lock DODGE RAM 2003 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 153 of 2895

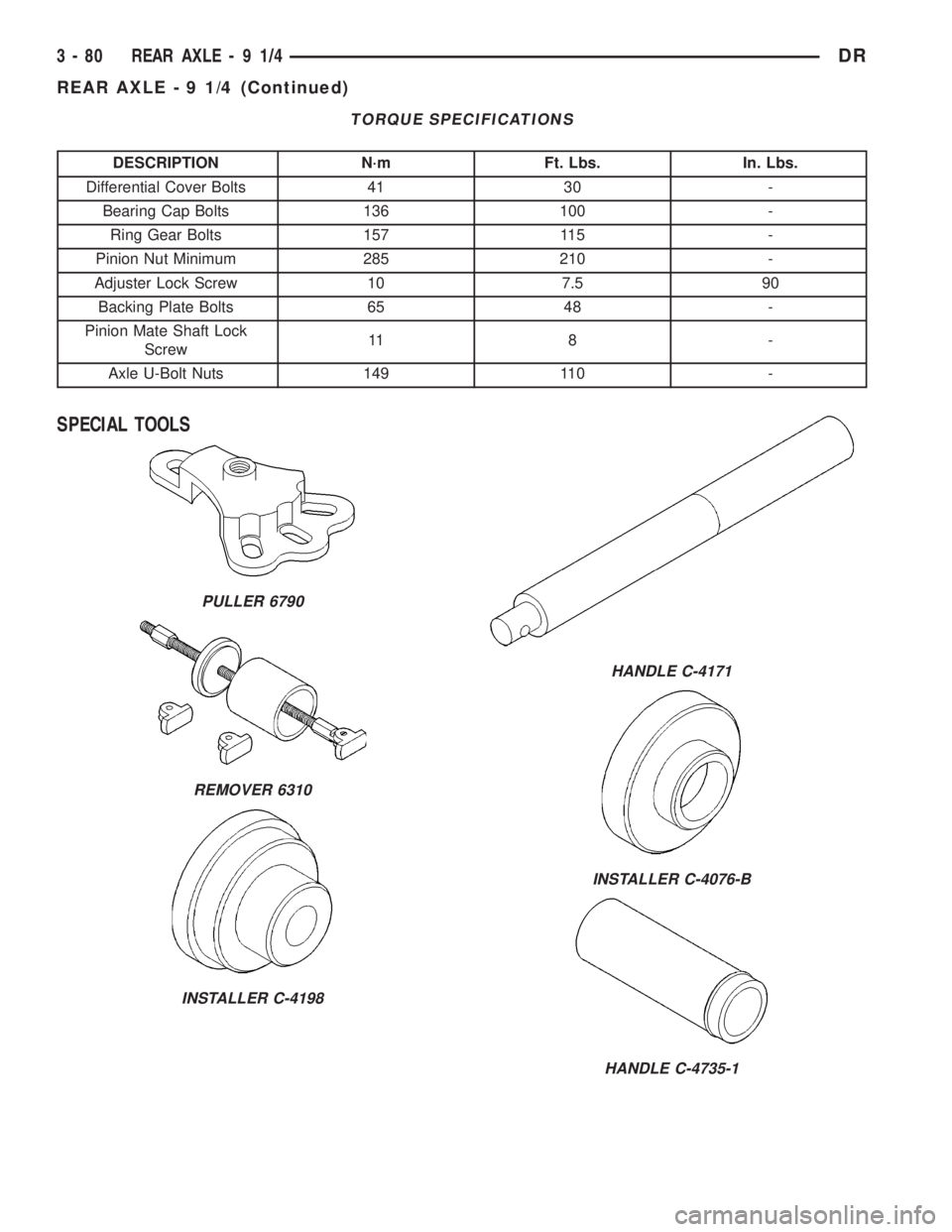

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Differential Cover Bolts 41 30 -

