Wiring under steering column DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 450 of 2895

Diagnostic logic is built into the heated seat mod-

ule to help the person trying to locate the problem by

the most efficient means possible. Anytime a problem

is suspected, locate the diagnosis and testing proce-

dure for the component in question and follow the

steps until the specific problem is located and

resolved. Once the problem is thought to be cor-

rected, verify correct system operation. If the heated

seat system is functioning correctly return the vehi-

cle to service.

If a problem could not be verified such as not find-

ing anything wrong when following the diagnostic

procedure, this is a good indication that a INTER-

MITTENT problem may be present. You must then

attempt to find the intermittent problem, such as

moving the heating element within the seat while

testing continuity or wiggling the wire harness's/elec-

trical connectors under the seat while testing conti-

nuity. Always, eliminate all other potential problems

before attempting to replace the heated seat module.

PRELIMINARY TEST

Refer toWiringfor the location of complete heated

seat system wiring diagrams. Before testing the indi-

vidual components in the heated seat system, per-

form the following preliminary checks:

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

CABLE, THEN WAIT TWO MINUTES FOR THE AIR-

BAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

²If the heated seat switch back lighting and the

cluster illumination lamps do not illuminate with the

headlamps or park lamps turned On, refer to the

Instrument Clustersection of the service manual

for the location of cluster illumination lamp diagnosis

and testing procedures. If the heated seat switch

back lighting does not illuminate, but the cluster illu-

mination lamps do illuminate with the headlamps or

park lamps turned On, refer toDiagnosis and Test-

ing the Heated Seat Switchin this section for the

location of the heated seat switch diagnosis and test-

ing procedures.

²If a single LED indicator lamp for one heated

seat switch does not operate and the heated seat ele-

ments do heat, refer toDiagnosis and Testing theHeated Seat Switchin this section for heated seat

switch diagnosis and testing procedures.

²If both LED indicator lamps for a heated seat

switch operate, but the heated seat elements do not

heat, refer toDiagnosis and Testing the Heated

Seat Modulein Electronic Control Modules for

heated seat module diagnosis and testing procedures.

²If the indicator lamp on either heated seat

switch remains illuminated after the heated seat has

been turned Off, refer toDiagnosis and Testing

the Heated Seat Modulein Electronic Control

Modules for heated seat module diagnosis and test-

ing procedures.

