Oss DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2267 of 2895

CLEANING

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary.

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

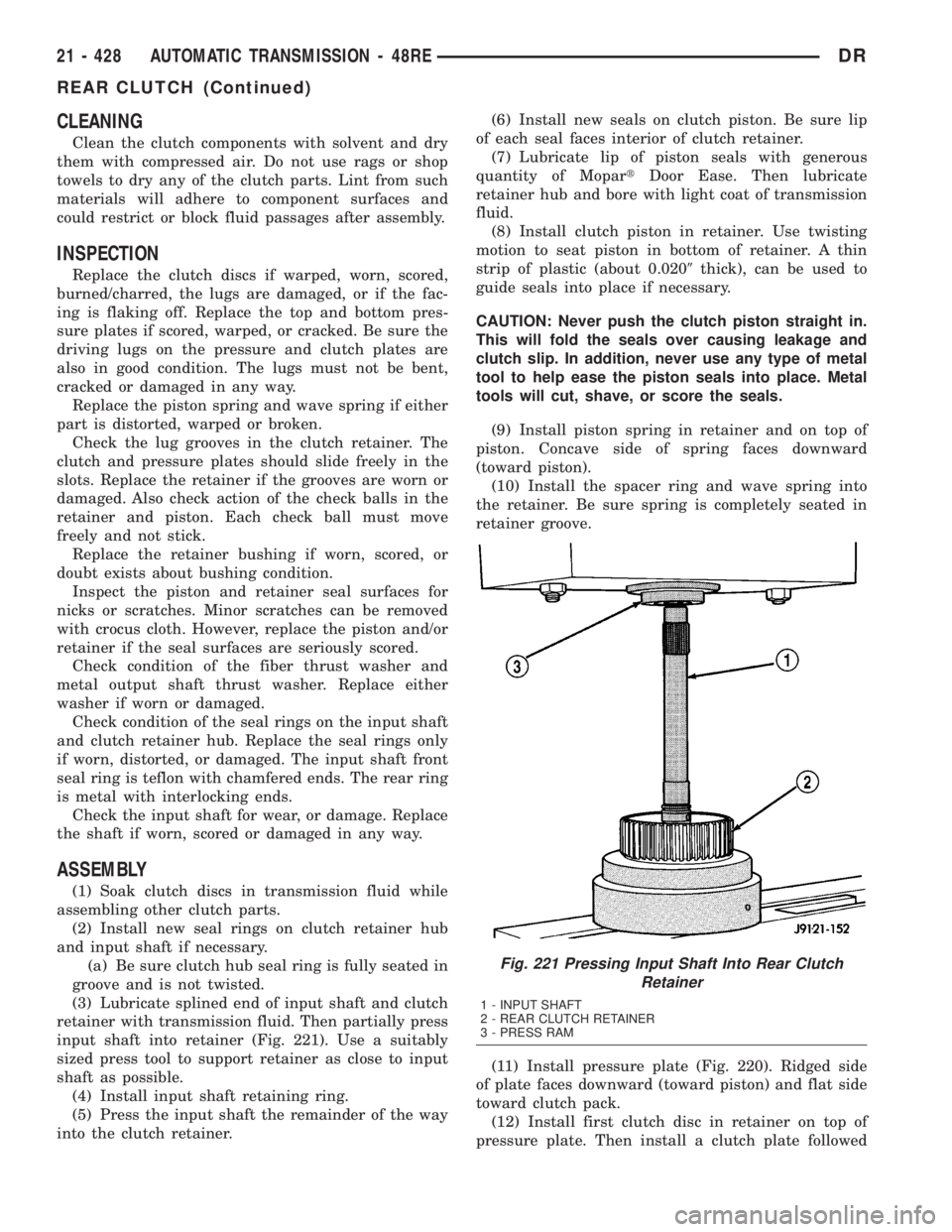

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then partially press

input shaft into retainer (Fig. 221). Use a suitably

sized press tool to support retainer as close to input

shaft as possible.

(4) Install input shaft retaining ring.

(5) Press the input shaft the remainder of the way

into the clutch retainer.(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston. Concave side of spring faces downward

(toward piston).

(10) Install the spacer ring and wave spring into

the retainer. Be sure spring is completely seated in

retainer groove.

(11) Install pressure plate (Fig. 220). Ridged side

of plate faces downward (toward piston) and flat side

toward clutch pack.

(12) Install first clutch disc in retainer on top of

pressure plate. Then install a clutch plate followed

Fig. 221 Pressing Input Shaft Into Rear Clutch

Retainer

1 - INPUT SHAFT

2 - REAR CLUTCH RETAINER

3 - PRESS RAM

21 - 428 AUTOMATIC TRANSMISSION - 48REDR

REAR CLUTCH (Continued)

Page 2268 of 2895

by a clutch disc until entire clutch pack is installed

(4 discs and 3 plates are required) (Fig. 220).