Bearing Cap Bolts 136 100 -

Ring Gear Bolts 157 115 -

Pinion Nut Minimum 285 210 -

Adjuster Lock Screw 10 7.5 90

Backing Plate Bolts 65 48 -

Pinion Mate Shaft Lock

Screw11 8 -

Axle U-Bolt Nuts 149 110 -

SPECIAL TOOLS

PULLER 6790

REMOVER 6310

INSTALLER C-4198

HANDLE C-4171

INSTALLER C-4076-B

HANDLE C-4735-1

3 - 80 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 155 of 2895

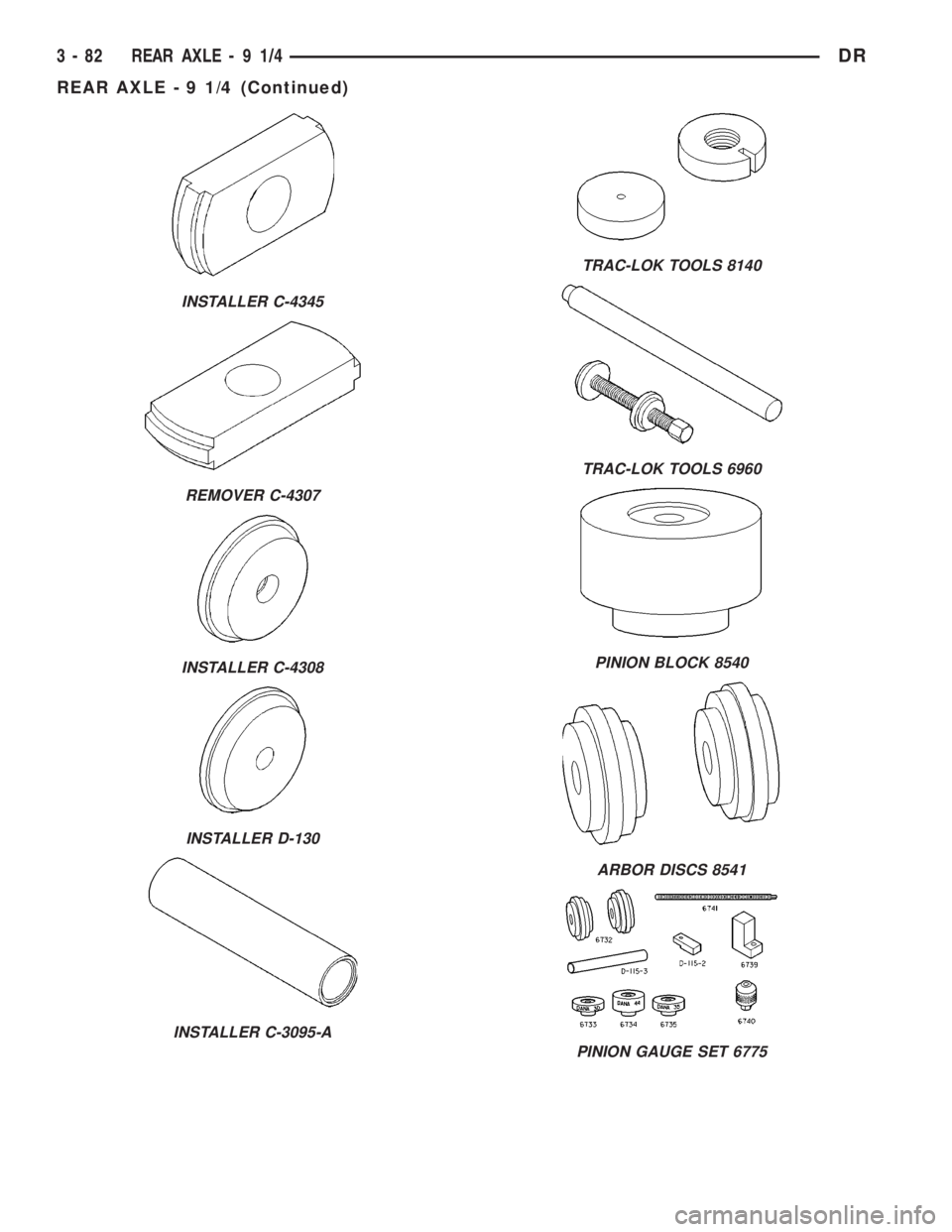

INSTALLER C-4345

REMOVER C-4307

INSTALLER C-4308

INSTALLER D-130

INSTALLER C-3095-A

TRAC-LOK TOOLS 8140

TRAC-LOK TOOLS 6960

PINION BLOCK 8540

ARBOR DISCS 8541

PINION GAUGE SET 6775

3 - 82 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 156 of 2895

AXLE SHAFTS

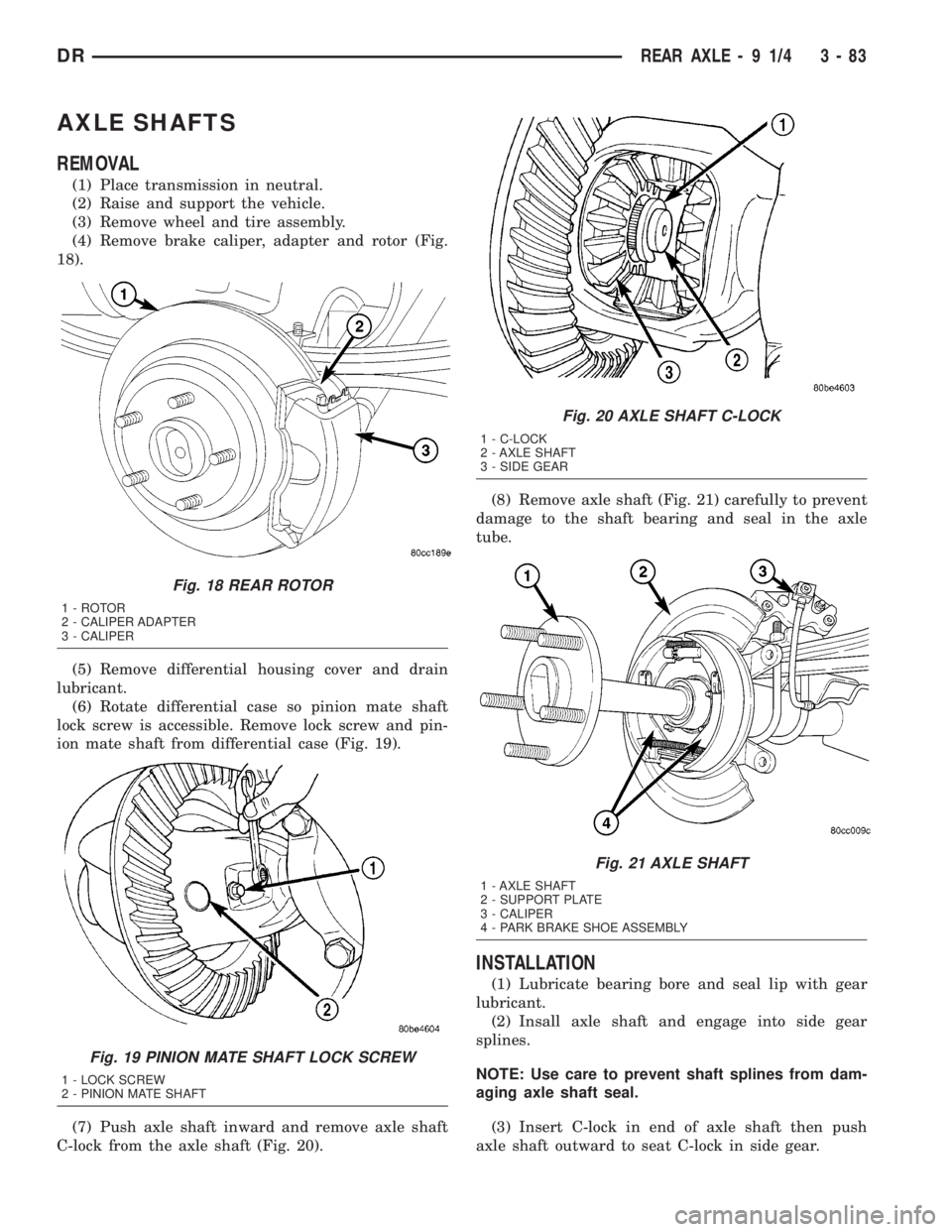

REMOVAL

(1) Place transmission in neutral.

