MODULE - INSTALLATION, FUEL....14-75

TANK MODULE - OPERATION, FUEL......14-75

TANK MODULE - REMOVAL, FUEL.......14-75

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC....................9-258,9-386

TASK MANAGER - DESCRIPTION.........25-1

TASK MANAGER - OPERATION...........25-5

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-21

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-38

TEMP INDICATOR - OPERATION, TRANS . . 8J-38

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-10

TEMP SENSOR - OPERATION, AMBIENT . . 8M-10

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-23

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-23

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-21

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION.........21-267,21-445,21-583

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT..............8M-11

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-47

TEMPERATURE SENSOR -

INSTALLATION, INTAKE AIR............14-38

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-21

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - OPERATION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION.........21-267,21-445,21-583

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-21

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-44

TEMPERATURE SENSOR - REMOVAL,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR CIRCUIT -

DIAGNOSIS AND TESTING, AMBIENT....8M-11

TEMPERATURE SENSOR/MAP SENSOR -

DESCRIPTION, INTAKE AIR.............14-93

TEMPERATURE SENSOR/MAP SENSOR -

INSTALLATION, INTAKE AIR............14-94

TEMPERATURE SENSOR/MAP SENSOR -

OPERATION, INTAKE AIR...............14-93

TEMPERATURE SENSOR/MAP SENSOR -

REMOVAL, INTAKE AIR................14-93

TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET AIR.....14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET AIR

.....14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET AIR

.......14-90

TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET AIR

........14-90

TEMPORARY - DESCRIPTION, SPARE

TIRE

................................22-5

TEMPORARY TIRE - DESCRIPTION,

SPARE

.............................22-15TENSION REDUCER - DESCRIPTION,

SEAT BELT .........................8O-48

TENSION REDUCER - DIAGNOSIS AND

TESTING, SEAT BELT.................8O-49

TENSION REDUCER - OPERATION, SEAT

BELT ..............................8O-49

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-47

TENSIONER - OPERATION, SEAT BELT....8O-48

TENSIONERS - 3.7L / 4.7L -

DESCRIPTION, BELT...................7-22

TENSIONERS - 3.7L / 4.7L -

INSTALLATION, BELT...................7-23

TENSIONERS - 3.7L / 4.7L - OPERATION,

BELT ...............................7-22

TENSIONERS - 3.7L / 4.7L - REMOVAL,

BELT ...............................7-22

TENSIONERS - 5.9L - DESCRIPTION,

BELT ...............................7-23

TENSIONERS - 5.9L - INSTALLATION,

BELT ...............................7-24

TENSIONERS - 5.9L - OPERATION, BELT . . . 7-23

TENSIONERS - 5.9L - REMOVAL, BELT.....7-23

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-24

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-25

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-24

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-25

TERMINAL - INSTALLATION.........8W-01-14

TERMINAL - REMOVAL..............8W-01-14

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE . . 21-140,21-321,21-493

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - DIAGNOSIS AND TESTING,

VACUUM SUPPLY.....................8P-2

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-11

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-10

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-8

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION..........................25-1

TEST MODE - DESCRIPTION, STATE

DISPLAY............................25-1

TESTER - STANDARD PROCEDURE,

USING MICRO 420 BATTERY............8F-12

TESTS - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION/LEAKAGE.....9-288

