wheel DODGE RAM 2500 DIESEL 2004 3.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2004 3.GPages: 426, PDF Size: 7.22 MB

Page 309 of 426

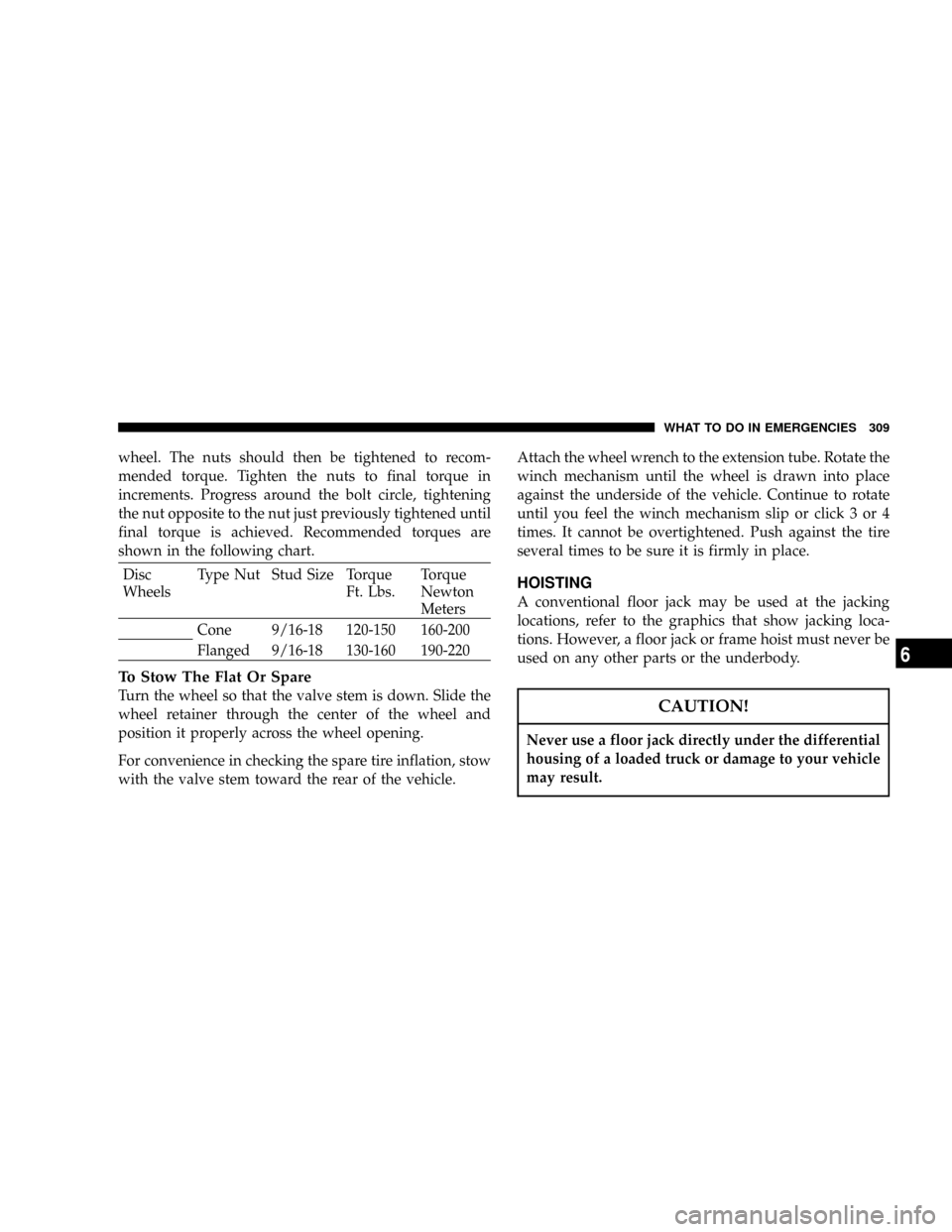

wheel. The nuts should then be tightened to recom-

mended torque. Tighten the nuts to final torque in

increments. Progress around the bolt circle, tightening

the nut opposite to the nut just previously tightened until

final torque is achieved. Recommended torques are

shown in the following chart.

Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip or click 3 or 4

times. It cannot be overtightened. Push against the tire

several times to be sure it is firmly in place.

HOISTING

A conventional floor jack may be used at the jacking

locations, refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

WHAT TO DO IN EMERGENCIES 309

6

Page 313 of 426

WARNING!

