Radio removal DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 364 of 2895

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - AUDIO..........2

AMPLIFIER

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................4

ANTENNA BODY & CABLE

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................4

REMOVAL.............................6

INSTALLATION..........................6

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................6

INSTALLATION..........................7

RADIO

DESCRIPTION..........................7OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................8

RADIO NOISE SUPPRESSION GROUND STRAP

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................9

INSTALLATION.........................10

REMOTE SWITCHES

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................11

REMOVAL.............................12

INSTALLATION.........................12

SPEAKER

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - SPEAKER......13

REMOVAL.............................13

INSTALLATION.........................15

AUDIO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model. Several combinations of

radio receivers and speaker systems are offered. The

audio system uses an ignition switched source of bat-

tery current so that the system will only operate

when the ignition switch is in the RUN or ACCES-

SORY positions.

The audio system includes the following compo-

nents:

²Antenna

²Power amplifier (with premium speaker system

only)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (if equipped)

²Speakers

Certain functions and features of the audio system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munication Interface (PCI) bus network. The data

bus network allows the sharing of sensor informa-

tion. For diagnosis of these electronic modules or of

the data bus network, the use of a DRB IIItscan tooland the proper Diagnostic Procedures manual are

recommended.

Refer to the appropriate wiring information for

complete standard and premium audio system circuit

diagrams. The wiring information includes proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

OPERATION

The audio system components are designed to pro-

vide audio entertainment and information through

the reception, tuning and amplification of locally

broadcast radio signals in both the Amplitude Modu-

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges.

The audio system components operate on battery

current received through a fuse in the Integrated

Power Module (IPM) on a fused ignition switch out-

put (run-acc) circuit so that the system will only

operate when the ignition switch is in the Run or

Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the Instrument Cluster

receives hard wired resistor multiplexed inputs from

the remote radio switches. The programming in the

DRAUDIO 8A - 1

Page 366 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

CLOCK WILL NOT KEEP

SET TIME1. Fuse faulty. 1. Check Ignition-Off Draw (IOD) fuse in the

Integrated Power Module (IPM). Replace fuse, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

POOR RADIO RECEPTION 1. Antenna faulty. 1. (Refer to 8 - ELECTRICAL/AUDIO/ANTENNA

BODY & CABLE - DIAGNOSIS AND TESTING).

2. Radio ground faulty. 2. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

3. Radio noise suppression

faulty.3. Repair or replace ground strap as necessary.

4. Radio faulty. 4. Refer to appropriate Diagnostic Service

Manual.

NO/POOR TAPE

OPERATION1. Faulty tape. 1. Insert known good tape and test operation.

2. Foreign objects behind

tape door.2. Remove foreign objects and test operation.

3. Dirty cassette tape head. 3. Clean head with Mopar Cassette Head

Cleaner.

4. Faulty tape deck. 4. Exchange or replace radio, if required.

NO COMPACT DISC

OPERATION1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on CD. 2. Clean CD and test operation.

3. Condensation on CD or

optics.3. Allow temperature of vehicle interior to stabilize

and test operation.

4. Faulty CD player. 4. Refer to appropriate Diagnostic Service

Manual.

AMPLIFIER

DESCRIPTION

The optional Infinity premium speaker system

includes a separate Infinity audio power amplifier.

The amplifier is a six channel unit and is rated at

240 total output watts. The amplifier is located

behind the glove box.

OPERATION

The power amplifier electronically increases the

frequency response of the normal audio signal output

from the radio amplifier in order to improve the

acoustic performance of the speakers. On vehiclesequipped with an amplifier, the amplifier section of

the radio becomes a pre-amplifier.

The amplifier receives audio signal inputs for

speaker channels from the radio, then sends ampli-

fied audio outputs through six separate channels

with dedicated feed and return circuits to the indi-

vidual speakers.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

DRAUDIO 8A - 3

AUDIO (Continued)

