service DODGE RAM 2003 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 222 of 2895

PINION GEAR/RING GEAR/

TONE RING

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Never replace the ring gear/pinion

gear without replacing the other matching gear.

(1) Mark pinion flange and propeller shaft for

installation alignment.

(2) Disconnect propeller shaft from pinion flange

and remove propeller shaft.

(3) Remove differential from the housing.

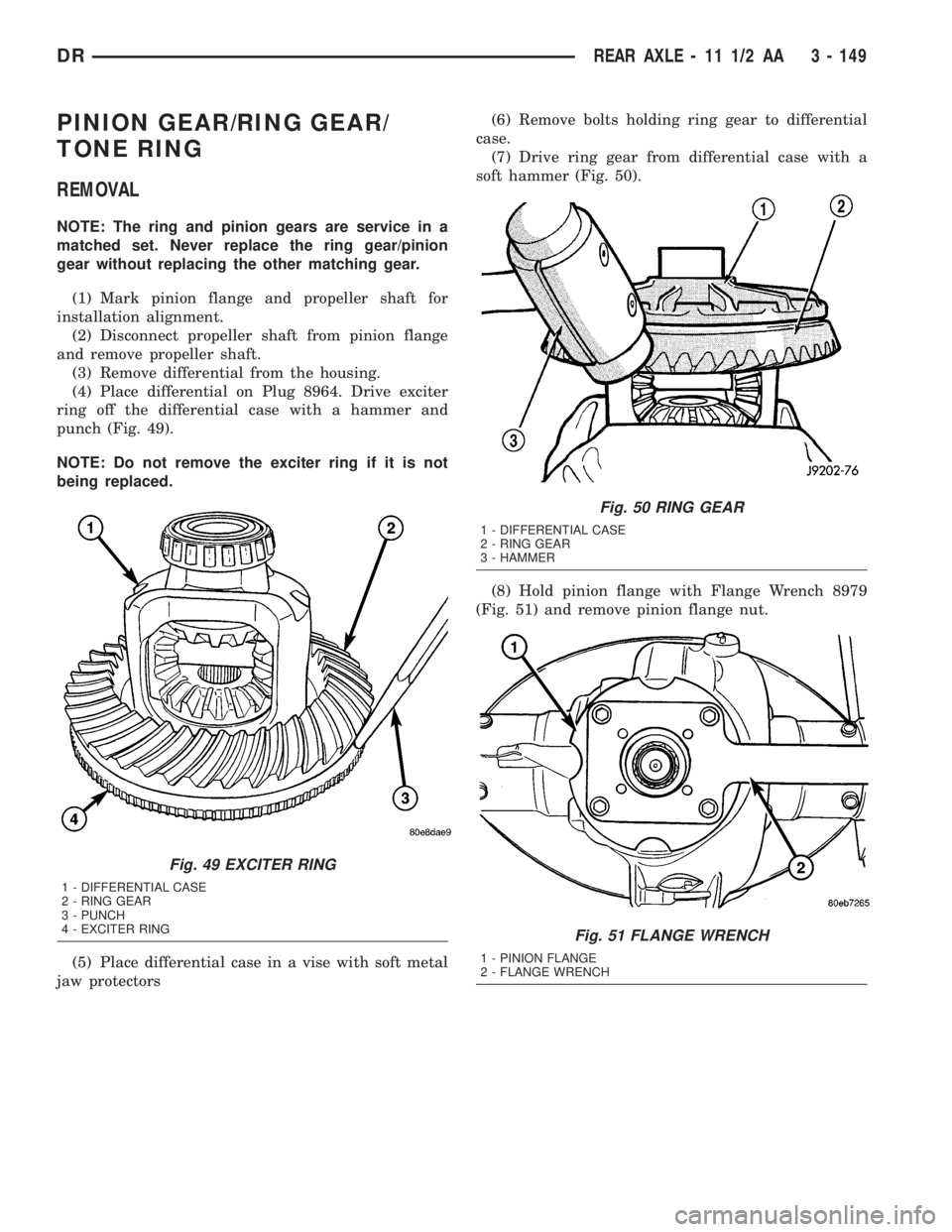

(4) Place differential on Plug 8964. Drive exciter

ring off the differential case with a hammer and

punch (Fig. 49).

NOTE: Do not remove the exciter ring if it is not

being replaced.

