diagram DODGE RAM 2003 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2327 of 2895

AUTOMATIC TRANSMISSION - 45RFE/545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 45RFE/545RFE

DESCRIPTION........................489

OPERATION..........................490

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................491

DIAGNOSIS AND TESTING - PRELIMINARY. . 491

DIAGNOSIS AND TESTING - ROAD

TESTING...........................491

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................493

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....494

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................495

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................495

REMOVAL............................495

DISASSEMBLY........................497

CLEANING...........................502

INSPECTION.........................503

ASSEMBLY...........................503

INSTALLATION........................510

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............513

SPECIFICATIONS

TRANSMISSION.....................534

SPECIAL TOOLS

RFE TRANSMISSION.................535

4C RETAINER/BULKHEAD

DISASSEMBLY........................538

ASSEMBLY...........................538

ADAPTER HOUSING SEAL

REMOVAL............................539

INSTALLATION........................539

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................540

OPERATION..........................540

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......540

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................540

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............541

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................541DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................541

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................542

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............542

STANDARD PROCEDURE - TRANSMISSION

FILL...............................544

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................544

REMOVAL............................544

INSTALLATION........................545

ADJUSTMENTS

GEARSHIFT CABLE..................546

HOLDING CLUTCHES

DESCRIPTION........................546

OPERATION..........................546

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................549

OPERATION..........................549

DISASSEMBLY........................550

ASSEMBLY...........................552

INPUT SPEED SENSOR

DESCRIPTION........................558

OPERATION..........................558

REMOVAL............................559

INSTALLATION........................559

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................559

OPERATION..........................559

REMOVAL............................559

INSTALLATION........................560

LOW/REVERSE CLUTCH

DISASSEMBLY........................560

CLEANING...........................561

INSPECTION.........................561

ASSEMBLY...........................561

OIL PUMP

DESCRIPTION........................562

OPERATION..........................562

