light DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1731 of 2895

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IACstepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

3.7L V-6

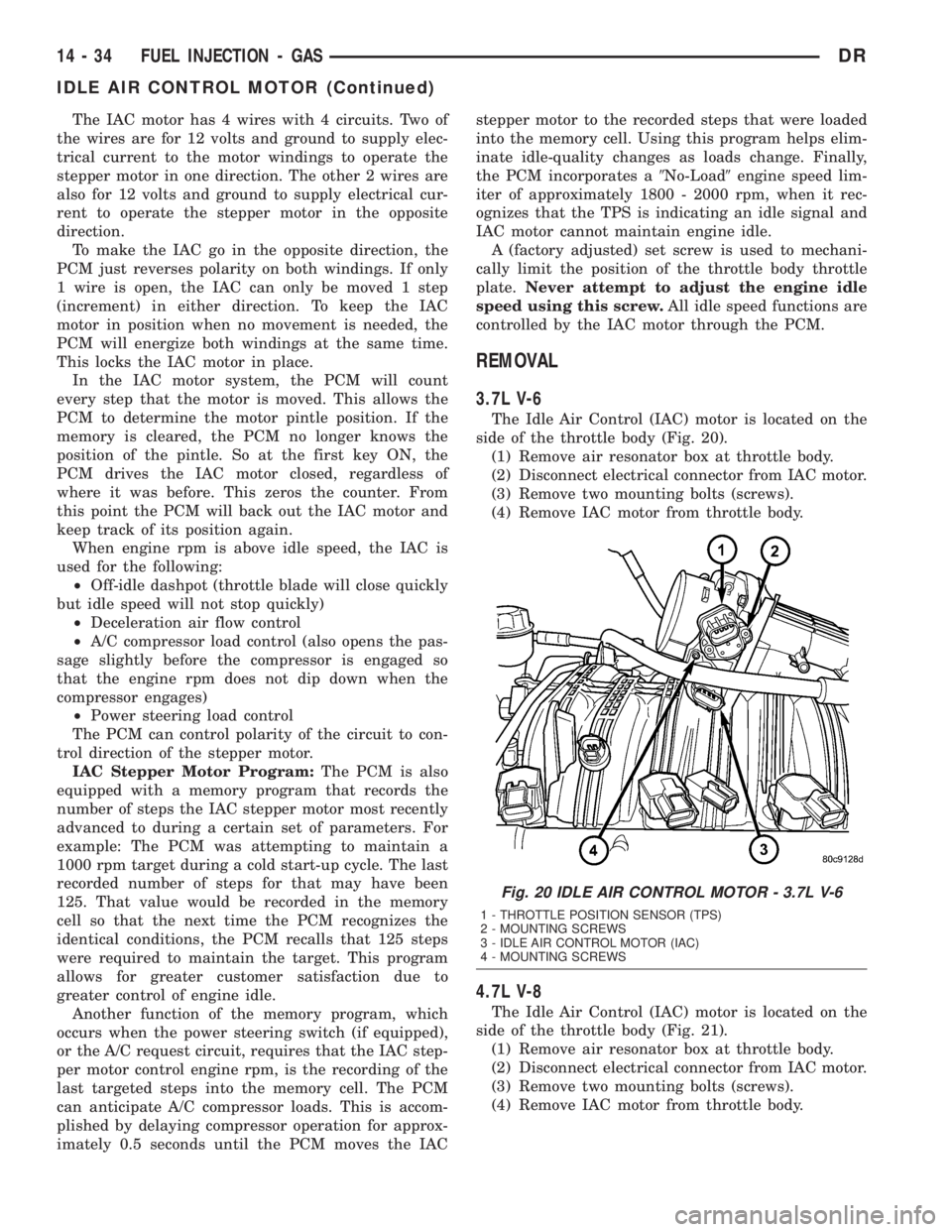

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 20).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 21).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

Fig. 20 IDLE AIR CONTROL MOTOR - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

14 - 34 FUEL INJECTION - GASDR

IDLE AIR CONTROL MOTOR (Continued)

