key DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2428 of 5267

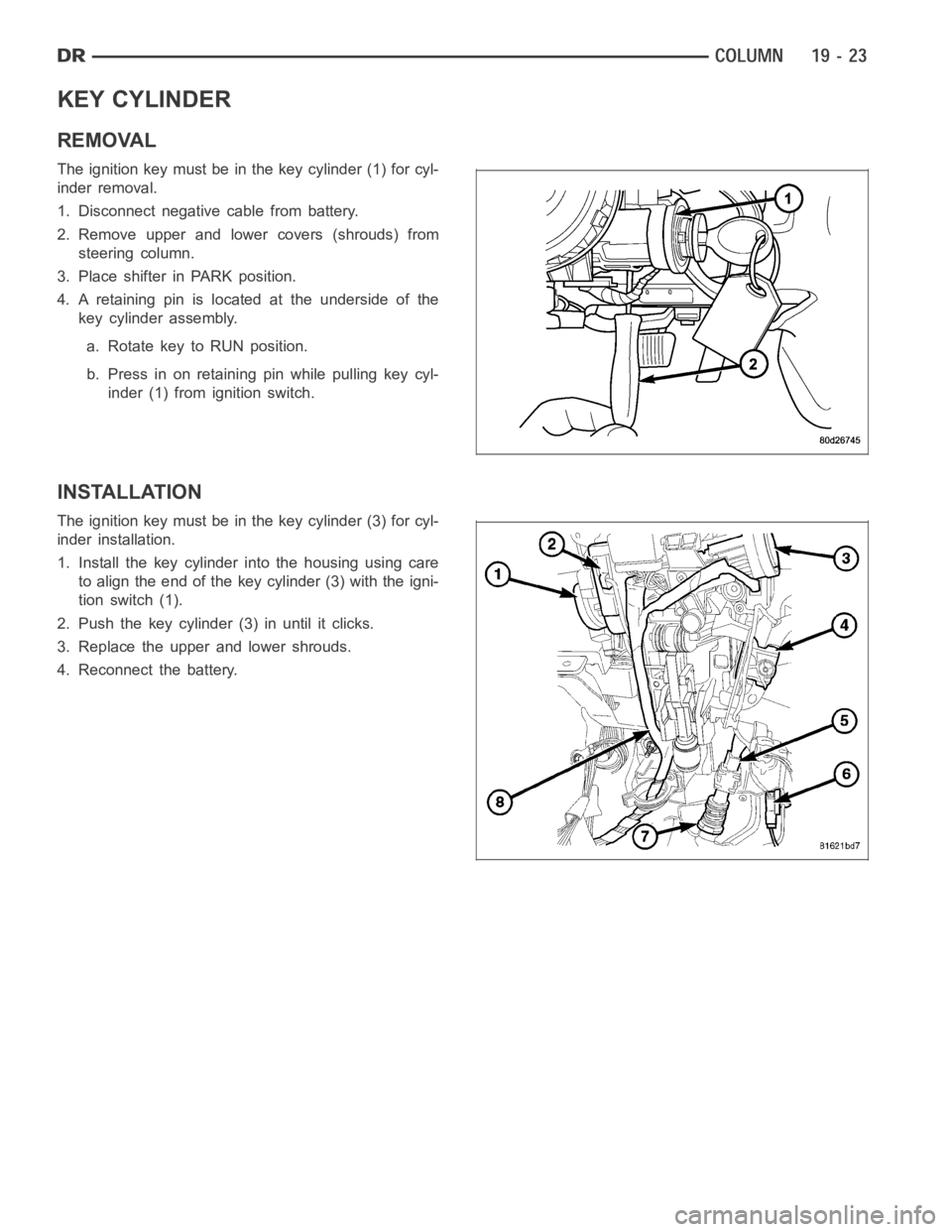

KEY CYLINDER

REMOVAL

The ignition key must be in the key cylinder (1) for cyl-

inder removal.

1. Disconnect negative cable from battery.

2. Remove upper and lower covers (shrouds) from

steering column.

3. Place shifter in PARK position.

4. A retaining pin is located at the underside of the

key cylinder assembly.

a. Rotate key to RUN position.

b. Press in on retaining pin while pulling key cyl-

inder (1) from ignition switch.

INSTALLATION

The ignition key must be in the key cylinder (3) for cyl-

inder installation.

1. Install the key cylinder into the housing using care

to align the end of the key cylinder (3) with the igni-

tion switch (1).

