service DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 26 of 2895

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

DRLUBRICATION & MAINTENANCE 0 - 13

Page 53 of 2895

STABILIZER BAR

DESCRIPTION

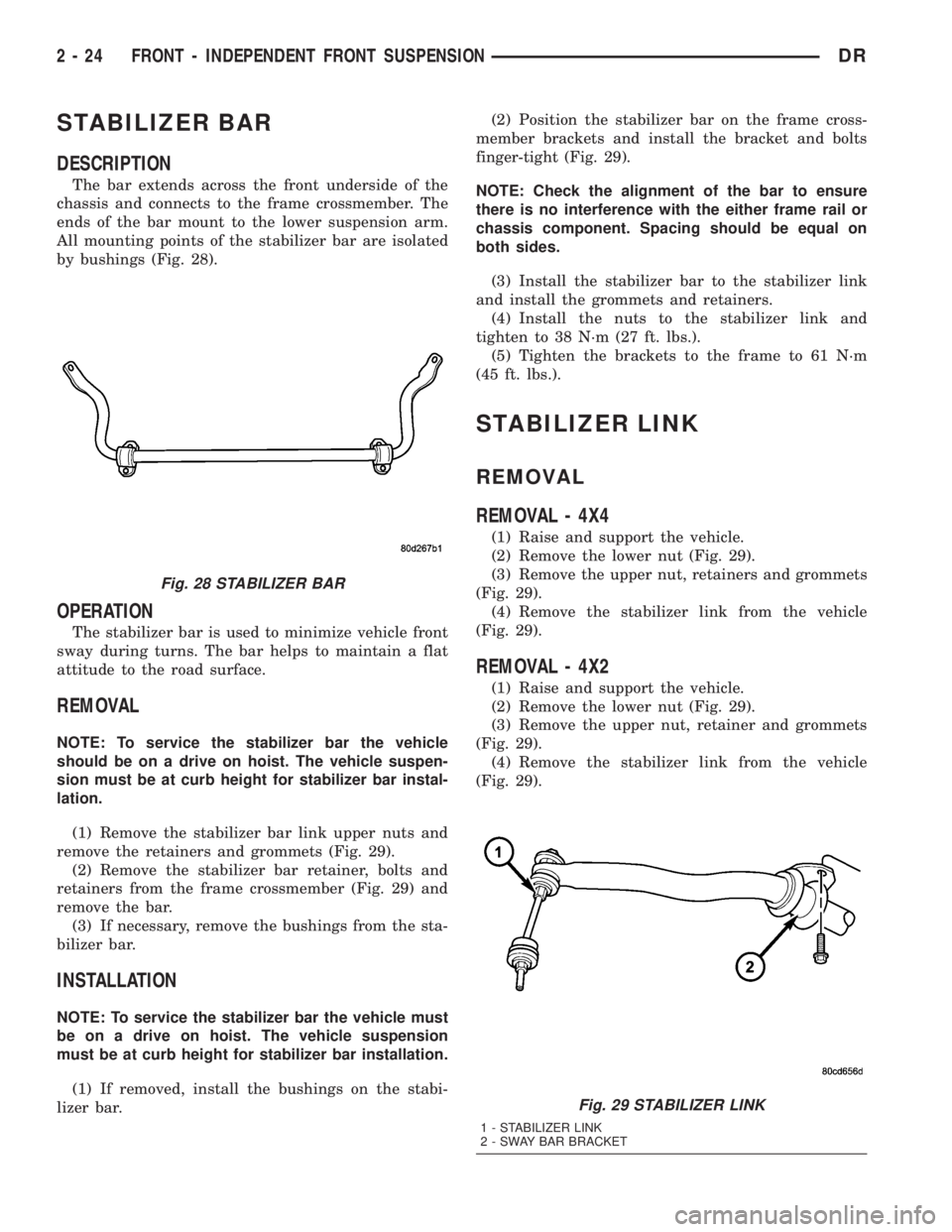

The bar extends across the front underside of the

chassis and connects to the frame crossmember. The

ends of the bar mount to the lower suspension arm.

All mounting points of the stabilizer bar are isolated

by bushings (Fig. 28).

OPERATION

The stabilizer bar is used to minimize vehicle front

sway during turns. The bar helps to maintain a flat

attitude to the road surface.

REMOVAL

NOTE: To service the stabilizer bar the vehicle

should be on a drive on hoist. The vehicle suspen-

sion must be at curb height for stabilizer bar instal-

lation.

(1) Remove the stabilizer bar link upper nuts and

remove the retainers and grommets (Fig. 29).

(2) Remove the stabilizer bar retainer, bolts and

retainers from the frame crossmember (Fig. 29) and

remove the bar.

(3) If necessary, remove the bushings from the sta-

bilizer bar.

INSTALLATION

NOTE: To service the stabilizer bar the vehicle must

be on a drive on hoist. The vehicle suspension

must be at curb height for stabilizer bar installation.