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................563

DISASSEMBLY........................564

CLEANING...........................566

INSPECTION.........................566

ASSEMBLY...........................566

21 - 488 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2352 of 2895

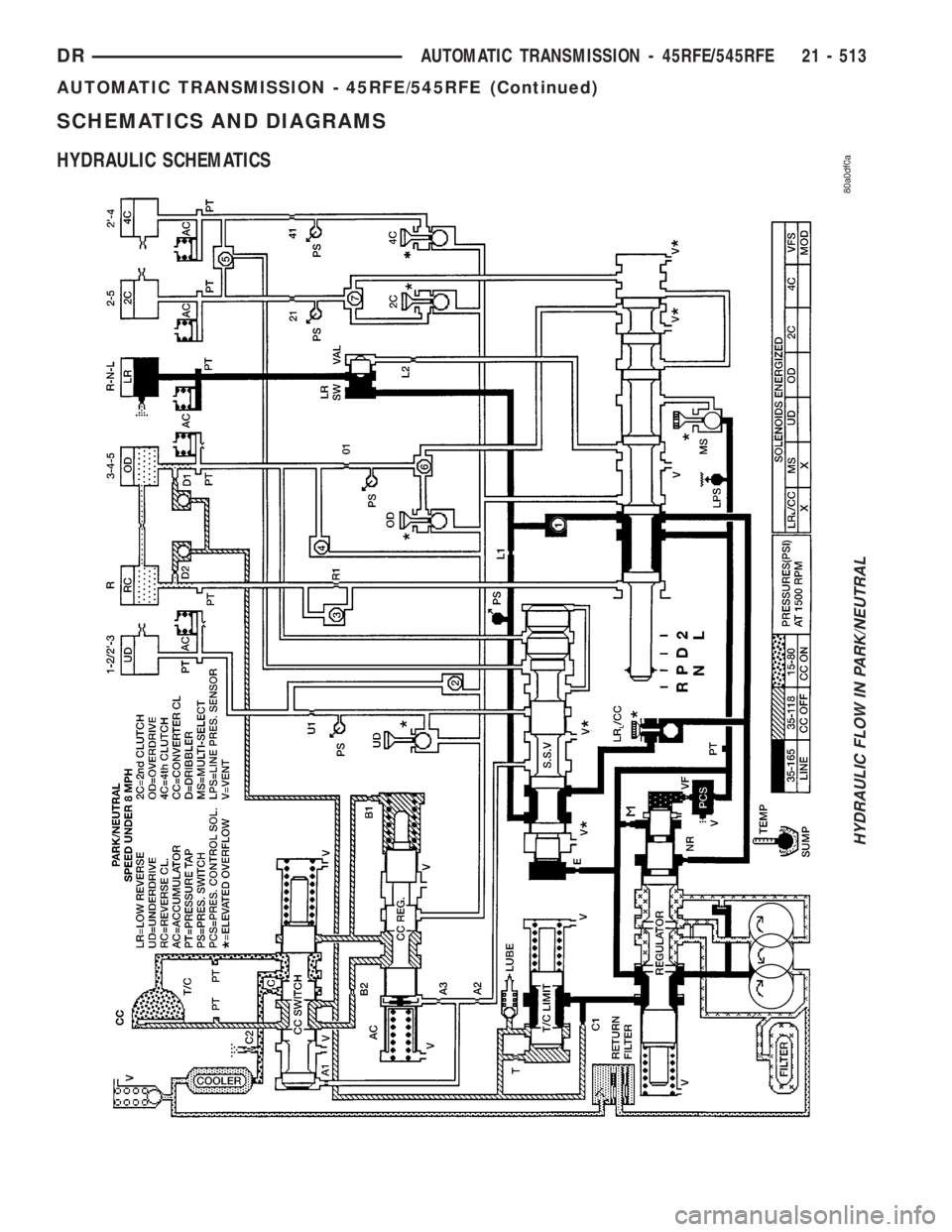

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS

HYDRAULIC FLOW IN PARK/NEUTRAL

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 513

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2782 of 2895

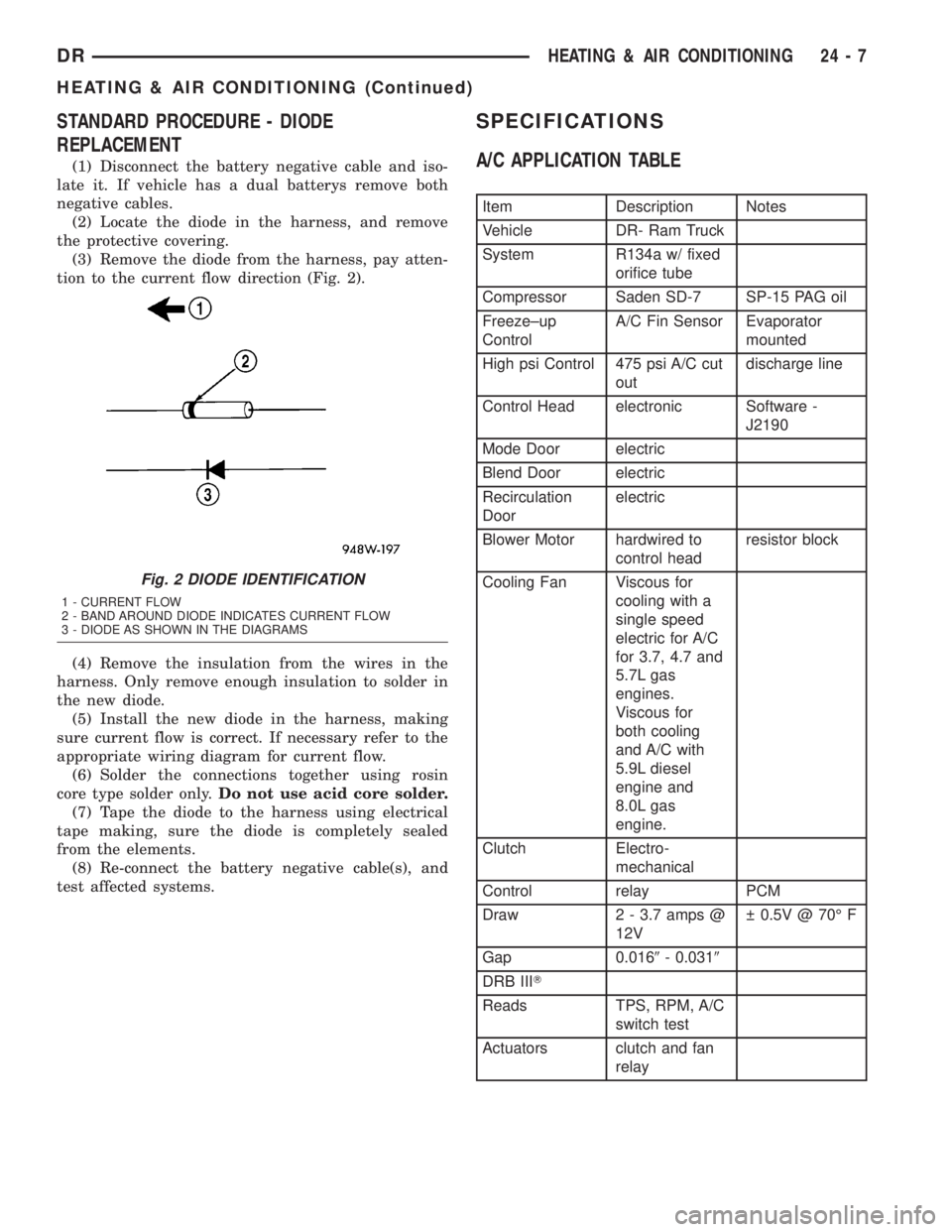

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect the battery negative cable and iso-

late it. If vehicle has a dual batterys remove both

negative cables.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 2).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connections together using rosin

core type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery negative cable(s), and

test affected systems.

SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

Vehicle DR- Ram Truck

System R134a w/ fixed

orifice tube

Compressor Saden SD-7 SP-15 PAG oil

Freeze±up

ControlA/C Fin Sensor Evaporator

mounted

High psi Control 475 psi A/C cut

outdischarge line

Control Head electronic Software -

J2190

Mode Door electric

Blend Door electric

Recirculation

Doorelectric

Blower Motor hardwired to

control headresistor block

Cooling Fan Viscous for

cooling with a

single speed

electric for A/C

for 3.7, 4.7 and

5.7L gas

engines.

Viscous for

both cooling

and A/C with

5.9L diesel

engine and

8.0L gas

engine.

Clutch Electro-

mechanical

Control relay PCM

Draw 2 - 3.7 amps @

12V 0.5V @ 70É F

Gap 0.0169- 0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch test

Actuators clutch and fan

relay

Fig. 2 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

DRHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2785 of 2895

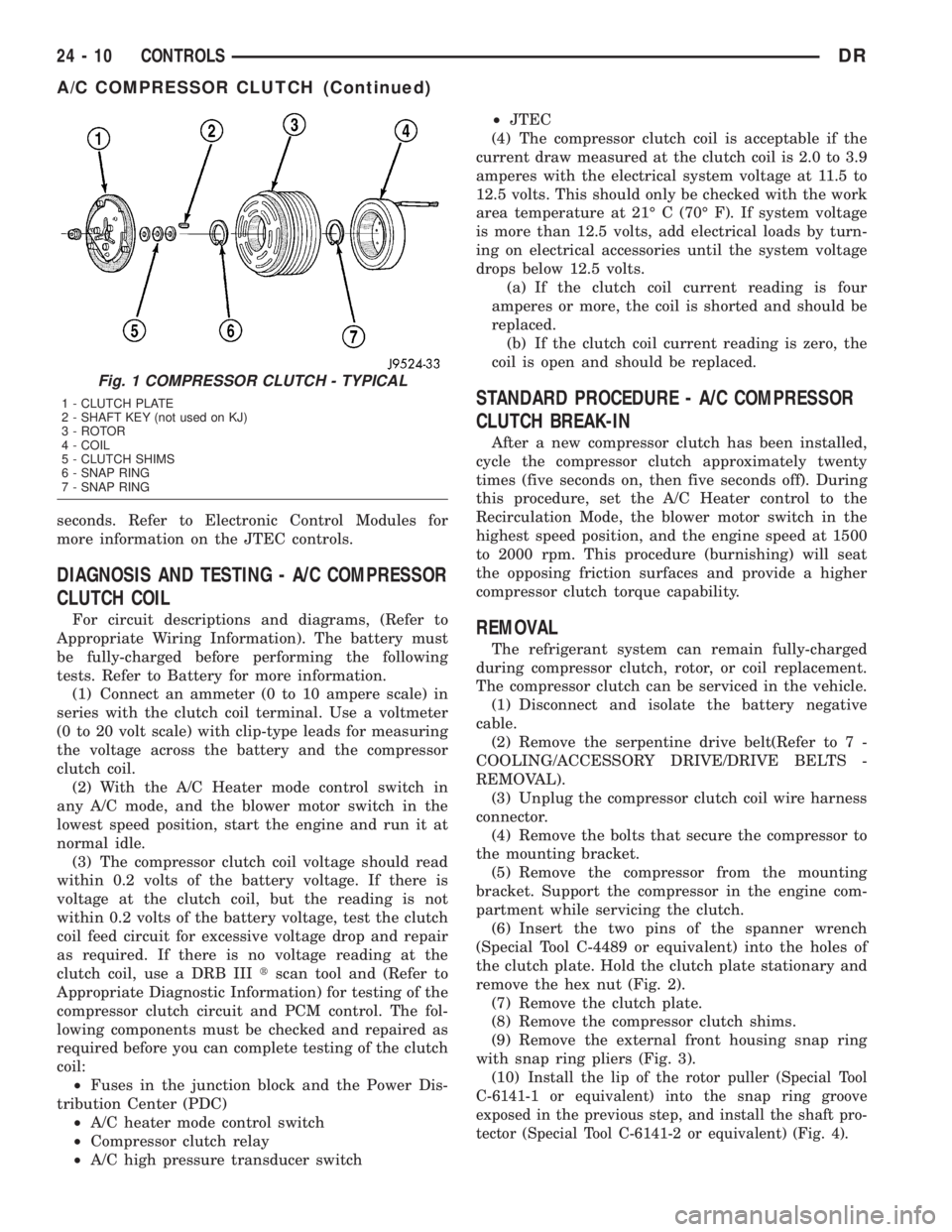

seconds. Refer to Electronic Control Modules for

more information on the JTEC controls.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the A/C Heater mode control switch in

any A/C mode, and the blower motor switch in the

lowest speed position, start the engine and run it at

normal idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of the

compressor clutch circuit and PCM control. The fol-

lowing components must be checked and repaired as

required before you can complete testing of the clutch

coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²Compressor clutch relay

²A/C high pressure transducer switch²JTEC

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C Heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Unplug the compressor clutch coil wire harness

connector.

(4) Remove the bolts that secure the compressor to

the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

(6) Insert the two pins of the spanner wrench

(Special Tool C-4489 or equivalent) into the holes of

the clutch plate. Hold the clutch plate stationary and

remove the hex nut (Fig. 2).

(7) Remove the clutch plate.