(2) Raise and support the vehicle.

(3) Remove wheel and tire assembly.

(4) Remove brake caliper, adapter and rotor (Fig.

18).

(5) Remove differential housing cover and drain

lubricant.

(6) Rotate differential case so pinion mate shaft

lock screw is accessible. Remove lock screw and pin-

ion mate shaft from differential case (Fig. 19).

(7) Push axle shaft inward and remove axle shaft

C-lock from the axle shaft (Fig. 20).(8) Remove axle shaft (Fig. 21) carefully to prevent

damage to the shaft bearing and seal in the axle

tube.

INSTALLATION

(1) Lubricate bearing bore and seal lip with gear

lubricant.

(2) Insall axle shaft and engage into side gear

splines.

NOTE: Use care to prevent shaft splines from dam-

aging axle shaft seal.

(3) Insert C-lock in end of axle shaft then push

axle shaft outward to seat C-lock in side gear.

Fig. 18 REAR ROTOR

1 - ROTOR

2 - CALIPER ADAPTER

3 - CALIPER

Fig. 19 PINION MATE SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION MATE SHAFT

Fig. 20 AXLE SHAFT C-LOCK

1 - C-LOCK

2 - AXLE SHAFT

3 - SIDE GEAR

Fig. 21 AXLE SHAFT

1 - AXLE SHAFT

2 - SUPPORT PLATE

3 - CALIPER

4 - PARK BRAKE SHOE ASSEMBLY

DRREAR AXLE - 9 1/4 3 - 83

Page 157 of 2895

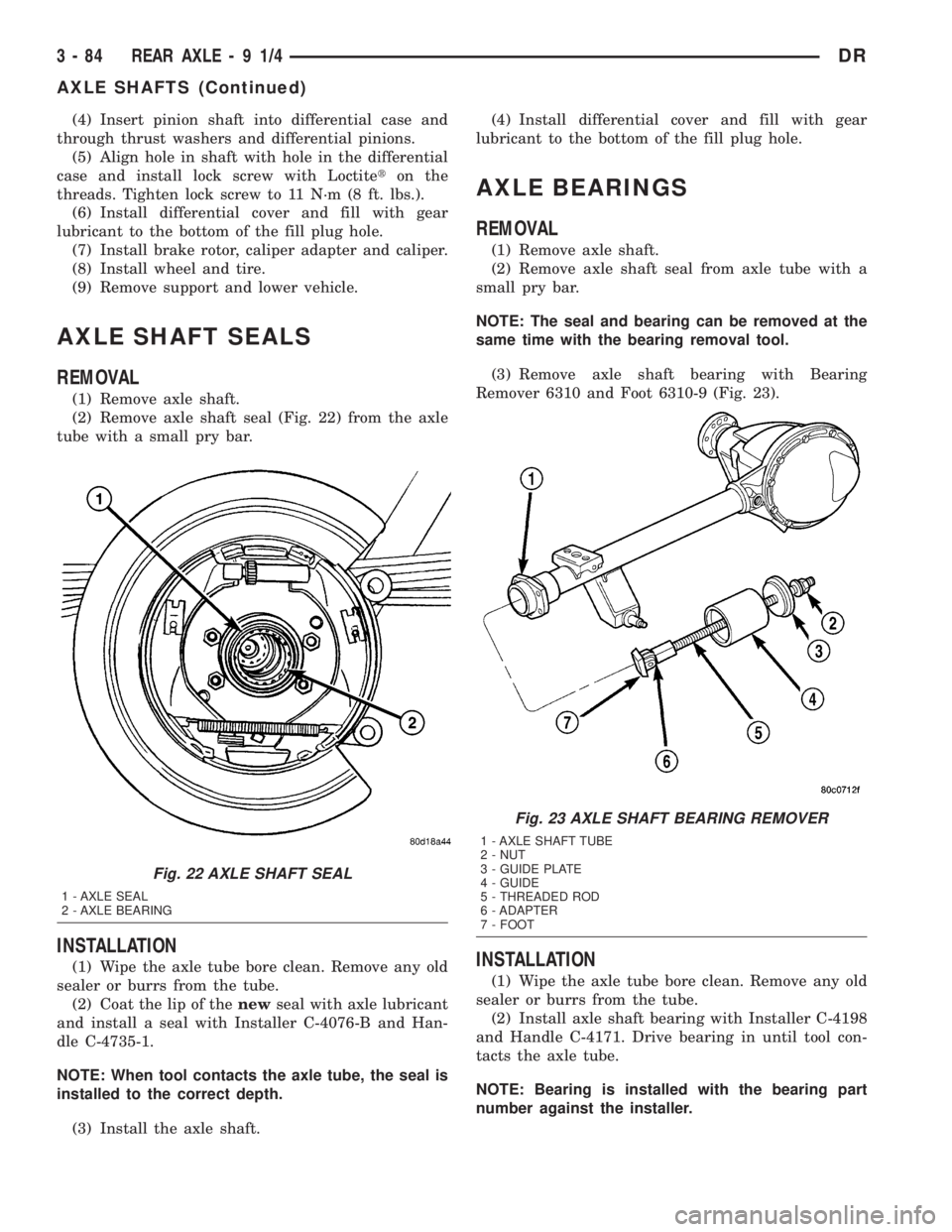

(4) Insert pinion shaft into differential case and

through thrust washers and differential pinions.

(5) Align hole in shaft with hole in the differential

case and install lock screw with Loctiteton the

threads. Tighten lock screw to 11 N´m (8 ft. lbs.).

(6) Install differential cover and fill with gear

lubricant to the bottom of the fill plug hole.

(7) Install brake rotor, caliper adapter and caliper.

(8) Install wheel and tire.

(9) Remove support and lower vehicle.

AXLE SHAFT SEALS

REMOVAL

(1) Remove axle shaft.

(2) Remove axle shaft seal (Fig. 22) from the axle

tube with a small pry bar.

INSTALLATION

(1) Wipe the axle tube bore clean. Remove any old

sealer or burrs from the tube.