(1) If removed, install the bushings on the stabi-

lizer bar.(2) Position the stabilizer bar on the frame cross-

member brackets and install the bracket and bolts

finger-tight (Fig. 29).

NOTE: Check the alignment of the bar to ensure

there is no interference with the either frame rail or

chassis component. Spacing should be equal on

both sides.

(3) Install the stabilizer bar to the stabilizer link

and install the grommets and retainers.

(4) Install the nuts to the stabilizer link and

tighten to 38 N´m (27 ft. lbs.).

(5) Tighten the brackets to the frame to 61 N´m

(45 ft. lbs.).

STABILIZER LINK

REMOVAL

REMOVAL - 4X4

(1) Raise and support the vehicle.

(2) Remove the lower nut (Fig. 29).

(3) Remove the upper nut, retainers and grommets

(Fig. 29).

(4) Remove the stabilizer link from the vehicle

(Fig. 29).

REMOVAL - 4X2

(1) Raise and support the vehicle.

(2) Remove the lower nut (Fig. 29).

(3) Remove the upper nut, retainer and grommets

(Fig. 29).

(4) Remove the stabilizer link from the vehicle

(Fig. 29).

Fig. 28 STABILIZER BAR

Fig. 29 STABILIZER LINK

1 - STABILIZER LINK

2 - SWAY BAR BRACKET

2 - 24 FRONT - INDEPENDENT FRONT SUSPENSIONDR

Page 82 of 2895

SINGLE CARDAN UNIVERSAL

JOINTS

DISASSEMBLY

NOTE: The following procedure is described for a

propeller shaft equipped with only a cardan joint in

the tube yoke. If the propeller shaft is equipped

with a companion yoke, simply repeat the following

steps to remove the cardan joint from the compan-

ion yoke after removing the cardan joint from the

tube yoke.

Individual components of cardan universal joints

are not serviceable. If worn or leaking, they must be

replaced as an assembly.

