fuse DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 624 of 2895

inflator connects the inflator initiator to the vehicle

electrical system through a yellow-jacketed, two-wire

pigtail harness of the clockspring.

The driver airbag cannot be repaired, and must be

replaced if deployed or in any way damaged.

OPERATION

The driver airbag is deployed by electrical signals

generated by the Airbag Control Module (ACM)

through the driver airbag squib circuit to the initia-

tor in the airbag inflator. When the ACM sends the

proper electrical signal to the initiator the electrical

energy generates enough heat to initiate a small

pyrotechnic charge which, in turn ignites chemical

pellets within the inflator. Once ignited, these chem-

ical pellets burn rapidly and produce a large quantity

of inert gas. The inflator is sealed to the back of the

airbag housing and a diffuser in the inflator directs

all of the inert gas into the airbag cushion, causing

the cushion to inflate. As the cushion inflates, the

driver airbag trim cover will split at predetermined

breakout lines, then fold back out of the way along

with the horn switch unit. Following an airbag

deployment, the airbag cushion quickly deflates by

venting the inert gas towards the instrument panel

through vent holes within the fabric used to con-

struct the back (steering wheel side) panel of the air-

bag cushion.

Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, all poten-

tially hazardous chemicals are burned during an air-

bag deployment event. The inert gas that is produced

when the chemicals are burned is harmless. How-

ever, a small amount of residue from the burned

chemicals may cause some temporary discomfort if it

contacts the skin, eyes, or breathing passages. If skin

or eye irritation is noted, rinse the affected area with

plenty of cool, clean water. If breathing passages are

irritated, move to another area where there is plenty

of clean, fresh air to breath. If the irritation is not

alleviated by these actions, contact a physician.

REMOVAL

The following procedure is for replacement of a

faulty or damaged driver airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the driver airbag has beendeployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG CUSHION AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) From the underside of the steering wheel,

remove the two screws that secure the two trim cov-

ers or speed control switches to each side of the

driver airbag trim cover.

(3) From the top of the steering wheel, remove the

two trim covers or speed control switches from the

pockets on each side of the driver airbag trim cover

to access the driver airbag mounting screws.

(4) Remove the two screws that secure the driver

airbag to the steering wheel armature (Fig. 23).

(5) Pull the driver airbag away from the steering

wheel far enough to access the two electrical connec-

tions at the back of the airbag housing.

(6) Disconnect the steering wheel wire harness

horn switch feed take out connector from the horn

switch feed pigtail wire connector insulator located

on the back of the driver airbag housing.

DRRESTRAINTS 8O - 23

DRIVER AIRBAG (Continued)

Page 650 of 2895

outboard seat belt and retractor unit must be

replaced. (Refer to 8 - ELECTRICAL/RESTRAINTS/

FRONT OUTBOARD SEAT BELT & RETRACTOR -

REMOVAL).

OPERATION

The seat belt tension reducer is controlled by a

ground signal received from the seat belt switch on

the seat belt switch sense circuit and a battery cur-

rent signal received from the ignition switch on the

fused ignition switch output (run-accessory) circuit.

When the seat belt switch is closed (the driver side

front seat belt is fastened) and the ignition switch is

in the On or Accessory positions, the seat belt tension

reducer solenoid is energized. When the solenoid is

energized, it actuates a mechanism within the driver

side front outboard seat belt retractor to reduce the

normal recoil spring tension exerted by the retractor

spool, which is designed to reel in the seat belt web-

bing onto the spool. When the driver side seat belt is

unbuckled or if the ignition switch is turned to any

position except On or Accessory, the tension reducer

solenoid is de-energized and the normal recoil spring

tension of the retractor is restored.

The action of the seat belt tension reducer results

in improved seat belt comfort for the driver. Reducing

the seat belt retractor recoil spring tension is desir-

able on standard cab models of this vehicle and not

on the quad cab model due to the different mounting

position required for the seat belt turning loop on the

B-pillar relative to the driver's seat position on the

standard cab model. The seat belt tension reducer

may be diagnosed using conventional diagnostic tools

and methods.

DIAGNOSIS AND TESTING - SEAT BELT

TENSION REDUCER

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINTSYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the body wire harness connector for

the seat belt tension reducer from the tension

reducer connector receptacle on the driver side front

outboard seat belt and retractor unit. Using an ohm-

meter, measure the resistance between the seat belt

switch sense circuit terminal pin and the fused igni-

tion switch output (run-accessory) circuit terminal

pin in the tension reducer connector receptacle on

the retractor. Resistance through the tension reducer

solenoid coil should be 53 ohms at 20É C (68É F). If

OK, go to Step 2. If not OK, replace the faulty driver

side front outboard seat belt and retractor unit.

(2) Check for continuity between the seat belt

switch sense circuit cavity of the body wire harness

connector for the seat belt tension reducer and a good

ground. There should be continuity with the driver

side front seat belt buckled, and no continuity with

the driver side front seat belt unbuckled. If OK, go to

Step 3. If not OK, repair the shorted or open seat

belt switch sense circuit between the tension reducer

and the seat belt switch as required.

(3) Reconnect the battery negative cable. Check for

battery current at the fused ignition switch output

(run-accessory) circuit of the body wire harness con-

nector for the seat belt tension reducer. There should

be battery current with the ignition switch in the On

or Accessory positions, and no battery current with

the ignition switch in any other position. If not OK,

repair the shorted or open fused ignition switch out-

put (run-accessory) circuit between the tension

reducer and the ignition switch as required.