(13) Install the reaction plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

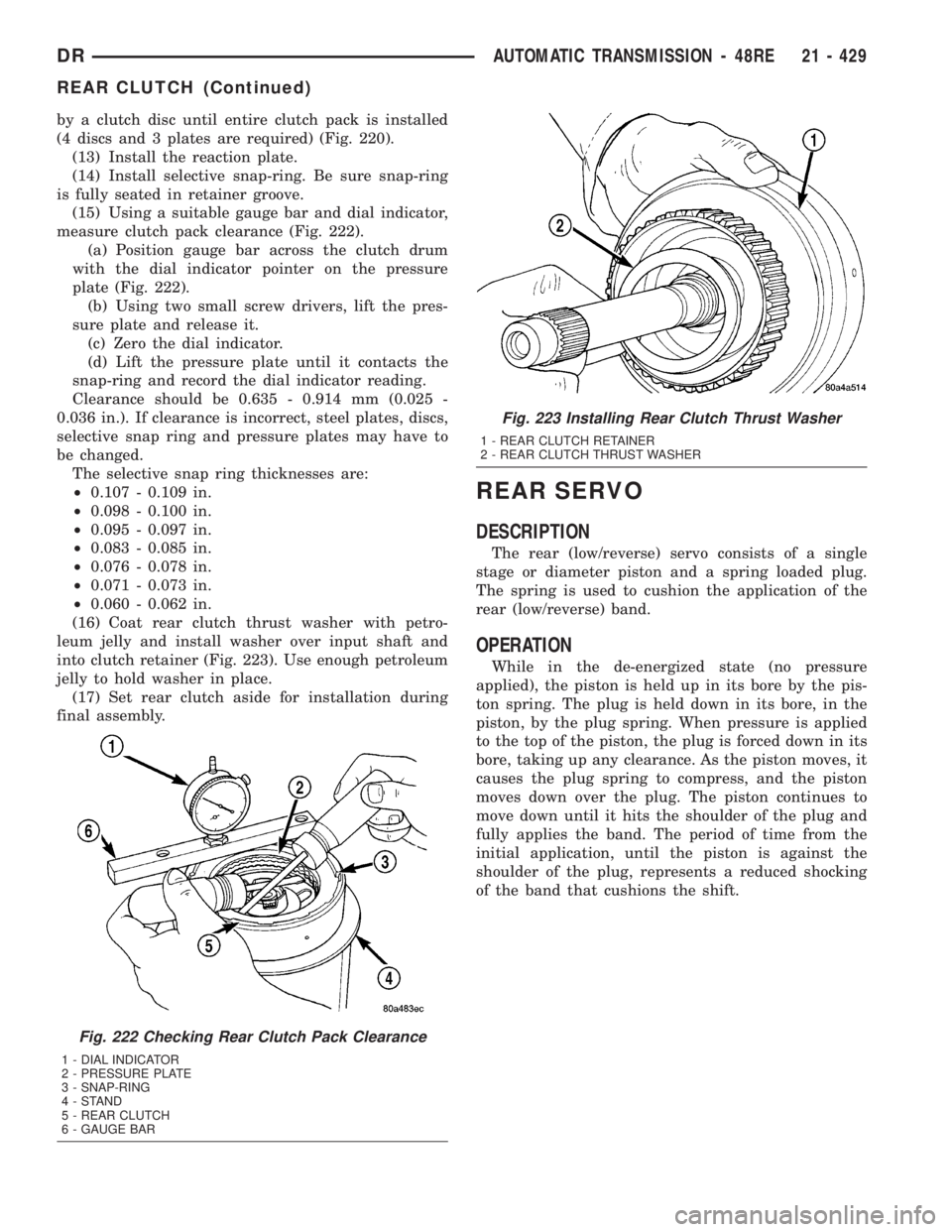

(15) Using a suitable gauge bar and dial indicator,

measure clutch pack clearance (Fig. 222).

(a) Position gauge bar across the clutch drum

with the dial indicator pointer on the pressure

plate (Fig. 222).

(b) Using two small screw drivers, lift the pres-

sure plate and release it.

(c) Zero the dial indicator.

(d) Lift the pressure plate until it contacts the

snap-ring and record the dial indicator reading.

Clearance should be 0.635 - 0.914 mm (0.025 -

0.036 in.). If clearance is incorrect, steel plates, discs,

selective snap ring and pressure plates may have to

be changed.

The selective snap ring thicknesses are:

²0.107 - 0.109 in.

²0.098 - 0.100 in.

²0.095 - 0.097 in.

²0.083 - 0.085 in.

²0.076 - 0.078 in.

²0.071 - 0.073 in.

²0.060 - 0.062 in.

(16) Coat rear clutch thrust washer with petro-

leum jelly and install washer over input shaft and

into clutch retainer (Fig. 223). Use enough petroleum

jelly to hold washer in place.

(17) Set rear clutch aside for installation during

final assembly.

REAR SERVO

DESCRIPTION

The rear (low/reverse) servo consists of a single

stage or diameter piston and a spring loaded plug.

The spring is used to cushion the application of the

rear (low/reverse) band.

OPERATION

While in the de-energized state (no pressure

applied), the piston is held up in its bore by the pis-

ton spring. The plug is held down in its bore, in the

piston, by the plug spring. When pressure is applied

to the top of the piston, the plug is forced down in its

bore, taking up any clearance. As the piston moves, it

causes the plug spring to compress, and the piston

moves down over the plug. The piston continues to

move down until it hits the shoulder of the plug and

fully applies the band. The period of time from the

initial application, until the piston is against the

shoulder of the plug, represents a reduced shocking

of the band that cushions the shift.

Fig. 222 Checking Rear Clutch Pack Clearance

1 - DIAL INDICATOR

2 - PRESSURE PLATE

3 - SNAP-RING

4-STAND

5 - REAR CLUTCH

6 - GAUGE BAR

Fig. 223 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER

DRAUTOMATIC TRANSMISSION - 48RE 21 - 429

REAR CLUTCH (Continued)

Page 2270 of 2895

SOLENOID

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

A solenoid can also be described by the method by

which it is controlled. Some of the possibilities

include variable force, pulse-width modulated, con-

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltageacross the solenoid to allow either full flow or no flow

through the solenoid's valve.OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

