light DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1638 of 2895

STANDARD PROCEDUREÐPISTON FITTING

Piston and cylinder wall must be clean and dry.

Specified clearance between the piston and the cylin-

der wall is 0.013-0.038 mm (0.0005-0.0015 inch). The

max. allowable clearance is 0.0762 mm (0.003 in.).

Piston diameter should be measured at the top of

skirt, 90É to piston pin axis. Cylinder bores should be

measured halfway down the cylinder bore and trans-

verse to the engine crankshaft center line.

Pistons and cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).

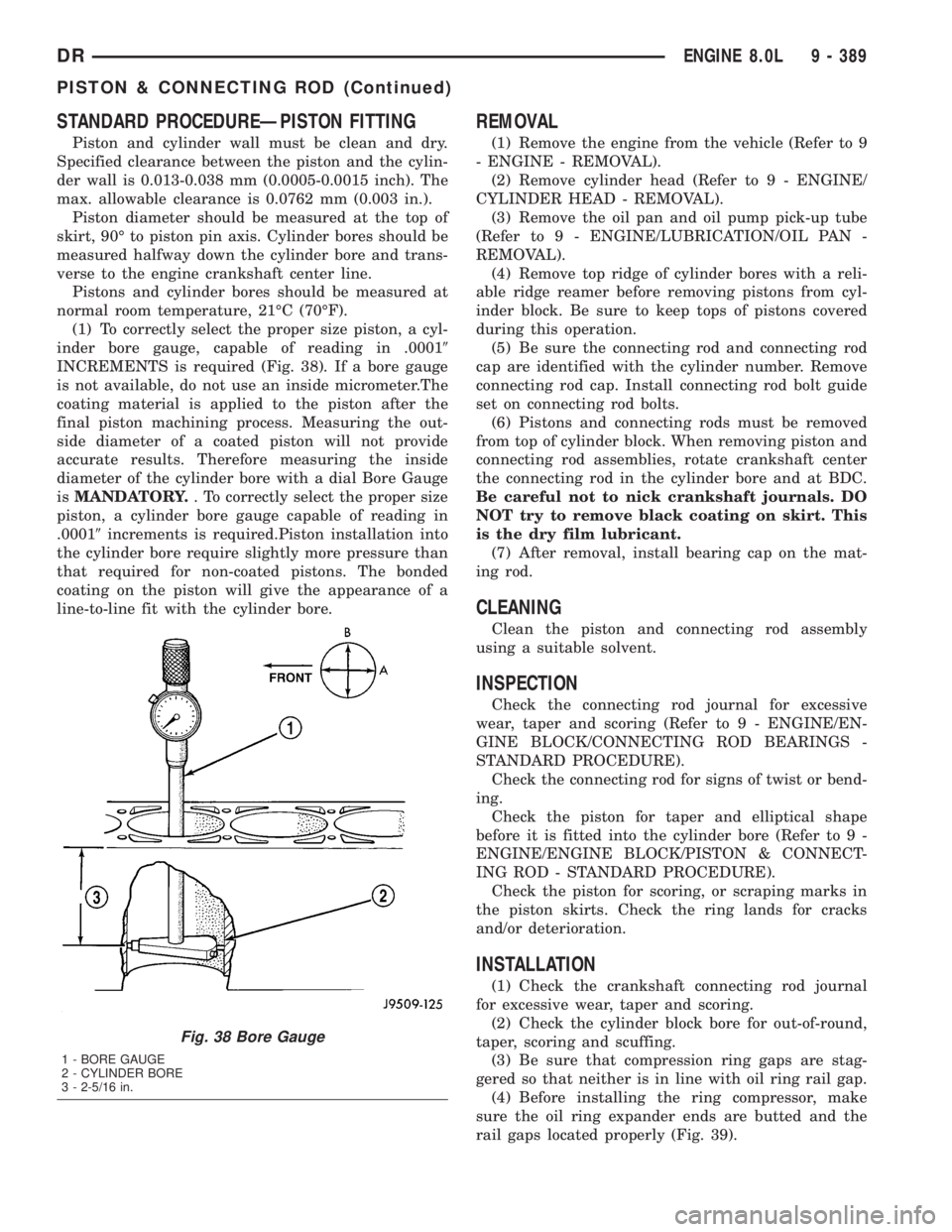

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in .00019

INCREMENTS is required (Fig. 38). If a bore gauge

is not available, do not use an inside micrometer.The

coating material is applied to the piston after the

final piston machining process. Measuring the out-

side diameter of a coated piston will not provide

accurate results. Therefore measuring the inside

diameter of the cylinder bore with a dial Bore Gauge

isMANDATORY.. To correctly select the proper size

piston, a cylinder bore gauge capable of reading in

.00019increments is required.Piston installation into

the cylinder bore require slightly more pressure than

that required for non-coated pistons. The bonded

coating on the piston will give the appearance of a

line-to-line fit with the cylinder bore.

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure the connecting rod and connecting rod

cap are identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing piston and

connecting rod assemblies, rotate crankshaft center

the connecting rod in the cylinder bore and at BDC.

Be careful not to nick crankshaft journals. DO

NOT try to remove black coating on skirt. This

is the dry film lubricant.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Check the crankshaft connecting rod journal

for excessive wear, taper and scoring.

(2) Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.

(3) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(4) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located properly (Fig. 39).

Fig. 38 Bore Gauge

1 - BORE GAUGE

2 - CYLINDER BORE

3 - 2-5/16 in.