Page 367 of 2895

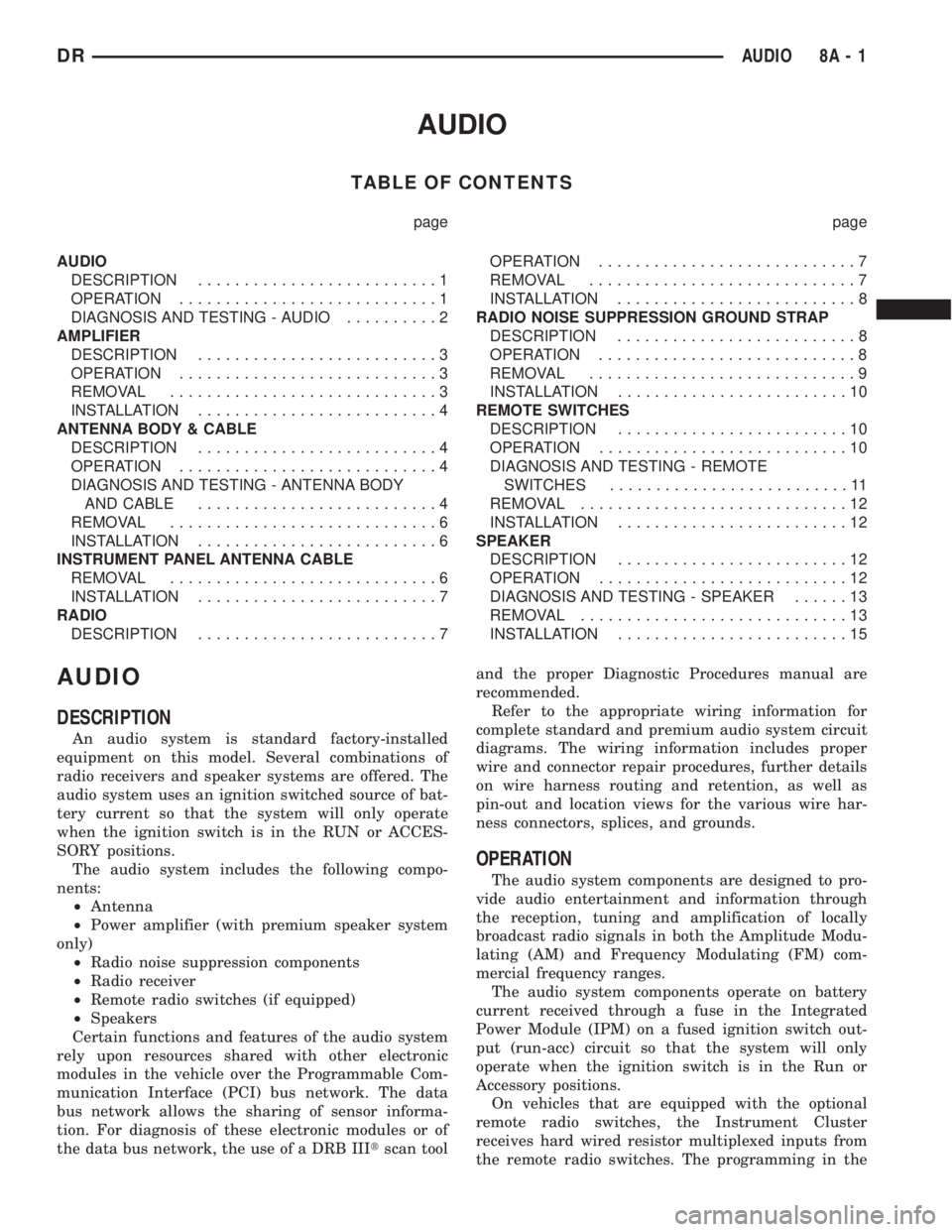

(3) Remove instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - REMOVAL).

(4) Remove instrument panel lower right center

bezel (Refer to 23 - BODY/INSTRUMENT PANEL/IP

LOWER RIGHT CENTER BEZEL - REMOVAL).

(5) Disconnect electrical harness connector from

amplifier (Fig. 1).

(6) Remove mounting bolts.

INSTALLATION

(1) Connect electrical harness connector and

install amplifier.

(2) Install mounting bolts. Tighten to 10 N´m (90

in. lbs.).

(3) Install instrument panel lower right center

bezel (Refer to 23 - BODY/INSTRUMENT PANEL/IP

LOWER RIGHT CENTER BEZEL - INSTALLA-

TION).

(4) Install instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - INSTALLATION).

(5) Install glove box (Refer to 23 - BODY/INSTRU-

MENT PANEL/GLOVE BOX - INSTALLATION).

(6) Connect battery negative cable.

ANTENNA BODY & CABLE

DESCRIPTION

The antenna body and cable is secured below the

fender panel by the antenna cap nut through a

mounting hole in the right front fender. The primary

coaxial antenna cable is then routed beneath the

fender sheet metal and through a entry hole in theright cowl side panel into the interior of the vehicle.

Inside the vehicle, the primary coaxial cable is con-

nected to a secondary instrument panel antenna

coaxial cable with an in-line connector that is located

behind the right kick panel. The secondary coaxial

cable is then routed behind the instrument panel to

the back of the radio.

OPERATION

The antenna body and cable connects the antenna

mast to the radio. The radio antenna is an electro-

magnetic circuit component used to capture radio fre-

quency signals that are broadcast by local

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to antenna coaxial cable

shield test.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The ohmmeter test lead connections for each test

are shown in the illustration (Fig. 2).

Fig. 1 AMPLIFIER MOUNTING

1 - INSTRUMENT PANEL

2 - AMPLIFIER

3 - MOUNTING BOLTS

4 - ELECTRICAL CONNECTOR

8A - 4 AUDIODR

AMPLIFIER (Continued)

Page 369 of 2895

antenna body to fender mating surfaces and tighten

the antenna cap nut to specifications.

(4) Check the resistance again with an ohmmeter.

If the resistance is still more then one ohm, replace

the faulty antenna body and cable.