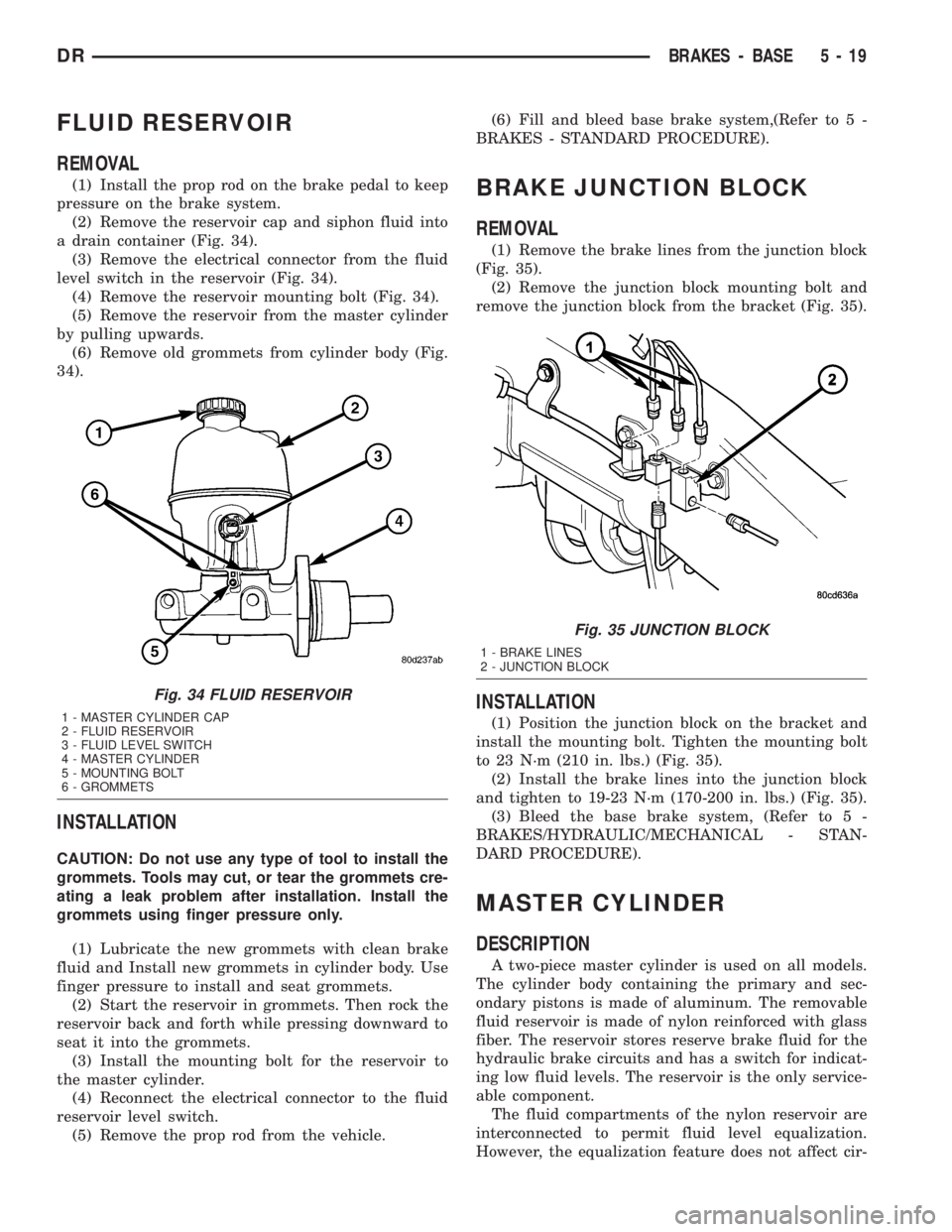

(5) Place differential case in a vise with soft metal

jaw protectors(6) Remove bolts holding ring gear to differential

case.

(7) Drive ring gear from differential case with a

soft hammer (Fig. 50).

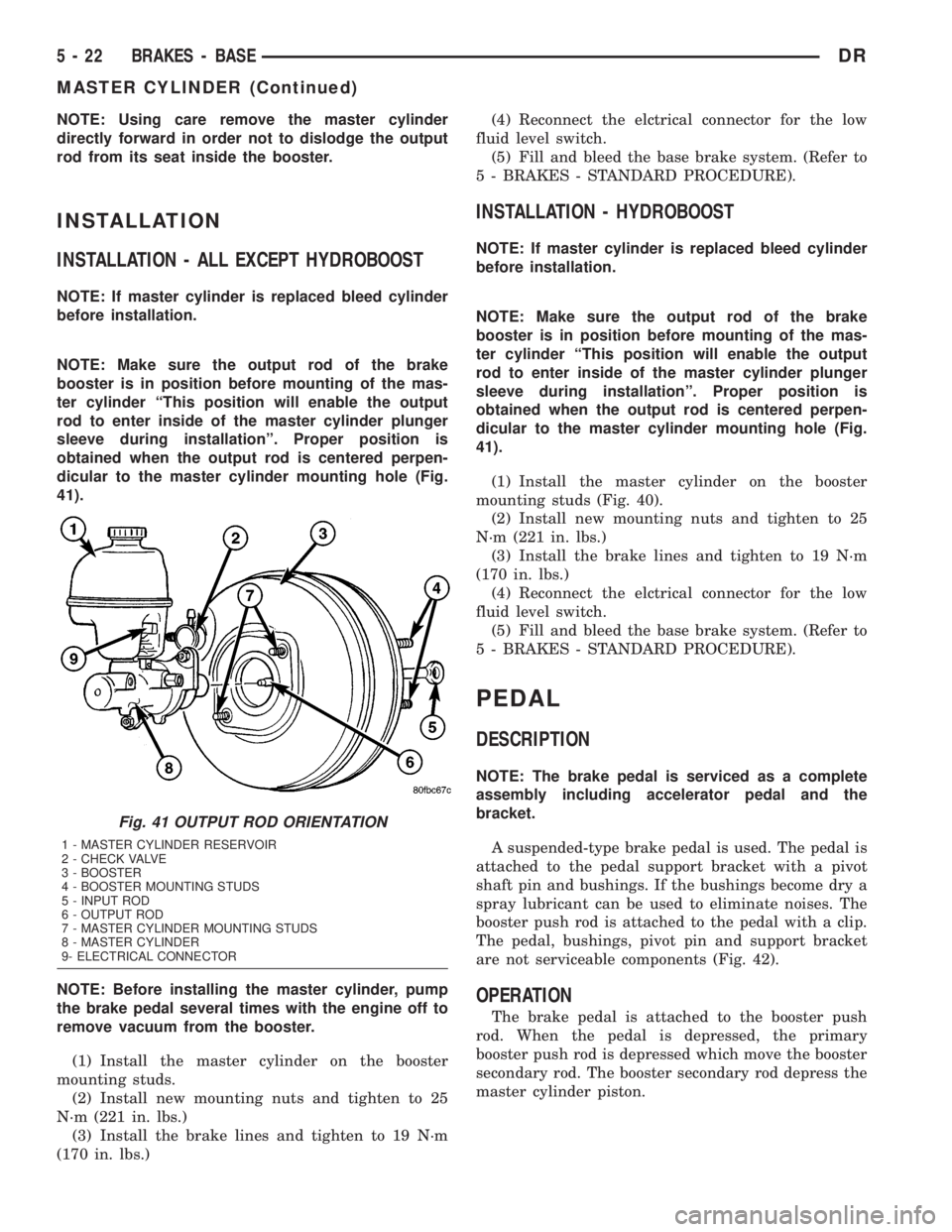

(8) Hold pinion flange with Flange Wrench 8979

(Fig. 51) and remove pinion flange nut.

Fig. 49 EXCITER RING

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - PUNCH

4 - EXCITER RING

Fig. 50 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 51 FLANGE WRENCH

1 - PINION FLANGE

2 - FLANGE WRENCH

DRREAR AXLE - 11 1/2 AA 3 - 149

Page 246 of 2895

FLUID RESERVOIR

REMOVAL

(1) Install the prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the reservoir cap and siphon fluid into

a drain container (Fig. 34).

(3) Remove the electrical connector from the fluid

level switch in the reservoir (Fig. 34).

(4) Remove the reservoir mounting bolt (Fig. 34).

(5) Remove the reservoir from the master cylinder

by pulling upwards.

(6) Remove old grommets from cylinder body (Fig.

34).

INSTALLATION

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.

(1) Lubricate the new grommets with clean brake

fluid and Install new grommets in cylinder body. Use

finger pressure to install and seat grommets.

(2) Start the reservoir in grommets. Then rock the

reservoir back and forth while pressing downward to

seat it into the grommets.

(3) Install the mounting bolt for the reservoir to

the master cylinder.

(4) Reconnect the electrical connector to the fluid

reservoir level switch.

(5) Remove the prop rod from the vehicle.(6) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

BRAKE JUNCTION BLOCK

REMOVAL

(1) Remove the brake lines from the junction block

(Fig. 35).

(2) Remove the junction block mounting bolt and

remove the junction block from the bracket (Fig. 35).

INSTALLATION

(1) Position the junction block on the bracket and

install the mounting bolt. Tighten the mounting bolt

to 23 N´m (210 in. lbs.) (Fig. 35).

(2) Install the brake lines into the junction block

and tighten to 19-23 N´m (170-200 in. lbs.) (Fig. 35).

(3) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

MASTER CYLINDER

DESCRIPTION

A two-piece master cylinder is used on all models.