(8) Remove the compressor clutch shims.

(9) Remove the external front housing snap ring

with snap ring pliers (Fig. 3).

(10)

Install the lip of the rotor puller (Special Tool

C-6141-1 or equivalent) into the snap ring groove

exposed in the previous step, and install the shaft pro-

tector (Special Tool C-6141-2 or equivalent) (Fig. 4).

Fig. 1 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY (not used on KJ)

3 - ROTOR

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

24 - 10 CONTROLSDR

A/C COMPRESSOR CLUTCH (Continued)

Page 2788 of 2895

NOTE: The air gap is determined by the spacer

shims. When installing an original, or a new clutch

assembly, try the original shims first. When install-

ing a new clutch onto a compressor that previously

did not have a clutch, use a 1.0, 0.50, and 0.13 mil-

limeter (0.040, 0.020, and 0.005 inch) shims from the

new clutch hardware package that is provided with

the new clutch.

(9) To complete the procedure, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

A/C COMPRESSOR CLUTCH

RELAY

DESCRIPTION

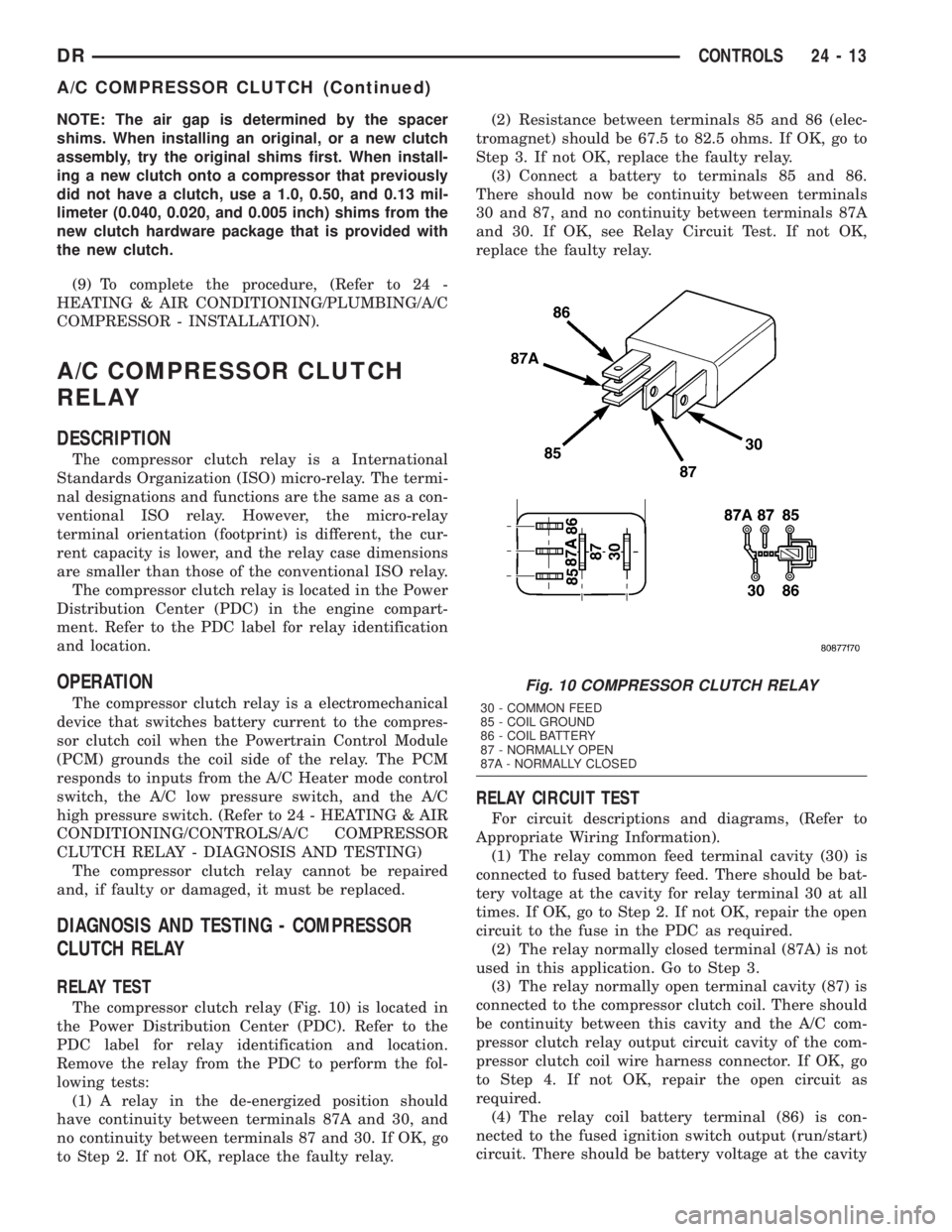

The compressor clutch relay is a International

Standards Organization (ISO) micro-relay. The termi-

nal designations and functions are the same as a con-

ventional ISO relay. However, the micro-relay

terminal orientation (footprint) is different, the cur-

rent capacity is lower, and the relay case dimensions

are smaller than those of the conventional ISO relay.

The compressor clutch relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment. Refer to the PDC label for relay identification

and location.

OPERATION

The compressor clutch relay is a electromechanical

device that switches battery current to the compres-

sor clutch coil when the Powertrain Control Module

(PCM) grounds the coil side of the relay. The PCM

responds to inputs from the A/C Heater mode control

switch, the A/C low pressure switch, and the A/C

high pressure switch. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH RELAY - DIAGNOSIS AND TESTING)

The compressor clutch relay cannot be repaired

and, if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY

RELAY TEST

The compressor clutch relay (Fig. 10) is located in

the Power Distribution Center (PDC). Refer to the

PDC label for relay identification and location.

Remove the relay from the PDC to perform the fol-

lowing tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 67.5 to 82.5 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)

circuit. There should be battery voltage at the cavity

Fig. 10 COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRCONTROLS 24 - 13

A/C COMPRESSOR CLUTCH (Continued)

Page 2793 of 2895

blower. The blower motor switch directs the ground

path through the correct resistor circuit to obtain the

selected speed.

The blower motor resistor cannot be repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the passenger side bottom of the

HVAC unit and unplug the wire harness connector

from the blower motor resistor.

(3) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor or blower motor relay as

required. If not OK, replace the faulty blower motor

resistor.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) The blower motor resistor is accessable from

the passenger side of the HVAC unit and is located

on the bottom of the HVAC unit.

(3) Pull out the lock on the blower motor resistor

wire harness connector to unlock the connector latch.

(4) Depress the latch on the blower motor resistor

wire harness connector and unplug the connector

from the resistor.

(5) Remove the two screws that secure the resistor

to the HVAC housing.

(6) Remove the resistor from the HVAC housing.

INSTALLATION

(1) Install the new resistor in the HVAC housing.

(2) Install the two screws that secure the resistor

to the HVAC housing and tighten to 2.2 N´m (20 in.

lbs.).

(3) Plug in the blower motor harness connector.

(4) Push in the lock on the blower motor resistor

harness connector.

(5) Close the glove box door.

(6) Connect the battery negative cable.

BLOWER MOTOR SWITCH

DESCRIPTION

The A/C Heater blower motor is controlled by a

four position rotary-type blower motor switch,

mounted in the A/C Heater control panel. The switch

allows the selection of one of four blower motor

speeds, but can only be turned off by selecting the

Off position on the blower motor switch.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C Heater control unit

must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

24 - 18 CONTROLSDR

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2801 of 2895

DIAGNOSIS AND TESTING - BLOWER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). Possible causes of

an inoperative blower motor include:

²Faulty fuse

²Faulty blower motor circuit wiring or wire har-

ness connectors

²Faulty blower motor resistor

²Faulty blower motor relay

²Faulty blower motor switch

²Faulty A/C Heater mode control switch

²Faulty blower motor.

