ESP DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3321 of 5267

P1736-GEAR RATIO ERROR IN 2ND PRIME

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

If the ratio of the Input RPM to the Output RPM does not match the current gearratio. This DTC can take up

to five minutes of problem identification before illuminating the MIL

Possible Causes

RELATED DTC’S PRESENT

INPUT SPEED SENSOR OR WIRING

LOW FLUID LEVEL

CRACKED OR MIS-INSTALLED PRIMARY OIL FILTER OR SEAL

WORN SOLENOID SWITCH VALVE OR PLUGS

STUCK OR STICKING MAIN REGULATOR VALVE

BURNED UD OR 4C CLUTCH

CUT 4C OR UD PISTON SEAL

BROKEN 4C PISTON CASTING

BROKEN OR MISSING 4C BLEED ORIFICE

BROKEN OR MISSING UD BLEED ORIFICE

CUT 4C OR UD ACCUMULATOR PISTON SEAL

CRACKED 4C OR UD ACCUMULATOR PISTON

EXTRA CHECK BALL IN PASSAGE DOWNSTREAM OF #7 CHECK BALL POCKET

TRANSMISSION SOLENOID/TRS ASSEMBLY

BROKEN WELD - REACTION CARRIER TO REVERSE SUN GEAR

MISSING TEETH ON INPUT CLUTCH HUB TONE WHEEL

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) When in gear, if the gear ratio does not compare to a known gear ratio, the corresponding in-gear trouble code

is set (DTCs P0731-36).

2) An excessive change in input or output speeds indicating signal intermittent which may result in the DTCs P0715

and/or P0720 to set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the signal from the input speed

sensor at idle in neutral. Since the input speed sensor reads 60 teeth from the input clutch hub and the output

speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause the

DTC P1794 to set when at a stop.

Page 3336 of 5267

When Monitored:

The gear ratio is monitored continuously while the Transmission is in gear.

Set Condition:

After a controller reset in neutral and a ratio of input to output, of 1 to 2. ThisDTCcantakeuptofiveminutes

of problem identification before illuminating the MIL.

Possible Causes

(T13) SPEED SENSOR GROUND CIRCUIT OPEN

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO GROUND

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) When in gear, if the gear ratio does not compare to a known gear ratio, the corresponding in-gear trouble code

is set (DTCs P0731–36).

2) An excessive change in input or output speeds indicating signal intermittent which may result in the DTCs P0715

and/or P0720 to set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the signal from the input speed

sensor at idle in neutral. Since the input speed sensor reads 60 teeth from the input clutch hub and the output

speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause the

DTC P1794 to set when at a stop.

Diagnostic Test

1.CHECK TO SEE IF DTC P1794 IS CURRENT

Engine Running, Shift lever in park.

With the scan tool, read the Transmission Output and Input Speed Sensor states.

Is the Output Speed Sensor reading twice the Input Speed Sensor reading?

Ye s>>

Go To 2

No>>

Go To 6

2.PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool 8333.

With the Transmission Simulator, set the Input/Output Speed selector switch to the

3000/1000position. Turn the

Input/Output Speed switch to

ON.

Ignition on, engine not running.

Page 3350 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TCM POWER INPUT DTCS PRESENT

(T118) MS SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T118) MS SOLENOID CONTROL CIRCUIT OPEN

(T118) MS SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.RELATED TCM POWER INPUT DTCS PRESENT

With the scan tool, check for other transmission DTCs.

Are there any TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.TRANSMISSION SOLENOID/TRS ASSEMBLY

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the MS Solenoid.

Page 3365 of 5267

AUTOMATIC TRANSMISSION - 45RFE/545RFE-SERVICEINFORMATION

DESCRIPTION

The 45RFE/545RFE automatic transmissions is a sophisticated, multi-range, electronically controlled transmission

which combines optimized gear ratios for responsive performance, state of the art efficiency features and low NVH.