DRRESTRAINTS 8O - 49

SEAT BELT TENSION REDUCER (Continued)

Page 655 of 2895

(SIACM) and its mounting bracket are secured with

four screws to the inside of each B-pillar behind

(standard cab) or above (quad cab) the front outboard

seat belt retractor, and concealed behind the B-pillar

trim (Fig. 50). Concealed within a hollow in the cen-

ter of the die cast aluminum SIACM housing is the

electronic circuitry of the SIACM which includes a

microprocessor and an electronic impact sensor.

The SIACM housing is secured to a die cast (stan-

dard cab) or stamped steel (quad cab) mounting

bracket, which is unique for the right or left side

application of this component. The SIACM should

never be removed from its mounting bracket. The

housing also receives a case ground through this

mounting bracket when it is secured to the vehicle. A

molded plastic electrical connector receptacle that

exits the top of the SIACM housing connects the unit

to the vehicle electrical system through a dedicated

take out and connector of the body wire harness.

Both the SIACM housing and its electrical connection

are sealed to protect the internal electronic circuitry

and components against moisture intrusion.

The impact sensor internal to the SIACM is cali-

brated for the specific vehicle, and is only serviced as

a unit with the SIACM. The SIACM cannot be

repaired or adjusted and, if damaged or faulty, it

must be replaced.

OPERATION

The microprocessor in the Side Impact Airbag Con-

trol Module (SIACM) contains the side curtain airbag

system logic circuits and controls all of the features

of only the side curtain airbag mounted on the same

side of the vehicle as the SIACM. The SIACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIItscan tool using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used by the

SIACM to communicate with the Airbag Control

Module (ACM) and for supplemental restraint system

diagnosis and testing through the 16-way data link

connector located on the driver side lower edge of the

instrument panel. The ACM communicates with both

the left and right SIACM over the PCI data bus.

The SIACM microprocessor continuously monitors

all of the side curtain airbag electrical circuits to

determine the system readiness. If the SIACM

detects a monitored system fault, it sets an activeand stored Diagnostic Trouble Code (DTC) and sends

electronic messages to the ACM over the PCI data

bus. The ACM will respond by sending an electronic

message to the EMIC to turn on the airbag indicator,

and by storing a DTC that will indicate whether the

left or the right SIACM has stored the DTC that ini-

tiated the airbag indicator illumination. An active

fault only remains for the current ignition switch

cycle, while a stored fault causes a DTC to be stored

in memory by the SIACM. For some DTCs, if a fault

does not recur for a number of ignition cycles, the

SIACM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

The SIACM receives battery current on a fused

ignition switch output (run-start) circuit through a

fuse in the Integrated Power Module (IPM). The

SIACM has a case ground through its mounting

bracket and also receives a power ground through a

ground circuit and take out of the body wire harness.

This take out has a single eyelet terminal connector

that is secured by a ground screw to the body sheet

metal. These connections allow the SIACM to be

operational whenever the ignition switch is in the

Start or On positions. An electronic impact sensor is

contained within the SIACM. The electronic impact

sensor is an accelerometer that senses the rate of

vehicle deceleration, which provides verification of

the direction and severity of an impact. A pre-pro-

grammed decision algorithm in the SIACM micropro-

cessor determines when the deceleration rate as

signaled by the impact sensor indicates a side impact

that is severe enough to require side curtain airbag

protection. When the programmed conditions are

met, the SIACM sends the proper electrical signals to

deploy the side curtain airbag.

The hard wired inputs and outputs for the SIACM

may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods will not prove conclusive in

the diagnosis of the SIACM, the PCI data bus net-

work, or the electronic message inputs to and outputs

from the SIACM. The most reliable, efficient, and

accurate means to diagnose the SIACM, the PCI data

bus network, and the electronic message inputs to

and outputs from the SIACM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

8O - 54 RESTRAINTSDR

SIDE IMPACT AIRBAG CONTROL MODULE (Continued)

Page 679 of 2895

²Wipe-After-Wash Mode- When the control

knob on the control stalk of the multi-function switch

is depressed to the momentary Wash position for

more than about one-half second with the wiper sys-

tem turned Off, the washer pump/motor and the wip-

ers will operate for as long as the washer switch is

held closed up to about thirty seconds, then provide

several additional wipe cycles after the control knob

is released before parking the wiper blades near the

base of the windshield. If the control knob is held in

the depressed Wash position for more than about

thirty seconds, washer system operation will be sus-

pended until the control knob is released for about

two seconds then cycled back to the Wash position.

OPERATION

The wiper and washer system is designed to pro-

vide the vehicle operator with a convenient, safe, and

reliable means of maintaining visibility through the

windshield glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blades to wipe the

outside surface of the glass, as well as into the

hydraulic action of the washer system to apply

washer fluid stored in an on-board reservoir to the

area of the glass to be wiped. When combined, these

components provide the means to effectively main-

tain clear visibility for the vehicle operator by remov-

ing excess accumulations of rain, snow, bugs, mud, or

other minor debris from the outside windshield glass

surface that might be encountered while driving the

vehicle under numerous types of inclement operating

conditions.

