ESP DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4312 of 5267

MOTOR-SHIFT

DESCRIPTION

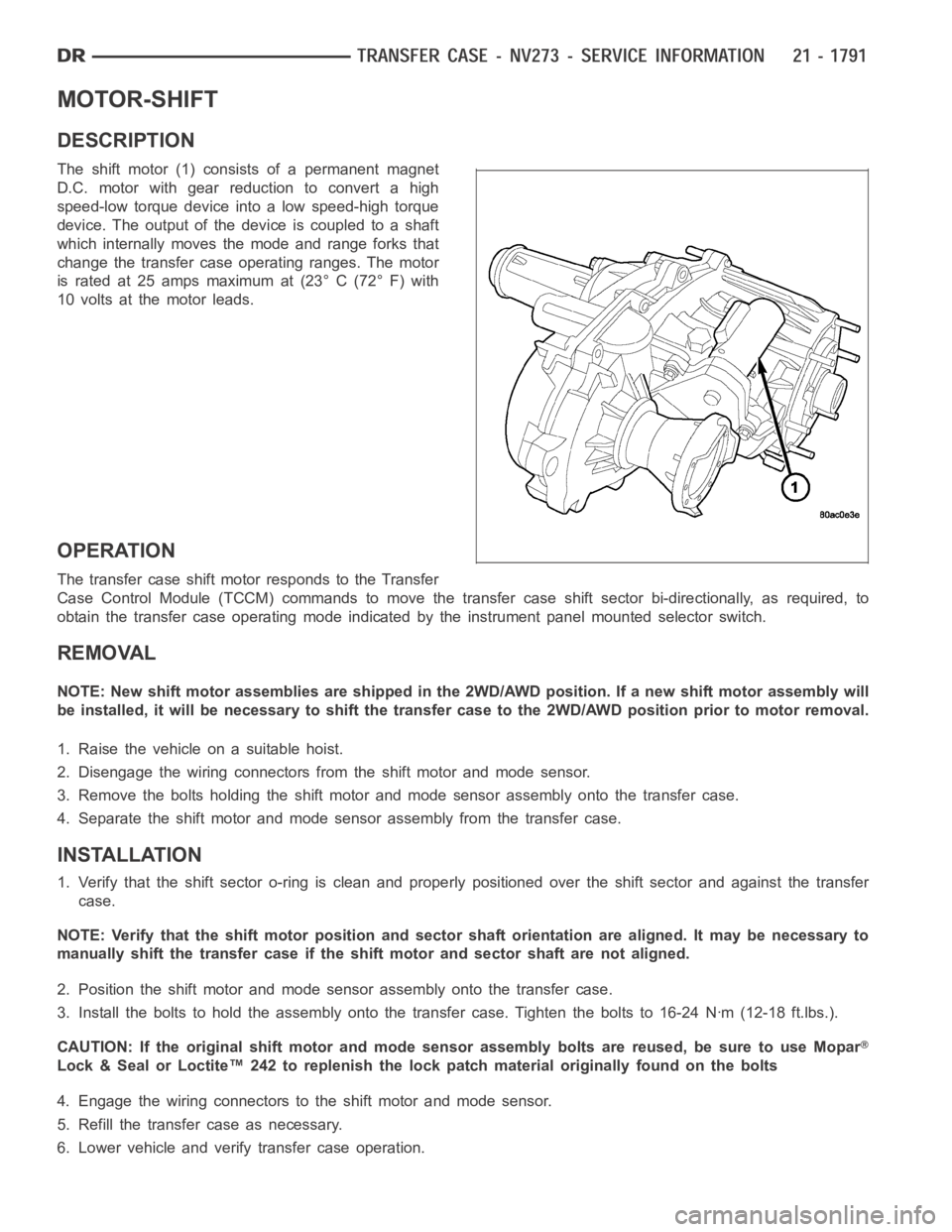

The shift motor (1) consists of a permanent magnet

D.C. motor with gear reduction to convert a high

speed-low torque device into a low speed-high torque

device. The output of the device is coupled to a shaft

which internally moves the mode and range forks that

change the transfer case operating ranges. The motor

is rated at 25 amps maximum at (23° C (72° F) with

10 volts at the motor leads.

OPERATION

The transfer case shift motor responds to the Transfer

Case Control Module (TCCM) commands to move the transfer case shift sectorbi-directionally, as required, to

obtain the transfer case operating mode indicated by the instrument panelmounted selector switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in the 2WD/AWD position. If a new shift motor assembly will

be installed, it will be necessary to shift the transfer case to the 2WD/AWDposition prior to motor removal.

1. Raise the vehicle on a suitable hoist.

2. Disengage the wiring connectors from the shift motor and mode sensor.

3. Remove the bolts holding the shift motor and mode sensor assembly onto the transfer case.

4. Separate the shift motor and mode sensor assembly from the transfer case.

INSTALLATION

1. Verify that the shift sector o-ring is clean and properly positioned over the shift sector and against the transfer

case.

NOTE: Verify that the shift motor position and sector shaft orientation are aligned. It may be necessary to

manually shift the transfer case if the shift motor and sector shaft are notaligned.

2. Position the shift motor and mode sensor assembly onto the transfer case.

3. Install the bolts to hold the assembly onto the transfer case. Tighten the bolts to 16-24 Nꞏm (12-18 ft.lbs.).

CAUTION: If the original shift motor and mode sensor assembly bolts are reused, be sure to use Mopar

Lock & Seal or Loctite™ 242 to replenish the lock patch material originallyfound on the bolts

4. Engage the wiring connectors to the shift motor and mode sensor.

5. Refill the transfer case as necessary.

6. Lower vehicle and verify transfer case operation.

Page 4441 of 5267

SIDE VIEW MIRROR GLASS

REMOVAL

STANDARD MIRROR

WARNING: Always wear eye and hand protection

when servicing the mirror assembly. Failure to

observe this warning may result in personal injury

from broken glass.

