automatic transmission DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 440 of 2895

(4) Remove 1 bolt and 1 nut if equipped with a

manual transmission (Fig. 9).

(5) Remove 2 bolts if equipped with an automatic

transmission (Fig. 10).

(6) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process, do not let starter motor hang from wire har-

ness.

(7) Tilt nose downwards and lower starter motor

far enough to access and remove nut that secures

battery positive cable wire harness connector eyelet

to solenoid battery terminal stud. Do not let starter

motor hang from wire harness.

(8) Remove battery positive cable wire harness

connector eyelet from solenoid battery terminal stud.

(9) Disconnect battery positive cable wire harness

connector from solenoid terminal connector recepta-

cle.

(10) Remove starter motor.

5.7L Gas

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Note: If equipped with 4WD and certain trans-

missions, a support bracket is used between front

axle and side of transmission. Remove 2 support

bracket bolts at transmission. Pry support bracket

slightly to gain access to lower starter mounting bolt.

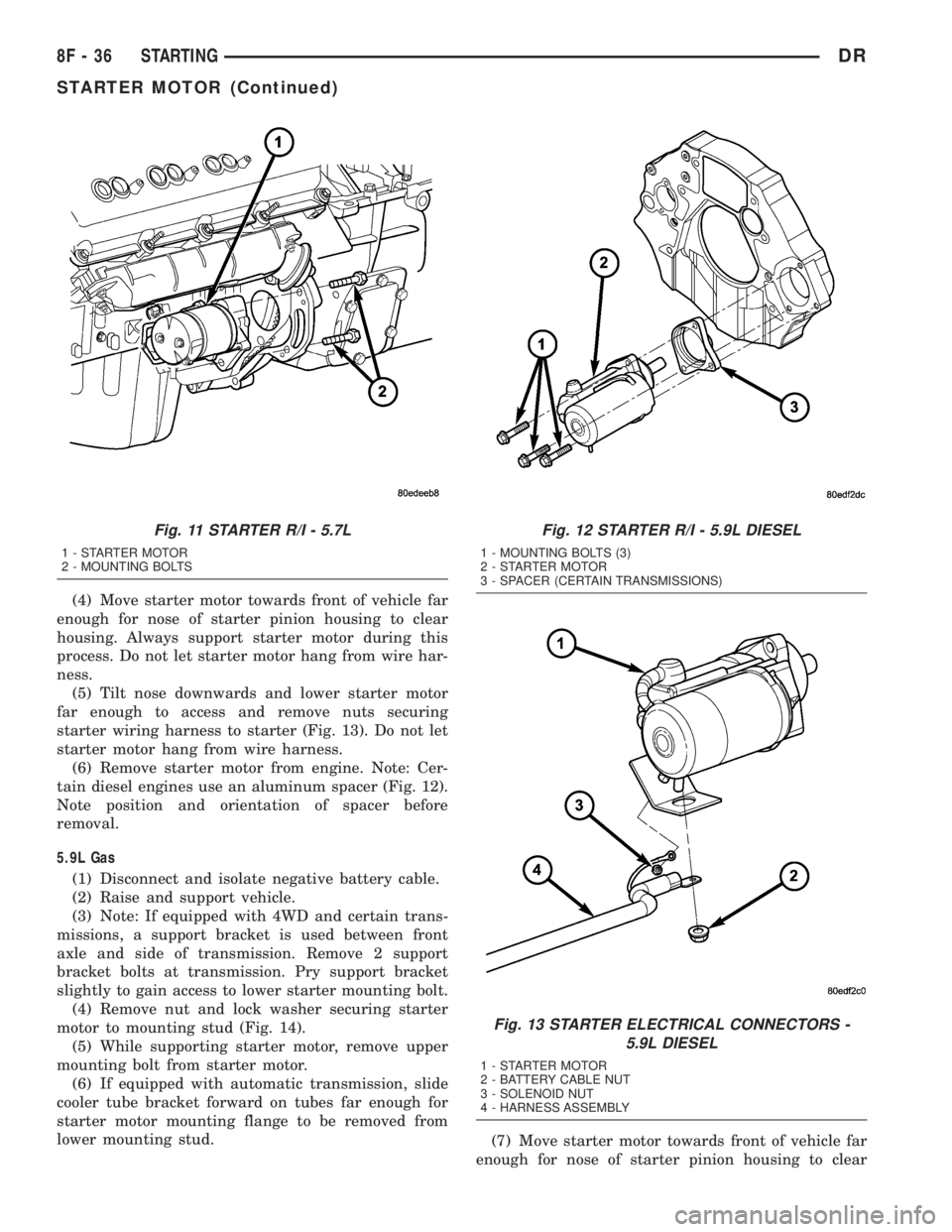

(4) Remove 2 mounting bolts (Fig. 11).

(5) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process, do not let starter motor hang from wire har-

ness.

(6) Tilt nose downwards and lower starter motor

far enough to access and remove nut that secures

battery positive cable wire harness connector eyelet

to solenoid battery terminal stud. Do not let starter

motor hang from wire harness.

(7) Remove battery positive cable wire harness

connector eyelet from solenoid battery terminal stud.(8) Disconnect battery positive cable wire harness

connector from solenoid terminal connector recepta-

cle.