2. Push the key cylinder (3) in until it clicks.

3. Replace the upper and lower shrouds.

4. Reconnect the battery.

Page 2435 of 5267

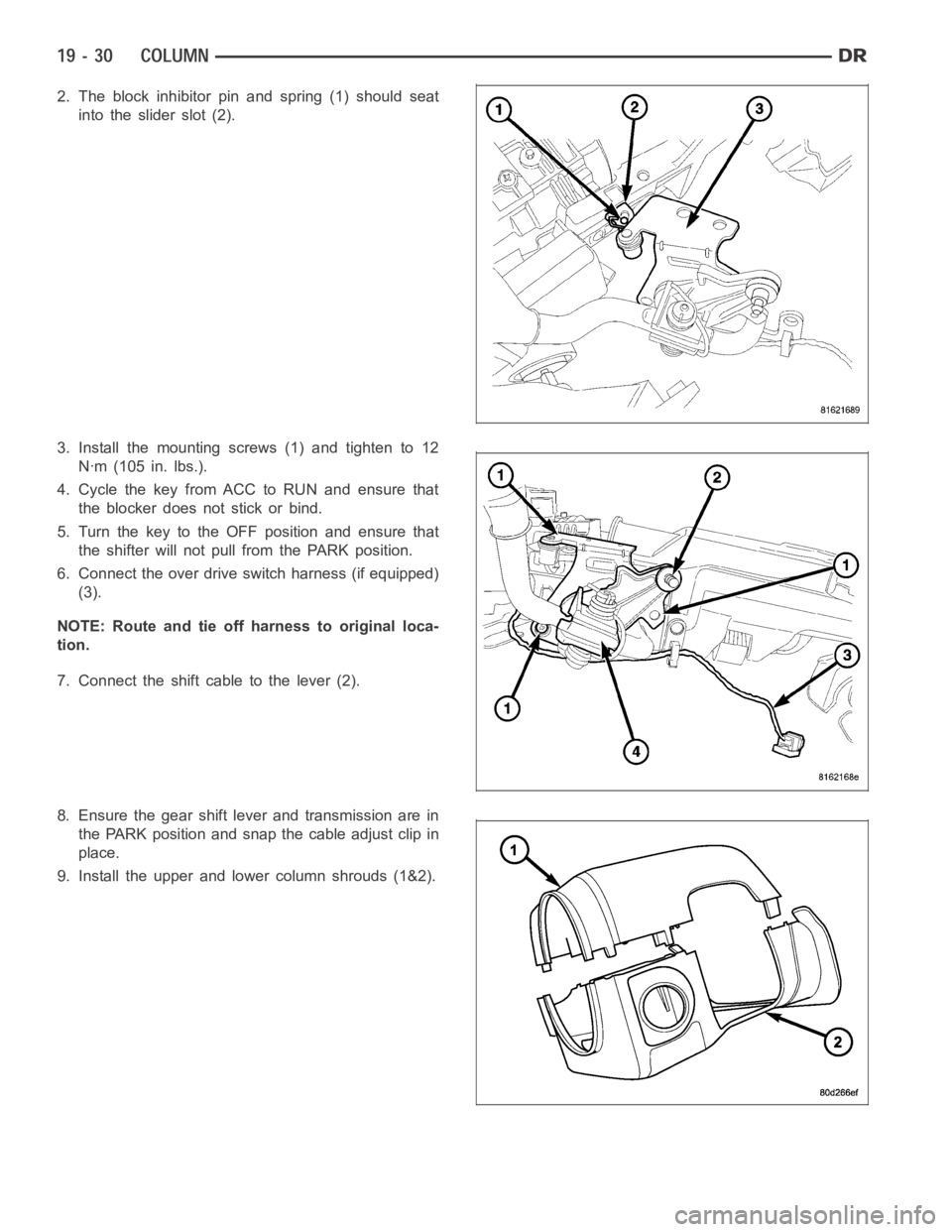

2. The block inhibitor pin and spring (1) should seat

into the slider slot (2).

3. Install the mounting screws (1) and tighten to 12

Nꞏm (105 in. lbs.).

4. Cycle the key from ACC to RUN and ensure that

the blocker does not stick or bind.

5. Turn the key to the OFF position and ensure that

the shifter will not pull from the PARK position.

6. Connect the over drive switch harness (if equipped)

(3).