Page 1751 of 2895

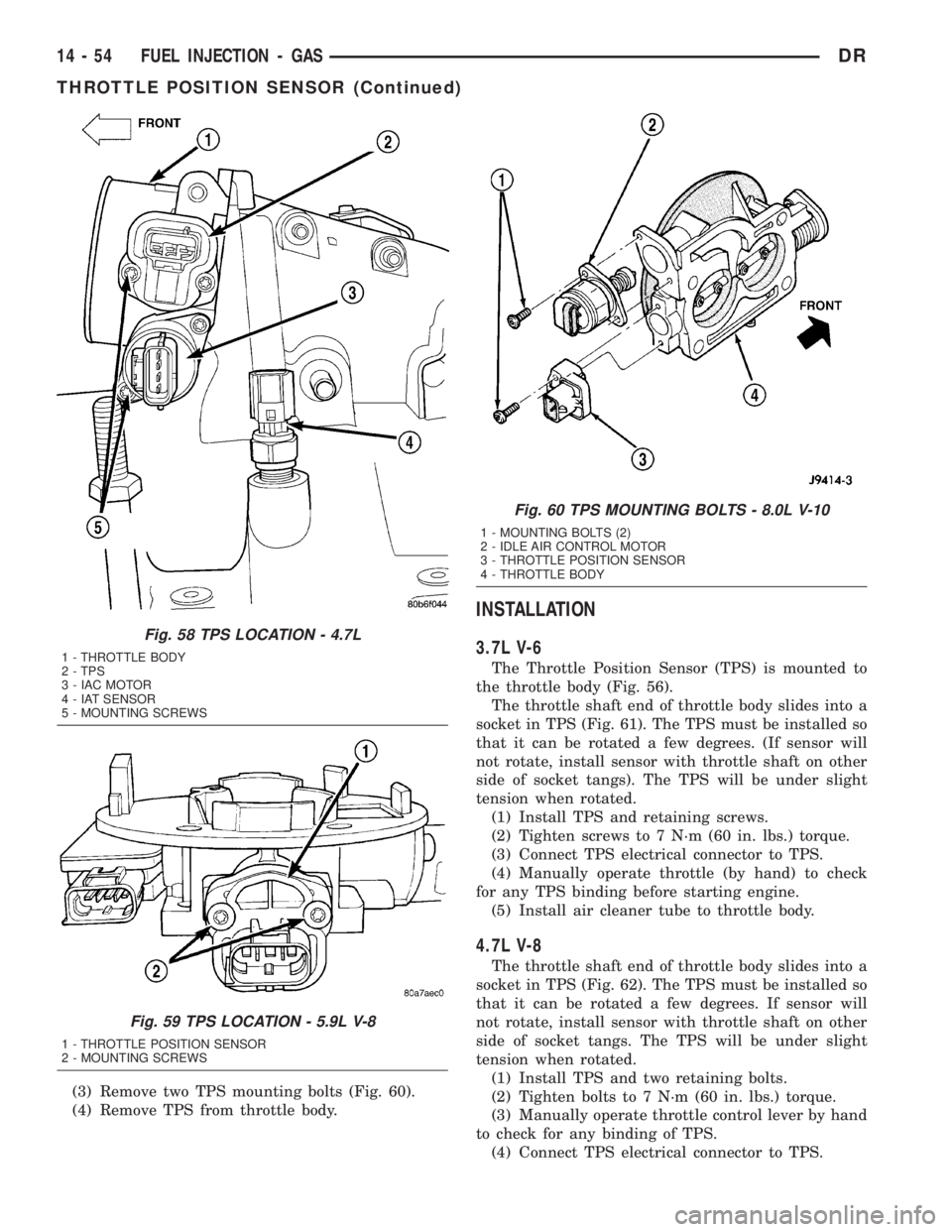

(3) Remove two TPS mounting bolts (Fig. 60).

(4) Remove TPS from throttle body.

INSTALLATION

3.7L V-6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 56).

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 61). The TPS must be installed so

that it can be rotated a few degrees. (If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs). The TPS will be under slight

tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

4.7L V-8

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 62). The TPS must be installed so

that it can be rotated a few degrees. If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs. The TPS will be under slight

tension when rotated.

(1) Install TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate throttle control lever by hand

to check for any binding of TPS.

(4) Connect TPS electrical connector to TPS.

Fig. 58 TPS LOCATION - 4.7L

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

Fig. 59 TPS LOCATION - 5.9L V-8

1 - THROTTLE POSITION SENSOR

2 - MOUNTING SCREWS

Fig. 60 TPS MOUNTING BOLTS - 8.0L V-10

1 - MOUNTING BOLTS (2)

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

14 - 54 FUEL INJECTION - GASDR

THROTTLE POSITION SENSOR (Continued)

Page 1752 of 2895

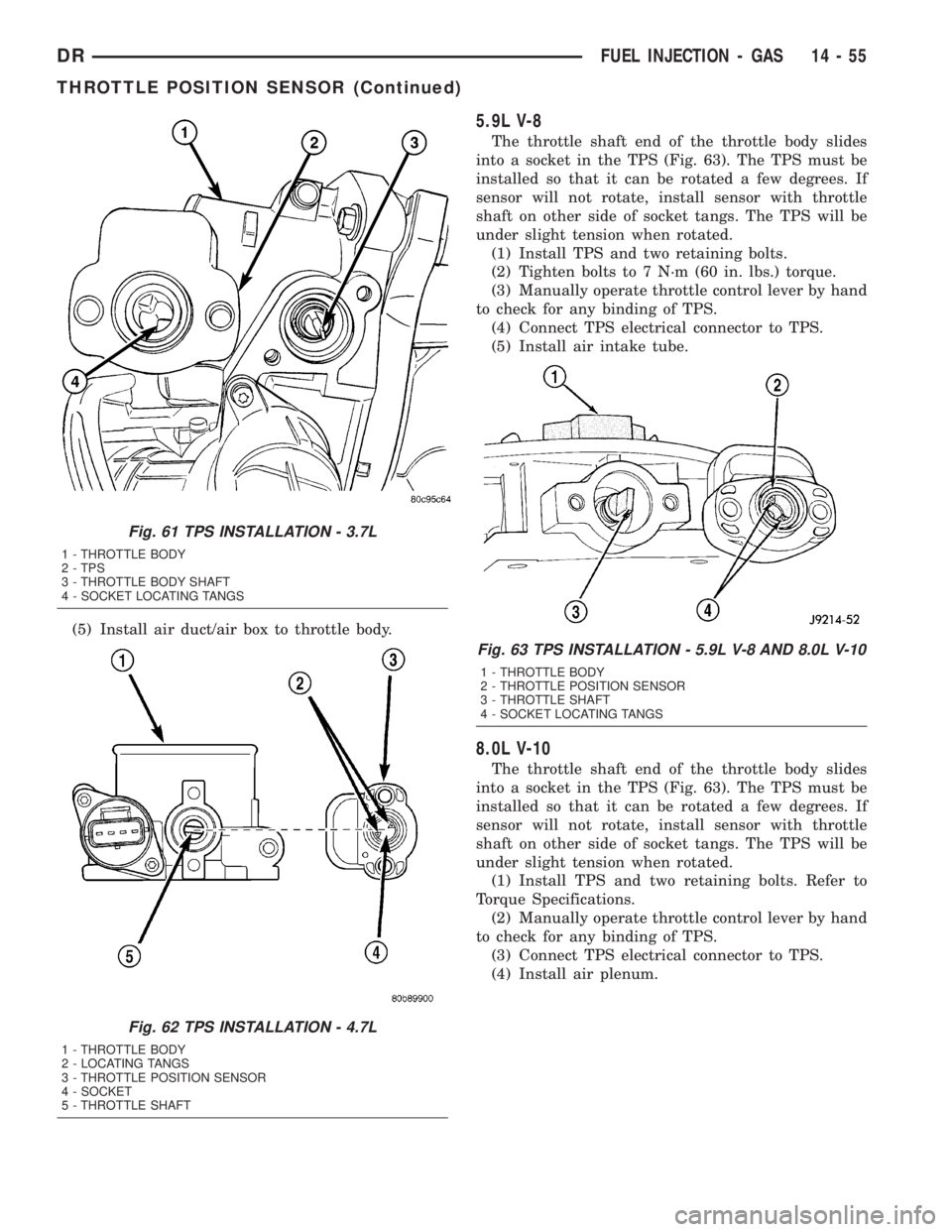

(5) Install air duct/air box to throttle body.

5.9L V-8

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 63). The TPS must be

installed so that it can be rotated a few degrees. If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs. The TPS will be

under slight tension when rotated.

(1) Install TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate throttle control lever by hand

to check for any binding of TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air intake tube.

8.0L V-10

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 63). The TPS must be

installed so that it can be rotated a few degrees. If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs. The TPS will be

under slight tension when rotated.

(1) Install TPS and two retaining bolts. Refer to

Torque Specifications.

(2) Manually operate throttle control lever by hand

to check for any binding of TPS.

(3) Connect TPS electrical connector to TPS.

(4) Install air plenum.

