Transmission DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2117 of 2895

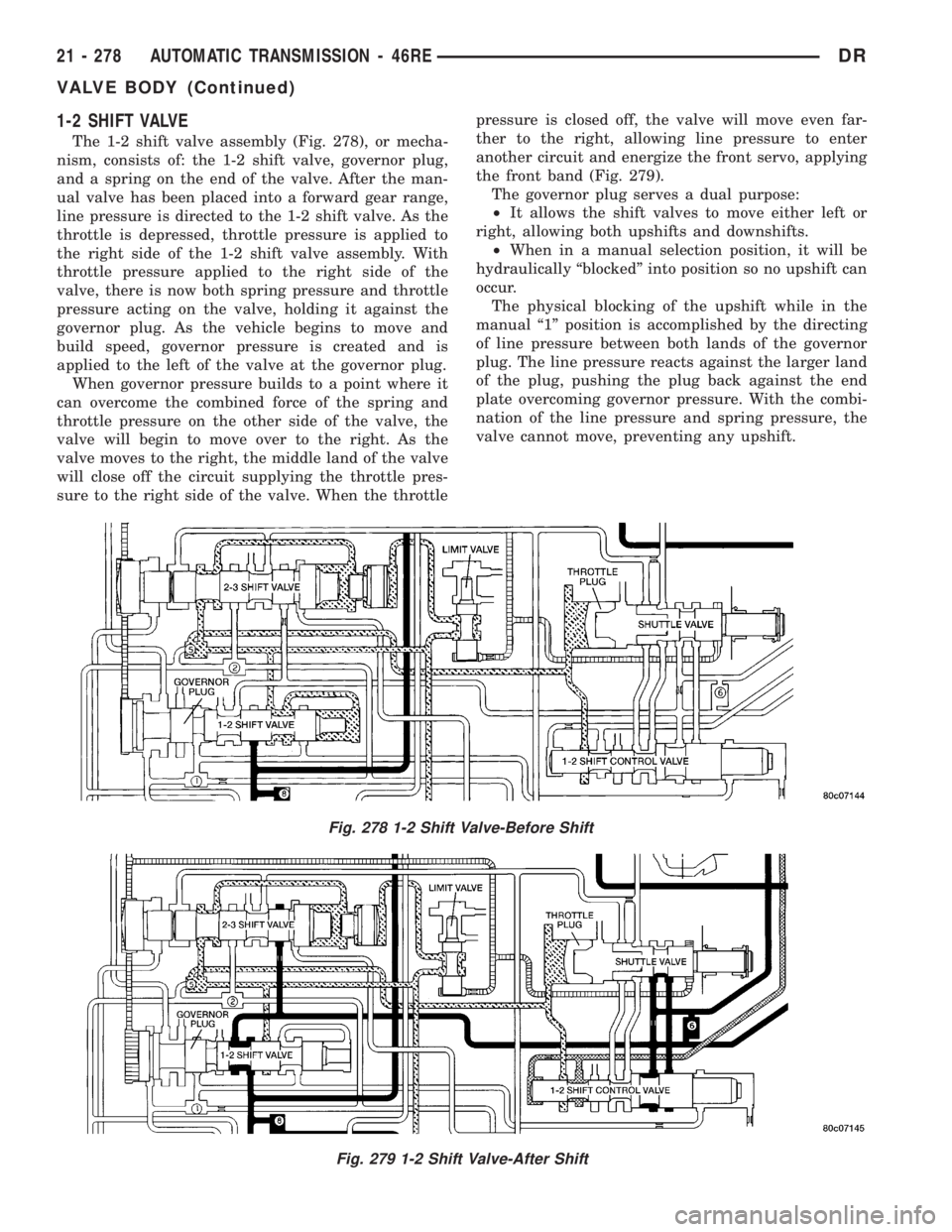

1-2 SHIFT VALVE

The 1-2 shift valve assembly (Fig. 278), or mecha-

nism, consists of: the 1-2 shift valve, governor plug,

and a spring on the end of the valve. After the man-

ual valve has been placed into a forward gear range,

line pressure is directed to the 1-2 shift valve. As the

throttle is depressed, throttle pressure is applied to

the right side of the 1-2 shift valve assembly. With

throttle pressure applied to the right side of the

valve, there is now both spring pressure and throttle

pressure acting on the valve, holding it against the

governor plug. As the vehicle begins to move and

build speed, governor pressure is created and is

applied to the left of the valve at the governor plug.

When governor pressure builds to a point where it

can overcome the combined force of the spring and

throttle pressure on the other side of the valve, the

valve will begin to move over to the right. As the

valve moves to the right, the middle land of the valve

will close off the circuit supplying the throttle pres-

sure to the right side of the valve. When the throttlepressure is closed off, the valve will move even far-

ther to the right, allowing line pressure to enter

another circuit and energize the front servo, applying

the front band (Fig. 279).

The governor plug serves a dual purpose:

²It allows the shift valves to move either left or

right, allowing both upshifts and downshifts.

²When in a manual selection position, it will be

hydraulically ªblockedº into position so no upshift can

occur.

The physical blocking of the upshift while in the

manual ª1º position is accomplished by the directing

of line pressure between both lands of the governor

plug. The line pressure reacts against the larger land

of the plug, pushing the plug back against the end

plate overcoming governor pressure. With the combi-

nation of the line pressure and spring pressure, the

valve cannot move, preventing any upshift.

