heating DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4454 of 5267

CLADDING-BODY SIDE - DOOR - SRT-10

REMOVAL

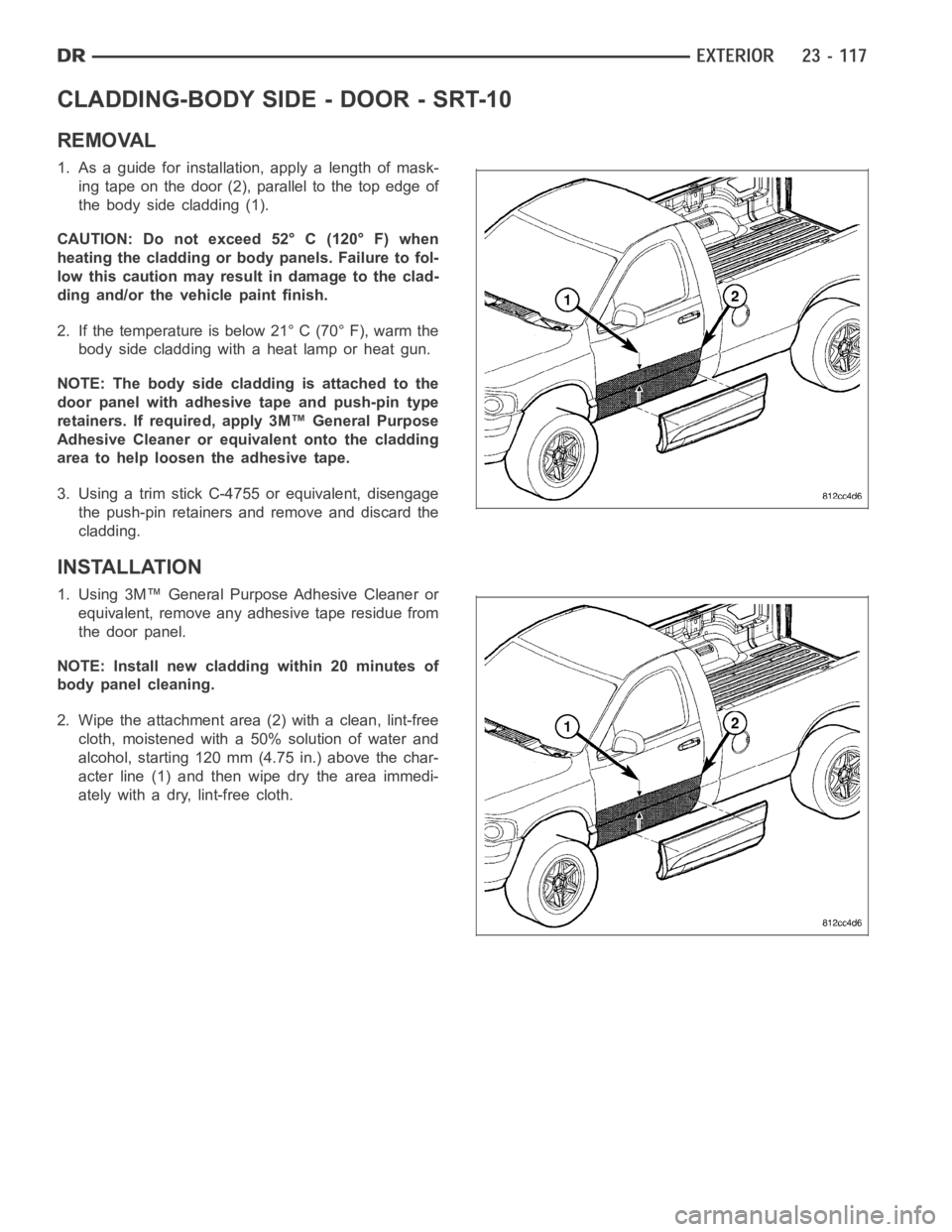

1. As a guide for installation, apply a length of mask-

ing tape on the door (2), parallel to the top edge of

the body side cladding (1).

CAUTION: Do not exceed 52° C (120° F) when

heating the cladding or body panels. Failure to fol-

low this caution may result in damage to the clad-

ding and/or the vehicle paint finish.

2. If the temperature is below 21° C (70° F), warm the

body side cladding with a heat lamp or heat gun.

NOTE: The body side cladding is attached to the

door panel with adhesive tape and push-pin type

retainers. If required, apply 3M™ General Purpose

Adhesive Cleaner or equivalent onto the cladding

area to help loosen the adhesive tape.

3. Using a trim stick C-4755 or equivalent, disengage

the push-pin retainers and remove and discard the

cladding.

INSTALLATION

1. Using 3M™ General Purpose Adhesive Cleaner or

equivalent, remove any adhesive tape residue from

the door panel.

NOTE: Install new cladding within 20 minutes of

body panel cleaning.