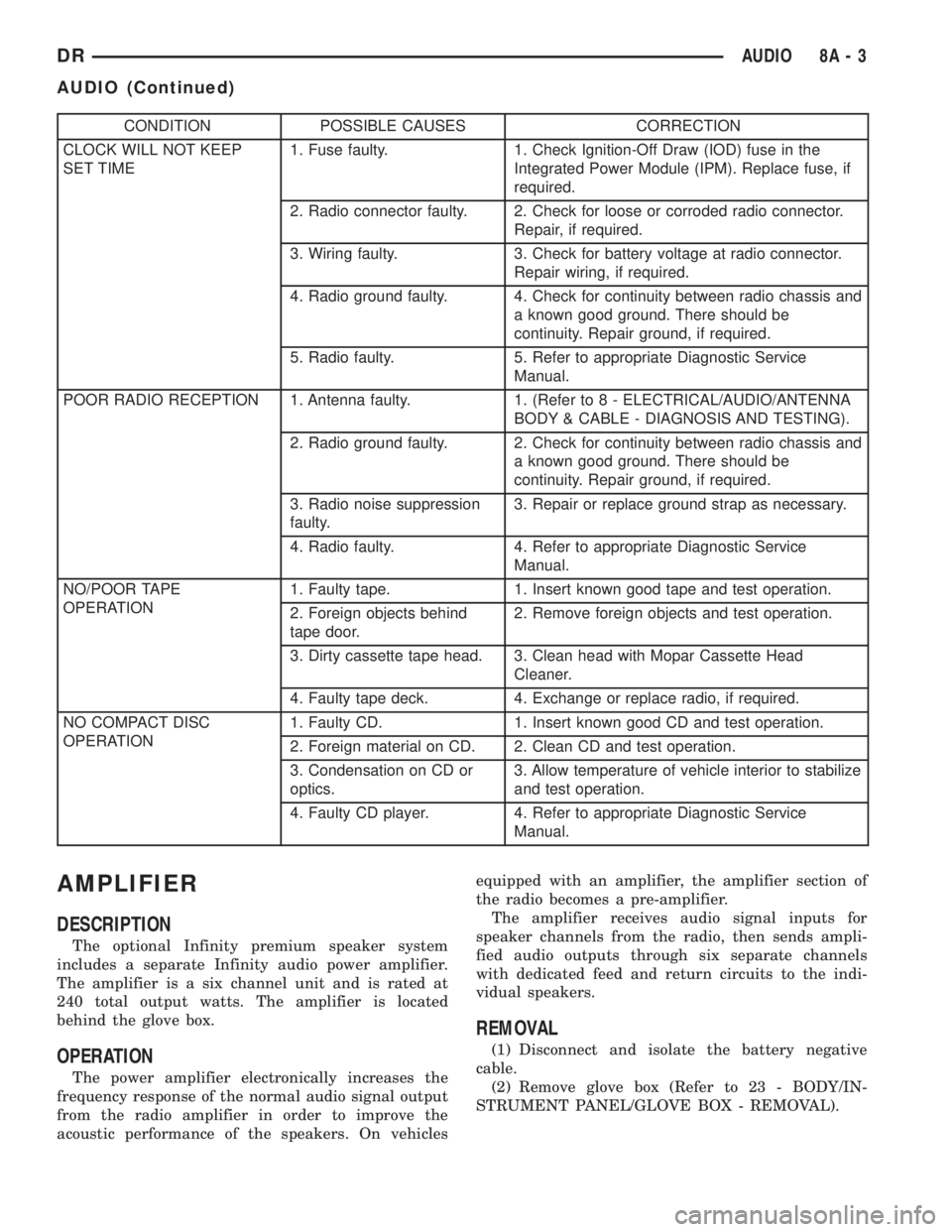

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right side kick panel.

(3) Disconnect antenna body cable from instru-

ment panel cable.

(4) Securely tie a suitable length of cord or twine

to the antenna half of the coaxial cable connector.

This cord will be used to pull the cable back into

position during installation.

(5) Remove the antenna mast.

(6) Remove the antenna cap nut using an antenna

nut wrench (Special Tool C-4816) (Fig. 3).

(7) Remove the antenna adapter.

(8) With the right door open, pull the antenna

body assembly out through the opening between the

fender and body.

INSTALLATION

(1) Tie the cord that was used during the removal

procedure to the cable being installed.

(2) Using the cord, pull the antenna cable through

the hole in the door opening and seat grommet into

place.

(3) Connect the antenna body and cable to the

instrument panel cable.

(4) Install the right side kick panel.

(5) Insert the antenna body through the hole in

the fender and install adapter.(6) Install the antenna cap nut. Tighten to 7 N´m

(65 in. lbs.).

(7) Install the antenna mast.

(8) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

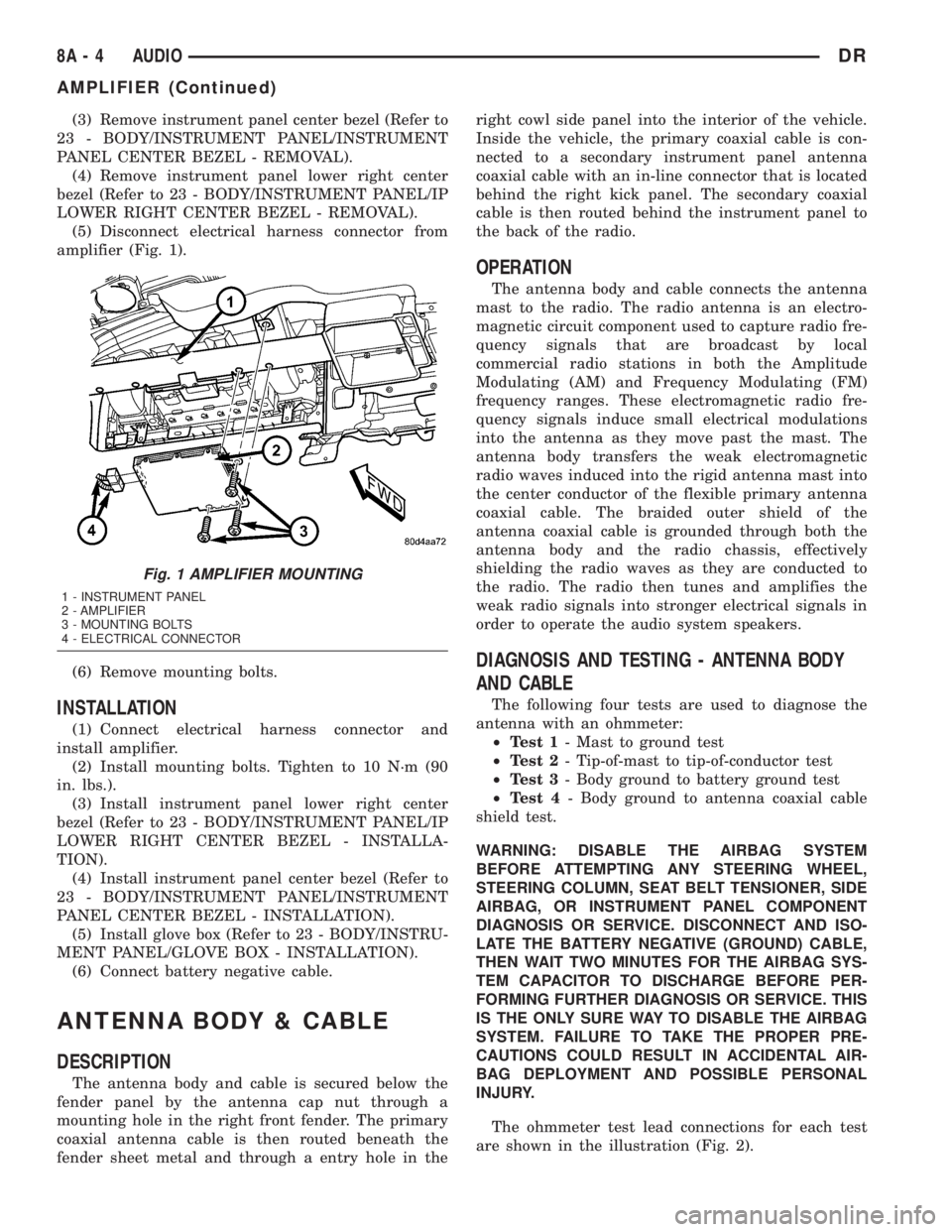

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

(3) Remove the instrument panel center bezel

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - REMOVAL).

(4) Remove the instrument panel lower right cen-

ter bezel (Refer to 23 - BODY/INSTRUMENT PAN-

EL/IP LOWER RIGHT CENTER BEZEL -

REMOVAL).

(5) Remove the radio (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - REMOVAL).