DRENGINE 8.0L 9 - 389

PISTON & CONNECTING ROD (Continued)

Page 1641 of 2895

VIBRATION DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the following:

²Radiator fan (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - REMOVAL)

²Accessory drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - REMOVAL)

²Radiator (Refer to 7 - COOLING/ENGINE/RA-

DIATOR - REMOVAL)

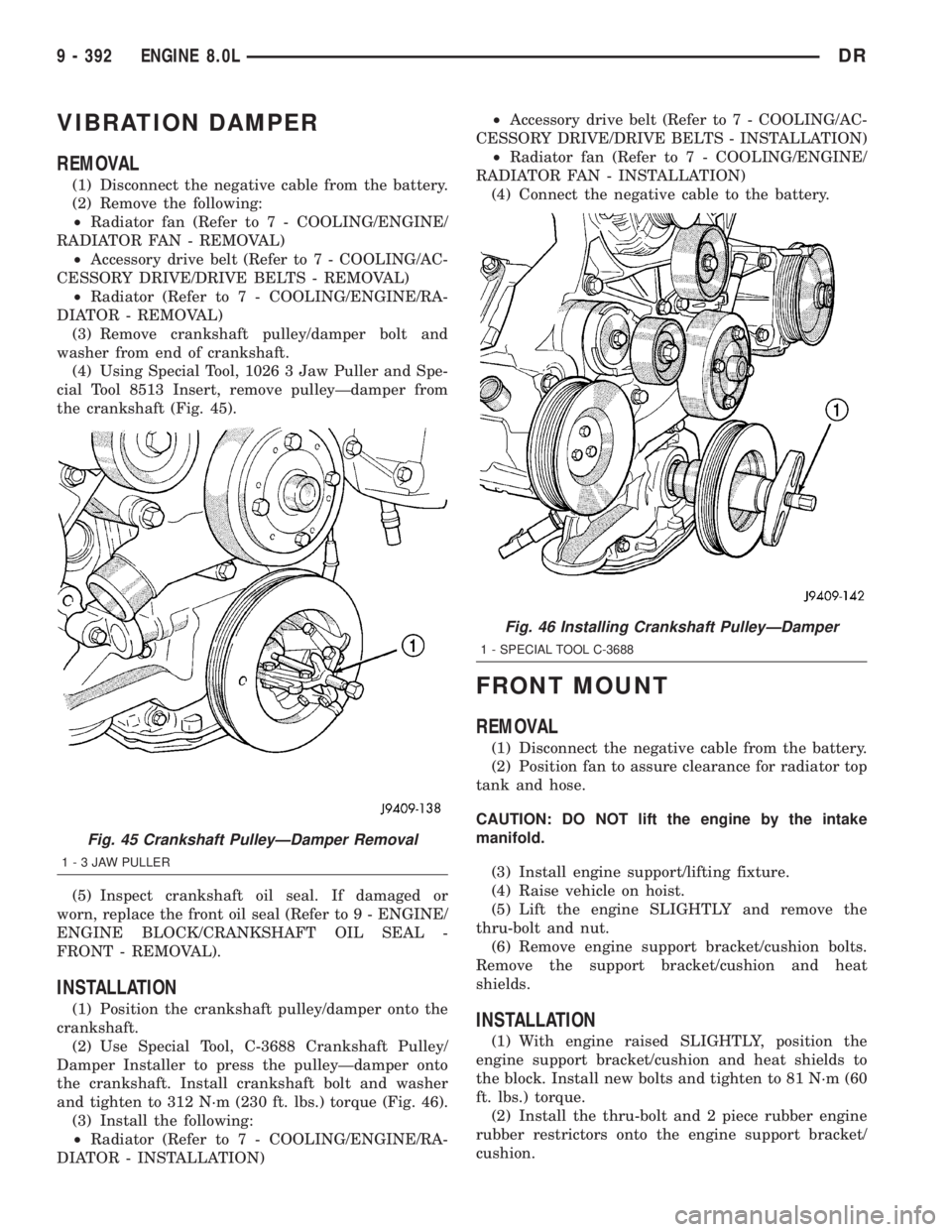

(3) Remove crankshaft pulley/damper bolt and

washer from end of crankshaft.

(4) Using Special Tool, 1026 3 Jaw Puller and Spe-

cial Tool 8513 Insert, remove pulleyÐdamper from

the crankshaft (Fig. 45).

(5) Inspect crankshaft oil seal. If damaged or

worn, replace the front oil seal (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL -

FRONT - REMOVAL).

INSTALLATION

(1) Position the crankshaft pulley/damper onto the

crankshaft.

(2) Use Special Tool, C-3688 Crankshaft Pulley/

Damper Installer to press the pulleyÐdamper onto

the crankshaft. Install crankshaft bolt and washer

and tighten to 312 N´m (230 ft. lbs.) torque (Fig. 46).

(3) Install the following:

²Radiator (Refer to 7 - COOLING/ENGINE/RA-

DIATOR - INSTALLATION)²Accessory drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLATION)

²Radiator fan (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION)

(4) Connect the negative cable to the battery.

FRONT MOUNT

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Position fan to assure clearance for radiator top

tank and hose.

CAUTION: DO NOT lift the engine by the intake

manifold.

(3) Install engine support/lifting fixture.

(4) Raise vehicle on hoist.

(5) Lift the engine SLIGHTLY and remove the

thru-bolt and nut.

(6) Remove engine support bracket/cushion bolts.

Remove the support bracket/cushion and heat

shields.

INSTALLATION

(1) With engine raised SLIGHTLY, position the

engine support bracket/cushion and heat shields to

the block. Install new bolts and tighten to 81 N´m (60

ft. lbs.) torque.

(2) Install the thru-bolt and 2 piece rubber engine

rubber restrictors onto the engine support bracket/

cushion.

Fig. 45 Crankshaft PulleyÐDamper Removal

1-3JAWPULLER

Fig. 46 Installing Crankshaft PulleyÐDamper

1 - SPECIAL TOOL C-3688

9 - 392 ENGINE 8.0LDR

Page 1642 of 2895

(3) Lower engine with support/lifting fixture while

guiding the engine bracket/cushion and thru-bolt into

support cushion brackets.

