Oss DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2636 of 2895

STEERING COLUMN OPENING

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

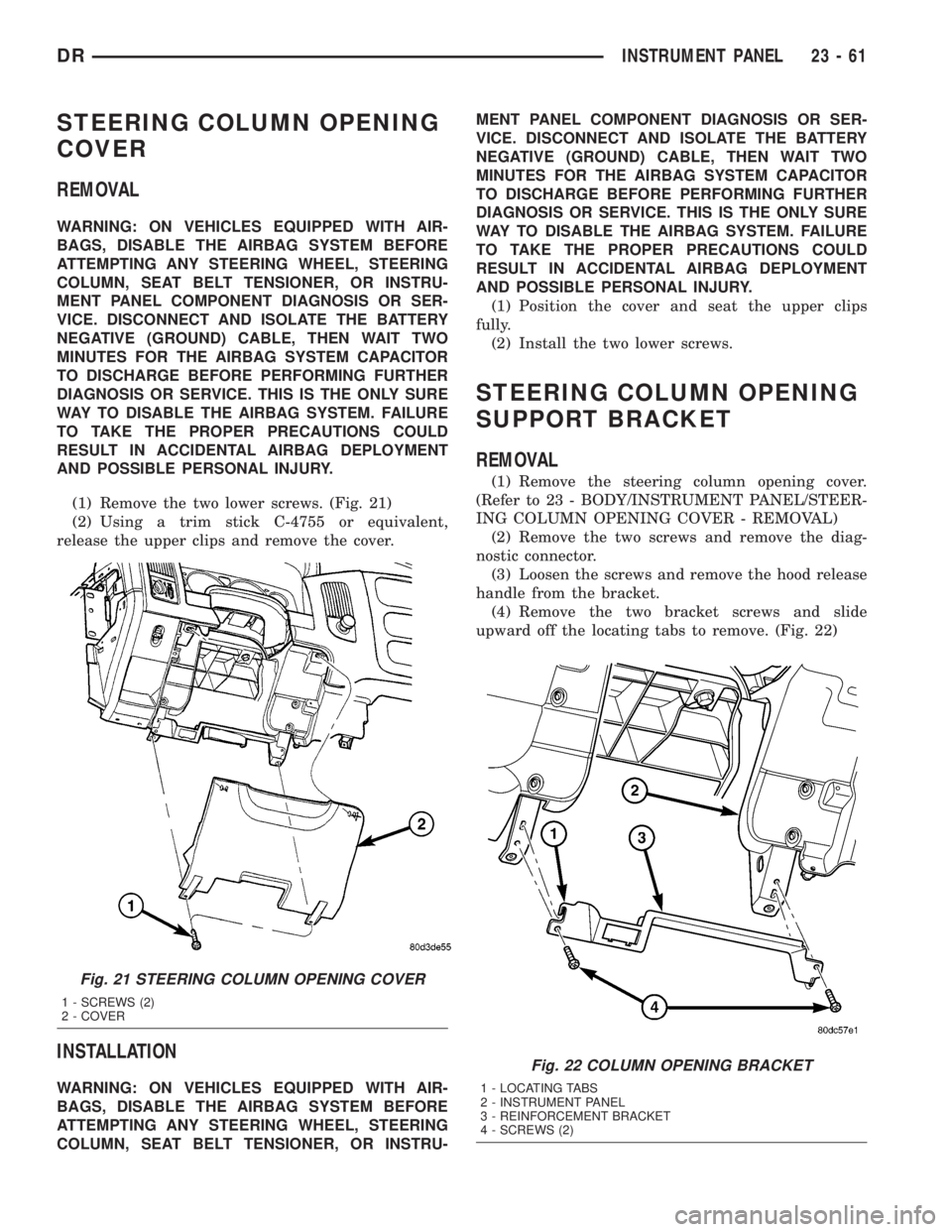

(1) Remove the two lower screws. (Fig. 21)

(2) Using a trim stick C-4755 or equivalent,

release the upper clips and remove the cover.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the cover and seat the upper clips

fully.

(2) Install the two lower screws.

STEERING COLUMN OPENING

SUPPORT BRACKET

REMOVAL

(1) Remove the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL)

(2) Remove the two screws and remove the diag-

nostic connector.

(3) Loosen the screws and remove the hood release

handle from the bracket.

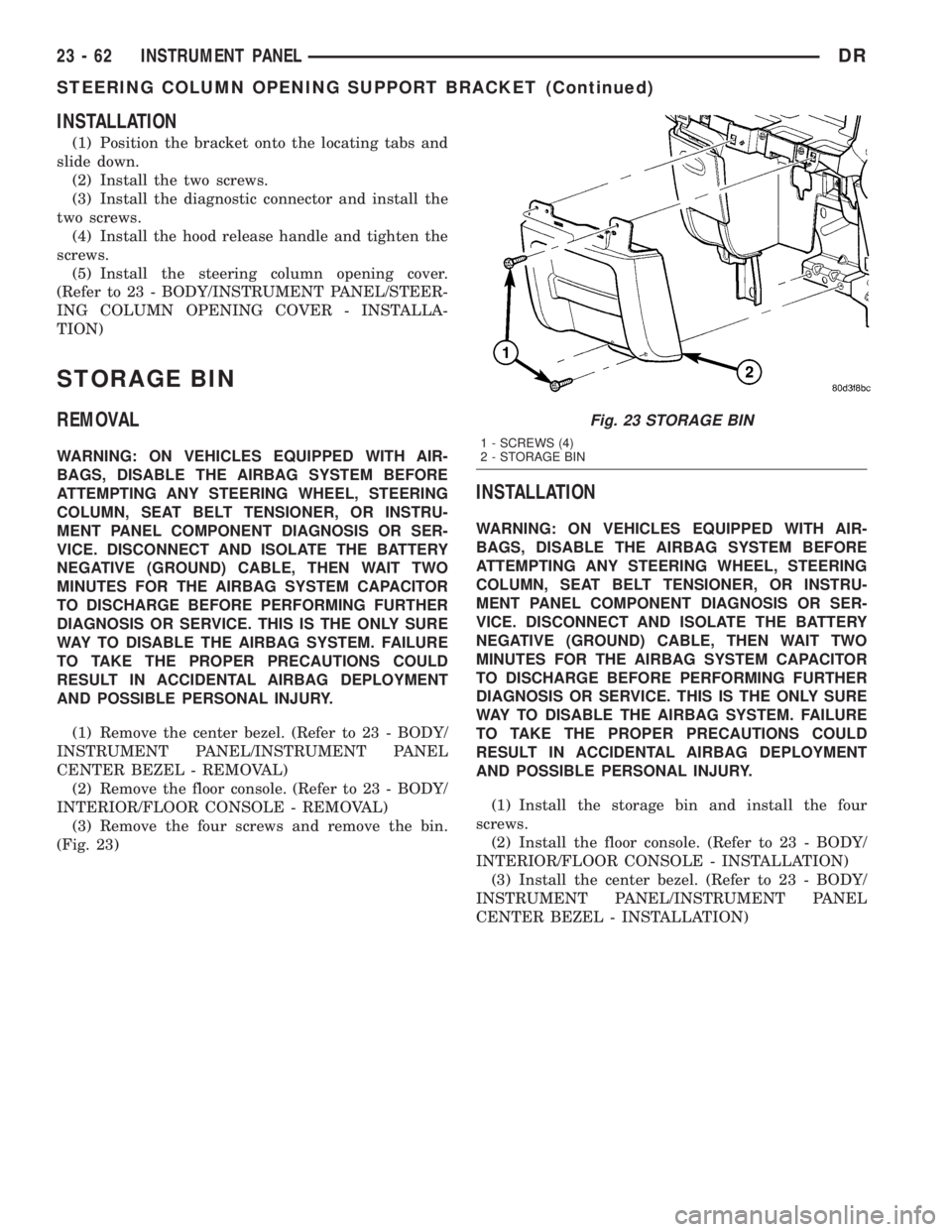

(4) Remove the two bracket screws and slide

upward off the locating tabs to remove. (Fig. 22)