Possible causes of the blower motor not operating

in all speeds include:

²Faulty blower motor switch

²Faulty blower motor resistor

²Faulty blower motor circuit wiring or wire har-

ness connectors.

VIBRATION

Possible causes of blower motor vibration include:

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower wheel out of balance or bent

²Blower motor faulty.

NOISE

To verify that the blower is the source of the noise,

unplug the blower motor wire harness connector and

operate the HVAC system. If the noise goes away,

possible causes include:

²Foreign material in the HVAC housing

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower motor faulty.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERINGCOLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

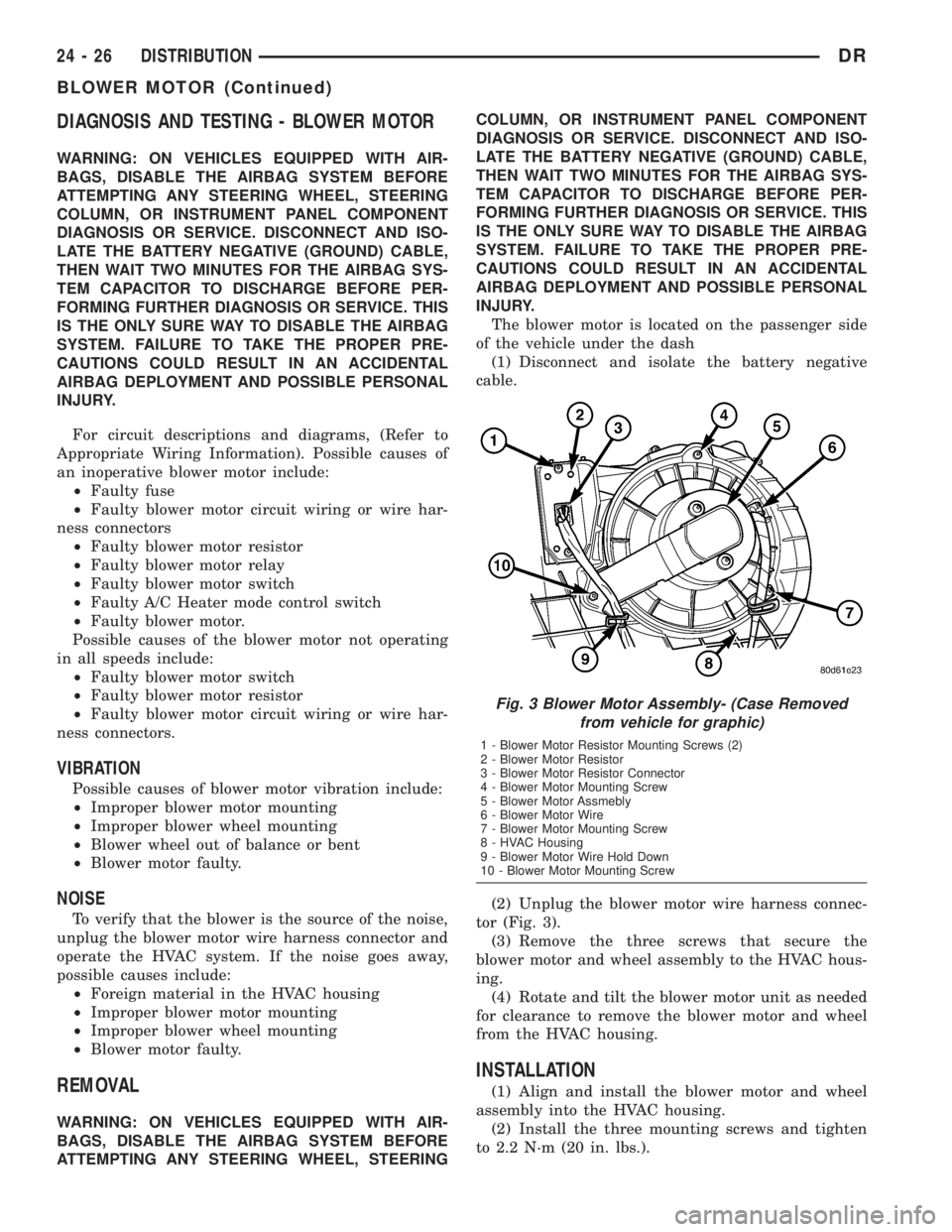

The blower motor is located on the passenger side

of the vehicle under the dash

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the blower motor wire harness connec-

tor (Fig. 3).

(3) Remove the three screws that secure the

blower motor and wheel assembly to the HVAC hous-

ing.

(4) Rotate and tilt the blower motor unit as needed

for clearance to remove the blower motor and wheel

from the HVAC housing.

INSTALLATION

(1) Align and install the blower motor and wheel

assembly into the HVAC housing.

(2) Install the three mounting screws and tighten

to 2.2 N´m (20 in. lbs.).

Fig. 3 Blower Motor Assembly- (Case Removed

from vehicle for graphic)

1 - Blower Motor Resistor Mounting Screws (2)

2 - Blower Motor Resistor

3 - Blower Motor Resistor Connector

4 - Blower Motor Mounting Screw

5 - Blower Motor Assmebly

6 - Blower Motor Wire

7 - Blower Motor Mounting Screw

8 - HVAC Housing

9 - Blower Motor Wire Hold Down

10 - Blower Motor Mounting Screw

24 - 26 DISTRIBUTIONDR

BLOWER MOTOR (Continued)

Page 2865 of 2895

CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-83

CUSHION / COVER - FRONT -

INSTALLATION, SEAT BACK............23-83

CUSHION / COVER - FRONT - REMOVAL,

SEAT ..............................23-83

CUSHION / COVER - FRONT - REMOVAL,

SEAT BACK.........................23-83

CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-85

CUSHION / COVER - REAR -

INSTALLATION, SEAT BACK............23-85

CUSHION / COVER - REAR - REMOVAL,

SEAT ..............................23-85

CUSHION / COVER - REAR - REMOVAL,

SEAT BACK.........................23-85

CUSHION - INSTALLATION, CENTER

SEAT ..............................23-80

CUSHION - REMOVAL, CENTER SEAT.....23-80

CUSHION COVER - INSTALLATION,

CENTER SEAT.......................23-81

CUSHION COVER - REMOVAL, CENTER

SEAT ..............................23-81

CUSHION FRAME - REAR -

INSTALLATION, SEAT.................23-85

CUSHION FRAME - REAR - REMOVAL,

SEAT ..............................23-85

CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-9

CV JOINT-INNER - INSTALLATION........3-16

CV JOINT-INNER - REMOVAL............3-16

CV JOINT-OUTER - INSTALLATION........3-13

CV JOINT-OUTER - REMOVAL............3-13

CYLINDER - DESCRIPTION, MASTER......5-19

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK.......19-11

CYLINDER - INSTALLATION, KEY........19-12

CYLINDER - INSTALLATION, LOAD

FLOOR SUPPORT....................23-73

CYLINDER - INSTALLATION, LOCK.......23-24

CYLINDER - INSTALLATION, SUPPORT....23-49

CYLINDER - OPERATION, MASTER........5-20

CYLINDER - REMOVAL, KEY............19-12

CYLINDER - REMOVAL, LOAD FLOOR

SUPPORT..........................23-73

CYLINDER - REMOVAL, LOCK...........23-24

CYLINDER - REMOVAL, SUPPORT.......23-48

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-20

CYLINDER BLOCK REFACING -

STANDARD PROCEDURE...............9-312

CYLINDER BORE - DE-GLAZE -

STANDARD PROCEDURE...............9-313

CYLINDER BORE HONING - STANDARD

PROCEDURE..........9-126,9-233,9-360,9-37

CYLINDER BORE REPAIR - STANDARD

PROCEDURE........................9-313

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING....9-182,

9-231,9-359,9-8,9-92

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING . . . 9-182,9-231,9-359,