(4) Install thru-bolt nuts and tighten the nuts to

68 N´m (50 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Remove lifting fixture.

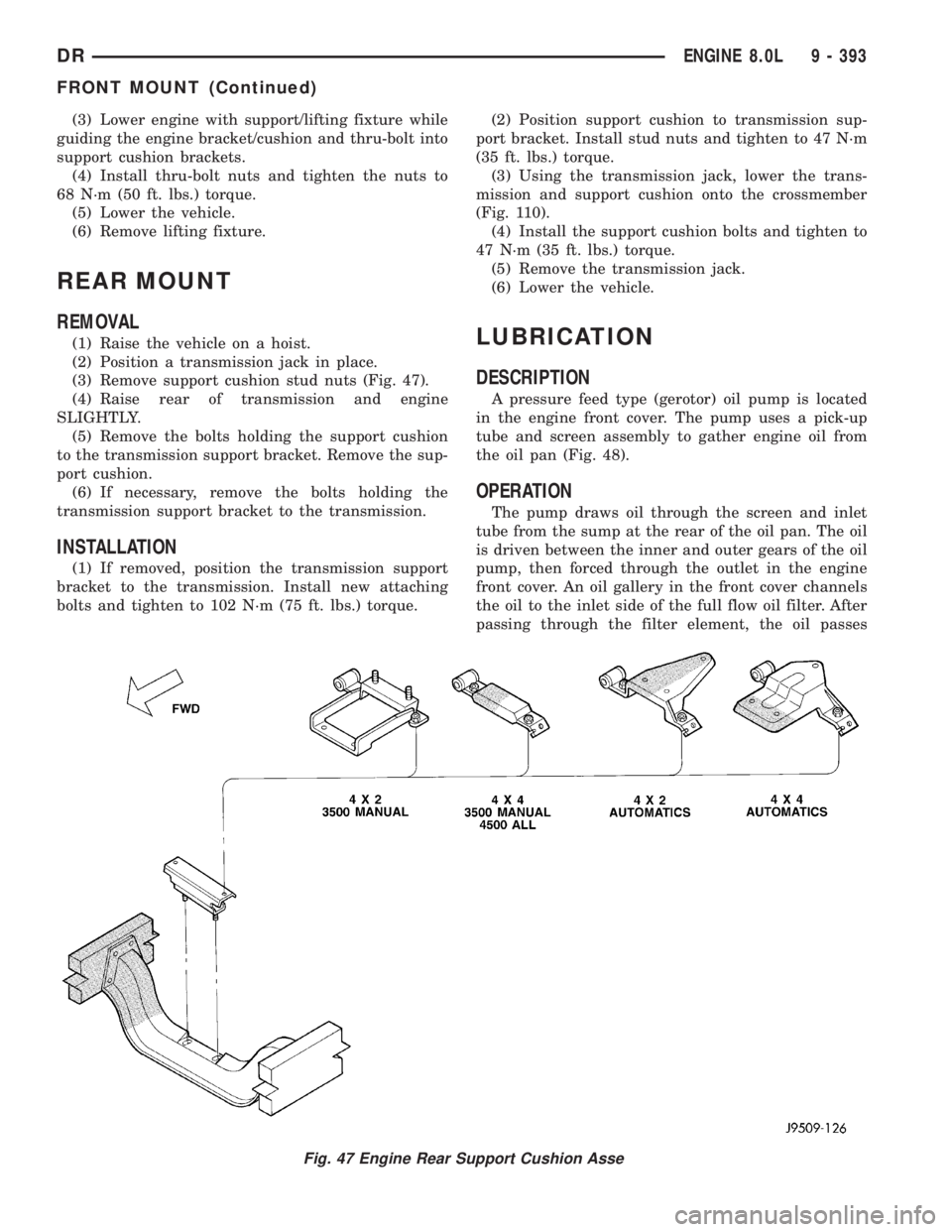

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Position a transmission jack in place.

(3) Remove support cushion stud nuts (Fig. 47).

(4) Raise rear of transmission and engine

SLIGHTLY.

(5) Remove the bolts holding the support cushion

to the transmission support bracket. Remove the sup-

port cushion.

(6) If necessary, remove the bolts holding the

transmission support bracket to the transmission.

INSTALLATION

(1) If removed, position the transmission support

bracket to the transmission. Install new attaching

bolts and tighten to 102 N´m (75 ft. lbs.) torque.(2) Position support cushion to transmission sup-

port bracket. Install stud nuts and tighten to 47 N´m

(35 ft. lbs.) torque.

(3) Using the transmission jack, lower the trans-

mission and support cushion onto the crossmember

(Fig. 110).

(4) Install the support cushion bolts and tighten to

47 N´m (35 ft. lbs.) torque.

(5) Remove the transmission jack.

(6) Lower the vehicle.