The vehicle operator initiates all wiper and washer

system functions with the control knob on the end of

the control stalk of the multi-function switch that

extends from the left side of the steering column, just

below the steering wheel. Rotating the control knob

on the end of the control stalk, selects the Off, Delay,

Low, or High wiper system operating modes. In the

Delay mode, the control knob also allows the vehicle

operator to select from one of five intermittent wipe

Delay intervals. Depressing the control knob towards

the steering column actuates the momentary washer

system switch, which selects the Wash, Wipe-After-

Wash, and Pulse Wipe Modes depending upon when

and how long the switch is held closed. The multi-

function switch provides hard wired resistor multi-

plexed inputs to the instrument cluster for all of the

wiper and washer system functions. The instrument

cluster then sends electronic messages to the Front

Control Module (FCM) over the Programmable Com-

munications Interface (PCI) data bus requesting the

appropriate wiper and washer system operating

modes.Wiper and washer system operation are completely

controlled by the instrument cluster and FCM logic

circuits, and that logic will only allow these systems

to operate when the ignition switch is in the Acces-

sory or On positions. Battery current is directed from

a B(+) fuse in the Integrated Power Module (IPM) to

the wiper on/off relay and the wiper high/low relay in

the IPM through a fused B(+) circuit. The FCM uses

low side drivers to control wiper system operation by

energizing or de-energizing the wiper high/low and

wiper on/off relays. The FCM uses a high side driver

to control the operation of the washer pump motor

unit. The multi-function switch circuitry receives a

clean ground output from the instrument cluster on a

multi-function switch return circuit, then provides

resistor multiplexed inputs to the instrument cluster

on an intermittent wipe mux circuit to indicate the

selected wiper system mode and on a wash/beam

select mux circuit to indicate the selected washer sys-

tem mode.

The hard wired circuits and components of the

wiper and washer system may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

instrument cluster, the FCM, or the electronic mes-

sage inputs to or outputs from the instrument cluster

or FCM that control the wiper and washer system

operating modes. The most reliable, efficient, and

accurate means to diagnose the instrument cluster or

the FCM inputs and outputs related to the various

wiper and washer system operating modes requires

the use of a DRBIIItscan tool. Refer to the appro-

priate diagnostic information.

OPERATING MODES

Following are paragraphs that briefly describe the

operation of each of the wiper and washer system

operating modes.

CONTINUOUS WIPE MODE

When the Low position of the control knob on the

control stalk of the multi-function switch is selected

the instrument cluster sends an electronic wiper

switch low message to the FCM, then the FCM ener-

gizes the wiper on/off relay. This directs battery cur-

rent through the normally open contacts of the

energized wiper on/off relay and the normally closed

contacts of the de-energized wiper high/low relay to

the low speed brush of the wiper motor, causing the

wipers to cycle at low speed.

When the High position of the control knob is

selected the instrument cluster sends an electronic

wiper switch high message to the FCM, then the

FCM energizes both the wiper on/off relay and the

wiper high/low relay. This directs battery current

8R - 4 WIPERS/WASHERSDR

WIPERS/WASHERS (Continued)

Page 696 of 2895

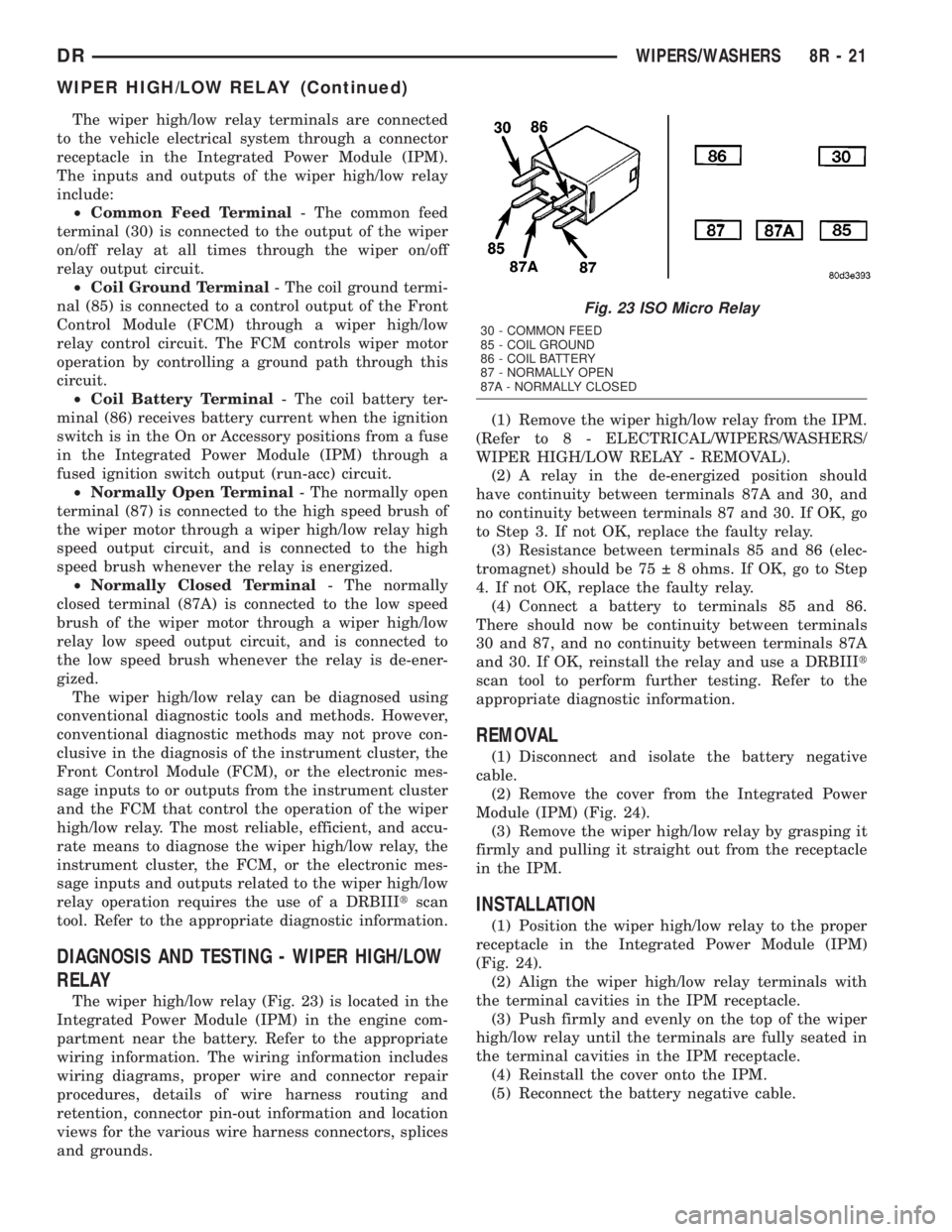

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper high/low

relay control circuit. The FCM controls wiper motor

operation by controlling a ground path through this

circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current when the ignition