Other features include driver adaptive shifting and three planetary gearsets to provide wide ratio capability with

precise ratio steps for optimum driveability. The three planetary gear sets also make available a unique alternate

second gear ratio. The primary 2nd gear ratio fits between 1st and 3rd gearsfor normal through-gear accelerations.

The alternate second gear ratio (2prime) allows smoother 4-2 kickdowns athigh speeds to provide 2nd gear pass-

ing performance over a wider highway cruising range.

The hydraulic portion of the transmission consists of the transmission fluid, fluid passages, hydraulic valves, and

various line pressure control components.

The primary mechanical components of the transmission consist of the following:

Three multiple disc input clutches

Three multiple disc holding clutches

Five hydraulic accumulators

Three planetary gear sets

Dual Stage Hydraulic oil pump

Valve body

Solenoid pack

The Transmission Control Module (TCM) is the “heart” or “brain” of the electronic control system and relies on infor-

mation from various direct and indirect inputs (sensors, switches, etc.)to determine driver demand and vehicle oper-

ating conditions. Depending on the vehicle configuration, the TCM may be astandalone module or it it may be

housed along with the Powertrain Control Module (PCM) in a single module. With this information, the TCM can

calculate and perform timely and quality shifts through various output orcontrol devices (solenoid pack, transmission

control relay, etc.).