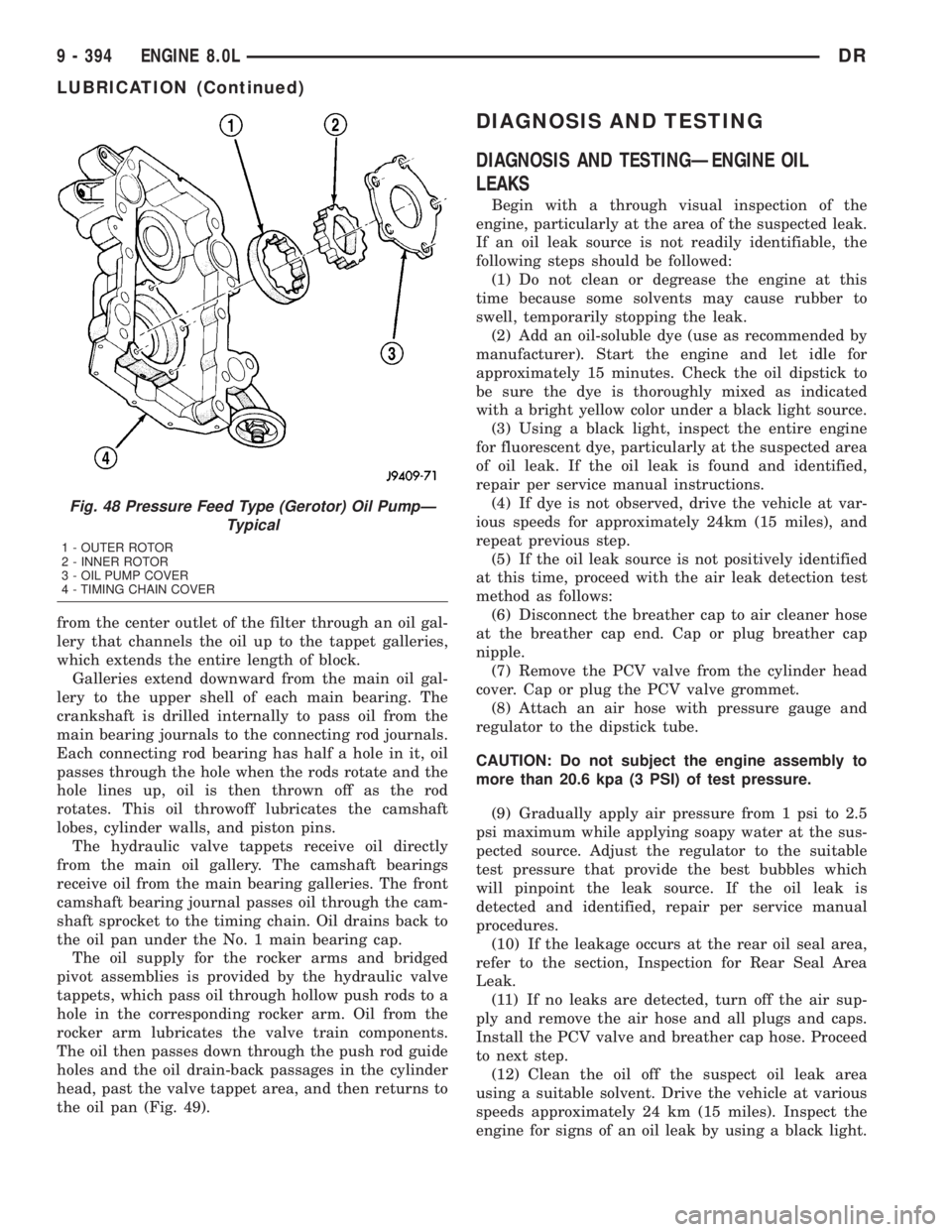

LUBRICATION

DESCRIPTION

A pressure feed type (gerotor) oil pump is located

in the engine front cover. The pump uses a pick-up

tube and screen assembly to gather engine oil from

the oil pan (Fig. 48).

OPERATION

The pump draws oil through the screen and inlet

tube from the sump at the rear of the oil pan. The oil

is driven between the inner and outer gears of the oil

pump, then forced through the outlet in the engine

front cover. An oil gallery in the front cover channels

the oil to the inlet side of the full flow oil filter. After

passing through the filter element, the oil passes

Fig. 47 Engine Rear Support Cushion Asse

DRENGINE 8.0L 9 - 393

FRONT MOUNT (Continued)

Page 1643 of 2895

from the center outlet of the filter through an oil gal-

lery that channels the oil up to the tappet galleries,

which extends the entire length of block.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals to the connecting rod journals.

Each connecting rod bearing has half a hole in it, oil

passes through the hole when the rods rotate and the

hole lines up, oil is then thrown off as the rod

rotates. This oil throwoff lubricates the camshaft

lobes, cylinder walls, and piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. The camshaft bearings

receive oil from the main bearing galleries. The front

camshaft bearing journal passes oil through the cam-

shaft sprocket to the timing chain. Oil drains back to

the oil pan under the No. 1 main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets, which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components.

The oil then passes down through the push rod guide

holes and the oil drain-back passages in the cylinder

head, past the valve tappet area, and then returns to

the oil pan (Fig. 49).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

Fig. 48 Pressure Feed Type (Gerotor) Oil PumpÐ

Typical

1 - OUTER ROTOR

2 - INNER ROTOR

3 - OIL PUMP COVER

4 - TIMING CHAIN COVER

9 - 394 ENGINE 8.0LDR

LUBRICATION (Continued)