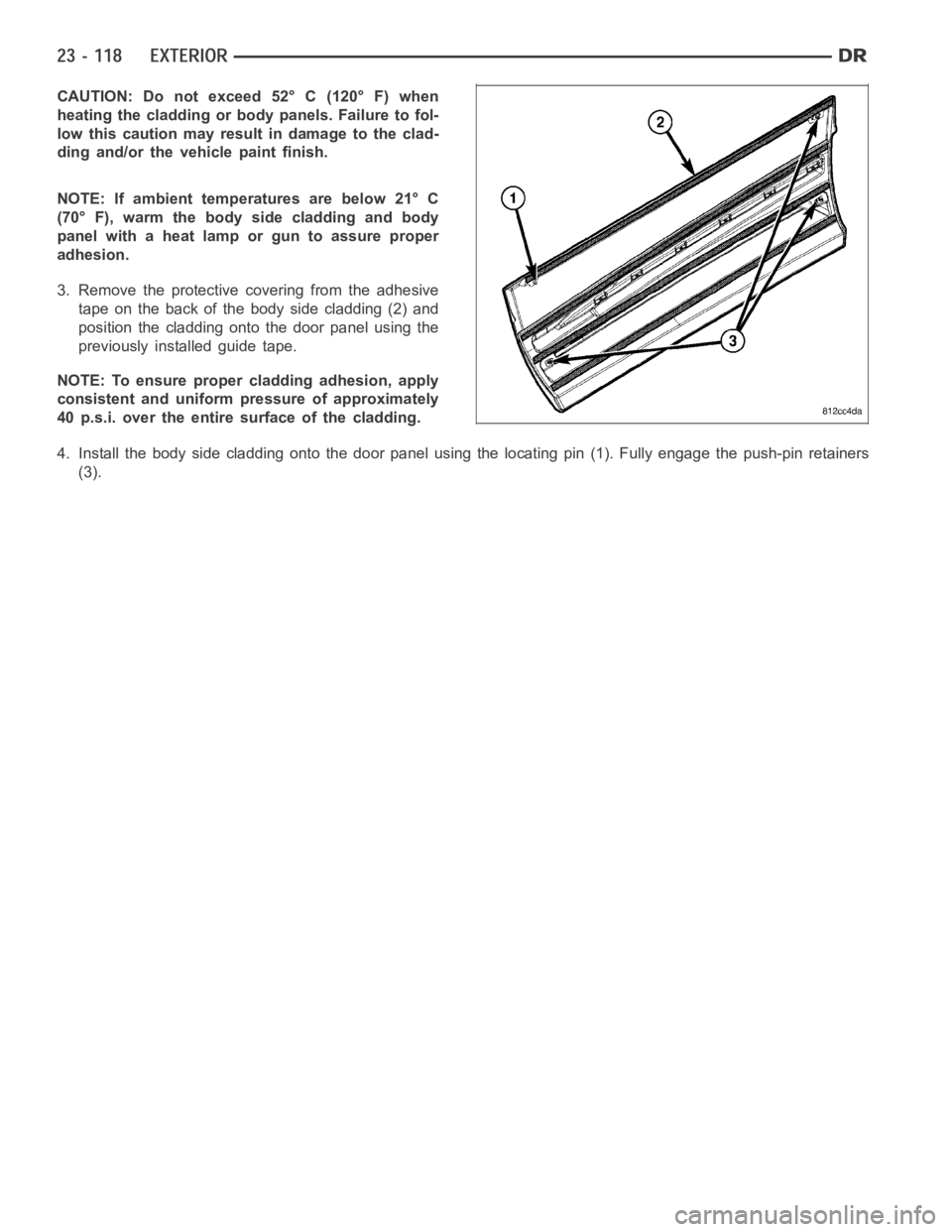

2. Wipe the attachment area (2) with a clean, lint-free

cloth, moistened with a 50% solution of water and

alcohol, starting 120 mm (4.75 in.) above the char-

acterline(1)andthenwipedrytheareaimmedi-

ately with a dry, lint-free cloth.

Page 4455 of 5267

CAUTION: Do not exceed 52° C (120° F) when

heating the cladding or body panels. Failure to fol-

low this caution may result in damage to the clad-

ding and/or the vehicle paint finish.

NOTE: If ambient temperatures are below 21° C

(70° F), warm the body side cladding and body

panel with a heat lamp or gun to assure proper

adhesion.

3. Remove the protective covering from the adhesive

tape on the back of the body side cladding (2) and

position the cladding onto the door panel using the

previously installed guide tape.

NOTE: To ensure proper cladding adhesion, apply

consistent and uniform pressure of approximately

40 p.s.i. over the entire surface of the cladding.

4. Install the body side cladding onto the door panel using the locating pin(1). Fully engage the push-pin retainers

(3).