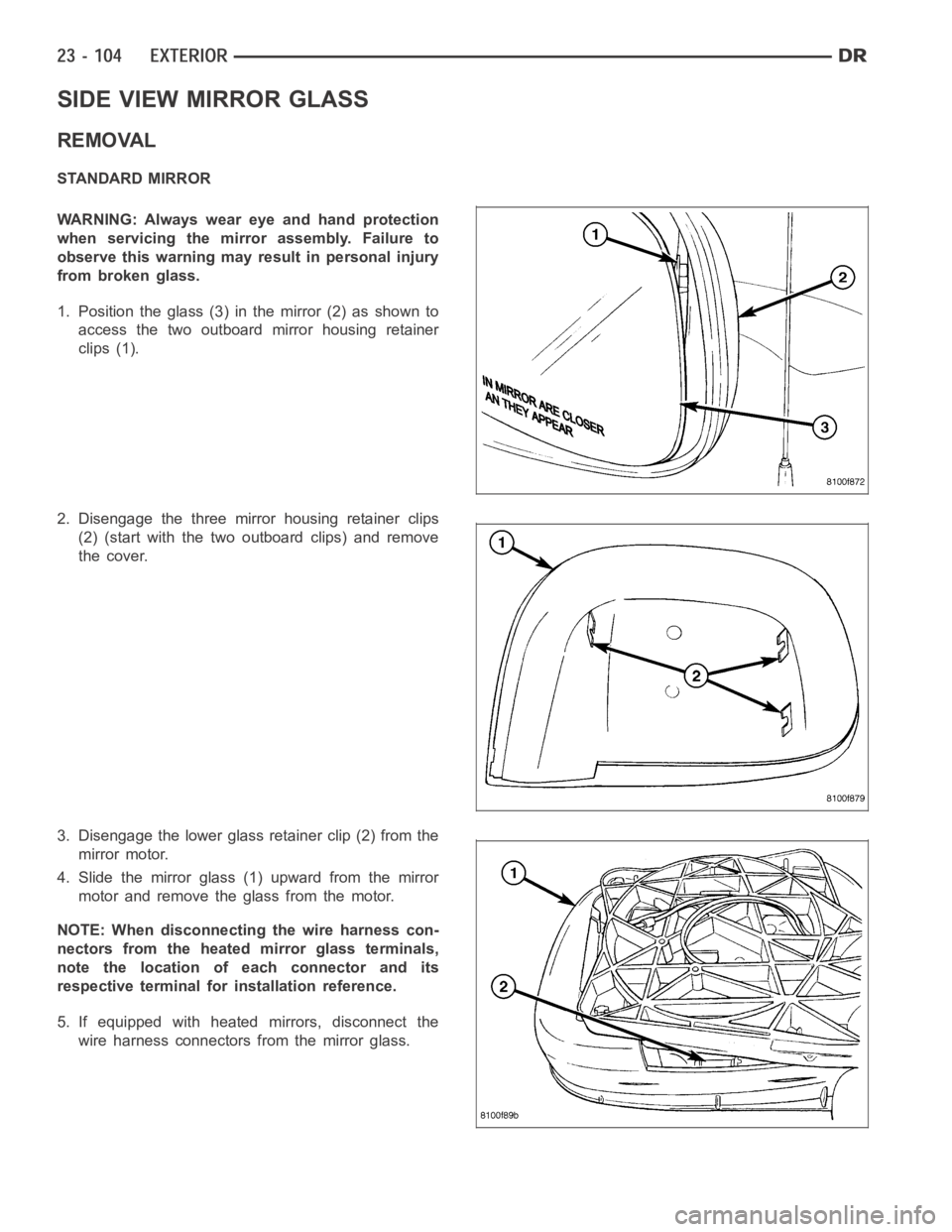

1. Position the glass (3) in the mirror (2) as shown to

access the two outboard mirror housing retainer

clips (1).

2. Disengage the three mirror housing retainer clips

(2) (start with the two outboard clips) and remove

the cover.

3. Disengage the lower glass retainer clip (2) from the

mirror motor.

4. Slide the mirror glass (1) upward from the mirror

motor and remove the glass from the motor.

NOTE: When disconnecting the wire harness con-

nectors from the heated mirror glass terminals,

note the location of each connector and its

respective terminal for installation reference.

5. If equipped with heated mirrors, disconnect the

wire harness connectors from the mirror glass.

