sensor DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4116 of 5267

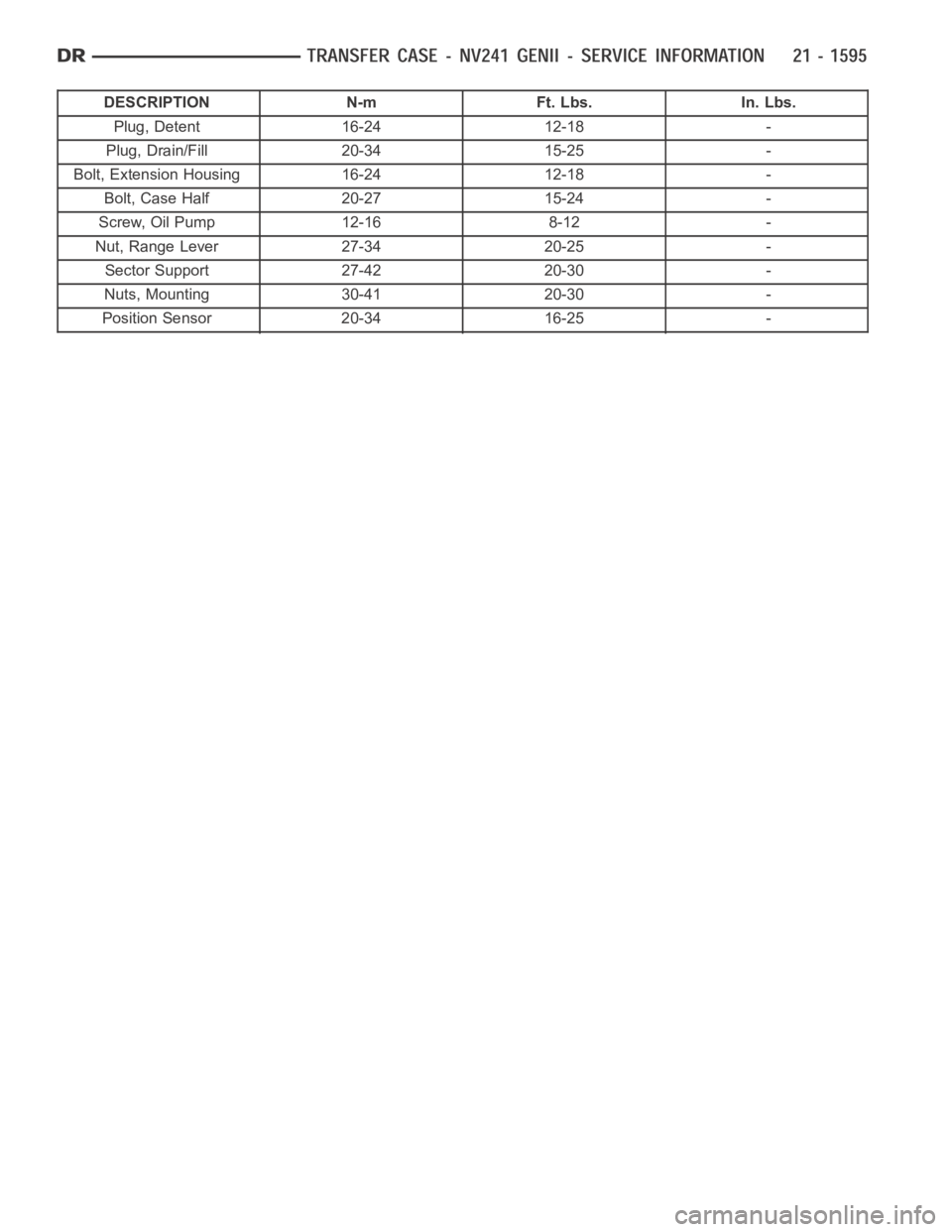

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 16-24 12-18 -

Bolt, Case Half 20-27 15-24 -

Screw, Oil Pump 12-16 8-12 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-42 20-30 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 16-25 -

Page 4126 of 5267

page page

TRANSFER CASE - NV271 - SERVICE

INFORMATION

DESCRIPTION ............................. 1606

OPERATION ............................... 1606

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV271 ............................ 1607