The cylinder body containing the primary and sec-

ondary pistons is made of aluminum. The removable

fluid reservoir is made of nylon reinforced with glass

fiber. The reservoir stores reserve brake fluid for the

hydraulic brake circuits and has a switch for indicat-

ing low fluid levels. The reservoir is the only service-

able component.

The fluid compartments of the nylon reservoir are

interconnected to permit fluid level equalization.

However, the equalization feature does not affect cir-

Fig. 34 FLUID RESERVOIR

1 - MASTER CYLINDER CAP

2 - FLUID RESERVOIR

3 - FLUID LEVEL SWITCH

4 - MASTER CYLINDER

5 - MOUNTING BOLT

6 - GROMMETS

Fig. 35 JUNCTION BLOCK

1 - BRAKE LINES

2 - JUNCTION BLOCK

DRBRAKES - BASE 5 - 19

Page 249 of 2895

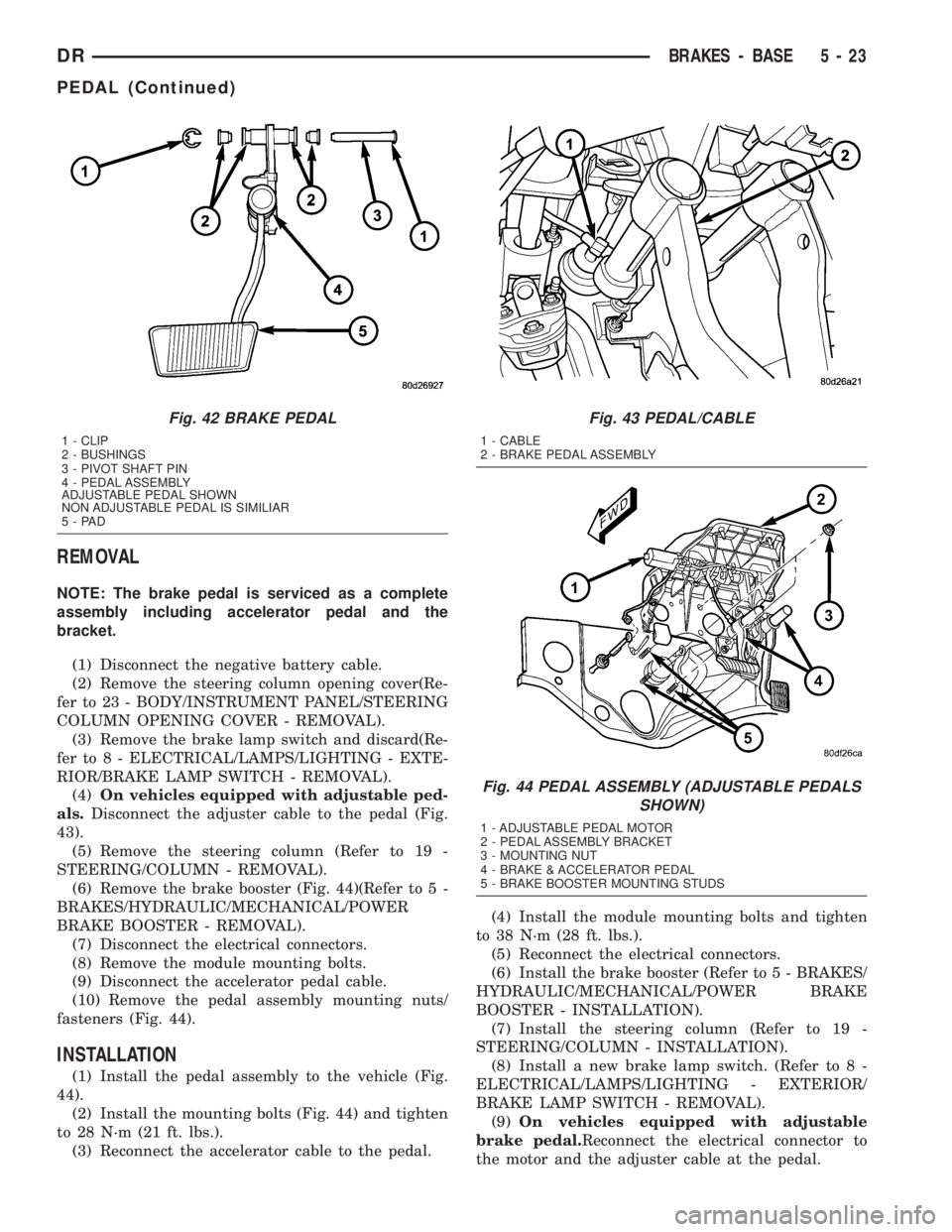

NOTE: Using care remove the master cylinder

directly forward in order not to dislodge the output

rod from its seat inside the booster.

INSTALLATION

INSTALLATION - ALL EXCEPT HYDROBOOST

NOTE: If master cylinder is replaced bleed cylinder

before installation.

NOTE: Make sure the output rod of the brake

booster is in position before mounting of the mas-

ter cylinder ªThis position will enable the output

rod to enter inside of the master cylinder plunger

sleeve during installationº. Proper position is

obtained when the output rod is centered perpen-

dicular to the master cylinder mounting hole (Fig.

41).

NOTE: Before installing the master cylinder, pump

the brake pedal several times with the engine off to

remove vacuum from the booster.

(1) Install the master cylinder on the booster

mounting studs.

(2) Install new mounting nuts and tighten to 25

N´m (221 in. lbs.)

(3) Install the brake lines and tighten to 19 N´m

(170 in. lbs.)(4) Reconnect the elctrical connector for the low

fluid level switch.

(5) Fill and bleed the base brake system. (Refer to

5 - BRAKES - STANDARD PROCEDURE).

INSTALLATION - HYDROBOOST

NOTE: If master cylinder is replaced bleed cylinder

before installation.

NOTE: Make sure the output rod of the brake

booster is in position before mounting of the mas-

ter cylinder ªThis position will enable the output

rod to enter inside of the master cylinder plunger

sleeve during installationº. Proper position is

obtained when the output rod is centered perpen-

dicular to the master cylinder mounting hole (Fig.

41).

(1) Install the master cylinder on the booster

mounting studs (Fig. 40).

(2) Install new mounting nuts and tighten to 25

N´m (221 in. lbs.)

(3) Install the brake lines and tighten to 19 N´m

(170 in. lbs.)

(4) Reconnect the elctrical connector for the low

fluid level switch.

(5) Fill and bleed the base brake system. (Refer to

5 - BRAKES - STANDARD PROCEDURE).

PEDAL

DESCRIPTION

NOTE: The brake pedal is serviced as a complete

assembly including accelerator pedal and the

bracket.

A suspended-type brake pedal is used. The pedal is

attached to the pedal support bracket with a pivot

shaft pin and bushings. If the bushings become dry a

spray lubricant can be used to eliminate noises. The

booster push rod is attached to the pedal with a clip.

The pedal, bushings, pivot pin and support bracket

are not serviceable components (Fig. 42).