switch is in the On or Accessory positions from a fuse

in the Integrated Power Module (IPM) through a

fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the wiper motor through a wiper high/low relay high

speed output circuit, and is connected to the high

speed brush whenever the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the low speed

brush of the wiper motor through a wiper high/low

relay low speed output circuit, and is connected to

the low speed brush whenever the relay is de-ener-

gized.

The wiper high/low relay can be diagnosed using

conventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

high/low relay. The most reliable, efficient, and accu-

rate means to diagnose the wiper high/low relay, the

instrument cluster, the FCM, or the electronic mes-

sage inputs and outputs related to the wiper high/low

relay operation requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - WIPER HIGH/LOW

RELAY

The wiper high/low relay (Fig. 23) is located in the

Integrated Power Module (IPM) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.(1) Remove the wiper high/low relay from the IPM.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER HIGH/LOW RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

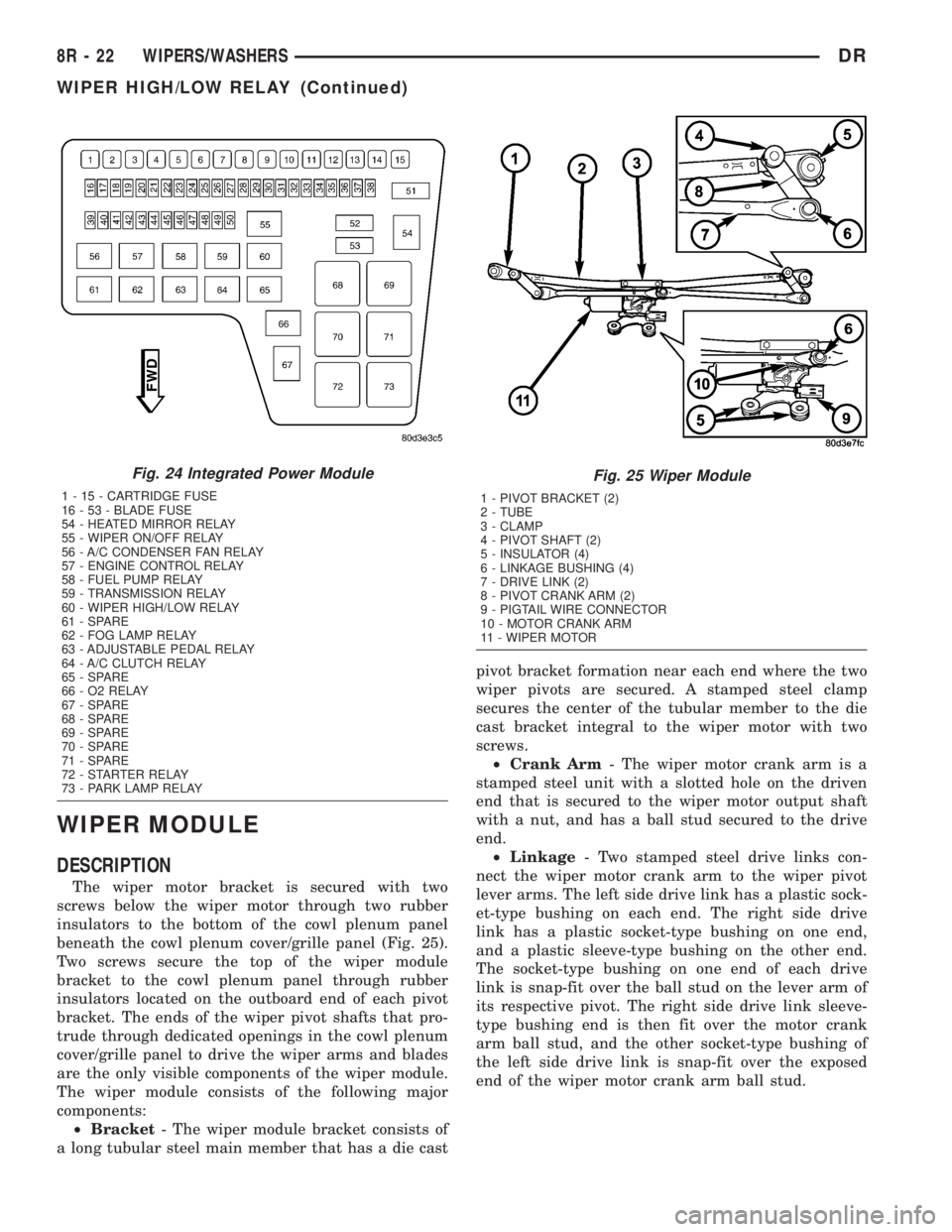

(2) Remove the cover from the Integrated Power

Module (IPM) (Fig. 24).

(3) Remove the wiper high/low relay by grasping it

firmly and pulling it straight out from the receptacle

in the IPM.