(2) Coat the lip of thenewseal with axle lubricant

and install a seal with Installer C-4076-B and Han-

dle C-4735-1.

NOTE: When tool contacts the axle tube, the seal is

installed to the correct depth.

(3) Install the axle shaft.(4) Install differential cover and fill with gear

lubricant to the bottom of the fill plug hole.

AXLE BEARINGS

REMOVAL

(1) Remove axle shaft.

(2) Remove axle shaft seal from axle tube with a

small pry bar.

NOTE: The seal and bearing can be removed at the

same time with the bearing removal tool.

(3) Remove axle shaft bearing with Bearing

Remover 6310 and Foot 6310-9 (Fig. 23).

INSTALLATION

(1) Wipe the axle tube bore clean. Remove any old

sealer or burrs from the tube.

(2) Install axle shaft bearing with Installer C-4198

and Handle C-4171. Drive bearing in until tool con-

tacts the axle tube.

NOTE: Bearing is installed with the bearing part

number against the installer.

Fig. 22 AXLE SHAFT SEAL

1 - AXLE SEAL

2 - AXLE BEARING

Fig. 23 AXLE SHAFT BEARING REMOVER

1 - AXLE SHAFT TUBE

2 - NUT

3 - GUIDE PLATE

4 - GUIDE

5 - THREADED ROD

6 - ADAPTER

7 - FOOT

3 - 84 REAR AXLE-91/4DR

AXLE SHAFTS (Continued)

Page 160 of 2895

(2) Remove differential cover and drain the lubri-

cant.

(3) Clean housing cavity with flushing oil, light

engine oil or a lint free cloth.

NOTE: Do not use steam, kerosene or gasoline to

clean the housing.

(4) Remove axle shafts.

(5) Remove RWAL/ABS sensor from housing.

NOTE: Side play resulting from bearing races being

loose on case hubs requires replacement of the dif-

ferential case.

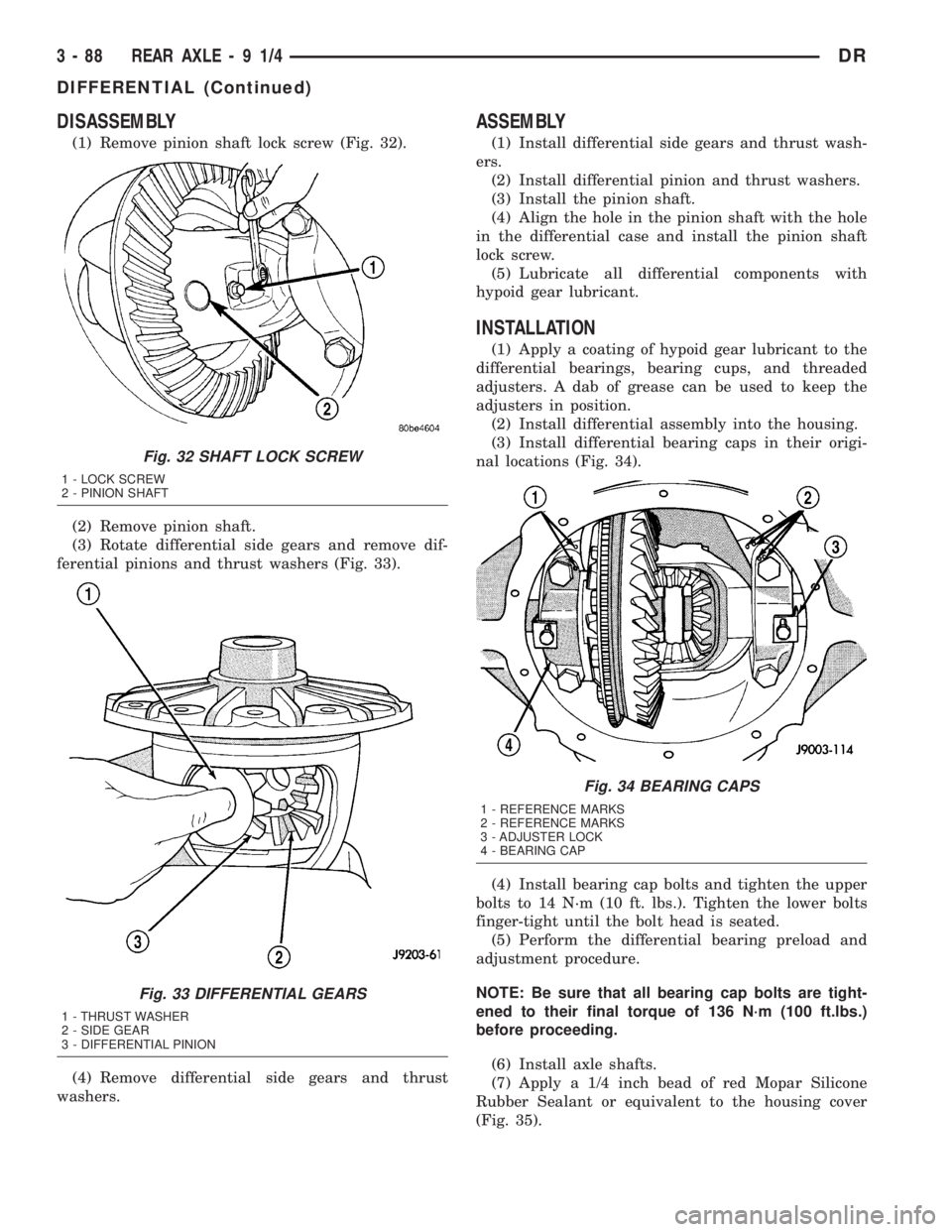

(6) Mark differential housing and bearing caps for

installation reference (Fig. 30).(7) Remove bearing threaded adjuster lock from

each bearing cap.

(8) Loosen differential bearing cap bolts.

(9) Loosen differential bearing adjusters through

the axle tubes with Wrench C-4164 (Fig. 31).

(10) Hold differential case while removing bearing

caps and adjusters.

(11) Remove differential case.

NOTE: Tag the differential bearing cups and

threaded adjusters to indicate their location.