(9) Remove starter motor.

5.9L Diesel

(1) Disconnect and isolate both negative battery

cables at both batteries.

(2) Raise and support vehicle.

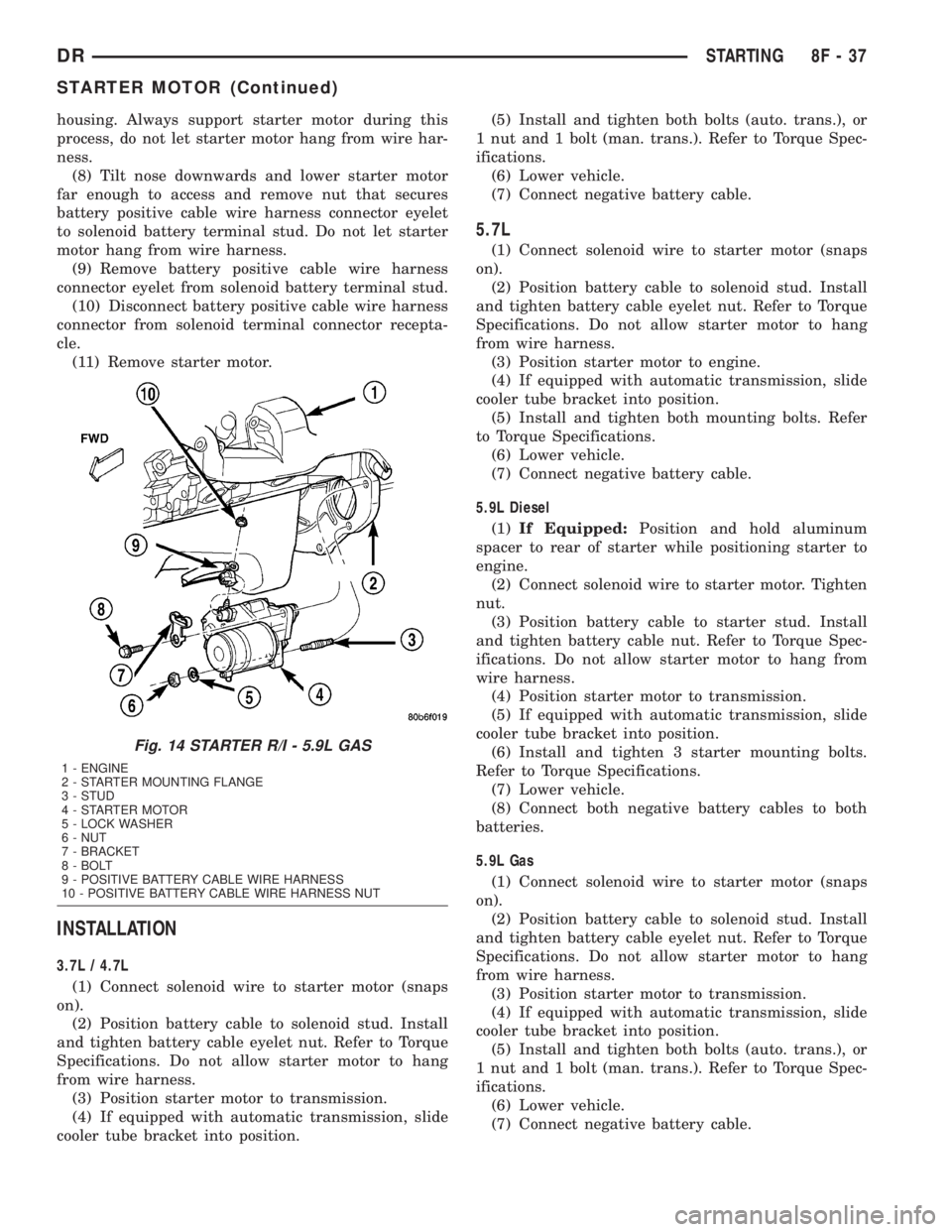

(3) Remove 3 starter mounting bolts (Fig. 12).

Fig. 8 CONTINUITY BETWEEN SOLENOID

TERMINAL AND CASE - TYPICAL

1 - SOLENOID TERMINAL

2 - OHMMETER

3 - SOLENOID

Fig. 9 STARTER R/I - 3.7L/4.7L - MAN. TRANS.

1 - EYELET TERMINAL

2 - NUT

3 - BRACKET

4 - STUD

5 - STARTER MOTOR

6 - LOCK WASHER

7 - WIRE HARNESS CONNECTOR

8 - NUT

9 - SCREW AND WASHER (2)

Fig. 10 STARTER R/I - 3.7L/4.7L - AUTO. TRANS.