INSTALLATION

(1) Position the wiper high/low relay to the proper

receptacle in the Integrated Power Module (IPM)

(Fig. 24).

(2) Align the wiper high/low relay terminals with

the terminal cavities in the IPM receptacle.

(3) Push firmly and evenly on the top of the wiper

high/low relay until the terminals are fully seated in

the terminal cavities in the IPM receptacle.

(4) Reinstall the cover onto the IPM.

(5) Reconnect the battery negative cable.

Fig. 23 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRWIPERS/WASHERS 8R - 21

WIPER HIGH/LOW RELAY (Continued)

Page 697 of 2895

WIPER MODULE

DESCRIPTION

The wiper motor bracket is secured with two

screws below the wiper motor through two rubber

insulators to the bottom of the cowl plenum panel

beneath the cowl plenum cover/grille panel (Fig. 25).

Two screws secure the top of the wiper module

bracket to the cowl plenum panel through rubber

insulators located on the outboard end of each pivot

bracket. The ends of the wiper pivot shafts that pro-

trude through dedicated openings in the cowl plenum

cover/grille panel to drive the wiper arms and blades

are the only visible components of the wiper module.

The wiper module consists of the following major

components:

²Bracket- The wiper module bracket consists of

a long tubular steel main member that has a die castpivot bracket formation near each end where the two

wiper pivots are secured. A stamped steel clamp

secures the center of the tubular member to the die

cast bracket integral to the wiper motor with two

screws.

²Crank Arm- The wiper motor crank arm is a

stamped steel unit with a slotted hole on the driven

end that is secured to the wiper motor output shaft

with a nut, and has a ball stud secured to the drive

end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the wiper pivot

lever arms. The left side drive link has a plastic sock-

et-type bushing on each end. The right side drive

link has a plastic socket-type bushing on one end,

and a plastic sleeve-type bushing on the other end.

The socket-type bushing on one end of each drive

link is snap-fit over the ball stud on the lever arm of

its respective pivot. The right side drive link sleeve-

type bushing end is then fit over the motor crank

arm ball stud, and the other socket-type bushing of

the left side drive link is snap-fit over the exposed

end of the wiper motor crank arm ball stud.

Fig. 24 Integrated Power Module

1 - 15 - CARTRIDGE FUSE

16 - 53 - BLADE FUSE

54 - HEATED MIRROR RELAY

55 - WIPER ON/OFF RELAY

56 - A/C CONDENSER FAN RELAY

57 - ENGINE CONTROL RELAY

58 - FUEL PUMP RELAY

59 - TRANSMISSION RELAY

60 - WIPER HIGH/LOW RELAY

61 - SPARE

62 - FOG LAMP RELAY

63 - ADJUSTABLE PEDAL RELAY

64 - A/C CLUTCH RELAY

65 - SPARE

66 - O2 RELAY

67 - SPARE

68 - SPARE

69 - SPARE

70 - SPARE

71 - SPARE

72 - STARTER RELAY

73 - PARK LAMP RELAY

Fig. 25 Wiper Module

1 - PIVOT BRACKET (2)

2 - TUBE

3 - CLAMP

4 - PIVOT SHAFT (2)

5 - INSULATOR (4)

6 - LINKAGE BUSHING (4)

7 - DRIVE LINK (2)

8 - PIVOT CRANK ARM (2)

9 - PIGTAIL WIRE CONNECTOR

10 - MOTOR CRANK ARM

11 - WIPER MOTOR

8R - 22 WIPERS/WASHERSDR

WIPER HIGH/LOW RELAY (Continued)