Page 4442 of 5267

TOW PACKAGE MIRROR

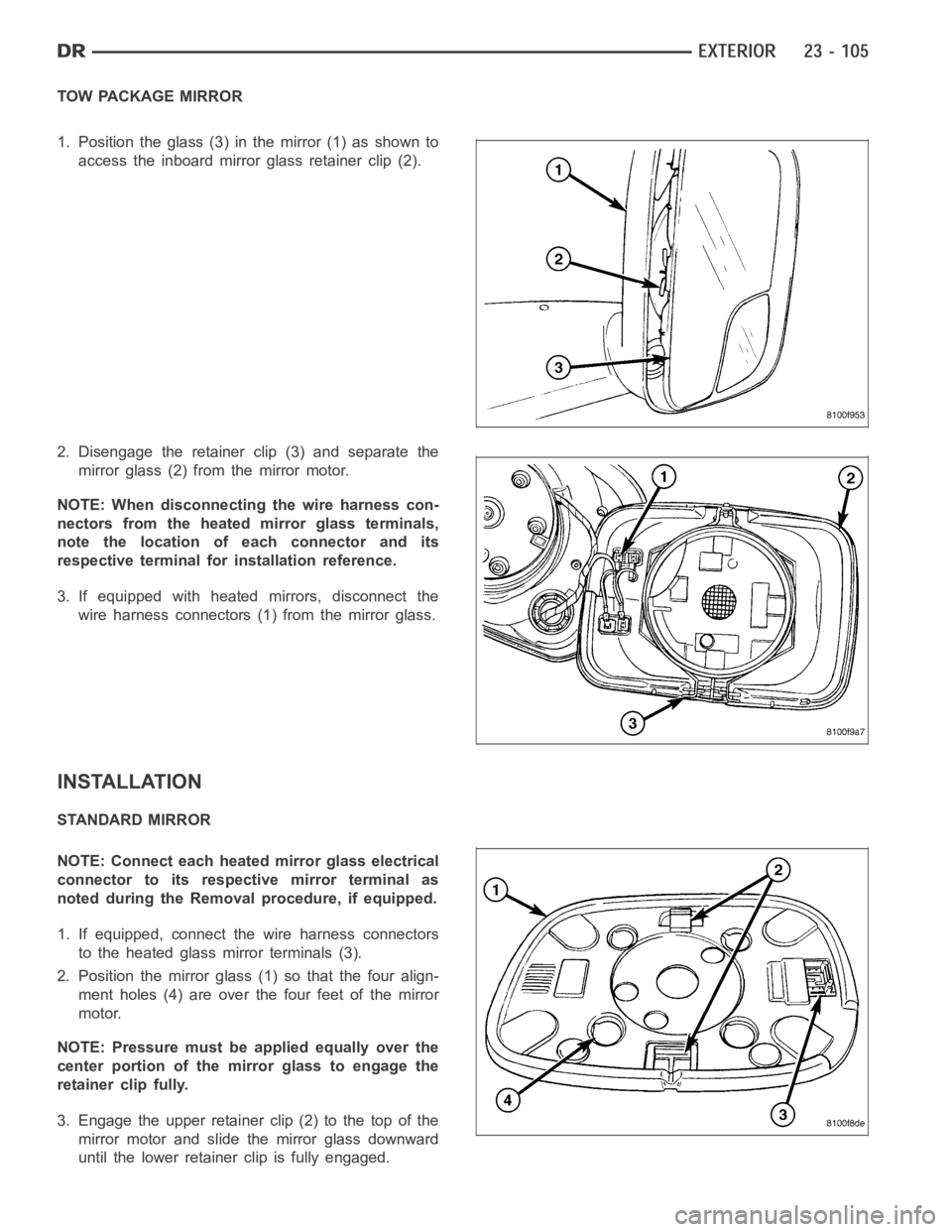

1. Position the glass (3) in the mirror (1) as shown to

access the inboard mirror glass retainer clip (2).

2. Disengage the retainer clip (3) and separate the

mirror glass (2) from the mirror motor.

NOTE: When disconnecting the wire harness con-

nectors from the heated mirror glass terminals,

note the location of each connector and its

respective terminal for installation reference.

3. If equipped with heated mirrors, disconnect the

wire harness connectors (1) from the mirror glass.

INSTALLATION

STANDARD MIRROR

NOTE: Connect each heated mirror glass electrical

connector to its respective mirror terminal as

noted during the Removal procedure, if equipped.

1. If equipped, connect the wire harness connectors

to the heated glass mirror terminals (3).

2. Position the mirror glass (1) so that the four align-

ment holes (4) are over the four feet of the mirror

motor.

NOTE: Pressure must be applied equally over the

center portion of the mirror glass to engage the

retainer clip fully.

3. Engage the upper retainer clip (2) to the top of the

mirror motor and slide the mirror glass downward

until the lower retainerclip is fully engaged.

Page 4443 of 5267

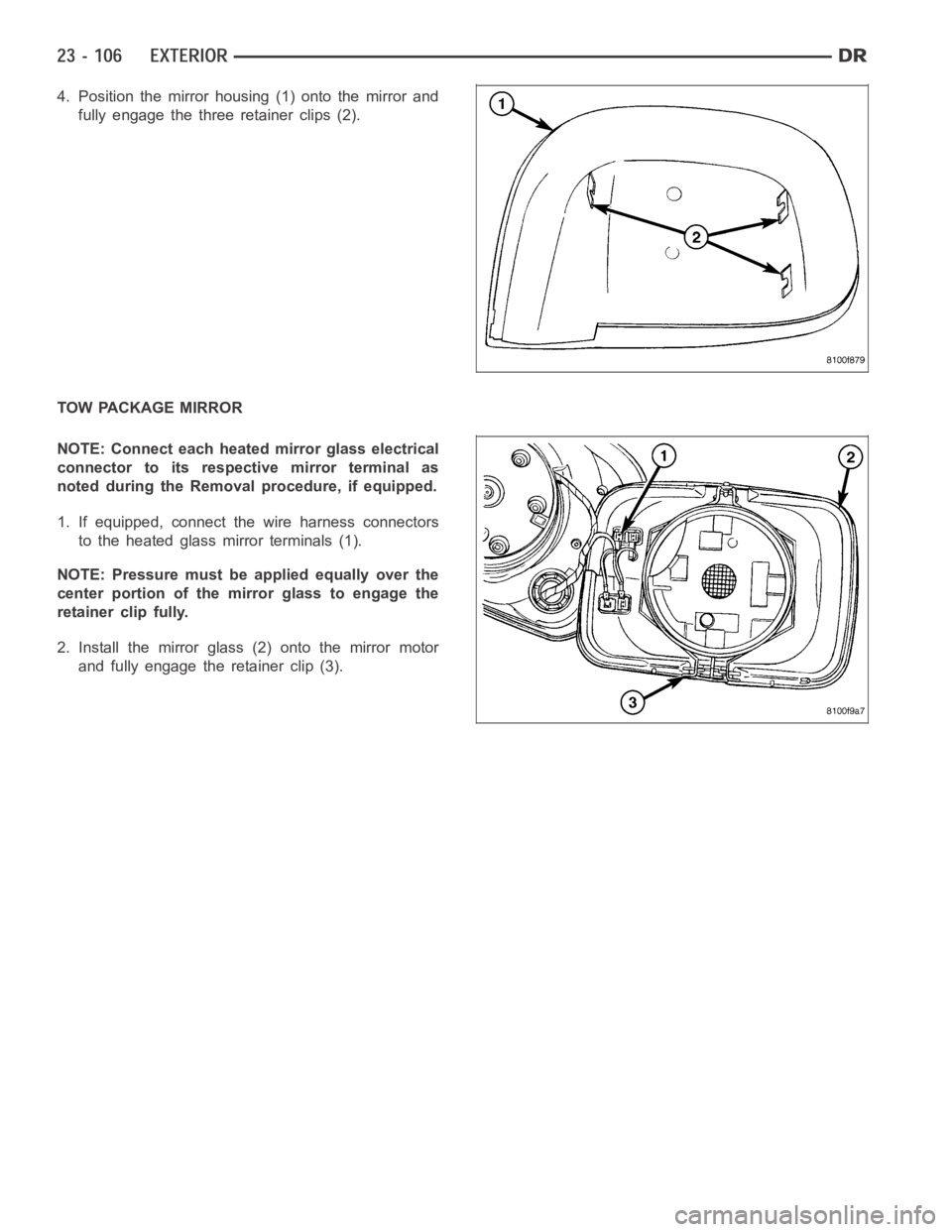

4. Position the mirror housing (1) onto the mirror and

fully engage the three retainer clips (2).

TOW PACKAGE MIRROR

NOTE: Connect each heated mirror glass electrical

connector to its respective mirror terminal as

noted during the Removal procedure, if equipped.

1. If equipped, connect the wire harness connectors

to the heated glass mirror terminals (1).

NOTE: Pressure must be applied equally over the

center portion of the mirror glass to engage the

retainer clip fully.

2. Install the mirror glass (2) onto the mirror motor

and fully engage the retainer clip (3).

Page 4556 of 5267

PA I N T T O U C H - U P

DESCRIPTION

If the painted metal surface of a vehicle becomes scratched or chipped, it should be touched-up as soon as pos-

sible to avoid corrosion.