Any procedure other than above could result in:

1. Personal injury caused by electrolyte squirting

out the battery vent;

2. Personal injury or property damage due to battery

explosion;

3. Damage to charging system of booster vehicle or

of immobilized vehicle.

With Portable Starting Unit

There are many types of these units available. Follow the

manufacturer's instructions for necessary precautions

and operation.

CAUTION!

It is very important that the starting unit operating

voltage does not exceed 12 Volts D.C. or damage to

battery, starter motor, alternator, or electrical system

may occur.

FREEING A STUCK VEHICLE

If vehicle becomes stuck in snow, sand, or mud, it can

often be moved by a rocking motion. Move the gear

selector rhythmically between DRIVE and REVERSE,

while applying slight pressure to the accelerator.

In general, the least amount of accelerator pedal pressure

to maintain the rocking motion without spinning the

wheels or racing the engine is most effective. Racing the

engine or spinning the wheels, due to the frustration of

not freeing the vehicle, may lead to transmission over-

heating and failure. Allow the engine to idle with the

WHAT TO DO IN EMERGENCIES 313

6

Page 315 of 426

TOWING A DISABLED VEHICLE

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for the purpose, following equip-

ment manufacturer's instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to

the main structural members of the vehicleÐnot to

bumpers or associated brackets. State and local laws

applying to vehicles under tow must be observed.

4-Wheel- Drive Vehicles

CAUTION!

To avoid damage to the transfer case while towing,

always use one of the following methods.

The manufacturer recommends towing with all wheels

off the ground. Acceptable methods are to tow vehicle on

a flatbed or with one end of vehicle raised and the

opposite end on a towing dolly.

2±Wheel- Drive Vehicles

Provided that the transmission is operable, tow with the

transmission in Neutral and the ignition key in the OFF

position along with the front wheels raised and the rear

wheels on the ground. Speed must not exceed 30 mph (50

km/h) and distance must not exceed 15 miles (25 km).

If the vehicle is to be towed more than 15 miles (25 km)

the vehicle must be towed with the rear wheels raised

and the front wheels on the ground. It may also be towed

on a flatbed or with the front wheels raised and the rear

wheels on a dolly.

WHAT TO DO IN EMERGENCIES 315

6

Page 318 of 426

NBody Lubrication.....................340

NWindshield Wiper Blades................341

NWindshield Washers...................341

NExhaust System......................342

NCooling System.......................343

NFan ...............................347

NCharge Air Cooler (Inter-Cooler)..........347

NHoses And Vacuum/Vapor Harnesses.......348

NBrake System........................348

NClutch Linkage.......................350

NClutch Hydraulic System................351

NPropeller Shaft Universal Joints...........351NRear Axle And 4X4 Front Driving Axle Fluid

Level..............................351

NTransfer Case Ð If Equipped.............352

NManual Transmission Ð If Equipped.......352

NAutomatic Transmission................353

NFront Wheel Bearings..................355

NSelection Of Lubricating Grease...........356

NNoise Control System Required

Maintenance & Warranty................357

NAppearance Care And Protection From

Corrosion...........................362

mFuse And Relay Center...................366

mVehicle Storage........................366

318 MAINTAINING YOUR VEHICLE

Page 319 of 426

mReplacement Light Bulbs.................367

mBulb Replacement......................367

NHeadlight (Halogen)/Front Park And Turn

Lights.............................367

NTail, Stop, Turn And Backup Lights.........371

NCenter High-Mounted Stoplight With Cargo

Light..............................373

NCab Top Clearance Lights Ð If Equipped....375

NTailgate ID Lights (Dual Rear Wheels).......376NSide Marker Lights (Dual Rear Wheels)......378

NFog Lights..........................378

mFluid Capacities........................379

mRecommended Fluids, Lubricants And Genuine

Parts................................380

NEngine.............................380

NChassis............................381

MAINTAINING YOUR VEHICLE 319

7

Page 355 of 426

It is important that proper lubricant is used in the

transmission. Refer to Recommended Fluids, Lubricants

and Genuine Parts for the correct lubricant type. A band

adjustment and filter change should be made at the time

of the oil change.

The fluid and filter should be changed and the bands

adjusted as specified in the Maintenance Schedule (Sec-

tion 8). Vehicles having severe usage should follow

Maintenance Schedule ªBº of the Maintenance Schedule

(Section 8).