OPERATION

The brake pedal is attached to the booster push

rod. When the pedal is depressed, the primary

booster push rod is depressed which move the booster

secondary rod. The booster secondary rod depress the

master cylinder piston.

Fig. 41 OUTPUT ROD ORIENTATION

1 - MASTER CYLINDER RESERVOIR

2 - CHECK VALVE

3 - BOOSTER

4 - BOOSTER MOUNTING STUDS

5 - INPUT ROD

6 - OUTPUT ROD

7 - MASTER CYLINDER MOUNTING STUDS

8 - MASTER CYLINDER

9- ELECTRICAL CONNECTOR

5 - 22 BRAKES - BASEDR

MASTER CYLINDER (Continued)

Page 250 of 2895

REMOVAL

NOTE: The brake pedal is serviced as a complete

assembly including accelerator pedal and the

bracket.

(1) Disconnect the negative battery cable.

(2) Remove the steering column opening cover(Re-

fer to 23 - BODY/INSTRUMENT PANEL/STEERING

COLUMN OPENING COVER - REMOVAL).

(3) Remove the brake lamp switch and discard(Re-

fer to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTE-

RIOR/BRAKE LAMP SWITCH - REMOVAL).

(4)On vehicles equipped with adjustable ped-

als.Disconnect the adjuster cable to the pedal (Fig.

43).

(5) Remove the steering column (Refer to 19 -

STEERING/COLUMN - REMOVAL).

(6) Remove the brake booster (Fig. 44)(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - REMOVAL).

(7) Disconnect the electrical connectors.

(8) Remove the module mounting bolts.

(9) Disconnect the accelerator pedal cable.

(10) Remove the pedal assembly mounting nuts/

fasteners (Fig. 44).

INSTALLATION

(1) Install the pedal assembly to the vehicle (Fig.

44).

(2) Install the mounting bolts (Fig. 44) and tighten

to 28 N´m (21 ft. lbs.).

(3) Reconnect the accelerator cable to the pedal.(4) Install the module mounting bolts and tighten

to 38 N´m (28 ft. lbs.).

(5) Reconnect the electrical connectors.

(6) Install the brake booster (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/POWER BRAKE

BOOSTER - INSTALLATION).

(7) Install the steering column (Refer to 19 -

STEERING/COLUMN - INSTALLATION).

(8) Install a new brake lamp switch. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(9)On vehicles equipped with adjustable

brake pedal.Reconnect the electrical connector to

the motor and the adjuster cable at the pedal.

Fig. 42 BRAKE PEDAL

1 - CLIP

2 - BUSHINGS

3 - PIVOT SHAFT PIN

4 - PEDAL ASSEMBLY

ADJUSTABLE PEDAL SHOWN

NON ADJUSTABLE PEDAL IS SIMILIAR

5-PAD

Fig. 43 PEDAL/CABLE

1 - CABLE

2 - BRAKE PEDAL ASSEMBLY

Fig. 44 PEDAL ASSEMBLY (ADJUSTABLE PEDALS

SHOWN)

1 - ADJUSTABLE PEDAL MOTOR

2 - PEDAL ASSEMBLY BRACKET

3 - MOUNTING NUT

4 - BRAKE & ACCELERATOR PEDAL

5 - BRAKE BOOSTER MOUNTING STUDS

DRBRAKES - BASE 5 - 23

PEDAL (Continued)

Page 251 of 2895

(10) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(11) Reconnect the negative battery cable.

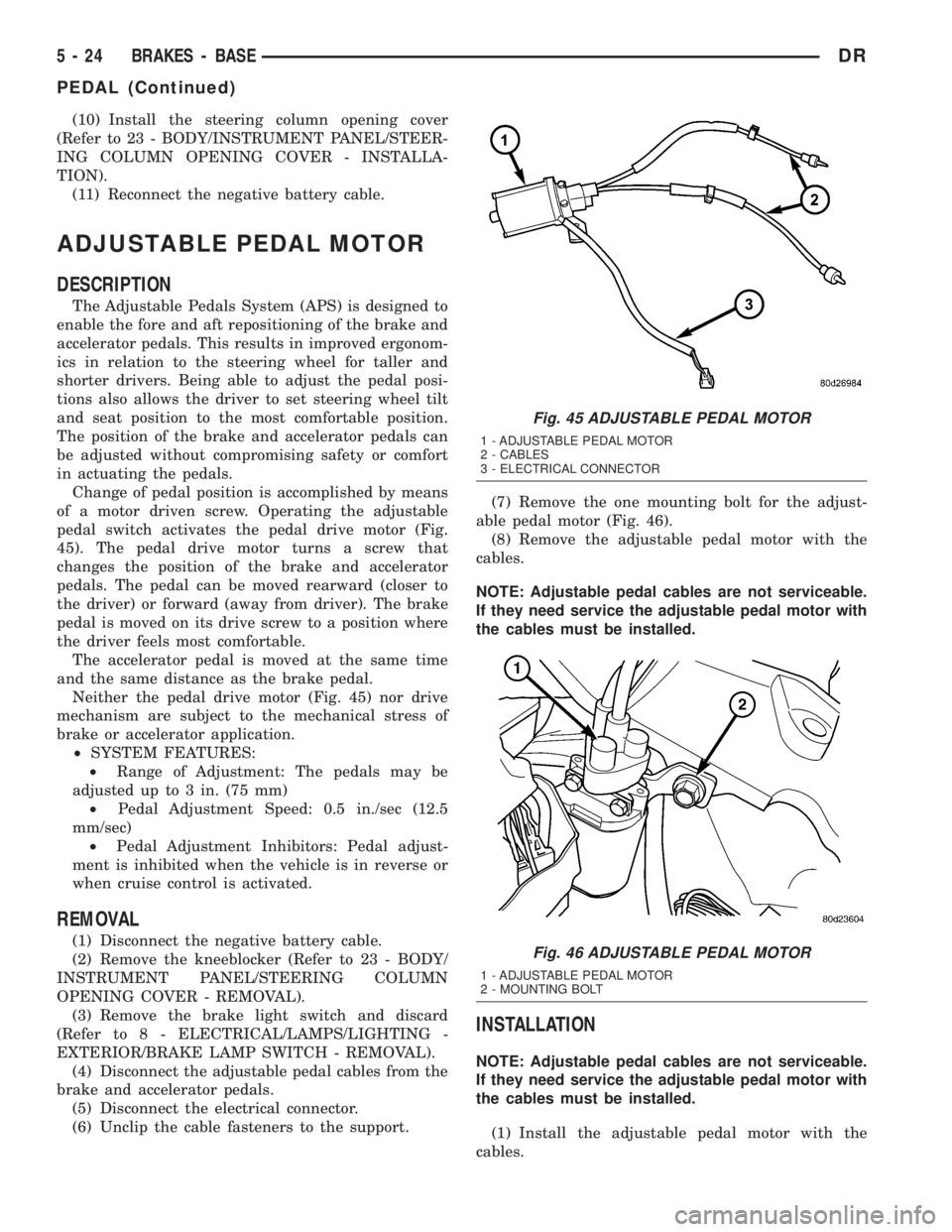

ADJUSTABLE PEDAL MOTOR

DESCRIPTION

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The position of the brake and accelerator pedals can

be adjusted without compromising safety or comfort

in actuating the pedals.

