wheel DODGE RAM 2500 DIESEL 2004 3.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2004 3.GPages: 426, PDF Size: 7.22 MB

Page 260 of 426

These cautions apply to all chain traction devices, includ-

ing link and cable (radial) chains.

Tire chain use is permitted only on the rear tires of Ram

4X2 trucks.

NOTE:The use of class ªUº chains is permitted on the

front and rear of 4X4, 2500 Ram Trucks with LT245/

70R17E tires.

NOTE:The use of class ªUº chains is permitted on the

front and rear of 4X4, 3500 Ram Trucks with Dual Rear

Wheels and LT235/80R17E tires.

NOTE:On 4X2 2500/3500 Ram Trucks, class ªUº snow

chains are permitted on the rear wheels only of vehicles

equipped with LT245/70R17, LT265/70R17, and LT235/

80R17 size tires.NOTE:On 4X4 2500/3500 Single Rear Wheel (SRW)

Ram Trucks, class ªUº snow chains are permitted on the

rear wheels only of vehicles equipped with LT265/70R17.

CAUTION!

Do not use tire chains on 4x4 Ram trucks equipped

with P265/70R17, LT275/70R17 tires. There may not

be adequate clearance for the chains and you are

risking structural or body damage to your vehicle.

Do not use tire chains on the 4X2 front wheels of

2500/3500 SRW (Single Rear Wheels) equipped with

LT245/70R17, LT265/70R17 tires or 4X4 front tires of

Ram Trucks equipped with LT265/70R17tires. There

may not be adequate clearance for the chains and

you are risking structural or body damage to your

vehicle.