Severe usage consists of:

²Off-the-highway operation;

²Trailer towing;

²Snow plow operation;

²Prolonged operation with heavy loading, especially in

hot weather.NOTE:If the transmission is disassembled for any

reason, the fluid and filter should be changed, and the

bands adjusted.

Special Additives

The manufacturer recommends against the addition of

any additives to the transmission. Exception to this

policy is the use of special dyes to aid in detecting fluid

leaks. The use of transmission sealers should be avoided,

since they may adversely affect seals.

Front Wheel Bearings

Front wheel bearings for all Dodge Ram Trucks are

sealed-for-life. They do not require greasing or seal

replacement. In some instances, these bearings will

ªpurgeº excess grease and the bearing housing will look

slightly wet. This is normal.

²Periodic inspection for excess play is recommended.

MAINTAINING YOUR VEHICLE 355

7

Page 356 of 426

²If a bearing assembly is accidentally separated when

servicing the brake rotors, it should be replaced.

Rear Wheel Bearings

Clean and repack when brake linings are replaced or

rotors resurfaced.

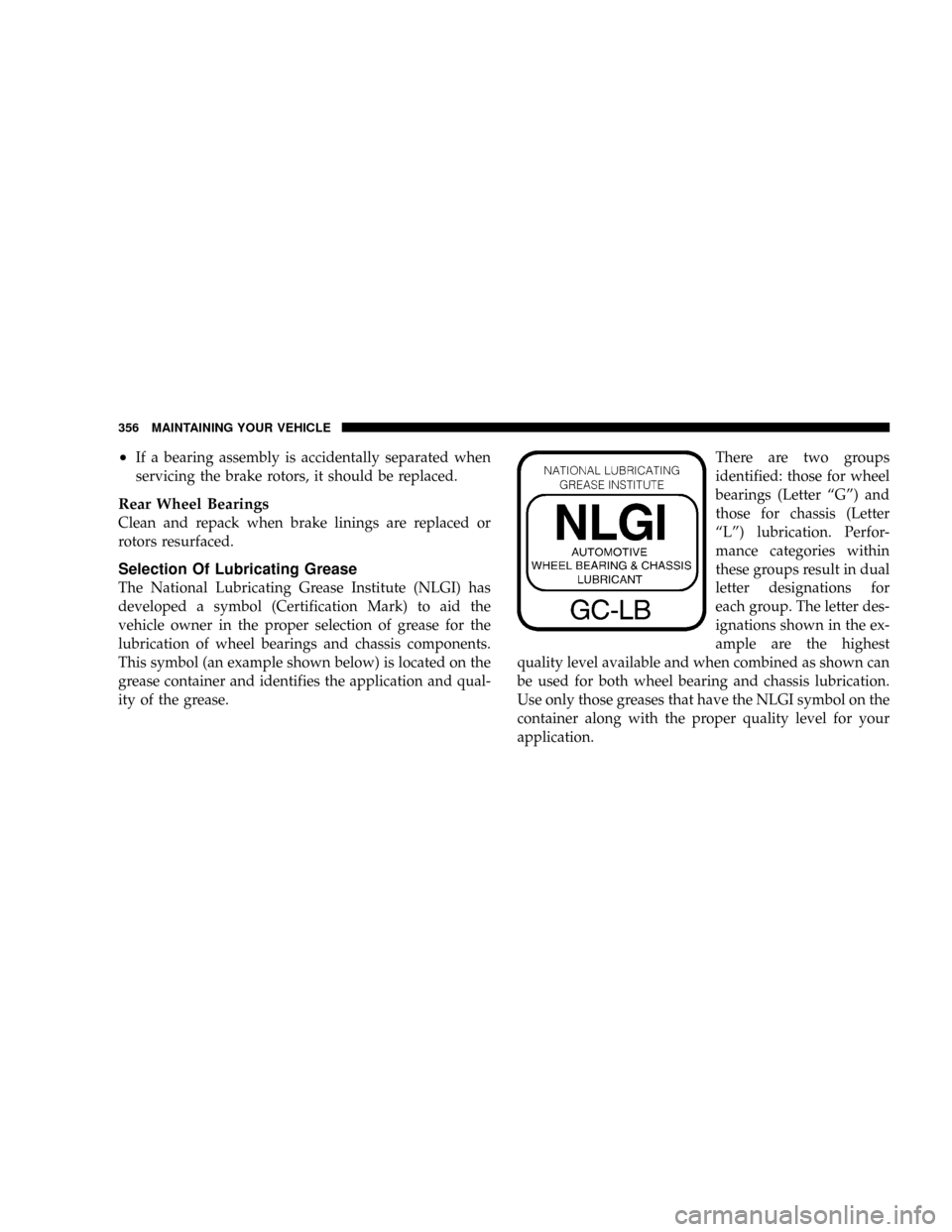

Selection Of Lubricating Grease

The National Lubricating Grease Institute (NLGI) has

developed a symbol (Certification Mark) to aid the

vehicle owner in the proper selection of grease for the

lubrication of wheel bearings and chassis components.