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(6) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

4)

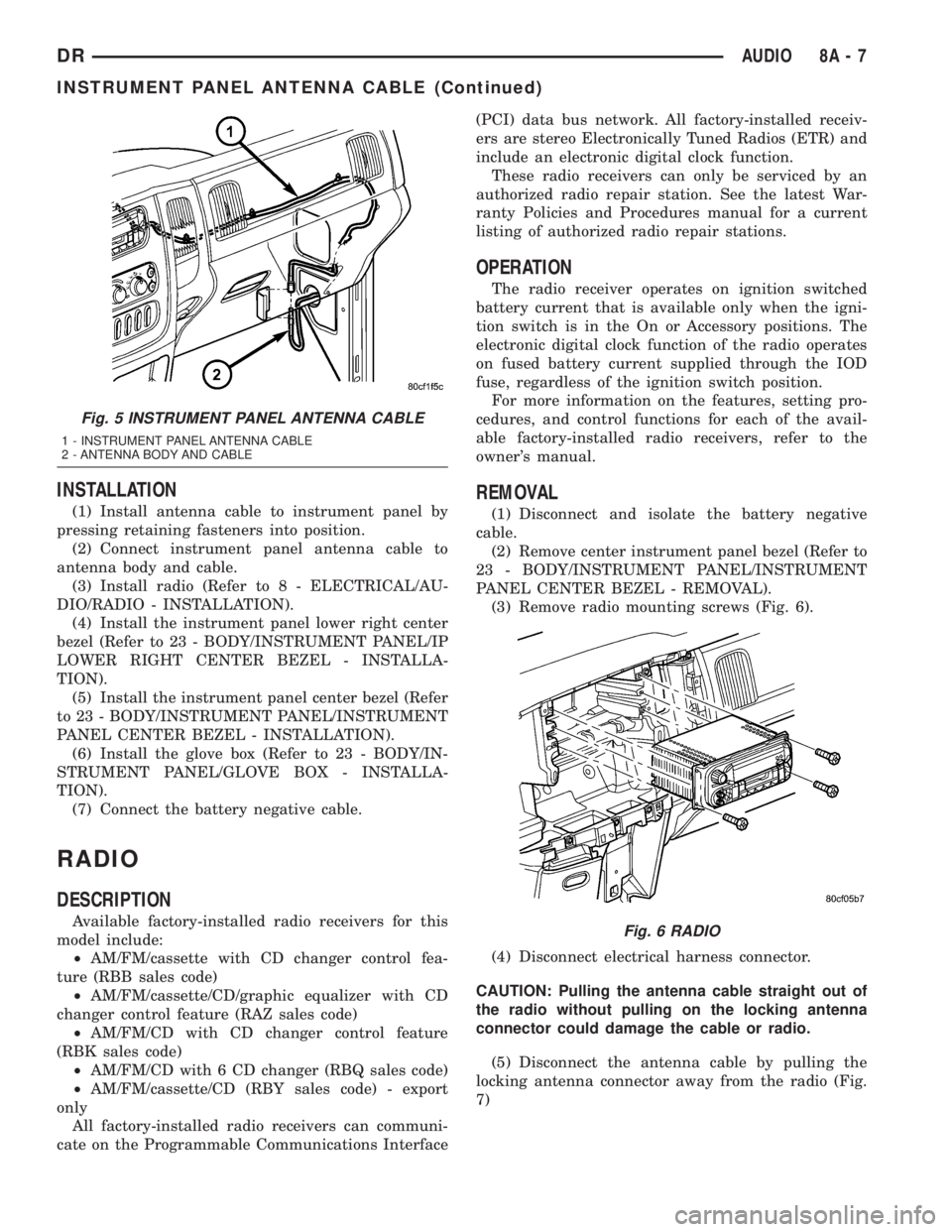

(7) Remove antenna cable from instrument panel

by pulling on retaining fasteners (Fig. 5).

Fig. 3 ANTENNA BODY AND CABLE

1 - NUT

2 - FENDER

3 - ANTENNA BODY AND CABLE

4 - ADAPTER

Fig. 4 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

8A - 6 AUDIODR

ANTENNA BODY & CABLE (Continued)

Page 370 of 2895

INSTALLATION

(1) Install antenna cable to instrument panel by

pressing retaining fasteners into position.

(2) Connect instrument panel antenna cable to

antenna body and cable.

(3) Install radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION).

(4) Install the instrument panel lower right center

bezel (Refer to 23 - BODY/INSTRUMENT PANEL/IP

LOWER RIGHT CENTER BEZEL - INSTALLA-

TION).

(5) Install the instrument panel center bezel (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - INSTALLATION).

(6) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(7) Connect the battery negative cable.

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include:

²AM/FM/cassette with CD changer control fea-

ture (RBB sales code)

²AM/FM/cassette/CD/graphic equalizer with CD

changer control feature (RAZ sales code)

²AM/FM/CD with CD changer control feature

(RBK sales code)

²AM/FM/CD with 6 CD changer (RBQ sales code)

²AM/FM/cassette/CD (RBY sales code) - export

only

All factory-installed radio receivers can communi-

cate on the Programmable Communications Interface(PCI) data bus network. All factory-installed receiv-

ers are stereo Electronically Tuned Radios (ETR) and

include an electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory positions. The

electronic digital clock function of the radio operates

on fused battery current supplied through the IOD

fuse, regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual.