Fig. 21 STEERING COLUMN OPENING COVER

1 - SCREWS (2)

2 - COVER

Fig. 22 COLUMN OPENING BRACKET

1 - LOCATING TABS

2 - INSTRUMENT PANEL

3 - REINFORCEMENT BRACKET

4 - SCREWS (2)

DRINSTRUMENT PANEL 23 - 61

Page 2637 of 2895

INSTALLATION

(1) Position the bracket onto the locating tabs and

slide down.

(2) Install the two screws.

(3) Install the diagnostic connector and install the

two screws.

(4) Install the hood release handle and tighten the

screws.

(5) Install the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

STORAGE BIN

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - REMOVAL)

(2) Remove the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL)

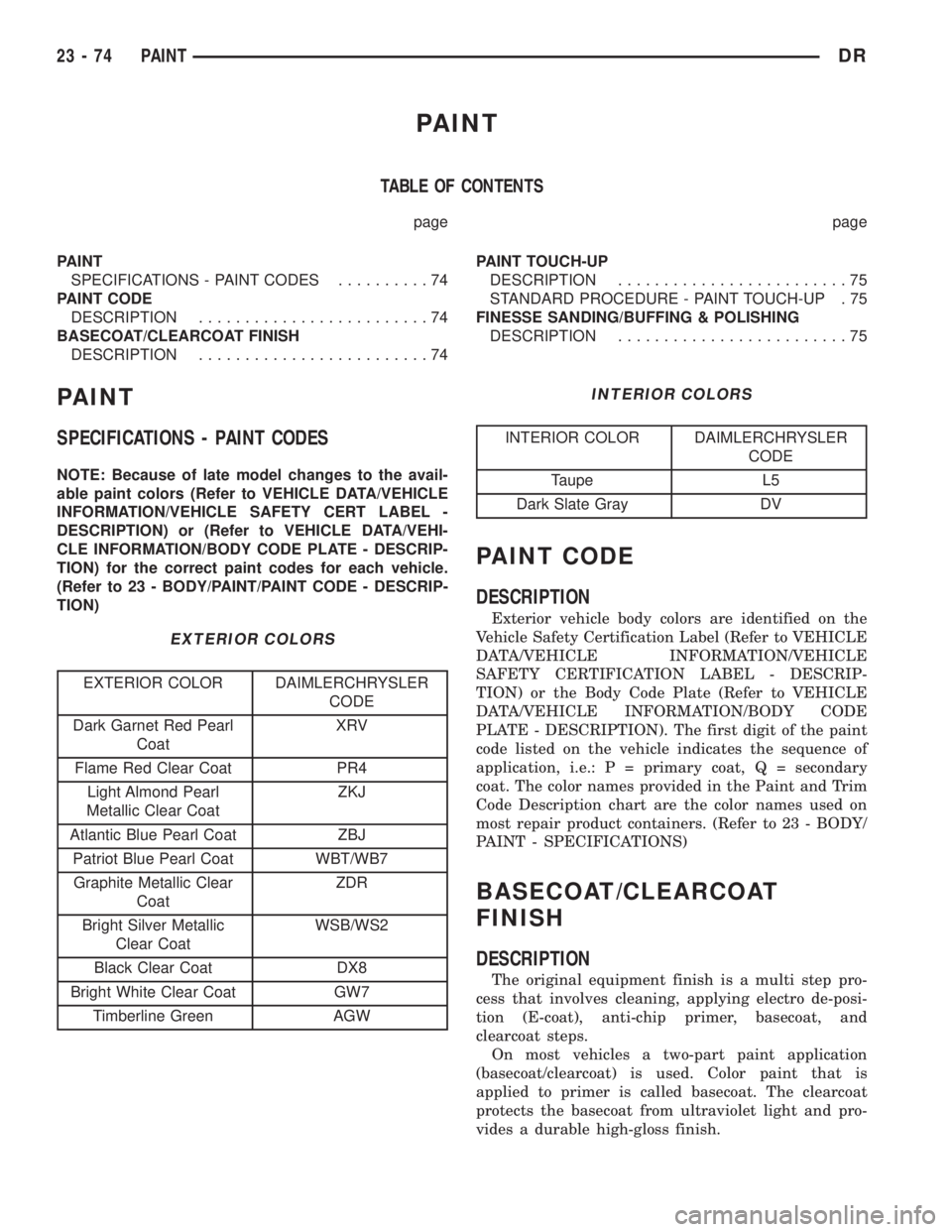

(3) Remove the four screws and remove the bin.

(Fig. 23)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install the storage bin and install the four

screws.

(2) Install the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION)

(3) Install the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

Fig. 23 STORAGE BIN

1 - SCREWS (4)

2 - STORAGE BIN

23 - 62 INSTRUMENT PANELDR

STEERING COLUMN OPENING SUPPORT BRACKET (Continued)

Page 2649 of 2895

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - PAINT CODES..........74

PAINT CODE

DESCRIPTION.........................74

BASECOAT/CLEARCOAT FINISH

DESCRIPTION.........................74PAINT TOUCH-UP

DESCRIPTION.........................75

STANDARD PROCEDURE - PAINT TOUCH-UP . 75

FINESSE SANDING/BUFFING & POLISHING

DESCRIPTION.........................75

PAINT

SPECIFICATIONS - PAINT CODES

NOTE: Because of late model changes to the avail-

able paint colors (Refer to VEHICLE DATA/VEHICLE

INFORMATION/VEHICLE SAFETY CERT LABEL -

DESCRIPTION) or (Refer to VEHICLE DATA/VEHI-

CLE INFORMATION/BODY CODE PLATE - DESCRIP-

TION) for the correct paint codes for each vehicle.