REMOVAL ................................. 1608

DISASSEMBLY ............................. 1608

CLEANING ................................. 1623

INSPECTION ............................... 1623

ASSEMBLY . ............................... 1626

INSTALLATION ............................. 1644

SPECIFICATIONS

TRANSFER CASE - NV271 ................ 1645

SPECIAL TOOLS

TRANSFER CASE NV271/NV273 ........... 1646

BOOT-EXTENSION HOUSING SEAL AND DUST

REMOVAL ................................. 1648INSTALLATION ............................. 1648

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL ................................... 1649

SEAL-FRONT OUTPUT SHAFT

REMOVAL ................................. 1650

INSTALLATION ............................. 1650

SENSOR-POSITION

DESCRIPTION ............................. 1651

OPERATION ............................... 1651

REMOVAL ................................. 1651

INSTALLATION ............................. 1652

LEVER-SHIFT

REMOVAL ................................. 1653

INSTALLATION ............................. 1654

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER............. 1655

Page 4129 of 5267

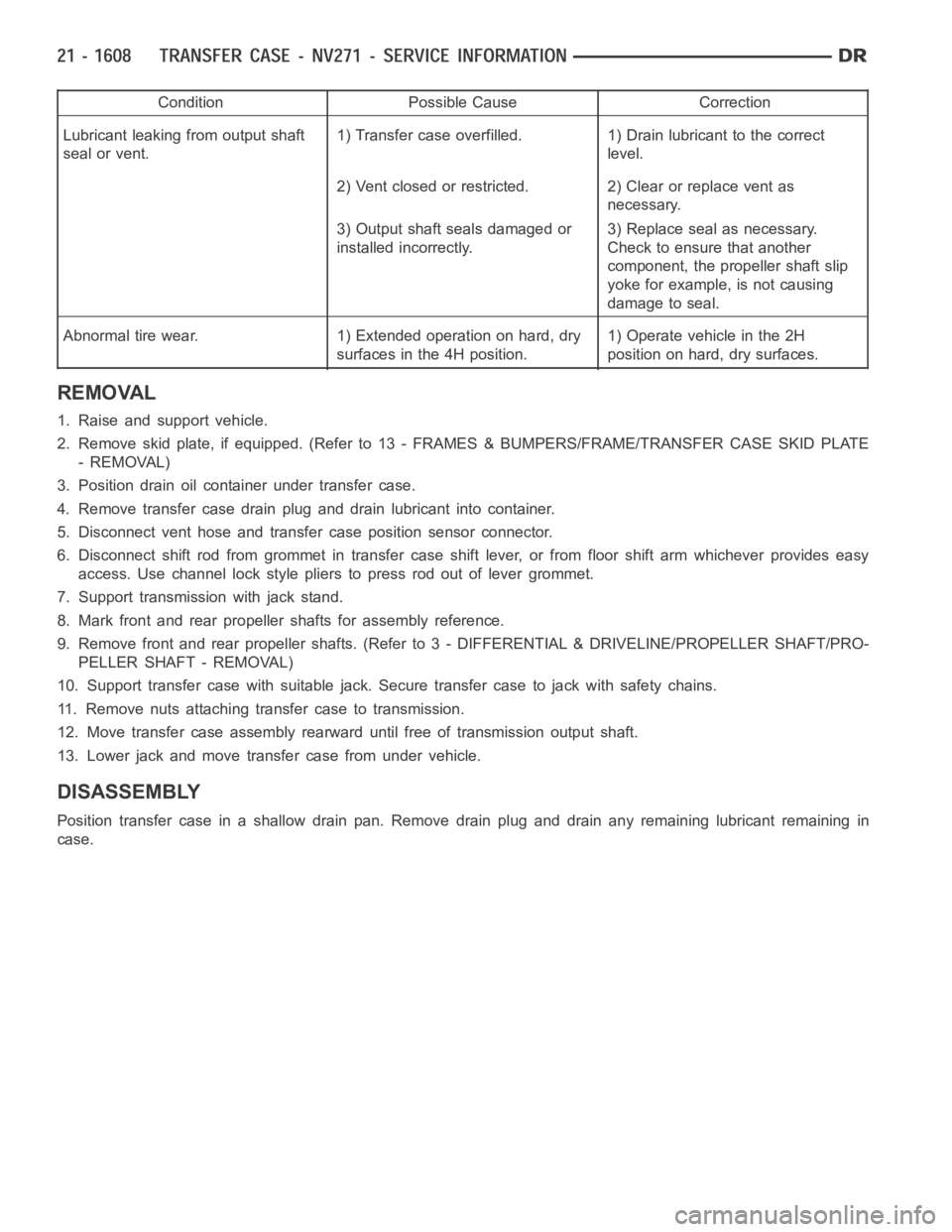

Condition Possible Cause Correction

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

1. Raise and support vehicle.

2. Remove skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE

- REMOVAL)