SPEED SENSOR

DESCRIPTION

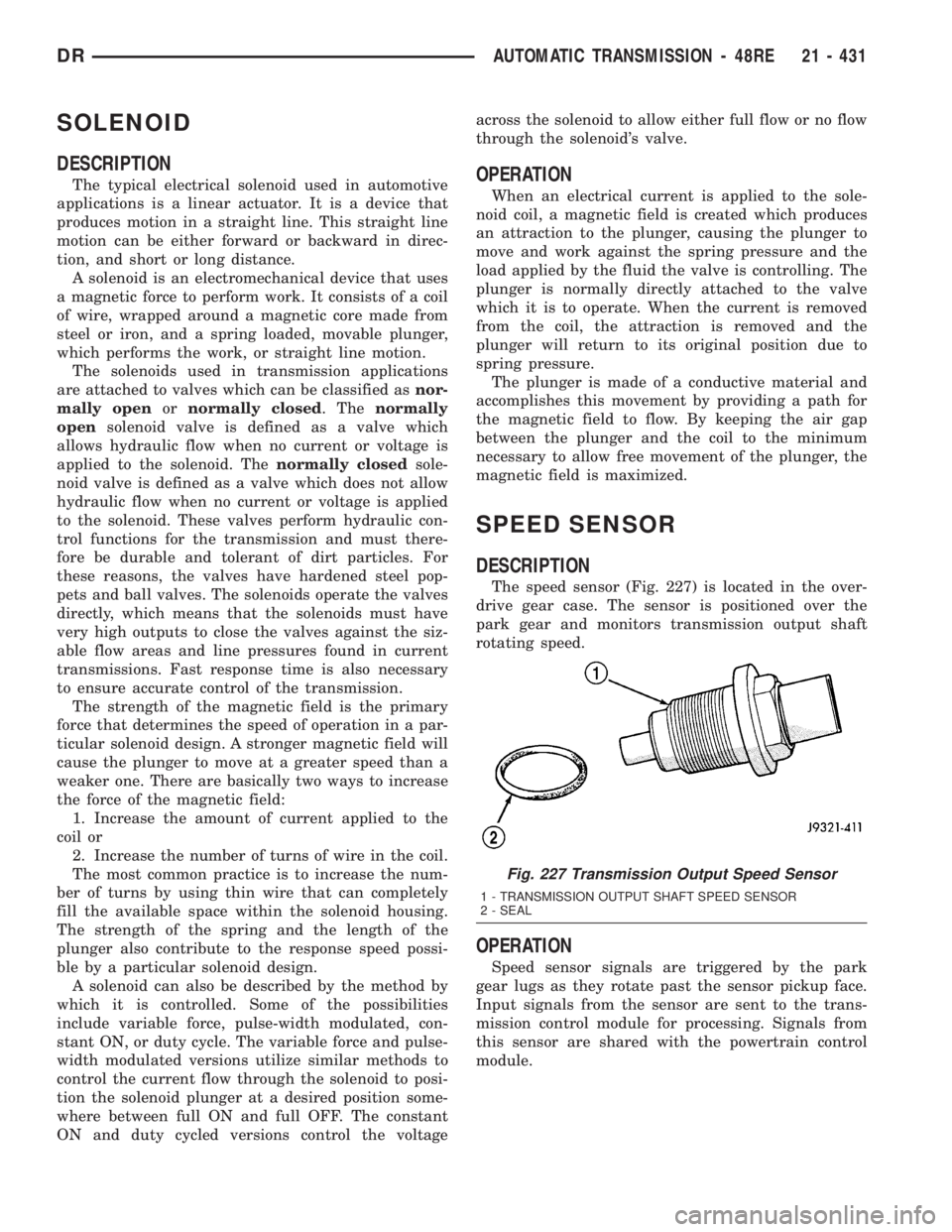

The speed sensor (Fig. 227) is located in the over-

drive gear case. The sensor is positioned over the

park gear and monitors transmission output shaft

rotating speed.

OPERATION

Speed sensor signals are triggered by the park

gear lugs as they rotate past the sensor pickup face.

Input signals from the sensor are sent to the trans-

mission control module for processing. Signals from

this sensor are shared with the powertrain control

module.