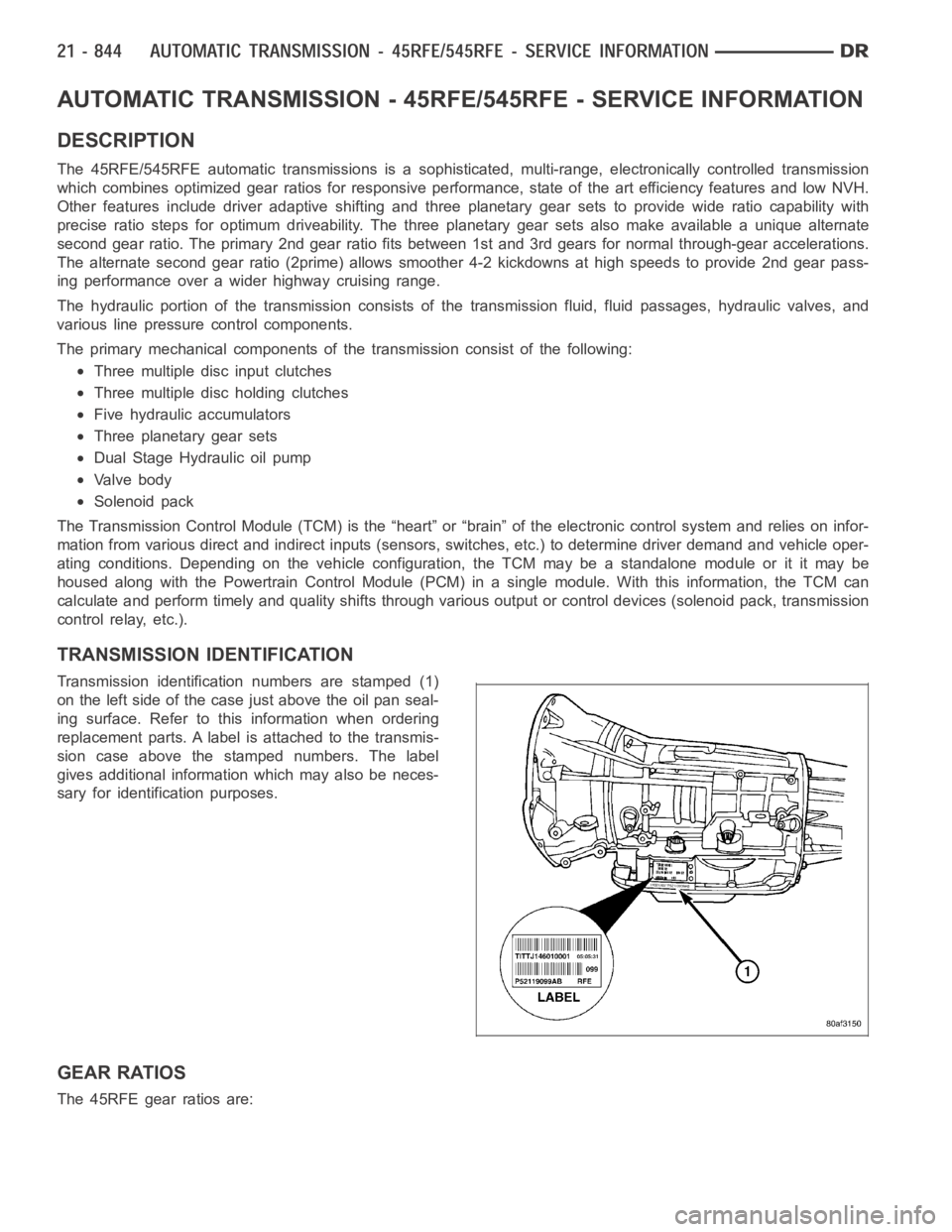

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped (1)

on the left side of the case just above the oil pan seal-

ing surface. Refer to this information when ordering

replacement parts. A label is attached to the transmis-

sion case above the stamped numbers. The label

gives additional information which may also be neces-

sary for identification purposes.

GEAR RATIOS

The 45RFE gear ratios are:

Page 3426 of 5267

6. Assemble and install the 4C clutch pack (3, 4) into the retainer/bulkhead (13) with the steel separator plate

against the piston.

7. Install the 4C reaction plate (8) and snap-ring (7) into the retainer/bulkhead (13). The 4C reaction plate is non-

directional.

8. Measure the 4C clutch clearance. The correct clutch clearance is 0.770-1.390 mm (0.030-0.055 in.). The snap-

ring (7) is selectable. Install the chosen snap-ring and re-measure to verify the selection.