3. Position drain oil container under transfer case.

4. Remove transfer case drain plug and drain lubricant into container.

5. Disconnect vent hose and transfer case position sensor connector.

6. Disconnect shift rod from grommet in transfer case shift lever, or from floor shift arm whichever provides easy

access. Use channel lock style pliers to press rod out of lever grommet.

7. Support transmission with jack stand.

8. Mark front and rear propeller shafts for assembly reference.

9. Remove front and rear propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - REMOVAL)

10. Support transfer case with suitable jack. Secure transfer case to jackwith safety chains.

11. Remove nuts attaching transfer case to transmission.

12. Move transfer case assembly rearward until free of transmission outputshaft.

13. Lower jack and move transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan. Remove drain plug and drain any remaining lubricant remaining in

case.

Page 4137 of 5267

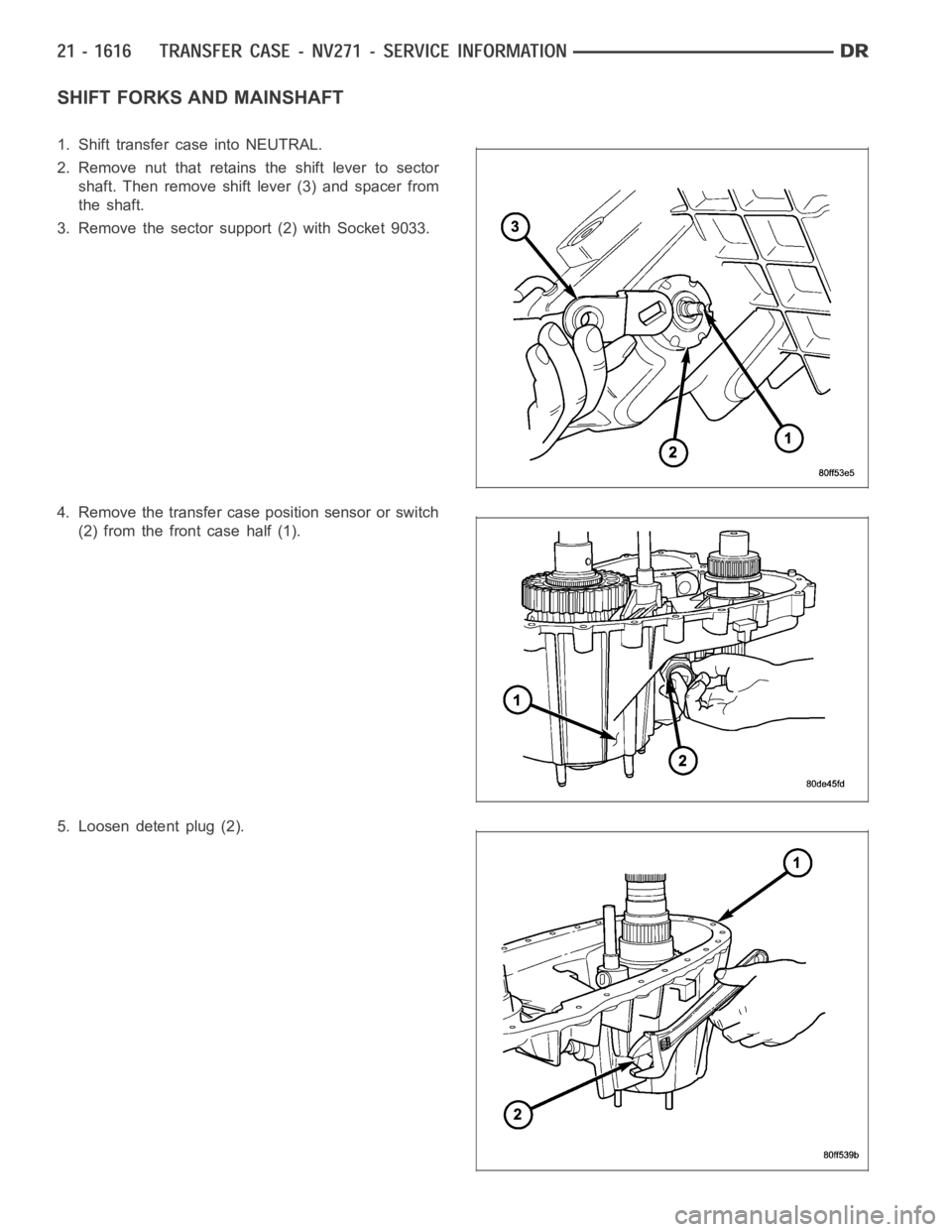

SHIFT FORKS AND MAINSHAFT

1. Shift transfer case into NEUTRAL.

2. Remove nut that retains the shift lever to sector

shaft. Then remove shift lever (3) and spacer from

the shaft.

3. Remove the sector support (2) with Socket 9033.

4. Remove the transfer case position sensor or switch

(2) from the front case half (1).

5. Loosen detent plug (2).

Page 4158 of 5267

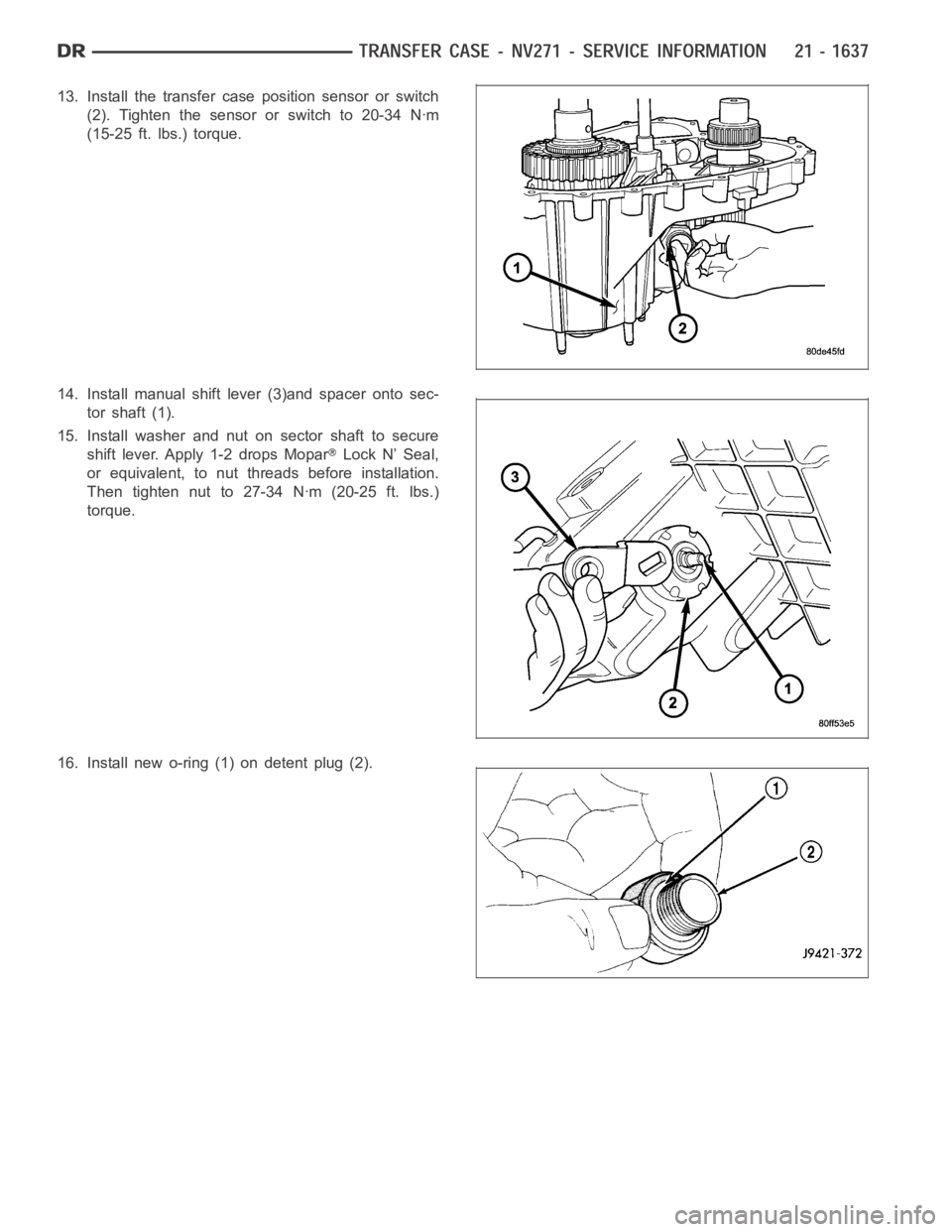

13. Install the transfer case position sensor or switch

(2). Tighten the sensor or switch to 20-34 Nꞏm

(15-25 ft. lbs.) torque.