Page 700 of 2895

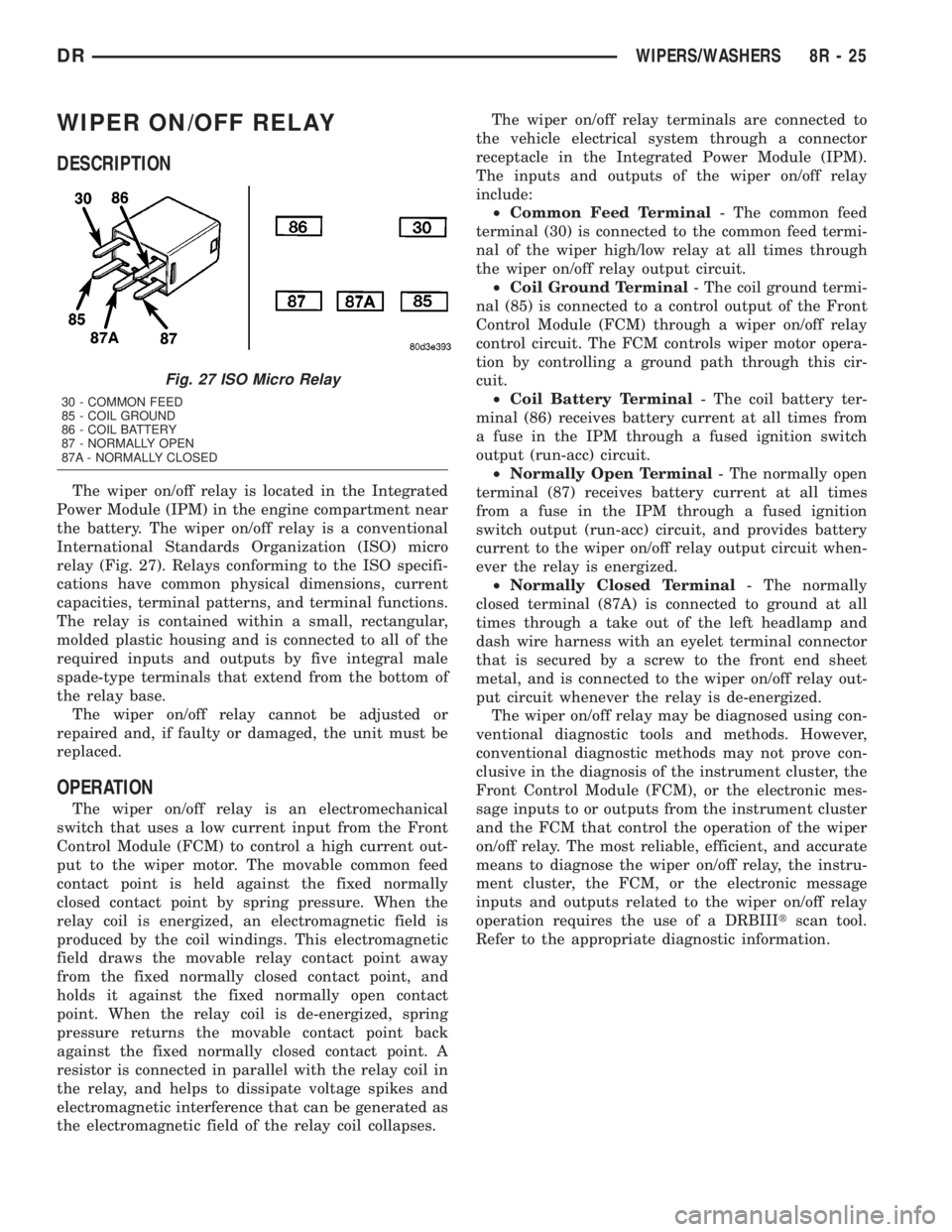

WIPER ON/OFF RELAY

DESCRIPTION

The wiper on/off relay is located in the Integrated

Power Module (IPM) in the engine compartment near

the battery. The wiper on/off relay is a conventional

International Standards Organization (ISO) micro

relay (Fig. 27). Relays conforming to the ISO specifi-

cations have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

The relay is contained within a small, rectangular,

molded plastic housing and is connected to all of the

required inputs and outputs by five integral male

spade-type terminals that extend from the bottom of

the relay base.

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper on/off relay

control circuit. The FCM controls wiper motor opera-

tion by controlling a ground path through this cir-

cuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the IPM through a fused ignition switch

output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a fuse in the IPM through a fused ignition

switch output (run-acc) circuit, and provides battery

current to the wiper on/off relay output circuit when-

ever the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to ground at all

times through a take out of the left headlamp and

dash wire harness with an eyelet terminal connector

that is secured by a screw to the front end sheet

metal, and is connected to the wiper on/off relay out-

put circuit whenever the relay is de-energized.

The wiper on/off relay may be diagnosed using con-

ventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

on/off relay. The most reliable, efficient, and accurate

means to diagnose the wiper on/off relay, the instru-

ment cluster, the FCM, or the electronic message

inputs and outputs related to the wiper on/off relay

operation requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

Fig. 27 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRWIPERS/WASHERS 8R - 25