1 - EYELET TERMINAL

2 - NUT

3 - SCREW AND WASHER (2)

4 - STARTER MOTOR

5 - WIRE HARNESS CONNECTOR

DRSTARTING 8F - 35

STARTER MOTOR (Continued)

Page 441 of 2895

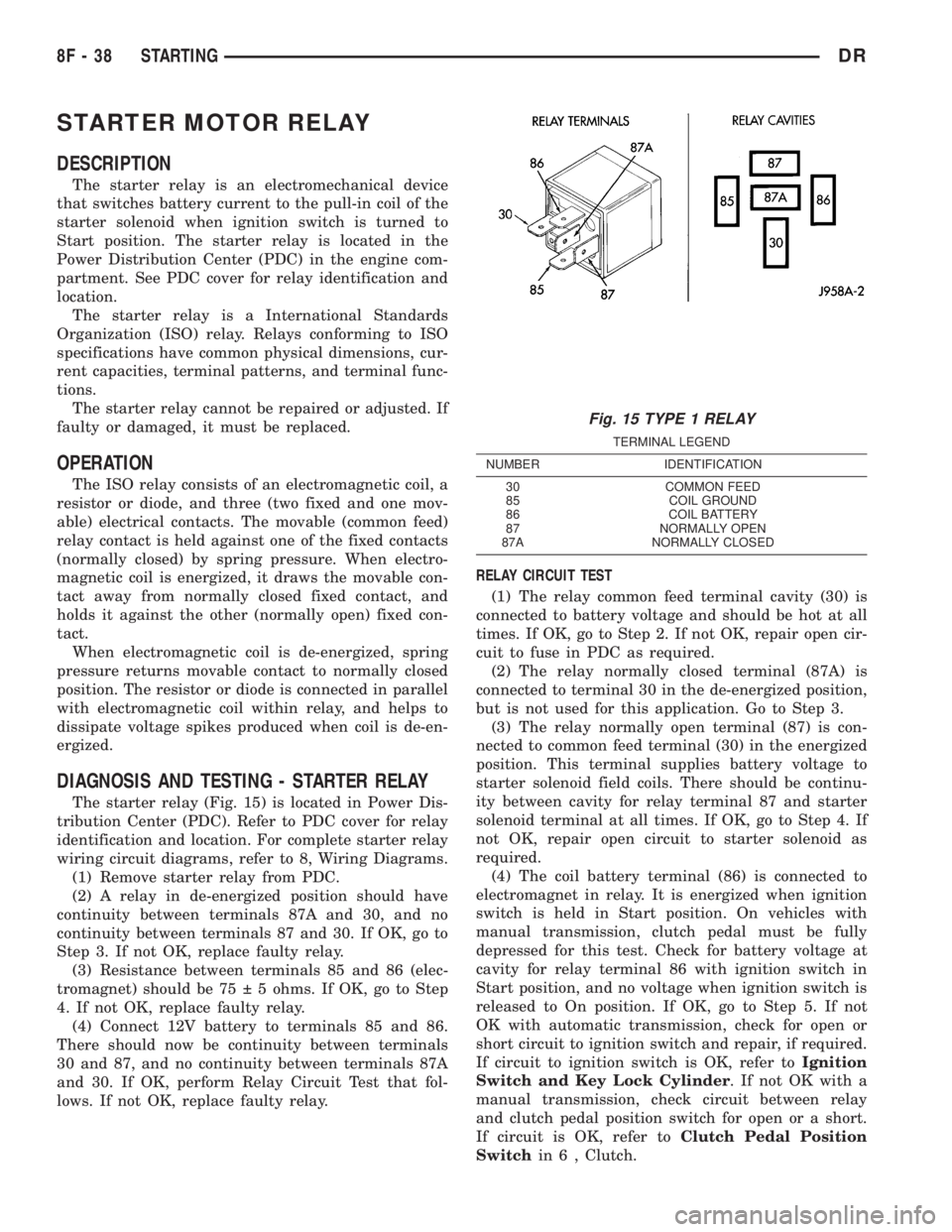

(4) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process. Do not let starter motor hang from wire har-

ness.

(5) Tilt nose downwards and lower starter motor

far enough to access and remove nuts securing

starter wiring harness to starter (Fig. 13). Do not let

starter motor hang from wire harness.

(6) Remove starter motor from engine. Note: Cer-

tain diesel engines use an aluminum spacer (Fig. 12).

Note position and orientation of spacer before

removal.