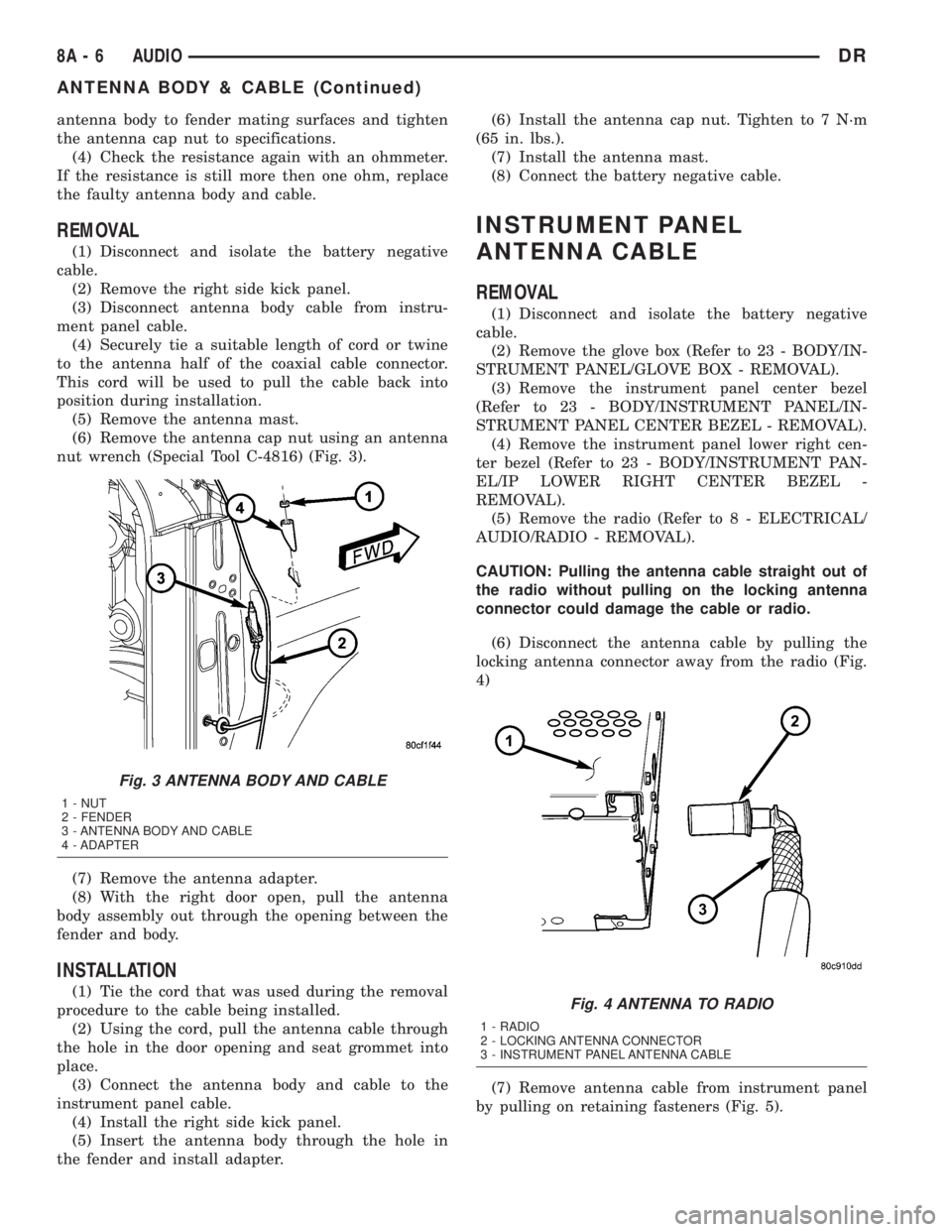

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove center instrument panel bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - REMOVAL).

(3) Remove radio mounting screws (Fig. 6).

(4) Disconnect electrical harness connector.

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(5) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

7)

Fig. 5 INSTRUMENT PANEL ANTENNA CABLE

1 - INSTRUMENT PANEL ANTENNA CABLE

2 - ANTENNA BODY AND CABLE

Fig. 6 RADIO

DRAUDIO 8A - 7

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 372 of 2895

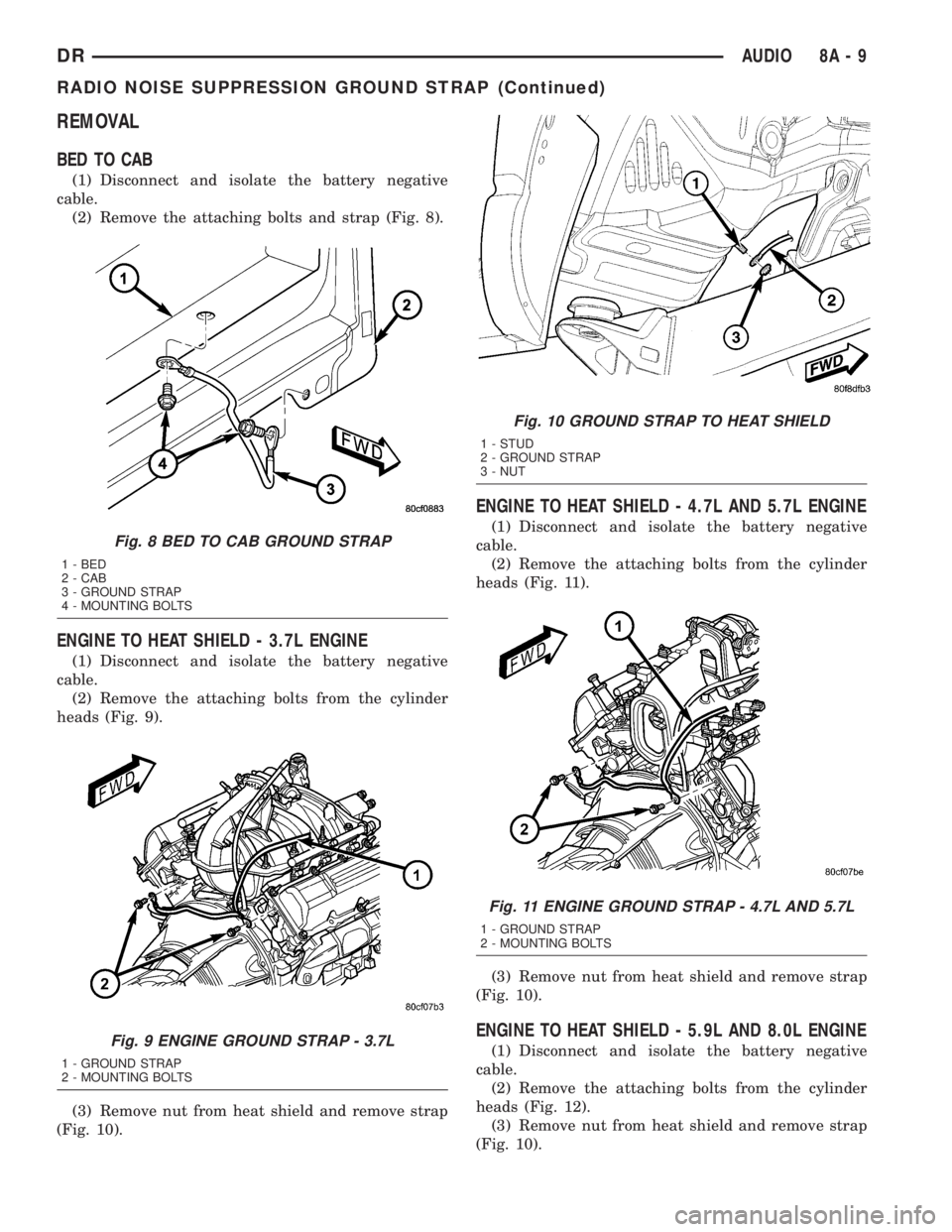

REMOVAL

BED TO CAB

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the attaching bolts and strap (Fig. 8).