9-8,9-92

CYLINDER COMPRESSION/LEAKAGE

TESTS - DIAGNOSIS AND TESTING......9-288

CYLINDER HEAD - CLEANING . 9-195,9-300,9-372

CYLINDER HEAD - DESCRIPTION . . 9-106,9-243,

9-298,9-370

CYLINDER HEAD - INSPECTION....9-195,9-301,

9-372

CYLINDER HEAD - INSTALLATION . . 9-195,9-372

CYLINDER HEAD - INSTALLATION, LEFT . . 9-110

CYLINDER HEAD - INSTALLATION,

RIGHT.............................9-111

CYLINDER HEAD - LEFT - INSTALLATION . . . 9-23

CYLINDER HEAD - LEFT - REMOVAL......9-21

CYLINDER HEAD - OPERATION.....9-194,9-243

CYLINDER HEAD - REMOVAL . 9-195,9-298,9-371

CYLINDER HEAD - REMOVAL, LEFT......9-106

CYLINDER HEAD - REMOVAL, RIGHT.....9-108

CYLINDER HEAD - RIGHT -

INSTALLATION

........................9-32

CYLINDER HEAD - RIGHT - REMOVAL

.....9-32

CYLINDER HEAD COVER -

INSTALLATION

.......................9-304

CYLINDER HEAD COVER - REMOVAL

.....9-304

CYLINDER HEAD COVER GASKET -

DESCRIPTION

.......................9-243CYLINDER HEAD COVER GASKET -

OPERATION.........................9-243

CYLINDER HEAD COVER(S) - CLEANING . . 9-245,

9-374

CYLINDER HEAD COVER(S) -

DESCRIPTION..............9-121,9-26,9-373

CYLINDER HEAD COVER(S) -

INSPECTION...................9-245,9-374

CYLINDER HEAD COVER(S) -

INSTALLATION....9-196,9-245,9-27,9-36,9-374

CYLINDER HEAD COVER(S) - REMOVAL . . 9-196,

9-245,9-26,9-35,9-373

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING........................9-20

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING . . . 9-194,9-243,9-370

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-20

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-2

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR . . 9-186,9-232,

9-289,9-361,9-9,9-93

DAMPER - INSPECTION, VIBRATION.....9-335

DAMPER - INSTALLATION..............19-35

DAMPER - INSTALLATION, VIBRATION . . . 9-142,

9-209,9-263,9-335,9-392,9-55

DAMPER - REMOVAL.................19-35

DAMPER - REMOVAL, VIBRATION . . 9-141,9-209,

9-263,9-335,9-392,9-54

DATA LINK CONNECTOR - DESCRIPTION . . . 8E-3

DATA LINK CONNECTOR - OPERATION......8E-3

DATA PLATE - DESCRIPTION, ENGINE....9-297

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-12

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-13

DEFINITION - DESCRIPTION, TRIP........25-4

DEFROST DOOR - INSTALLATION........24-27

DEFROST DOOR - INSTALLATION, FLOOR . 24-30

DEFROST DOOR - REMOVAL...........24-27

DEFROST DOOR - REMOVAL, FLOOR.....24-30

DEFROST DOOR ACTUATOR -

INSTALLATION, FLOOR................24-20

DEFROST DOOR ACTUATOR - REMOVAL,

FLOOR.............................24-19

DEGAS CONTAINER-3.7L/4.7L -

DESCRIPTION, COOLANT...............7-38

DEGAS CONTAINER-3.7L/4.7L -

INSTALLATION, COOLANT...............7-39

DEGAS CONTAINER-3.7L/4.7L -

OPERATION, COOLANT.................7-38

DEGAS CONTAINER-3.7L/4.7L -

REMOVAL, COOLANT..................7-39

DE-GLAZE - STANDARD PROCEDURE,

CYLINDER BORE.....................9-313

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-4

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT

............8O-7

DETECTION ASSY - DESCRIPTION,

NATURAL VAC LEAK

..................25-23

DETECTION ASSY - INSTALLATION,

NATURAL VAC LEAK

..................25-24

DETECTION ASSY - OPERATION,

NATURAL VAC LEAK

..................25-23

DETECTION ASSY - REMOVAL, NATURAL

VAC LEAK

..........................25-24

DETECTION PUMP - DESCRIPTION, LEAK

. 25-13

DETECTION PUMP - INSTALLATION,

LEAK

..............................25-16

DETECTION PUMP - OPERATION, LEAK

. . . 25-14

DETECTION PUMP - REMOVAL, LEAK

....25-16

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE

........................8W-01-8

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION

........................25-1

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD

...................7-5

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING

......................8W-01-1DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS...........21-175,21-355,21-513

DIESEL - CLEANING, RADIATOR - 5.9L....7-60

DIESEL - CLEANING, RADIATOR FAN -

5.9L................................7-41

DIESEL - CLEANING, WATER PUMP -

5.9L................................7-67

DIESEL - DESCRIPTION...............14-73

DIESEL - DESCRIPTION, 5.9L............11-2

DIESEL - DESCRIPTION, BELT

TENSIONERS - 5.9L...................7-24

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-2

DIESEL - DESCRIPTION, ENGINE 5.9L....9-282

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-43

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-52

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-55

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-59

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-73

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-67

DIESEL - FUEL INJECTOR FIRING ORDER . 14-60

DIESEL - FUEL SYSTEM PRESSURE......14-60

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-60

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-41

DIESEL - INSPECTION, TAILPIPE - 5.9L....11-9

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-68

DIESEL - INSTALLATION...............14-74

DIESEL - INSTALLATION.....19-25,19-30,19-41

DIESEL - INSTALLATION, BELT

TENSIONERS - 5.9L...................7-25

DIESEL - INSTALLATION, DRIVE BELTS -

5.9L................................7-34

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L........................7-44

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-53

DIESEL - INSTALLATION, EXCEPT........14-22

DIESEL - INSTALLATION, MUFFLER -

5.9L................................11-9

DIESEL - INSTALLATION, RADIATOR -

5.9L................................7-60

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L..............................7-41