WARNING: Use an OSHA approved respirator and safety glasses when sprayingpaint or solvents in a con-

fined area. Failure to follow this warning may result in possible personalinjury or death.

When repairing painted metal surfaces, for best results, use MOPAR

Scratch Filler/Primer, Touch-Up Paints and

Clear Top Coat (Refer to VEHICLE DATA/VEHICLE INFORMATION/BODY CODE PLATE - DESCRIPTION) for

Body Code Plate information.

STANDARD PROCEDURE

PA I N T T O U C H - U P

1. Scrape any loose paint and corrosion from inside the scratch or chip.

WARNING: Avoid prolonged skin contact with petroleum or alcohol–based cleaning solvents. Failure to fol-

low this warning can result in possible personal injury or death.

2. Clean affected area with MOPAR

Tar/Road Oil Remover or equivalent, and allow to dry.

3. Fill the inside of the scratch or chip with a coat of filler/primer. Do notoverlap primer onto good surface finish.

The applicator brush should be wet enough to puddle-fill the scratch or chip without running. Do not stroke brush

applicator on body surface. Allow the filler/primer to dry hard.

4. Cover the filler/primer with color touch-up paint. Do not overlap touch-up color onto the original color coat around

the scratch or chip. Butt the new color to the original color, if possible. Do not stroke applicator brush on body

surface. Allow touch-up paint to dry hard.

5. On vehicles without clearcoat, the touch-up color can be lightly finesse sanded (1500 grit) and polished with

rubbing compound.

6. On vehicles with clearcoat, apply clear top coat to touch-up paint with the same technique as described in Step

4. Allow clear top coat to dry hard. If desired, the clearcoat can be lightlyfinesse sanded (1500 grit) and polished

with rubbing compound.

Page 4599 of 5267

WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS

Do not operate the vehicle within 24 hours of windshield installation. It takes at least 24 hours for urethane

adhesive to cure. If it is not cured, the windshield may not perform properlyinanaccident.

Urethane adhesives are applied as a system. Use glass cleaner, glass prep solvent, glass primer, PVC

(vinyl) primer and pinch weld (fence) primer provided by the adhesive manufacturer. If not, structural

integrity could be compromised.

DaimlerChrysler does not recommend glass adhesive by brand. Techniciansshould review product

labels and technical data sheets, and use only adhesives that their manufactures warranty and will

restore a vehicle to the requirements of fmvss 212. Technicians should also insure that primers and

cleaners are compatible with the particular adhesive used.

Be sure to refer to the urethane manufacturer’s directions for curing timespecifications and do not

use adhesive after its expiration date.

Vapors that are emitted from the urethane adhesive or primer could cause personal injury or death.

Use them in a well-ventilated area.

Skin contact with urethane adhesive should be avoided. Personal injury ordeath may result.

Always wear eye and hand protection when working with glass.

Protect all painted and trimmed surfaces from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when removing moldings or cutting urethane around windshield.

REMOVAL

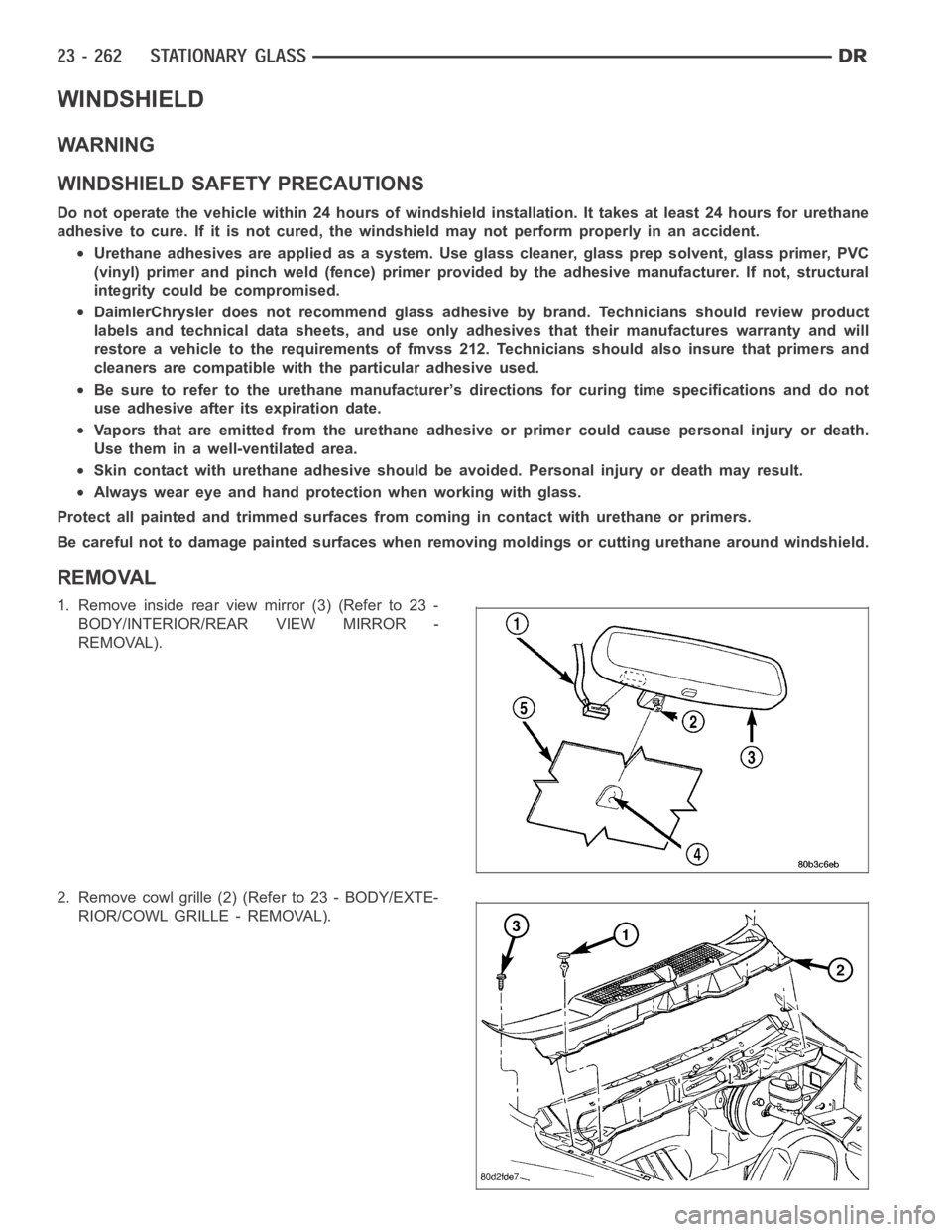

1. Remove inside rear view mirror (3) (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR -

REMOVAL).