Fig. 227 Transmission Output Speed Sensor

1 - TRANSMISSION OUTPUT SHAFT SPEED SENSOR

2 - SEAL

DRAUTOMATIC TRANSMISSION - 48RE 21 - 431

Page 2279 of 2895

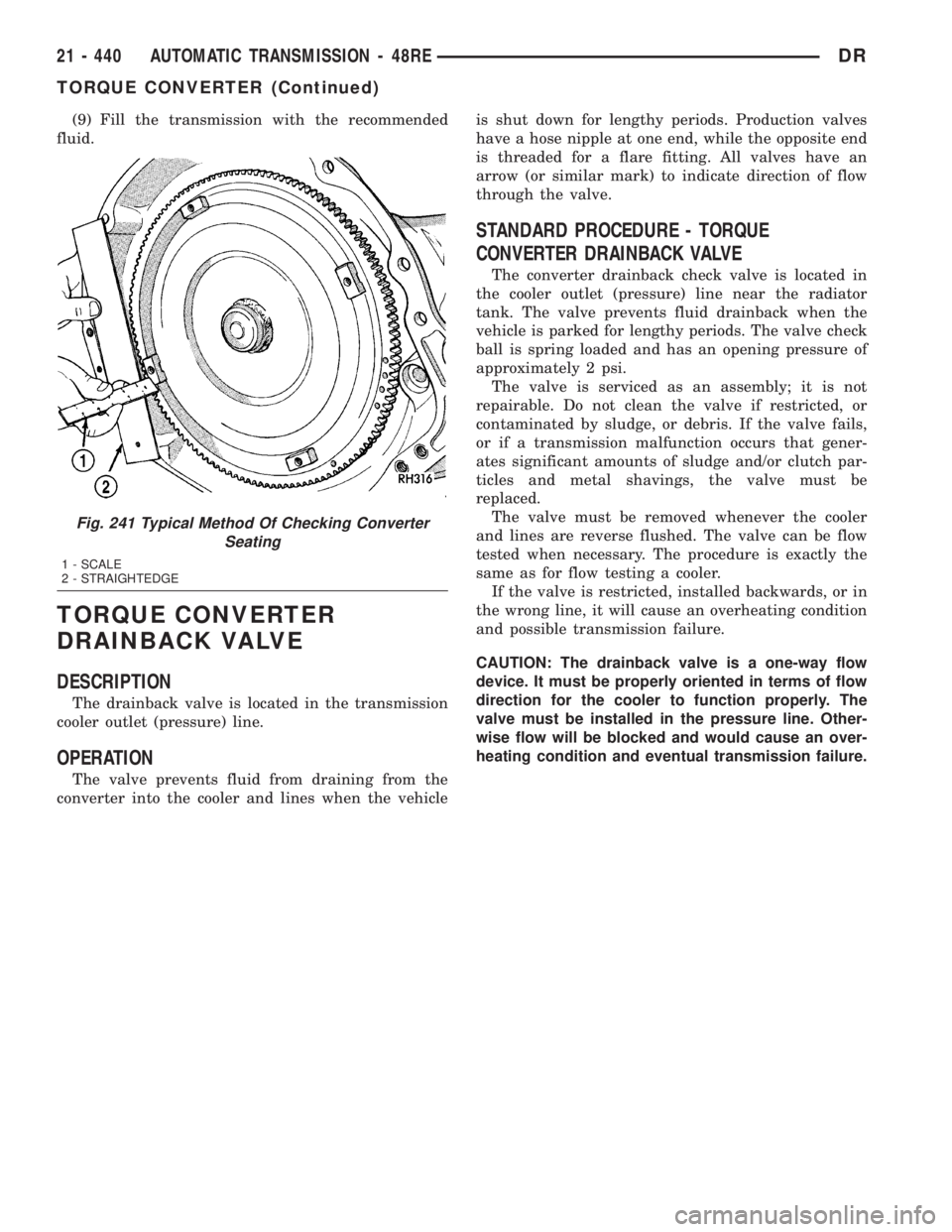

(9) Fill the transmission with the recommended

fluid.

TORQUE CONVERTER

DRAINBACK VALVE

DESCRIPTION

The drainback valve is located in the transmission

cooler outlet (pressure) line.

OPERATION

The valve prevents fluid from draining from the

converter into the cooler and lines when the vehicleis shut down for lengthy periods. Production valves

have a hose nipple at one end, while the opposite end

is threaded for a flare fitting. All valves have an

arrow (or similar mark) to indicate direction of flow

through the valve.

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

tank. The valve prevents fluid drainback when the

vehicle is parked for lengthy periods. The valve check

ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not

repairable. Do not clean the valve if restricted, or

contaminated by sludge, or debris. If the valve fails,

or if a transmission malfunction occurs that gener-

ates significant amounts of sludge and/or clutch par-

ticles and metal shavings, the valve must be

replaced.

The valve must be removed whenever the cooler

and lines are reverse flushed. The valve can be flow

tested when necessary. The procedure is exactly the

same as for flow testing a cooler.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow

device. It must be properly oriented in terms of flow

direction for the cooler to function properly. The

valve must be installed in the pressure line. Other-

wise flow will be blocked and would cause an over-

heating condition and eventual transmission failure.

Fig. 241 Typical Method Of Checking Converter

Seating

1 - SCALE

2 - STRAIGHTEDGE

21 - 440 AUTOMATIC TRANSMISSION - 48REDR

TORQUE CONVERTER (Continued)