Fig. 61 TPS INSTALLATION - 3.7L

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

Fig. 62 TPS INSTALLATION - 4.7L

1 - THROTTLE BODY

2 - LOCATING TANGS

3 - THROTTLE POSITION SENSOR

4 - SOCKET

5 - THROTTLE SHAFT

Fig. 63 TPS INSTALLATION - 5.9L V-8 AND 8.0L V-10

1 - THROTTLE BODY

2 - THROTTLE POSITION SENSOR

3 - THROTTLE SHAFT

4 - SOCKET LOCATING TANGS

DRFUEL INJECTION - GAS 14 - 55

THROTTLE POSITION SENSOR (Continued)

Page 1760 of 2895

(c) Position new element to canister lid. Place

this assembly into canister by rotating clockwise.

(d) Tighten cap to 34 N´m (25 ft. lbs.) torque. Do

not overtighten cap.

(3)Water-In-Fuel (WIF) Sensor:

(a) Install new o-ring seal to WIF sensor.

(b) Apply a light film of clean diesel oil to o-ring

seal.

(c) Install sensor into housing.

(d) Tighten sensor to 4.5 N´m (39 in. lbs.) torque.

(e) Connect electrical connector to WIF sensor.

(4)Fuel Heater Element:

(a) Install fuel heater into fuel filter housing.

(b) Install fuel heater thermostat into fuel filter

housing.

(c) Install fuel heater mounting screws and

tighten to 1-1.5 N´m torque.

(d) Connect electrical connector to fuel heater

thermostat.

(e) Install new filter cover O-ring onto fuel filter

housing cover and lubricate with 30W oil.

(f) Tighten fuel filter housing cover (lid) to 34

N´m (25 ft. lbs.).

(5)Drain Valve:

(a) Install 2 new o-rings to valve and filter hous-

ing.

(b) Lubricate with silicon grease.

(c) Install fuel drain valve.

(d) Install 4 mounting screws and tighten to

1±1.5 N´m (8±13 in. lbs.) torque.

(e) Connect drain hose to drain valve.

(6) Start engine and check for leaks.

FUEL HEATER

DESCRIPTION

The fuel heater assembly is located on the side of

the fuel filter housing (Fig. 3) or (Fig. 4).

The heater/element assembly is equipped with a

temperature sensor (thermostat) that senses fuel

temperature. This sensor is attached to the fuel heat-

er/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

When the temperature is below 45 8 degrees F,

the temperature sensor allows current to flow to the

heater element warming the fuel. When the temper-

ature is above 75 8 degrees F, the sensor stops cur-

rent flow to the heater element.

Battery voltage to operate the fuel heater element

is supplied from the ignition switch and through the

fuel heater relay. Also refer to Fuel Heater Relay.The fuel heater element and fuel heater relay

are not computer controlled.

The heater element operates on 12 volts, 300 watts

at 0 degrees F.

DIAGNOSIS AND TESTING - FUEL HEATER

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

NOTE: The fuel heater element, fuel heater relay

and fuel heater temperature sensor are not con-

trolled by the Engine Control Module (ECM), or the

Powertrain Control Module (PCM).

A malfunctioning fuel heater can cause a wax

build-up in the fuel filter/water separator. Wax

build-up in the filter/separator can cause engine

starting problems and prevent the engine from rev-

ving up. It can also cause blue or white fog-like

exhaust. If the heater is not operating in cold tem-

peratures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of

fuel filter housing.

The heater assembly is equipped with a built-in

fuel temperature sensor (thermostat) that senses fuel

temperature. When fuel temperature drops below 45

degrees 8 degrees F, the sensor allows current to

flow to built-in heater element to warm fuel. When

fuel temperature rises above 75 degrees 8 degrees

F, the sensor stops current flow to heater element

(circuit is open).

Voltage to operate fuel heater element is supplied

from ignition switch, through fuel heater relay (also

refer to Fuel Heater Relay), to fuel temperature sen-

sor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts

at 0 degrees F. As temperature increases, power

requirements decrease.

A minimum of 7 volts is required to operate fuel

heater. The resistance value of heater element is less

than 1 ohm (cold) and up to 1000 ohms warm.

TESTING

(1) Disconnect electrical connector from thermostat

(Fig. 3) or (Fig. 4).

Ambient temperature must be below circuit close

temperature, If necessary, induce this ambient tem-

perature by placing ice packs on thermostat to pro-

duce an effective ambient temperature below circuit

close temperature. For first check of thermostat you

can hear click of thermostat when circuit closes.

Measure resistance across two pins. Operating

range is 0.3 Ð 0.45 Ohms.

(2) If resistance is out of range, remove thermostat

and check resistance across terminal connections of

DRFUEL DELIVERY - DIESEL 14 - 63

FUEL FILTER / WATER SEPARATOR (Continued)

Page 1765 of 2895

(4) Apply clean engine oilto injection pump

o-ring only.

The machined tapers on both injection pump

shaft and injection pump gear must be abso-

lutely dry, clean and free of any dirt or oil film.

This will ensure proper gear-to-shaft tighten-

ing.

(5) Clean pump gear and pump shaft at machined

tapers with an evaporative type cleaner such as

brake cleaner.

(6) Position injection pump to mounting flange on

gear cover while aligning injection pump shaft

through back of injection pump gear.

(7) After pump is positioned flat to mounting

flange, install 3 pump mounting nuts and tighten

finger tight only.Do not attempt a final tightening

at this time.Do not attempt to tighten (pull)

pump to gear cover using mounting nuts. Dam-

age to pump or gear cover may occur. The

pump must be positioned flat to its mounting

flange before attempting to tighten 3 mounting

nuts.

(8) To prevent damage or cracking of components,

install and tighten nuts in the following sequence:

(a) Install injection pump shaft washer and nut

to pump shaft. Tighten nutfinger tight only.

(b) Do preliminary (light) tightening of injection

pump shaft nut.

(c) Tighten 3 injection pump mounting nuts to 8

N´m (70.8 in. lbs.).

(d) Do a final tightening of pump shaft nut to

105 N´m (77 ft. lbs.).

(9) Install drive gear access cover (plate) using a

1/2 inch drive ratchet. Plate is threaded to timing

gear cover.

(10) Install Engine Control Module (ECM) to left

side of engine.

(11) Install fuel line (injection pump-to-overflow

valve). Tighten bolts to 24 N´m (17 ft. lbs.) torque.

(12) Install fuel line (injection pump-to-fuel rail).

Tighten to 24 N´m (17 ft. lbs.) torque.

(13) Install fuel line (injection pump-to-fuel filter

housing). Tighten to 24 N´m (17 ft. lbs.) torque.

(14) Connect Fuel Control Actuator (FCA) electri-

cal connector to rear of injection pump.

(15) Install intake manifold air intake tube (above

injection pump). Tighten clamps.

(16) Install accessory drive belt.

(17) Install cooling fan shroud.

(18) Install cooling fan assembly.

(19) Connect both negative battery cables to both

batteries.