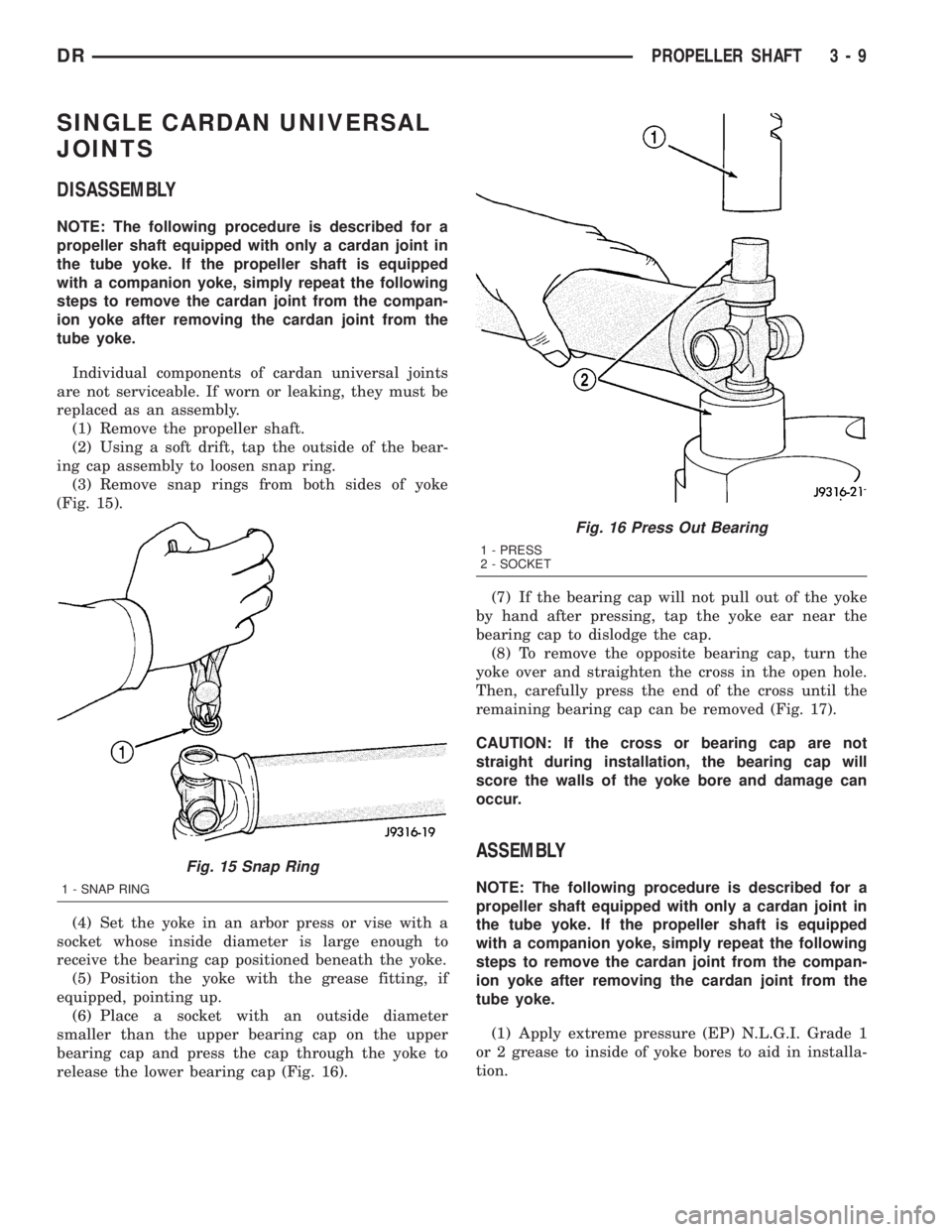

(1) Remove the propeller shaft.

(2) Using a soft drift, tap the outside of the bear-

ing cap assembly to loosen snap ring.

(3) Remove snap rings from both sides of yoke

(Fig. 15).

(4) Set the yoke in an arbor press or vise with a

socket whose inside diameter is large enough to

receive the bearing cap positioned beneath the yoke.

(5) Position the yoke with the grease fitting, if

equipped, pointing up.

(6) Place a socket with an outside diameter

smaller than the upper bearing cap on the upper

bearing cap and press the cap through the yoke to

release the lower bearing cap (Fig. 16).(7) If the bearing cap will not pull out of the yoke

by hand after pressing, tap the yoke ear near the

bearing cap to dislodge the cap.

(8) To remove the opposite bearing cap, turn the

yoke over and straighten the cross in the open hole.

Then, carefully press the end of the cross until the

remaining bearing cap can be removed (Fig. 17).

CAUTION: If the cross or bearing cap are not

straight during installation, the bearing cap will

score the walls of the yoke bore and damage can

occur.

ASSEMBLY

NOTE: The following procedure is described for a

propeller shaft equipped with only a cardan joint in

the tube yoke. If the propeller shaft is equipped

with a companion yoke, simply repeat the following

steps to remove the cardan joint from the compan-

ion yoke after removing the cardan joint from the

tube yoke.

(1) Apply extreme pressure (EP) N.L.G.I. Grade 1

or 2 grease to inside of yoke bores to aid in installa-

tion.

Fig. 15 Snap Ring

1 - SNAP RING

Fig. 16 Press Out Bearing

1 - PRESS

2 - SOCKET

DRPROPELLER SHAFT 3 - 9

Page 84 of 2895

HALF SHAFT

TABLE OF CONTENTS

page page

HALF SHAFT

CAUTION.............................11

DIAGNOSIS AND TESTING................11

REMOVAL.............................11

INSTALLATION.........................12

SPECIFICATIONS.......................12

SPECIAL TOOLS.......................12CV JOINT-OUTER

REMOVAL.............................13

INSTALLATION.........................13

CV JOINT-INNER

REMOVAL.............................16

INSTALLATION.........................16

HALF SHAFT

CAUTION

CAUTION:: Never grasp half shaft assembly by the

boots. This may cause the boot to pucker or crease

and reduce the service life of the boot.

Avoid over angulating or stroking the C/V joints

when handling the half shaft.

Half shafts exposed to battery acid, transmission

fluid, brake fluid, differential fluid or gasoline may

cause the boots to deteriorate.

DIAGNOSIS AND TESTING

Check for grease at the inboard and outboard C/V

joint. This is a sign of boot or boot clamp damage.

NOISE/VIBRATION IN TURNS

A clicking noise or a vibration in turns could be

caused by a damaged outer C/V or inner tripod joint

seal boot or seal boot clamps. This will result in the

loss/contamination of the joint grease, resulting in

inadequate lubrication of the joint. Noise could also

be caused by another component of the vehicle com-

ing in contact with the half shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of a damaged or worn

C/V joint. A torn boot or loose/missing clamp on the

inner/outer joint which has allowed the grease to be

lost will damage the C/V joint.

SHUDDER/VIBRATION DURING ACCELERATION

This problem could be a result of a worn/damaged

inner tripod joint or a sticking tripod joint. Improper

wheel alignment may also cause a shudder or vibra-

tion.

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of out of balance

front tires or tire/wheel runout. Foreign material

(mud, etc.) packed on the backside of the wheel(s)

will also cause a vibration.