2. Remove cowl grille (2) (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL).

Page 4609 of 5267

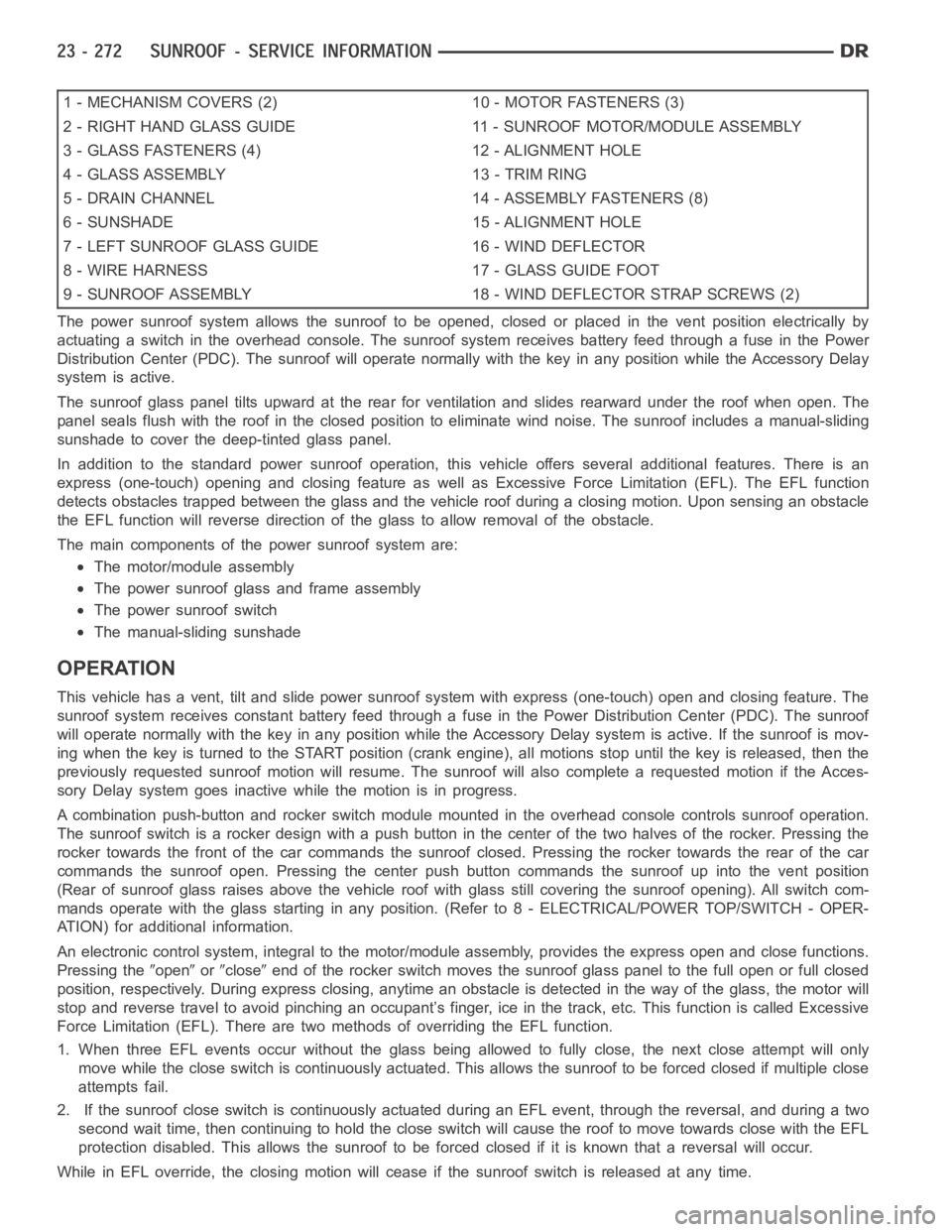

1 - MECHANISM COVERS (2) 10 - MOTOR FASTENERS (3)

2 - RIGHT HAND GLASS GUIDE 11 - SUNROOF MOTOR/MODULE ASSEMBLY

3 - GLASS FASTENERS (4) 12 - ALIGNMENT HOLE

4 - GLASS ASSEMBLY 13 - TRIM RING

5 - DRAIN CHANNEL 14 - ASSEMBLY FASTENERS (8)

6 - SUNSHADE 15 - ALIGNMENT HOLE

7 - LEFT SUNROOF GLASS GUIDE 16 - WIND DEFLECTOR

8 - WIRE HARNESS 17 - GLASS GUIDE FOOT

9 - SUNROOF ASSEMBLY 18 - WIND DEFLECTOR STRAP SCREWS (2)

The power sunroof system allows the sunroof to be opened, closed or placed in the vent position electrically by

actuating a switch in the overhead console. The sunroof system receives battery feed through a fuse in the Power

Distribution Center (PDC). The sunroof will operate normally with the keyin any position while the Accessory Delay

system is active.

The sunroof glass panel tilts upward at the rear for ventilation and slidesrearward under the roof when open. The

panel seals flush with the roof in the closed position to eliminate wind noise. The sunroof includes a manual-sliding

sunshade to cover the deep-tinted glass panel.

In addition to the standard power sunroof operation, this vehicle offers several additional features. There is an

express (one-touch) opening and closing feature as well as Excessive Force Limitation (EFL). The EFL function

detects obstacles trapped between the glass and the vehicle roof during a closing motion. Upon sensing an obstacle

the EFL function will reverse direction of the glass to allow removal of theobstacle.

The main components of thepower sunroof system are:

The motor/module assembly

The power sunroof glass and frame assembly

The power sunroof switch

The manual-sliding sunshade

OPERATION

This vehicle has a vent, tilt and slide power sunroof system with express (one-touch) open and closing feature. The

sunroof system receives constant battery feed through a fuse in the Power Distribution Center (PDC). The sunroof

will operate normally with the key in any position while the Accessory Delay system is active. If the sunroof is mov-

ing when the key is turned to the START position (crank engine), all motionsstop until the key is released, then the

previously requested sunroof motion will resume. The sunroof will also complete a requested motion if the Acces-

sory Delay system goes inactivewhile the motion is in progress.

A combination push-button and rocker switch module mounted in the overhead console controls sunroof operation.