(Refer to 23 - BODY/PAINT/PAINT CODE - DESCRIP-

TION)

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

CODE

Dark Garnet Red Pearl

CoatXRV

Flame Red Clear Coat PR4

Light Almond Pearl

Metallic Clear CoatZKJ

Atlantic Blue Pearl Coat ZBJ

Patriot Blue Pearl Coat WBT/WB7

Graphite Metallic Clear

CoatZDR

Bright Silver Metallic

Clear CoatWSB/WS2

Black Clear Coat DX8

Bright White Clear Coat GW7

Timberline Green AGW

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER

CODE

Taupe L5

Dark Slate Gray DV

PAINT CODE

DESCRIPTION

Exterior vehicle body colors are identified on the

Vehicle Safety Certification Label (Refer to VEHICLE

DATA/VEHICLE INFORMATION/VEHICLE

SAFETY CERTIFICATION LABEL - DESCRIP-

TION) or the Body Code Plate (Refer to VEHICLE

DATA/VEHICLE INFORMATION/BODY CODE

PLATE - DESCRIPTION). The first digit of the paint

code listed on the vehicle indicates the sequence of

application, i.e.: P = primary coat, Q = secondary

coat. The color names provided in the Paint and Trim

Code Description chart are the color names used on

most repair product containers. (Refer to 23 - BODY/

PAINT - SPECIFICATIONS)

BASECOAT/CLEARCOAT

FINISH

DESCRIPTION

The original equipment finish is a multi step pro-

cess that involves cleaning, applying electro de-posi-

tion (E-coat), anti-chip primer, basecoat, and

clearcoat steps.

On most vehicles a two-part paint application

(basecoat/clearcoat) is used. Color paint that is

applied to primer is called basecoat. The clearcoat

protects the basecoat from ultraviolet light and pro-

vides a durable high-gloss finish.

23 - 74 PAINTDR

Page 2650 of 2895

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning solvents

on painted surfaces. Damage to finish or color can

result.

PAINT TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use MOPARt

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. (Refer to VEHICLE DATA/VEHICLE INFOR-

MATION/BODY CODE PLATE - DESCRIPTION) for

Body Code Plate information.

WARNING: USE AN OSHA APPROVED RESPIRATOR

AND SAFETY GLASSES WHEN SPRAYING PAINT

OR SOLVENTS IN A CONFINED AREA. PERSONAL

INJURY CAN RESULT.

STANDARD PROCEDURE - PAINT TOUCH-UP

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MOPARtTar/Road

Oil Remover or equivalent, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the scratch or chip without run-

ning. Do not stroke brush applicator on body surface.

Allow the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the newcolor to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clearcoat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.

(6) On vehicles with clearcoat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

FINESSE SANDING/BUFFING &

POLISHING

DESCRIPTION

CAUTION: Do not remove more than .5 mils of

clearcoat finish, if equipped. Basecoat paint must

retain clearcoat for durability.

Use a Paint Thickness Gauge #PR-ETG-2X or equiv-

alent to determine film thickness before and after

the repair.

Minor acid etching, orange peel, or smudging in

clearcoat or single-stage finishes can be reduced with

light finesse sanding, hand buffing, and polishing.If

the finish has been finesse sanded in the past,

it cannot be repeated. Finesse sanding opera-

tion should be performed by a trained automo-

tive paint technician.

DRPAINT 23 - 75

BASECOAT/CLEARCOAT FINISH (Continued)

Page 2664 of 2895

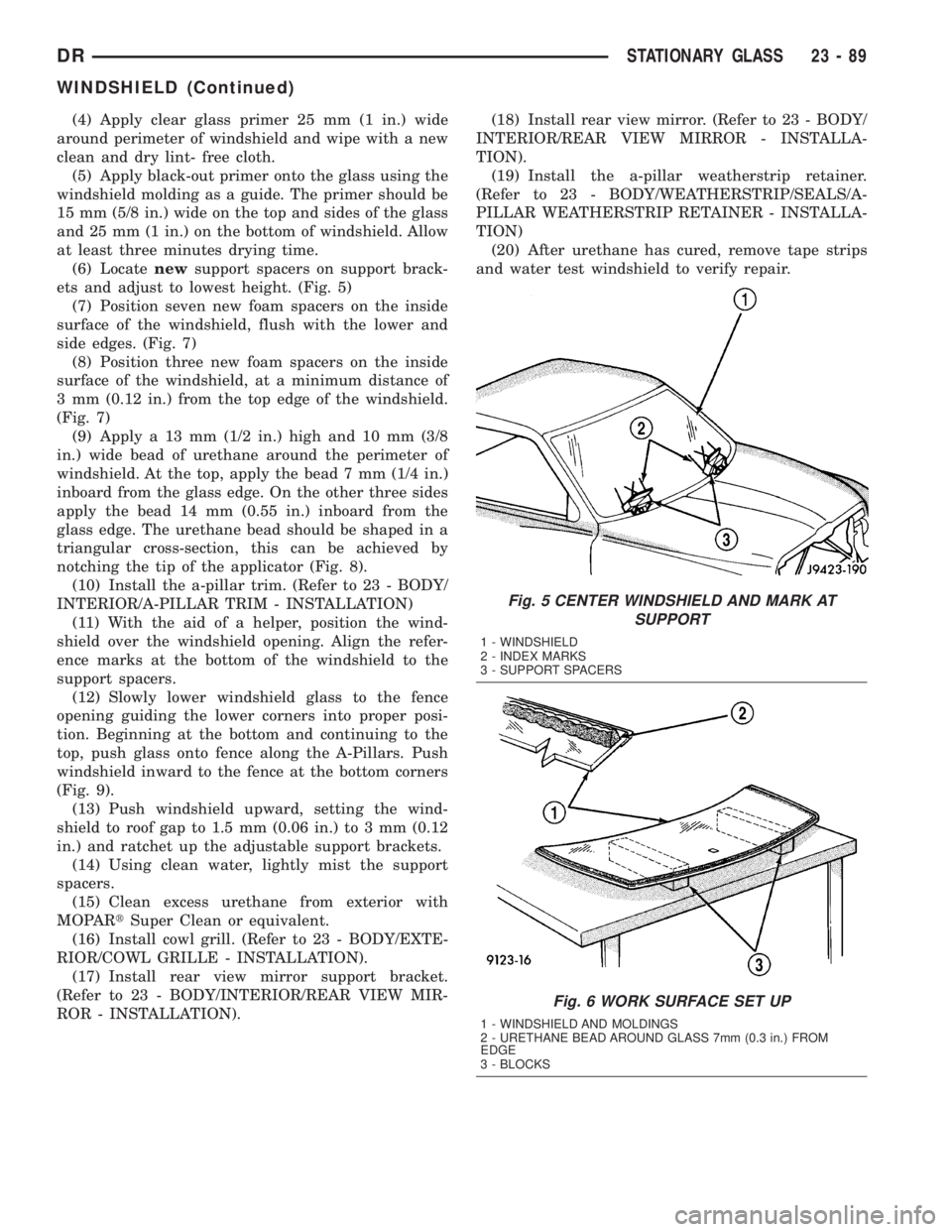

(4) Apply clear glass primer 25 mm (1 in.) wide

around perimeter of windshield and wipe with a new

clean and dry lint- free cloth.

(5) Apply black-out primer onto the glass using the

windshield molding as a guide. The primer should be

15 mm (5/8 in.) wide on the top and sides of the glass

and 25 mm (1 in.) on the bottom of windshield. Allow

at least three minutes drying time.

(6) Locatenewsupport spacers on support brack-

ets and adjust to lowest height. (Fig. 5)

(7) Position seven new foam spacers on the inside

surface of the windshield, flush with the lower and

side edges. (Fig. 7)

(8) Position three new foam spacers on the inside

surface of the windshield, at a minimum distance of

3 mm (0.12 in.) from the top edge of the windshield.

