sensor DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4265 of 5267

TRANSFER CASE - NV273 - SERVICE INFORMATION

DESCRIPTION

The NV273 is an electronically controlled part-time transfer case with a low range gear reduction system. The

NV273 has three operating ranges plus a NEUTRAL position. The low range system provides a gear reduction ratio

for increased low speed torque capability.

The geartrain is mounted in two aluminum case halves attached with bolts. The mainshaft front and rear bearings

are mounted in aluminum case halves.

OPERATING RANGES

Transfer case operating ranges are:

2WD (2-wheel drive).

4HI (4-wheel drive).

4LO (4-wheel drive low range).

NEUTRAL.

The 2WD range is for use on any road surface at any time.

The 4HI and 4LO ranges are for off road use only. They are not for use on hard surface roads. The only exception

being when the road surface is wet or slippery or covered by ice and snow.

The low range reduction gear system is operative in 4LO range only. This range is for extra pulling power in off road

situations. Low range reduction ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash mounted shift selector switch. The shift selector switch provides a input

to the Transfer Case Control Module (TCCM) to indicate the driver’s desireto change operating ranges. The TCCM

uses this input, along with input from the transfer case mounted mode sensor and information from the vehicle’s

bus, to determine if a shift is permitted. If the TCCM decides the shift is permitted, the TCCM controls the shift

motor, mounted to the exterior of the transfer case, to perform the shift.

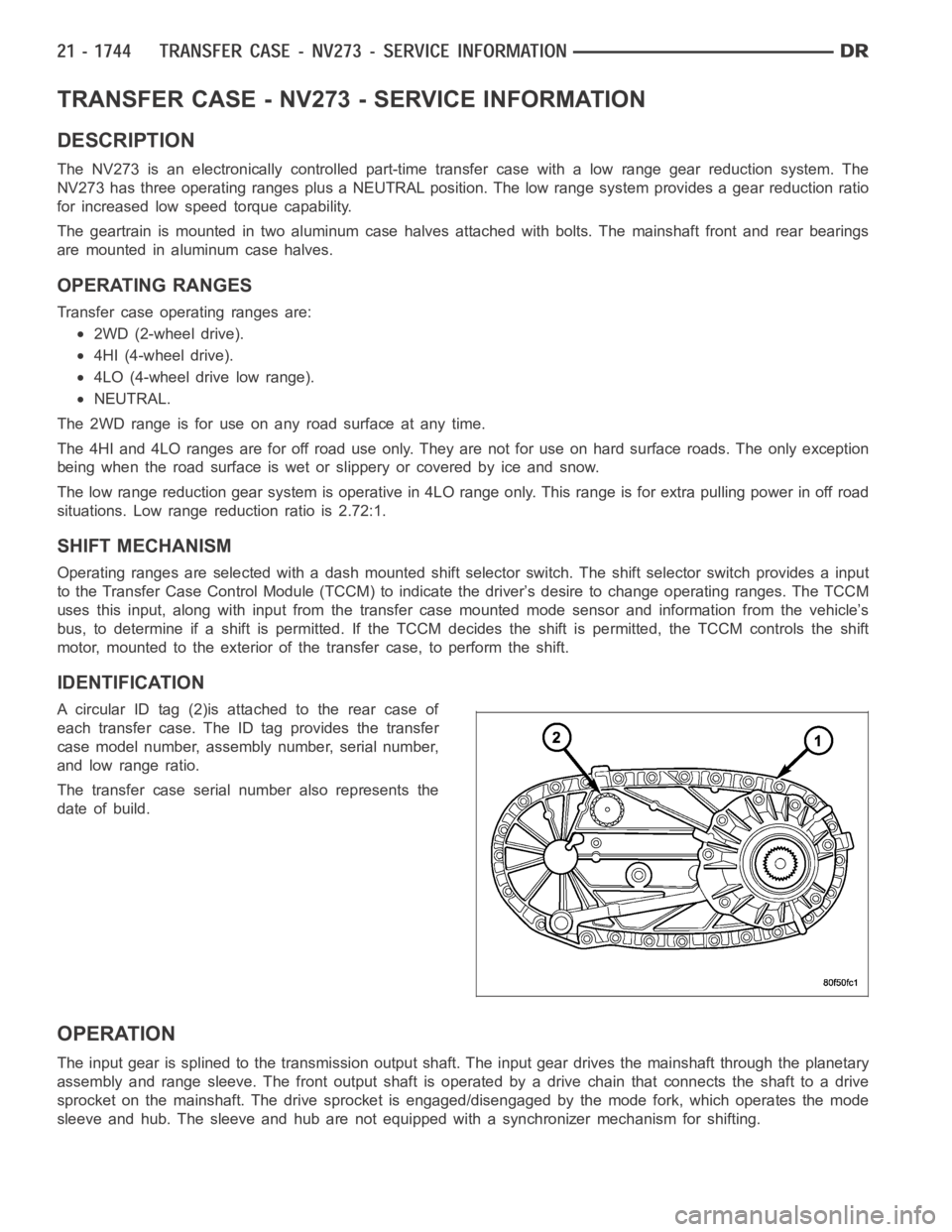

IDENTIFICATION

A circular ID tag (2)is attached to the rear case of

each transfer case. The ID tag provides the transfer

case model number, assembly number, serial number,

and low range ratio.