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor (Fig.

45). The pedal drive motor turns a screw that

changes the position of the brake and accelerator

pedals. The pedal can be moved rearward (closer to

the driver) or forward (away from driver). The brake

pedal is moved on its drive screw to a position where

the driver feels most comfortable.

The accelerator pedal is moved at the same time

and the same distance as the brake pedal.

Neither the pedal drive motor (Fig. 45) nor drive

mechanism are subject to the mechanical stress of

brake or accelerator application.

²SYSTEM FEATURES:

²Range of Adjustment: The pedals may be

adjusted up to 3 in. (75 mm)

²Pedal Adjustment Speed: 0.5 in./sec (12.5

mm/sec)

²Pedal Adjustment Inhibitors: Pedal adjust-

ment is inhibited when the vehicle is in reverse or

when cruise control is activated.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the kneeblocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(3) Remove the brake light switch and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

(4) Disconnect the adjustable pedal cables from the

brake and accelerator pedals.

(5) Disconnect the electrical connector.

(6) Unclip the cable fasteners to the support.(7) Remove the one mounting bolt for the adjust-

able pedal motor (Fig. 46).

(8) Remove the adjustable pedal motor with the

cables.

NOTE: Adjustable pedal cables are not serviceable.

If they need service the adjustable pedal motor with

the cables must be installed.

INSTALLATION

NOTE: Adjustable pedal cables are not serviceable.

If they need service the adjustable pedal motor with

the cables must be installed.

(1) Install the adjustable pedal motor with the

cables.

Fig. 45 ADJUSTABLE PEDAL MOTOR

1 - ADJUSTABLE PEDAL MOTOR

2 - CABLES

3 - ELECTRICAL CONNECTOR

Fig. 46 ADJUSTABLE PEDAL MOTOR

1 - ADJUSTABLE PEDAL MOTOR

2 - MOUNTING BOLT

5 - 24 BRAKES - BASEDR

PEDAL (Continued)

Page 256 of 2895

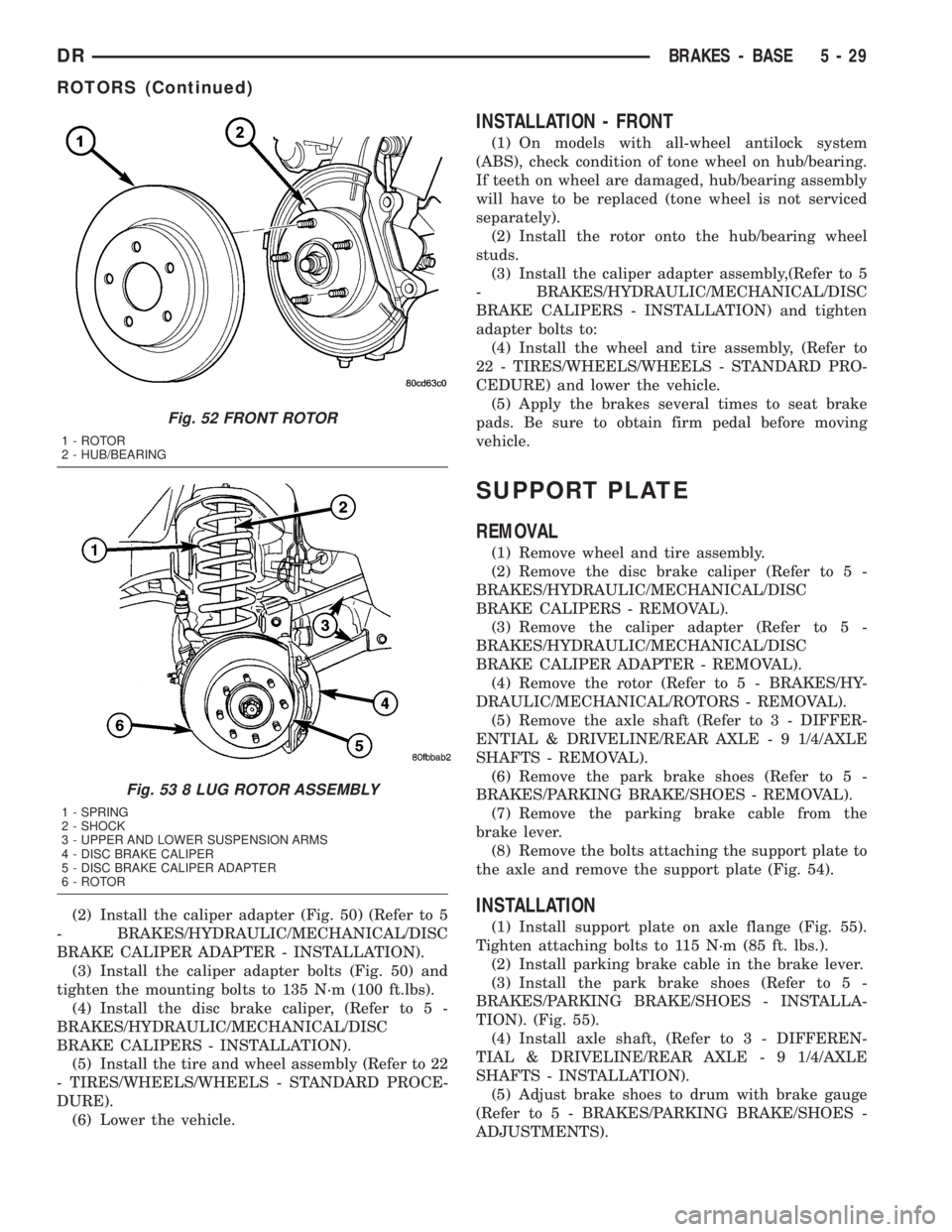

(2) Install the caliper adapter (Fig. 50) (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the caliper adapter bolts (Fig. 50) and

tighten the mounting bolts to 135 N´m (100 ft.lbs).

(4) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(6) Lower the vehicle.

INSTALLATION - FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake

pads. Be sure to obtain firm pedal before moving

vehicle.

SUPPORT PLATE

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 54).

INSTALLATION

(1) Install support plate on axle flange (Fig. 55).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(2) Install parking brake cable in the brake lever.

(3) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 55).

(4) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(5) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

Fig. 52 FRONT ROTOR

1 - ROTOR

2 - HUB/BEARING

Fig. 53 8 LUG ROTOR ASSEMBLY

1 - SPRING

2 - SHOCK

3 - UPPER AND LOWER SUSPENSION ARMS

4 - DISC BRAKE CALIPER

5 - DISC BRAKE CALIPER ADAPTER

6 - ROTOR

DRBRAKES - BASE 5 - 29

ROTORS (Continued)

Page 264 of 2895

(5) Tighten the front cable grommet to the floor-

pan and the cable retainer, roll the carpet back.