The sunroof switch is a rocker design with a push button in the center of the two halves of the rocker. Pressing the

rocker towards the front of the car commands the sunroof closed. Pressing the rocker towards the rear of the car

commands the sunroof open. Pressing the center push button commands the sunroof up into the vent position

(Rear of sunroof glass raises above the vehicle roof with glass still covering the sunroof opening). All switch com-

mands operate with the glass startingin any position. (Refer to 8 - ELECTRICAL/POWER TOP/SWITCH - OPER-

ATION) for additional information.

An electronic control system, integralto the motor/module assembly, provides the express open and close functions.

Pressing the

openorcloseend of the rocker switch moves the sunroof glass panel to the full open or fullclosed

position, respectively. During express closing, anytime an obstacle is detected in the way of the glass, the motor will

stop and reverse travel to avoid pinching an occupant’s finger, ice in the track, etc. This function is called Excessive

Force Limitation (EFL). There are two methods of overriding the EFL function.

1. When three EFL events occur without the glass being allowed to fully close, the next close attempt will only

move while the close switch is continuously actuated. This allows the sunrooftobeforcedclosedifmultipleclose

attempts fail.

2. If the sunroof close switch is continuously actuated during an EFL event, through the reversal, and during a two

second wait time, then continuing to hold the close switch will cause the roof to move towards close with the EFL

protection disabled. This allows the sunroof to be forced closed if it is known that a reversal will occur.

While in EFL override, the closing motion will cease if the sunroof switch is released at any time.

Page 4610 of 5267

The motor/module is programmed to learn the speed required to drive the panel based on position and recalibrates

itself as needed. If the sunroof becomes uncalibrated, it will only respond to the vent switch. If the vent switch is

pressed, the glass will move toward vent; if the switch is released, all motion stops. In the event that the sunroof

system becomes uncalibrated performthe sunroof position calibration procedure, (Refer to 8 - ELECTRICAL/

POWER TOP/MOTOR - STANDARD PROCEDURE -SUNROOF POSITION CALIBRATION).

DIAGNOSIS AND TESTING

POWER TOP - SUNROOF

Any diagnosis of the power sunroof system should begin with the use of a scantool and the proper Diagnostic

Procedures Information. The scan tool can provide confirmation that the Controller Area Network (CAN) Data Bus is

functional, that all of the electronic modules are sending and receiving the proper messages on the CAN Data Bus,

and that the power sunroof motor is being sent the proper hard wired output by the sunroof switch.

For complete circuit diagrams, refer to the appropriate wiring information. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures, details of wire harness routing and retention, connector pin-out

information and location views for the various wire harness connectors, splices and grounds.

Refer to the appropriate diagnostic information.

SUNROOF

Refer to SUNROOF DIAGNOSIS CHART for possible causes. Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating condition. If not, a common electrical problem may exist. Refer to

Wiring Diagrams, in this publication for circuit, splice and component descriptions. Check the condition of the circuit

protection (20 amp circuit breaker in the Junction Block). Inspect all wiring connector pins for proper engagement

and continuity. Check for battery voltage at the power sunroof controller, refer to Wiring Diagrams, for circuit infor-

mation. If battery voltage of more than 10 volts is detected at the controller, proceed with the following tests (the

controller will not operate at less than 10 volts).

Before beginning diagnosis for wind noise or water leaks, verify that the problem was not caused by releasing the

control switch before the sunroof was fully closed. The sunroof module hasa water-management system. If how-

ever, the sunroof glass is in a partial closed position, high pressure water may be forced beyond the water man-

agement system boundariesand onto the headlining.

Every time the sunroof module loses power it must be initialized. This is done by connecting power to the sunroof

and moving the sunroof toward the closed position. When initialization occurs a slight “kick” in the sunroof module

will be seen and heard. This is the indication that the sunroof module is initialized

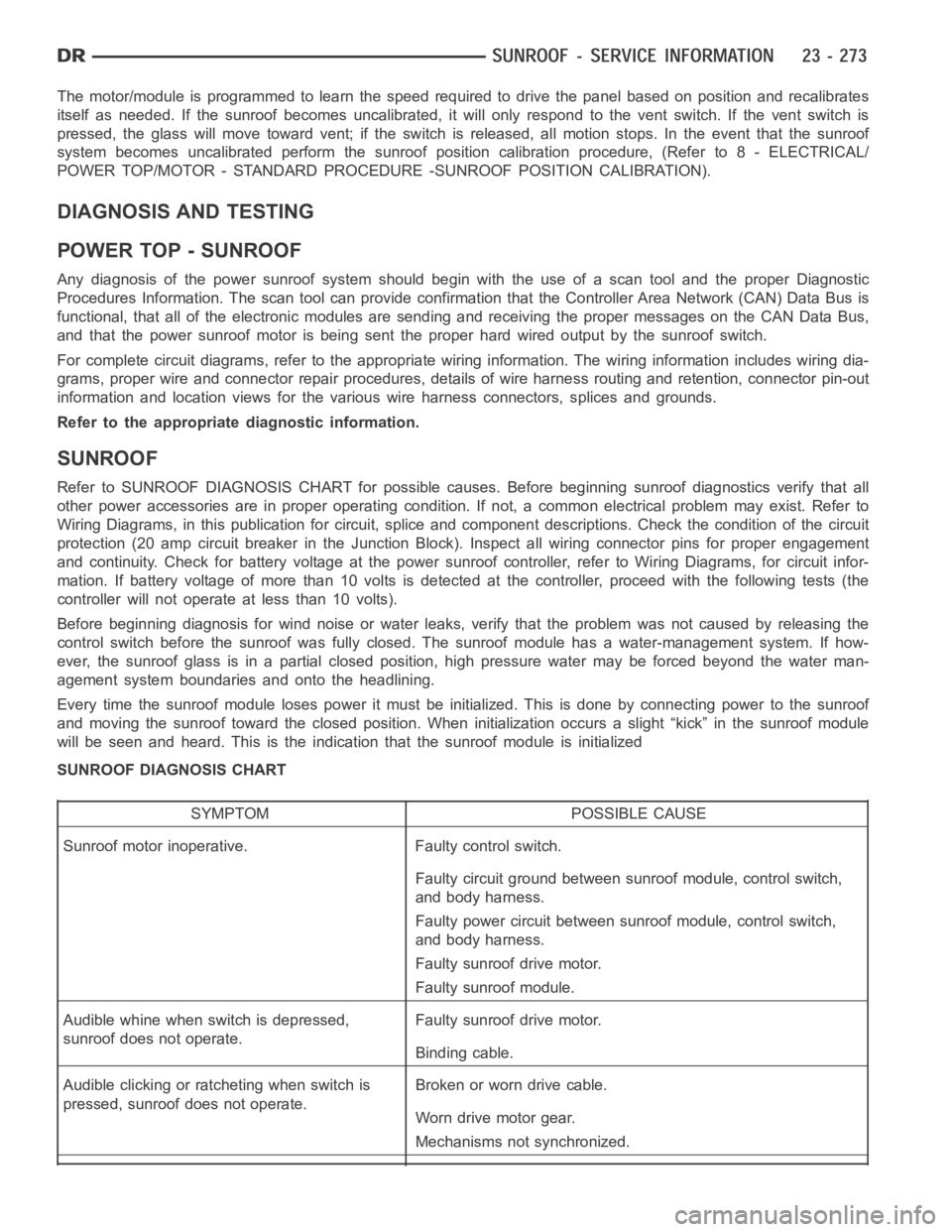

SUNROOF DIAGNOSIS CHART

SYMPTOM POSSIBLE CAUSE

Sunroof motor inoperative. Faulty control switch.