260 STARTING AND OPERATING

Page 263 of 426

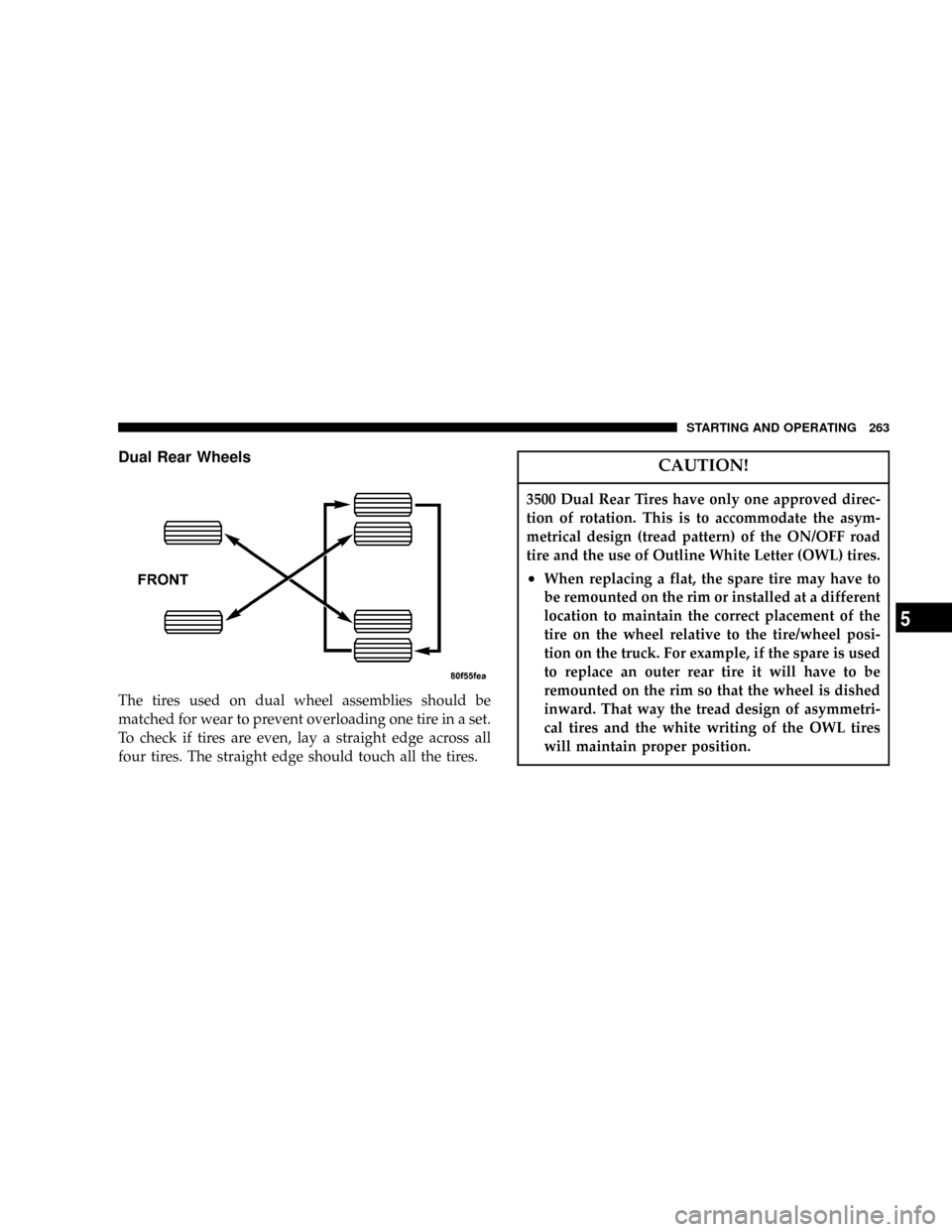

Dual Rear Wheels

The tires used on dual wheel assemblies should be

matched for wear to prevent overloading one tire in a set.

To check if tires are even, lay a straight edge across all

four tires. The straight edge should touch all the tires.

CAUTION!

3500 Dual Rear Tires have only one approved direc-

tion of rotation. This is to accommodate the asym-

metrical design (tread pattern) of the ON/OFF road

tire and the use of Outline White Letter (OWL) tires.

²When replacing a flat, the spare tire may have to

be remounted on the rim or installed at a different

location to maintain the correct placement of the

tire on the wheel relative to the tire/wheel posi-

tion on the truck. For example, if the spare is used

to replace an outer rear tire it will have to be

remounted on the rim so that the wheel is dished

inward. That way the tread design of asymmetri-

cal tires and the white writing of the OWL tires

will maintain proper position.

STARTING AND OPERATING 263

5

Page 269 of 426

VEHICLE LOADING

Certification Label

As required by National Highway Traffic Safety Admin-

istration Regulations, your vehicle has a certification

label affixed to the driver's side door or pillar.

This label contains the month and year of manufacture,

Gross Vehicle Weight Rating (GVWR), Gross Axle Weight

Rating (GAWR) front and rear, and Vehicle Identification

Number (VIN). A Month-Day-Hour (MDH) number is

included on this label and indicates the Month, Day and

Hour of manufacture. The bar code that appears on the

bottom of the label is your Vehicle Identification Number

(VIN).

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your vehicle

including driver, passengers, vehicle, options and cargo.

The label also specifies maximum capacities of front andrear axle systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable load

weight a truck can carry, including the weight of the

driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the front

and rear axles. The load must be distributed in the cargo

area so that the GAWR of each axle is not exceeded.

Each axle GAWR is determined by the components in the

system with the lowest load carrying capacity (axle,

springs, tires or wheels). Heavier axles or suspension

components sometimes specified by purchasers for in-

creased durability does not necessarily increase the vehi-

cle's GVWR.

STARTING AND OPERATING 269

5

Page 275 of 426

²Use an approved wiring harness connector on the

trailer. Standard equipment on all RAM pickup mod-

els provides a 4-way trailer tow connector located

under the bumper. This connector contains the follow-

ing vehicle circuits: park/tail lamps, left stop/turn

lamp, right stop/turn lamp, and ground. With the

optional Trailer Tow Prep package a 7-way connector

is provided with the following additional circuits:

backup lamp, trailer battery and electric brake.