ENGINE TO HEAT SHIELD - 3.7L ENGINE

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the attaching bolts from the cylinder

heads (Fig. 9).

(3) Remove nut from heat shield and remove strap

(Fig. 10).

ENGINE TO HEAT SHIELD - 4.7L AND 5.7L ENGINE

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the attaching bolts from the cylinder

heads (Fig. 11).

(3) Remove nut from heat shield and remove strap

(Fig. 10).

ENGINE TO HEAT SHIELD - 5.9L AND 8.0L ENGINE

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the attaching bolts from the cylinder

heads (Fig. 12).

(3) Remove nut from heat shield and remove strap

(Fig. 10).

Fig. 8 BED TO CAB GROUND STRAP

1 - BED

2 - CAB

3 - GROUND STRAP

4 - MOUNTING BOLTS

Fig. 9 ENGINE GROUND STRAP - 3.7L

1 - GROUND STRAP

2 - MOUNTING BOLTS

Fig. 10 GROUND STRAP TO HEAT SHIELD

1 - STUD

2 - GROUND STRAP

3 - NUT

Fig. 11 ENGINE GROUND STRAP - 4.7L AND 5.7L

1 - GROUND STRAP

2 - MOUNTING BOLTS

DRAUDIO 8A - 9

RADIO NOISE SUPPRESSION GROUND STRAP (Continued)

Page 374 of 2895

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

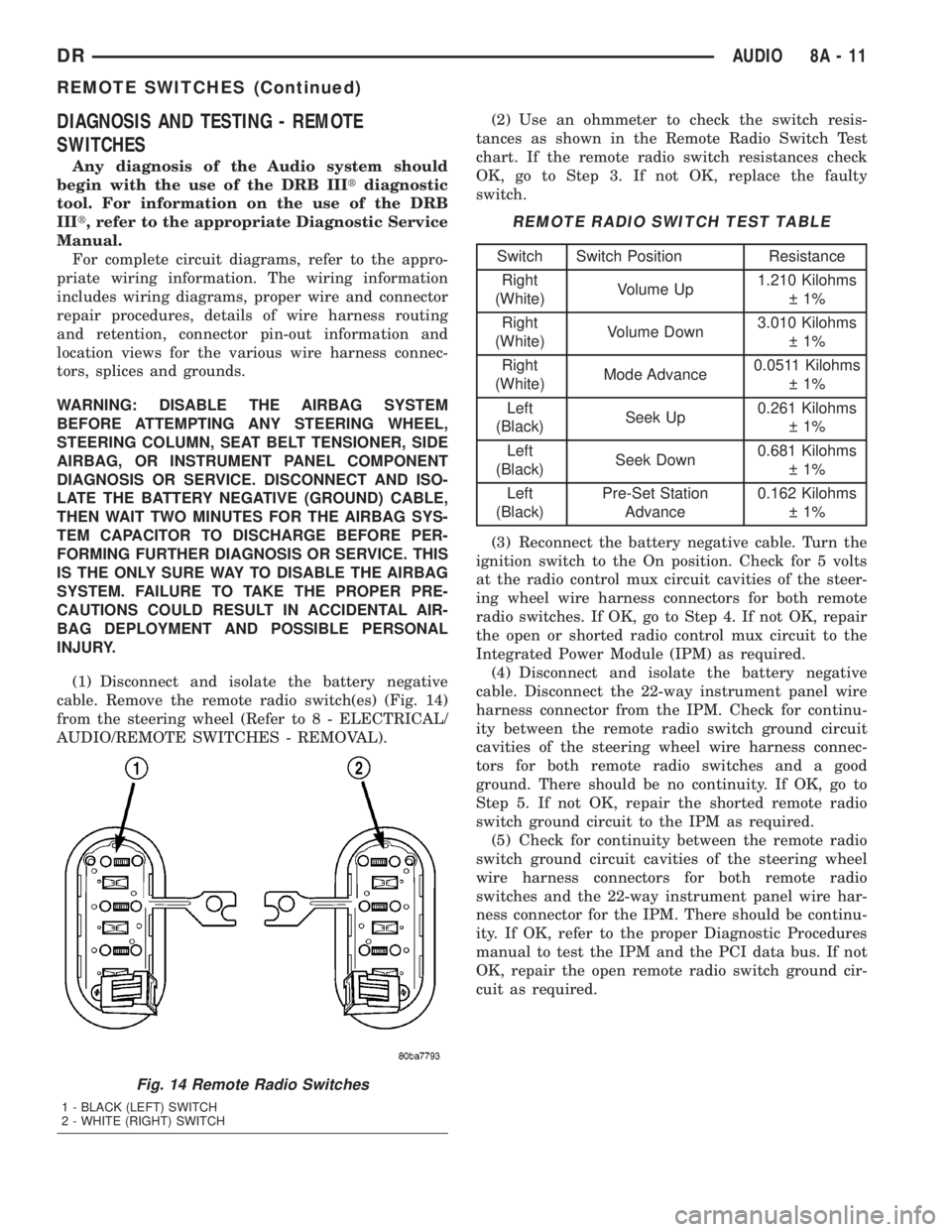

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 14)

from the steering wheel (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

REMOTE RADIO SWITCH TEST TABLE

Switch Switch Position Resistance

Right

(White)Volume Up1.210 Kilohms

1%

Right

(White)Volume Down3.010 Kilohms

1%

Right

(White)Mode Advance0.0511 Kilohms

1%

Left

(Black)Seek Up0.261 Kilohms

1%

Left

(Black)Seek Down0.681 Kilohms

1%

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

1%

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Integrated Power Module (IPM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the IPM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the IPM as required.