Page 2280 of 2895

TRANSMISSION RANGE

SENSOR

DESCRIPTION

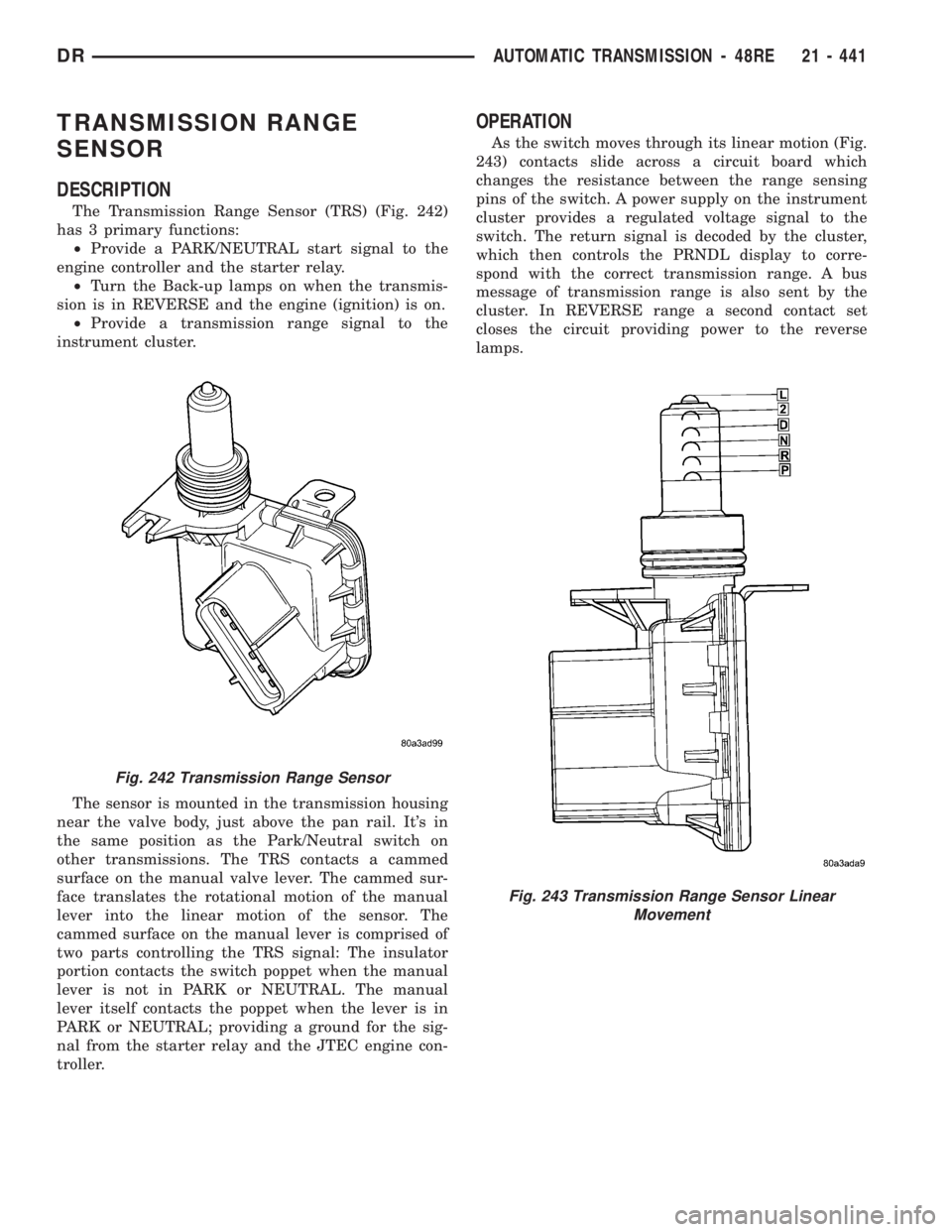

The Transmission Range Sensor (TRS) (Fig. 242)

has 3 primary functions:

²Provide a PARK/NEUTRAL start signal to the

engine controller and the starter relay.

²Turn the Back-up lamps on when the transmis-

sion is in REVERSE and the engine (ignition) is on.

²Provide a transmission range signal to the

instrument cluster.

The sensor is mounted in the transmission housing

near the valve body, just above the pan rail. It's in

the same position as the Park/Neutral switch on

other transmissions. The TRS contacts a cammed

surface on the manual valve lever. The cammed sur-

face translates the rotational motion of the manual

lever into the linear motion of the sensor. The

cammed surface on the manual lever is comprised of

two parts controlling the TRS signal: The insulator

portion contacts the switch poppet when the manual

lever is not in PARK or NEUTRAL. The manual

lever itself contacts the poppet when the lever is in

PARK or NEUTRAL; providing a ground for the sig-

nal from the starter relay and the JTEC engine con-

troller.

OPERATION

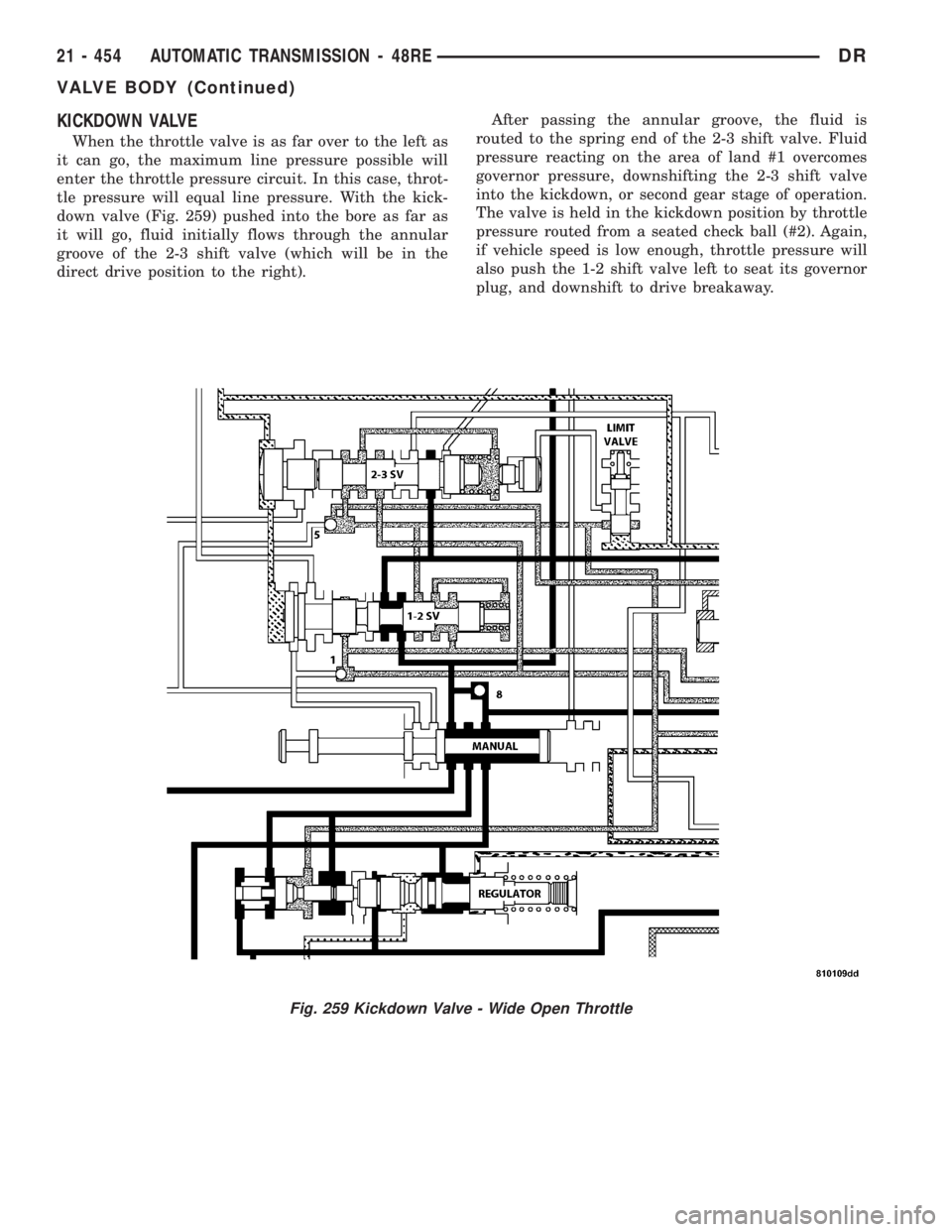

As the switch moves through its linear motion (Fig.