NOTE: Route and tie off harness to original loca-

tion.

7. Connect the shift cable to the lever (2).

8. Ensure the gear shift lever and transmission are in

the PARK position and snap the cable adjust clip in

place.

9. Install the upper and lower column shrouds (1&2).

Page 2437 of 5267

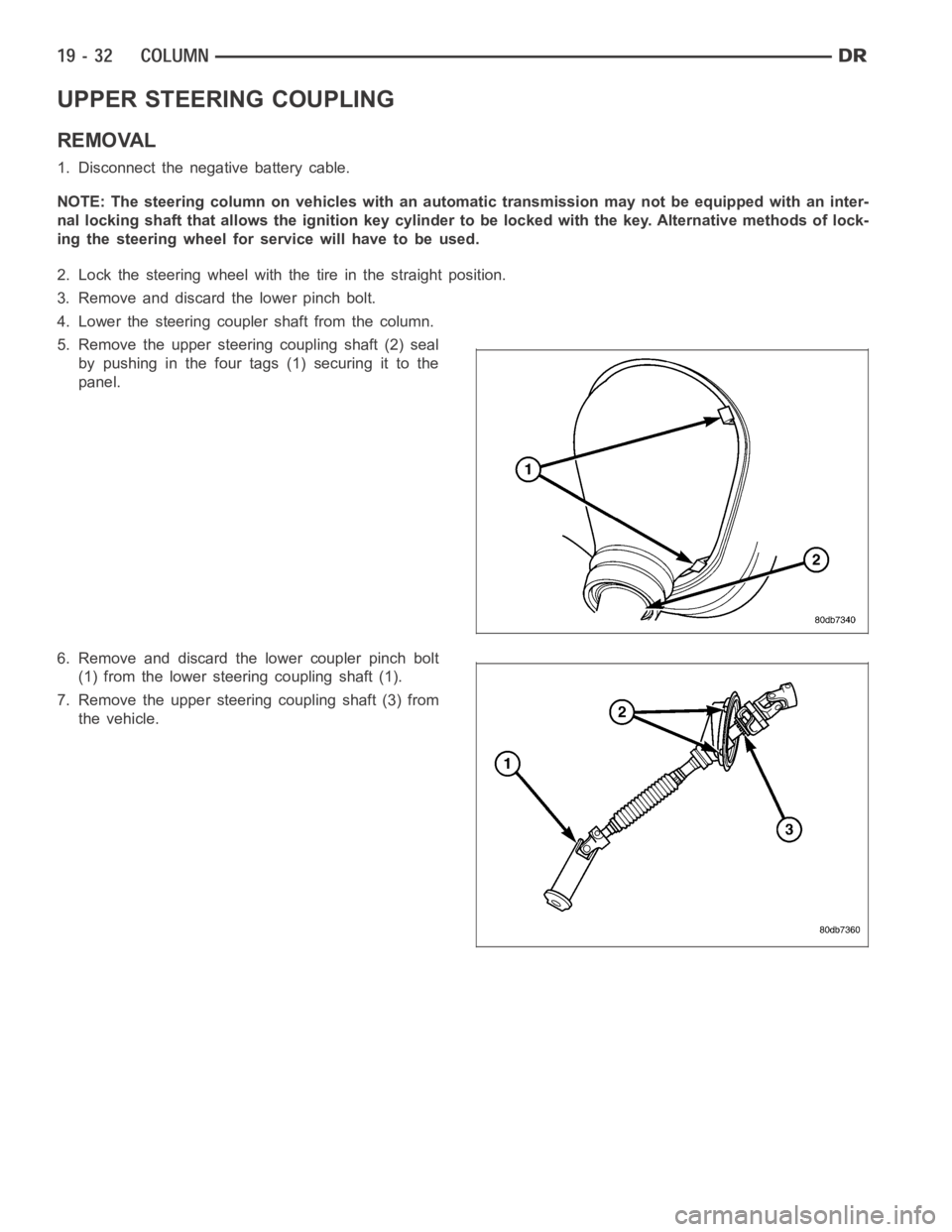

UPPER STEERING COUPLING

REMOVAL

1. Disconnect the negative battery cable.

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

2. Lock the steering wheel with the tire in the straight position.

3. Remove and discard the lower pinch bolt.

4. Lower the steering coupler shaft from the column.

5. Remove the upper steering coupling shaft (2) seal

by pushing in the four tags (1) securing it to the

panel.