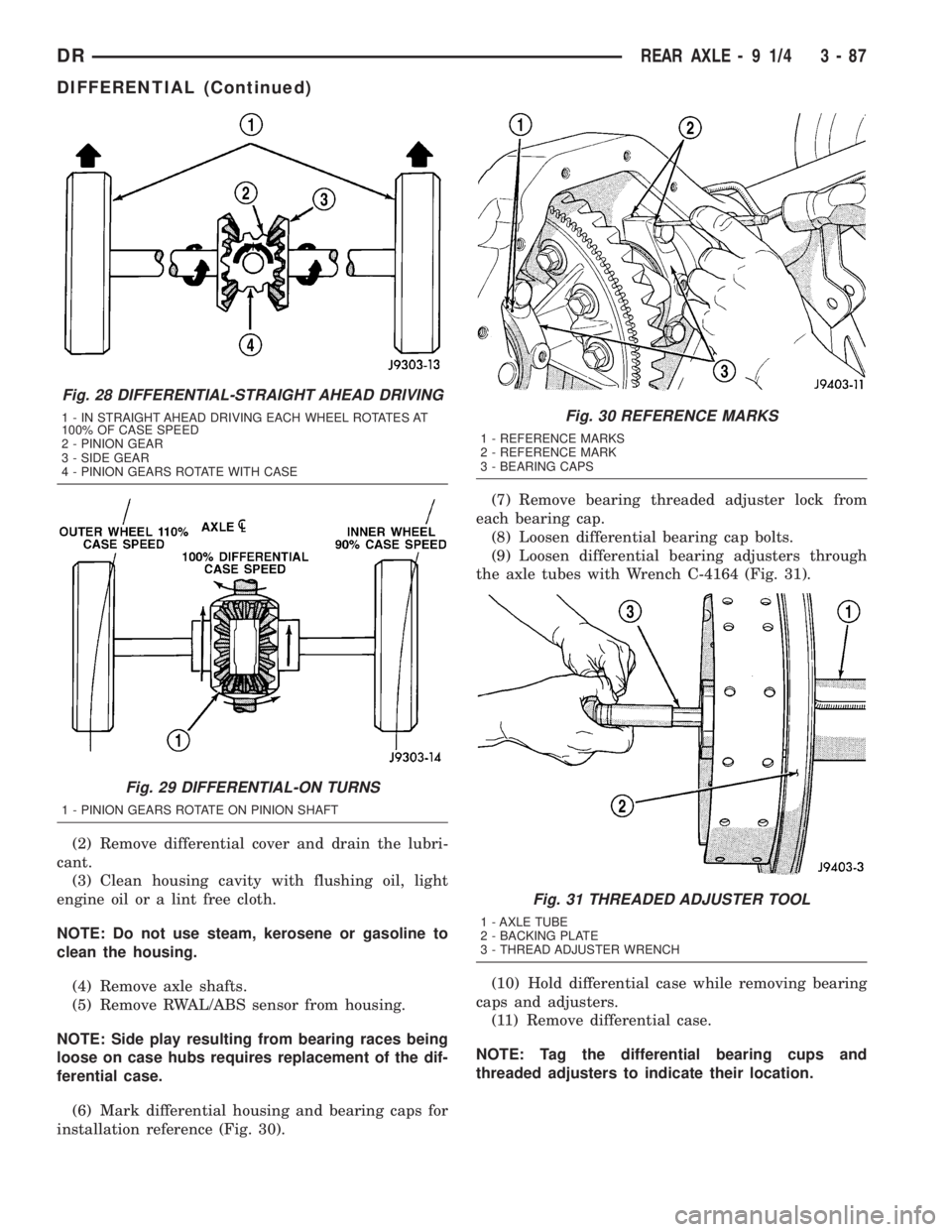

Fig. 28 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

Fig. 29 DIFFERENTIAL-ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

Fig. 30 REFERENCE MARKS

1 - REFERENCE MARKS

2 - REFERENCE MARK

3 - BEARING CAPS

Fig. 31 THREADED ADJUSTER TOOL

1 - AXLE TUBE

2 - BACKING PLATE

3 - THREAD ADJUSTER WRENCH

DRREAR AXLE - 9 1/4 3 - 87

DIFFERENTIAL (Continued)