Fig. 278 1-2 Shift Valve-Before Shift

Fig. 279 1-2 Shift Valve-After Shift

21 - 278 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2118 of 2895

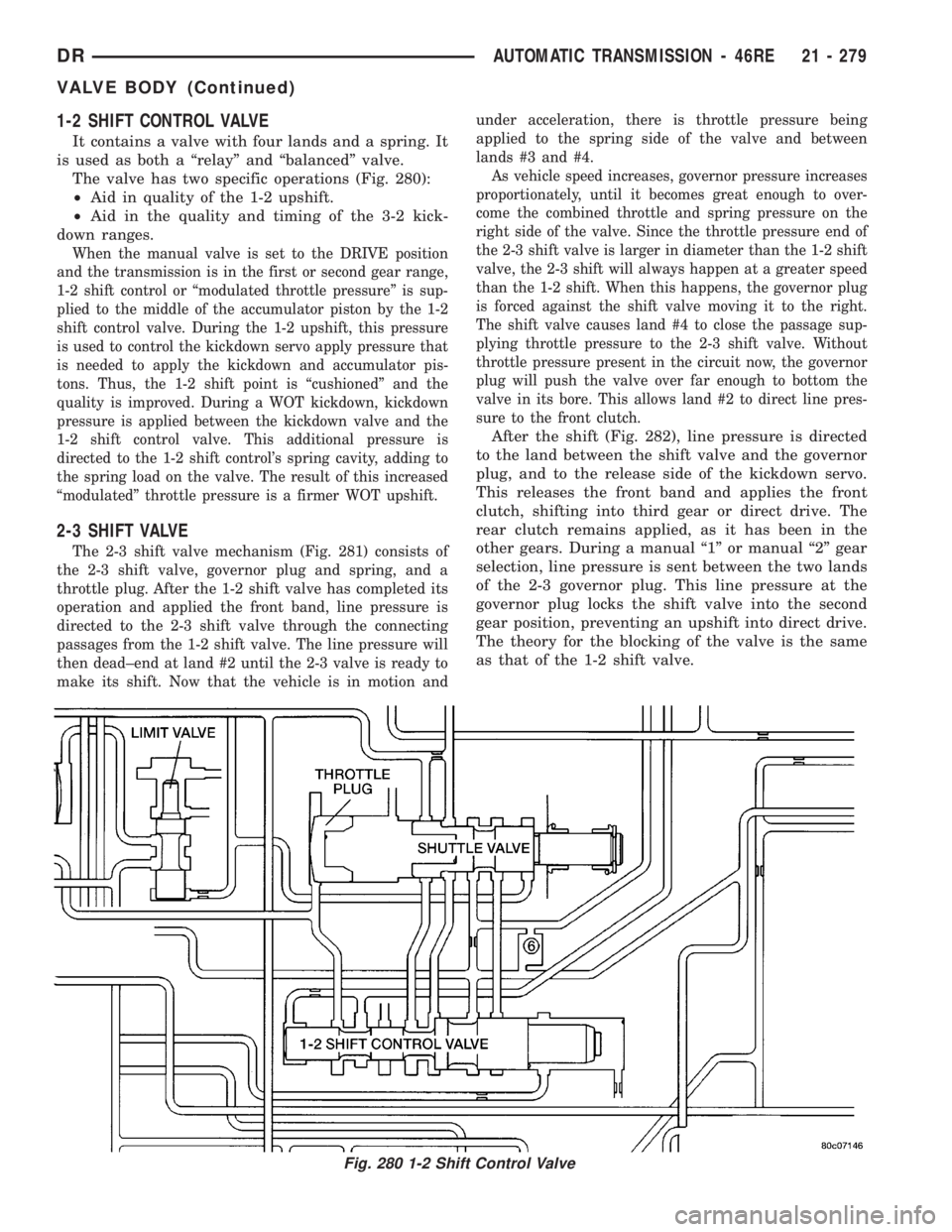

1-2 SHIFT CONTROL VALVE

It contains a valve with four lands and a spring. It

is used as both a ªrelayº and ªbalancedº valve.

The valve has two specific operations (Fig. 280):

²Aid in quality of the 1-2 upshift.

²Aid in the quality and timing of the 3-2 kick-

down ranges.

When the manual valve is set to the DRIVE position

and the transmission is in the first or second gear range,

1-2 shift control or ªmodulated throttle pressureº is sup-

plied to the middle of the accumulator piston by the 1-2

shift control valve. During the 1-2 upshift, this pressure

is used to control the kickdown servo apply pressure that

is needed to apply the kickdown and accumulator pis-

tons. Thus, the 1-2 shift point is ªcushionedº and the

quality is improved. During a WOT kickdown, kickdown

pressure is applied between the kickdown valve and the

1-2 shift control valve. This additional pressure is

directed to the 1-2 shift control's spring cavity, adding to

the spring load on the valve. The result of this increased

ªmodulatedº throttle pressure is a firmer WOT upshift.

2-3 SHIFT VALVE

The 2-3 shift valve mechanism (Fig. 281) consists of

the 2-3 shift valve, governor plug and spring, and a

throttle plug. After the 1-2 shift valve has completed its

operation and applied the front band, line pressure is

directed to the 2-3 shift valve through the connecting

passages from the 1-2 shift valve. The line pressure will

then dead±end at land #2 until the 2-3 valve is ready to

make its shift. Now that the vehicle is in motion andunder acceleration, there is throttle pressure being

applied to the spring side of the valve and between

lands #3 and #4.

As vehicle speed increases, governor pressure increases

proportionately, until it becomes great enough to over-

come the combined throttle and spring pressure on the

right side of the valve. Since the throttle pressure end of

the 2-3 shift valve is larger in diameter than the 1-2 shift

valve, the 2-3 shift will always happen at a greater speed

than the 1-2 shift. When this happens, the governor plug

is forced against the shift valve moving it to the right.

The shift valve causes land #4 to close the passage sup-

plying throttle pressure to the 2-3 shift valve. Without

throttle pressure present in the circuit now, the governor

plug will push the valve over far enough to bottom the

valve in its bore. This allows land #2 to direct line pres-

sure to the front clutch.

After the shift (Fig. 282), line pressure is directed

to the land between the shift valve and the governor

plug, and to the release side of the kickdown servo.

This releases the front band and applies the front

clutch, shifting into third gear or direct drive. The

rear clutch remains applied, as it has been in the

other gears. During a manual ª1º or manual ª2º gear

selection, line pressure is sent between the two lands

of the 2-3 governor plug. This line pressure at the

governor plug locks the shift valve into the second

gear position, preventing an upshift into direct drive.

The theory for the blocking of the valve is the same

as that of the 1-2 shift valve.