6. Remove and discard the lower coupler pinch bolt

(1) from the lower steering coupling shaft (1).

7. Remove the upper steering coupling shaft (3) from

the vehicle.

Page 2439 of 5267

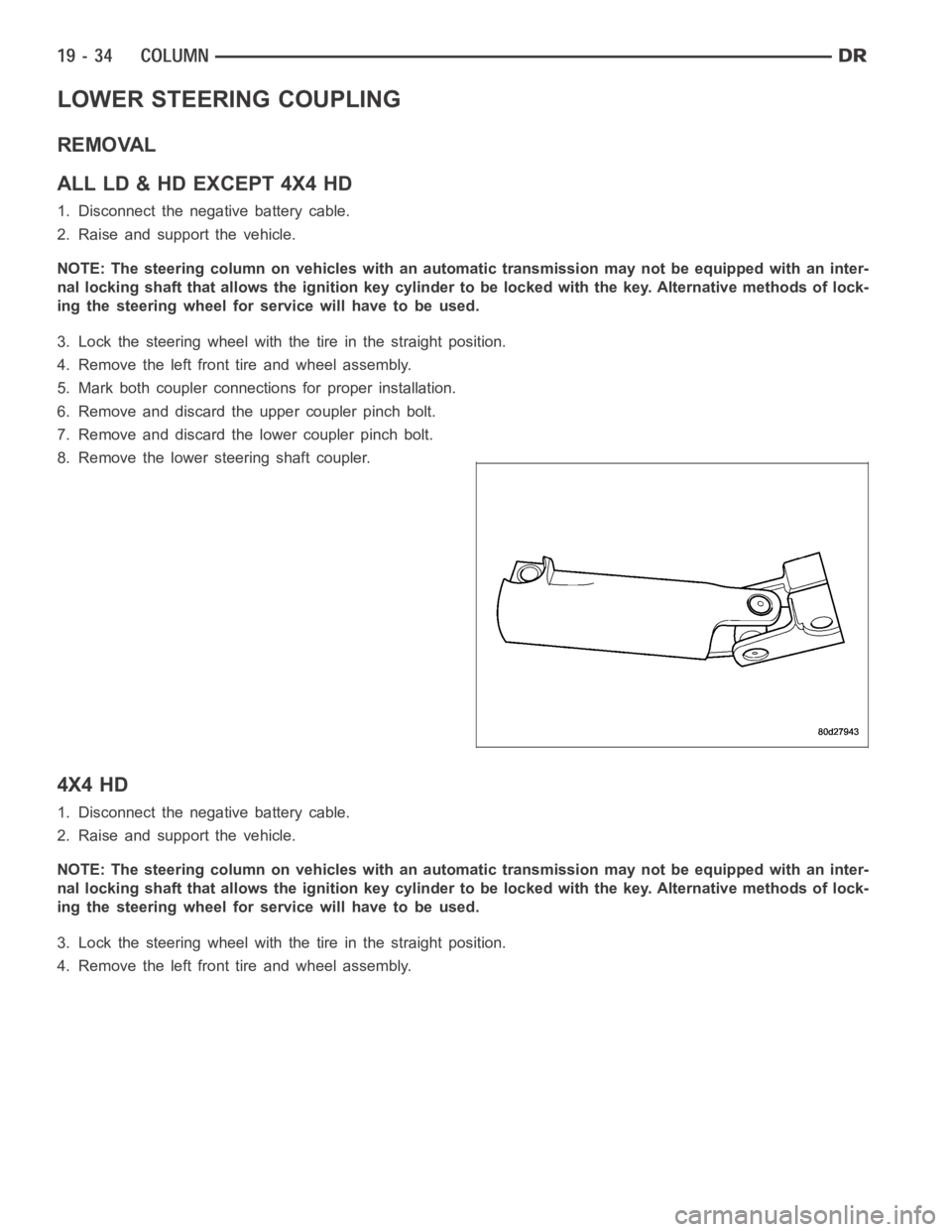

LOWER STEERING COUPLING

REMOVAL

ALLLD&HDEXCEPT4X4HD

1. Disconnect the negative battery cable.

2. Raise and support the vehicle.

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

3. Lock the steering wheel with the tire in the straight position.

4. Remove the left front tire and wheel assembly.

5. Mark both coupler connections for proper installation.

6. Remove and discard the upper coupler pinch bolt.

7. Remove and discard the lower coupler pinch bolt.