Page 701 of 2895

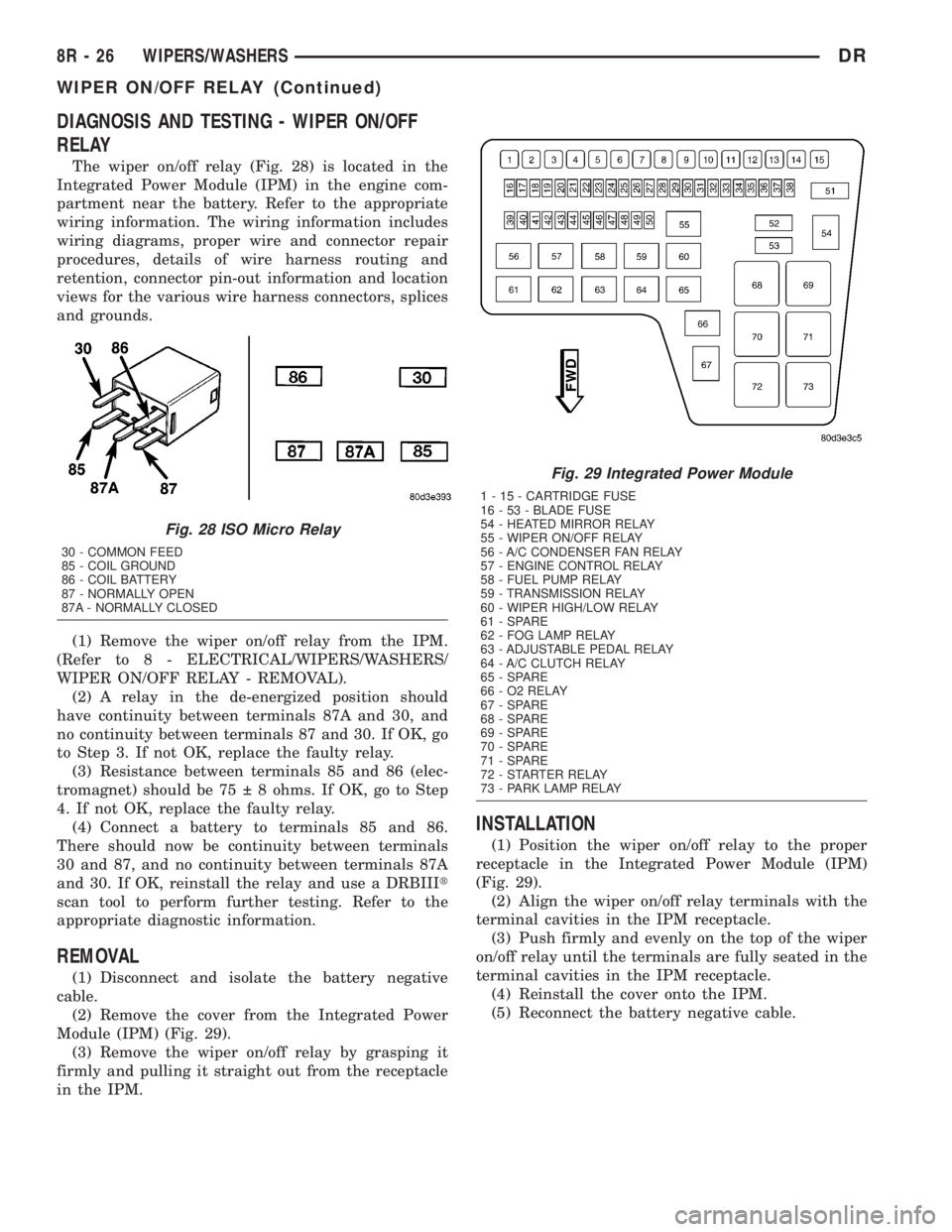

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY

The wiper on/off relay (Fig. 28) is located in the

Integrated Power Module (IPM) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper on/off relay from the IPM.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ON/OFF RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Integrated Power

Module (IPM) (Fig. 29).

(3) Remove the wiper on/off relay by grasping it

firmly and pulling it straight out from the receptacle

in the IPM.

INSTALLATION

(1) Position the wiper on/off relay to the proper

receptacle in the Integrated Power Module (IPM)

(Fig. 29).

(2) Align the wiper on/off relay terminals with the

terminal cavities in the IPM receptacle.

(3) Push firmly and evenly on the top of the wiper

on/off relay until the terminals are fully seated in the

terminal cavities in the IPM receptacle.

(4) Reinstall the cover onto the IPM.

(5) Reconnect the battery negative cable.

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 29 Integrated Power Module

1 - 15 - CARTRIDGE FUSE

16 - 53 - BLADE FUSE

54 - HEATED MIRROR RELAY

55 - WIPER ON/OFF RELAY

56 - A/C CONDENSER FAN RELAY

57 - ENGINE CONTROL RELAY

58 - FUEL PUMP RELAY

59 - TRANSMISSION RELAY

60 - WIPER HIGH/LOW RELAY

61 - SPARE

62 - FOG LAMP RELAY

63 - ADJUSTABLE PEDAL RELAY

64 - A/C CLUTCH RELAY

65 - SPARE

66 - O2 RELAY

67 - SPARE

68 - SPARE

69 - SPARE

70 - SPARE

71 - SPARE

72 - STARTER RELAY

73 - PARK LAMP RELAY

8R - 26 WIPERS/WASHERSDR

WIPER ON/OFF RELAY (Continued)

Page 704 of 2895

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....5

DESCRIPTION - CIRCUIT FUNCTIONS......6

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................6

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............7

WARNING

WARNINGS - GENERAL.................7

DIAGNOSIS AND TESTING - WIRING

HARNESS............................7

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................8

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................9

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................9STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................9