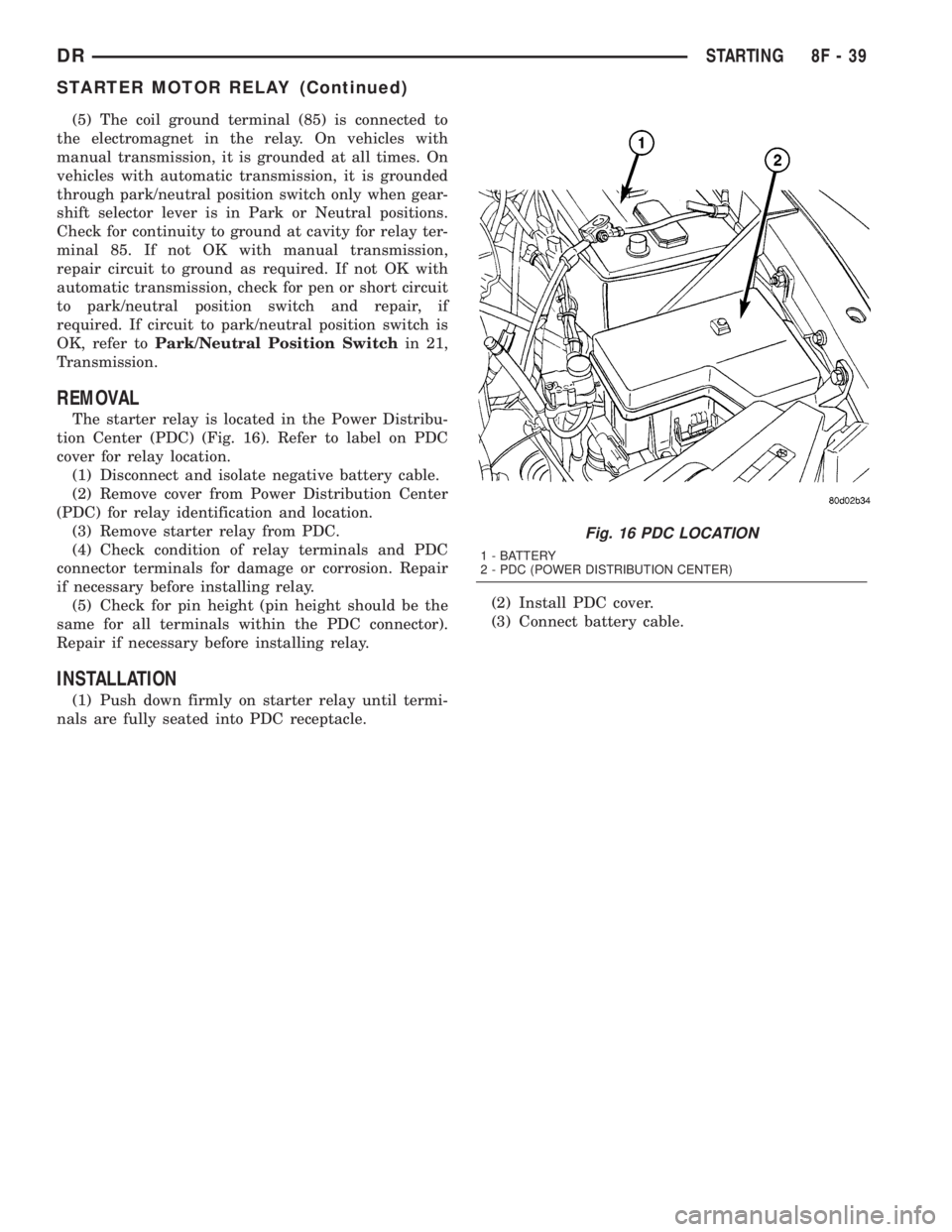

5.9L Gas

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Note: If equipped with 4WD and certain trans-

missions, a support bracket is used between front

axle and side of transmission. Remove 2 support

bracket bolts at transmission. Pry support bracket

slightly to gain access to lower starter mounting bolt.

(4) Remove nut and lock washer securing starter

motor to mounting stud (Fig. 14).

(5) While supporting starter motor, remove upper

mounting bolt from starter motor.

(6) If equipped with automatic transmission, slide

cooler tube bracket forward on tubes far enough for

starter motor mounting flange to be removed from

lower mounting stud.

(7) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

Fig. 11 STARTER R/I - 5.7L

1 - STARTER MOTOR

2 - MOUNTING BOLTS

Fig. 12 STARTER R/I - 5.9L DIESEL

1 - MOUNTING BOLTS (3)

2 - STARTER MOTOR

3 - SPACER (CERTAIN TRANSMISSIONS)

Fig. 13 STARTER ELECTRICAL CONNECTORS -

5.9L DIESEL

1 - STARTER MOTOR

2 - BATTERY CABLE NUT

3 - SOLENOID NUT

4 - HARNESS ASSEMBLY

8F - 36 STARTINGDR

STARTER MOTOR (Continued)

Page 442 of 2895

housing. Always support starter motor during this

process, do not let starter motor hang from wire har-

ness.

(8) Tilt nose downwards and lower starter motor

far enough to access and remove nut that secures

battery positive cable wire harness connector eyelet

to solenoid battery terminal stud. Do not let starter

motor hang from wire harness.

(9) Remove battery positive cable wire harness

connector eyelet from solenoid battery terminal stud.

(10) Disconnect battery positive cable wire harness

connector from solenoid terminal connector recepta-

cle.

(11) Remove starter motor.

INSTALLATION

3.7L / 4.7L

(1) Connect solenoid wire to starter motor (snaps

on).

(2) Position battery cable to solenoid stud. Install

and tighten battery cable eyelet nut. Refer to Torque

Specifications. Do not allow starter motor to hang

from wire harness.

(3) Position starter motor to transmission.

(4) If equipped with automatic transmission, slide

cooler tube bracket into position.(5) Install and tighten both bolts (auto. trans.), or

1 nut and 1 bolt (man. trans.). Refer to Torque Spec-

ifications.

(6) Lower vehicle.

(7) Connect negative battery cable.

5.7L

(1) Connect solenoid wire to starter motor (snaps

on).

(2) Position battery cable to solenoid stud. Install

and tighten battery cable eyelet nut. Refer to Torque

Specifications. Do not allow starter motor to hang

from wire harness.

(3) Position starter motor to engine.

(4) If equipped with automatic transmission, slide

cooler tube bracket into position.

(5) Install and tighten both mounting bolts. Refer

to Torque Specifications.

(6) Lower vehicle.

(7) Connect negative battery cable.

5.9L Diesel

(1)If Equipped:Position and hold aluminum

spacer to rear of starter while positioning starter to

engine.