14. Install manual shift lever (3)and spacer onto sec-

tor shaft (1).

15. Install washer and nut on sector shaft to secure

shift lever. Apply 1-2 drops Mopar

Lock N’ Seal,

or equivalent, to nut threads before installation.

Then tighten nut to 27-34 Nꞏm (20-25 ft. lbs.)

torque.

16. Install new o-ring (1) on detent plug (2).

Page 4165 of 5267

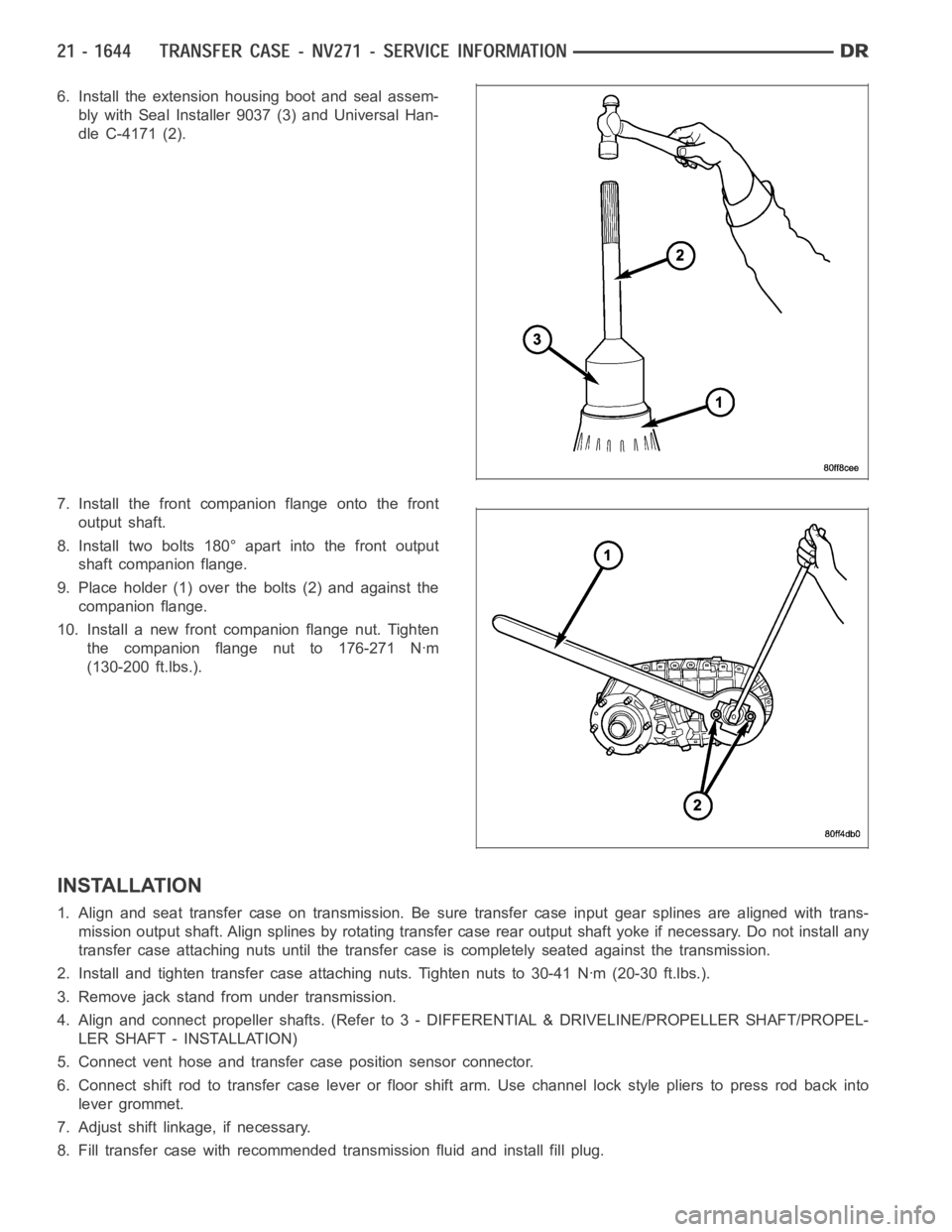

6. Install the extension housing boot and seal assem-

bly with Seal Installer 9037 (3) and Universal Han-

dle C-4171 (2).