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS...........10

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP......................10

SPECIAL TOOLS

WIRING/TERMINAL....................10

CONNECTOR

REMOVAL.............................11

INSTALLATION.........................11

DIODE

REMOVAL.............................14

INSTALLATION.........................14

TERMINAL

REMOVAL.............................14

INSTALLATION.........................14

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 15

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

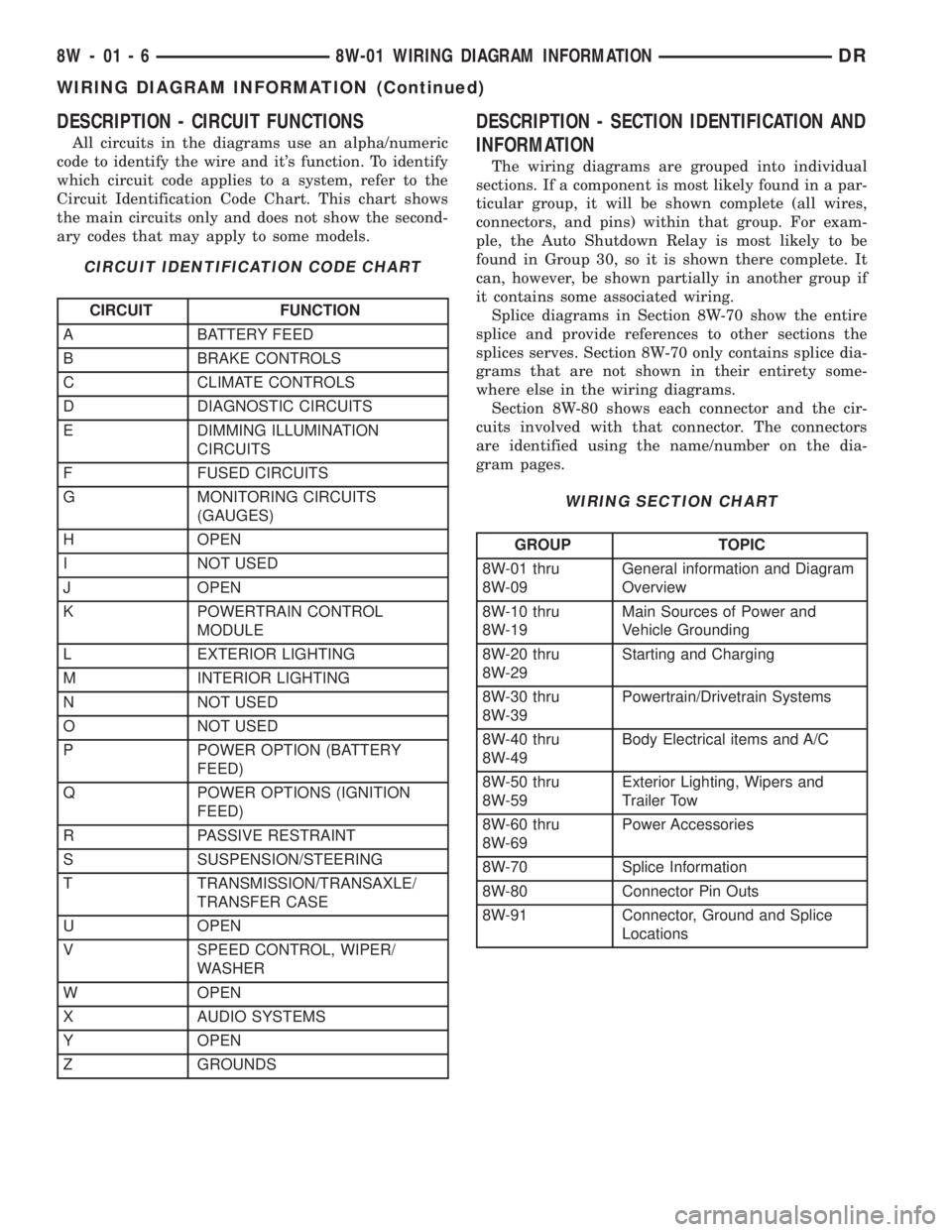

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 1

Page 709 of 2895

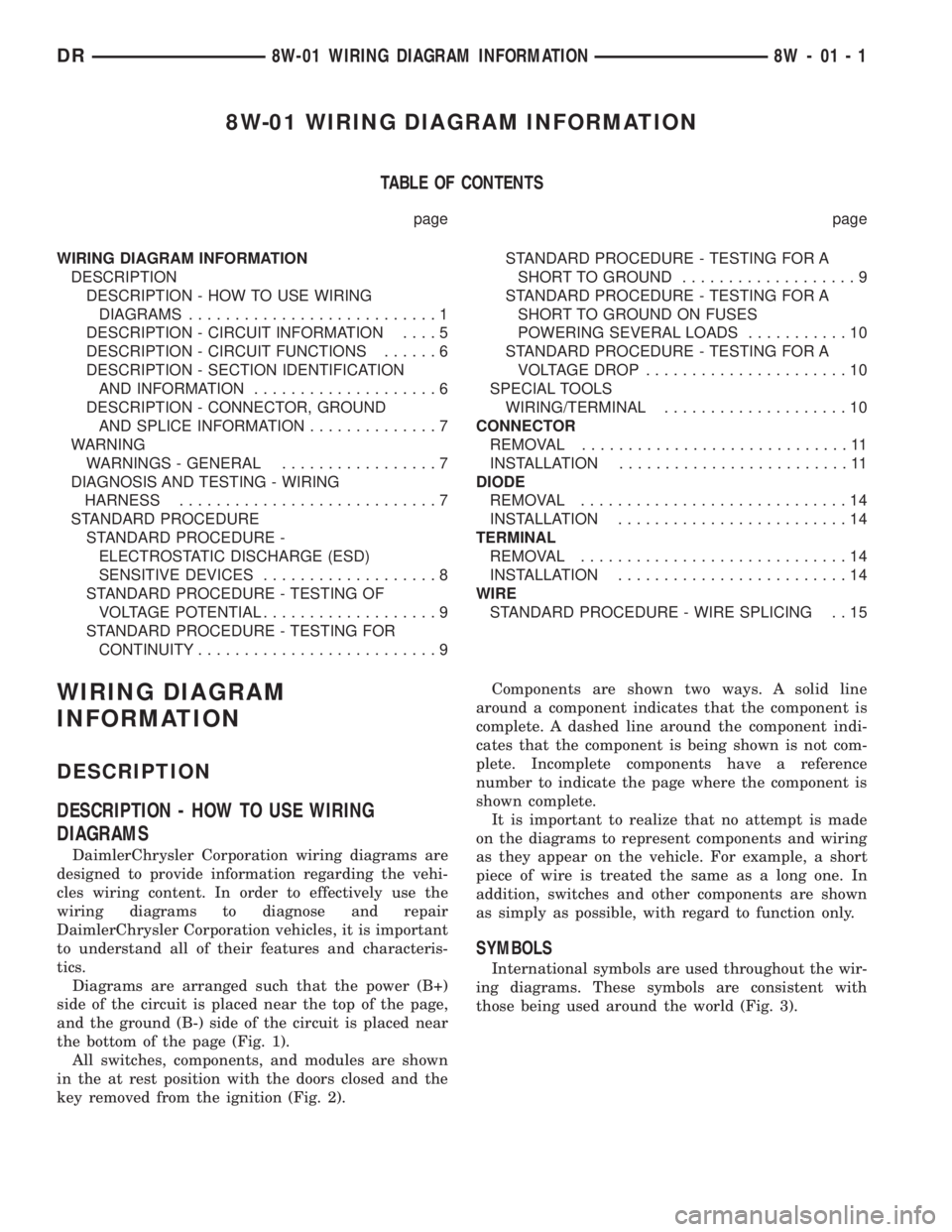

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)