Page 4456 of 5267

CLADDING-BODY SIDE - FENDER SRT-10

REMOVAL

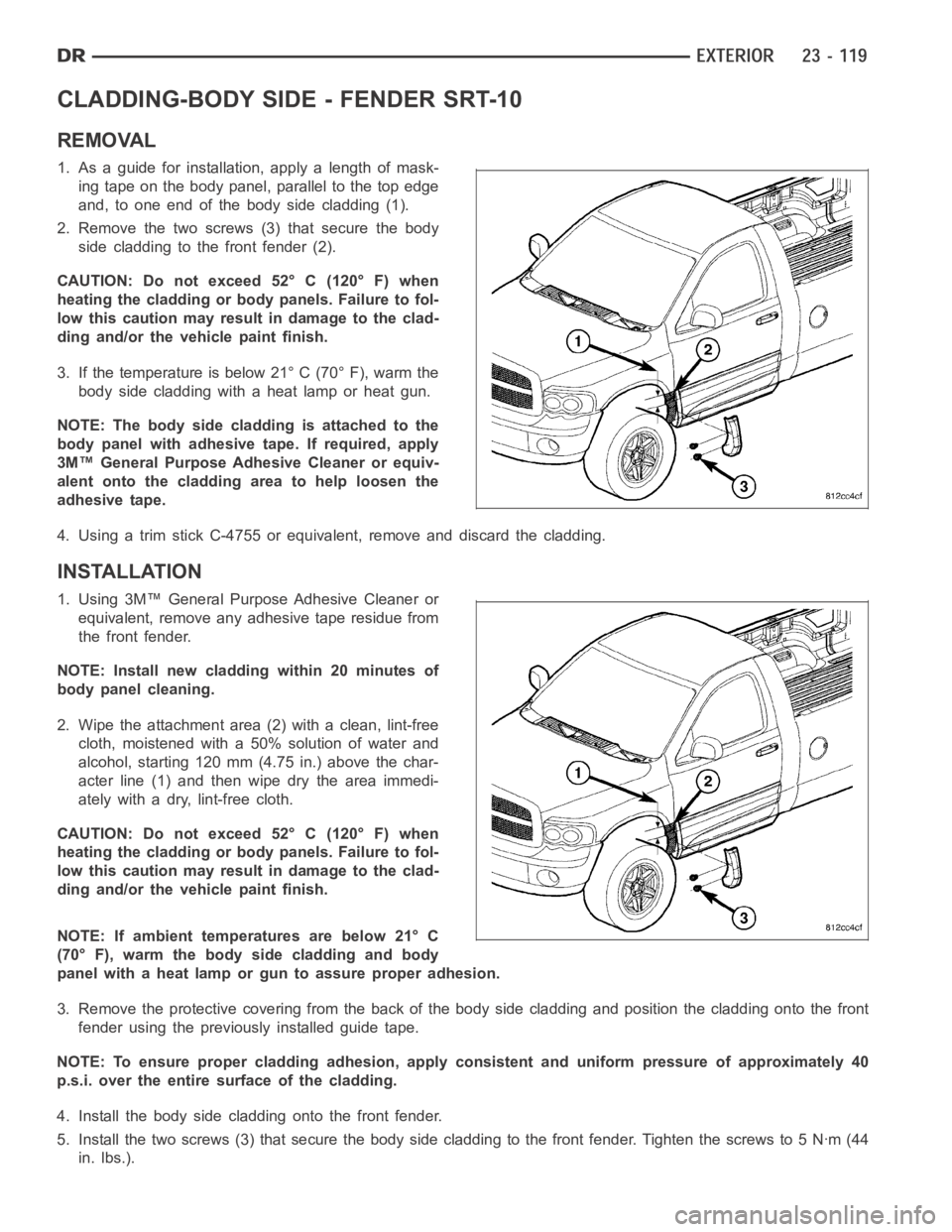

1. As a guide for installation, apply a length of mask-

ing tape on the body panel, parallel to the top edge

and, to one end of the body side cladding (1).

2. Remove the two screws (3) that secure the body

side cladding to the front fender (2).

CAUTION: Do not exceed 52° C (120° F) when

heating the cladding or body panels. Failure to fol-

low this caution may result in damage to the clad-

ding and/or the vehicle paint finish.

3. If the temperature is below 21° C (70° F), warm the

body side cladding with a heat lamp or heat gun.

NOTE: The body side cladding is attached to the

body panel with adhesive tape. If required, apply

3M™ General Purpose Adhesive Cleaner or equiv-

alent onto the cladding area to help loosen the

adhesive tape.

4. Using a trim stick C-4755 or equivalent, remove and discard the cladding.

INSTALLATION

1. Using 3M™ General Purpose Adhesive Cleaner or

equivalent, remove any adhesive tape residue from

the front fender.

NOTE: Install new cladding within 20 minutes of

body panel cleaning.

2. Wipe the attachment area (2) with a clean, lint-free

cloth, moistened with a 50% solution of water and

alcohol, starting 120 mm (4.75 in.) above the char-

acterline(1)andthenwipedrytheareaimmedi-

ately with a dry, lint-free cloth.

CAUTION: Do not exceed 52° C (120° F) when

heating the cladding or body panels. Failure to fol-

low this caution may result in damage to the clad-

ding and/or the vehicle paint finish.

NOTE: If ambient temperatures are below 21° C

(70° F), warm the body side cladding and body

panel with a heat lamp or gun to assure proper adhesion.

3. Remove the protective covering from the back of the body side cladding and position the cladding onto the front

fender using the previously installed guide tape.

NOTE: To ensure proper cladding adhesion, apply consistent and uniform pressure of approximately 40

p.s.i. over the entire surface of the cladding.

4. Install the body side cladding onto the front fender.

5. Install the two screws (3) that secure the body side cladding to the frontfender. Tighten the screws to 5 Nꞏm (44

in. lbs.).