(2) Connect solenoid wire to starter motor. Tighten

nut.

(3) Position battery cable to starter stud. Install

and tighten battery cable nut. Refer to Torque Spec-

ifications. Do not allow starter motor to hang from

wire harness.

(4) Position starter motor to transmission.

(5) If equipped with automatic transmission, slide

cooler tube bracket into position.

(6) Install and tighten 3 starter mounting bolts.

Refer to Torque Specifications.

(7) Lower vehicle.

(8) Connect both negative battery cables to both

batteries.

5.9L Gas

(1) Connect solenoid wire to starter motor (snaps

on).

(2) Position battery cable to solenoid stud. Install

and tighten battery cable eyelet nut. Refer to Torque

Specifications. Do not allow starter motor to hang

from wire harness.

(3) Position starter motor to transmission.

(4) If equipped with automatic transmission, slide

cooler tube bracket into position.

(5) Install and tighten both bolts (auto. trans.), or

1 nut and 1 bolt (man. trans.). Refer to Torque Spec-

ifications.

(6) Lower vehicle.

(7) Connect negative battery cable.

Fig. 14 STARTER R/I - 5.9L GAS

1 - ENGINE

2 - STARTER MOUNTING FLANGE

3 - STUD

4 - STARTER MOTOR

5 - LOCK WASHER

6 - NUT

7 - BRACKET

8 - BOLT

9 - POSITIVE BATTERY CABLE WIRE HARNESS

10 - POSITIVE BATTERY CABLE WIRE HARNESS NUT

DRSTARTING 8F - 37

STARTER MOTOR (Continued)

Page 443 of 2895

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted. If

faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When electro-

magnetic coil is energized, it draws the movable con-

tact away from normally closed fixed contact, and

holds it against the other (normally open) fixed con-

tact.

When electromagnetic coil is de-energized, spring

pressure returns movable contact to normally closed

position. The resistor or diode is connected in parallel

with electromagnetic coil within relay, and helps to

dissipate voltage spikes produced when coil is de-en-

ergized.

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 15) is located in Power Dis-

tribution Center (PDC). Refer to PDC cover for relay

identification and location. For complete starter relay

wiring circuit diagrams, refer to 8, Wiring Diagrams.

(1) Remove starter relay from PDC.

(2) A relay in de-energized position should have

continuity between terminals 87A and 30, and no

continuity between terminals 87 and 30. If OK, go to

Step 3. If not OK, replace faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace faulty relay.

(4) Connect 12V battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform Relay Circuit Test that fol-

lows. If not OK, replace faulty relay.RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair open cir-

cuit to fuse in PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to common feed terminal (30) in the energized

position. This terminal supplies battery voltage to

starter solenoid field coils. There should be continu-

ity between cavity for relay terminal 87 and starter

solenoid terminal at all times. If OK, go to Step 4. If

not OK, repair open circuit to starter solenoid as

required.

(4) The coil battery terminal (86) is connected to

electromagnet in relay. It is energized when ignition

switch is held in Start position. On vehicles with

manual transmission, clutch pedal must be fully

depressed for this test. Check for battery voltage at

cavity for relay terminal 86 with ignition switch in

Start position, and no voltage when ignition switch is

released to On position. If OK, go to Step 5. If not

OK with automatic transmission, check for open or

short circuit to ignition switch and repair, if required.

If circuit to ignition switch is OK, refer toIgnition

Switch and Key Lock Cylinder. If not OK with a

manual transmission, check circuit between relay

and clutch pedal position switch for open or a short.

If circuit is OK, refer toClutch Pedal Position

Switchin 6 , Clutch.

Fig. 15 TYPE 1 RELAY

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8F - 38 STARTINGDR

Page 444 of 2895

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with

manual transmission, it is grounded at all times. On

vehicles with automatic transmission, it is grounded

through park/neutral position switch only when gear-

shift selector lever is in Park or Neutral positions.

Check for continuity to ground at cavity for relay ter-

minal 85. If not OK with manual transmission,

repair circuit to ground as required. If not OK with

automatic transmission, check for pen or short circuit

to park/neutral position switch and repair, if

required. If circuit to park/neutral position switch is

OK, refer toPark/Neutral Position Switchin 21,

Transmission.

REMOVAL

The starter relay is located in the Power Distribu-

tion Center (PDC) (Fig. 16). Refer to label on PDC

cover for relay location.

(1) Disconnect and isolate negative battery cable.

(2) Remove cover from Power Distribution Center

(PDC) for relay identification and location.

(3) Remove starter relay from PDC.

(4) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(5) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

(1) Push down firmly on starter relay until termi-

nals are fully seated into PDC receptacle.(2) Install PDC cover.

(3) Connect battery cable.