NOTE:Connect trailer lighting and brakes using factory

harnesses only. Do not cut or splice wiring to the brake

circuits.

²Be sure the trailer is loaded heavier in front, with 60%

to 65% of the weight in front of the axle(s). Loads

balanced over the wheels or heavier in the rear can

cause the trailer to sway severely side to side which

will cause loss of control of vehicle and trailer. Failureto load trailers heavier in front is the cause of many

trailer accidents. (For a95th Wheel9style trailer, this

range of loading on the9King Pin9should be between

15% and 25%.)

²Make certain that the load is secured in the trailer and

will not shift during travel. When towing cargo such

as livestock, dynamic load shifts can occur that require

the driver to maintain attention.

Trailer Towing Ð Hitches

With a Class I Hitch, your vehicle can be equipped to tow

trailers with a Gross Trailer Weight (GTW) of 2,000 lbs

(907 kg) maximum.

With a Class II Hitch, your vehicle can be equipped to

tow trailers with a Gross Trailer Weight (GTW) of 3,500

lbs (1 587 kg) maximum. Tongue weight must be equal to

at least 10% of GTW, but no more than 15% of GTW.

STARTING AND OPERATING 275

5

Page 279 of 426

NOTE: When towing a trailer, the following require-

ments must be adhered to:

²GCWR must not be exceeded

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

(4) ratings are not exceeded:

1.GVWR

2.GTW

3.Tongue weight rating for the trailer hitch utilized

(This requirement may limit the ability to always

achieve the 10% to 15% range of tongue weight [15%

to 25% for a(5th Wheel(style trailer] as a percentage

of total trailer weight.)

4.GAWR ratings

Trailer Towing Information (Maximum Trailer

Weight Ratings)

(Trailer Towing Guide(

NOTE:For trailer towing information (maximum trailer

weight ratings) refer to the following website address:

http:// www.dodge.com/towing.

In Canada, refer to the following website address:http://

www.dodge.ca.

Trailer Towing Mirrors Ð If Equipped

These mirrors are designed with an adjustable mirror

head to provide a greater vision range when towing

extra-wide loads. To change position inboard or out-

board, the mirror head should be rotated (flipped Out or

In). A small blindspot mirror is integrated onto the main

mirror surface.

STARTING AND OPERATING 279

5

Page 283 of 426

Before plowing

²

Check the hydraulic system for leaks and proper fluid

level.

²Check the mounting bolts and nuts for proper tight-

ness.

²Check the runners and cutting edge for excessive wear.

The cutting edge should be 1/4 to 1/2 inch above

ground in snow plowing position.

²Check that snowplow lighting is connected and func-

tioning properly.

Snowplow Prep Package Model Availability

For Information about snowplow applications visit

www.dodge.com or refer to the 2004 Dodge Truck Body

Builders Guide.

1. The maximum number of occupants in the truck

should not exceed two.2. The total GVWR or the Front GAWR or the Rear

GAWR should never be exceeded.

3. The snowplow prep packages are not available with

the Sport Package.

4. Cargo capacity will be reduced by the addition of

options or passengers, etc.

The loaded vehicle weight, including the snowplow

system, all aftermarket accessories, driver, passengers,

options, and cargo, must not exceed either the Gross

Vehicle Weight (GVWR) or Gross Axle Weight (GAWR)

ratings. These weights are specified on the Safety Com-

pliance Certification Label on the driver's side door

opening.

NOTE:Detach the snowplow when transporting pas-

sengers.

Vehicle front end wheel alignment was set to specifica-

tions at the factory without consideration for the weight

STARTING AND OPERATING 283

5

Page 285 of 426

NOTE:During snowplow usage on vehicles equipped

with an overhead console module, the outside tempera-

ture display will show higher temperatures than the

outside ambient temperature. The higher displayed tem-

perature is due to blocked or reduced airflow to the

underhood ambient temperature sensor by the snow-

plow. This is common and outside temperature display

operation will return to normal when the snowplow is

removed.