The transfer case serial number also represents the

date of build.

OPERATION

The input gear is splined to the transmission output shaft. The input gear drives the mainshaft through the planetary

assembly and range sleeve. The front output shaft is operated by a drive chain that connects the shaft to a drive

sprocket on the mainshaft. The drive sprocket is engaged/disengaged by themodefork,whichoperatesthemode

sleeve and hub. The sleeve and hub are not equipped with a synchronizer mechanism for shifting.

Page 4267 of 5267

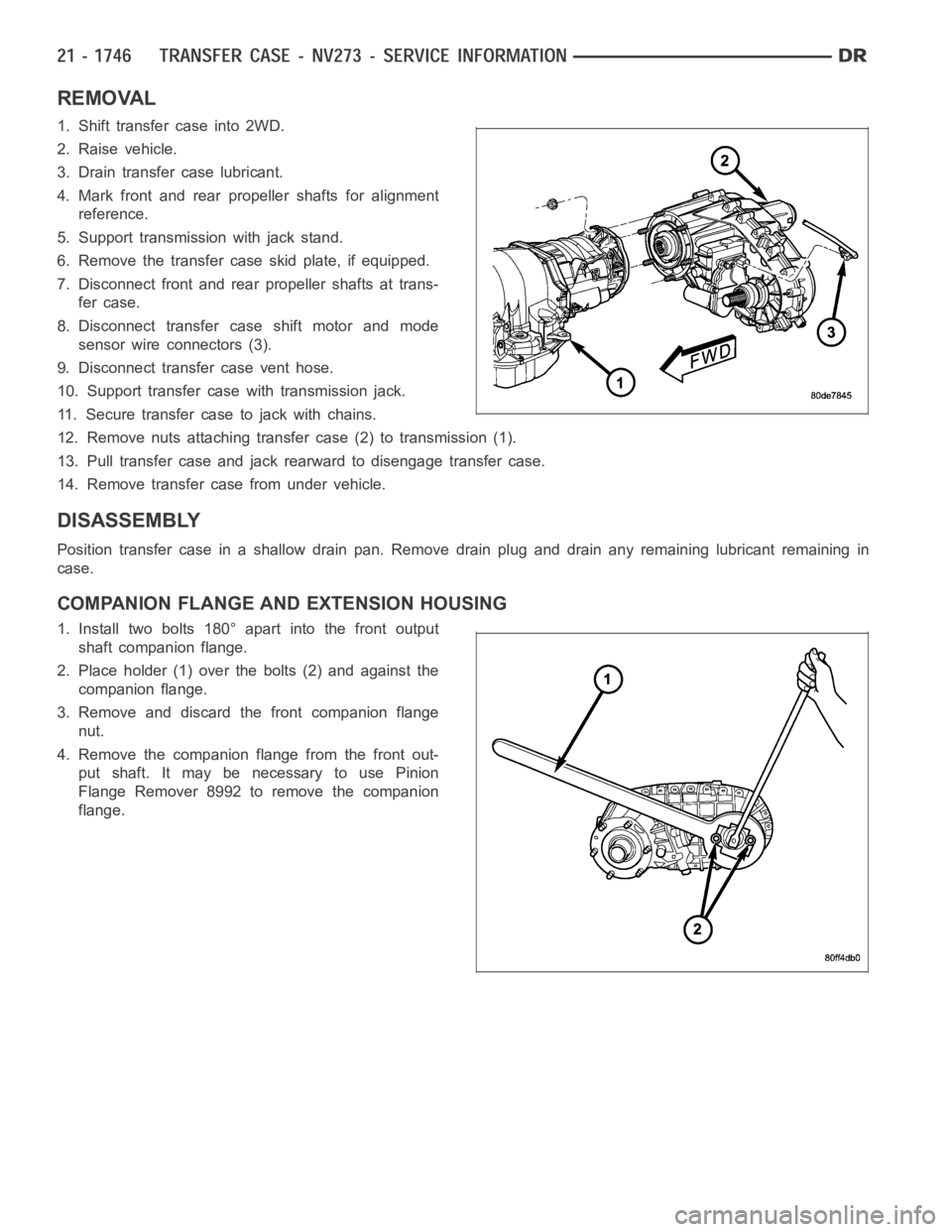

REMOVAL

1. Shift transfer case into 2WD.

2. Raise vehicle.

3. Drain transfer case lubricant.

4. Mark front and rear propeller shafts for alignment

reference.

5. Support transmission with jack stand.

6. Remove the transfer case skid plate, if equipped.

7. Disconnect front and rear propeller shafts at trans-

fer case.

8. Disconnect transfer case shift motor and mode

sensor wire connectors (3).