Page 4842 of 5267

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

page page

HVAC - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

B10AA–RIGHT BLEND DOOR CONTROL

CIRCUIT LOW (DUAL-ZONE).................. 4

B10AB–RIGHT BLEND DOOR CONTROL

CIRCUIT HIGH (DUAL-ZONE)................. 8

B10AC–RIGHT BLEND DOOR CONTROL

CIRCUIT OPEN (DUAL-ZONE)................ 11

B10AD–RIGHT BLEND DOOR TRAVEL

RANGE TOO SMALL (DUAL-ZONE)........... 14

B10AE–RIGHT BLEND DOOR TRAVEL

RANGE TOO LARGE (DUAL-ZONE).......... 16

B10A2–LEFT BLEND DOOR CONTROL

CIRCUIT/PERFORMANCE (DUAL-ZONE)...... 18

B10A3–LEFT BLEND DOOR CONTROL

CIRCUIT LOW (DUAL-ZONE)................. 19

B10A4–LEFT BLEND DOOR CONTROL

CIRCUIT HIGH (DUAL-ZONE)................ 23

B10A5–LEFT BLEND DOOR CONTROL

CIRCUIT OPEN (DUAL-ZONE)................ 26

B10A6–LEFT BLEND DOOR TRAVEL

RANGE TOO SMALL (DUAL-ZONE)........... 29

B10A7–LEFT BLEND DOOR TRAVEL

RANGE TOO LARGE (DUAL-ZONE).......... 31

B10A9–RIGHT BLEND DOOR CONTROL

CIRCUIT/PERFORMANCE (DUAL-ZONE)...... 33

B10BE–CONDENSER FAN CONTROL

CIRCUIT LOW (TIPM)....................... 34

B10BF–CONDENSER FAN CONTROL

CIRCUIT HIGH (TIPM)....................... 37

B10B2–A/C COOL DOWN TEST

PERFORMANCE (DUAL-ZONE).............. 40

B10C0–CONDENSER FAN CONTROL

CIRCUIT OPEN (TIPM)...................... 42

B10EC–BLOWER MOTOR CONTROL

CIRCUIT OVERCURRENT (TIPM)............. 45B10EE–CONDENSER FAN CONTROL

CIRCUIT OVERCURRENT (TIPM)............. 50

B10E9–BLOWER MOTOR CONTROL

CIRCUIT LOW (TIPM)....................... 54

B104A–FLOOR/DEFROST MODE DOOR

TRAVEL RANGE TOO SMALL................ 57

B104B–FLOOR/DEFROST MODE DOOR

TRAVEL RANGE TOO LARGE................ 59

B104C–BLEND DOOR CONTROL CIRCUIT/

PERFORMANCE (SINGLE-ZONE)............ 61

B104D–BLEND DOOR CONTROL CIRCUIT

LOW (SINGLE-ZONE)....................... 62

B104E–BLEND DOOR CONTROL CIRCUIT

HIGH (SINGLE-ZONE)....................... 66

B104F–BLEND DOOR CONTROL CIRCUIT

OPEN (SINGLE-ZONE)...................... 69

B105A–RECIRCULATION DOOR CONTROL

CIRCUIT HIGH (DUAL-ZONE)................ 72

B105A–RECIRCULATION DOOR CONTROL

CIRCUIT HIGH (SINGLE-ZONE).............. 75

B105B–RECIRCULATION DOOR CONTROL

CIRCUIT OPEN (DUAL-ZONE)................ 78

B105B–RECIRCULATION DOOR CONTROL

CIRCUIT OPEN (SINGLE-ZONE).............. 81

B105C–RECIRCULATION DOOR TRAVEL

RANGE TOO SMALL........................ 84

B105D–RECIRCULATION DOOR TRAVEL

RANGE TOO LARGE........................ 86

B105F–CLIMATE CONTROL MOTOR(S)

COMMON 1 CONTROL CIRCUIT LOW

(DUAL-ZONE)............................... 88

B105F–CLIMATE CONTROL MOTOR(S)

COMMON 1 CONTROL CIRCUIT LOW

(SINGLE-ZONE)............................. 96

B1001–A/C SWITCH REQUEST INPUT

CIRCUIT LOW (SINGLE-ZONE).............. 103

Page 5046 of 5267

*HVAC SYSTEM TEST

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The HVAC System Test provides a starting point in the diagnostic process byidentifying the appropriate diagnostic

procedure or system test to perform when diagnosing a given symptom, condition, or DTC. It also provides a means

for testing the entire HVAC system byutilizing the A/C-heater control’s On-Board System Tests. The On-Board Sys-

tem Tests can also assist in diagnosing stored DTCs. (Refer to 24 - HEATING &AIR CONDITIONING - DIAGNOSIS

AND TESTING) for additional information about on-board diagnostics.

Diagnostic Test

1.HVAC SYSTEM TEST

NOTE: Diagnose and repair all active DTCs before diagnosing and repairingstored DTCs.

Make a selection based on the symptom, condition, or DTC that you want to diagnose.

For Any Active DTC

Refer to the Table of Contents in this Section for a complete list of HVAC related symptoms.

Scan Tool Indicates HVAC Not Active On Bus

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING) for no

response related diagnostic procedures.

Blower Motor Inoperative

Refer to *Blower Motor Inoperative in this Section.

Complete HVAC System Test

Go To 2

A/C System Performance Test

Go To 2

Mode Switch & Door Actuator Ckt Test

Go To 3

Actuator DTC Detection Test

Go To 4

Actuator Calibration Test

Go To 5

2.A/C SYSTEM PERFORMANCE TEST

NOTE: The following are prerequisites of the Cooldown Test. Verify each ofthe following before running the

test:

If active, diagnose and repair Evaporator Temperature Sensor related DTCs before proceeding. Refer to

the Table of Contents in this Section for a complete list of HVAC related symptoms.