(Fig. 7)

(9) Apply a 13 mm (1/2 in.) high and 10 mm (3/8

in.) wide bead of urethane around the perimeter of

windshield. At the top, apply the bead 7 mm (1/4 in.)

inboard from the glass edge. On the other three sides

apply the bead 14 mm (0.55 in.) inboard from the

glass edge. The urethane bead should be shaped in a

triangular cross-section, this can be achieved by

notching the tip of the applicator (Fig. 8).

(10) Install the a-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - INSTALLATION)

(11) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

(12) Slowly lower windshield glass to the fence

opening guiding the lower corners into proper posi-

tion. Beginning at the bottom and continuing to the

top, push glass onto fence along the A-Pillars. Push

windshield inward to the fence at the bottom corners

(Fig. 9).

(13) Push windshield upward, setting the wind-

shield to roof gap to 1.5 mm (0.06 in.) to 3 mm (0.12

in.) and ratchet up the adjustable support brackets.

(14) Using clean water, lightly mist the support

spacers.

(15) Clean excess urethane from exterior with

MOPARtSuper Clean or equivalent.

(16) Install cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION).

(17) Install rear view mirror support bracket.

(Refer to 23 - BODY/INTERIOR/REAR VIEW MIR-

ROR - INSTALLATION).(18) Install rear view mirror. (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR - INSTALLA-

TION).

(19) Install the a-pillar weatherstrip retainer.

(Refer to 23 - BODY/WEATHERSTRIP/SEALS/A-

PILLAR WEATHERSTRIP RETAINER - INSTALLA-

TION)

(20) After urethane has cured, remove tape strips

and water test windshield to verify repair.

Fig. 5 CENTER WINDSHIELD AND MARK AT

SUPPORT

1 - WINDSHIELD

2 - INDEX MARKS

3 - SUPPORT SPACERS

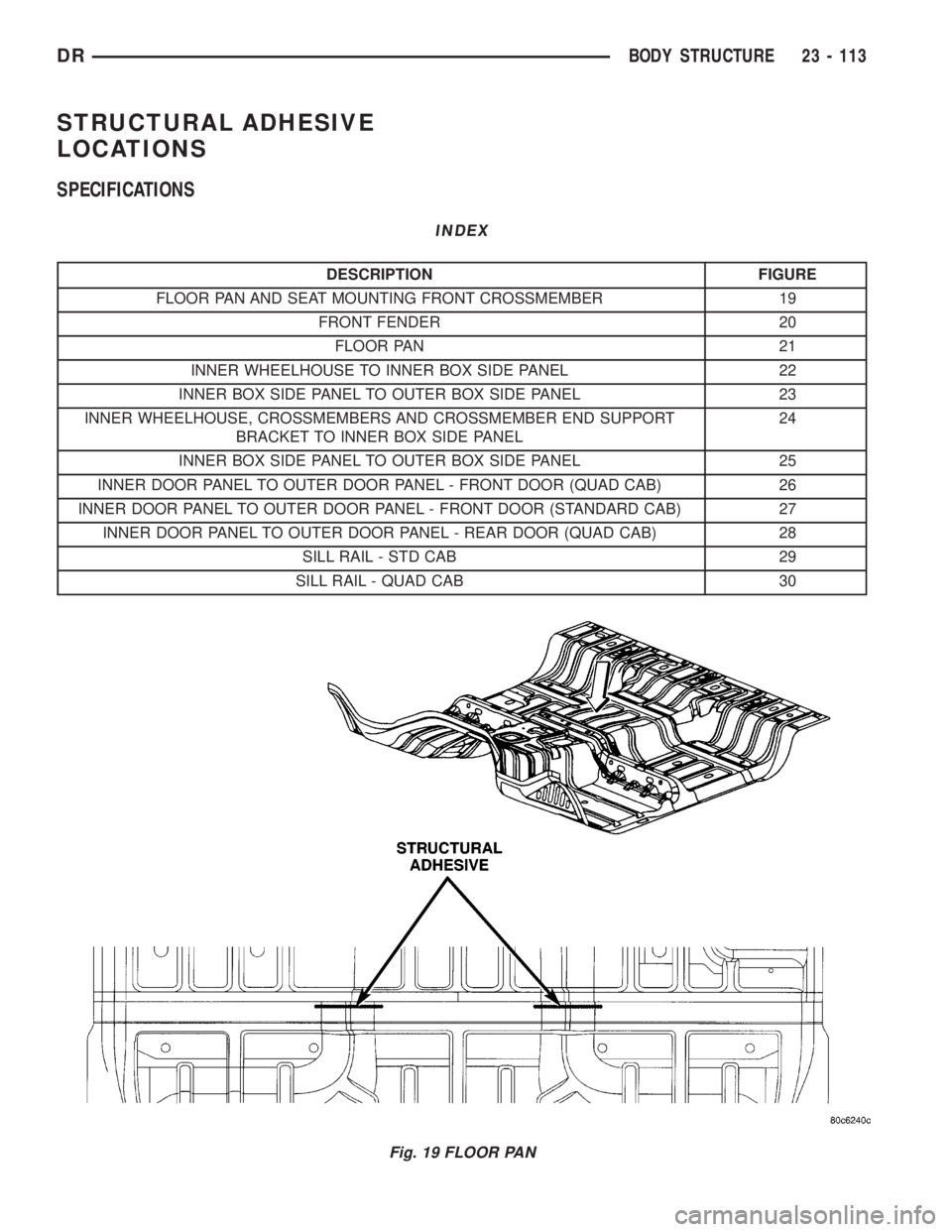

Fig. 6 WORK SURFACE SET UP

1 - WINDSHIELD AND MOLDINGS

2 - URETHANE BEAD AROUND GLASS 7mm (0.3 in.) FROM

EDGE

3 - BLOCKS

DRSTATIONARY GLASS 23 - 89

WINDSHIELD (Continued)