DIESEL - INSTALLATION, TAILPIPE - 5.9L . . 11-9

DIESEL - INSTALLATION, WATER PUMP -

5.9L................................7-68

DIESEL - OPERATION, BELT

TENSIONERS - 5.9L...................7-24

DIESEL - OPERATION, ENGINE BLOCK

HEATER - 5.9L........................7-43

DIESEL - OPERATION, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-52

DIESEL - OPERATION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-55

DIESEL - OPERATION, RADIATOR - 5.9L . . . 7-59

DIESEL - OPERATION, TRANS COOLER -

5.9L................................7-74

DIESEL - OPERATION, WATER PUMP -

5.9L................................7-67

DIESEL - REMOVAL...................14-73

DIESEL - REMOVAL.........19-24,19-30,19-40

DIESEL - REMOVAL, BELT TENSIONERS -

5.9L................................7-25

DIESEL - REMOVAL, DRIVE BELTS - 5.9L . . 7-34

DIESEL - REMOVAL, ENGINE BLOCK

HEATER - 5.9L........................7-43

DIESEL - REMOVAL, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-53

DIESEL - REMOVAL, EXCEPT...........14-20

DIESEL - REMOVAL, MUFFLER - 5.9L.....11-9

DIESEL - REMOVAL, RADIATOR - 5.9L.....7-59

DIESEL - REMOVAL, RADIATOR FAN -

5.9L

................................7-41

DIESEL - REMOVAL, TAILPIPE - 5.9L

......11-9

DIESEL - REMOVAL, WATER PUMP -

5.9L

................................7-67

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS

.......................0-1

DIESEL ENGINE - DIAGNOSIS AND

TESTING

............................11-3

10 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2872 of 2895

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-69

HINGE - INSTALLATION.....23-16,23-22,23-31,

23-46

HINGE - INSTALLATION, CENTER SEAT

BACK..............................23-80

HINGE - REMOVAL....23-16,23-22,23-31,23-46

HINGE - REMOVAL, CENTER SEAT BACK . . 23-79

HINGE COVER - INSTALLATION, CENTER

SEAT BACK INERTIA..................23-78

HINGE COVER - REMOVAL, CENTER

SEAT BACK INERTIA..................23-78

HITCH - INSTALLATION, TRAILER........13-25

HITCH - REMOVAL, TRAILER...........13-25

HOAT COOLANT - DESCRIPTION..........7-37

HOISTING - STANDARD PROCEDURE......0-14

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-14

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-14

HOLDDOWN - OPERATION, BATTERY.....8F-14

HOLDDOWN - REMOVAL, BATTERY......8F-14

HOLDER - INSTALLATION, CUP.........23-52

HOLDER - REMOVAL, CUP.............23-52

HOLDING CLUTCHES - DESCRIPTION....21-546

HOLDING CLUTCHES - OPERATION.....21-546

HOLE PLUG - INSTALLATION, CAMSHAFT

CORE..............................9-201

HOLE PLUG - REMOVAL, CAMSHAFT

CORE..............................9-200

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-9

HONING - STANDARD PROCEDURE,

CYLINDER BORE.......9-126,9-233,9-360,9-37

HOOD - INSTALLATION................23-47

HOOD - REMOVAL....................23-47

HOOK - INSTALLATION, COAT...........23-67

HOOK - REMOVAL, COAT..............23-67

HOOK ASSEMBLY - INSTALLATION,

FRONT TOW........................13-26

HOOK ASSEMBLY - REMOVAL, FRONT

TOW ..............................13-26

HORN - DIAGNOSIS AND TESTING.......8H-1

HORN - INSTALLATION.................8H-2

HORN - REMOVAL....................8H-2

HORN SWITCH - DESCRIPTION..........8H-2

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-2

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - GEAR TO COOLER -

INSTALLATION, RETURN..........19-43,19-44

HOSE - GEAR TO COOLER - REMOVAL,

RETURN............................19-43

HOSE - INSTALLATION, FRONT BRAKE......5-9

HOSE - INSTALLATION, PRESSURE . 19-43,19-44

HOSE - INSTALLATION, REAR BRAKE.......5-9

HOSE - REMOVAL, FRONT...............5-9

HOSE - REMOVAL, PRESSURE.....19-43,19-44

HOSE - REMOVAL, REAR BRAKE..........5-8

HOSE - RESERVOIR TO COOLER -

INSTALLATION, RETURN..........19-43,19-44

HOSE - RESERVOIR TO COOLER -

REMOVAL, RETURN.............19-43,19-44

HOSE ASSEMBLY - INSTALLATION, REAR

TUBE................................5-9

HOSE ASSEMBLY - REMOVAL, REAR

TUBE................................5-8

HOSE CLAMPS - DESCRIPTION...........7-3

HOSE CLAMPS - OPERATION.............7-5

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-70

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-68

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-70

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-69

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT..............24-33

HOSES/TUBES - DESCRIPTION, WASHER . 8R-11

HOSES/TUBES - OPERATION, WASHER . . . 8R-11

HOUSING - ASSEMBLY, HVAC

...........24-28

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH

..............................6-8

HOUSING - DISASSEMBLY, HVAC

........24-28

HOUSING - INSTALLATION, CLUTCH

......6-10

HOUSING - INSTALLATION, GEAR

........9-349HOUSING - INSTALLATION, HVAC........24-29

HOUSING - INSTALLATION, ROCKER.....9-304

HOUSING - REMOVAL, CLUTCH..........6-10

HOUSING - REMOVAL, GEAR...........9-348

HOUSING - REMOVAL, HVAC...........24-27

HOUSING - REMOVAL, ROCKER.........9-304

HOUSING BUSHING - INSTALLATION,

EXTENSION........................21-200

HOUSING BUSHING - REMOVAL,

EXTENSION........................21-200

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-616,21-682

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION.........21-616,21-682

HOUSING COVER - INSTALLATION, GEAR . 9-350

HOUSING COVER - REMOVAL, GEAR.....9-349

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER . . . 21-143,21-324,21-495

HOUSING SEAL - INSTALLATION,

ADAPTER...............21-127,21-539,21-83

HOUSING SEAL - INSTALLATION,

EXTENSION.......21-127,21-200,21-380,21-83

HOUSING SEAL - REMOVAL, ADAPTER . . 21-127,

21-539,21-83

HOUSING SEAL - REMOVAL,

EXTENSION.......21-127,21-200,21-380,21-83

HOUSING SEAL AND DUST BOOT -

INSTALLATION, EXTENSION.....21-652,21-716

HOUSING SEAL AND DUST BOOT -

REMOVAL, EXTENSION.........21-652,21-716

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

H-SECTION REPLACEMENT - STANDARD

PROCEDURE, REAR FRAME............13-15

HUB / BEARING - INSTALLATION.........2-31

HUB / BEARING - REMOVAL.............2-30

HVAC HOUSING - ASSEMBLY...........24-28

HVAC HOUSING - DISASSEMBLY........24-28

HVAC HOUSING - INSTALLATION........24-29

HVAC HOUSING - REMOVAL............24-27

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-25

HYDRAULIC LASH ADJUSTER -

DIAGNOSIS AND TESTING.........9-124,9-31

HYDRAULIC LIFTERS - CLEANING . . 9-260,9-388

HYDRAULIC LIFTERS - INSTALLATION . . . 9-260,

9-388

HYDRAULIC LIFTERS - REMOVAL . . . 9-259,9-387

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING......21-140,21-321,

21-493

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS........21-175,21-355,21-513

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING......................9-258,9-386

HYDROBOOST - INSTALLATION..........5-22

HYDROBOOST - INSTALLATION, ALL

EXCEPT.............................5-22

HYDROBOOST - REMOVAL..............5-21

HYDROBOOST - REMOVAL, ALL EXCEPT . . . 5-21

HYDRO-BOOST BRAKE BOOSTER -

INSTALLATION........................5-27

HYDRO-BOOST BRAKE BOOSTER -

REMOVAL...........................5-27

HYDROFORM FENDER RAIL REPAIR -

STANDARD PROCEDURE...............13-12

HYDROSTATIC LOCK - STANDARD

PROCEDURE.........9-186,9-232,9-290,9-361

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-6

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-2

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-33

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-35

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-33

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-34

IDLER SHAFT - INSTALLATION......9-175,9-80

IDLER SHAFT - REMOVAL

..........9-175,9-79

IGNITION - SPECIFICATIONS, TORQUE

.....8I-3

IGNITION CIRCUIT SENSE -

DESCRIPTION

.......................8E-10

IGNITION CIRCUIT SENSE - OPERATION

. . 8E-12

IGNITION COIL - DESCRIPTION

..........8I-19IGNITION COIL - INSTALLATION.........8I-24

IGNITION COIL - OPERATION............8I-20

IGNITION COIL - REMOVAL.............8I-23

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-33

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-33

IGNITION COIL CAPACITOR - OPERATION . . 8I-33

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-33

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-6

IGNITION COIL RESISTANCE, 4.7L V-8.....8I-6

IGNITION COIL RESISTANCE, 5.7L V-8.....8I-6

IGNITION COIL RESISTANCE, 5.9L.........8I-6

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-6

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION SWITCH - DESCRIPTION........19-9