Verify that the refrigerant system has an adequate charge. Check and repair as necessary before pro-

ceeding. (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - DIAGNOSIS ANDTESTING).

Verify that the blower motor operates correctly in all speeds. Diagnose and repair all blower related faults

before proceeding.

Verify that the work area ambient temperature is above 15.6°C (60°F) before proceeding. Move the vehicle

to a warmer work area if necessary.

Verify that the evaporator temperature is above 13°C (55°F) before proceeding.

Verify that the Mode Select control is set to the panel position.

Verify that the A/C compressor is not running. If the compressor is running, turn the A/C off and allow the

evaporator to warm up before proceeding.

NOTE: Running the AC Cooldown test will cause the A/C status indicator to flash.

NOTE: One or more status messages will display on the scan tool after running the Cooldown Test. These

messages will clear after paging back out of this test function. Therefore, it is important to note all mes-

sages before doing so.

Start the engine.

Turn the Blower control to the high speed position.

Page 5049 of 5267

page page

HVAC - SERVICE INFORMATION

DESCRIPTION ............................... 209

OPERATION ................................. 209

DIAGNOSIS AND TESTING

HEATING-A/C SYSTEM DIAGNOSTICS ...... 211

A/C PERFORMANCE ....................... 212

HEATER PERFORMANCE .................. 215

SPECIFICATIONS

A/C SYSTEM .............................. 216TORQUE .................................. 216

SPECIAL TOOLS

A/C SYSTEM .............................. 218

CONTROLS............................219

DISTRIBUTION.........................253

PLUMBING............................284

Page 5050 of 5267

HVAC - SERVICE INFORMATION

DESCRIPTION

A manually controlled single zone type heating-air conditioning system or a manually controlleddualzonetypeheat-

ing-air conditioning system is available on this model.

To maintain the performance level of the heating, ventilation and air conditioning (HVAC) system, the engine cooling

system must be properly maintained. The use of a bug screen is not recommended. Any obstructions in front of the

radiator or A/C condenser will reduce the performance of the A/C and enginecooling systems.

The engine cooling system includes the radiator, thermostat, radiator hoses and the engine coolant pump. Refer to

7 - Cooling for more information before opening or attempting any service to the engine cooling system.