Fig. 16 PDC LOCATION

1 - BATTERY

2 - PDC (POWER DISTRIBUTION CENTER)

DRSTARTING 8F - 39

STARTER MOTOR RELAY (Continued)

Page 480 of 2895

The PCM adjusts ignition timing based on inputs it

receives from:

²The engine coolant temperature sensor

²The crankshaft position sensor (engine speed)

²The camshaft position sensor (crankshaft posi-

tion)

²The manifold absolute pressure (MAP) sensor

²The throttle position sensor

²Transmission gear selection

REMOVAL

3.7L V-6

An individual ignition coil is used for each spark

plug (Fig. 30). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 31). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

30) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector from coil by

pushing downward on release lock on top of connec-

tor and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 31).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

4.7L V-8

An individual ignition coil is used for each spark

plug (Fig. 30). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 32). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

30) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.(2) Disconnect electrical connector (Fig. 32) from

coil by pushing downward on release lock on top of

connector and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 32).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

5.7L V-8

Before removing or disconnecting any spark plug

cables, note their original position. Remove cables

one-at-a-time. To prevent ignition crossfire, spark

plug cablesMUSTbe placed in cable tray (routing

loom) into their original position.

An individual ignition coil (Fig. 33) is used at each

cylinder. The coil mounts to the top of the valve cover

with 2 bolts (Fig. 34). The bottom of the coil is

equipped with a rubber boot to seal the spark plug to

the coil. Inside each rubber boot is a spring. The

spring is used for a mechanical contact between the

coil and the top of the spark plug.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Unlock electrical connector (Fig. 34) by moving

slide lock first. Press on release lock (Fig. 34) while

pulling electrical connector from coil.

(3) Disconnect secondary high-voltage cable from

coil with a twisting action.

(4) Clean area at base of coil with compressed air

before removal.

(5) Remove 2 mounting bolts (note that mounting

bolts are retained to coil).

(6) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(7) Remove coil from vehicle.

(8) Before installing spark plug cables to either the

spark plugs or coils, or before installing a coil to a

spark plug, apply dielectric grease to inside of boots.

5.9L V-8

The coil is not oil filled. The coil windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the coil to be

mounted on the engine. If the coil is replaced, it must

be replaced with the same type.

5.9L V-8 LDC-Gas Engines: The coil is mounted to

a bracket that is bolted to the front of the right

engine cylinder head (Fig. 35). This bracket is

mounted on top of the automatic belt tensioner

bracket using common bolts.

DRIGNITION CONTROL 8I - 23

IGNITION COIL (Continued)

Page 496 of 2895

molded plastic cluster housing serves as the carrier

for the cluster circuit board and circuitry, the cluster

connector receptacles, the RKE interface connector,

the gauges, a Light Emitting Diode (LED) for each

cluster indicator, two VFD units, an audible tone

generator, the cluster overlay, the gauge pointers, the

odometer/trip odometer switch and the switch button.

The cluster overlay is a laminated plastic unit. The

dark, visible, outer surface of the overlay is marked

with all of the gauge dial faces and graduations, but

this layer is also translucent. The darkness of this

outer layer prevents the cluster from appearing clut-

tered or busy by concealing the cluster indicators

that are not illuminated, while the translucence of

this layer allows those indicators and icons that are

illuminated to be readily visible. The underlying

layer of the overlay is opaque and allows light from

the LED for each of the various indicators and the

incandescent illumination lamps behind it to be visi-

ble through the outer layer of the overlay only

through predetermined stencil-like cutouts. A rectan-

gular opening in the overlay at the base of both the

speedometer and tachometer dial faces has a smoked

clear lens through which the illuminated VFD units

can be viewed.

Several versions of the EMIC module are offered

on this model. These versions accommodate all of the

variations of optional equipment and regulatory

requirements for the various markets in which the

vehicle will be offered. The microprocessor-based

EMIC utilizes integrated circuitry and information

carried on the Programmable Communications Inter-

face (PCI) data bus network along with several hard

wired analog and multiplexed inputs to monitor sen-

sors and switches throughout the vehicle. In response

to those inputs, the internal circuitry and program-

ming of the EMIC allow it to control and integrate

many electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/COMMUNICATION - DESCRIPTION -

PCI BUS).

Besides typical instrument cluster gauge and indi-

cator support, the electronic functions and features

that the EMIC supports or controls include the fol-

lowing:

²Audible Warnings- The EMIC electronic cir-

cuit board is equipped with an audible tone generator

and programming that allows it to provide various

audible alerts to the vehicle operator, including

chime tones and beep tones. An electromechanical

relay is also soldered onto the circuit board to pro-

duce audible clicks that emulate the sound of a con-

ventional turn signal or hazard warning flasher.(Refer to 8 - ELECTRICAL/CHIME/BUZZER -

DESCRIPTION).

²Brake Lamp Control- The EMIC provides

electronic brake lamp request messages to the Front

Control Module (FCM) located on the Integrated

Power Module (IPM) for brake lamp control, exclud-

ing control of the Center High Mounted Stop Lamp

(CHMSL), which remains controlled by a direct hard

wired output of the brake lamp switch.

²Brake Transmission Shift Interlock Control

- The EMIC monitors inputs from the brake lamp

switch, ignition switch, and the Transmission Range

Sensor (TRS), then controls a high-side driver output

to operate the Brake Transmission Shift Interlock

(BTSI) solenoid that locks and unlocks the automatic

transmission gearshift selector lever on the steering

column.

²Cargo Lamp Control- The EMIC provides

direct control of cargo lamp operation with a load

shedding (battery saver) feature which will automat-

ically turn off the cargo lamp if it remains on after a

timed interval.