Faulty circuit ground between sunroof module, control switch,

and body harness.

Faulty power circuit between sunroof module, control switch,

and body harness.

Faulty sunroof drive motor.

Faulty sunroof module.

Audible whine when switch is depressed,

sunroof does not operate.Faulty sunroof drive motor.

Binding cable.

Audible clicking or ratcheting when switch is

pressed, sunroof does not operate.Broken or worn drive cable.

Worn drive motor gear.

Mechanisms not synchronized.

Page 4659 of 5267

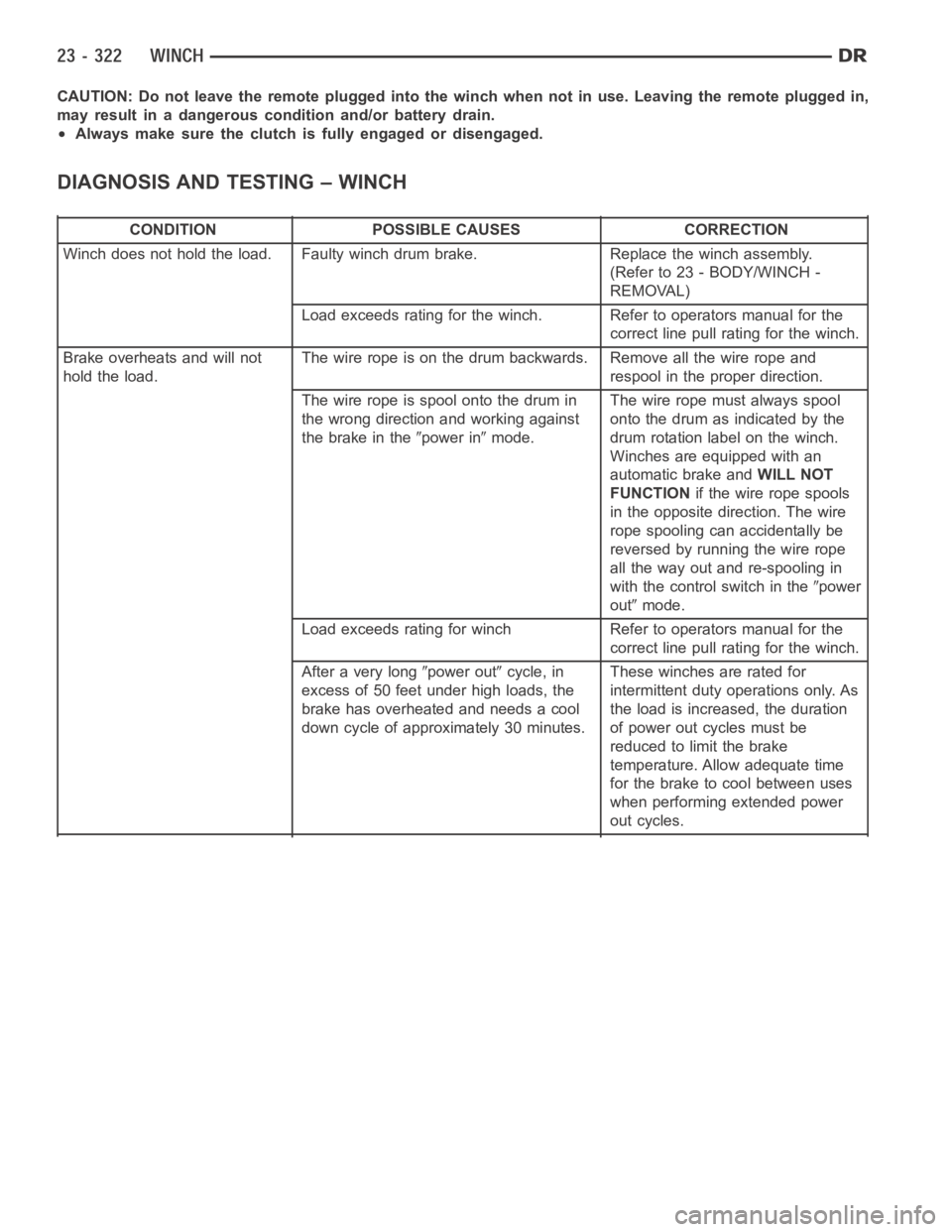

CAUTION: Do not leave the remote plugged into the winch when not in use. Leaving the remote plugged in,

may result in a dangerous condition and/or battery drain.

Always make sure the clutch is fully engaged or disengaged.

DIAGNOSIS AND TESTING – WINCH

CONDITION POSSIBLE CAUSES CORRECTION

Winch does not hold the load. Faulty winch drum brake. Replace the winch assembly.

(Refer to 23 - BODY/WINCH -

REMOVAL)

Load exceeds rating for the winch. Refer to operators manual for the

correct line pull rating for the winch.

Brake overheats and will not

hold the load.The wire rope is on the drum backwards. Remove all the wire rope and

respool in the proper direction.

Thewireropeisspoolontothedrumin

the wrong direction and working against

the brake in the

power inmode.The wire rope must always spool

onto the drum as indicated by the

drum rotation label on the winch.

Winches are equipped with an

automatic brake andWILL NOT

FUNCTIONif the wire rope spools

intheoppositedirection.Thewire

rope spooling can accidentally be

reversed by running the wire rope

all the way out and re-spooling in

with the control switch in the

power

out

mode.

Load exceeds rating for winch Refer to operators manual for the

correct line pull rating for the winch.

After a very long

power outcycle, in

excess of 50 feet under high loads, the

brake has overheated and needs a cool

down cycle of approximately 30 minutes.These winches are rated for

intermittent duty operations only. As

the load is increased, the duration

of power out cycles must be

reduced to limit the brake

temperature. Allow adequate time

for the brake to cool between uses

when performing extended power

out cycles.