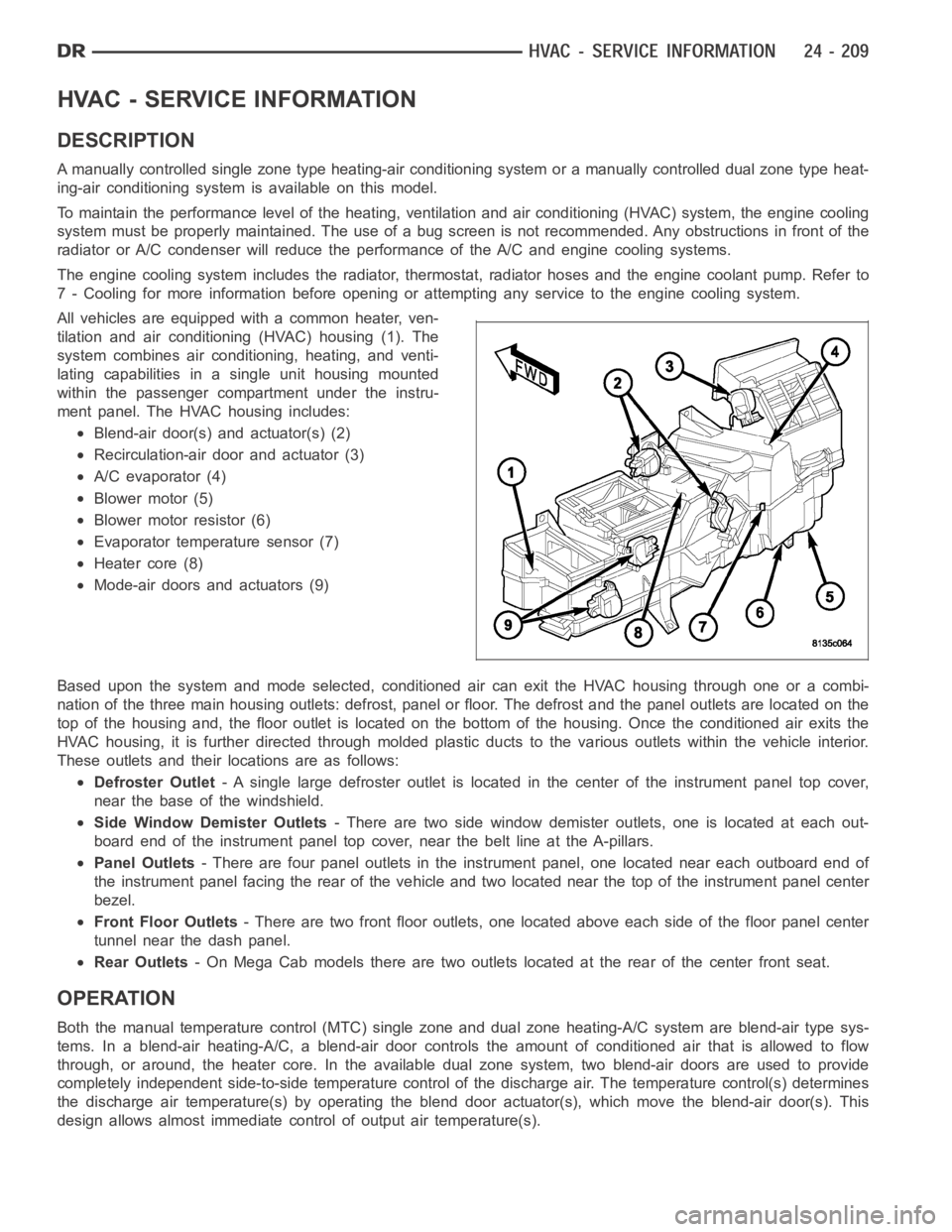

All vehicles are equipped with a common heater, ven-

tilation and air conditioning (HVAC) housing (1). The

system combines air conditioning, heating, and venti-

lating capabilities in a single unit housing mounted

within the passenger compartment under the instru-

ment panel. The HVAC housing includes:

Blend-air door(s) and actuator(s) (2)

Recirculation-air door and actuator (3)

A/C evaporator (4)

Blower motor (5)

Blower motor resistor (6)

Evaporator temperature sensor (7)

Heater core (8)

Mode-air doors and actuators (9)

Based upon the system and mode selected, conditioned air can exit the HVAC housing through one or a combi-

nation of the three main housing outlets: defrost, panel or floor. The defrost and the panel outlets are located on the

top of the housing and, the floor outlet is located on the bottom of the housing. Once the conditioned air exits the

HVAC housing, it is further directed through molded plastic ducts to the various outlets within the vehicle interior.

These outlets and their locations are as follows:

Defroster Outlet- A single large defroster outlet is located in the center of the instrumentpanel top cover,

near the base of the windshield.

Side Window Demister Outlets- There are two side window demister outlets, one is located at each out-

board end of the instrument panel top cover, near the belt line at the A-pillars.

Panel Outlets- There are four panel outlets in the instrument panel, one located near each outboard end of

the instrument panel facing the rear of the vehicle and two located near thetop of the instrument panel center

bezel.

Front Floor Outlets- There are two front floor outlets, one located above each side of the floorpanel center

tunnel near the dash panel.

Rear Outlets- On Mega Cab models there are two outlets located at the rear of the center front seat.

OPERATION

Both the manual temperature control (MTC) single zone and dual zone heating-A/C system are blend-air type sys-

tems. In a blend-air heating-A/C, a blend-air door controls the amount of conditioned air that is allowed to flow

through, or around, the heater core.In the available dual zone system, twoblend-air doors are used to provide

completely independent side-to-side temperature control of the discharge air. The temperature control(s) determines

the discharge air temperature(s) by operating the blend door actuator(s), which move the blend-air door(s). This

design allows almost immediate control of output air temperature(s).