7. Install the front companion flange onto the front

output shaft.

8. Install two bolts 180° apart into the front output

shaft companion flange.

9. Place holder (1) over the bolts (2) and against the

companion flange.

10. Install a new front companion flange nut. Tighten

the companion flange nut to 176-271 Nꞏm

(130-200 ft.lbs.).

INSTALLATION

1. Align and seat transfer case on transmission. Be sure transfer case input gear splines are aligned with trans-

mission output shaft. Align splines by rotating transfer case rear outputshaft yoke if necessary. Do not install any

transfer case attaching nuts until the transfer case is completely seatedagainst the transmission.

2. Install and tighten transfer case attaching nuts. Tighten nuts to 30-41Nꞏm (20-30 ft.lbs.).

3. Remove jack stand from under transmission.

4. Align and connect propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPEL-

LER SHAFT - INSTALLATION)

5. Connect vent hose and transfer case position sensor connector.

6. Connect shift rod to transfer case lever or floor shift arm. Use channel lock style pliers to press rod back into

lever grommet.

7. Adjust shift linkage, if necessary.

8. Fill transfer case with recommended transmission fluid and install fillplug.

Page 4166 of 5267

9. Install skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE -

INSTALLATION)

10. Lower vehicle

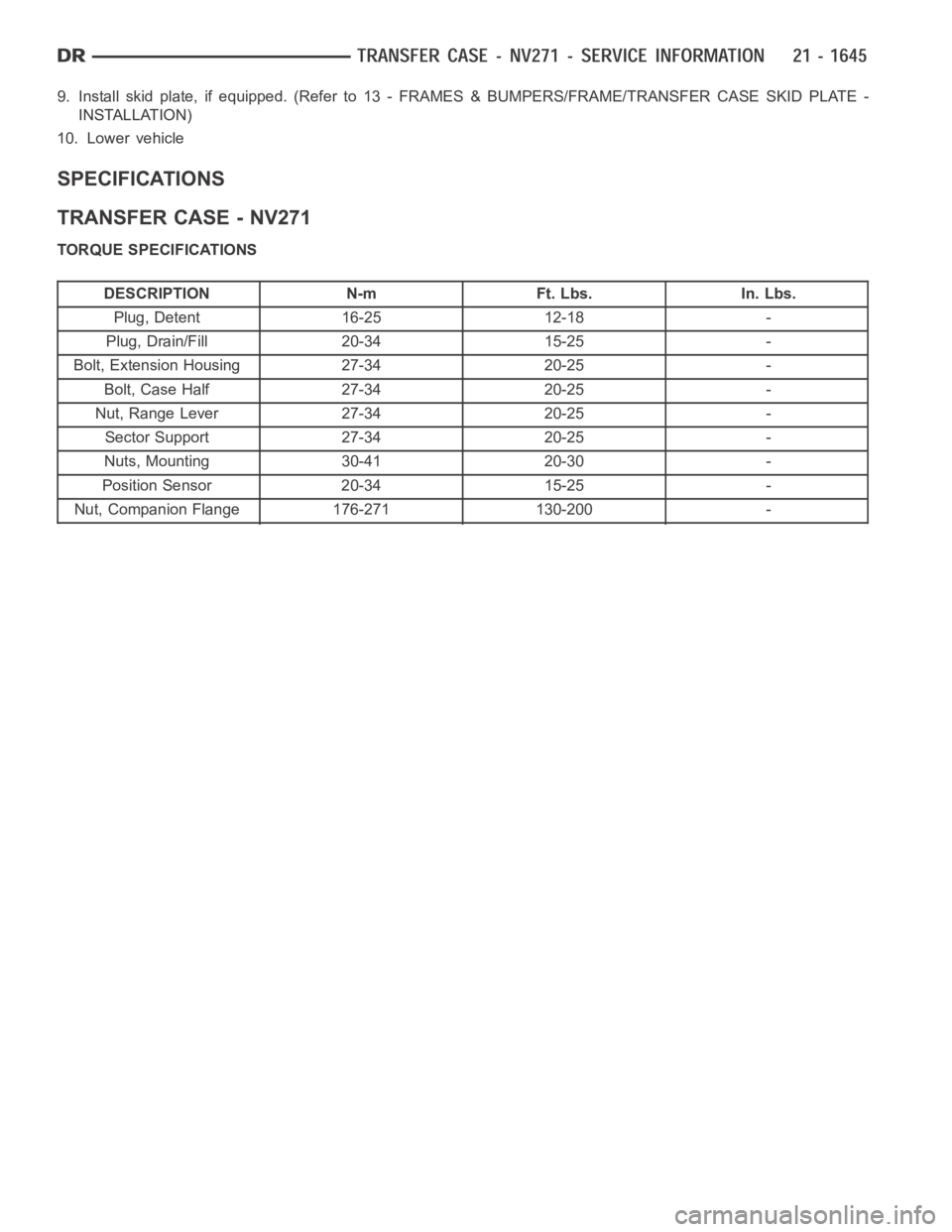

SPECIFICATIONS

TRANSFER CASE - NV271

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-25 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 27-34 20-25 -

Bolt, Case Half 27-34 20-25 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-34 20-25 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 15-25 -