243) contacts slide across a circuit board which

changes the resistance between the range sensing

pins of the switch. A power supply on the instrument

cluster provides a regulated voltage signal to the

switch. The return signal is decoded by the cluster,

which then controls the PRNDL display to corre-

spond with the correct transmission range. A bus

message of transmission range is also sent by the

cluster. In REVERSE range a second contact set

closes the circuit providing power to the reverse

lamps.

Fig. 242 Transmission Range Sensor

Fig. 243 Transmission Range Sensor Linear

Movement

DRAUTOMATIC TRANSMISSION - 48RE 21 - 441

Page 2293 of 2895

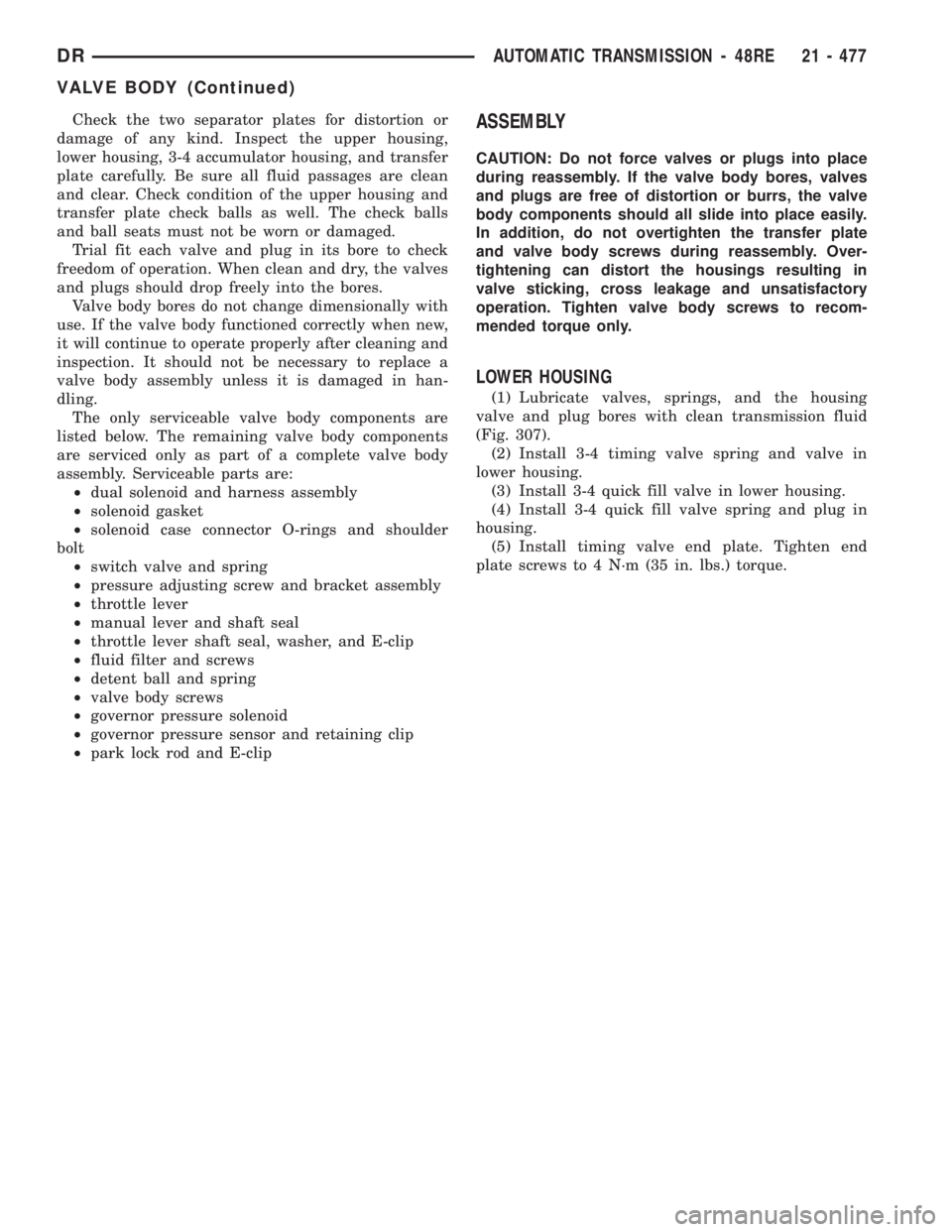

KICKDOWN VALVE

When the throttle valve is as far over to the left as

it can go, the maximum line pressure possible will

enter the throttle pressure circuit. In this case, throt-

tle pressure will equal line pressure. With the kick-

down valve (Fig. 259) pushed into the bore as far as

it will go, fluid initially flows through the annular

groove of the 2-3 shift valve (which will be in the

direct drive position to the right).After passing the annular groove, the fluid is

routed to the spring end of the 2-3 shift valve. Fluid

pressure reacting on the area of land #1 overcomes

governor pressure, downshifting the 2-3 shift valve

into the kickdown, or second gear stage of operation.