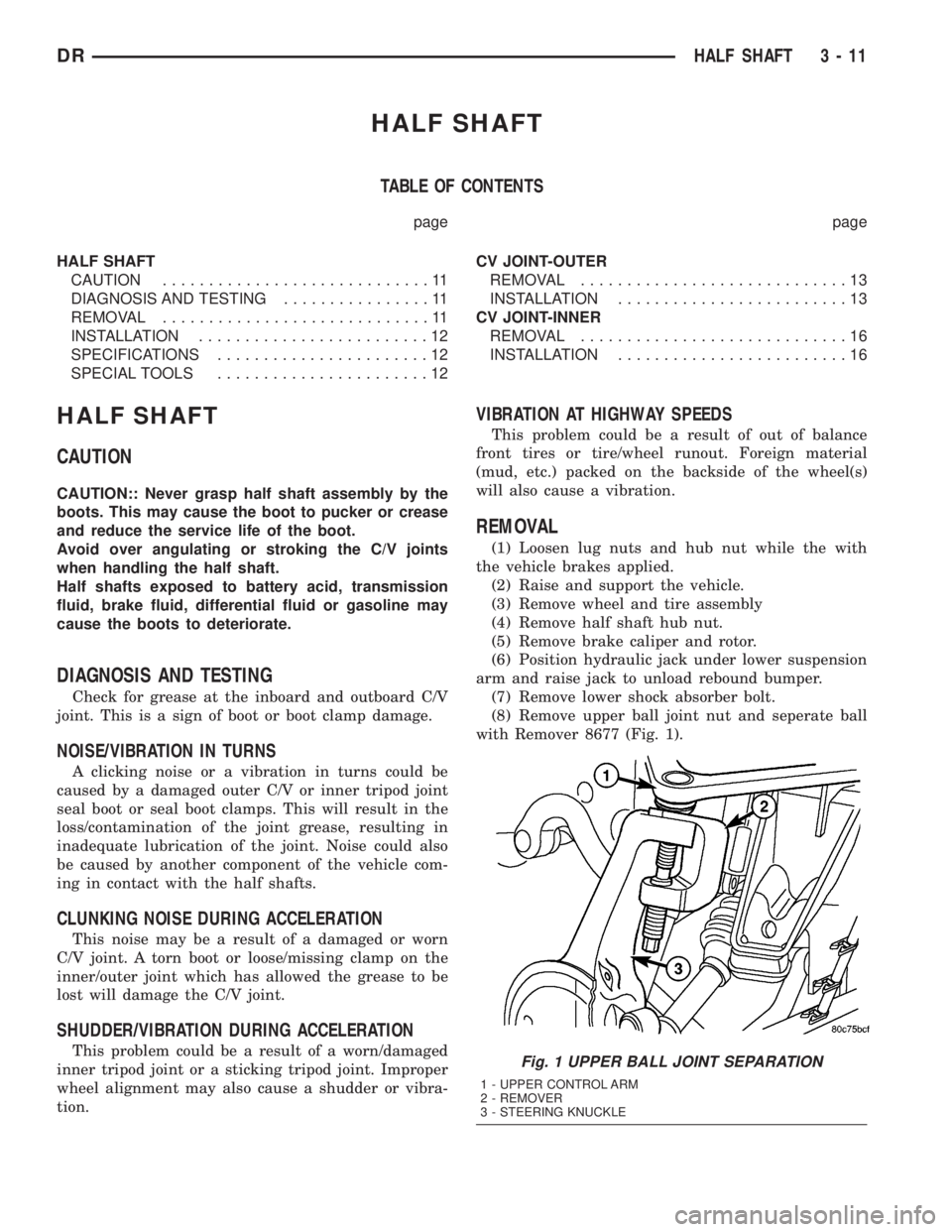

REMOVAL

(1) Loosen lug nuts and hub nut while the with

the vehicle brakes applied.

(2) Raise and support the vehicle.

(3) Remove wheel and tire assembly

(4) Remove half shaft hub nut.

(5) Remove brake caliper and rotor.

(6) Position hydraulic jack under lower suspension

arm and raise jack to unload rebound bumper.

(7) Remove lower shock absorber bolt.

(8) Remove upper ball joint nut and seperate ball

with Remover 8677 (Fig. 1).

Fig. 1 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

DRHALF SHAFT 3 - 11

Page 93 of 2895

Condition Possible Causes Correction

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

and bearings for further damage.

Set ring gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears

and bearings for further damage.

Avoid excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears

and bearings for further damage.

Avoid erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

3 - 20 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 113 of 2895

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one without replacing

the other.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft jaw

(Fig. 46).

(3) Remove bolts holding ring gear to differential

case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 46).