²Central Locking- The EMIC provides support

for the central locking feature of the power lock sys-

tem. This feature will lock or unlock all doors based

upon the input from the door cylinder lock switch.

Door cylinder lock switches are used only on models

equipped with the optional Vehicle Theft Security

System (VTSS).

²Door Lock Inhibit- The EMIC inhibits locking

of the doors with the power lock switch when the key

is in the ignition switch and the driver side front

door is ajar. However, operation of the door locks is

not inhibited under the same conditions when the

Lock button of the optional RKE transmitter is

depressed.

²Enhanced Accident Response- The EMIC

monitors an input from the Airbag Control Module

(ACM) and, following an airbag deployment, will

immediately disable the power lock output, unlock all

doors by activating the power unlock output, then

enables the power lock output if the power lock

switch input remains inactive for two seconds. This

feature, like all other enhanced accident response

features, is dependent upon a functional vehicle elec-

trical system following the vehicle impact event.

²Exterior Lighting Control- The EMIC pro-

vides electronic head lamp and/or park lamp request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate exterior lamp control of standard head and

park lamps, as well as optional front fog lamps. This

includes support for headlamp beam selection and

the optical horn feature, also known as flash-to-pass.

²Exterior Lighting Fail-safe- In the absence of

a headlamp switch input, the EMIC will turn on the

DRINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 498 of 2895

the vehicle speed remains greater than about twenty-

four kilometers-per-hour (fifteen miles-per-hour).

²Vacuum Fluorescent Display Synchroniza-

tion- The EMIC transmits electronic panel lamp

dimming level messages which allows all other elec-

tronic modules on the PCI data bus with Vacuum

Fluorescent Display (VFD) units to coordinate their

illumination intensity with that of the EMIC VFD

units.

²Vehicle Theft Security System- The EMIC

monitors inputs from the door cylinder lock switch-

(es), the door ajar switches, the ignition switch, and

the Remote Keyless Entry (RKE) receiver module,

then provides electronic horn and lighting request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate VTSS alarm output features.

²Wiper/Washer System Control- The EMIC

provides electronic wiper and/or washer request mes-

sages to the Front Control Module (FCM) located on

the Integrated Power Module (IPM) for the appropri-

ate wiper and washer system features. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - DESCRIP-

TION).

The EMIC houses six analog gauges and has pro-

visions for up to twenty-three indicators (Fig. 3) or

(Fig. 4). The EMIC includes the following analog

gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

3) or (Fig. 4):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS or Rear Wheel Anti-Lock [RWAL]

brakes only)

²Brake Indicator

²Cargo Lamp Indicator

²Check Gauges Indicator

²Cruise Indicator (with Speed Control only)

²Door Ajar Indicator

²Electronic Throttle Control (ETC) Indicator

(with 5.7L Gasoline Engine only)²Gear Selector Indicator (with Automatic

Transmission only)

²High Beam Indicator

²Lamp Out Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (with Automatic

Transmission only)

²Seatbelt Indicator

²Security Indicator (with Sentry Key Immo-

bilizer & Vehicle Theft Security Systems only)

²Service Four-Wheel Drive Indicator (with

Four-Wheel Drive only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Upshift Indicator (with Manual Transmis-

sion only)

²Washer Fluid Indicator

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC, except those located

within one of the VFD units, is illuminated by a ded-

icated LED that is soldered onto the EMIC electronic

circuit board. The LED units are not available for

service replacement and, if damaged or faulty, the

entire EMIC must be replaced. Cluster illumination

is accomplished by dimmable incandescent back

lighting, which illuminates the gauges for visibility

when the exterior lighting is turned on. Each of the

incandescent bulbs is secured by an integral bulb

holder to the electronic circuit board from the back of

the cluster housing.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator, a

VFD unit, the electronic circuit board, the circuit

board hardware, the cluster overlay, or the EMIC

housing are damaged or faulty, the entire EMIC mod-

DRINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 501 of 2895

dles at several predetermined calibration points

across the gauge faces, and illuminating all segments

of the odometer/trip odometer and gear selector indi-

cator Vacuum-Fluorescent Display (VFD) units.

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). See the owner's

manual in the vehicle glove box for more information

on the features, use and operation of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry only when the ignition switch is in

the On or Start positions. With the ignition switch in

the Off position battery current is not supplied to

any gauges, and the EMIC circuitry is programmed

to move all of the gauge needles back to the low end

of their respective scales. Therefore, the gauges do

not accurately indicate any vehicle condition unless

the ignition switch is in the On or Start positions.

All of the EMIC gauges are air core magnetic

units. Two fixed electromagnetic coils are located

within each gauge. These coils are wrapped at right

angles to each other around a movable permanent

magnet. The movable magnet is suspended within

the coils on one end of a pivot shaft, while the gauge

needle is attached to the other end of the shaft. One

of the coils has a fixed current flowing through it to

maintain a constant magnetic field strength. Current

flow through the second coil changes, which causes

changes in its magnetic field strength. The current

flowing through the second coil is changed by the

EMIC circuitry in response to messages received over

the PCI data bus. The gauge needle moves as the

movable permanent magnet aligns itself to the

changing magnetic fields created around it by the

electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control each gauge require the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for each gauge may

be found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAYS

The Vacuum-Fluorescent Display (VFD) units are

soldered to the EMIC electronic circuit board. With

the ignition switch in the Off or Accessory positions,

the odometer display is activated when the driver

door is opened (Rental Car mode) and is deactivated

when the driver door is closed. Otherwise, both dis-

play units are active when the ignition switch is in

the On or Start positions, and inactive when the igni-

tion switch is in the Off or Accessory positions.The illumination intensity of the VFD units is con-

trolled by the EMIC circuitry based upon an input

from the headlamp switch and a dimming level input

received from the headlamp dimmer switch. The

EMIC synchronizes the illumination intensity of

other VFD units with that of the units in the EMIC

by sending electronic dimming level messages to

other electronic modules in the vehicle over the PCI

data bus.