General Maintenance

Snowplows should be maintained in accordance with the

plow manufacturer's instructions.

Keep all snowplow electrical connections and battery

terminals clean and free of corrosion.

When plowing snow, to avoid transmission and driv-

etrain damage, the following precautions should be ob-

served.

²Operate with transfer case in 4L when plowing small

or congested areas where speeds are not likely to

exceed 15 mph (24 km/h). At higher speeds operate in

4H.

²Vehicles with 48RE transmissions should use 4L range

when plowing deep or heavy snow for extended

periods of time to avoid transmission overheating.

²Do not shift the transmission unless the engine has

returned to idle and wheels have stopped. Make a

practice of stepping on the brake pedal before shifting

the transmission.

STARTING AND OPERATING 285

5

Page 286 of 426

RECREATIONAL TOWING Ð 4±WHEEL DRIVE

VEHICLES (BEHIND MOTORHOME, ETC.)

CAUTION!

Internal damage to the transfer case will occur if a

front or rear wheel lift is used when recreational

towing.

NOTE:Both the Manual Shift and Electronic Shift

transfer cases must be shifted into Neutral (N) for

recreational towing. Automatic transmissions must be

placed in P (Park) position for recreational towing.

Manual transmissions must be left in gear (not in neutral)

for recreational towing. Refer below for the proper trans-

fer case Neutral shifting procedure for your vehicle.

Recreational Towing Procedure Ð Manual Shift

Transfer Case Ð If Equipped

Use the following procedure to prepare your vehicle for

recreational towing:

CAUTION!

It is necessary to follow these steps to be certain that

the transfer case is fully in N (NEUTRAL) before

recreational towing to prevent damage to internal

parts.

1. Bring the vehicle to a complete stop.

2. Shut OFF the engine.

3. Depress the brake pedal.

4. Shift automatic transmission to N (NEUTRAL), or

depress the clutch on manual transmissions.

286 STARTING AND OPERATING

Page 293 of 426

If you must back down a hill, back straight down using

REVERSE gear. Never back down in NEUTRAL, or

diagonally across the hill.

When driving over sand, mud, and other soft terrain,

shift to low gear and drive steadily. Apply the accelerator

slowly to avoid spinning the wheels.

DO NOT REDUCE the tire pressures for this type of

driving.

NOTE:After off-road usage, particularly in sand or

mud, inspect the underside of the vehicle for accumu-

lated dirt at the propeller shaft, axles, U-joints, brake

rotors and calipers.

Use a hose to clean off any accumulation of dirt or mud.

Check the exhaust system and all exposed components

for any sign of damage.If you experience unusual vibration after driving in mud,

slush or similar conditions, check the wheels for im-

pacted material. Impacted foreign material can cause a

wheel imbalance. Removing the foreign material from

the wheels will correct the situation.

TRACTION

When driving on wet or slushy roads, it is possible for a

wedge of water to build up between the tire and road

surface. This is known as hydroplaning and may cause

partial or complete loss of vehicle control and stopping

ability. To reduce this possibility, the following precau-

tions should be observed:

1. Slow down during rainstorms or when roads are

slushy.

2. Slow down if road has standing water or puddles.

STARTING AND OPERATING 293

5

Page 295 of 426

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Lights..................296

mAdding Fuel Ð 24±Valve Cummins Turbo

Diesel...............................297

mJack Location..........................298

NAll Models..........................298

mChanging A Flat Tire....................299

NRemoving The Spare Tire................299

NTire Changing Procedure................300

mHoisting.............................309mJump-Starting.........................310

NWith Portable Starting Unit..............313

mFreeing A Stuck Vehicle..................313

mEmergency Tow Hooks Ð If Equipped........314

mTowing A Disabled Vehicle................315

N4-Wheel- Drive Vehicles.................315

N2±Wheel- Drive Vehicles................315

6