(20) Check system for fuel or engine oil leaks.FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel tank module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel tank module on diesel powered models

has 3 different circuits (wires). Two of these circuits

are used at the fuel gauge sending unit for fuel

gauge operation. The other wire is used for a ground.

The diesel engine does not have a fuel tank module

mounted electric fuel pump. The electric fuel pump

(fuel transfer pump) is mounted to the engine.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-

fied with the circuit opened (fuel tank module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about .6 volts at FULL, to about 7.0 volts at

EMPTY.The resistor track is used to vary the volt-

age (resistance) depending on fuel tank float level. As

fuel level increases, the float and arm move up,

which decreases voltage. As fuel level decreases, the

float and arm move down, which increases voltage.

The varied voltage signal is returned back to the

ECM through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the ECM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the ECM, the ECM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

REMOVAL

REMOVAL/INSTALLATION

For diesel removal and installation procedures,

refer to the gas section of Fuel System/Fuel Delivery.

See Fuel Level Sending Unit/Sensor Removal/Instal-

lation.

14 - 68 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1780 of 2895

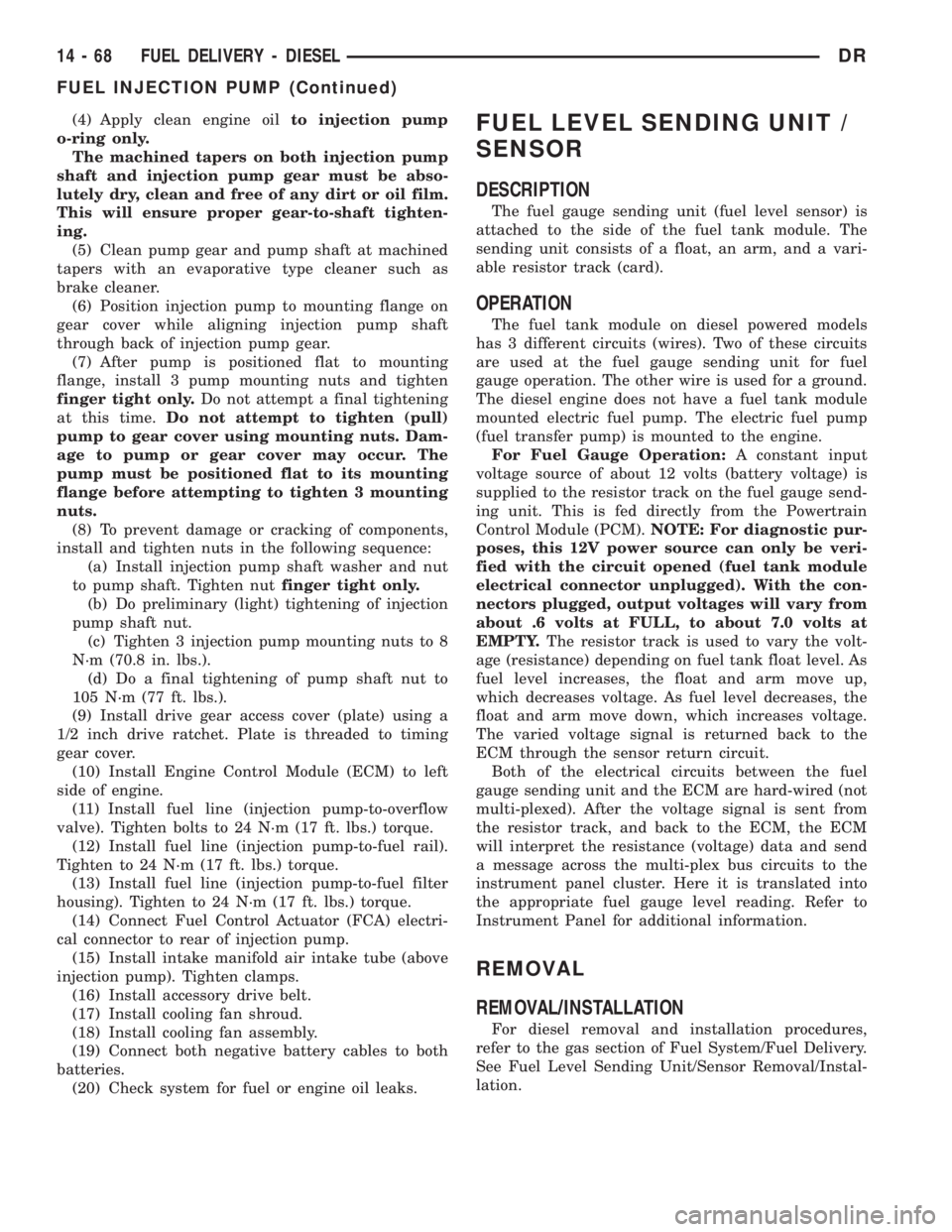

The CMP (Fig. 8) provides a signal to the Engine

Control Module (ECM) at all times when the engine

is running. The ECM uses the CMP information pri-

marily on engine start-up. Once the engine is run-

ning, the ECM uses the CMP as a backup sensor for

engine speed. The Crankshaft Position Sensor (CKP)

is the primary engine speed indicator for the engine

after the engine is running.