The EMIC VFD units have several display capabil-

ities including odometer, trip odometer, engine hours,

gear selector indication (PRNDL) for models with an

automatic transmission, several warning or reminder

indications, and various diagnostic information when

certain fault conditions exist. An odometer/trip odom-

eter switch on the EMIC circuit board is used to con-

trol some of the display modes. This switch is

actuated manually by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens, just left of the tachom-

eter. Actuating this switch momentarily with the

ignition switch in the On position will toggle the

VFD between the odometer and trip odometer modes.

Depressing the switch button for about two seconds

while the VFD is in the trip odometer mode will

reset the trip odometer value to zero. While in the

odometer mode with the ignition switch in the On

position and the engine not running, depressing this

switch for about six seconds will display the engine

hours information. Holding this switch depressed

while turning the ignition switch from the Off posi-

tion to the On position will initiate the EMIC self-di-

agnostic actuator test. Refer to the appropriate

diagnostic information for additional details on this

VFD function. The EMIC microprocessor remembers

which display mode is active when the ignition

switch is turned to the Off position, and returns the

VFD display to that mode when the ignition switch is

turned On again.

The VFD units are diagnosed using the EMIC self-

diagnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control some of the VFD functions requires the

use of a DRBIIItscan tool. Refer to the appropriate

diagnostic information. Specific operation details for

the odometer, the trip odometer, the gear selector

indicator and the various warning and reminder indi-

cator functions of the VFD may be found elsewhere

in this service information.

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC elec-

tronic circuit board. The cargo lamp indicator, door

8J - 8 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 504 of 2895

CAUTION: Instrument clusters used in this model

automatically configure themselves for compatibil-

ity with the features and optional equipment in the

vehicle in which they are initially installed. The

instrument cluster is programmed to do this by

embedding the Vehicle Identification Number (VIN)

and other information critical to proper cluster

operation into electronic memory. This embedded

information is learned through electronic messages

received from other electronic modules in the vehi-

cle over the Programmable Communications Inter-

face (PCI) data bus, and through certain hard wired

inputs received when the cluster is connected to

the vehicle electrically. Once configured, the instru-

ment cluster memory may be irreparably damaged

and certain irreversible configuration errors may

occur if the cluster is connected electrically to

another vehicle; or, if an electronic module from

another vehicle is connected that provides data to

the instrument cluster (including odometer values)

that conflicts with that which was previously

learned and stored. Therefore, the practice of

exchanging (swapping) instrument clusters and

other electronic modules in this vehicle with those

removed from another vehicle must always be

avoided. Failure to observe this caution may result

in instrument cluster damage, which is not reim-

bursable under the terms of the product warranty.

Service replacement instrument clusters are pro-

vided with the correct VIN, and the certified odom-

eter and engine hours values embedded into cluster

memory, but will otherwise be automatically config-

ured for compatibility with the features and optional

equipment in the vehicle in which they are initially

installed.

NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated or deactivated for

compatibility with certain optional equipment. If the

problem being diagnosed involves improper illumi-

nation of the cruise indicator, the electronic throttle

control indicator, the overdrive-off indicator, the

service four-wheel drive indicator, the transmission

overtemp indicator, the upshift indicator, the secu-

rity indicator or the gear selector indicator, discon-

nect and isolate the battery negative cable. After

about five minutes, reconnect the battery negative

cable and turn the ignition switch to the On posi-

tion. The instrument cluster should automatically

relearn the equipment in the vehicle and properly

configure the configurable indicators accordingly.PRELIMINARY DIAGNOSIS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Check the fused B(+) fuse (Fuse 28 - 10

ampere) in the Integrated Power Module (IPM). If

OK, go to Step 2. If not OK, repair the shorted circuit

or component as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 28 - 10 ampere) in the IPM. If OK, go to Step

3. If not OK, repair the open fused B(+) circuit

between the IPM and the battery as required.

(3) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Reconnect the

battery negative cable. Check for battery voltage at

the fused B(+) circuit cavity of the instrument panel

wire harness connector (Connector C1) for the instru-

ment cluster. If OK, go to Step 4. If not OK, repair

the open fused B(+) circuit between the instrument

cluster and the IPM as required.

(4) Check for continuity between the signal ground

circuit cavity of the instrument panel wire harness

connector (Connector C1) for the instrument cluster

and a good ground. There should be continuity. If

OK, refer to ACTUATOR TEST. If not OK, repair the

open ground circuit to ground (G202) as required.

DRINSTRUMENT CLUSTER 8J - 11

INSTRUMENT CLUSTER (Continued)