Nut, Companion Flange 176-271 130-200 -

Page 4172 of 5267

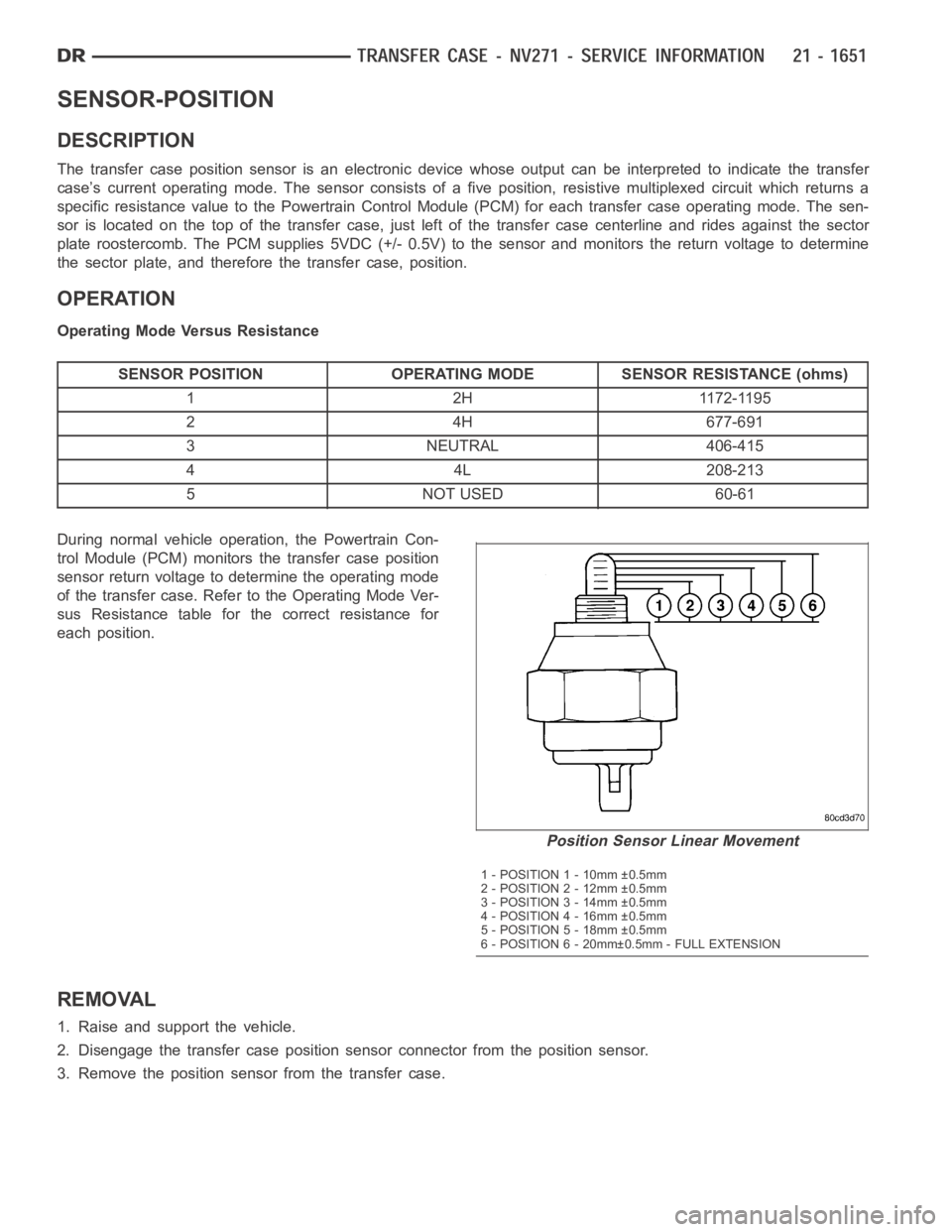

SENSOR-POSITION

DESCRIPTION

The transfer case position sensor is an electronic device whose output canbe interpreted to indicate the transfer

case’s current operating mode. The sensor consists of a five position, resistive multiplexed circuit which returns a

specific resistance value to the Powertrain Control Module (PCM) for eachtransfer case operating mode. The sen-

sor is located on the top of the transfer case, just left of the transfer casecenterline and rides against the sector

plate roostercomb. The PCM supplies 5VDC (+/- 0.5V) to the sensor and monitors the return voltage to determine

the sector plate, and therefore the transfer case, position.

OPERATION

Operating Mode Versus Resistance

SENSOR POSITION OPERATING MODE SENSOR RESISTANCE (ohms)

1 2H 1172-1195

24H677-691

3 NEUTRAL 406-415

44L208-213

5 NOT USED 60-61

During normal vehicle operation, the Powertrain Con-

trol Module (PCM) monitors the transfer case position

sensor return voltage to determine the operating mode

of the transfer case. Refer to the Operating Mode Ver-

sus Resistance table for the correct resistance for

each position.

REMOVAL

1. Raise and support the vehicle.

2. Disengage the transfer case position sensor connector from the positionsensor.

3. Remove the position sensor from the transfer case.

Position Sensor Linear Movement

1 - POSITION 1 - 10mm ±0.5mm

2 - POSITION 2 - 12mm ±0.5mm

3 - POSITION 3 - 14mm ±0.5mm

4 - POSITION 4 - 16mm ±0.5mm

5 - POSITION 5 - 18mm ±0.5mm

6 - POSITION 6 - 20mm±0.5mm - FULL EXTENSION

Page 4173 of 5267

INSTALLATION

1. Inspect the o-ring seal on the transfer case position sensor. Replace the o-ring if necessary.