Fig. 280 1-2 Shift Control Valve

DRAUTOMATIC TRANSMISSION - 46RE 21 - 279

VALVE BODY (Continued)

Page 2119 of 2895

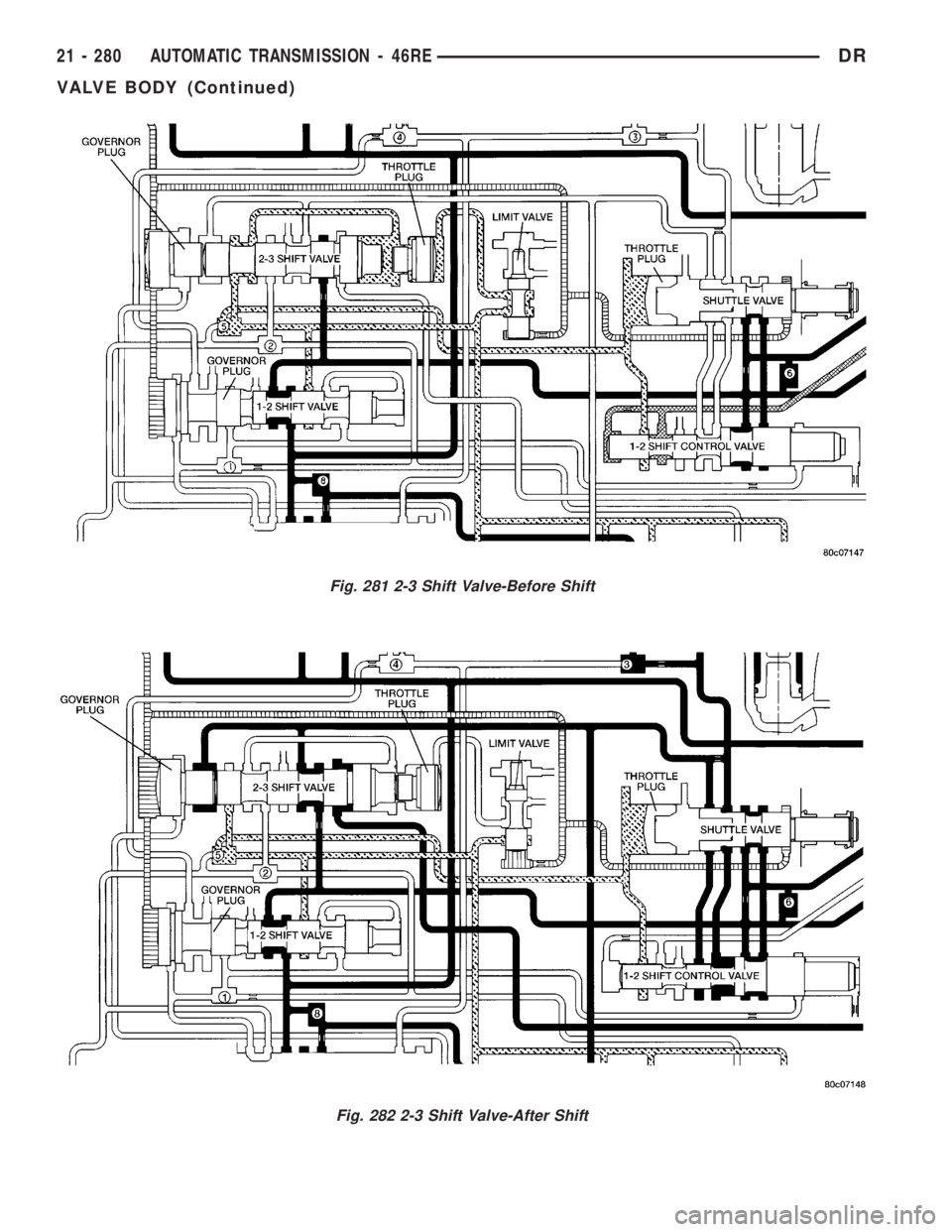

Fig. 281 2-3 Shift Valve-Before Shift

Fig. 282 2-3 Shift Valve-After Shift

21 - 280 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2120 of 2895

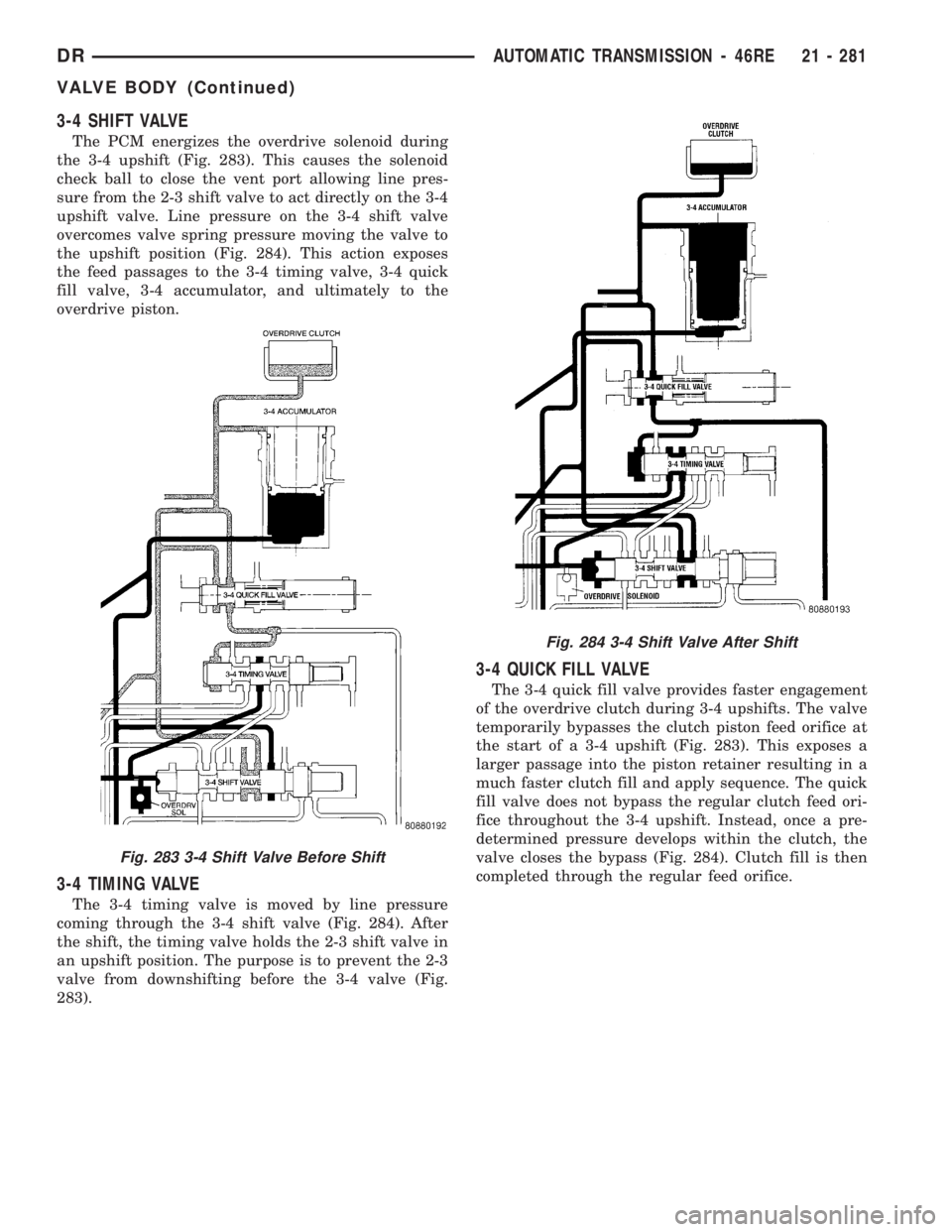

3-4 SHIFT VALVE

The PCM energizes the overdrive solenoid during

the 3-4 upshift (Fig. 283). This causes the solenoid

check ball to close the vent port allowing line pres-

sure from the 2-3 shift valve to act directly on the 3-4

upshift valve. Line pressure on the 3-4 shift valve

overcomes valve spring pressure moving the valve to

the upshift position (Fig. 284). This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston.

3-4 TIMING VALVE

The 3-4 timing valve is moved by line pressure

coming through the 3-4 shift valve (Fig. 284). After

the shift, the timing valve holds the 2-3 shift valve in

an upshift position. The purpose is to prevent the 2-3

valve from downshifting before the 3-4 valve (Fig.

283).

3-4 QUICK FILL VALVE

The 3-4 quick fill valve provides faster engagement

of the overdrive clutch during 3-4 upshifts. The valve