(6) Connect the wires to the brake lamp switch.

(7) Install the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(8) Raise the vehicle.

(9) Adjust the parking brake cable tensioner (Refer

to 5 - BRAKES/PARKING BRAKE/CABLE TEN-

SIONER - ADJUSTMENTS).

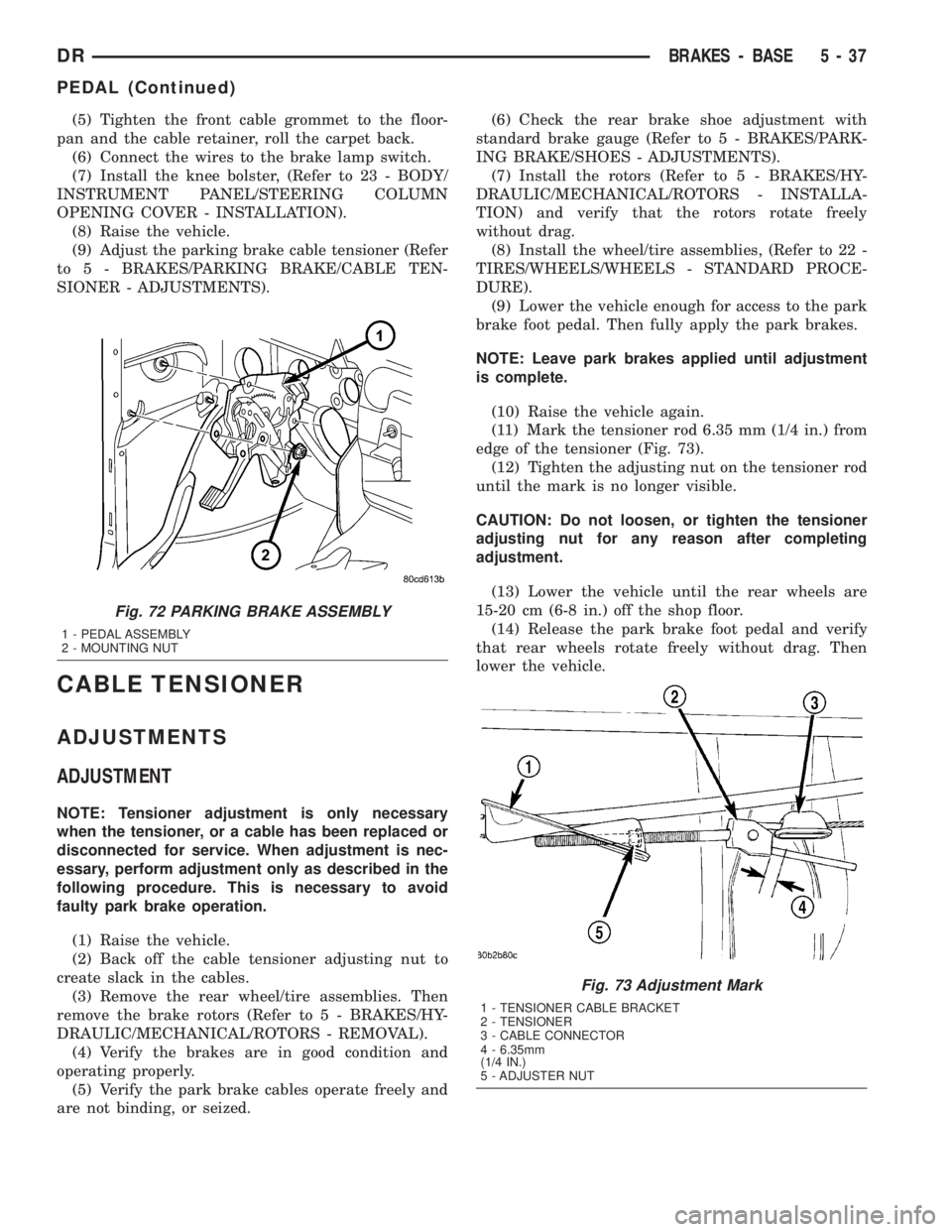

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT

NOTE: Tensioner adjustment is only necessary

when the tensioner, or a cable has been replaced or

disconnected for service. When adjustment is nec-

essary, perform adjustment only as described in the

following procedure. This is necessary to avoid

faulty park brake operation.

(1) Raise the vehicle.

(2) Back off the cable tensioner adjusting nut to

create slack in the cables.

(3) Remove the rear wheel/tire assemblies. Then

remove the brake rotors (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(4) Verify the brakes are in good condition and

operating properly.

(5) Verify the park brake cables operate freely and

are not binding, or seized.(6) Check the rear brake shoe adjustment with

standard brake gauge (Refer to 5 - BRAKES/PARK-

ING BRAKE/SHOES - ADJUSTMENTS).

(7) Install the rotors (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION) and verify that the rotors rotate freely

without drag.

(8) Install the wheel/tire assemblies, (Refer to 22 -

TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Lower the vehicle enough for access to the park

brake foot pedal. Then fully apply the park brakes.

NOTE: Leave park brakes applied until adjustment

is complete.

(10) Raise the vehicle again.

(11) Mark the tensioner rod 6.35 mm (1/4 in.) from

edge of the tensioner (Fig. 73).

(12) Tighten the adjusting nut on the tensioner rod

until the mark is no longer visible.

CAUTION: Do not loosen, or tighten the tensioner

adjusting nut for any reason after completing

adjustment.

(13) Lower the vehicle until the rear wheels are

15-20 cm (6-8 in.) off the shop floor.

(14) Release the park brake foot pedal and verify

that rear wheels rotate freely without drag. Then

lower the vehicle.

Fig. 72 PARKING BRAKE ASSEMBLY

1 - PEDAL ASSEMBLY

2 - MOUNTING NUT

Fig. 73 Adjustment Mark

1 - TENSIONER CABLE BRACKET

2 - TENSIONER

3 - CABLE CONNECTOR

4 - 6.35mm

(1/4 IN.)

5 - ADJUSTER NUT

DRBRAKES - BASE 5 - 37

PEDAL (Continued)

Page 275 of 2895

WARNING

WARNING:: EXERCISE CARE WHEN SERVICING

CLUTCH COMPONENTS. FACTORY INSTALLED

CLUTCH DISCS DO NOT CONTAIN ASBESTOS

FIBERS. DUST AND DIRT ON CLUTCH PARTS MAY

CONTAIN ASBESTOS FIBERS FROM AFTERMAR-

KET COMPONENTS. BREATHING EXCESSIVE CON-

CENTRATIONS OF THESE FIBERS CAN CAUSE

SERIOUS BODILY HARM. WEAR A RESPIRATOR

DURING SERVICE AND NEVER CLEAN CLUTCH

COMPONENTS WITH COMPRESSED AIR OR WITH

A DRY BRUSH. EITHER CLEAN THE COMPONENTS

WITH A WATER DAMPENED RAGS OR USE A VAC-

UUM CLEANER SPECIFICALLY DESIGNED FOR

REMOVING ASBESTOS FIBERS AND DUST. DO NOT

CREATE DUST BY SANDING A CLUTCH DISC.