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-11

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-9

IGNITION SWITCH - INSTALLATION......19-11

IGNITION SWITCH - OPERATION.........19-9

IGNITION SWITCH - REMOVAL..........19-10

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-11

IGNITION TIMING, SPECIFICATIONS.......8I-6

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE..........................8F-11

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY........................8E-15

IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY KEY......8Q-5

IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY KEY........8Q-5

IMMOBILIZER SYSTEM INITIALIZATION,

STANDARD PROCEDURE - SENTRY

KEY................................8Q-3

IMMOBILIZER SYSTEM (SKIS),

DESCRIPTION - SENTRY KEY............8Q-1

IMMOBILIZER SYSTEM TRANSPONDER

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY.............8Q-4

IMPACT AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE..................8O-53

IMPACT AIRBAG CONTROL MODULE -

OPERATION, SIDE....................8O-54

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF.....21-201,21-381,

21-541

INDEPENDENT FRONT SUSPENSION -

DESCRIPTION, GEAR..................19-16

INDEPENDENT FRONT SUSPENSION -

INSTALLATION, GEAR.................19-17

INDEPENDENT FRONT SUSPENSION -

REMOVAL, GEAR.....................19-16

INDICATOR - DESCRIPTION, ABS........8J-17

INDICATOR - DESCRIPTION, AIRBAG.....8J-18

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-18

INDICATOR - DESCRIPTION, CARGO

LAMP..............................8J-20

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-21

INDICATOR - DESCRIPTION, CRUISE.....8J-22

INDICATOR - DESCRIPTION, DOOR AJAR . . 8J-23

INDICATOR - DESCRIPTION, ETC........8J-24

INDICATOR - DESCRIPTION, GEAR

SELECTOR..........................8J-26

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-27

INDICATOR - DESCRIPTION, LAMP OUT . . . 8J-28

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-29

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-33

INDICATOR - DESCRIPTION, SEATBELT

. . . 8J-34

INDICATOR - DESCRIPTION, SECURITY

. . . 8J-34

INDICATOR - DESCRIPTION, SERVICE

4WD

...............................8J-35

INDICATOR - DESCRIPTION, TRANS

TEMP

..............................8J-38

INDICATOR - DESCRIPTION, TURN

SIGNAL

............................8J-39

DRINDEX 17

Description Group-Page Description Group-Page Description Group-Page

Page 2884 of 2895

RETURN - DESCRIPTION, SENSOR.......8E-10

RETURN HOSE - GEAR TO COOLER -

INSTALLATION..................19-43,19-44

RETURN HOSE - GEAR TO COOLER -

REMOVAL..........................19-43

RETURN HOSE - RESERVOIR TO

COOLER - INSTALLATION.........19-43,19-44

RETURN HOSE - RESERVOIR TO

COOLER - REMOVAL.............19-43,19-44

REVOLUTIONS PER MILE,

SPECIFICATIONS - TIRE...............22-10

RFE TRANSMISSION, SPECIAL TOOLS . . . 21-535

RIGHT - DESCRIPTION, CAMSHAFT(S)....9-117

RIGHT - INSTALLATION.................2-34

RIGHT - INSTALLATION, CAMSHAFT(S) . . . 9-118

RIGHT - INSTALLATION, CYLINDER

HEAD...............................9-32

RIGHT - REMOVAL....................2-34

RIGHT - REMOVAL, CAMSHAFT(S).......9-117

RIGHT - REMOVAL, CYLINDER HEAD......9-32

RIGHT CYLINDER HEAD - INSTALLATION . . 9-111

RIGHT CYLINDER HEAD - REMOVAL.....9-108

RIGHT OUTBOARD - INSTALLATION,

CENTER ANCHOR....................8O-45

RIGHT OUTBOARD - REMOVAL, CENTER

ANCHOR...........................8O-43

RIGHT REAR CABLE - INSTALLATION......5-32

RIGHT REAR CABLE - REMOVAL.........5-31

RIGHT SIDE - INSTALLATION...........9-121

RIGHT SIDE - REMOVAL...............9-121

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE......3-123,3-150,3-96

RING - REMOVAL, PINION GEAR/RING

GEAR/TONE................3-122,3-149,3-94

RING FITTING - STANDARD

PROCEDURE, PISTON . 9-140,9-207,9-262,9-333,

9-52

RINGS - STANDARD PROCEDURE,

FITTING PISTON.....................9-390

RKE TRANSMITTER BATTERIES -

STANDARD PROCEDURE...............8N-9

RKE TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE.........................8N-9