8. Remove the lower steering shaft coupler.

4X4 HD

1. Disconnect the negative battery cable.

2. Raise and support the vehicle.

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

3. Lock the steering wheel with the tire in the straight position.

4. Remove the left front tire and wheel assembly.

Page 2444 of 5267

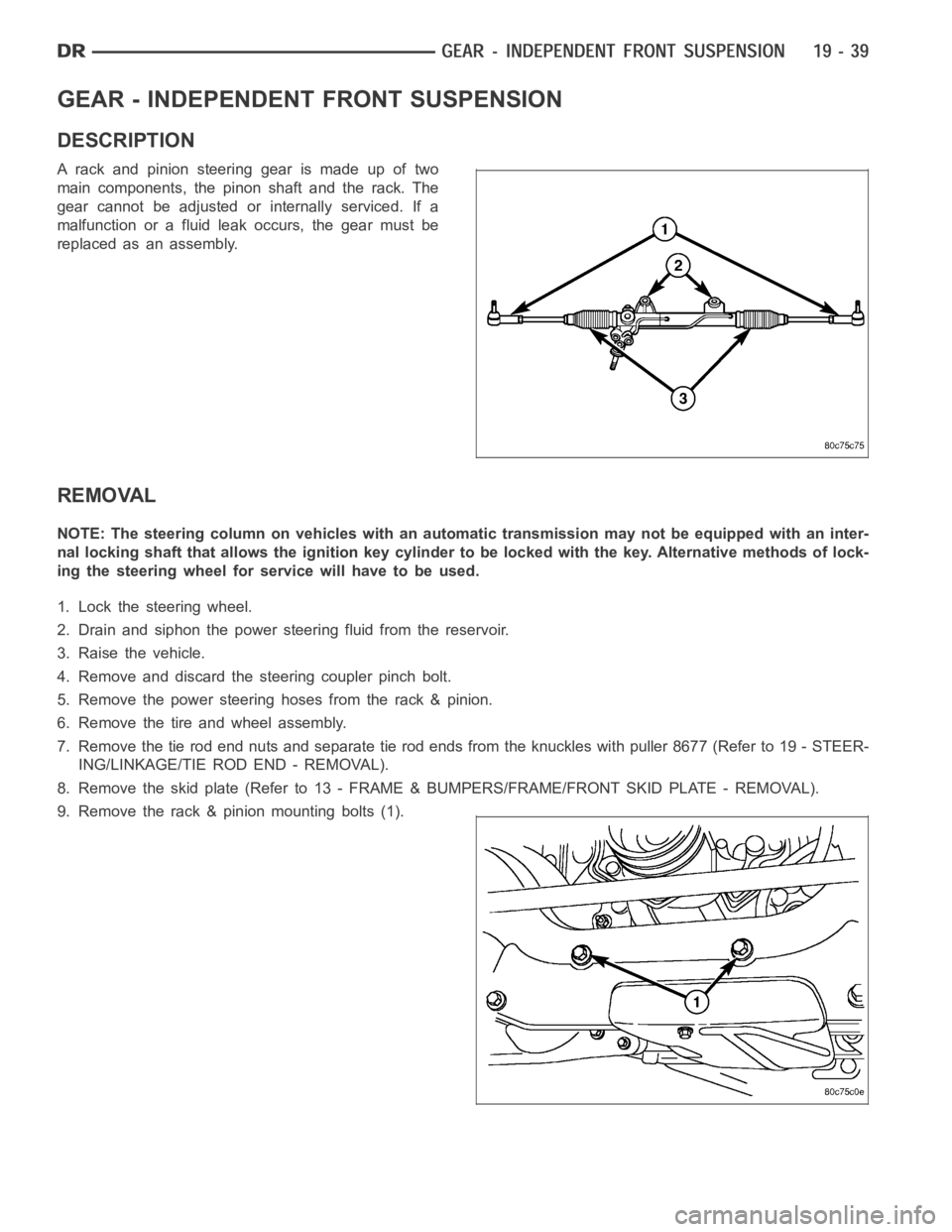

GEAR - INDEPENDENT FRONT SUSPENSION

DESCRIPTION

A rack and pinion steering gear is made up of two

main components, the pinon shaft and the rack. The

gear cannot be adjusted or internally serviced. If a

malfunction or a fluid leak occurs, the gear must be

replaced as an assembly.