Page 5051 of 5267

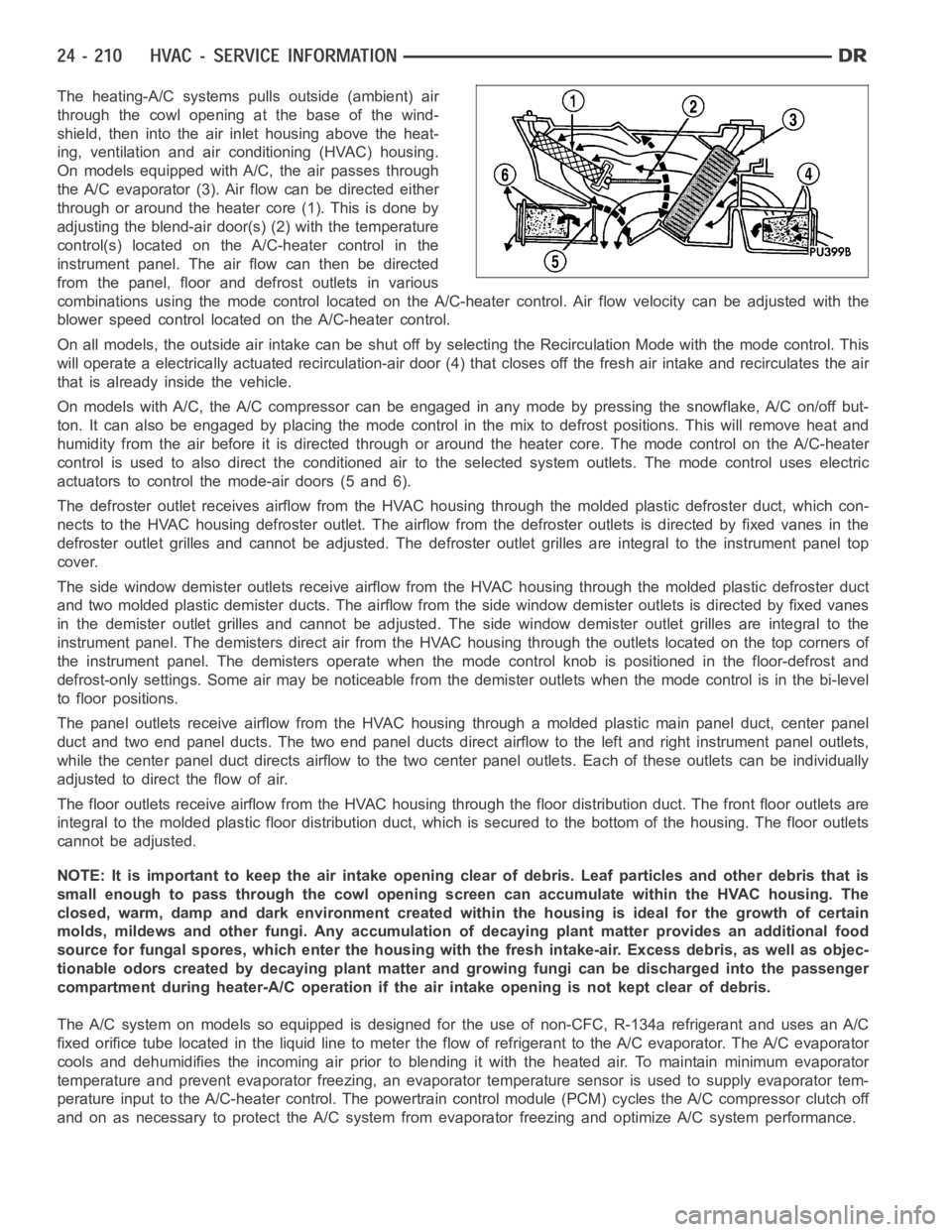

The heating-A/C systems pulls outside (ambient) air

through the cowl opening at the base of the wind-

shield, then into the air inlet housing above the heat-

ing, ventilation and air conditioning (HVAC) housing.

On models equipped with A/C, the air passes through

the A/C evaporator (3). Air flow can be directed either

through or around the heater core (1). This is done by

adjusting the blend-air door(s) (2) with the temperature

control(s) located on the A/C-heater control in the

instrument panel. The air flow can then be directed

from the panel, floor and defrost outlets in various

combinations using the mode control located on the A/C-heater control. Air flow velocity can be adjusted with the

blower speed control located on the A/C-heater control.

On all models, the outside air intake can be shut off by selecting the Recirculation Mode with the mode control. This

will operate a electrically actuated recirculation-air door (4) that closes off the fresh air intake and recirculates the air

that is already inside the vehicle.

On models with A/C, the A/C compressor can be engaged in any mode by pressingthe snowflake, A/C on/off but-

ton. It can also be engaged by placing the mode control in the mix to defrost positions. This will remove heat and

humidity from the air before it is directed through or around the heater core. The mode control on the A/C-heater

control is used to also direct the conditioned air to the selected system outlets. The mode control uses electric

actuators to control the mode-air doors (5 and 6).

The defroster outlet receives airflow from the HVAC housing through the molded plastic defroster duct, which con-

nects to the HVAC housing defroster outlet. The airflow from the defrosteroutlets is directed by fixed vanes in the

defroster outlet grilles and cannot be adjusted. The defroster outlet grilles are integral to the instrument panel top

cover.

The side window demister outlets receive airflow from the HVAC housing through the molded plastic defroster duct

and two molded plastic demister ducts. The airflow from the side window demister outlets is directed by fixed vanes

in the demister outlet grilles and cannot be adjusted. The side window demister outlet grilles are integral to the

instrument panel. The demisters direct air from the HVAC housing through the outlets located on the top corners of

the instrument panel. The demisters operate when the mode control knob is positioned in the floor-defrost and

defrost-only settings. Some air may be noticeable from the demister outlets when the mode control is in the bi-level

to floor positions.

The panel outlets receive airflow from the HVAC housing through a molded plastic main panel duct, center panel

duct and two end panel ducts. The two end panel ducts direct airflow to the left and right instrument panel outlets,

while the center panel duct directs airflow to the two center panel outlets. Each of these outlets can be individually

adjusted to direct the flow of air.

The floor outlets receive airflow from the HVAC housing through the floor distribution duct. The front floor outlets are

integral to the molded plastic floor distribution duct, which is secured to the bottom of the housing. The floor outlets

cannot be adjusted.

NOTE: It is important to keep the air intake opening clear of debris. Leaf particles and other debris that is

small enough to pass through the cowl opening screen can accumulate withinthe HVAC housing. The

closed, warm, damp and dark environment created within the housing is ideal for the growth of certain

molds, mildews and other fungi. Any accumulation of decaying plant matterprovides an additional food

source for fungal spores, which enter the housing with the fresh intake-air. Excess debris, as well as objec-

tionable odors created by decaying plant matter and growing fungi can be discharged into the passenger

compartment during heater-A/C operation if the air intake opening is not kept clear of debris.

The A/C system on models so equipped is designed for the use of non-CFC, R-134a refrigerant and uses an A/C

fixedorificetubelocatedintheliquidlinetometertheflowofrefrigerant to the A/C evaporator. The A/C evaporator

cools and dehumidifies the incoming air prior to blending it with the heated air. To maintain minimum evaporator

temperature and prevent evaporator freezing, an evaporator temperaturesensor is used to supply evaporator tem-

perature input to the A/C-heater control. The powertrain control module (PCM) cycles the A/C compressor clutch off

and on as necessary to protect the A/C system from evaporator freezing and optimize A/C system performance.

Page 5052 of 5267

DIAGNOSIS AND TESTING

HEATING-A/C SYSTEM DIAGNOSTICS

CAUTION: Do not exchange A/C Heater Controls from vehicle to vehicle. Software versions differ between

models and model years. Installing an A/C Heater Control with software that is incompatible for a given

vehicle can result in either improper or failed HVAC system operation.