REPLACE THE DISC IF THE FRICTION MATERIAL IS

DAMAGED OR CONTAMINATED. DISPOSE OF ALL

DUST AND DIRT CONTAINING ASBESTOS FIBERS

IN SEALED BAGS OR CONTAINERS. THIS WILL

HELP MINIMIZE EXPOSURE TO YOURSELF AND TO

OTHERS. FOLLOW ALL RECOMMENDED SAFETY

PRACTICES PRESCRIBED BY THE OCCUPATIONAL

SAFETY AND HEALTH ADMINISTRATION (OSHA)

AND THE ENVIRONMENTAL SAFETY AGENCY(EPA), FOR THE HANDLING AND DISPOSAL OF

PRODUCTS CONTAINING ASBESTOS.

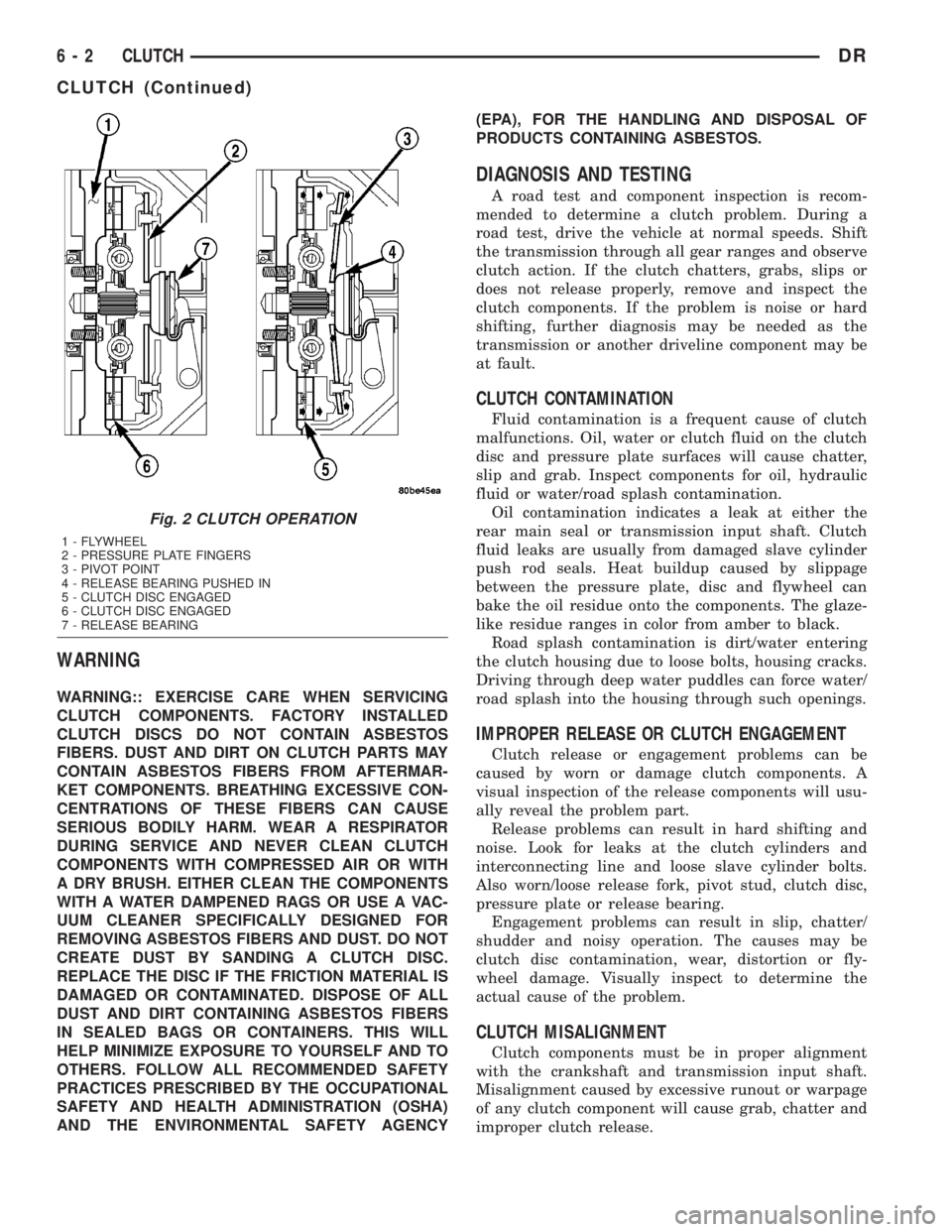

DIAGNOSIS AND TESTING

A road test and component inspection is recom-

mended to determine a clutch problem. During a

road test, drive the vehicle at normal speeds. Shift

the transmission through all gear ranges and observe

clutch action. If the clutch chatters, grabs, slips or

does not release properly, remove and inspect the

clutch components. If the problem is noise or hard

shifting, further diagnosis may be needed as the

transmission or another driveline component may be

at fault.

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, water or clutch fluid on the clutch

disc and pressure plate surfaces will cause chatter,

slip and grab. Inspect components for oil, hydraulic

fluid or water/road splash contamination.

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft. Clutch

fluid leaks are usually from damaged slave cylinder

push rod seals. Heat buildup caused by slippage

between the pressure plate, disc and flywheel can

bake the oil residue onto the components. The glaze-

like residue ranges in color from amber to black.

Road splash contamination is dirt/water entering

the clutch housing due to loose bolts, housing cracks.

Driving through deep water puddles can force water/

road splash into the housing through such openings.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems can be

caused by worn or damage clutch components. A

visual inspection of the release components will usu-

ally reveal the problem part.

Release problems can result in hard shifting and

noise. Look for leaks at the clutch cylinders and

interconnecting line and loose slave cylinder bolts.

Also worn/loose release fork, pivot stud, clutch disc,

pressure plate or release bearing.

Engagement problems can result in slip, chatter/

shudder and noisy operation. The causes may be

clutch disc contamination, wear, distortion or fly-

wheel damage. Visually inspect to determine the

actual cause of the problem.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

Fig. 2 CLUTCH OPERATION

1 - FLYWHEEL

2 - PRESSURE PLATE FINGERS

3 - PIVOT POINT

4 - RELEASE BEARING PUSHED IN

5 - CLUTCH DISC ENGAGED

6 - CLUTCH DISC ENGAGED

7 - RELEASE BEARING

6 - 2 CLUTCHDR

CLUTCH (Continued)

Page 287 of 2895

(6) Install plastic clip securing hydraulic line to

the dash panel into the lower dash panel flange.

(7) Install plastic clip securing hydraulic line to

the dash panel onto the upper dash panel stud.

(8) Raise vehicle.

(9) Install slave cylinder and verify cylinder rod is

properly seated in release lever.