temporarily bypasses the clutch piston feed orifice at

the start of a 3-4 upshift (Fig. 283). This exposes a

larger passage into the piston retainer resulting in a

much faster clutch fill and apply sequence. The quick

fill valve does not bypass the regular clutch feed ori-

fice throughout the 3-4 upshift. Instead, once a pre-

determined pressure develops within the clutch, the

valve closes the bypass (Fig. 284). Clutch fill is then

completed through the regular feed orifice.

Fig. 283 3-4 Shift Valve Before Shift

Fig. 284 3-4 Shift Valve After Shift

DRAUTOMATIC TRANSMISSION - 46RE 21 - 281

VALVE BODY (Continued)

Page 2121 of 2895

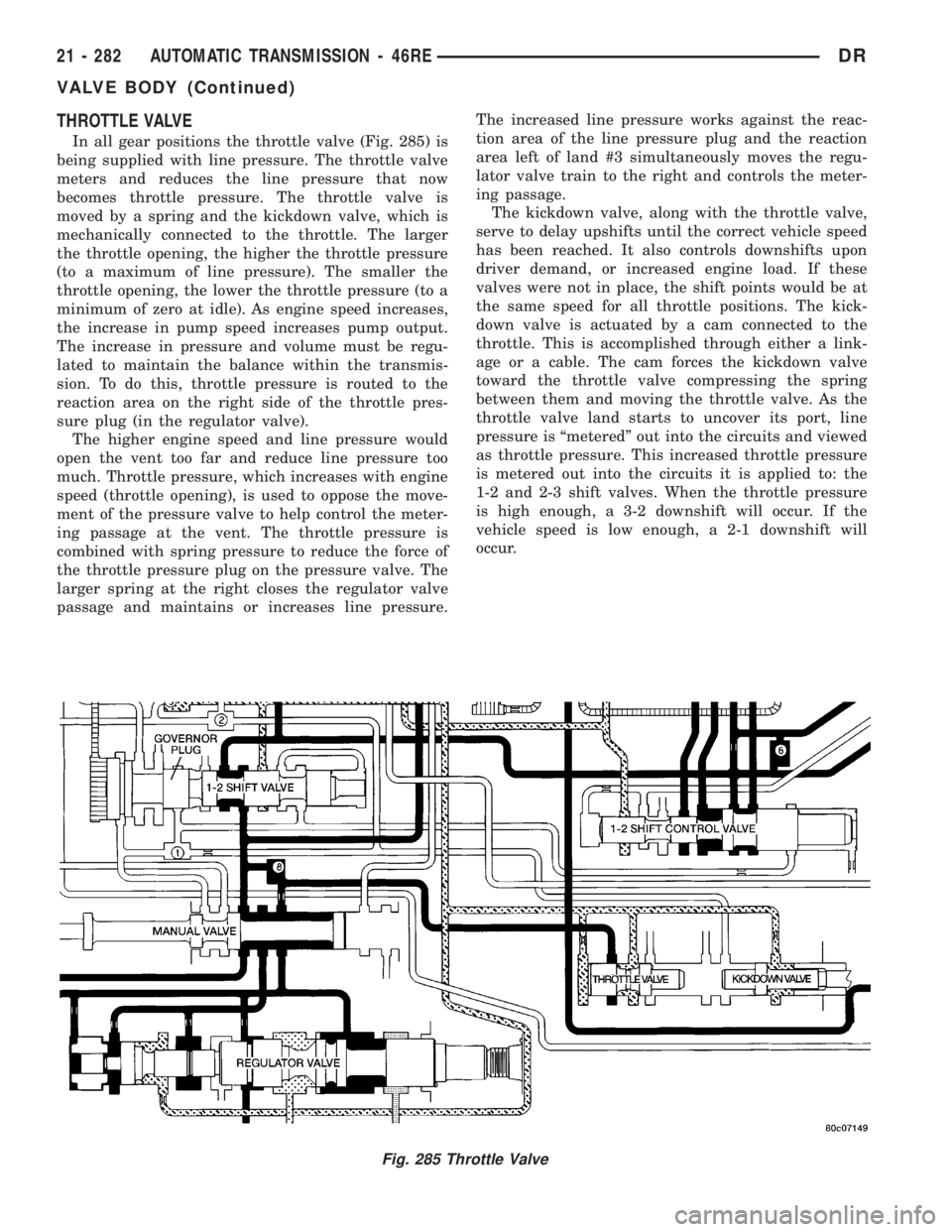

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 285) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller the

throttle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,

the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valve

passage and maintains or increases line pressure.The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction

area left of land #3 simultaneously moves the regu-

lator valve train to the right and controls the meter-

ing passage.