Page 2688 of 2895

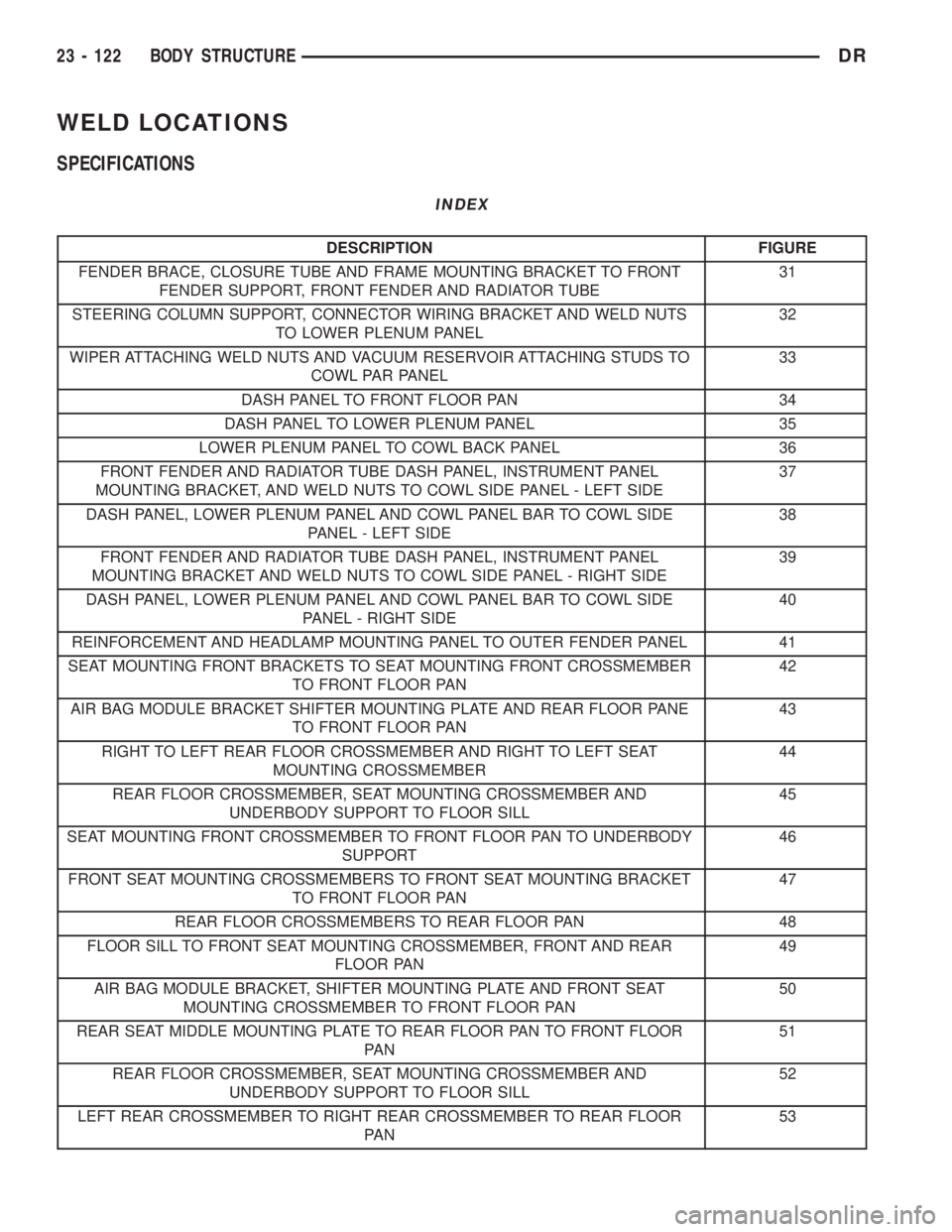

STRUCTURAL ADHESIVE

LOCATIONS

SPECIFICATIONS

INDEX

DESCRIPTION FIGURE

FLOOR PAN AND SEAT MOUNTING FRONT CROSSMEMBER 19

FRONT FENDER 20

FLOOR PAN 21

INNER WHEELHOUSE TO INNER BOX SIDE PANEL 22

INNER BOX SIDE PANEL TO OUTER BOX SIDE PANEL 23

INNER WHEELHOUSE, CROSSMEMBERS AND CROSSMEMBER END SUPPORT

BRACKET TO INNER BOX SIDE PANEL24

INNER BOX SIDE PANEL TO OUTER BOX SIDE PANEL 25

INNER DOOR PANEL TO OUTER DOOR PANEL - FRONT DOOR (QUAD CAB) 26

INNER DOOR PANEL TO OUTER DOOR PANEL - FRONT DOOR (STANDARD CAB) 27

INNER DOOR PANEL TO OUTER DOOR PANEL - REAR DOOR (QUAD CAB) 28

SILL RAIL - STD CAB 29

SILL RAIL - QUAD CAB 30

Fig. 19 FLOOR PAN

DRBODY STRUCTURE 23 - 113

Page 2697 of 2895

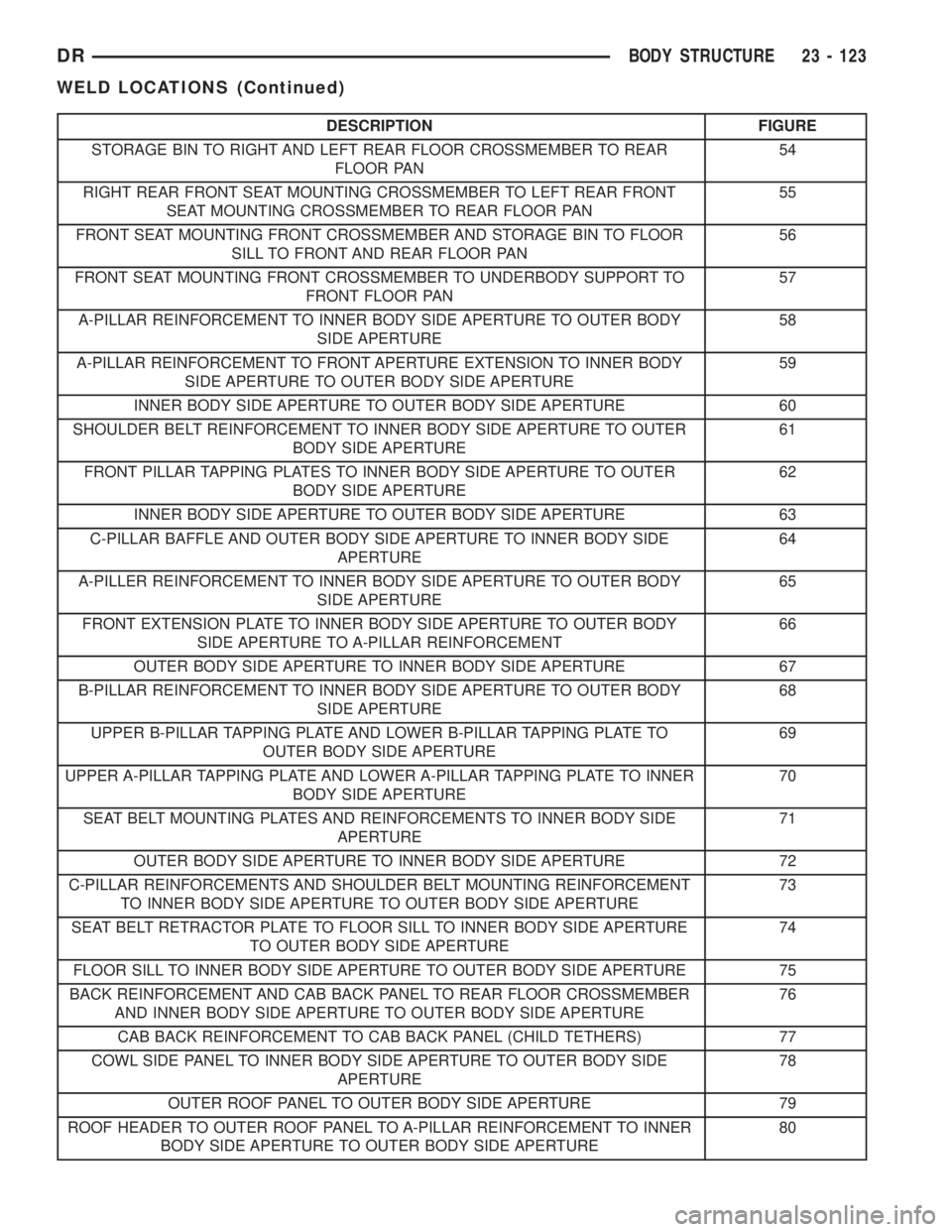

WELD LOCATIONS

SPECIFICATIONS

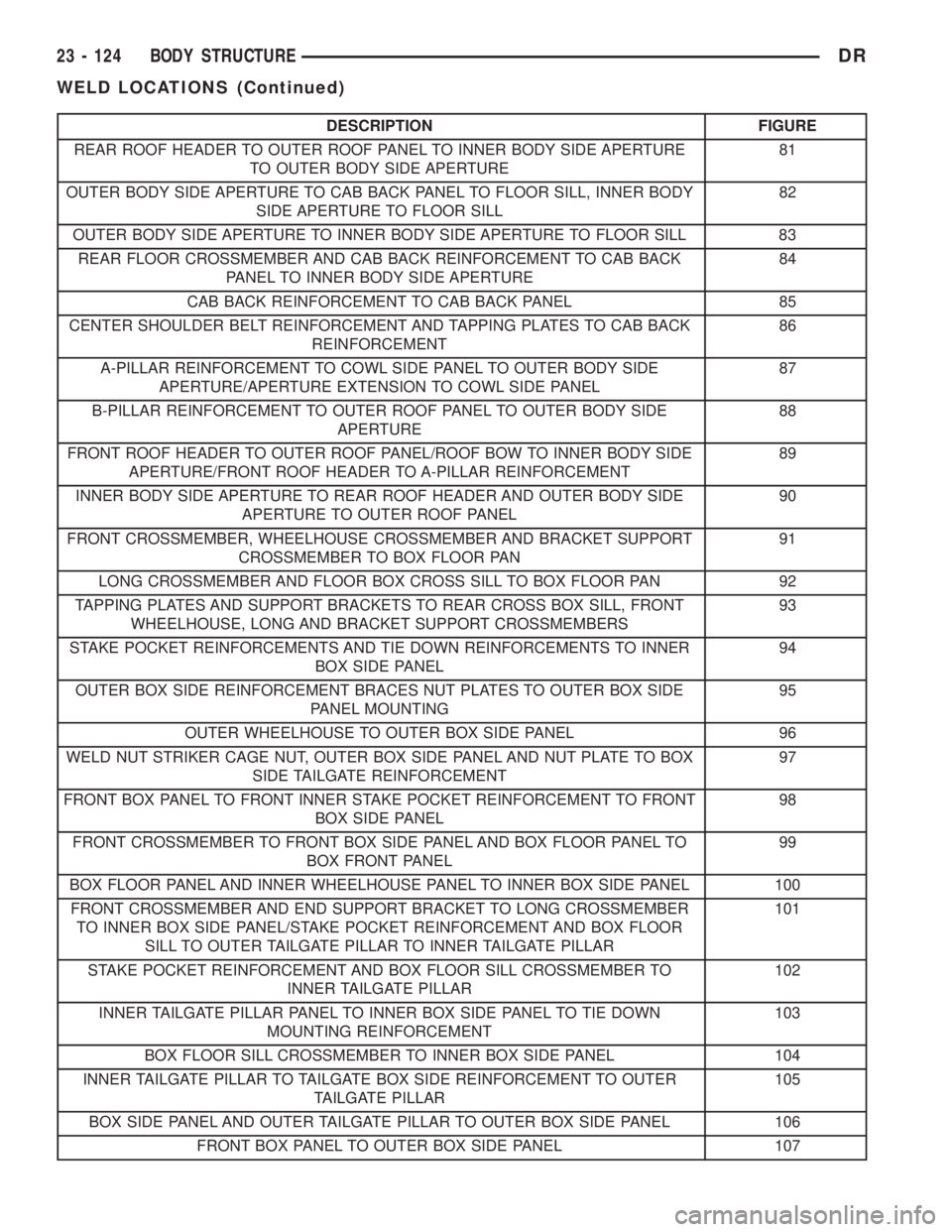

INDEX

DESCRIPTION FIGURE

FENDER BRACE, CLOSURE TUBE AND FRAME MOUNTING BRACKET TO FRONT

FENDER SUPPORT, FRONT FENDER AND RADIATOR TUBE31

STEERING COLUMN SUPPORT, CONNECTOR WIRING BRACKET AND WELD NUTS

TO LOWER PLENUM PANEL32

WIPER ATTACHING WELD NUTS AND VACUUM RESERVOIR ATTACHING STUDS TO

COWL PAR PANEL33

DASH PANEL TO FRONT FLOOR PAN 34

DASH PANEL TO LOWER PLENUM PANEL 35

LOWER PLENUM PANEL TO COWL BACK PANEL 36

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET, AND WELD NUTS TO COWL SIDE PANEL - LEFT SIDE37

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - LEFT SIDE38

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET AND WELD NUTS TO COWL SIDE PANEL - RIGHT SIDE39

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - RIGHT SIDE40

REINFORCEMENT AND HEADLAMP MOUNTING PANEL TO OUTER FENDER PANEL 41

SEAT MOUNTING FRONT BRACKETS TO SEAT MOUNTING FRONT CROSSMEMBER

TO FRONT FLOOR PAN42

AIR BAG MODULE BRACKET SHIFTER MOUNTING PLATE AND REAR FLOOR PANE

TO FRONT FLOOR PAN43

RIGHT TO LEFT REAR FLOOR CROSSMEMBER AND RIGHT TO LEFT SEAT

MOUNTING CROSSMEMBER44

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL45

SEAT MOUNTING FRONT CROSSMEMBER TO FRONT FLOOR PAN TO UNDERBODY

SUPPORT46

FRONT SEAT MOUNTING CROSSMEMBERS TO FRONT SEAT MOUNTING BRACKET

TO FRONT FLOOR PAN47

REAR FLOOR CROSSMEMBERS TO REAR FLOOR PAN 48

FLOOR SILL TO FRONT SEAT MOUNTING CROSSMEMBER, FRONT AND REAR

FLOOR PAN49

AIR BAG MODULE BRACKET, SHIFTER MOUNTING PLATE AND FRONT SEAT

MOUNTING CROSSMEMBER TO FRONT FLOOR PAN50

REAR SEAT MIDDLE MOUNTING PLATE TO REAR FLOOR PAN TO FRONT FLOOR

PA N51