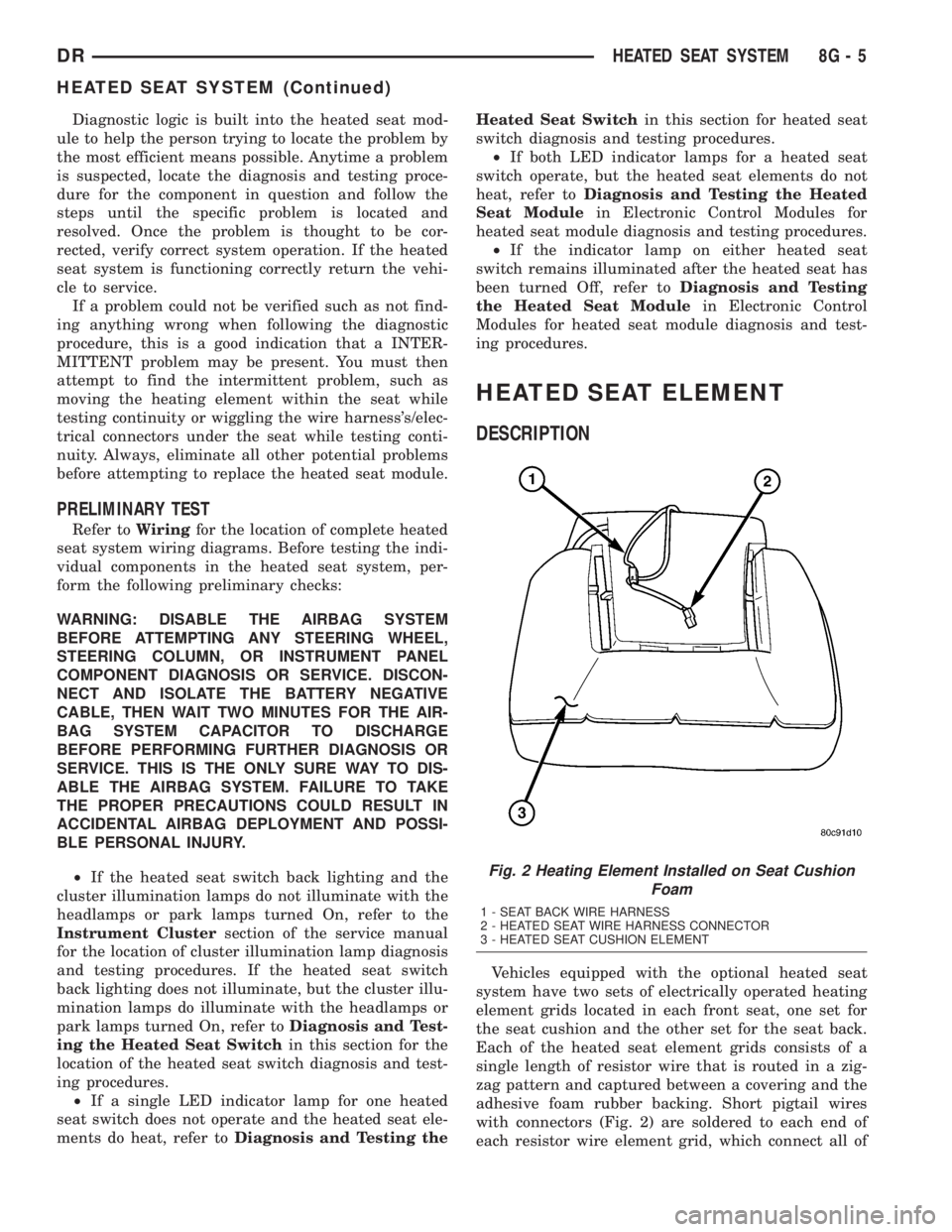

HEATED SEAT ELEMENT

DESCRIPTION

Vehicles equipped with the optional heated seat

system have two sets of electrically operated heating

element grids located in each front seat, one set for

the seat cushion and the other set for the seat back.

Each of the heated seat element grids consists of a

single length of resistor wire that is routed in a zig-

zag pattern and captured between a covering and the

adhesive foam rubber backing. Short pigtail wires

with connectors (Fig. 2) are soldered to each end of

each resistor wire element grid, which connect all of

Fig. 2 Heating Element Installed on Seat Cushion

Foam

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

DRHEATED SEAT SYSTEM 8G - 5

HEATED SEAT SYSTEM (Continued)