The valve is held in the kickdown position by throttle

pressure routed from a seated check ball (#2). Again,

if vehicle speed is low enough, throttle pressure will

also push the 1-2 shift valve left to seat its governor

plug, and downshift to drive breakaway.

Fig. 259 Kickdown Valve - Wide Open Throttle

21 - 454 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2316 of 2895

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clipASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 307).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

DRAUTOMATIC TRANSMISSION - 48RE 21 - 477

VALVE BODY (Continued)

Page 2325 of 2895

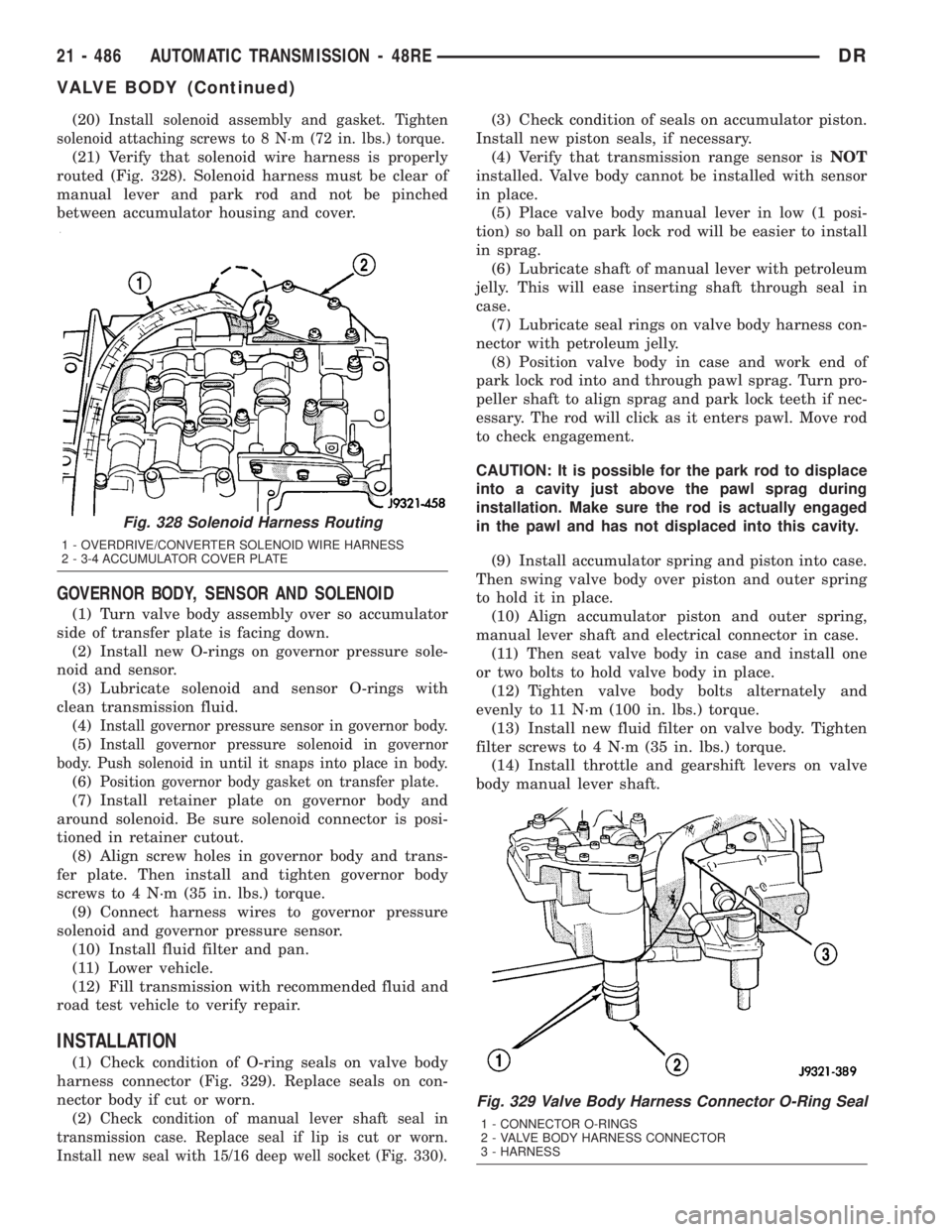

(20)Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.) torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 328). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4)

Install governor pressure sensor in governor body.

(5)Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in body.

(6)Position governor body gasket on transfer plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 329). Replace seals on con-

nector body if cut or worn.

(2)

Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig. 330).

(3) Check condition of seals on accumulator piston.

Install new piston seals, if necessary.

(4) Verify that transmission range sensor isNOT

installed. Valve body cannot be installed with sensor

in place.

(5) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(6) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(7) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(8) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(9) Install accumulator spring and piston into case.

Then swing valve body over piston and outer spring

to hold it in place.

(10) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(11) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(12) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(13) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(14) Install throttle and gearshift levers on valve

body manual lever shaft.

Fig. 329 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

Fig. 328 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

21 - 486 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2329 of 2895

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS

The 45RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

Reverse.............................3.00:1

GEAR RATIOS

The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse.............................3.00:1

OPERATION

The 45RFE/545RFE offers full electronic control of

all automatic up and downshifts, and features real-

time adaptive closed-loop shift and pressure control.

Electronic shift and torque converter clutch controls

help protect the transmission from damage due to

high temperatures, which can occur under severe

operating conditions. By altering shift schedules, line

pressure, and converter clutch control, these controls

reduce heat generation and increase transmission

cooling.