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL52

LEFT REAR CROSSMEMBER TO RIGHT REAR CROSSMEMBER TO REAR FLOOR

PA N53

23 - 122 BODY STRUCTUREDR

Page 2698 of 2895

DESCRIPTION FIGURE

STORAGE BIN TO RIGHT AND LEFT REAR FLOOR CROSSMEMBER TO REAR

FLOOR PAN54

RIGHT REAR FRONT SEAT MOUNTING CROSSMEMBER TO LEFT REAR FRONT

SEAT MOUNTING CROSSMEMBER TO REAR FLOOR PAN55

FRONT SEAT MOUNTING FRONT CROSSMEMBER AND STORAGE BIN TO FLOOR

SILL TO FRONT AND REAR FLOOR PAN56

FRONT SEAT MOUNTING FRONT CROSSMEMBER TO UNDERBODY SUPPORT TO

FRONT FLOOR PAN57

A-PILLAR REINFORCEMENT TO INNER BODY SIDE APERTURE TO OUTER BODY

SIDE APERTURE58

A-PILLAR REINFORCEMENT TO FRONT APERTURE EXTENSION TO INNER BODY

SIDE APERTURE TO OUTER BODY SIDE APERTURE59

INNER BODY SIDE APERTURE TO OUTER BODY SIDE APERTURE 60

SHOULDER BELT REINFORCEMENT TO INNER BODY SIDE APERTURE TO OUTER

BODY SIDE APERTURE61

FRONT PILLAR TAPPING PLATES TO INNER BODY SIDE APERTURE TO OUTER

BODY SIDE APERTURE62

INNER BODY SIDE APERTURE TO OUTER BODY SIDE APERTURE 63

C-PILLAR BAFFLE AND OUTER BODY SIDE APERTURE TO INNER BODY SIDE

APERTURE64

A-PILLER REINFORCEMENT TO INNER BODY SIDE APERTURE TO OUTER BODY

SIDE APERTURE65

FRONT EXTENSION PLATE TO INNER BODY SIDE APERTURE TO OUTER BODY

SIDE APERTURE TO A-PILLAR REINFORCEMENT66

OUTER BODY SIDE APERTURE TO INNER BODY SIDE APERTURE 67

B-PILLAR REINFORCEMENT TO INNER BODY SIDE APERTURE TO OUTER BODY

SIDE APERTURE68

UPPER B-PILLAR TAPPING PLATE AND LOWER B-PILLAR TAPPING PLATE TO

OUTER BODY SIDE APERTURE69

UPPER A-PILLAR TAPPING PLATE AND LOWER A-PILLAR TAPPING PLATE TO INNER

BODY SIDE APERTURE70

SEAT BELT MOUNTING PLATES AND REINFORCEMENTS TO INNER BODY SIDE

APERTURE71

OUTER BODY SIDE APERTURE TO INNER BODY SIDE APERTURE 72

C-PILLAR REINFORCEMENTS AND SHOULDER BELT MOUNTING REINFORCEMENT

TO INNER BODY SIDE APERTURE TO OUTER BODY SIDE APERTURE73

SEAT BELT RETRACTOR PLATE TO FLOOR SILL TO INNER BODY SIDE APERTURE

TO OUTER BODY SIDE APERTURE74

FLOOR SILL TO INNER BODY SIDE APERTURE TO OUTER BODY SIDE APERTURE 75

BACK REINFORCEMENT AND CAB BACK PANEL TO REAR FLOOR CROSSMEMBER

AND INNER BODY SIDE APERTURE TO OUTER BODY SIDE APERTURE76

CAB BACK REINFORCEMENT TO CAB BACK PANEL (CHILD TETHERS) 77

COWL SIDE PANEL TO INNER BODY SIDE APERTURE TO OUTER BODY SIDE

APERTURE78

OUTER ROOF PANEL TO OUTER BODY SIDE APERTURE 79

ROOF HEADER TO OUTER ROOF PANEL TO A-PILLAR REINFORCEMENT TO INNER

BODY SIDE APERTURE TO OUTER BODY SIDE APERTURE80