(10) Install and tighten slave cylinder nuts to 23

N´m (17 ft. lbs.).

(11) Ifnewclutch linkage is being installed, con-

nect the clutch hydraulic line to the clutch slave cyl-

inder.

CAUTION: Once the clutch hydraulic line is con-

nected to the slave cylinder, it should never be dis-

connected.

(12) Lower vehicle.

(13) Operate linkage several times to verify proper

operation.

CLUTCH PEDAL POSITION

SWITCH

DESCRIPTION

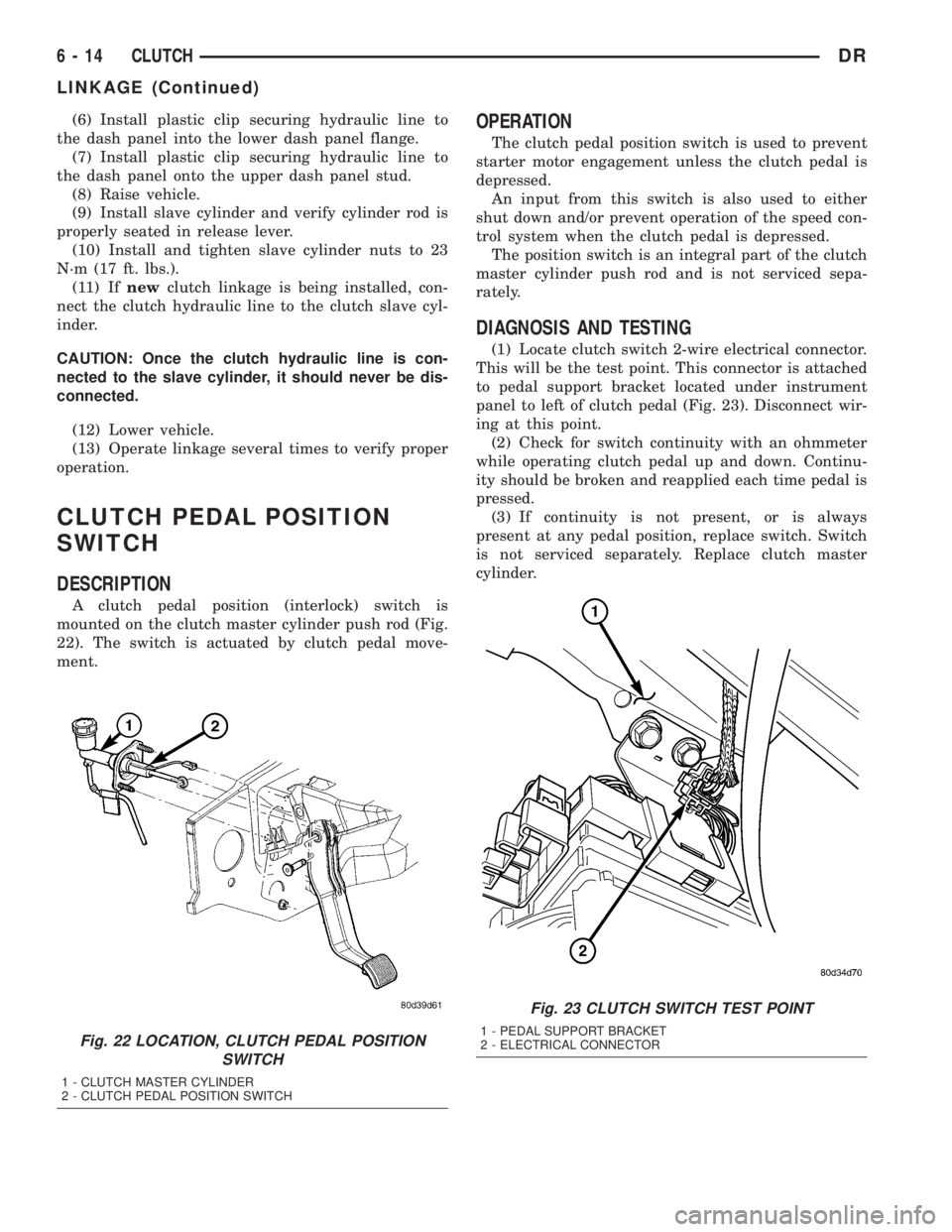

A clutch pedal position (interlock) switch is

mounted on the clutch master cylinder push rod (Fig.

22). The switch is actuated by clutch pedal move-

ment.

OPERATION

The clutch pedal position switch is used to prevent

starter motor engagement unless the clutch pedal is

depressed.

An input from this switch is also used to either

shut down and/or prevent operation of the speed con-

trol system when the clutch pedal is depressed.

The position switch is an integral part of the clutch

master cylinder push rod and is not serviced sepa-

rately.

DIAGNOSIS AND TESTING

(1) Locate clutch switch 2-wire electrical connector.

This will be the test point. This connector is attached

to pedal support bracket located under instrument

panel to left of clutch pedal (Fig. 23). Disconnect wir-

ing at this point.

(2) Check for switch continuity with an ohmmeter

while operating clutch pedal up and down. Continu-

ity should be broken and reapplied each time pedal is

pressed.

(3) If continuity is not present, or is always

present at any pedal position, replace switch. Switch

is not serviced separately. Replace clutch master

cylinder.

Fig. 22 LOCATION, CLUTCH PEDAL POSITION

SWITCH

1 - CLUTCH MASTER CYLINDER

2 - CLUTCH PEDAL POSITION SWITCH

Fig. 23 CLUTCH SWITCH TEST POINT

1 - PEDAL SUPPORT BRACKET

2 - ELECTRICAL CONNECTOR

6 - 14 CLUTCHDR

LINKAGE (Continued)

Page 292 of 2895

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

5.9L, 5.9L Diesel, and 8.0L engines utilize an

ambient overflow bottle for coolant recovery/reserve.

The 3.7L and 4.7L engines utilize a pressurized

degas bottle for coolant deaeration and reserve. This

degas bottle has coolant flowing through it continu-

ously, supplied by a vent in the hot side radiator

tank and returning to the heater return hose.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

OPERATIONÐHOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The Engine Control Module (ECM) has been pro-

grammed to monitor certain cooling system compo-

nents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.²If an open or shorted condition has developed in

the electronically controlled viscous fan clutch circuit,

a Diagnostic Trouble Code (DTC) can be set.

²If fan speed is not detected a DTC will be set.

²Coolant temperature sensor circuit problems can

set a DTC.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the ECM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the

DRBIIItscan tool to erase a DTC. Refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice information for operation of the DRBIIItscan

tool.

DIAGNOSIS AND TESTINGÐCOOLING SYSTEM

- TESTING FOR LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate the engine until the radi-

ator upper hose is warm to the touch. Aim the com-

mercially available black light tool at the components

to be checked. If leaks are present, the black light

will cause the additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if the cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inside of the filler neck and examine the

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

DRCOOLING 7 - 5

COOLING (Continued)