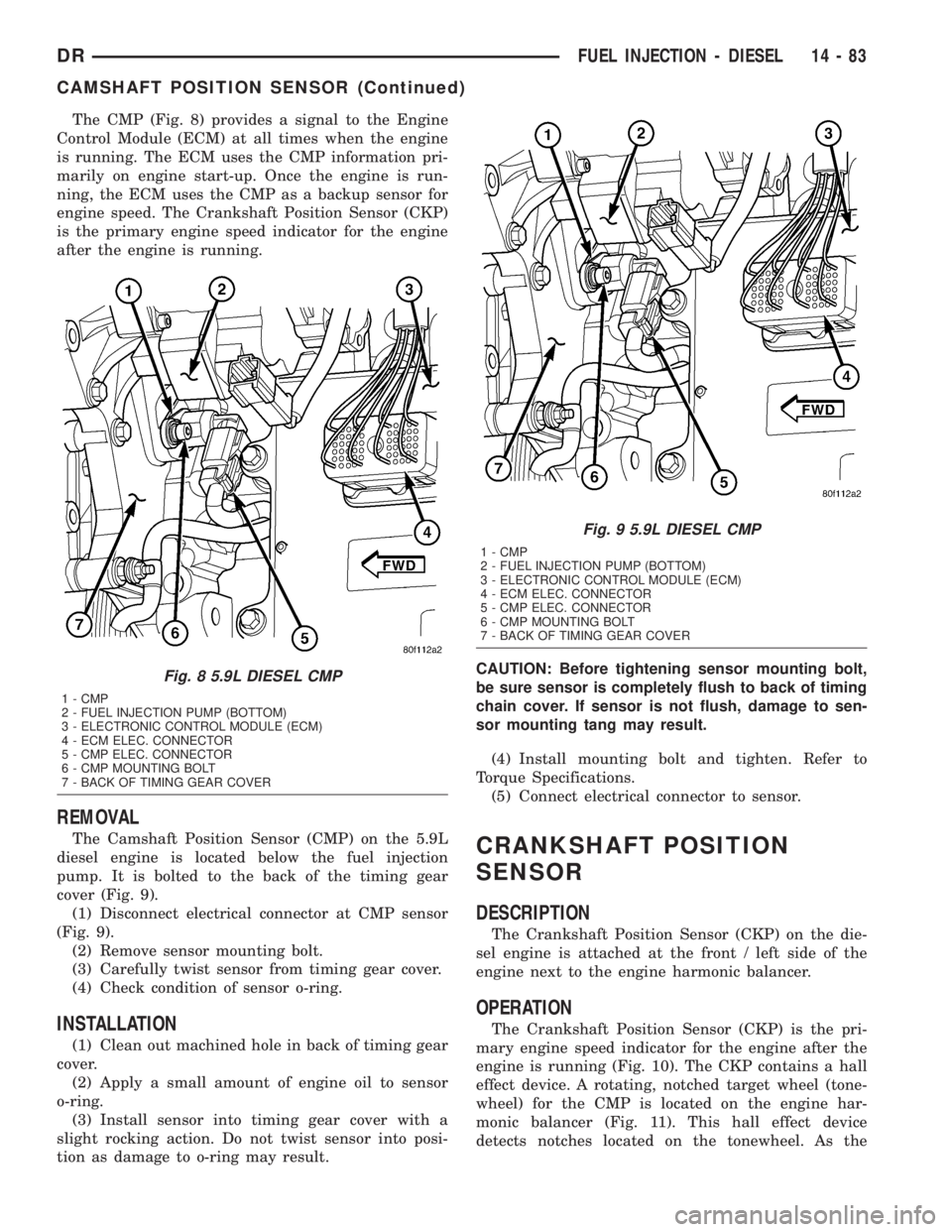

REMOVAL

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

cover (Fig. 9).

(1) Disconnect electrical connector at CMP sensor

(Fig. 9).

(2) Remove sensor mounting bolt.

(3) Carefully twist sensor from timing gear cover.

(4) Check condition of sensor o-ring.

INSTALLATION

(1) Clean out machined hole in back of timing gear

cover.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into timing gear cover with a

slight rocking action. Do not twist sensor into posi-

tion as damage to o-ring may result.CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to back of timing

chain cover. If sensor is not flush, damage to sen-

sor mounting tang may result.

(4) Install mounting bolt and tighten. Refer to

Torque Specifications.

(5) Connect electrical connector to sensor.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

The Crankshaft Position Sensor (CKP) on the die-

sel engine is attached at the front / left side of the

engine next to the engine harmonic balancer.

OPERATION

The Crankshaft Position Sensor (CKP) is the pri-

mary engine speed indicator for the engine after the

engine is running (Fig. 10). The CKP contains a hall

effect device. A rotating, notched target wheel (tone-

wheel) for the CMP is located on the engine har-

monic balancer (Fig. 11). This hall effect device

detects notches located on the tonewheel. As the

Fig. 8 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR COVER

Fig. 9 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR COVER

DRFUEL INJECTION - DIESEL 14 - 83

CAMSHAFT POSITION SENSOR (Continued)

Page 1782 of 2895

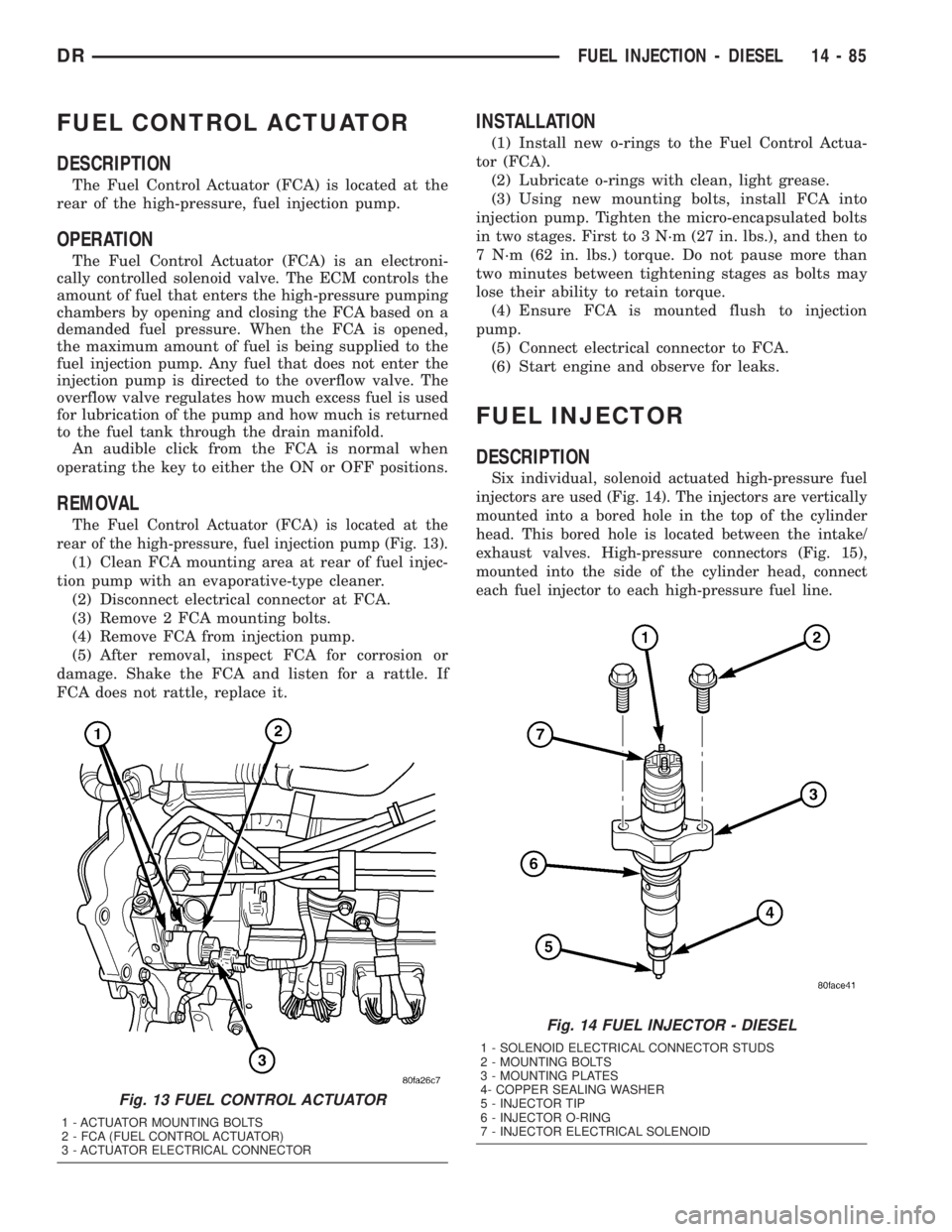

FUEL CONTROL ACTUATOR

DESCRIPTION

The Fuel Control Actuator (FCA) is located at the

rear of the high-pressure, fuel injection pump.