DRBODY STRUCTURE 23 - 123

WELD LOCATIONS (Continued)

Page 2699 of 2895

DESCRIPTION FIGURE

REAR ROOF HEADER TO OUTER ROOF PANEL TO INNER BODY SIDE APERTURE

TO OUTER BODY SIDE APERTURE81

OUTER BODY SIDE APERTURE TO CAB BACK PANEL TO FLOOR SILL, INNER BODY

SIDE APERTURE TO FLOOR SILL82

OUTER BODY SIDE APERTURE TO INNER BODY SIDE APERTURE TO FLOOR SILL 83

REAR FLOOR CROSSMEMBER AND CAB BACK REINFORCEMENT TO CAB BACK

PANEL TO INNER BODY SIDE APERTURE84

CAB BACK REINFORCEMENT TO CAB BACK PANEL 85

CENTER SHOULDER BELT REINFORCEMENT AND TAPPING PLATES TO CAB BACK

REINFORCEMENT86

A-PILLAR REINFORCEMENT TO COWL SIDE PANEL TO OUTER BODY SIDE

APERTURE/APERTURE EXTENSION TO COWL SIDE PANEL87

B-PILLAR REINFORCEMENT TO OUTER ROOF PANEL TO OUTER BODY SIDE

APERTURE88

FRONT ROOF HEADER TO OUTER ROOF PANEL/ROOF BOW TO INNER BODY SIDE

APERTURE/FRONT ROOF HEADER TO A-PILLAR REINFORCEMENT89

INNER BODY SIDE APERTURE TO REAR ROOF HEADER AND OUTER BODY SIDE

APERTURE TO OUTER ROOF PANEL90

FRONT CROSSMEMBER, WHEELHOUSE CROSSMEMBER AND BRACKET SUPPORT

CROSSMEMBER TO BOX FLOOR PAN91

LONG CROSSMEMBER AND FLOOR BOX CROSS SILL TO BOX FLOOR PAN 92

TAPPING PLATES AND SUPPORT BRACKETS TO REAR CROSS BOX SILL, FRONT

WHEELHOUSE, LONG AND BRACKET SUPPORT CROSSMEMBERS93

STAKE POCKET REINFORCEMENTS AND TIE DOWN REINFORCEMENTS TO INNER

BOX SIDE PANEL94

OUTER BOX SIDE REINFORCEMENT BRACES NUT PLATES TO OUTER BOX SIDE

PANEL MOUNTING95

OUTER WHEELHOUSE TO OUTER BOX SIDE PANEL 96

WELD NUT STRIKER CAGE NUT, OUTER BOX SIDE PANEL AND NUT PLATE TO BOX

SIDE TAILGATE REINFORCEMENT97

FRONT BOX PANEL TO FRONT INNER STAKE POCKET REINFORCEMENT TO FRONT

BOX SIDE PANEL98

FRONT CROSSMEMBER TO FRONT BOX SIDE PANEL AND BOX FLOOR PANEL TO

BOX FRONT PANEL99

BOX FLOOR PANEL AND INNER WHEELHOUSE PANEL TO INNER BOX SIDE PANEL 100

FRONT CROSSMEMBER AND END SUPPORT BRACKET TO LONG CROSSMEMBER

TO INNER BOX SIDE PANEL/STAKE POCKET REINFORCEMENT AND BOX FLOOR

SILL TO OUTER TAILGATE PILLAR TO INNER TAILGATE PILLAR101

STAKE POCKET REINFORCEMENT AND BOX FLOOR SILL CROSSMEMBER TO

INNER TAILGATE PILLAR102

INNER TAILGATE PILLAR PANEL TO INNER BOX SIDE PANEL TO TIE DOWN

MOUNTING REINFORCEMENT103

BOX FLOOR SILL CROSSMEMBER TO INNER BOX SIDE PANEL 104

INNER TAILGATE PILLAR TO TAILGATE BOX SIDE REINFORCEMENT TO OUTER

TAILGATE PILLAR105

BOX SIDE PANEL AND OUTER TAILGATE PILLAR TO OUTER BOX SIDE PANEL 106

FRONT BOX PANEL TO OUTER BOX SIDE PANEL 107

23 - 124 BODY STRUCTUREDR

WELD LOCATIONS (Continued)