9. Install the 2C piston (2) into the retainer/bulkhead (13).

10. Position the 2C Belleville spring (5) onto the 2C piston (2).

11. Position the 2C Belleville spring snap-ring (6) onto the 2C Bellevillespring (5).

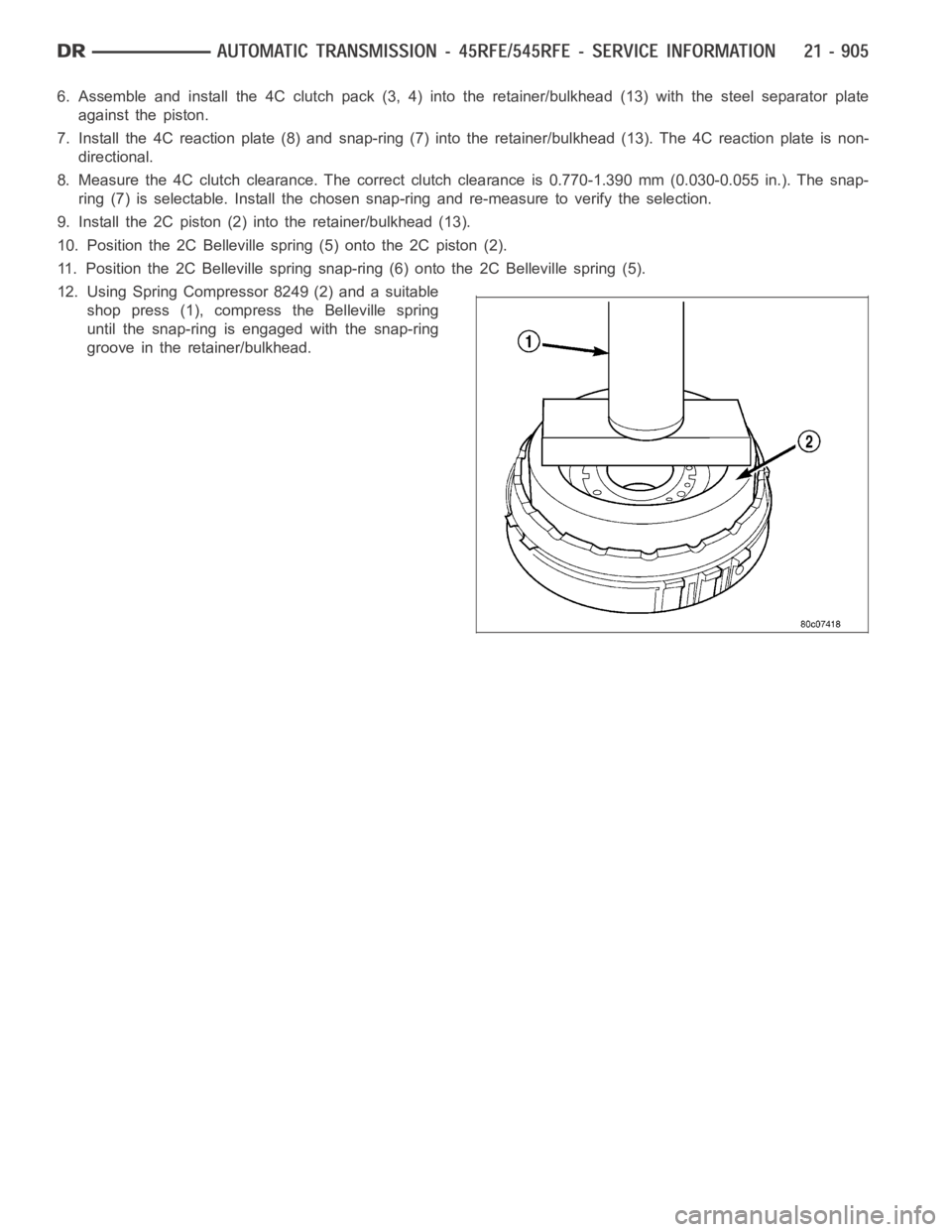

12. Using Spring Compressor 8249 (2) and a suitable

shop press (1), compress the Belleville spring

until the snap-ring is engaged with the snap-ring

groove in the retainer/bulkhead.

Page 3441 of 5267

OPERATION

The three input clutches are responsible for driving different components of the planetary geartrain.

UNDERDRIVE CLUTCH

The underdrive clutch is hydraulically applied in first, second, second prime, and third (direct) gears by pressurized

fluid against the underdrive piston. When the underdrive clutch is applied, the underdrive hub drives the input sun

gear.

OVERDRIVE CLUTCH

The overdrive clutch is hydraulically applied in third (direct), fourth,and fifth gears by pressurized fluid against the

overdrive/reverse piston. When the overdrive clutch isapplied, the overdrive hub drives the reverse carrier/input

annulus assembly.

REVERSE CLUTCH

The reverse clutch is hydraulically applied in reverse gear by pressurized fluid against the overdrive/reverse piston.

When the reverse clutch is applied, the reaction annulus gear is driven.

DISASSEMBLY

NOTE: If the input clutch assembly is being reconditioned (clutch/seal replacement) or replaced, it is nec-

essary to perform the Quick Learn Procedure using the scan tool (Refer to 8 -ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL MODULE - STANDARD PROCEDURE).

Page 3556 of 5267

Theory of Operation

The 3-4 Solenoid is used the engage the gear change form 3rd gear to 4th gear.

The solenoids used in transmission applications are attached to valves which can be classified as normally open or

normally closed. The normally open solenoid valve is defined as a valve which allows hydraulic flow when no cur-

rent or voltage is applied to the solenoid. The normally closed solenoid valve is defined as a valve which does not

allow hydraulic flow when no current or voltage is applied to the solenoid.These valves perform hydraulic control

functions for the transmission and must therefore be durable and tolerantof dirt particles. For these reasons, the

valves have hardened steel poppets and ball valves. The solenoids operatethe valves directly, which means that

the solenoids must have very high outputs to close the valves against the sizable flow areas and line pressures

found in current transmissions. Fastresponse time is also necessary to ensure accurate control.

When Monitored:

Continuously with ignition on.