OPERATION

The Fuel Control Actuator (FCA) is an electroni-

cally controlled solenoid valve. The ECM controls the

amount of fuel that enters the high-pressure pumping

chambers by opening and closing the FCA based on a

demanded fuel pressure. When the FCA is opened,

the maximum amount of fuel is being supplied to the

fuel injection pump. Any fuel that does not enter the

injection pump is directed to the overflow valve. The

overflow valve regulates how much excess fuel is used

for lubrication of the pump and how much is returned

to the fuel tank through the drain manifold.

An audible click from the FCA is normal when

operating the key to either the ON or OFF positions.

REMOVAL

The Fuel Control Actuator (FCA) is located at the

rear of the high-pressure, fuel injection pump (Fig. 13).

(1) Clean FCA mounting area at rear of fuel injec-

tion pump with an evaporative-type cleaner.

(2) Disconnect electrical connector at FCA.

(3) Remove 2 FCA mounting bolts.

(4) Remove FCA from injection pump.

(5) After removal, inspect FCA for corrosion or

damage. Shake the FCA and listen for a rattle. If

FCA does not rattle, replace it.

INSTALLATION

(1) Install new o-rings to the Fuel Control Actua-

tor (FCA).

(2) Lubricate o-rings with clean, light grease.

(3) Using new mounting bolts, install FCA into

injection pump. Tighten the micro-encapsulated bolts

in two stages. First to 3 N´m (27 in. lbs.), and then to

7 N´m (62 in. lbs.) torque. Do not pause more than

two minutes between tightening stages as bolts may

lose their ability to retain torque.

(4) Ensure FCA is mounted flush to injection

pump.

(5) Connect electrical connector to FCA.

(6) Start engine and observe for leaks.

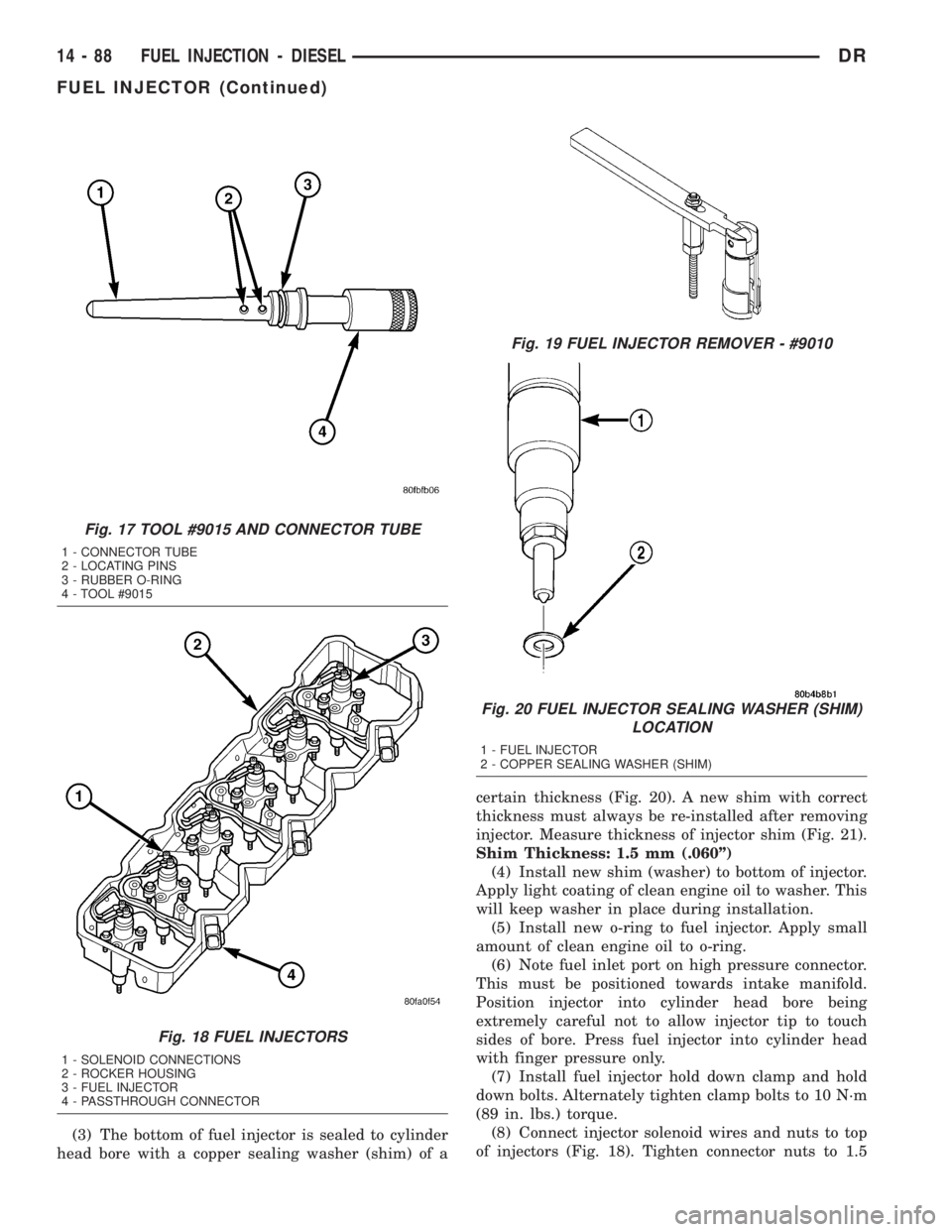

FUEL INJECTOR

DESCRIPTION

Six individual, solenoid actuated high-pressure fuel

injectors are used (Fig. 14). The injectors are vertically

mounted into a bored hole in the top of the cylinder

head. This bored hole is located between the intake/

exhaust valves. High-pressure connectors (Fig. 15),

mounted into the side of the cylinder head, connect

each fuel injector to each high-pressure fuel line.