THEFT SECURITY SYSTEM, DIAGNOSIS

AND TESTING - VEHICLE...............8Q-3

THERMOSTAT - 3.7L/4.7L -

DESCRIPTION, ENGINE COOLANT.........7-50

THERMOSTAT - 3.7L/4.7L -

INSTALLATION, ENGINE COOLANT........7-51

THERMOSTAT - 3.7L/4.7L - OPERATION,

ENGINE COOLANT.....................7-51

THERMOSTAT - 3.7L/4.7L - REMOVAL,

ENGINE COOLANT.....................7-51

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT.........7-52

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT........7-53

THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE COOLANT..........7-52

THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE COOLANT............7-53

THERMOSTAT - DIAGNOSIS AND

TESTING....................7-48,7-51,7-52

THERMOSTAT-5.7L/5.9L - DESCRIPTION,

ENGINE COOLANT.....................7-47

THERMOSTAT-5.7L/5.9L -

INSTALLATION, ENGINE COOLANT........7-49

THERMOSTAT-5.7L/5.9L - OPERATION,

ENGINE COOLANT

.....................7-48

THERMOSTAT-5.7L/5.9L - REMOVAL,

ENGINE COOLANT

.....................7-48

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM

. 21-156,21-337,21-495

THREADED HOLE REPAIR -

DESCRIPTION

......................Intro.-9

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN

.....9-186,9-232,

9-289,9-361,9-9,9-93THROTTLE BODY - DESCRIPTION........14-45

THROTTLE BODY - INSTALLATION.......14-47

THROTTLE BODY - OPERATION.........14-45

THROTTLE BODY - REMOVAL...........14-45

THROTTLE CONTROL CABLE -

INSTALLATION..................14-51,14-96

THROTTLE CONTROL CABLE - REMOVAL . 14-49,

14-94

THROTTLE POSITION SENSOR -

DESCRIPTION.......................14-52

THROTTLE POSITION SENSOR -

INSTALLATION.......................14-54

THROTTLE POSITION SENSOR -

OPERATION.........................14-52

THROTTLE POSITION SENSOR -

REMOVAL..........................14-53

THROTTLE VALVE CABLE -

ADJUSTMENTS...............21-255,21-432

THROTTLE VALVE CABLE -

DESCRIPTION................21-254,21-432

TIE DOWN - INSTALLATION, CARGO BOX . 23-37

TIE DOWN - REMOVAL, CARGO BOX.....23-37

TIE ROD END - DIAGNOSIS AND

TESTING, OUTER.....................19-31

TIE ROD END - INSTALLATION..........19-37

TIE ROD END - INSTALLATION, OUTER . . . 19-32

TIE ROD END - REMOVAL..............19-36

TIE ROD END - REMOVAL, OUTER.......19-31

TIMING - DESCRIPTION, VALVE..........9-75

TIMING - DIAGNOSIS AND TESTING,

FUEL INJECTION PUMP...............14-65

TIMING - OPERATION, VALVE............9-75

TIMING - VERIFICATION - STANDARD

PROCEDURE, ENGINE.................9-165

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........9-169,9-278,9-404,9-81

TIMING BELT / CHAIN COVER(S) -

REMOVAL............9-168,9-278,9-404,9-80

TIMING BELT/CHAIN AND SPROCKETS -

INSPECTION....................9-171,9-83

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION........9-172,9-279,9-406,9-84

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL............9-169,9-279,9-405,9-81

TIMING CHAIN STRETCH - INSPECTION,

MEASURING...................9-279,9-405

TIMING CHAIN WEAR - STANDARD

PROCEDURE, MEASURING.............9-165

TIMING CHAIN WEAR, STANDARD

PROCEDURE - MEASURING.............9-76

TIMING CHAIN/TENSIONER -

DESCRIPTION.......................9-222

TIMING CHAIN/TENSIONER - OPERATION . 9-222

TIMING DRIVE SYSTEM - DESCRIPTION . . 9-164

TIMING DRIVE SYSTEM - OPERATION....9-164

TIMING, SPECIFICATIONS - IGNITION......8I-6

TIMING VERIFICATION - SERVICE

PROCEDURE.........................9-76

TIMING VERIFICATION - STANDARD

PROCEDURE........................9-348

TIMING/CHAIN AND SPROCKETS -

INSTALLATION.......................9-222

TIMING/CHAIN AND SPROCKETS -

REMOVAL..........................9-221

TIMING/CHAIN COVER - INSTALLATION

. . . 9-221

TIMING/CHAIN COVER - REMOVAL

.......9-220

TIP INSERTS - INSTALLATION, SPRING

....2-42

TIP INSERTS - REMOVAL, SPRING

........2-41

TIP REPLACEMENT - STANDARD

PROCEDURE, LIGHT DUTY FRONT

FRAME RAIL

.........................13-4

TIRE - DESCRIPTION, FULL SIZE, SPARE

WHEEL WITH MATCHING

..............22-15

TIRE - DESCRIPTION, SPARE /

TEMPORARY

........................22-15

TIRE / TEMPORARY - DESCRIPTION,

SPARE

..............................22-5

TIRE AND WHEEL BALANCE -

STANDARD PROCEDURE

................22-4

TIRE AND WHEEL RUNOUT - DIAGNOSIS

AND TESTING

........................22-1

TIRE INFLATION PRESSURES -

DESCRIPTION

........................22-6

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING

........................22-7

TIRE PRESSURE FOR HIGH SPEEDS -

DESCRIPTION

........................22-6

34 INDEXDR

Description Group-Page Description Group-Page Description Group-Page