Set Condition:

This DTC will set if the voltage detected on the 3-4 Shift Solenoid Control circuit at the PCM is different then

the expected voltage. Note: To clear this DTC it is necessary to drive the vehicle at a sustained speed which

would allow the TCC and/or Overdrive Clutch to operate

Possible Causes

TRANSMISSION CONTROL OUTPUT DTC PRESENT

(T9) 3-4 SOLENOID CONTROL CIRCUIT OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

(T9) 3-4 SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

(T9) 3-4 SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T16) TRANSMISSION RELAY OUTPUT CIRCUIT SHORT TO GROUND

(T9) 3-4 SOLENOID CIRCUIT SHORT TO OTHER CIRCUITS

TOTALLY INTEGRATED POWER MODULE

3-4 SHIFT SOLENOID

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission category, and perform the appropriate symptom(s).

No>>

Go To 2

Page 3610 of 5267

2.CHECK FOR OTHER TRANSMISSION DTC’S PRESENT

Are there any Park/Neutral or other Transmission DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom(s). If a Park/Neutral DTC is

present, perform its respective test first. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

48RE - DIAGNOSIS AND TESTING)

No>>

Go To 3

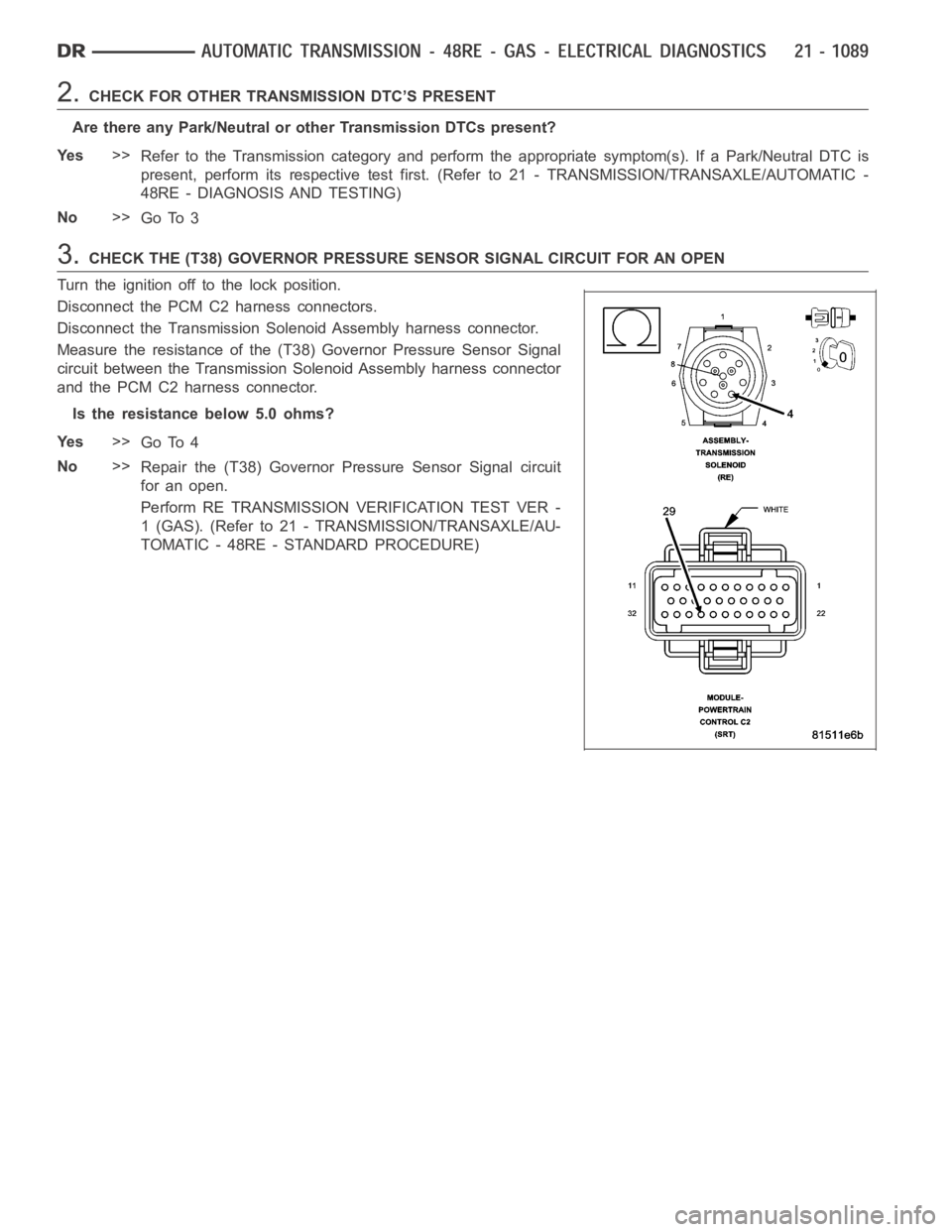

3.CHECK THE (T38) GOVERNOR PRESSURE SENSOR SIGNAL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C2 harness connectors.

Disconnect the Transmission Solenoid Assembly harness connector.

Measure the resistance of the (T38) Governor Pressure Sensor Signal

circuit between the Transmission Solenoid Assembly harness connector

and the PCM C2 harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 4

No>>

Repair the (T38) Governor Pressure Sensor Signal circuit

for an open.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

Page 3616 of 5267

Theory of Operation