Page 161 of 2895

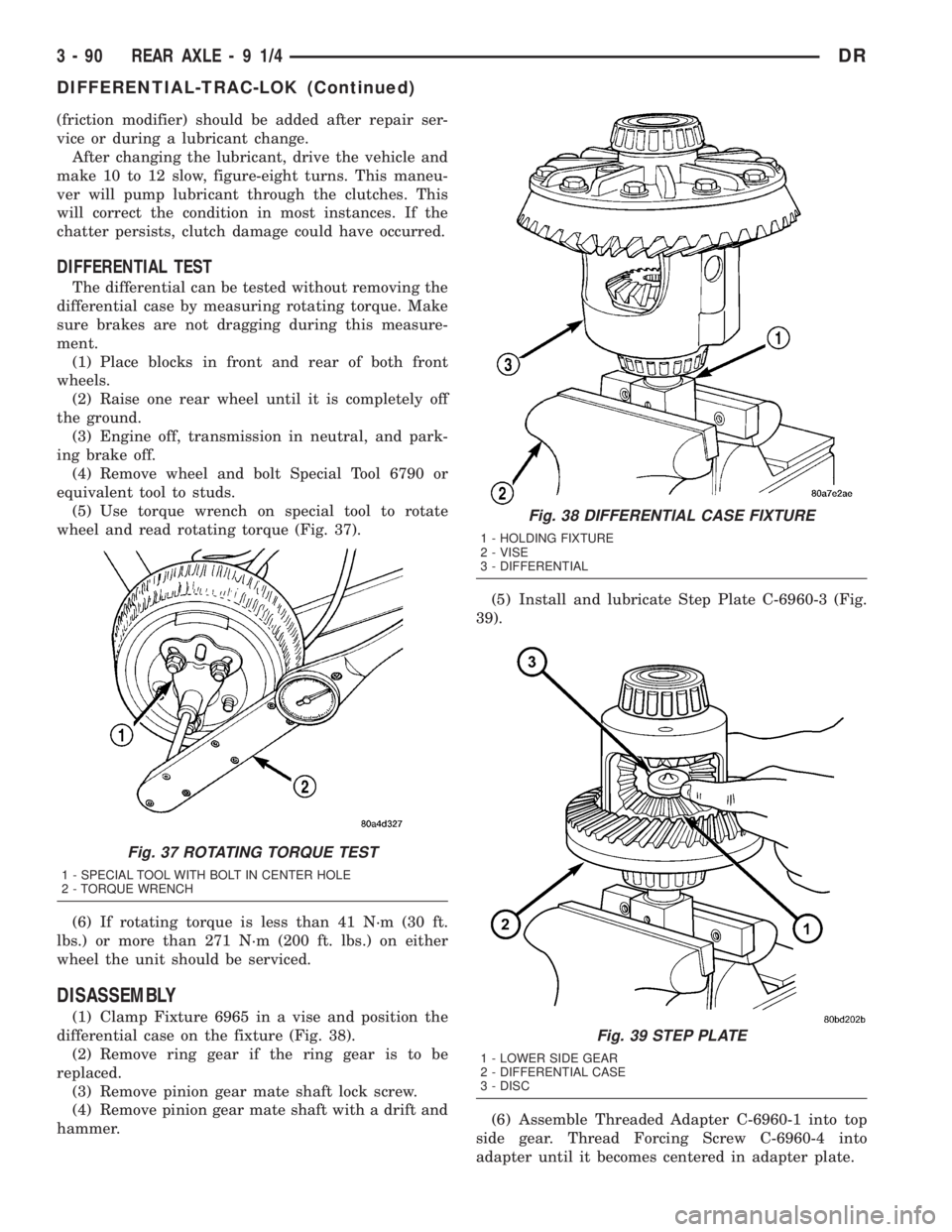

DISASSEMBLY

(1) Remove pinion shaft lock screw (Fig. 32).

(2) Remove pinion shaft.

(3) Rotate differential side gears and remove dif-

ferential pinions and thrust washers (Fig. 33).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion and thrust washers.

(3) Install the pinion shaft.

(4) Align the hole in the pinion shaft with the hole

in the differential case and install the pinion shaft

lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

(1) Apply a coating of hypoid gear lubricant to the

differential bearings, bearing cups, and threaded

adjusters. A dab of grease can be used to keep the

adjusters in position.

(2) Install differential assembly into the housing.

(3) Install differential bearing caps in their origi-

nal locations (Fig. 34).

(4) Install bearing cap bolts and tighten the upper

bolts to 14 N´m (10 ft. lbs.). Tighten the lower bolts

finger-tight until the bolt head is seated.

(5) Perform the differential bearing preload and

adjustment procedure.

NOTE: Be sure that all bearing cap bolts are tight-

ened to their final torque of 136 N´m (100 ft.lbs.)

before proceeding.

(6) Install axle shafts.

(7) Apply a 1/4 inch bead of red Mopar Silicone

Rubber Sealant or equivalent to the housing cover

(Fig. 35).

Fig. 32 SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 33 DIFFERENTIAL GEARS

1 - THRUST WASHER

2 - SIDE GEAR

3 - DIFFERENTIAL PINION

Fig. 34 BEARING CAPS

1 - REFERENCE MARKS

2 - REFERENCE MARKS

3 - ADJUSTER LOCK

4 - BEARING CAP

3 - 88 REAR AXLE-91/4DR

DIFFERENTIAL (Continued)