REMOVAL

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

1. Lock the steering wheel.

2. Drain and siphon the power steering fluid from the reservoir.

3. Raise the vehicle.

4. Remove and discard the steering coupler pinch bolt.

5. Remove the power steering hoses from the rack & pinion.

6. Remove the tire and wheel assembly.

7. Remove the tie rod end nuts and separate tie rod ends from the knuckles withpuller8677(Referto19-STEER-

ING/LINKAGE/TIE ROD END - REMOVAL).

8. Remove the skid plate (Refer to 13 - FRAME & BUMPERS/FRAME/FRONT SKID PLATE - REMOVAL).

9. Remove the rack & pinion mounting bolts (1).

Page 2449 of 5267

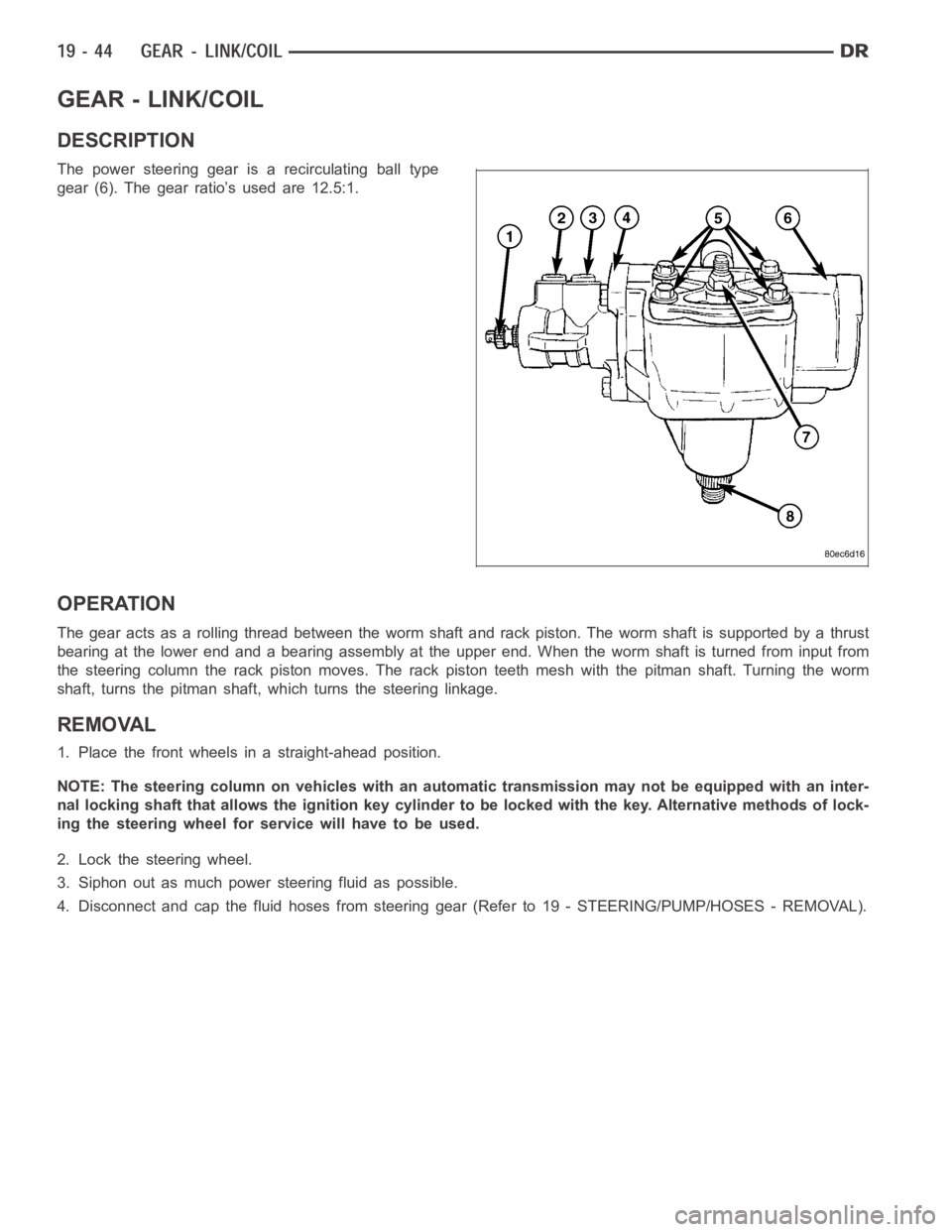

GEAR - LINK/COIL

DESCRIPTION

The power steering gear is a recirculating ball type

gear (6). The gear ratio’s used are 12.5:1.