Page 1646 of 2895

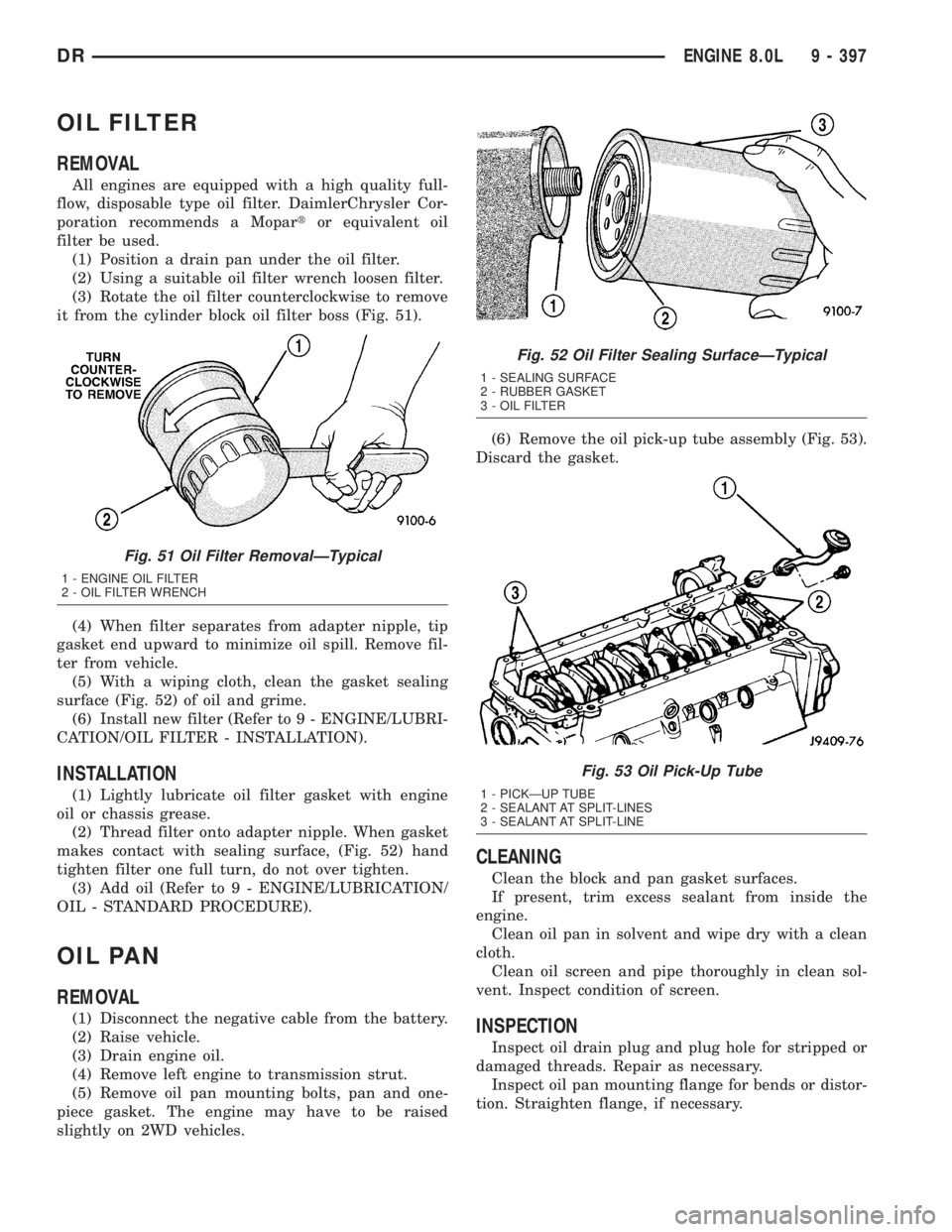

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

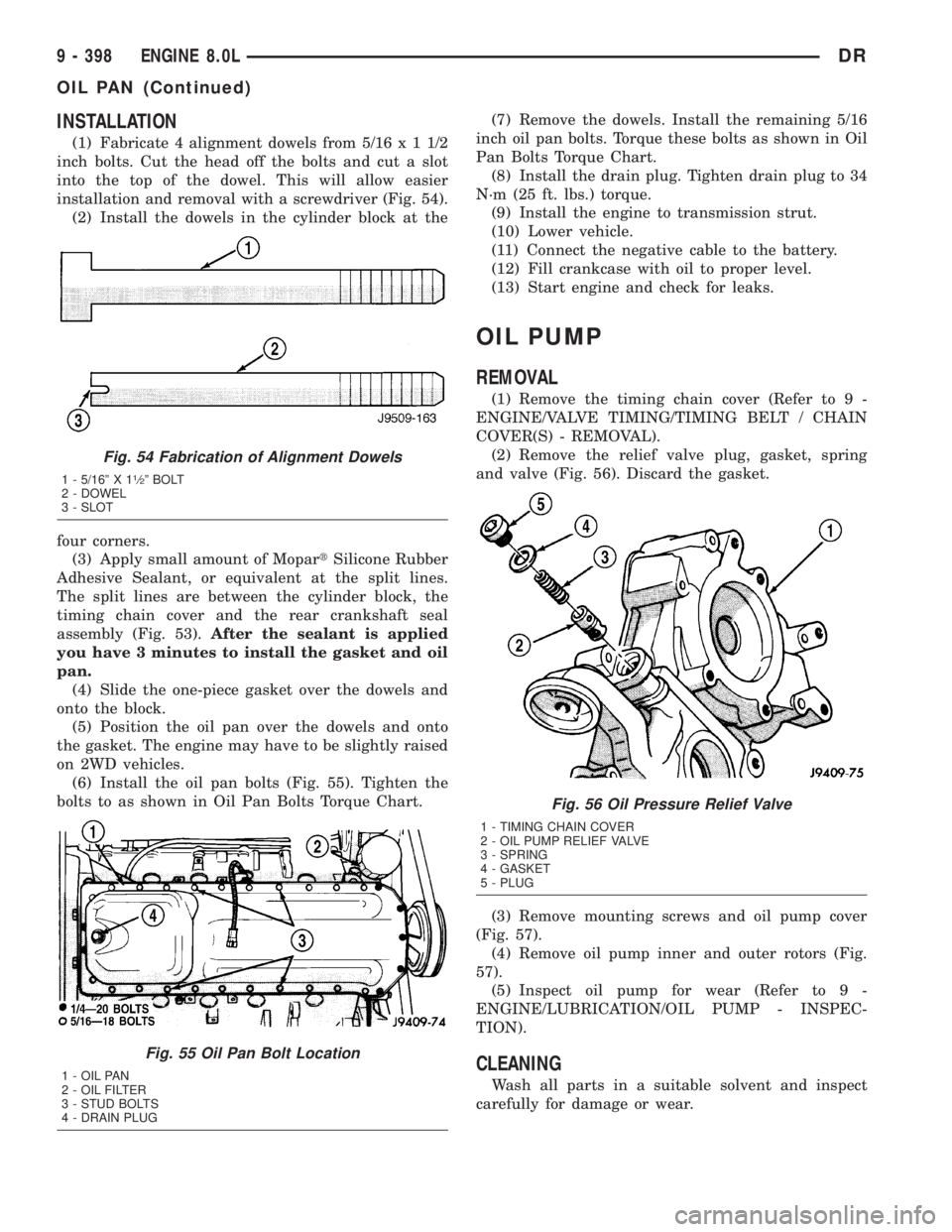

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 52) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