The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

throttle. This is accomplished through either a link-

age or a cable. The cam forces the kickdown valve

toward the throttle valve compressing the spring

between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line

pressure is ªmeteredº out into the circuits and viewed

as throttle pressure. This increased throttle pressure

is metered out into the circuits it is applied to: the

1-2 and 2-3 shift valves. When the throttle pressure

is high enough, a 3-2 downshift will occur. If the

vehicle speed is low enough, a 2-1 downshift will

occur.

Fig. 285 Throttle Valve

21 - 282 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2122 of 2895

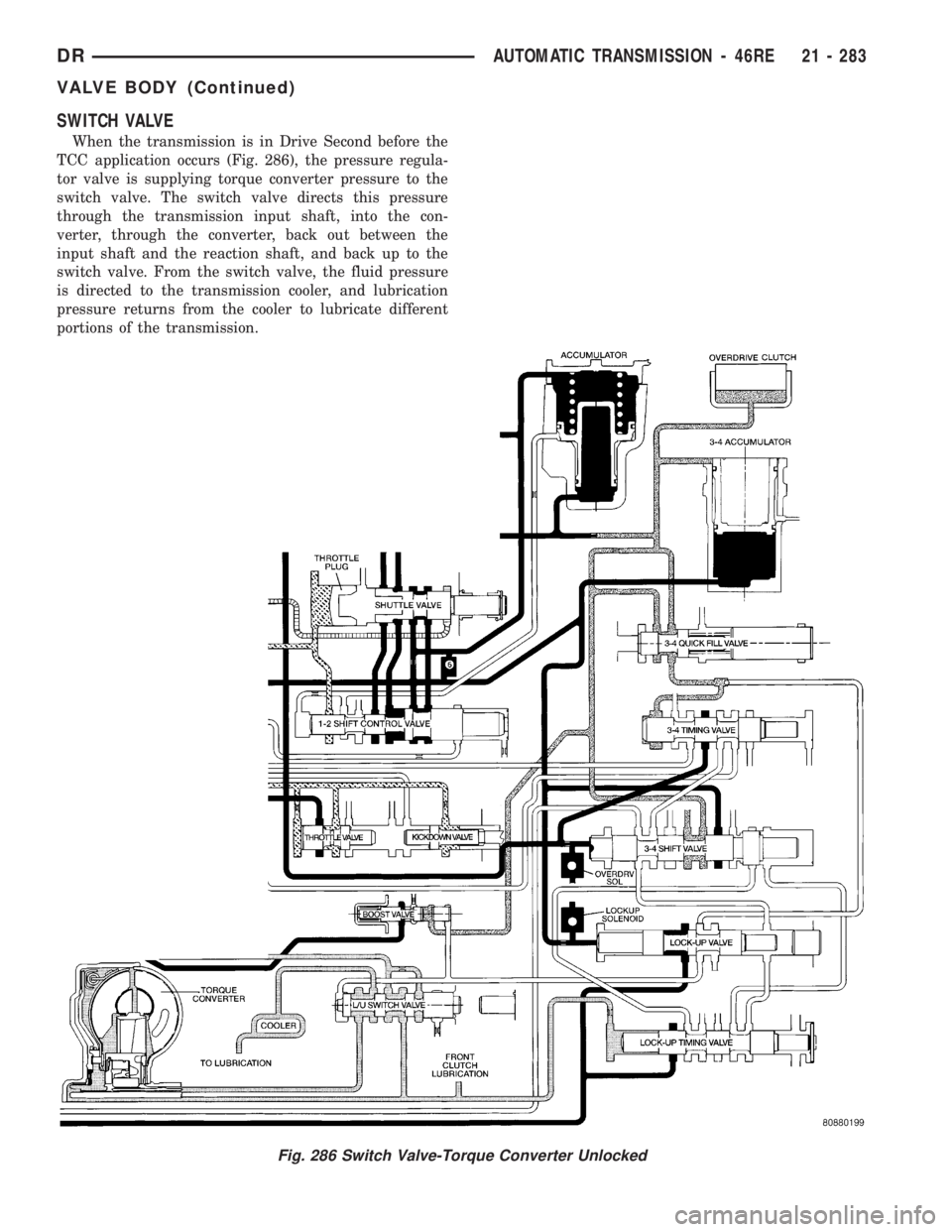

SWITCH VALVE

When the transmission is in Drive Second before the

TCC application occurs (Fig. 286), the pressure regula-

tor valve is supplying torque converter pressure to the

switch valve. The switch valve directs this pressure

through the transmission input shaft, into the con-

verter, through the converter, back out between the

input shaft and the reaction shaft, and back up to the

switch valve. From the switch valve, the fluid pressure

is directed to the transmission cooler, and lubrication

pressure returns from the cooler to lubricate different

portions of the transmission.

Fig. 286 Switch Valve-Torque Converter Unlocked

DRAUTOMATIC TRANSMISSION - 46RE 21 - 283

VALVE BODY (Continued)