Fig. 13 FUEL CONTROL ACTUATOR

1 - ACTUATOR MOUNTING BOLTS

2 - FCA (FUEL CONTROL ACTUATOR)

3 - ACTUATOR ELECTRICAL CONNECTOR

Fig. 14 FUEL INJECTOR - DIESEL

1 - SOLENOID ELECTRICAL CONNECTOR STUDS

2 - MOUNTING BOLTS

3 - MOUNTING PLATES

4- COPPER SEALING WASHER

5 - INJECTOR TIP

6 - INJECTOR O-RING

7 - INJECTOR ELECTRICAL SOLENOID

DRFUEL INJECTION - DIESEL 14 - 85

Page 1785 of 2895

(3) The bottom of fuel injector is sealed to cylinder

head bore with a copper sealing washer (shim) of acertain thickness (Fig. 20). A new shim with correct

thickness must always be re-installed after removing

injector. Measure thickness of injector shim (Fig. 21).

Shim Thickness: 1.5 mm (.060º)

(4) Install new shim (washer) to bottom of injector.

Apply light coating of clean engine oil to washer. This

will keep washer in place during installation.

(5) Install new o-ring to fuel injector. Apply small

amount of clean engine oil to o-ring.

(6) Note fuel inlet port on high pressure connector.

This must be positioned towards intake manifold.

Position injector into cylinder head bore being

extremely careful not to allow injector tip to touch

sides of bore. Press fuel injector into cylinder head

with finger pressure only.

(7) Install fuel injector hold down clamp and hold

down bolts. Alternately tighten clamp bolts to 10 N´m

(89 in. lbs.) torque.

(8) Connect injector solenoid wires and nuts to top

of injectors (Fig. 18). Tighten connector nuts to 1.5

Fig. 17 TOOL #9015 AND CONNECTOR TUBE

1 - CONNECTOR TUBE

2 - LOCATING PINS

3 - RUBBER O-RING

4 - TOOL #9015

Fig. 18 FUEL INJECTORS

1 - SOLENOID CONNECTIONS

2 - ROCKER HOUSING

3 - FUEL INJECTOR

4 - PASSTHROUGH CONNECTOR

Fig. 19 FUEL INJECTOR REMOVER - #9010

Fig. 20 FUEL INJECTOR SEALING WASHER (SHIM)

LOCATION

1 - FUEL INJECTOR

2 - COPPER SEALING WASHER (SHIM)

14 - 88 FUEL INJECTION - DIESELDR

FUEL INJECTOR (Continued)

Page 1787 of 2895

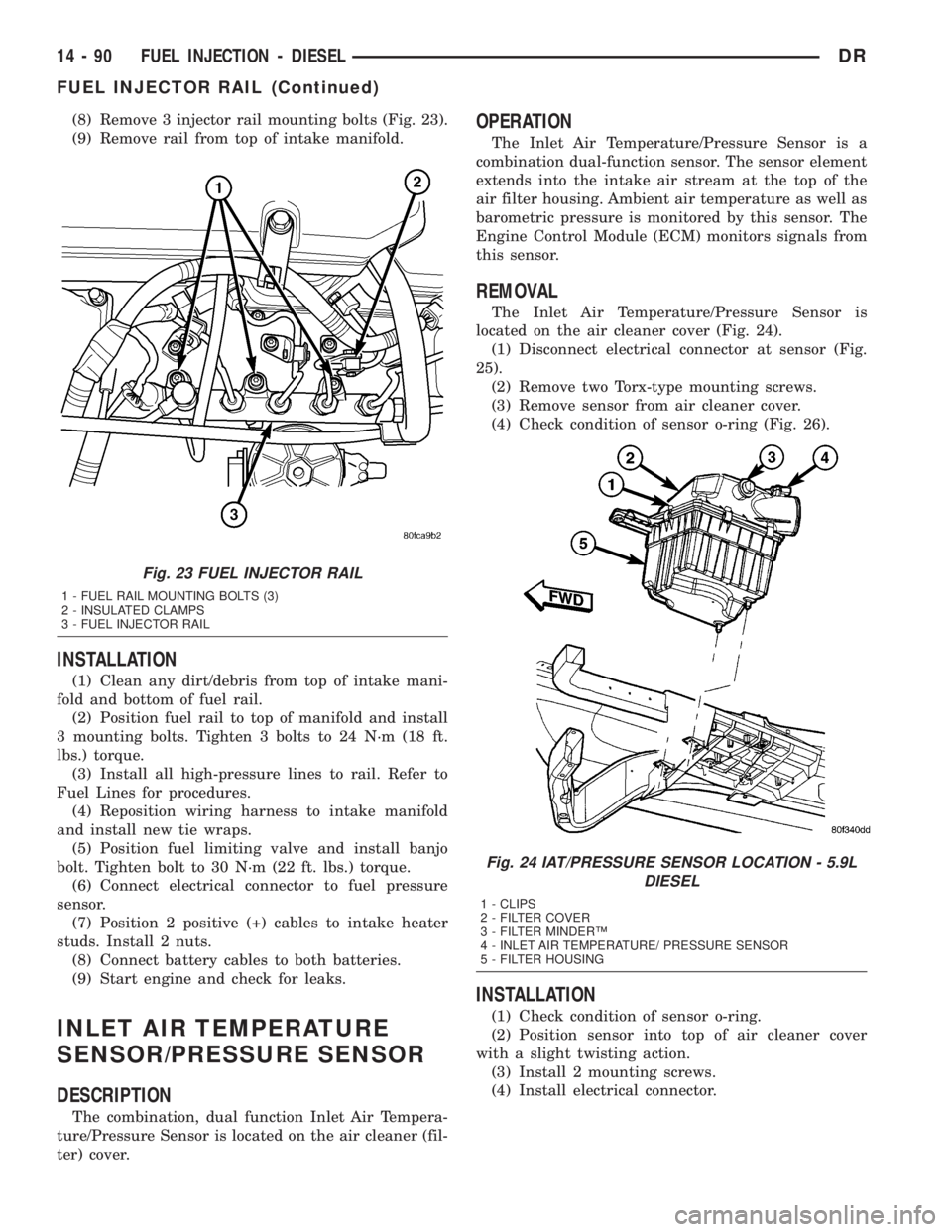

(8) Remove 3 injector rail mounting bolts (Fig. 23).

(9) Remove rail from top of intake manifold.

INSTALLATION

(1) Clean any dirt/debris from top of intake mani-

fold and bottom of fuel rail.

(2) Position fuel rail to top of manifold and install

3 mounting bolts. Tighten 3 bolts to 24 N´m (18 ft.

lbs.) torque.

(3) Install all high-pressure lines to rail. Refer to

Fuel Lines for procedures.

(4) Reposition wiring harness to intake manifold

and install new tie wraps.

(5) Position fuel limiting valve and install banjo

bolt. Tighten bolt to 30 N´m (22 ft. lbs.) torque.