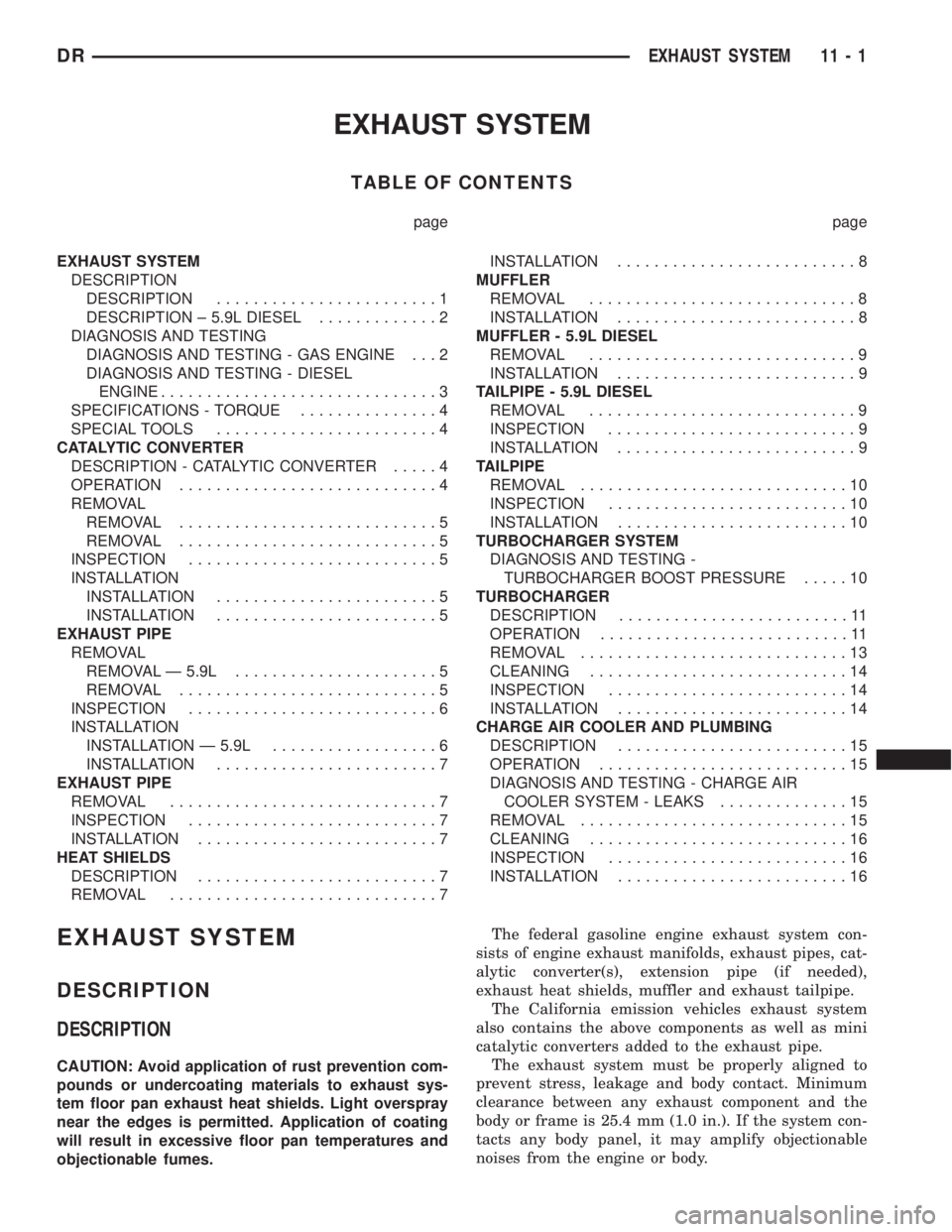

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle.

(3) Drain engine oil.

(4) Remove left engine to transmission strut.

(5) Remove oil pan mounting bolts, pan and one-

piece gasket. The engine may have to be raised

slightly on 2WD vehicles.(6) Remove the oil pick-up tube assembly (Fig. 53).

Discard the gasket.

CLEANING

Clean the block and pan gasket surfaces.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 53 Oil Pick-Up Tube

1 - PICKÐUP TUBE

2 - SEALANT AT SPLIT-LINES

3 - SEALANT AT SPLIT-LINE

DRENGINE 8.0L 9 - 397

Page 1647 of 2895

INSTALLATION

(1) Fabricate 4 alignment dowels from 5/16x11/2

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 54).

(2) Install the dowels in the cylinder block at the

four corners.

(3) Apply small amount of MopartSilicone Rubber

Adhesive Sealant, or equivalent at the split lines.

The split lines are between the cylinder block, the

timing chain cover and the rear crankshaft seal

assembly (Fig. 53).After the sealant is applied

you have 3 minutes to install the gasket and oil

pan.

(4) Slide the one-piece gasket over the dowels and

onto the block.

(5) Position the oil pan over the dowels and onto

the gasket. The engine may have to be slightly raised

on 2WD vehicles.

(6) Install the oil pan bolts (Fig. 55). Tighten the

bolts to as shown in Oil Pan Bolts Torque Chart.(7) Remove the dowels. Install the remaining 5/16

inch oil pan bolts. Torque these bolts as shown in Oil

Pan Bolts Torque Chart.

(8) Install the drain plug. Tighten drain plug to 34

N´m (25 ft. lbs.) torque.

(9) Install the engine to transmission strut.

(10) Lower vehicle.

(11) Connect the negative cable to the battery.

(12) Fill crankcase with oil to proper level.

(13) Start engine and check for leaks.

OIL PUMP

REMOVAL

(1) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(2) Remove the relief valve plug, gasket, spring

and valve (Fig. 56). Discard the gasket.

(3) Remove mounting screws and oil pump cover

(Fig. 57).

(4) Remove oil pump inner and outer rotors (Fig.

57).

(5) Inspect oil pump for wear (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - INSPEC-

TION).

CLEANING

Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

Fig. 54 Fabrication of Alignment Dowels

1 - 5/16º X 11¤2º BOLT

2 - DOWEL

3 - SLOT

Fig. 55 Oil Pan Bolt Location

1 - OIL PAN

2 - OIL FILTER

3 - STUD BOLTS

4 - DRAIN PLUG

Fig. 56 Oil Pressure Relief Valve

1 - TIMING CHAIN COVER

2 - OIL PUMP RELIEF VALVE

3 - SPRING

4 - GASKET

5 - PLUG

9 - 398 ENGINE 8.0LDR

OIL PAN (Continued)

Page 1656 of 2895

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION........................1

DESCRIPTION ± 5.9L DIESEL.............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE . . . 2

DIAGNOSIS AND TESTING - DIESEL

ENGINE..............................3

SPECIFICATIONS - TORQUE...............4

SPECIAL TOOLS........................4

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER.....4

OPERATION............................4

REMOVAL

REMOVAL............................5

REMOVAL............................5

INSPECTION...........................5

INSTALLATION

INSTALLATION........................5

INSTALLATION........................5

EXHAUST PIPE

REMOVAL

REMOVAL Ð 5.9L......................5

REMOVAL............................5

INSPECTION...........................6

INSTALLATION

INSTALLATION Ð 5.9L..................6

INSTALLATION........................7

EXHAUST PIPE

REMOVAL.............................7

INSPECTION...........................7

INSTALLATION..........................7

HEAT SHIELDS

DESCRIPTION..........................7

REMOVAL.............................7INSTALLATION..........................8

MUFFLER

REMOVAL.............................8

INSTALLATION..........................8

MUFFLER - 5.9L DIESEL

REMOVAL.............................9

INSTALLATION..........................9

TAILPIPE - 5.9L DIESEL

REMOVAL.............................9

INSPECTION...........................9

INSTALLATION..........................9

TAILPIPE

REMOVAL.............................10

INSPECTION..........................10

INSTALLATION.........................10

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING -

TURBOCHARGER BOOST PRESSURE.....10

TURBOCHARGER

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................13

CLEANING............................14

INSPECTION..........................14

INSTALLATION.........................14

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS..............15

REMOVAL.............................15

CLEANING............................16

INSPECTION..........................16

INSTALLATION.........................16

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.The federal gasoline engine exhaust system con-

sists of engine exhaust manifolds, exhaust pipes, cat-

alytic converter(s), extension pipe (if needed),

exhaust heat shields, muffler and exhaust tailpipe.

The California emission vehicles exhaust system

also contains the above components as well as mini

catalytic converters added to the exhaust pipe.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. Minimum

clearance between any exhaust component and the

body or frame is 25.4 mm (1.0 in.). If the system con-

tacts any body panel, it may amplify objectionable

noises from the engine or body.

DREXHAUST SYSTEM 11 - 1

Page 1657 of 2895

DESCRIPTION ± 5.9L DIESEL

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

The diesel engine exhaust system consists of an

engine exhaust manifold, turbocharger, exhaust pipe,resonator, extension pipe (if needed), muffler and

exhaust tailpipe.