Page 2123 of 2895

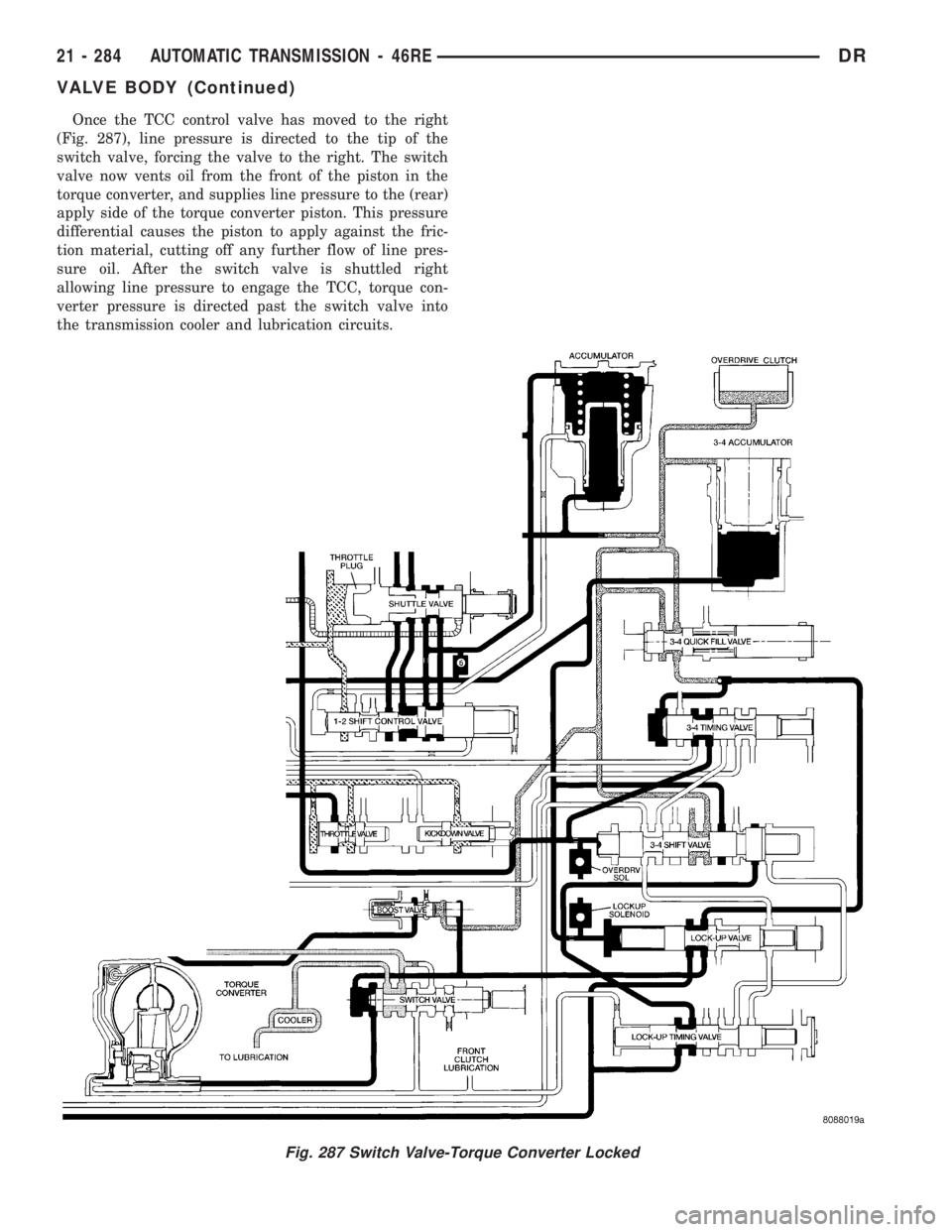

Once the TCC control valve has moved to the right

(Fig. 287), line pressure is directed to the tip of the

switch valve, forcing the valve to the right. The switch

valve now vents oil from the front of the piston in the

torque converter, and supplies line pressure to the (rear)

apply side of the torque converter piston. This pressure

differential causes the piston to apply against the fric-

tion material, cutting off any further flow of line pres-

sure oil. After the switch valve is shuttled right

allowing line pressure to engage the TCC, torque con-

verter pressure is directed past the switch valve into

the transmission cooler and lubrication circuits.