Page 163 of 2895

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

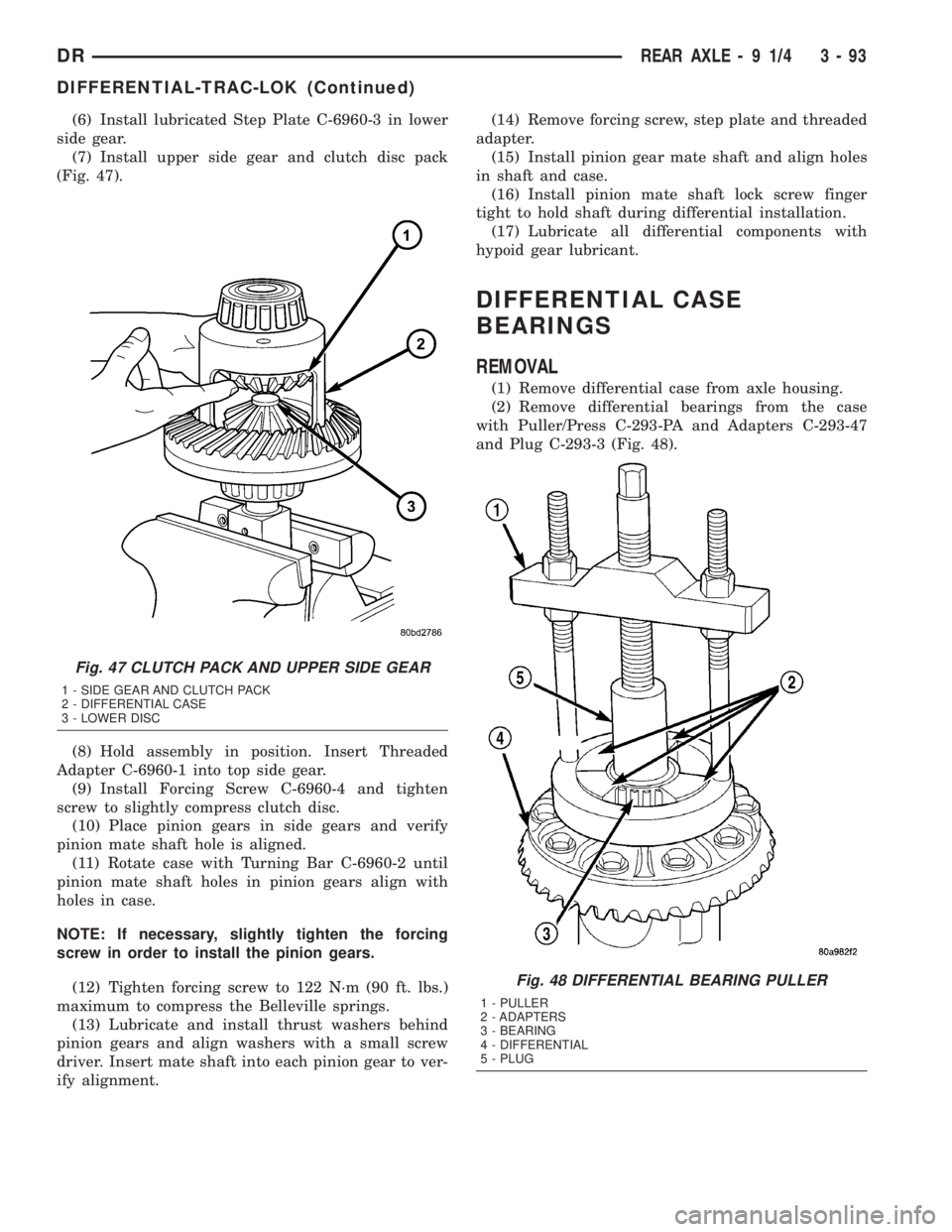

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 37).

(6) If rotating torque is less than 41 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

(1) Clamp Fixture 6965 in a vise and position the

differential case on the fixture (Fig. 38).

(2) Remove ring gear if the ring gear is to be

replaced.

(3) Remove pinion gear mate shaft lock screw.

(4) Remove pinion gear mate shaft with a drift and

hammer.(5) Install and lubricate Step Plate C-6960-3 (Fig.

39).

(6) Assemble Threaded Adapter C-6960-1 into top

side gear. Thread Forcing Screw C-6960-4 into

adapter until it becomes centered in adapter plate.

Fig. 37 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 38 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 39 STEP PLATE

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - DISC

3 - 90 REAR AXLE-91/4DR

DIFFERENTIAL-TRAC-LOK (Continued)

Page 166 of 2895

(6) Install lubricated Step Plate C-6960-3 in lower

side gear.

(7) Install upper side gear and clutch disc pack

(Fig. 47).

(8) Hold assembly in position. Insert Threaded

Adapter C-6960-1 into top side gear.

(9) Install Forcing Screw C-6960-4 and tighten

screw to slightly compress clutch disc.

(10) Place pinion gears in side gears and verify

pinion mate shaft hole is aligned.

(11) Rotate case with Turning Bar C-6960-2 until

pinion mate shaft holes in pinion gears align with

holes in case.

NOTE: If necessary, slightly tighten the forcing

screw in order to install the pinion gears.

(12) Tighten forcing screw to 122 N´m (90 ft. lbs.)

maximum to compress the Belleville springs.

(13) Lubricate and install thrust washers behind

pinion gears and align washers with a small screw

driver. Insert mate shaft into each pinion gear to ver-

ify alignment.(14) Remove forcing screw, step plate and threaded

adapter.

(15) Install pinion gear mate shaft and align holes

in shaft and case.

(16) Install pinion mate shaft lock screw finger

tight to hold shaft during differential installation.

(17) Lubricate all differential components with

hypoid gear lubricant.

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential case from axle housing.

(2) Remove differential bearings from the case

with Puller/Press C-293-PA and Adapters C-293-47

and Plug C-293-3 (Fig. 48).

Fig. 47 CLUTCH PACK AND UPPER SIDE GEAR

1 - SIDE GEAR AND CLUTCH PACK

2 - DIFFERENTIAL CASE

3 - LOWER DISC

Fig. 48 DIFFERENTIAL BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

DRREAR AXLE - 9 1/4 3 - 93

DIFFERENTIAL-TRAC-LOK (Continued)

Page 176 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block

and axle vent hose.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers and rotors.

(9) Mark propeller shaft and companion flange for

installation alignment reference.

(10) Remove propeller shaft.

(11) Remove shock absorbers from axle.

(12) Remove U-bolts from axle.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Install brake calipers.

(7) Connect brake hose to the axle junction block

and axle vent hose.

(8) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(9) Install the wheels and tires.

DRREAR AXLE - 10 1/2 AA 3 - 103

REAR AXLE - 10 1/2 AA (Continued)

Page 177 of 2895

(10) Fill differential to specifications.

(11) Remove lifting device from axle and lower the

vehicle.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. Compensation for pinion depth variance is

achieved with a select shim. The shim is located

between the rear pinion bearing and the pinion gear

head.