California emission vehicales include a catalytic

converter.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. The

exhaust components should be kept a minimum of

25.4 mm (1.0 in.) away from the body and frame. If

the system contacts any body panel, it may amplify

objectionable noises from the engine or body.

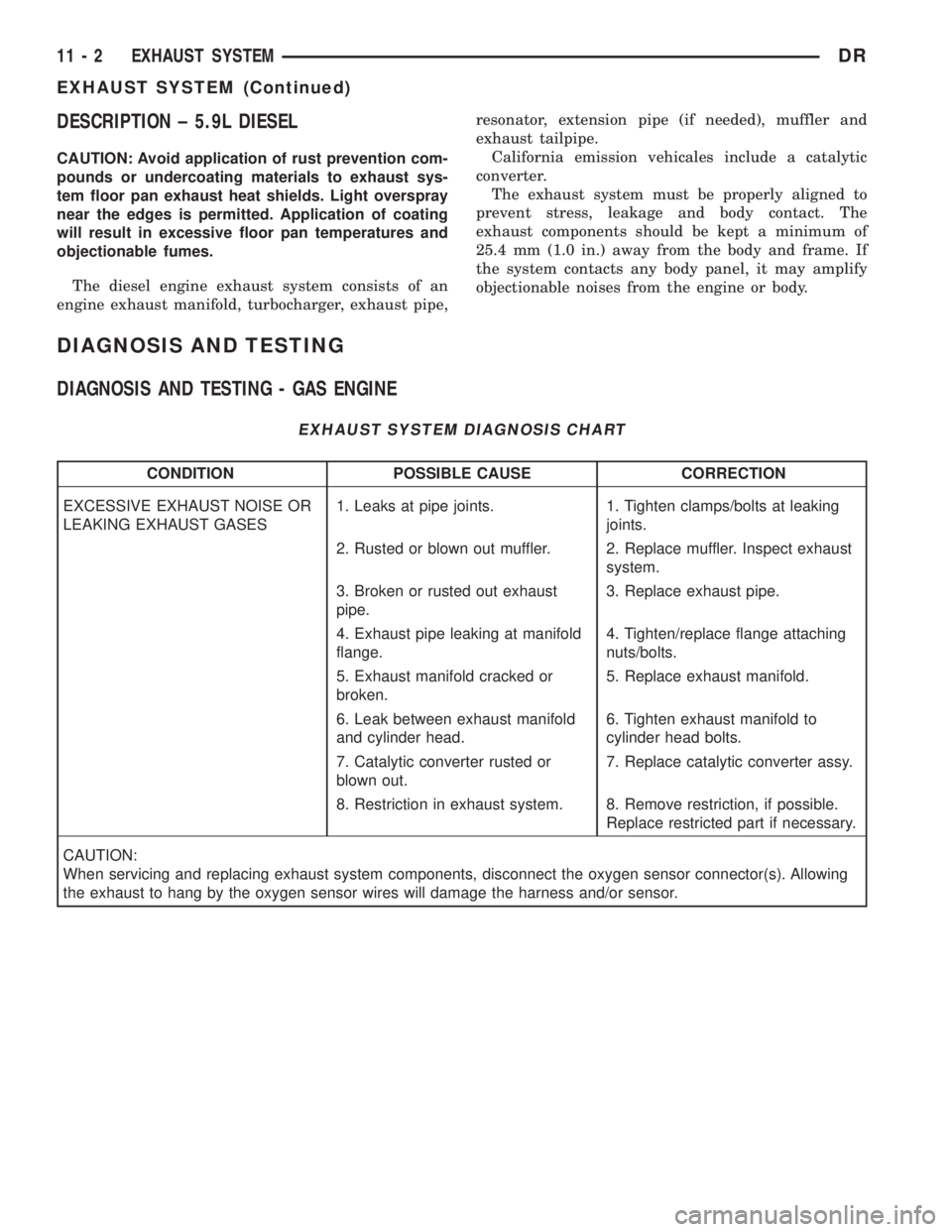

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking

joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts.

7. Catalytic converter rusted or

blown out.7. Replace catalytic converter assy.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

CAUTION:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

11 - 2 EXHAUST SYSTEMDR

EXHAUST SYSTEM (Continued)