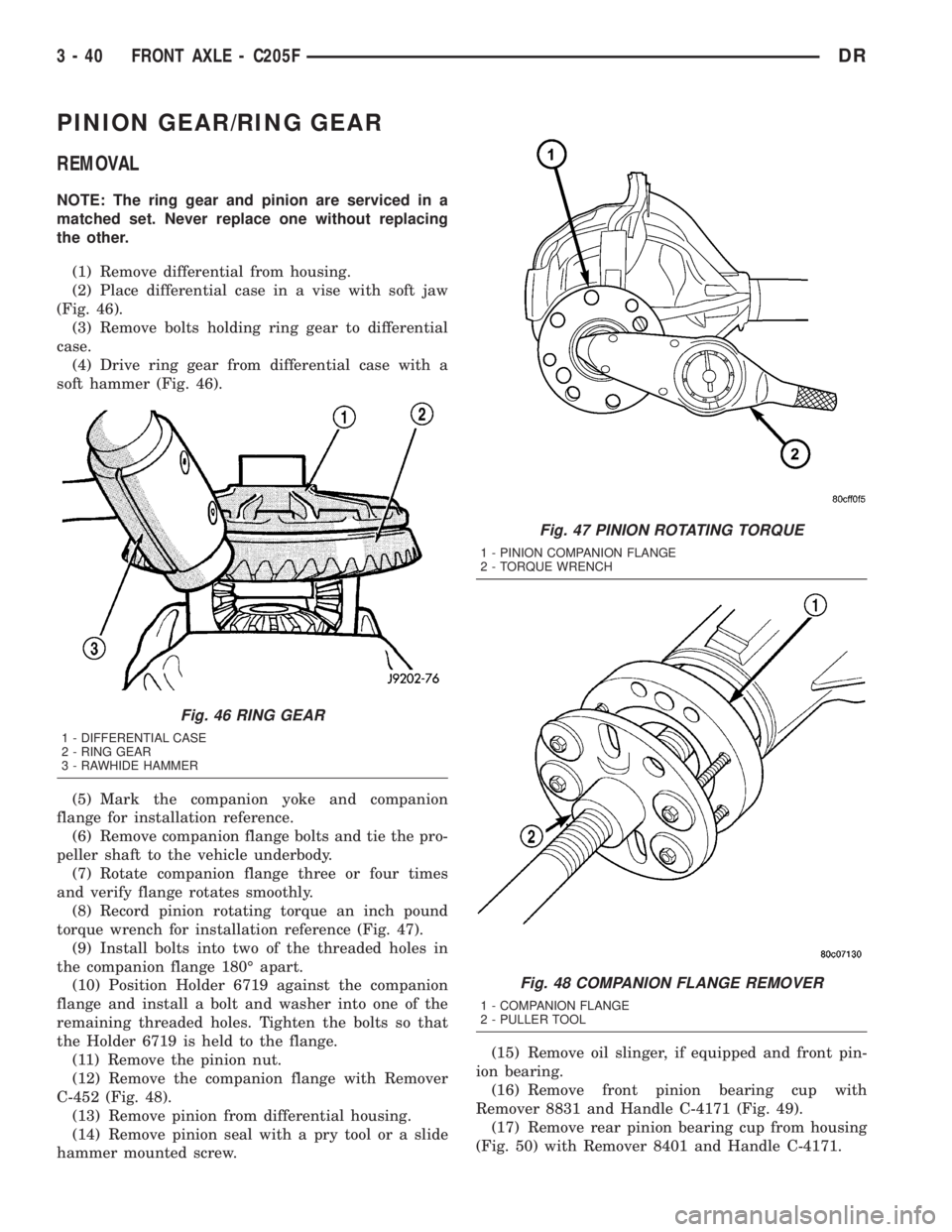

(5) Mark the companion yoke and companion

flange for installation reference.

(6) Remove companion flange bolts and tie the pro-

peller shaft to the vehicle underbody.

(7) Rotate companion flange three or four times

and verify flange rotates smoothly.

(8) Record pinion rotating torque an inch pound

torque wrench for installation reference (Fig. 47).

(9) Install bolts into two of the threaded holes in

the companion flange 180É apart.

(10) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so that

the Holder 6719 is held to the flange.

(11) Remove the pinion nut.

(12) Remove the companion flange with Remover

C-452 (Fig. 48).

(13) Remove pinion from differential housing.

(14) Remove pinion seal with a pry tool or a slide

hammer mounted screw.(15) Remove oil slinger, if equipped and front pin-

ion bearing.

(16) Remove front pinion bearing cup with

Remover 8831 and Handle C-4171 (Fig. 49).

(17) Remove rear pinion bearing cup from housing

(Fig. 50) with Remover 8401 and Handle C-4171.