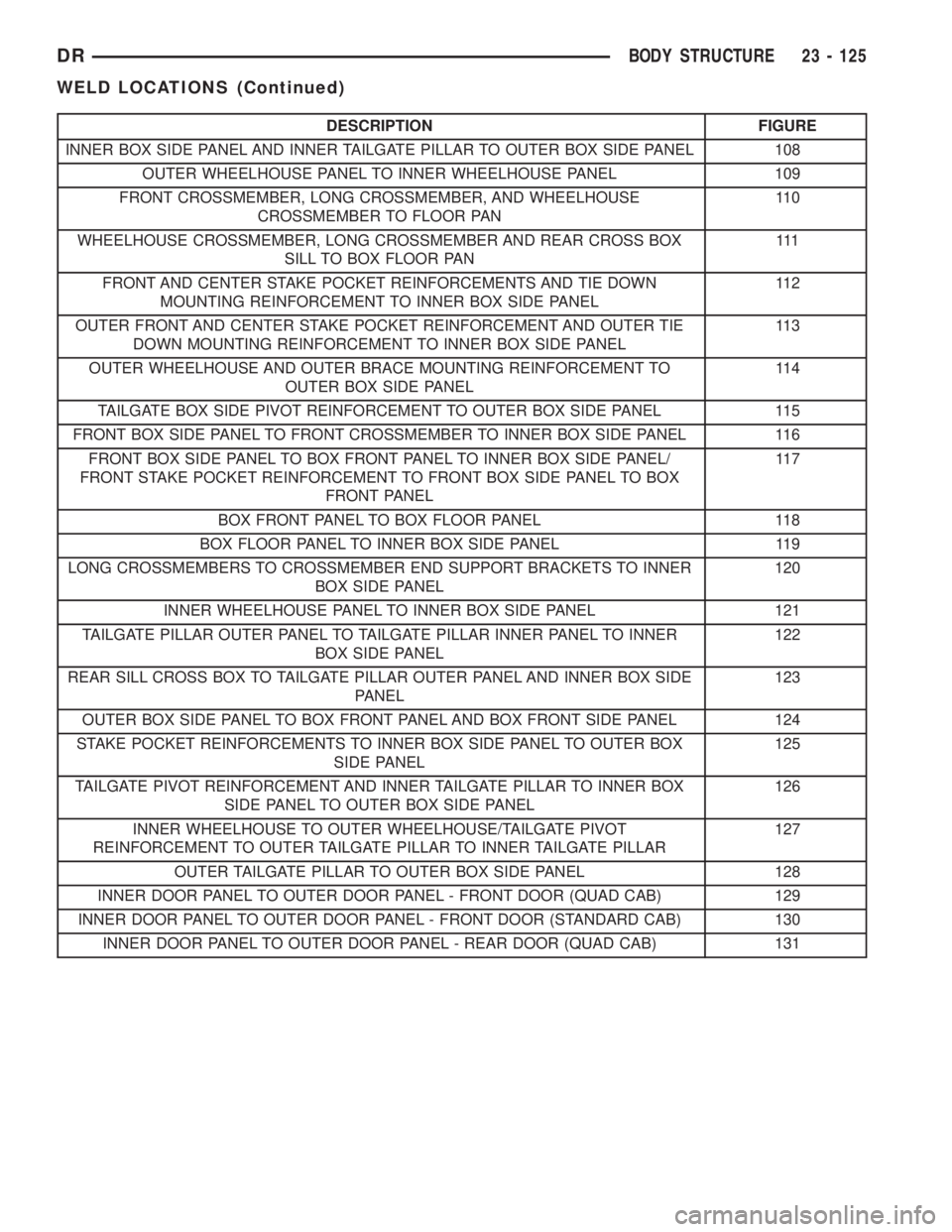

Page 2700 of 2895

DESCRIPTION FIGURE

INNER BOX SIDE PANEL AND INNER TAILGATE PILLAR TO OUTER BOX SIDE PANEL 108

OUTER WHEELHOUSE PANEL TO INNER WHEELHOUSE PANEL 109

FRONT CROSSMEMBER, LONG CROSSMEMBER, AND WHEELHOUSE

CROSSMEMBER TO FLOOR PAN11 0

WHEELHOUSE CROSSMEMBER, LONG CROSSMEMBER AND REAR CROSS BOX

SILL TO BOX FLOOR PAN111

FRONT AND CENTER STAKE POCKET REINFORCEMENTS AND TIE DOWN

MOUNTING REINFORCEMENT TO INNER BOX SIDE PANEL11 2

OUTER FRONT AND CENTER STAKE POCKET REINFORCEMENT AND OUTER TIE

DOWN MOUNTING REINFORCEMENT TO INNER BOX SIDE PANEL11 3

OUTER WHEELHOUSE AND OUTER BRACE MOUNTING REINFORCEMENT TO

OUTER BOX SIDE PANEL11 4

TAILGATE BOX SIDE PIVOT REINFORCEMENT TO OUTER BOX SIDE PANEL 115

FRONT BOX SIDE PANEL TO FRONT CROSSMEMBER TO INNER BOX SIDE PANEL 116

FRONT BOX SIDE PANEL TO BOX FRONT PANEL TO INNER BOX SIDE PANEL/

FRONT STAKE POCKET REINFORCEMENT TO FRONT BOX SIDE PANEL TO BOX

FRONT PANEL11 7

BOX FRONT PANEL TO BOX FLOOR PANEL 118

BOX FLOOR PANEL TO INNER BOX SIDE PANEL 119

LONG CROSSMEMBERS TO CROSSMEMBER END SUPPORT BRACKETS TO INNER

BOX SIDE PANEL120

INNER WHEELHOUSE PANEL TO INNER BOX SIDE PANEL 121

TAILGATE PILLAR OUTER PANEL TO TAILGATE PILLAR INNER PANEL TO INNER

BOX SIDE PANEL122

REAR SILL CROSS BOX TO TAILGATE PILLAR OUTER PANEL AND INNER BOX SIDE

PANEL123

OUTER BOX SIDE PANEL TO BOX FRONT PANEL AND BOX FRONT SIDE PANEL 124

STAKE POCKET REINFORCEMENTS TO INNER BOX SIDE PANEL TO OUTER BOX

SIDE PANEL125

TAILGATE PIVOT REINFORCEMENT AND INNER TAILGATE PILLAR TO INNER BOX

SIDE PANEL TO OUTER BOX SIDE PANEL126

INNER WHEELHOUSE TO OUTER WHEELHOUSE/TAILGATE PIVOT

REINFORCEMENT TO OUTER TAILGATE PILLAR TO INNER TAILGATE PILLAR127

OUTER TAILGATE PILLAR TO OUTER BOX SIDE PANEL 128

INNER DOOR PANEL TO OUTER DOOR PANEL - FRONT DOOR (QUAD CAB) 129

INNER DOOR PANEL TO OUTER DOOR PANEL - FRONT DOOR (STANDARD CAB) 130

INNER DOOR PANEL TO OUTER DOOR PANEL - REAR DOOR (QUAD CAB) 131

DRBODY STRUCTURE 23 - 125

WELD LOCATIONS (Continued)