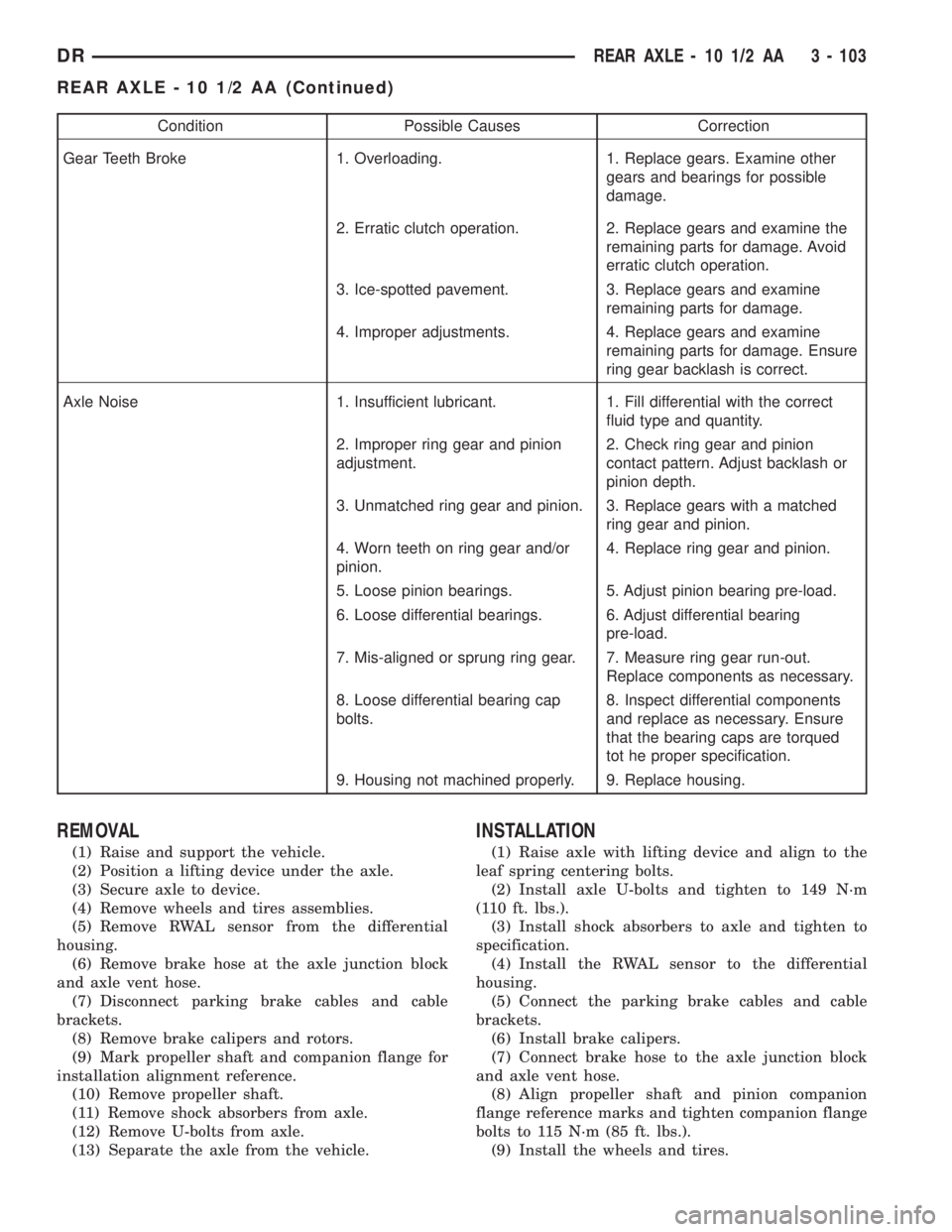

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 1).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8899 and rear pinion bearing onto Screw 6741

(Fig. 1).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 2).

(3) Install front pinion bearing and install the

Cone-nut 6740 hand tight. Then check tool rotating

torque with an inch pound torque wrench. The rotat-ing torque should be 1.7-2.26 N´m (15-20 in. lbs.)

(Fig. 1).

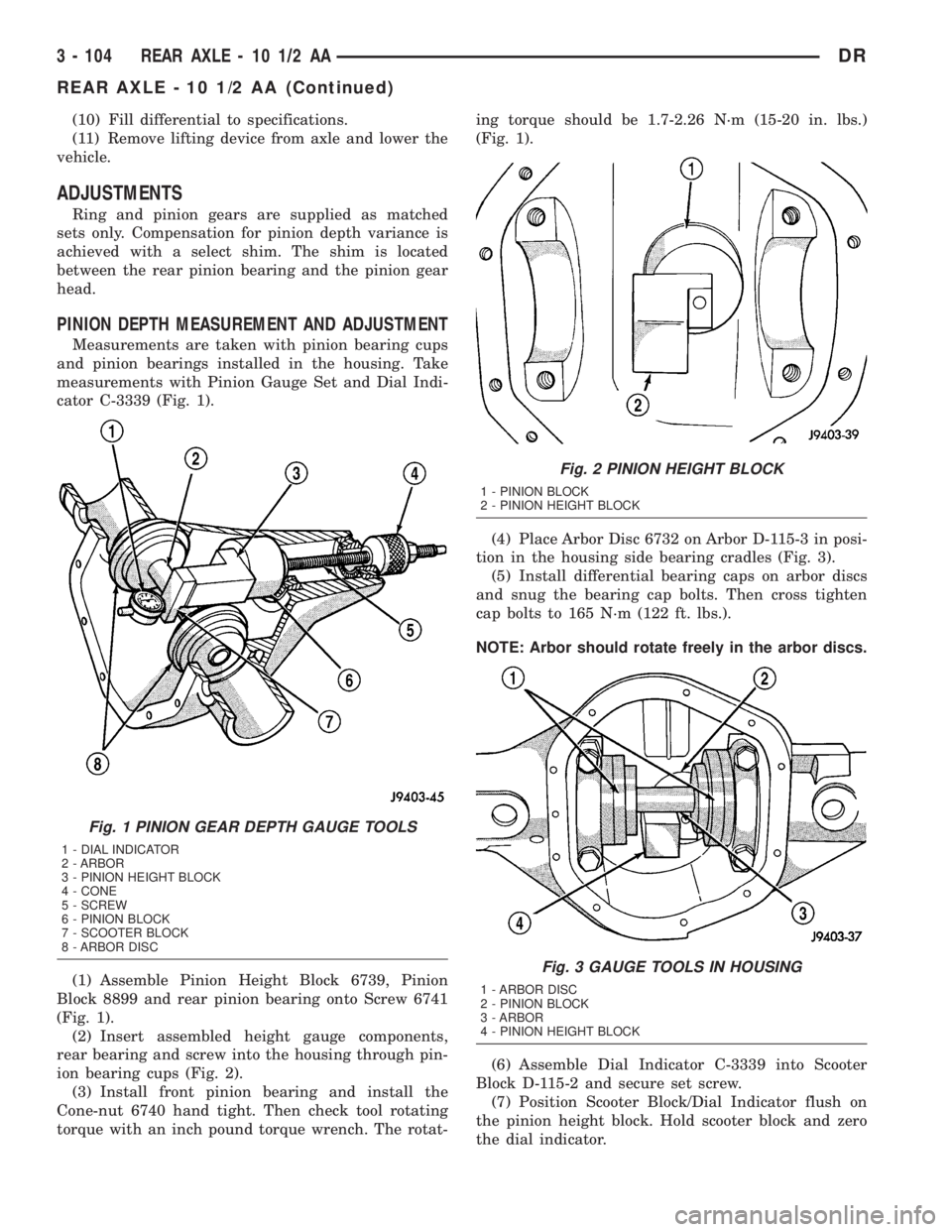

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 3).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 165 N´m (122 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor discs.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

Fig. 1 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 2 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 3 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

3 - 104 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)