Fig. 46 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - RAWHIDE HAMMER

Fig. 47 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

Fig. 48 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

3 - 40 FRONT AXLE - C205FDR

Page 115 of 2895

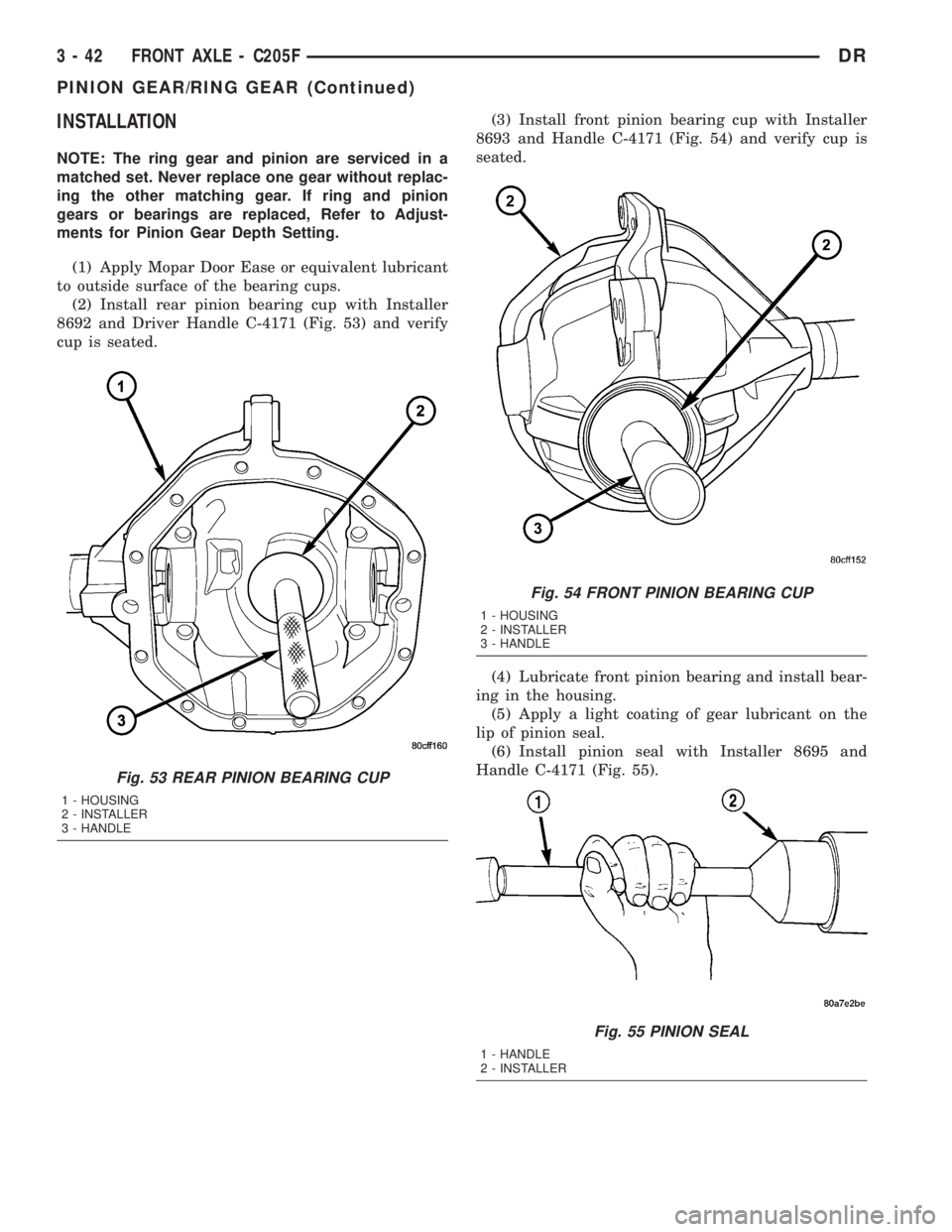

INSTALLATION

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one gear without replac-

ing the other matching gear. If ring and pinion

gears or bearings are replaced, Refer to Adjust-

ments for Pinion Gear Depth Setting.

(1) Apply Mopar Door Ease or equivalent lubricant

to outside surface of the bearing cups.

(2) Install rear pinion bearing cup with Installer

8692 and Driver Handle C-4171 (Fig. 53) and verify

cup is seated.(3) Install front pinion bearing cup with Installer

8693 and Handle C-4171 (Fig. 54) and verify cup is

seated.

(4) Lubricate front pinion bearing and install bear-

ing in the housing.

(5) Apply a light coating of gear lubricant on the

lip of pinion seal.

(6) Install pinion seal with Installer 8695 and

Handle C-4171 (Fig. 55).

Fig. 53 REAR PINION BEARING CUP

1 - HOUSING

2 - INSTALLER

3 - HANDLE

Fig. 54 FRONT PINION BEARING CUP

1 - HOUSING

2 - INSTALLER

3 - HANDLE

Fig. 55 PINION SEAL

1 - HANDLE

2 - INSTALLER

3 - 42 FRONT AXLE - C205FDR

PINION GEAR/RING GEAR (Continued)

Page 120 of 2895

Condition Possible Causes Correction

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

and bearings for further damage.

Set ring gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears

and bearings for further damage.

Avoid excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears

and bearings for further damage.