(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the IPM. There should be continu-

ity. If OK, refer to the proper Diagnostic Procedures

manual to test the IPM and the PCI data bus. If not

OK, repair the open remote radio switch ground cir-

cuit as required.

Fig. 14 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

DRAUDIO 8A - 11

REMOTE SWITCHES (Continued)

Page 375 of 2895

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

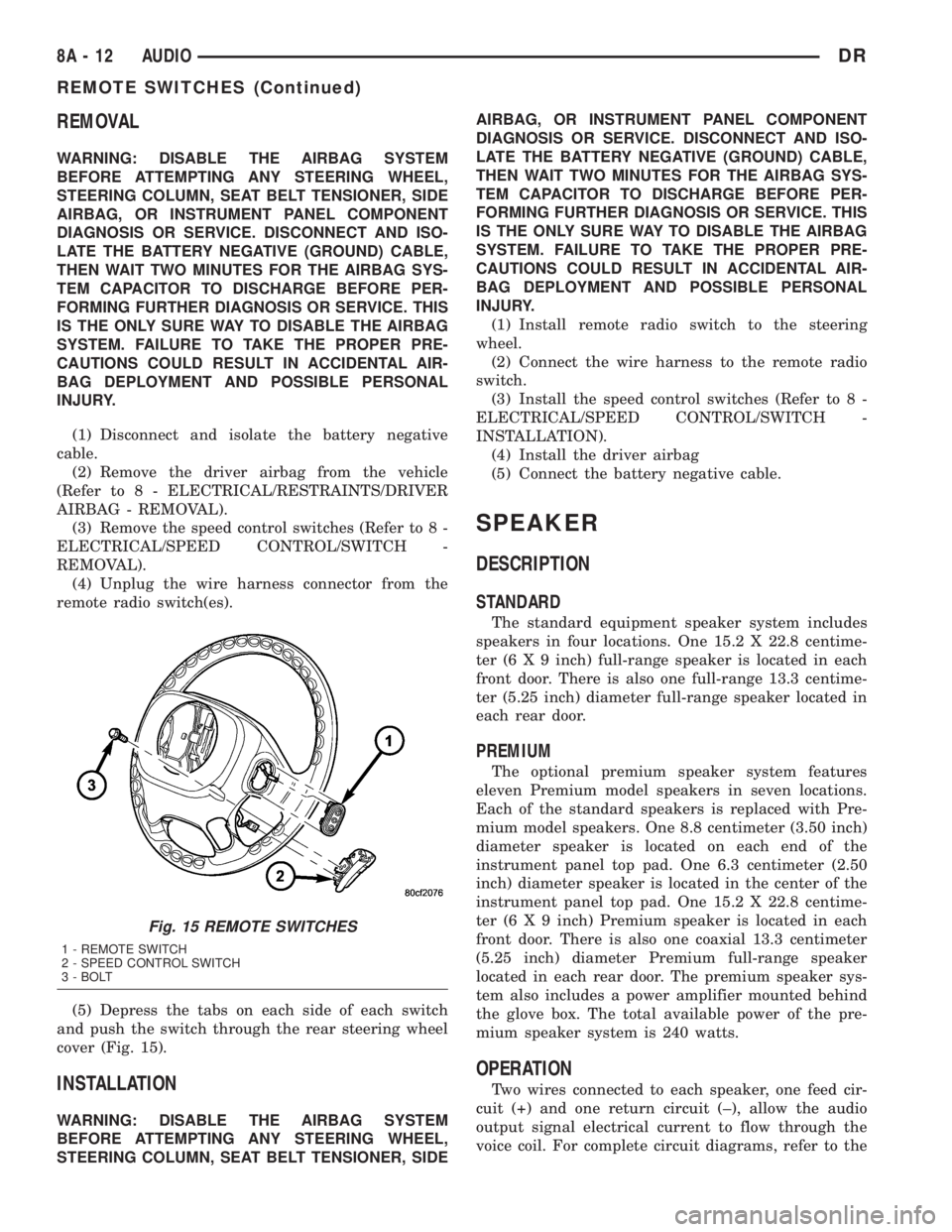

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver airbag from the vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(3) Remove the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch(es).

(5) Depress the tabs on each side of each switch

and push the switch through the rear steering wheel

cover (Fig. 15).

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDEAIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Connect the wire harness to the remote radio

switch.

(3) Install the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

INSTALLATION).

(4) Install the driver airbag

(5) Connect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in four locations. One 15.2 X 22.8 centime-

ter (6 X 9 inch) full-range speaker is located in each

front door. There is also one full-range 13.3 centime-

ter (5.25 inch) diameter full-range speaker located in

each rear door.

PREMIUM

The optional premium speaker system features

eleven Premium model speakers in seven locations.

Each of the standard speakers is replaced with Pre-

mium model speakers. One 8.8 centimeter (3.50 inch)

diameter speaker is located on each end of the

instrument panel top pad. One 6.3 centimeter (2.50

inch) diameter speaker is located in the center of the

instrument panel top pad. One 15.2 X 22.8 centime-

ter (6 X 9 inch) Premium speaker is located in each

front door. There is also one coaxial 13.3 centimeter

(5.25 inch) diameter Premium full-range speaker

located in each rear door. The premium speaker sys-

tem also includes a power amplifier mounted behind

the glove box. The total available power of the pre-

mium speaker system is 240 watts.

OPERATION

Two wires connected to each speaker, one feed cir-

cuit (+) and one return circuit (±), allow the audio

output signal electrical current to flow through the

voice coil. For complete circuit diagrams, refer to the

Fig. 15 REMOTE SWITCHES

1 - REMOTE SWITCH

2 - SPEED CONTROL SWITCH

3 - BOLT

8A - 12 AUDIODR

REMOTE SWITCHES (Continued)

Page 376 of 2895

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

and/or amplifier may result.