2. Install the transfer case position sensor into the transfer case. Torque the sensor to 27 Nꞏm (20 ft.lbs.).

3. Engage the transfer case position sensor connector to the position sensor.

4. Lower vehicle.

5. Verify proper sensor operation.

Page 4177 of 5267

page page

TRANSFER CASE - NV243 - SERVICE

INFORMATION

DESCRIPTION ............................. 1657

OPERATION ............................... 1657

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV243 ............................ 1658

REMOVAL ................................. 1659

DISASSEMBLY ............................. 1659

CLEANING ................................. 1671

INSPECTION ............................... 1671

ASSEMBLY . ............................... 1674

INSTALLATION ............................. 1686

SPECIFICATIONS

TRANSFER CASE - NV243 ................ 1686

SPECIAL TOOLS

TRANSFER CASE - NV243 ................ 1687

SEAL-EXTENSION HOUSING

REMOVAL ................................. 1689

INSTALLATION ............................. 1689

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL ................................... 1690SEAL-FRONT OUTPUT SHAFT

REMOVAL ................................. 1691

INSTALLATION ............................. 1692

SENSOR-MODE

DESCRIPTION ............................. 1693

OPERATION ............................... 1693

SWITCH-SELECTOR

DESCRIPTION ............................. 1695

OPERATION ............................... 1695

MOTOR-SHIFT

DESCRIPTION ............................. 1697

OPERATION ............................... 1697

REMOVAL ................................. 1697

INSTALLATION ............................. 1697

ASSEMBLY-SHIFT MOTOR/MODE SENSOR

DESCRIPTION ............................. 1699

OPERATION ............................... 1699