The Governor Pressure Sensor is used by the PCM to adjust the Governor Pressure to a desired level for shifts in

first, second, and third gear. If the PCM detects the monitored sense voltage is greater than or less than a prede-

termined specification, the PCM will set the desired DTC.

When Monitored:

Continuously with the ignition on and the engine running.

Set Condition:

This DTC will set if the monitored voltage from the Governor Pressure Sensor drops below 0.12 volts for the

period of 8.5 seconds.

Possible Causes

PARK NEUTRAL DTC PRESENT OR OTHER TRANSMISSION DTC’S PRESENT

(T38) GOVERNOR PRESSURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

(T38) GOVERNOR PRESSURE SENSOR SIGNAL CIRCUIT SHORT TO OTHER CIRCUITS

TRANSMISSION SOLENOID ASSEMBLY

GOVERNOR PRESSURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 7

2.CHECK FOR OTHER TRANSMISSION DTC’S PRESENT

Are there any Park/Neutral or other Transmission DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom(s). If a Park/Neutral DTC is

present, perform its respective test first. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

48RE - DIAGNOSIS AND TESTING)

No>>

Go To 3

Page 3621 of 5267

Theory of Operation

The Transmission Control Output supplies power to the TCC, Overdrive, andGovernor Pressure Solenoids when in

normal operating mode. The Transmission Control Output Control circuit is constantly monitored by the PCM. If the

expected state of the Transmission Control Output Control circuit is different then the expected state, a correspond-

ing DTC will set and the PCM will de-energize the Transmission Control Output and place the transmission in Limp-

in.

When Monitored:

Continuously with the Ignition on.

Set Condition:

This DTC will set if the PCM monitored voltage of the Transmission Control Output Control circuit is different

than the expected voltage for the period 3.0 seconds.