To help reduce efficiency-robbing parasitic losses,

the transmissions includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 45RFE/545RFE pump-pressure

control system monitors input torque and adjusts the

pump pressure accordingly. The primary stage of the

pump works continuously; the second stage is

bypassed when demand is low. The control system

also monitors input and output speed and, if incipi-

ent clutch slip is observed, the pressure control sole-

noid duty cycle is varied, increasing pressure in

proportion to demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 45RFE/545RFE is packaged in

a one-piece die-cast aluminum case. To reduce NVH,

the case has high lateral, vertical and torsional stiff-

ness. It is also designed to maximize the benefit of

the structural dust cover that connects the bottom of

the bell housing to the engine bedplate, enhancing

overall power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRBtscan tool.

Fig. 1 Transmission Part And Serial Number

Location

1 - IDENTIFICATION NUMBERS (STAMPED)

21 - 490 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2334 of 2895

NOTE: The air supply which is used must be free of

moisture and dirt. Use a pressure of 30 psi to test

clutch operation.

Apply air pressure at each port. If the clutch is

functioning, a soft thump will be heard as the clutch

is applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

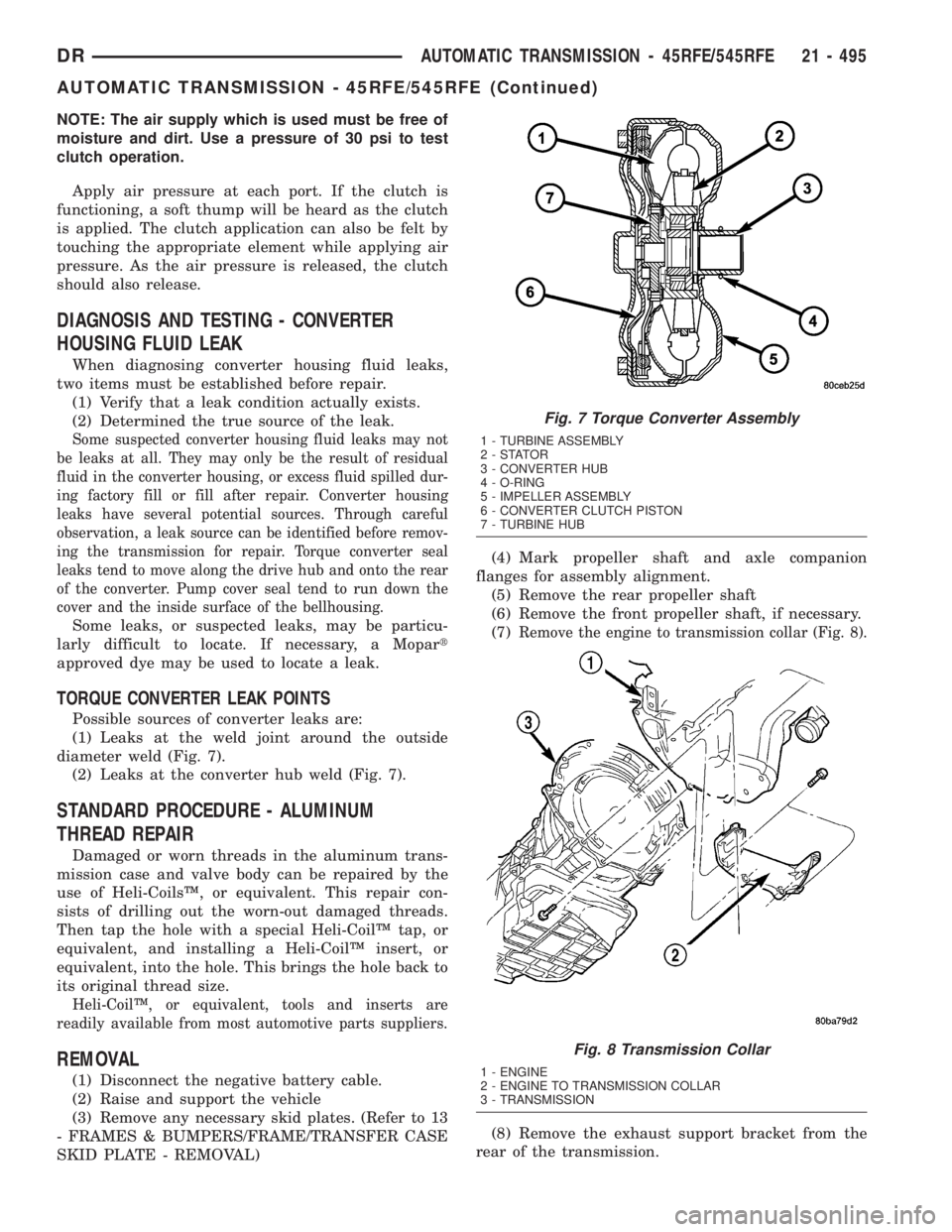

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may not

be leaks at all. They may only be the result of residual

fluid in the converter housing, or excess fluid spilled dur-

ing factory fill or fill after repair. Converter housing

leaks have several potential sources. Through careful

observation, a leak source can be identified before remov-

ing the transmission for repair. Torque converter seal

leaks tend to move along the drive hub and onto the rear

of the converter. Pump cover seal tend to run down the

cover and the inside surface of the bellhousing.

Some leaks, or suspected leaks, may be particu-

larly difficult to locate. If necessary, a Mopart

approved dye may be used to locate a leak.

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppliers.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Remove any necessary skid plates. (Refer to 13

- FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)(4) Mark propeller shaft and axle companion

flanges for assembly alignment.

(5) Remove the rear propeller shaft

(6) Remove the front propeller shaft, if necessary.

(7)

Remove the engine to transmission collar (Fig. 8).

(8) Remove the exhaust support bracket from the

rear of the transmission.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 495

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)