Fig. 287 Switch Valve-Torque Converter Locked

21 - 284 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2124 of 2895

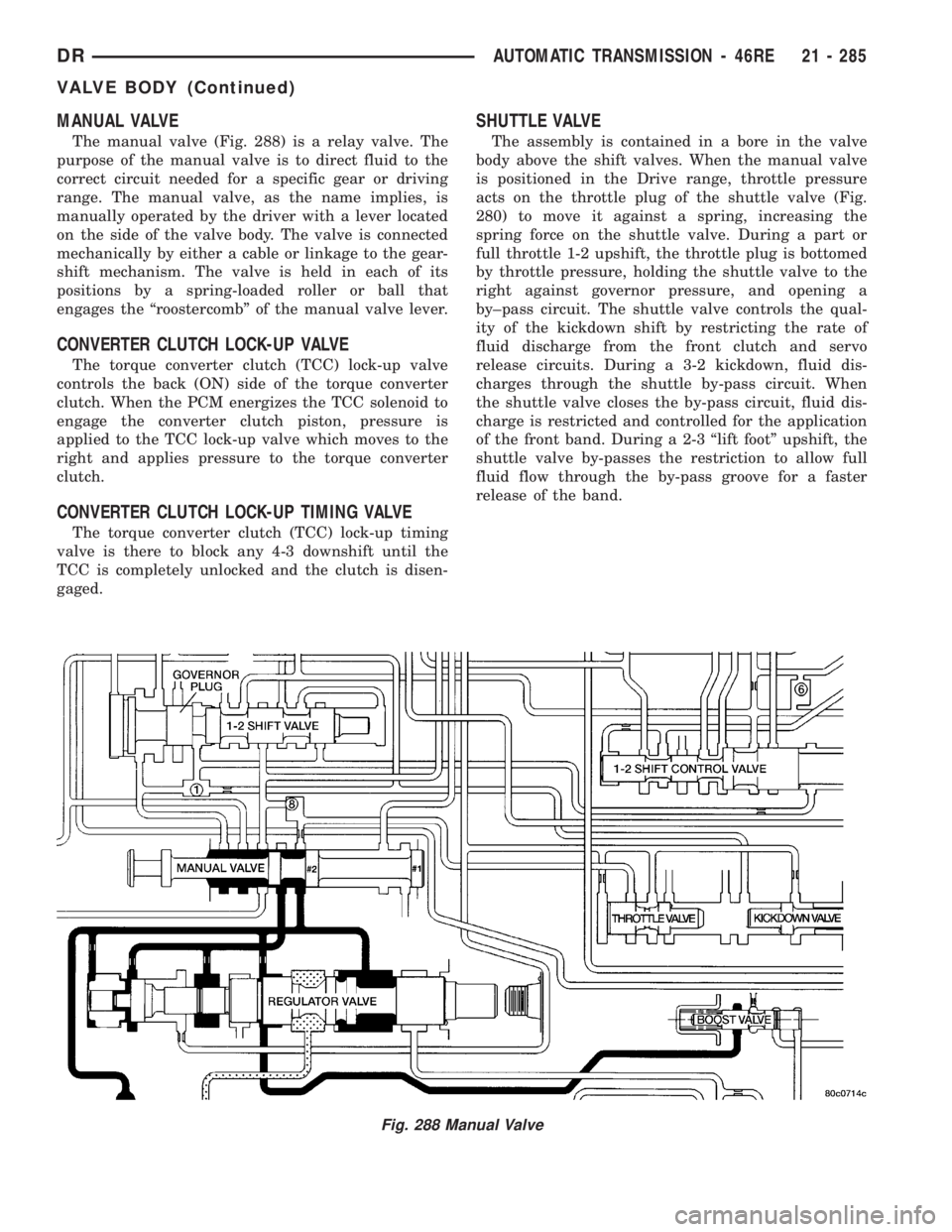

MANUAL VALVE

The manual valve (Fig. 288) is a relay valve. The

purpose of the manual valve is to direct fluid to the

correct circuit needed for a specific gear or driving

range. The manual valve, as the name implies, is

manually operated by the driver with a lever located

on the side of the valve body. The valve is connected

mechanically by either a cable or linkage to the gear-

shift mechanism. The valve is held in each of its

positions by a spring-loaded roller or ball that

engages the ªroostercombº of the manual valve lever.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve

controls the back (ON) side of the torque converter

clutch. When the PCM energizes the TCC solenoid to

engage the converter clutch piston, pressure is

applied to the TCC lock-up valve which moves to the

right and applies pressure to the torque converter

clutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing

valve is there to block any 4-3 downshift until the

TCC is completely unlocked and the clutch is disen-

gaged.

SHUTTLE VALVE

The assembly is contained in a bore in the valve

body above the shift valves. When the manual valve

is positioned in the Drive range, throttle pressure

acts on the throttle plug of the shuttle valve (Fig.

280) to move it against a spring, increasing the

spring force on the shuttle valve. During a part or

full throttle 1-2 upshift, the throttle plug is bottomed

by throttle pressure, holding the shuttle valve to the

right against governor pressure, and opening a

by±pass circuit. The shuttle valve controls the qual-

ity of the kickdown shift by restricting the rate of

fluid discharge from the front clutch and servo

release circuits. During a 3-2 kickdown, fluid dis-

charges through the shuttle by-pass circuit. When

the shuttle valve closes the by-pass circuit, fluid dis-

charge is restricted and controlled for the application

of the front band. During a 2-3 ªlift footº upshift, the

shuttle valve by-passes the restriction to allow full

fluid flow through the by-pass groove for a faster

release of the band.

Fig. 288 Manual Valve

DRAUTOMATIC TRANSMISSION - 46RE 21 - 285

VALVE BODY (Continued)

Page 2125 of 2895

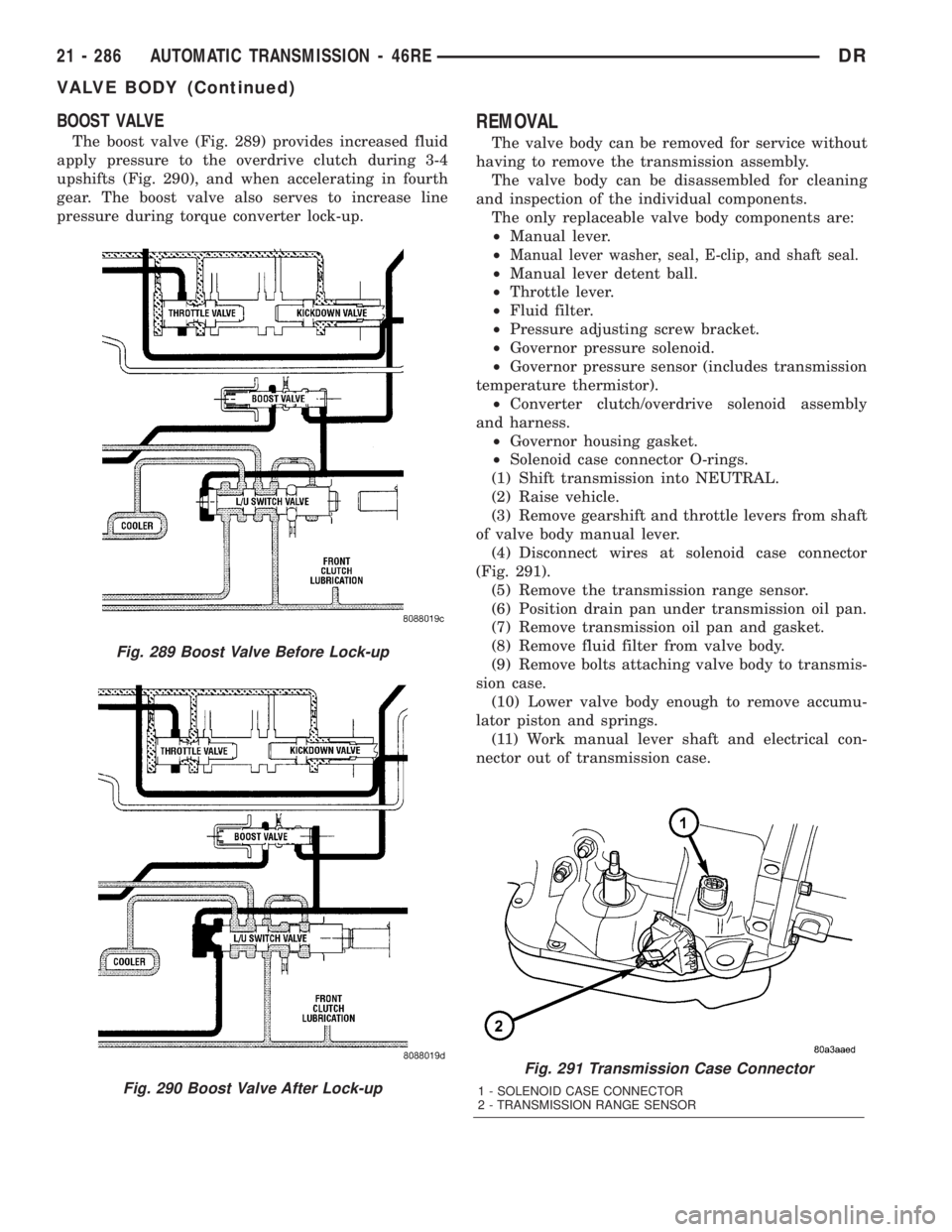

BOOST VALVE

The boost valve (Fig. 289) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 290), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²

Manual lever washer, seal, E-clip, and shaft seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 291).