This symbol (an example shown below) is located on the

grease container and identifies the application and qual-

ity of the grease.There are two groups

identified: those for wheel

bearings (Letter ªGº) and

those for chassis (Letter

ªLº) lubrication. Perfor-

mance categories within

these groups result in dual

letter designations for

each group. The letter des-

ignations shown in the ex-

ample are the highest

quality level available and when combined as shown can

be used for both wheel bearing and chassis lubrication.

Use only those greases that have the NLGI symbol on the

container along with the proper quality level for your

application.

356 MAINTAINING YOUR VEHICLE

Page 357 of 426

Noise Control System Required Maintenance &

Warranty

For 3500 Two-Wheel Drive and Four-Wheel Drive mod-

els over 10,000 lbs. (4 535 kg) Gross Vehicle Weight

Rating.

All vehicles built over 10,000 lbs. (4 535 kg) Gross Vehicle

Weight Rating and manufactured for sale and use in the

United States are required to comply with the Federal

Government's Exterior Noise Regulations. These vehicles

can be identified by the Noise Emission Control Label

located in the operator's compartment.

Required Maintenance For Noise Control Systems

The following maintenance services must be performed

every 6 months or 6,000 miles (9 600 km), whichever

comes first, to assure proper operation of the noise

control systems. In addition, inspection and service

should be performed anytime a malfunction is observed

MAINTAINING YOUR VEHICLE 357

7

Page 363 of 426

²Avoid using abrasive compounds and power buffing

that may diminish the gloss or thin out the paint

finish.

CAUTION!

Do not use abrasive or strong cleaning materials

such as steel wool or scouring powder, which will

scratch metal and painted surfaces.

Special Care

²

If you drive on salted or dusty roads or if you drive

near the ocean, hose off the undercarriage at least once

a month.

²It is important that the drain holes in the lower edges

of the doors, rocker panels and tailgate be kept clear

and open.

²If you detect any stone chips or scratches in the paint,

touch them up immediately. The cost of such repairs is

considered the responsibility of the owner.

²If your vehicle is damaged due to an accident or

similar cause which destroys the paint and protective

coating have your vehicle repaired as soon as possible.

The cost of such repairs is considered the responsibil-

ity of the owner.

²All wheels and wheel trim, especially aluminum and

chrome plated wheels should be cleaned regularly

with mild soap and water to prevent corrosion. To

remove heavy soil, select a nonabrasive, non-acidic

cleaner. Do not use scouring pads, steel wool, a bristle

brush or metal polishes. Only Mopar cleaners are

recommended. Do not use oven cleaner. Avoid auto-

matic car washes that use acidic solutions or harsh

brushes that may damage the wheels' protective fin-

ish.

MAINTAINING YOUR VEHICLE 363

7

Page 364 of 426

²If you carry special cargo such as chemicals, fertilizers,

de-icer salt, etc., be sure that such materials are well

packaged and sealed.

²If a lot of driving is done on gravel roads, consider

mud or stone shields behind each wheel.

²Use Mopar touch up paint on scratches as soon as

possible. Your dealer has touch up paint to match the

color of your vehicle.

Interior Care

Use Mopar Fabric Cleaner to clean fabric upholstery and

carpeting.

Use Mopar Vinyl Cleaner to clean vinyl upholstery and

trim.

Mopar Total Clean is specifically recommended for

leather upholstery.Your leather upholstery can be best preserved by regular

cleaning with a damp soft cloth. Small particles of dirt

can act as an abrasive and damage the leather upholstery

and should be removed promptly with a damp cloth.

Stubborn soils can be removed easily with a soft cloth

and Mopar Total Clean. Care should be taken to avoid

soaking your leather upholstery with any liquid. Please

do not use polishes, oils, cleaning fluids, solvents, deter-

gents, or ammonia based cleaners to clean your leather

upholstery. Application of a leather conditioner is not

required to maintain the original condition.

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

364 MAINTAINING YOUR VEHICLE