ON-BOARD DIAGNOSTICS

The A/C-heater control communicates on the controller area network (CAN)B bus and is fully addressable with a

scan tool.

The A/C-heater control’s primary means of fault detection is through active and stored diagnostic trouble codes

(DTCs). Active DTCs are those which currently exist in the system. The condition causing the fault must be repaired

in order to clear this type of DTC. Stored DTCs are those which occurred in the system since the A/C-heater control

received the last clear diagnostic info message. DTCs must be read with a scan tool. Refer to 24 - HVAC - Elec-

trical Diagnostics for HVAC DTC diagnostic test procedures.

The A/C-heater control’s secondary means of fault detection is through system tests. These tests include the HVAC

System Test, the A/C Cooldown Test, Actuator Calibration, and Actuator DTC Detection. Refer to System Tests in

this Section for a detailed description of each test.

SYSTEM TESTS

HVAC System Test

The HVAC System Test, found in 24 - HVAC - Electrical Diagnostics, providesa starting point in the diagnostic

process by identifying the appropriate diagnostic procedure or system test to perform when diagnosing a given

symptom, condition, or DTC. It also provides a means for testing the entireHVAC system by utilizing the A/C-heater

control’s On-Board System Tests. The On-Board System Tests can also assistindiagnosingstoredDTCs.

A/CCOOLDOWNTEST

The A/C Cooldown Test:

is actuated with a scan tool.

tests A/C system performance based on evaporator temperature sensor input.

will fail if evaporator temperature isbelow 13°C (55°F) when initiating the test.

will pass if the evaporator temperature drops 11°C (20°F).

indicates an outcome by displaying one or more test status messages on the scan tool. These test status

messages will clear after paging back out of this test function. Therefore, is it important to note all of the mes-

sages before doing so.

will cause the A/C status indicator to flash while the test is running.

ACTUATOR CALIBRATION FUNCTION

The Actuator Calibration function:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

homes and repositions door actuators.

monitors for door span faults. Door span faults (XXX Door Travel Range Too Large or XXX Door Travel Range

Too Small) will only display after calibration.

will cause the electric backlight (EBL) status indicator (if equipped) toflash while the test is running.

Page 5053 of 5267

ACTUATOR DTC DETECTION TEST — DUAL-ZONE

The Actuator DTC Detection Test:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

supplements the continuous diagnostics on the actuator drive system.

monitors for shorted actuator circuits allowing service to easily diagnose and troubleshoot up to three simul-

taneous shorts. Shorted actuator circuit faults (XXX Control Circuit High or XXX Control Circuit Low) will only

display after running the Actuator DTC Detection Test.

After repairing each DTC, cycle the ignition switch, and then run the Actuator DTC Detection Test again to ensure

that no new DTCs exist. If multiple DTCs are present, beginning with the passenger blend door, diagnose and repair

all short high faults and then short low faults. When the test returns passed, clear all faults and run the Actuator

Calibration function as a final check of system health.

ACTUATOR DTC DETECTION TEST — SINGLE-ZONE

The Actuator DTC Detection Test:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

supplements the continuous diagnostics on the actuator drive system.

monitors for shorted actuator circuits allowing service to easily diagnose and troubleshoot up to three simul-

taneous shorts. Shorted actuator circuit faults (XXX Control Circuit High or XXX Control Circuit Low) will only

display after running the Actuator DTC Detection Test.

After repairing each DTC, cycle the ignition switch, and then run the Actuator DTC Detection Test again to ensure

that no new DTCs exist. If multiple DTCs are present, beginning with the common circuit, diagnose and repair all

short high faults and then short low faults. When the test returns passed, clear all faults and run the Actuator Cal-

ibration function as a final check of system health.

A/C PERFORMANCE

The A/C system is designed to provide the passenger compartment with low temperature and low humidity air. The

A/C evaporator, located in the HVAC housing is cooled to temperatures nearthe freezing point. As warm damp air

passes over the fins of the A/C evaporator, the air transfers its heat to therefrigerant in the evaporator coils and the

moisture in the air condenses on the evaporator fins. During periods of high heat and humidity, an A/C system will

be more effective in the Recirculation mode (max-A/C). With the system in the Recirculation mode, only air from the

passenger compartment passes through the A/C evaporator. As the passenger compartment air dehumidifies, the

A/C system performance levels rise.

Humidity has an important bearing on the temperature of the air delivered to the interior of the vehicle. It is impor-

tant to understand the effect that humidity has on the performance of the A/C system. When humidity is high, the

A/C evaporator has to perform a double duty. It must lower the air temperature, and it must lower the temperature

of the moisture in the air that condenses on the evaporator fins. Condensing the moisture in the air transfers heat

energy into the evaporator fins and coils. This reduces the amount of heat the A/C evaporator can absorb from the

air. High humidity greatly reduces the ability of the A/C evaporator to lower the temperature of the air.

However, evaporator capacity used to reduce the amount of moisture in the air is not wasted. Wringing some of the

moisture out of the air entering the vehicle adds to the comfort of the passengers. Although, an owner may expect

too much from their A/C system on humid days. A performance test is the best way to determine whether the sys-

tem is performing up to design standards. This test also provides valuableclues as to the possible cause of trouble

with the A/C system. The ambient air temperature in the location where the vehicle will be tested must be a mini-

mum of 21° C (70° F) for this test.

A/C PERFORMANCE TEST

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.