Avoid erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

DRFRONT AXLE - 9 1/4 AA 3 - 47

FRONT AXLE - 9 1/4 AA (Continued)

Page 129 of 2895

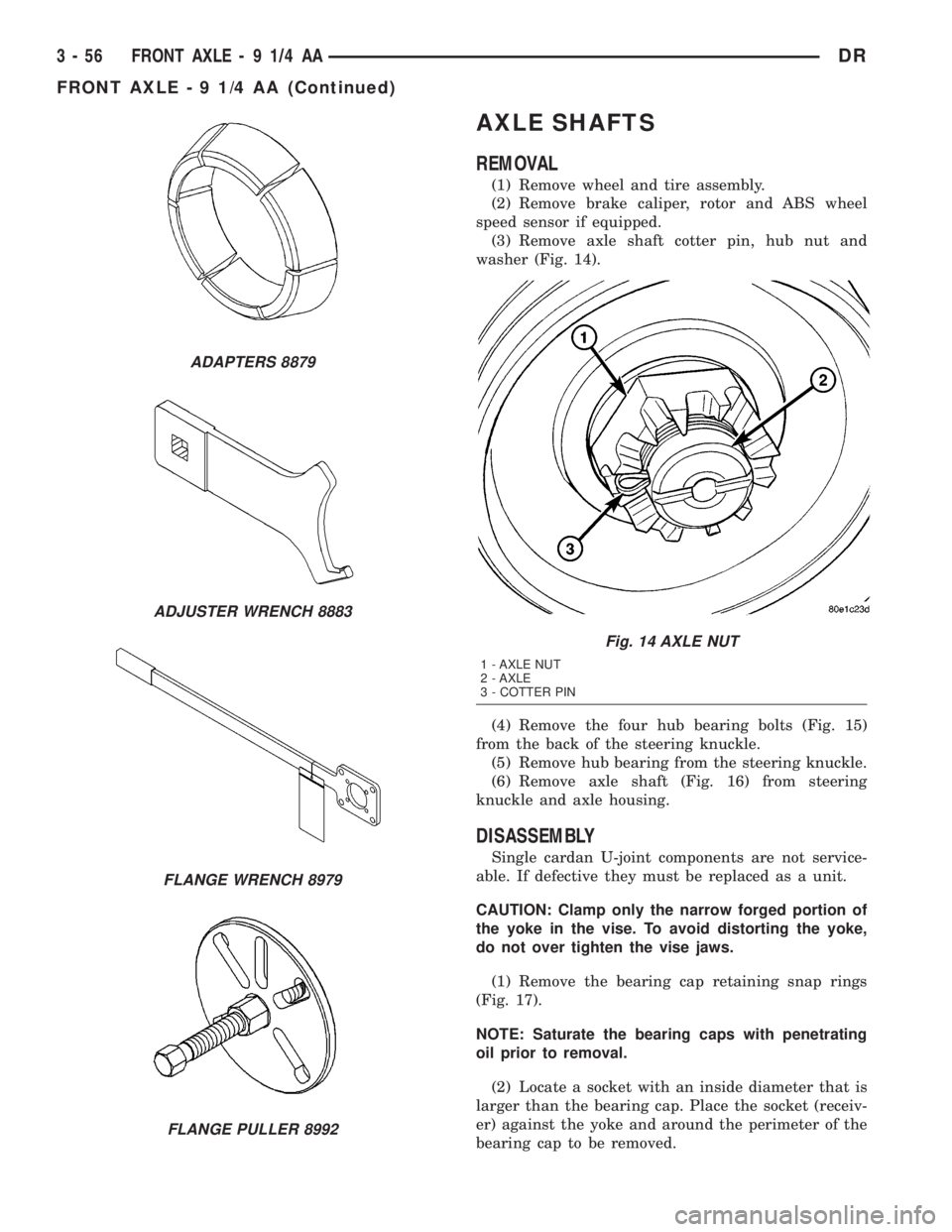

AXLE SHAFTS

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove brake caliper, rotor and ABS wheel

speed sensor if equipped.

(3) Remove axle shaft cotter pin, hub nut and

washer (Fig. 14).

(4) Remove the four hub bearing bolts (Fig. 15)

from the back of the steering knuckle.

(5) Remove hub bearing from the steering knuckle.

(6) Remove axle shaft (Fig. 16) from steering

knuckle and axle housing.

DISASSEMBLY

Single cardan U-joint components are not service-

able. If defective they must be replaced as a unit.

CAUTION: Clamp only the narrow forged portion of

the yoke in the vise. To avoid distorting the yoke,

do not over tighten the vise jaws.

(1) Remove the bearing cap retaining snap rings

(Fig. 17).

NOTE: Saturate the bearing caps with penetrating

oil prior to removal.

(2) Locate a socket with an inside diameter that is

larger than the bearing cap. Place the socket (receiv-

er) against the yoke and around the perimeter of the

bearing cap to be removed.

ADAPTERS 8879

ADJUSTER WRENCH 8883

FLANGE WRENCH 8979

FLANGE PULLER 8992

Fig. 14 AXLE NUT

1 - AXLE NUT

2 - AXLE

3 - COTTER PIN

3 - 56 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 138 of 2895

INSTALLATION

(1) Set differential case on Plug 8888.

(2) Install differenial case bearings with Installer

8881 and Handle C-4171 (Fig. 41).

(3) Install differentail case into housing.