Page 2697 of 2895

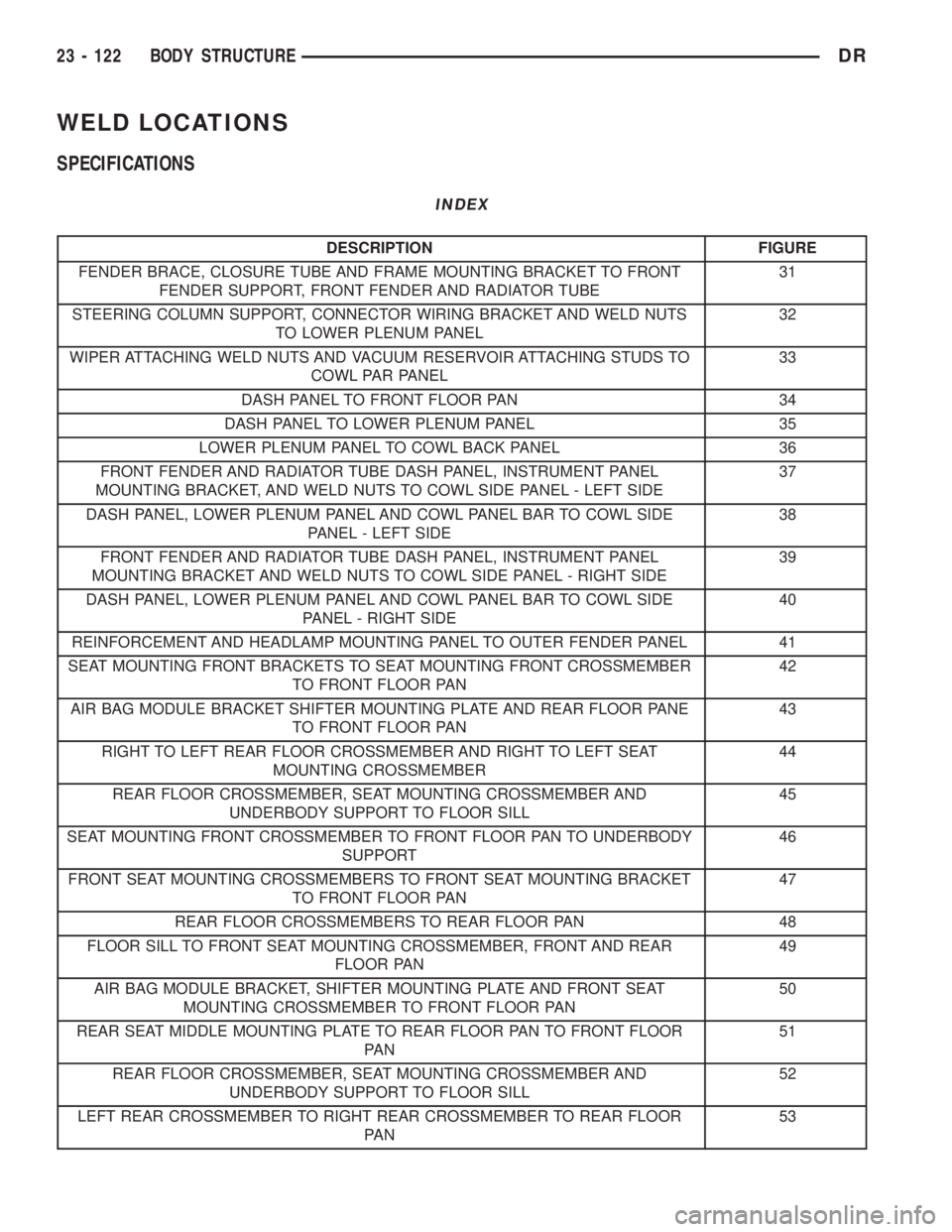

WELD LOCATIONS

SPECIFICATIONS

INDEX

DESCRIPTION FIGURE

FENDER BRACE, CLOSURE TUBE AND FRAME MOUNTING BRACKET TO FRONT

FENDER SUPPORT, FRONT FENDER AND RADIATOR TUBE31

STEERING COLUMN SUPPORT, CONNECTOR WIRING BRACKET AND WELD NUTS

TO LOWER PLENUM PANEL32

WIPER ATTACHING WELD NUTS AND VACUUM RESERVOIR ATTACHING STUDS TO

COWL PAR PANEL33

DASH PANEL TO FRONT FLOOR PAN 34

DASH PANEL TO LOWER PLENUM PANEL 35

LOWER PLENUM PANEL TO COWL BACK PANEL 36

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET, AND WELD NUTS TO COWL SIDE PANEL - LEFT SIDE37

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - LEFT SIDE38

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET AND WELD NUTS TO COWL SIDE PANEL - RIGHT SIDE39

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - RIGHT SIDE40

REINFORCEMENT AND HEADLAMP MOUNTING PANEL TO OUTER FENDER PANEL 41

SEAT MOUNTING FRONT BRACKETS TO SEAT MOUNTING FRONT CROSSMEMBER

TO FRONT FLOOR PAN42

AIR BAG MODULE BRACKET SHIFTER MOUNTING PLATE AND REAR FLOOR PANE

TO FRONT FLOOR PAN43

RIGHT TO LEFT REAR FLOOR CROSSMEMBER AND RIGHT TO LEFT SEAT

MOUNTING CROSSMEMBER44

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL45

SEAT MOUNTING FRONT CROSSMEMBER TO FRONT FLOOR PAN TO UNDERBODY

SUPPORT46

FRONT SEAT MOUNTING CROSSMEMBERS TO FRONT SEAT MOUNTING BRACKET

TO FRONT FLOOR PAN47

REAR FLOOR CROSSMEMBERS TO REAR FLOOR PAN 48

FLOOR SILL TO FRONT SEAT MOUNTING CROSSMEMBER, FRONT AND REAR

FLOOR PAN49

AIR BAG MODULE BRACKET, SHIFTER MOUNTING PLATE AND FRONT SEAT

MOUNTING CROSSMEMBER TO FRONT FLOOR PAN50

REAR SEAT MIDDLE MOUNTING PLATE TO REAR FLOOR PAN TO FRONT FLOOR

PA N51

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL52

LEFT REAR CROSSMEMBER TO RIGHT REAR CROSSMEMBER TO REAR FLOOR

PA N53

23 - 122 BODY STRUCTUREDR

Page 2793 of 2895

blower. The blower motor switch directs the ground

path through the correct resistor circuit to obtain the

selected speed.

The blower motor resistor cannot be repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the passenger side bottom of the

HVAC unit and unplug the wire harness connector

from the blower motor resistor.

(3) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor or blower motor relay as

required. If not OK, replace the faulty blower motor

resistor.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) The blower motor resistor is accessable from

the passenger side of the HVAC unit and is located