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE..............8N-10

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-3

ROAD TESTING - DIAGNOSIS AND

TESTING..............21-139,21-320,21-491

ROCKER ARM / ADJUSTER ASSEMBLY -

DESCRIPTION.......................9-124

ROCKER ARM / ADJUSTER ASSEMBLY -

INSTALLATION..................9-124,9-249

ROCKER ARM / ADJUSTER ASSEMBLY -

REMOVAL.....................9-124,9-249

ROCKER ARM / ADJUSTER ASSY -

CLEANING..........................9-310

ROCKER ARM / ADJUSTER ASSY -

DESCRIPTION.......................9-310

ROCKER ARM / ADJUSTER ASSY -

INSPECTION........................9-311

ROCKER ARM / ADJUSTER ASSY -

INSTALLATION.............9-198,9-312,9-379

ROCKER ARM / ADJUSTER ASSY -

REMOVAL................9-198,9-310,9-379

ROCKER ARM - DESCRIPTION

.......9-30,9-36

ROCKER ARM - INSTALLATION

..........9-30

ROCKER ARM - REMOVAL

..........9-30,9-36

ROCKER HOUSING - INSTALLATION

......9-304

ROCKER HOUSING - REMOVAL

.........9-304

ROD - CLEANING, PISTON &

CONNECTING

........9-138,9-206,9-261,9-389

ROD - CLEANING, PISTON AND

CONNECTING

........................9-331

ROD - DESCRIPTION, PISTON &

CONNECTING

. . . 9-137,9-205,9-260,9-329,9-388,

9-47

ROD - INSPECTION, CONNECTING

.......9-332

ROD - INSPECTION, PISTON &

CONNECTING

........9-138,9-206,9-261,9-389

ROD - INSTALLATION, PISTON &

CONNECTING

........9-139,9-207,9-261,9-389

ROD - REMOVAL, PISTON &

CONNECTING

. . . 9-137,9-205,9-261,9-330,9-389

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING

............9-321ROD BEARING FITTING - STANDARD

PROCEDURE, CONNECTING . . 9-128,9-251,9-382

ROD BEARING FITTING, STANDARD

PROCEDURE - CONNECTING.............9-48

ROD END - DIAGNOSIS AND TESTING,

OUTER TIE..........................19-31

ROD END - INSTALLATION, OUTER TIE . . . 19-32

ROD END - INSTALLATION, TIE.........19-37

ROD END - REMOVAL, OUTER TIE.......19-31

ROD END - REMOVAL, TIE.............19-36

ROTATION - STANDARD PROCEDURE,

TIRE................................22-2

ROTOR - 5.9L V-8 - DIAGNOSIS AND

TESTING, DISTRIBUTOR...............8I-19

ROUTING, 5.7L V-8 ENGINE - FIRING

ORDER / CABLE.......................8I-4

RUN CHANNEL - INSTALLATION, GLASS . . 23-21,

23-31

RUN CHANNEL - REMOVAL, GLASS . 23-21,23-30

RUN WEATHERSTRIP - INSTALLATION,

FRONT DOOR GLASS.................23-92

RUN WEATHERSTRIP - INSTALLATION,

REAR DOOR GLASS..................23-93

RUN WEATHERSTRIP - REMOVAL,

FRONT DOOR GLASS.................23-92

RUN WEATHERSTRIP - REMOVAL, REAR

DOOR GLASS.......................23-93

RUNOUT - DIAGNOSIS AND TESTING,

TIRE AND WHEEL.....................22-1

RWAL VALVE - DESCRIPTION............5-44

RWAL VALVE - INSTALLATION...........5-45

RWAL VALVE - OPERATION.............5-44

RWAL VALVE - REMOVAL...............5-45

SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE..............Intro.-1

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SAFETY PRECAUTIONS, STANDARD

PROCEDURE.........................8L-7

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD........................23-88

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE...............23-75

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-6

SCHEMATICS AND DIAGRAMS -

HYDRAULIC SCHEMATICS . 21-175,21-355,21-513

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - HYDRAULIC . 21-175,21-355,21-513

SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER NECK.........7-61

SEAL - FRONT - DESCRIPTION,

CRANKSHAFT OIL....................9-254

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL . 9-134,9-203,9-255,9-324,9-45

SEAL - FRONT - OPERATION,

CRANKSHAFT OIL....................9-254

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL . 9-134,9-203,9-254,9-323,9-44

SEAL - FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL.............9-384

SEAL - FRONT COVER INSTALLED -

REMOVAL, FRONT OIL................9-384

SEAL - FRONT COVER REMOVED -

INSTALLATION, FRONT OIL.............9-384

SEAL - FRONT COVER REMOVED -

REMOVAL, FRONT OIL................9-384

SEAL - INSTALLATION, ADAPTER

HOUSING...............21-127,21-539,21-83

SEAL - INSTALLATION, DOOR OPENING . . . 23-92

SEAL - INSTALLATION, EXTENSION

HOUSING.........21-127,21-200,21-380,21-83

SEAL - INSTALLATION, EXTENSION

HOUSING BUSHING............21-616,21-682

SEAL - INSTALLATION, FRONT OUTPUT

SHAFT..........21-618,21-653,21-683,21-717

SEAL - INSTALLATION, OIL PUMP

FRONT............................21-567

SEAL - INSTALLATION, PINION

....3-113,3-140,

3-35,3-60,3-85

SEAL - INSTALLATION, STEERING GEAR

INPUT SHAFT

.......................19-28

SEAL - INSTALLATION, VALVE STEM

.....9-378

SEAL - REAR - DESCRIPTION,

CRANKSHAFT OIL

....................9-255

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL

....9-136,9-204,9-256,9-325,

9-385,9-46SEAL - REAR - OPERATION,

CRANKSHAFT OIL....................9-255

SEAL - REAR - REMOVAL, CRANKSHAFT

OIL .......9-135,9-204,9-255,9-325,9-385,9-45

SEAL - REMOVAL, ADAPTER HOUSING . . 21-127,

21-539,21-83

SEAL - REMOVAL, DOOR OPENING......23-92

SEAL - REMOVAL, EXTENSION

HOUSING.........21-127,21-200,21-380,21-83

SEAL - REMOVAL, EXTENSION HOUSING

BUSHING....................21-616,21-682

SEAL - REMOVAL, FRONT OUTPUT

SHAFT..........21-617,21-653,21-683,21-717

SEAL - REMOVAL, OIL PUMP FRONT....21-567

SEAL - REMOVAL, PINION....3-113,3-140,3-34,

3-60,3-85

SEAL - REMOVAL, STEERING GEAR

INPUT SHAFT.......................19-25

SEAL AND DUST BOOT - INSTALLATION,

EXTENSION HOUSING..........21-652,21-716

SEAL AND DUST BOOT - REMOVAL,

EXTENSION HOUSING..........21-652,21-716

SEAL AREA LEAKS - DIAGNOSIS AND

TESTING, REAR.............9-135,9-204,9-64

SEAL RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL.....9-205,9-326,9-386

SEAL RETAINER - REMOVAL,

CRANKSHAFT REAR OIL.....9-204,9-326,9-386

SEALER LOCATIONS - SPECIFICATIONS . . 23-103

SEALERS - STANDARD PROCEDURE,

FORM-IN-PLACE GASKETS . . . 9-232,9-289,9-360,

9-9,9-93

SEALS - DESCRIPTION, VALVE GUIDE . . . 9-31,9-36

SEALS - DESCRIPTION, VALVE STEM....9-126,

9-198

SEALS - INSTALLATION, AXLE SHAFT . 3-33,3-58,

3-84

SEALS - REMOVAL, AXLE SHAFT . 3-33,3-58,3-84

SEALS - REMOVAL, VALVE SPRINGS.....9-308

SEALS - REMOVAL, VALVE STEM........9-377

SEAT - FRONT - INSTALLATION.........23-82

SEAT - FRONT - REMOVAL.............23-82

SEAT - INSTALLATION, CENTER.........23-77

SEAT - REAR - INSTALLATION..........23-84

SEAT - REAR - REMOVAL..............23-84

SEAT - REMOVAL, CENTER.............23-76

SEAT BACK - INSTALLATION, CENTER

ARMREST..........................23-78

SEAT BACK - REAR - INSTALLATION.....23-84

SEAT BACK - REAR - REMOVAL.........23-84

SEAT BACK - REMOVAL, CENTER

ARMREST..........................23-77

SEAT BACK CUSHION / COVER - FRONT

- INSTALLATION.....................23-83

SEAT BACK CUSHION / COVER - FRONT

- REMOVAL.........................23-83

SEAT BACK CUSHION / COVER - REAR -

INSTALLATION.......................23-85

SEAT BACK CUSHION / COVER - REAR -

REMOVAL..........................23-85

SEAT BACK HINGE - INSTALLATION,

CENTER............................23-80

SEAT BACK HINGE - REMOVAL, CENTER . . 23-79

SEAT BACK INERTIA HINGE COVER -

INSTALLATION, CENTER

...............23-78

SEAT BACK INERTIA HINGE COVER -

REMOVAL, CENTER

...................23-78

SEAT BACK LID - INSTALLATION,

CENTER

............................23-80

SEAT BACK LID - REMOVAL, CENTER

....23-80

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION

............23-85

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL

................23-85

SEAT BELT - INSTALLATION, FRONT

CENTER

............................8O-27

SEAT BELT - REMOVAL, FRONT CENTER

. . 8O-26

SEAT BELT & RETRACTOR -

INSTALLATION, FRONT CENTER

.........8O-26

SEAT BELT & RETRACTOR -

INSTALLATION, REAR CENTER

..........8O-40

SEAT BELT & RETRACTOR -

INSTALLATION, REAR OUTBOARD

.......8O-42

SEAT BELT & RETRACTOR - REMOVAL,

FRONT CENTER

......................8O-25

SEAT BELT & RETRACTOR - REMOVAL,

REAR CENTER

.......................8O-39

DRINDEX 29

Description Group-Page Description Group-Page Description Group-Page