Page 1671 of 2895

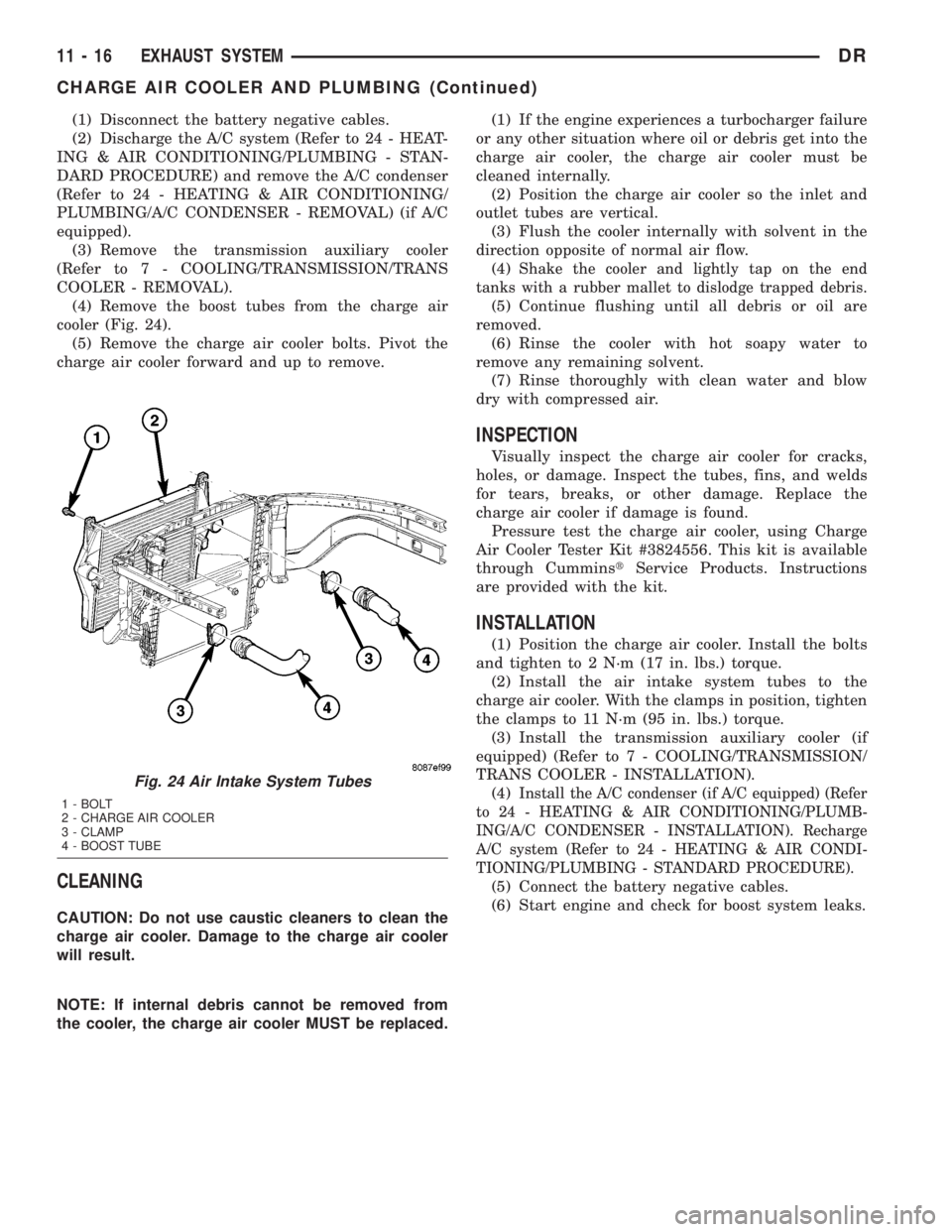

(1) Disconnect the battery negative cables.

(2) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

(3) Remove the transmission auxiliary cooler

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

(4) Remove the boost tubes from the charge air

cooler (Fig. 24).

(5) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4)

Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4)

Install the A/C condenser (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - INSTALLATION). Recharge

A/C system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(5) Connect the battery negative cables.

(6) Start engine and check for boost system leaks.

Fig. 24 Air Intake System Tubes

1 - BOLT

2 - CHARGE AIR COOLER

3 - CLAMP

4 - BOOST TUBE

11 - 16 EXHAUST SYSTEMDR

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1672 of 2895

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................3

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................4

INSTALLATION..........................4

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................12

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............15SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 17

SPECIFICATIONS - TORQUE............23

FRONT CROSSMEMBER

REMOVAL.............................23

INSTALLATION.........................23

FRONT SKID PLATE

REMOVAL.............................24

INSTALLATION.........................24

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................25

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................26

INSTALLATION.........................26

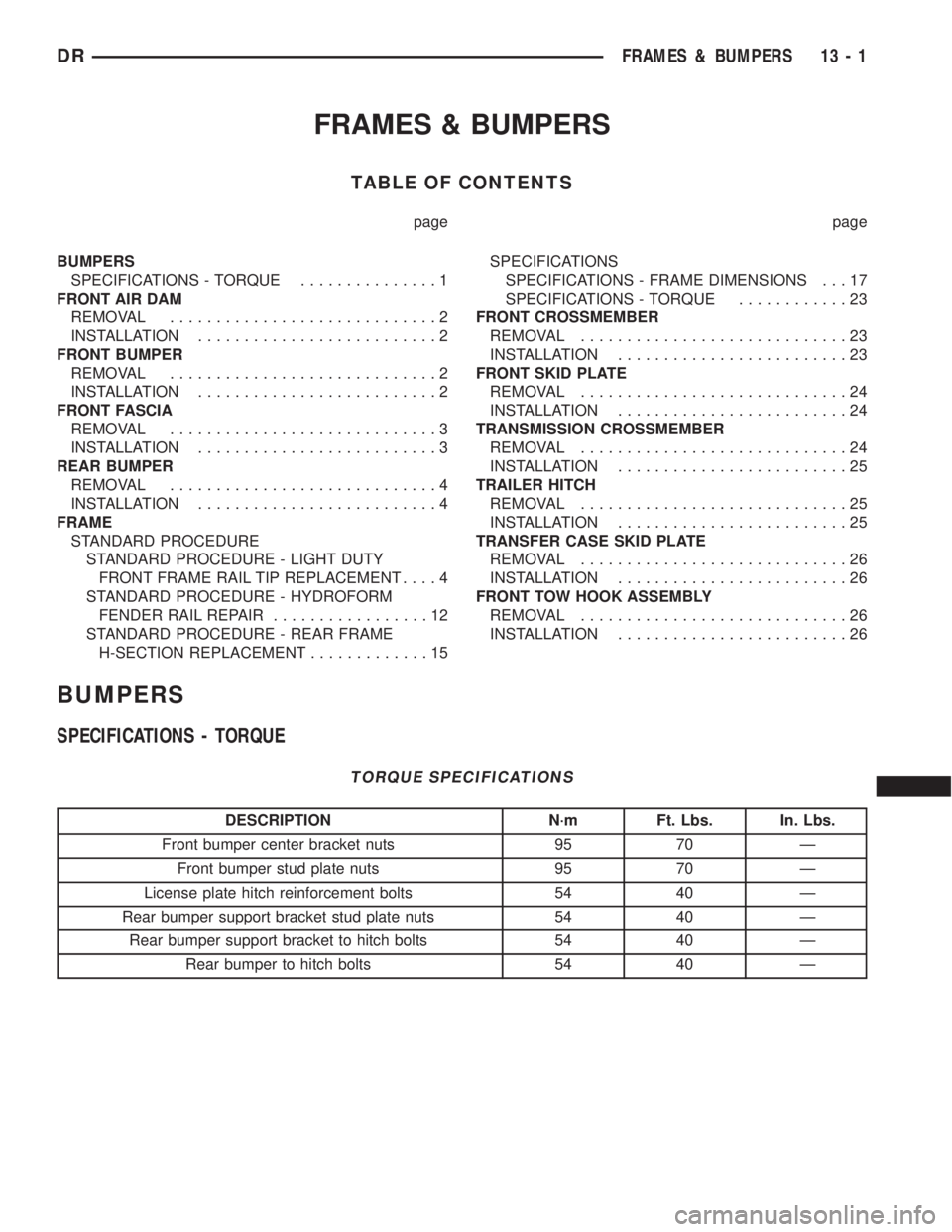

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1