(6) Connect electrical connector to fuel pressure

sensor.

(7) Position 2 positive (+) cables to intake heater

studs. Install 2 nuts.

(8) Connect battery cables to both batteries.

(9) Start engine and check for leaks.

INLET AIR TEMPERATURE

SENSOR/PRESSURE SENSOR

DESCRIPTION

The combination, dual function Inlet Air Tempera-

ture/Pressure Sensor is located on the air cleaner (fil-

ter) cover.

OPERATION

The Inlet Air Temperature/Pressure Sensor is a

combination dual-function sensor. The sensor element

extends into the intake air stream at the top of the

air filter housing. Ambient air temperature as well as

barometric pressure is monitored by this sensor. The

Engine Control Module (ECM) monitors signals from

this sensor.

REMOVAL

The Inlet Air Temperature/Pressure Sensor is

located on the air cleaner cover (Fig. 24).

(1) Disconnect electrical connector at sensor (Fig.

25).

(2) Remove two Torx-type mounting screws.

(3) Remove sensor from air cleaner cover.

(4) Check condition of sensor o-ring (Fig. 26).

INSTALLATION

(1) Check condition of sensor o-ring.

(2) Position sensor into top of air cleaner cover

with a slight twisting action.

(3) Install 2 mounting screws.

(4) Install electrical connector.

Fig. 23 FUEL INJECTOR RAIL

1 - FUEL RAIL MOUNTING BOLTS (3)

2 - INSULATED CLAMPS

3 - FUEL INJECTOR RAIL

Fig. 24 IAT/PRESSURE SENSOR LOCATION - 5.9L

DIESEL

1 - CLIPS

2 - FILTER COVER

3 - FILTER MINDERŸ

4 - INLET AIR TEMPERATURE/ PRESSURE SENSOR

5 - FILTER HOUSING

14 - 90 FUEL INJECTION - DIESELDR

FUEL INJECTOR RAIL (Continued)

Page 1801 of 2895

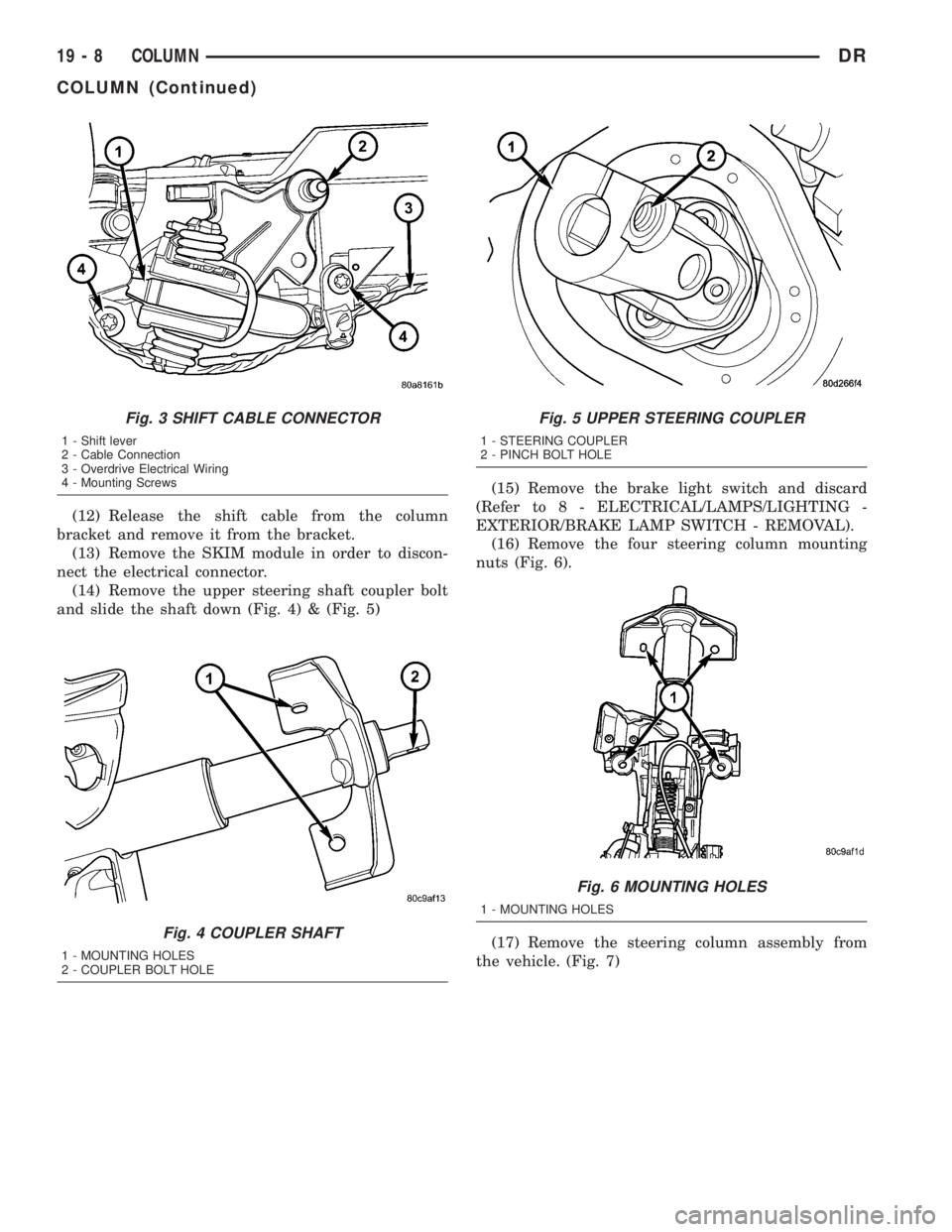

(12) Release the shift cable from the column

bracket and remove it from the bracket.

(13) Remove the SKIM module in order to discon-

nect the electrical connector.

(14) Remove the upper steering shaft coupler bolt

and slide the shaft down (Fig. 4) & (Fig. 5)(15) Remove the brake light switch and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

(16) Remove the four steering column mounting

nuts (Fig. 6).

(17) Remove the steering column assembly from

the vehicle. (Fig. 7)

Fig. 3 SHIFT CABLE CONNECTOR

1 - Shift lever

2 - Cable Connection

3 - Overdrive Electrical Wiring

4 - Mounting Screws

Fig. 4 COUPLER SHAFT

1 - MOUNTING HOLES

2 - COUPLER BOLT HOLE

Fig. 5 UPPER STEERING COUPLER

1 - STEERING COUPLER

2 - PINCH BOLT HOLE

Fig. 6 MOUNTING HOLES

1 - MOUNTING HOLES

19 - 8 COLUMNDR

COLUMN (Continued)