(1) If all speakers are inoperative, check the fuses

in the Integrated Power Module (IPM). If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

IPM. If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negativecable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 5.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(6) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector or if equipped, the amplifier

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

REMOVAL

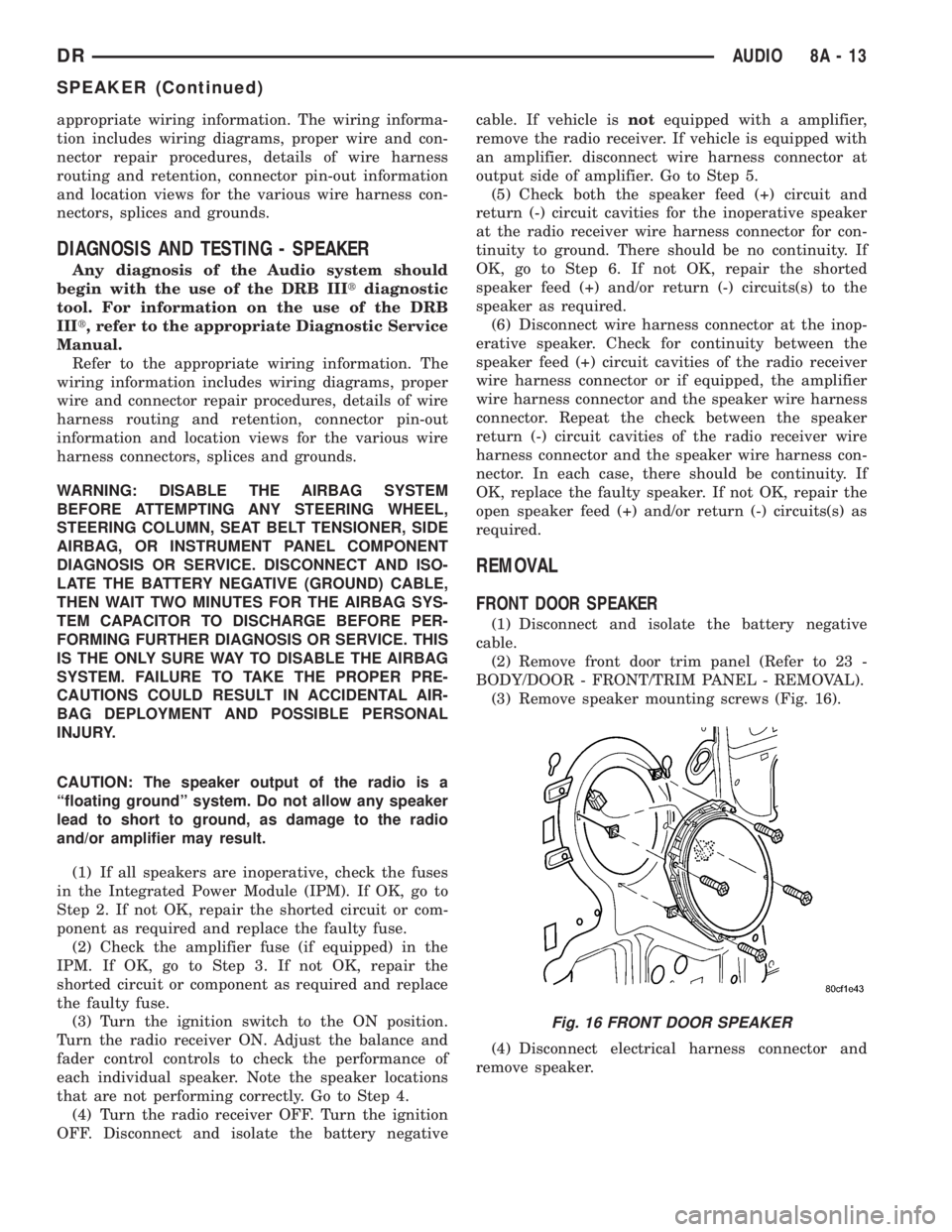

FRONT DOOR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove front door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove speaker mounting screws (Fig. 16).

(4) Disconnect electrical harness connector and

remove speaker.

Fig. 16 FRONT DOOR SPEAKER

DRAUDIO 8A - 13

SPEAKER (Continued)

Page 448 of 2895

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................3

OPERATION............................4

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM.............................4

HEATED SEAT ELEMENT

DESCRIPTION..........................5

OPERATION............................6

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT............................6

REMOVAL.............................6

INSTALLATION..........................6

HEATED SEAT SENSOR

DESCRIPTION..........................7OPERATION............................7

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR.............................7

REMOVAL.............................7

HEATED SEAT SWITCH

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH.............................8

REMOVAL.............................9

INSTALLATION..........................9

HEATED SEAT SYSTEM

DESCRIPTION

Individually controlled, electrically heated front

seats are available as a factory-installed option on

some DR models. Vehicles with this option can be

visually identified by the leather trim seats and two

separate heated seat switches mounted in the lower

center of the instrument panel. The heated seat sys-

tem allows the front seat driver and passenger to

select from two different levels of electrical seat heat-

ing, or no seat heating to suit their individual com-

fort requirements. The heated seat system for this

vehicle includes the following major components,

which are described in further detail later in this sec-

tion:

²Heated Seat Switches- Two heated seat

switches are used per vehicle. One switch is used for

each front seat. The switches are mounted in the

instrument panel, below the radio (Fig. 1). Each

switch also includes two Light-Emitting Diode (LED)

indicator lamps and an incandescent back lighting

bulb.

²Heated Seat Module- also referred to as the

Seat Heat Interface Module (SHIM), this module con-

tains the solid state electronic control and diagnostic

logic circuitry for the heated seat system. One heated

seat module is used per vehicle and is mounted

under the drivers front seat cushion (Fig. 1). Refer to

the Electronic Control Modules section of the service

manual for additional heated seat module informa-

tion.²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle. One element is used for

each front seat back and one element and sensor

assembly is used for each front seat cushion (Fig. 1).

The heating elements are integral to the individual

front seat and seat back cushions and cannot be

removed once installed at the factory. Replacement

seat heating elements are available, without having

to replace the entire seat cushion or trim cover. Refer

to the detailed procedure later in this section.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle. One heated seat tempera-

ture sensor is used for each front seat cushion. The

sensors are integral to the individual front seat cush-

ion heating elements (Fig. 1) and cannot be removed

once installed at the factory. Replacement seat heat-

ing elements with the sensors are available, without

having to replace the entire seat cushion or trim

cover. Refer to the detailed procedure later in this

section.

Following are general descriptions and operations

of the major components in the heated seat system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the heated seat system. Refer toWiringfor the

location of complete heated seat system wiring dia-

grams.

DRHEATED SEAT SYSTEM 8G - 3