Page 4881 of 5267

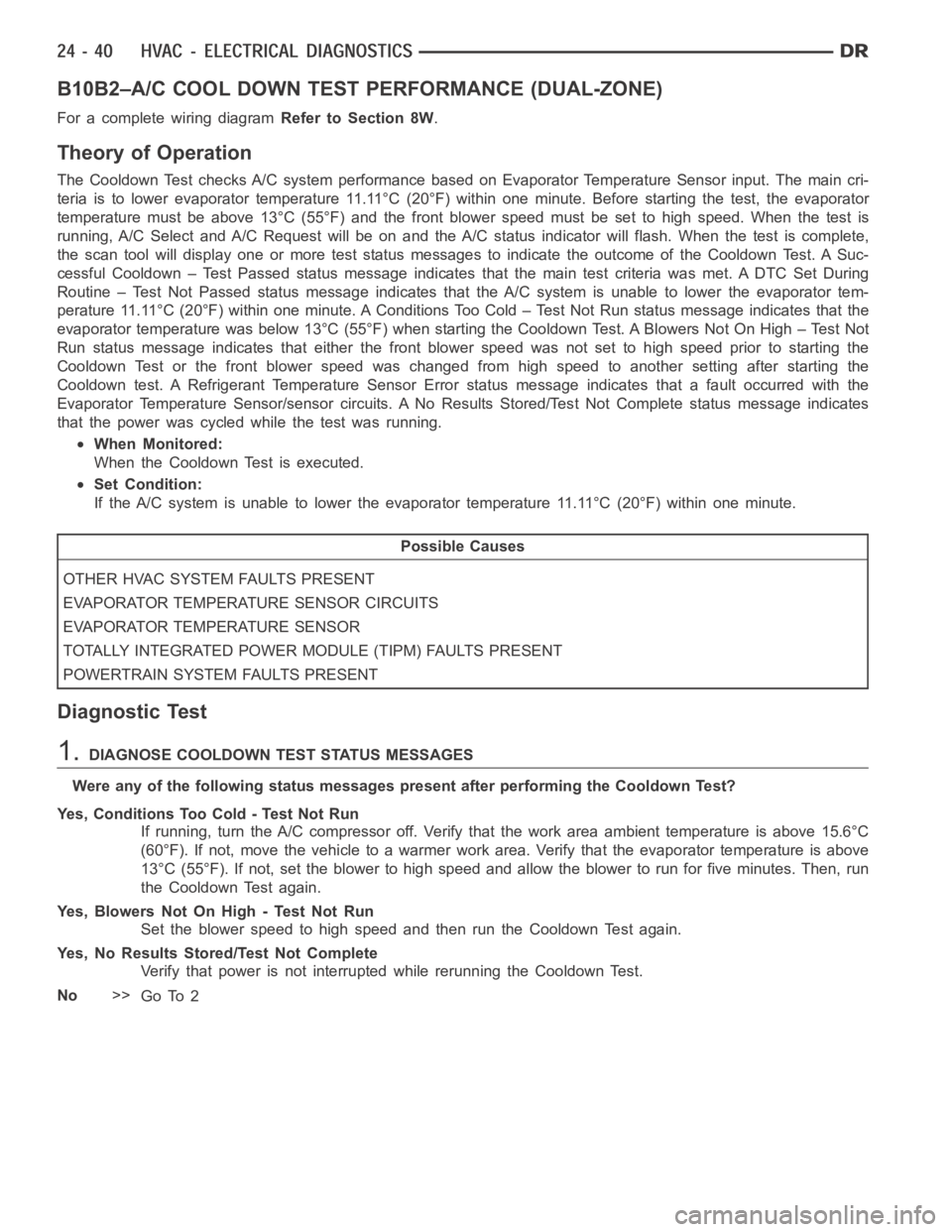

B10B2–A/C COOL DOWN TEST PERFORMANCE (DUAL-ZONE)

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The Cooldown Test checks A/C system performance based on Evaporator Temperature Sensor input. The main cri-

teria is to lower evaporator temperature 11.11°C (20°F) within one minute. Before starting the test, the evaporator

temperature must be above 13°C (55°F) and the front blower speed must be setto high speed. When the test is

running, A/C Select and A/C Request will be on and the A/C status indicator will flash. When the test is complete,

the scan tool will display one or more test status messages to indicate the outcome of the Cooldown Test. A Suc-

cessful Cooldown – Test Passed status message indicates that the main testcriteria was met. A DTC Set During

Routine – Test Not Passed status message indicates that the A/C system is unable to lower the evaporator tem-

perature 11.11°C (20°F) within one minute. A Conditions Too Cold – Test NotRun status message indicates that the

evaporator temperature was below 13°C (55°F) when starting the Cooldown Test. A Blowers Not On High – Test Not

Run status message indicates that either the front blower speed was not setto high speed prior to starting the

Cooldown Test or the front blower speed was changed from high speed to another setting after starting the

Cooldown test. A Refrigerant Temperature Sensor Error status message indicates that a fault occurred with the

Evaporator Temperature Sensor/sensor circuits. A No Results Stored/Test Not Complete status message indicates

that the power was cycled while the test was running.

When Monitored:

When the Cooldown Test is executed.

Set Condition:

If the A/C system is unable to lower the evaporator temperature 11.11°C (20°F) within one minute.

Possible Causes

OTHER HVAC SYSTEM FAULTS PRESENT

EVAPORATOR TEMPERATURE SENSOR CIRCUITS

EVAPORATOR TEMPERATURE SENSOR

TOTALLY INTEGRATED POWER MODULE (TIPM) FAULTS PRESENT

POWERTRAIN SYSTEM FAULTS PRESENT

Diagnostic Test

1.DIAGNOSE COOLDOWN TEST STATUS MESSAGES

WereanyofthefollowingstatusmessagespresentafterperformingtheCooldown Test?

Yes, Conditions Too Cold - Test Not Run

If running, turn the A/C compressor off. Verify that the work area ambient temperature is above 15.6°C

(60°F). If not, move the vehicle to a warmer work area. Verify that the evaporator temperature is above

13°C (55°F). If not, set the blower to high speed and allow the blower to run for five minutes. Then, run

the Cooldown Test again.

Yes, Blowers Not On High - Test Not Run

Set the blower speed to high speed and then run the Cooldown Test again.

Yes, No Results Stored/Test Not Complete

Verify that power is not interrupted while rerunning the Cooldown Test.

No>>

Go To 2