on the bottom of the HVAC unit.

(3) Pull out the lock on the blower motor resistor

wire harness connector to unlock the connector latch.

(4) Depress the latch on the blower motor resistor

wire harness connector and unplug the connector

from the resistor.

(5) Remove the two screws that secure the resistor

to the HVAC housing.

(6) Remove the resistor from the HVAC housing.

INSTALLATION

(1) Install the new resistor in the HVAC housing.

(2) Install the two screws that secure the resistor

to the HVAC housing and tighten to 2.2 N´m (20 in.

lbs.).

(3) Plug in the blower motor harness connector.

(4) Push in the lock on the blower motor resistor

harness connector.

(5) Close the glove box door.

(6) Connect the battery negative cable.

BLOWER MOTOR SWITCH

DESCRIPTION

The A/C Heater blower motor is controlled by a

four position rotary-type blower motor switch,

mounted in the A/C Heater control panel. The switch

allows the selection of one of four blower motor

speeds, but can only be turned off by selecting the

Off position on the blower motor switch.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C Heater control unit

must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

24 - 18 CONTROLSDR

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2801 of 2895

DIAGNOSIS AND TESTING - BLOWER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). Possible causes of

an inoperative blower motor include:

²Faulty fuse

²Faulty blower motor circuit wiring or wire har-

ness connectors

²Faulty blower motor resistor

²Faulty blower motor relay

²Faulty blower motor switch

²Faulty A/C Heater mode control switch

²Faulty blower motor.

Possible causes of the blower motor not operating

in all speeds include:

²Faulty blower motor switch

²Faulty blower motor resistor

²Faulty blower motor circuit wiring or wire har-

ness connectors.

VIBRATION

Possible causes of blower motor vibration include:

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower wheel out of balance or bent

²Blower motor faulty.

NOISE

To verify that the blower is the source of the noise,

unplug the blower motor wire harness connector and

operate the HVAC system. If the noise goes away,

possible causes include:

²Foreign material in the HVAC housing

²Improper blower motor mounting

²Improper blower wheel mounting

²Blower motor faulty.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERINGCOLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