Possible Causes

(T515) TRANSMISSION CONTROL CIRCUIT OPEN

(T515) TRANSMISSION CONTROL CIRCUIT SHORT TO VOLTAGE

(T515) TRANSMISSION CONTROL CIRCUIT SHORT TO GROUND

TOTALLY INTEGRATED POWER MODULE

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 6

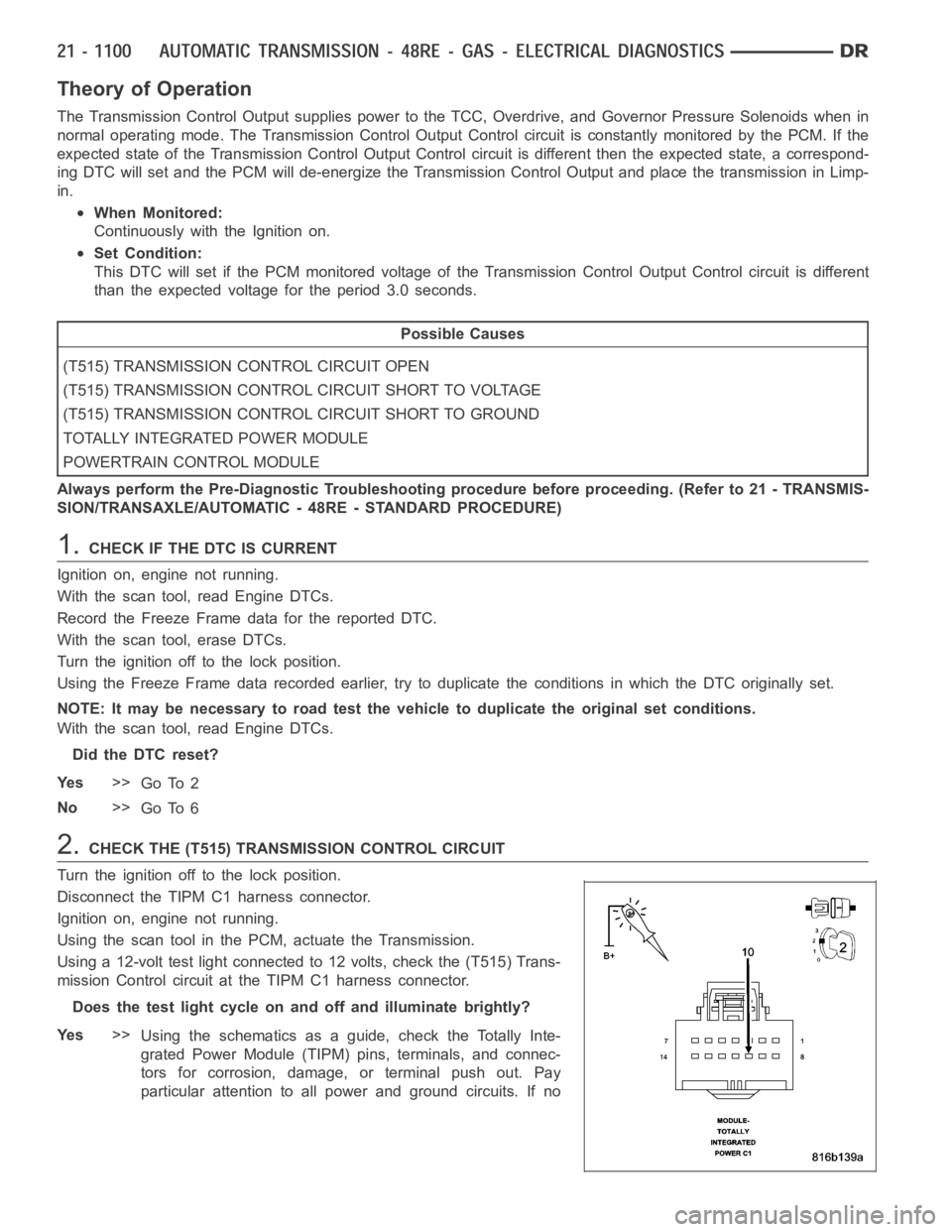

2.CHECK THE (T515) TRANSMISSION CONTROL CIRCUIT

Turn the ignition off to the lock position.

Disconnect the TIPM C1 harness connector.

Ignition on, engine not running.

Using the scan tool in the PCM, actuate the Transmission.

Using a 12-volt test light connected to 12 volts, check the (T515) Trans-

mission Control circuit at the TIPM C1 harness connector.

Does the test light cycle on and off and illuminate brightly?

Ye s>>

Using the schematics as a guide, check the Totally Inte-

grated Power Module (TIPM) pins, terminals, and connec-

tors for corrosion, damage, or terminal push out. Pay

particular attention to all power and ground circuits. If no