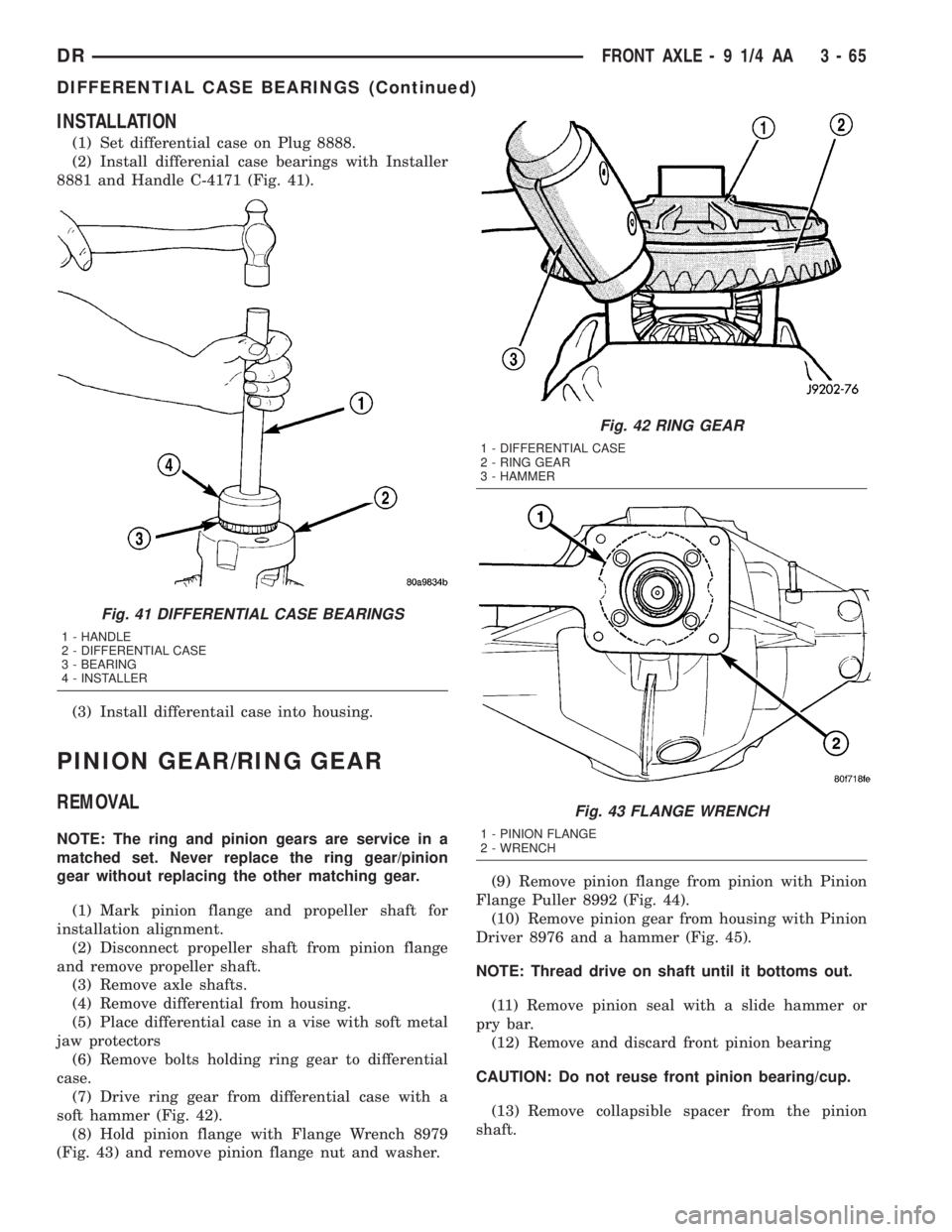

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Never replace the ring gear/pinion

gear without replacing the other matching gear.

(1) Mark pinion flange and propeller shaft for

installation alignment.

(2) Disconnect propeller shaft from pinion flange

and remove propeller shaft.

(3) Remove axle shafts.

(4) Remove differential from housing.

(5) Place differential case in a vise with soft metal

jaw protectors

(6) Remove bolts holding ring gear to differential

case.

(7) Drive ring gear from differential case with a

soft hammer (Fig. 42).

(8) Hold pinion flange with Flange Wrench 8979

(Fig. 43) and remove pinion flange nut and washer.(9) Remove pinion flange from pinion with Pinion

Flange Puller 8992 (Fig. 44).

(10) Remove pinion gear from housing with Pinion

Driver 8976 and a hammer (Fig. 45).

NOTE: Thread drive on shaft until it bottoms out.

(11) Remove pinion seal with a slide hammer or

pry bar.

(12) Remove and discard front pinion bearing

CAUTION: Do not reuse front pinion bearing/cup.

(13) Remove collapsible spacer from the pinion

shaft.

Fig. 41 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

Fig. 42 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 43 FLANGE WRENCH

1 - PINION FLANGE

2 - WRENCH

DRFRONT AXLE - 9 1/4 AA 3 - 65

DIFFERENTIAL CASE BEARINGS (Continued)