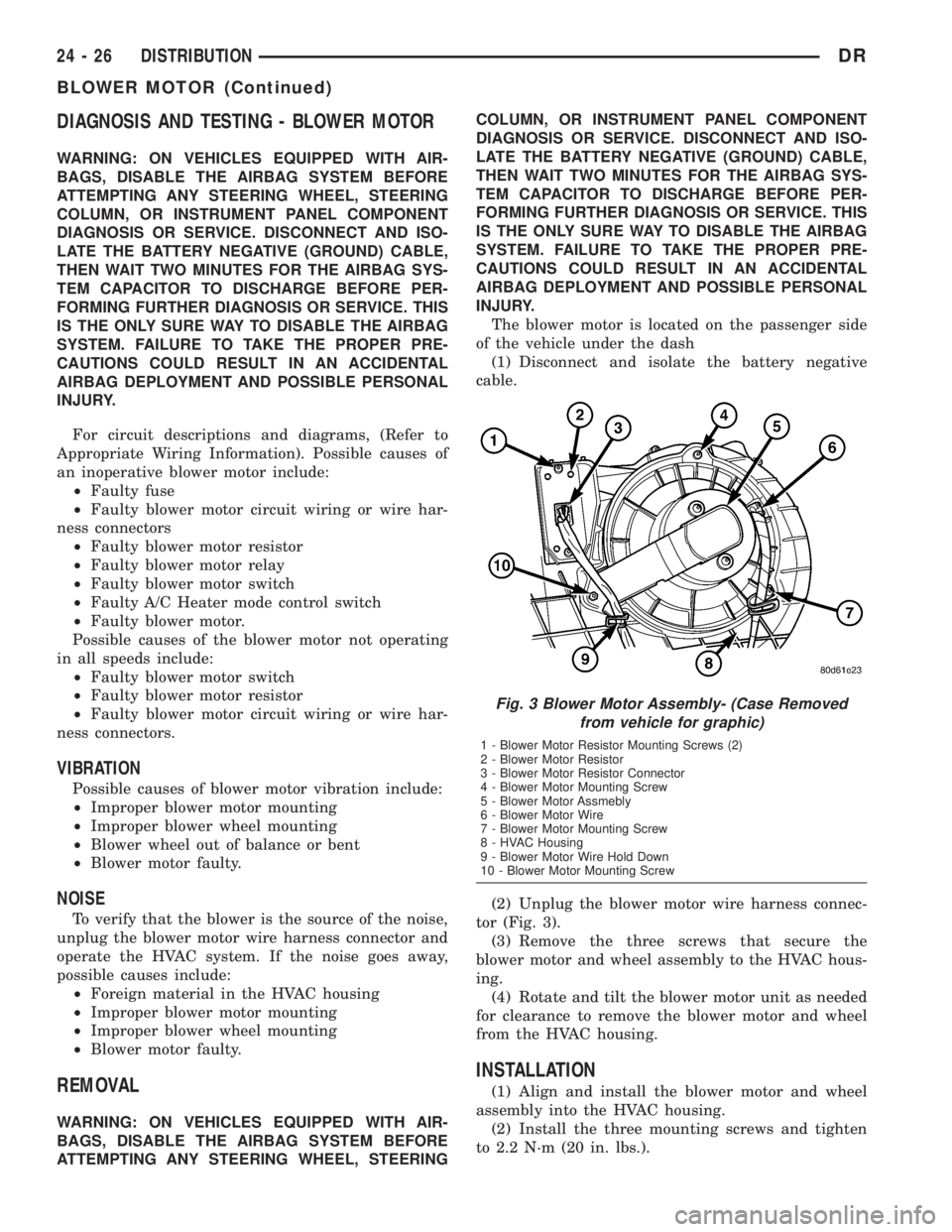

The blower motor is located on the passenger side

of the vehicle under the dash

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the blower motor wire harness connec-

tor (Fig. 3).

(3) Remove the three screws that secure the

blower motor and wheel assembly to the HVAC hous-

ing.

(4) Rotate and tilt the blower motor unit as needed

for clearance to remove the blower motor and wheel

from the HVAC housing.

INSTALLATION

(1) Align and install the blower motor and wheel

assembly into the HVAC housing.

(2) Install the three mounting screws and tighten

to 2.2 N´m (20 in. lbs.).

Fig. 3 Blower Motor Assembly- (Case Removed

from vehicle for graphic)

1 - Blower Motor Resistor Mounting Screws (2)

2 - Blower Motor Resistor

3 - Blower Motor Resistor Connector

4 - Blower Motor Mounting Screw

5 - Blower Motor Assmebly

6 - Blower Motor Wire

7 - Blower Motor Mounting Screw

8 - HVAC Housing

9 - Blower Motor Wire Hold Down

10 - Blower Motor Mounting Screw

24 - 26 DISTRIBUTIONDR

BLOWER MOTOR (Continued)