(5) Remove the transmission range sensor.

(6) Position drain pan under transmission oil pan.

(7) Remove transmission oil pan and gasket.

(8) Remove fluid filter from valve body.

(9) Remove bolts attaching valve body to transmis-

sion case.

(10) Lower valve body enough to remove accumu-

lator piston and springs.

(11) Work manual lever shaft and electrical con-

nector out of transmission case.

Fig. 291 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - TRANSMISSION RANGE SENSOR

Fig. 289 Boost Valve Before Lock-up

Fig. 290 Boost Valve After Lock-up

21 - 286 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2126 of 2895

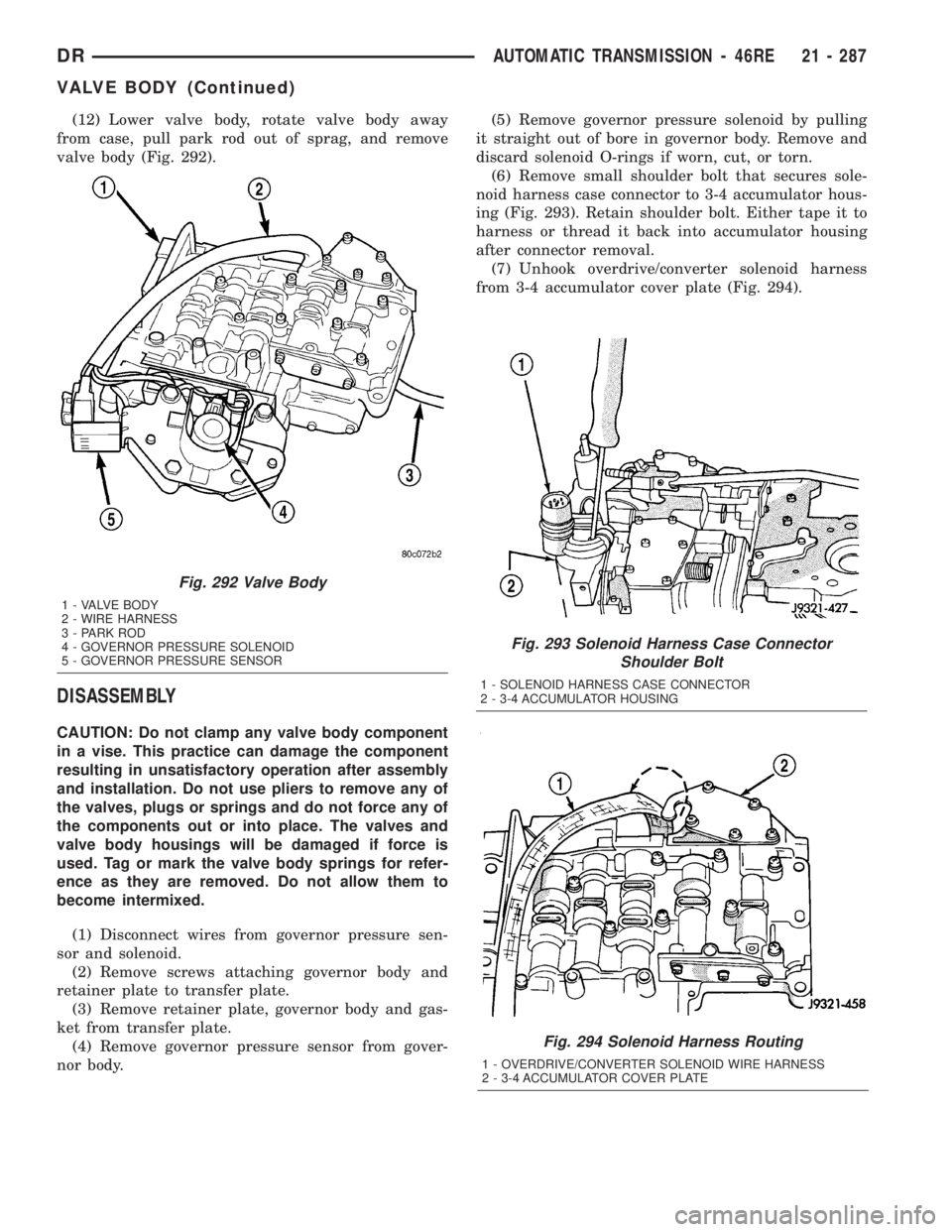

(12) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 292).

DISASSEMBLY

CAUTION: Do not clamp any valve body component

in a vise. This practice can damage the component

resulting in unsatisfactory operation after assembly

and installation. Do not use pliers to remove any of

the valves, plugs or springs and do not force any of

the components out or into place. The valves and

valve body housings will be damaged if force is

used. Tag or mark the valve body springs for refer-

ence as they are removed. Do not allow them to

become intermixed.

(1) Disconnect wires from governor pressure sen-

sor and solenoid.

(2) Remove screws attaching governor body and

retainer plate to transfer plate.

(3) Remove retainer plate, governor body and gas-

ket from transfer plate.

(4) Remove governor pressure sensor from gover-

nor body.(5) Remove governor pressure solenoid by pulling

it straight out of bore in governor body. Remove and

discard solenoid O-rings if worn, cut, or torn.

(6) Remove small shoulder bolt that secures sole-

noid harness case connector to 3-4 accumulator hous-

ing (Fig. 293). Retain shoulder bolt. Either tape it to

harness or thread it back into accumulator housing

after connector removal.

(7) Unhook overdrive/converter solenoid harness

from 3-4 accumulator cover plate (Fig. 294).

Fig. 293 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

Fig. 294 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

Fig. 292 Valve Body

1 - VALVE BODY

2 - WIRE HARNESS

3 - PARK ROD

4 - GOVERNOR PRESSURE SOLENOID

5 - GOVERNOR PRESSURE SENSOR

DRAUTOMATIC TRANSMISSION - 46RE 21 - 287

VALVE BODY (Continued)