OPERATION

The gear acts as a rolling thread between the worm shaft and rack piston. Theworm shaft is supported by a thrust

bearing at the lower end and a bearing assembly at the upper end. When the worm shaft is turned from input from

the steering column the rack piston moves. The rack piston teeth mesh with the pitman shaft. Turning the worm

shaft, turns the pitman shaft, which turns the steering linkage.

REMOVAL

1. Place the front wheels in a straight-ahead position.

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

2. Lock the steering wheel.

3. Siphon out as much power steering fluid as possible.

4. Disconnect and cap the fluid hoses from steering gear (Refer to 19 - STEERING/PUMP/HOSES - REMOVAL).

Page 2739 of 5267

P0604-INTERNAL CONTROL MODULE RAM

For a complete wiring diagramRefer to Section 8W.

When Monitored:

One time after the ignition key is turned to the run position.

Set Condition:

The read value does not match the written value in any RAM location.

Possible Causes

PCM - INTERNAL ERROR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

After the controller is reset, the microprocessor checks the integrity ofeach RAM location by writing to it and read-

ing back from it. The read value should be the same as the written value. MIL on after 10 seconds of vehicle oper-

ation and transmission will be placed in limp-in.

Diagnostic Test

1.PCM - INTERNAL ERROR

If there are no possible causes remaining, view repair.

Repair

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for Ser-

vice Information Tune-ups or Service Bulletins for any possible causes that may apply. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2740 of 5267

P0605-INTERNAL CONTROL MODULE ROM

For a complete wiring diagramRefer to Section 8W.

When Monitored:

One time after the ignition key is turned to the run position.

Set Condition:

If the ROM checksum does not match a known constant.

Possible Causes

PCM - INTERNAL ERROR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

After the controller is reset, the microprocessor checksthe integrity ofthe program memory (ROM). A checksum is

calculated by adding all used bytes in the program memory. The sum should bethesameasaknownconstant

stored in memory. MIL on after 10 seconds of vehicle operation and transmission will be placed in limp-in.

Diagnostic Test

1.PCM - INTERNAL ERROR

Using the schematics as a guide, inspect the wiring and connectors. Repairas necessary. Pay particular attention

to all power and ground circuits.

If there are no possible causes remaining, view repair.

Repair

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for Ser-

vice Information Tune-ups or Service Bulletins for any possible causes that may apply. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2741 of 5267

P0613-INTERNAL TRANSMISSION PROCESSOR

For a complete wiring diagramRefer to Section 8W.

When Monitored:

After the ignition key is turned to the run position and 60 seconds thereafter.

Set Condition:

Either of the following conditions occur 3 times in less than 590 milliseconds: The watchdog line remains high

after the watchdog test or the transmission relay coil is energized and remains on after the watchdog delay

expires.

Possible Causes

PCM - INTERNAL ERROR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The internal watchdog is a separate hardware circuit which continuously monitors the microprocessor. To make sure

the transmission is operating properly, the watchdog must receive a signal from the microprocessor within a specific

time window. MIL on after 10 seconds of vehicle operation and transmissionwill be placed in limp-in.

Diagnostic Test

1.PCM - INTERNAL ERROR

Using the schematics as a guide, inspect the wiring and connectors. Repairas necessary. Pay particular attention

to all power and ground circuits.

If there are no possible causes remaining, view repair.

Repair

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. Check for Ser-

vice Information Tune-ups or Service Bulletins for any possible causes that may apply. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2801 of 5267

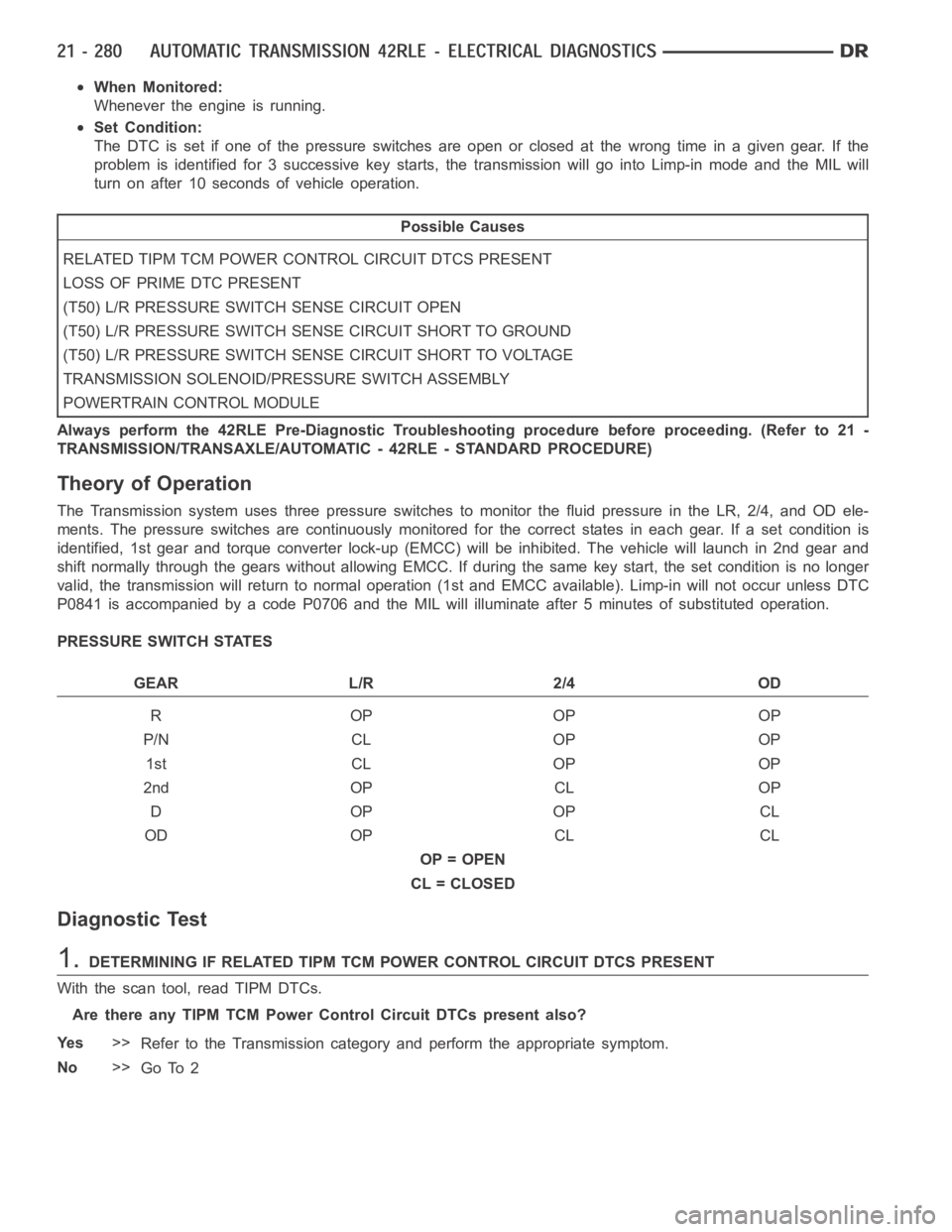

When Monitored:

Whenever the engine is running.

Set Condition:

The DTC is set if one of the pressure switches are open or closed at the wrong time in a given gear. If the

problem is identified for 3 successive key starts, the transmission will go into Limp-in mode and the MIL will

turn on after 10 seconds of vehicle operation.

Possible Causes

RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

LOSS OF PRIME DTC PRESENT

(T50) L/R PRESSURE SWITCH SENSE CIRCUIT OPEN

(T50) L/R PRESSURE SWITCH SENSE CIRCUIT SHORT TO GROUND

(T50) L/R PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The Transmission system uses three pressure switches to monitor the fluidpressure in the LR, 2/4, and OD ele-

ments. The pressure switches are continuously monitored for the correct states in each gear. If a set condition is

identified, 1st gear and torque converter lock-up (EMCC) will be inhibited. The vehicle will launch in 2nd gear and

shift normally through the gears without allowing EMCC. If during the samekey start, the set condition is no longer

valid, the transmission will return to normal operation (1st and EMCC available). Limp-in will not occur unless DTC

P0841 is accompanied by a code P0706 and the MIL will illuminate after 5 minutes of substituted operation.

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP

1st CL OP OP

2nd OP CL OP

DOPOPCL

OD OP CL CL

OP = OPEN

CL = CLOSED

Diagnostic Test

1.DETERMINING IF RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2