9. Disconnect transfer case vent hose.

10. Support transfer case with transmission jack.

11. Secure transfer case to jack with chains.

12. Remove nuts attaching transfer case (2) to transmission (1).

13. Pull transfer case and jack rearward to disengage transfer case.

14. Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan. Remove drain plug and drain any remaining lubricant remaining in

case.

COMPANION FLANGE AND EXTENSION HOUSING

1. Install two bolts 180° apart into the front output

shaft companion flange.

2. Place holder (1) over the bolts (2) and against the

companion flange.

3. Remove and discard the front companion flange

nut.

4. Remove the companion flange from the front out-

put shaft. It may be necessary to use Pinion

Flange Remover 8992 to remove the companion

flange.

Page 4295 of 5267

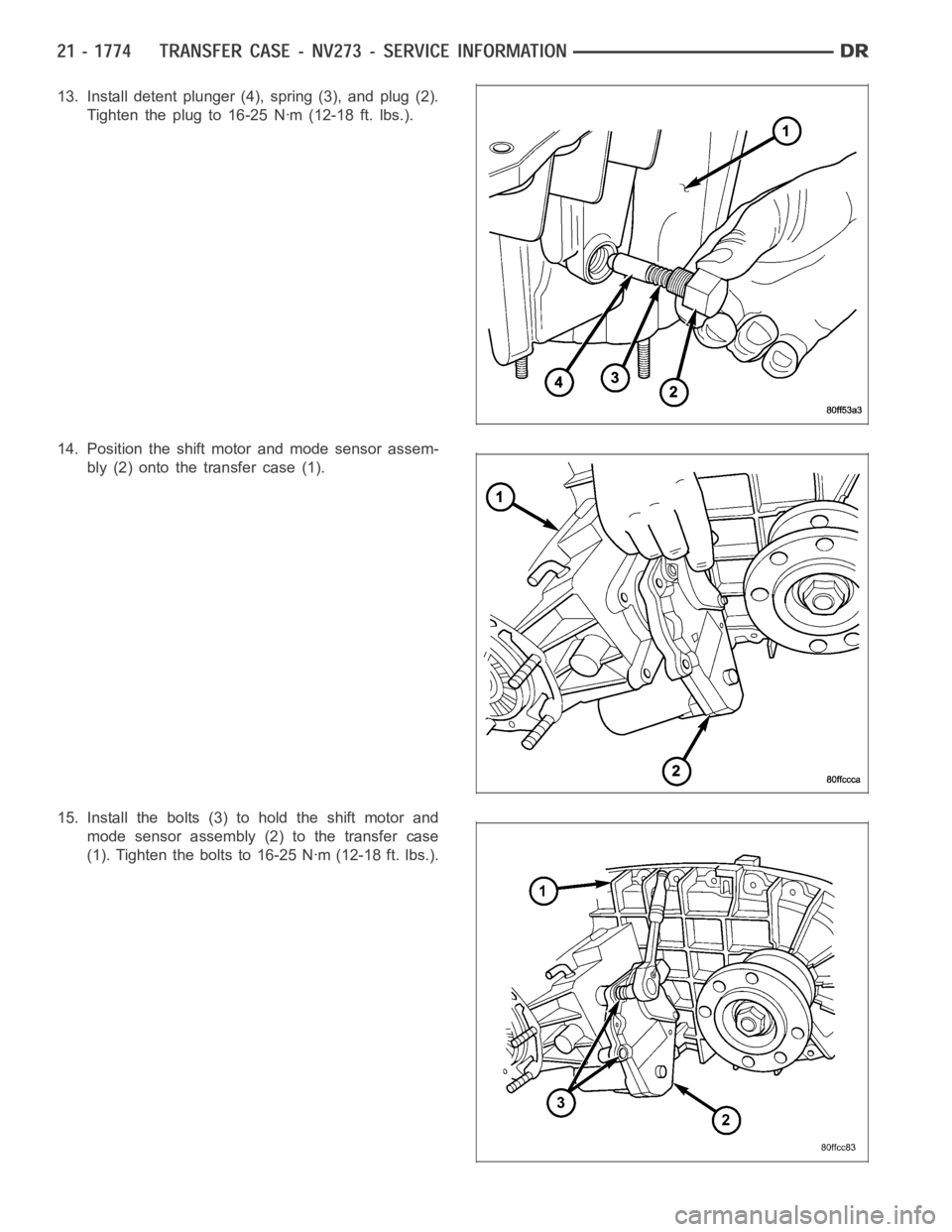

13. Install detent plunger (4), spring (3), and plug (2).

Tighten the plug to 16-25 Nꞏm (12-18 ft. lbs.).

14. Position the shift motor and mode sensor assem-

bly (2) onto the transfer case (1).

15. Install the bolts (3) to hold the shift motor and

mode sensor assembly (2) to the transfer case

(1). Tighten the bolts to 16-25 Nꞏm (12-18 ft. lbs.).

Page 4301 of 5267

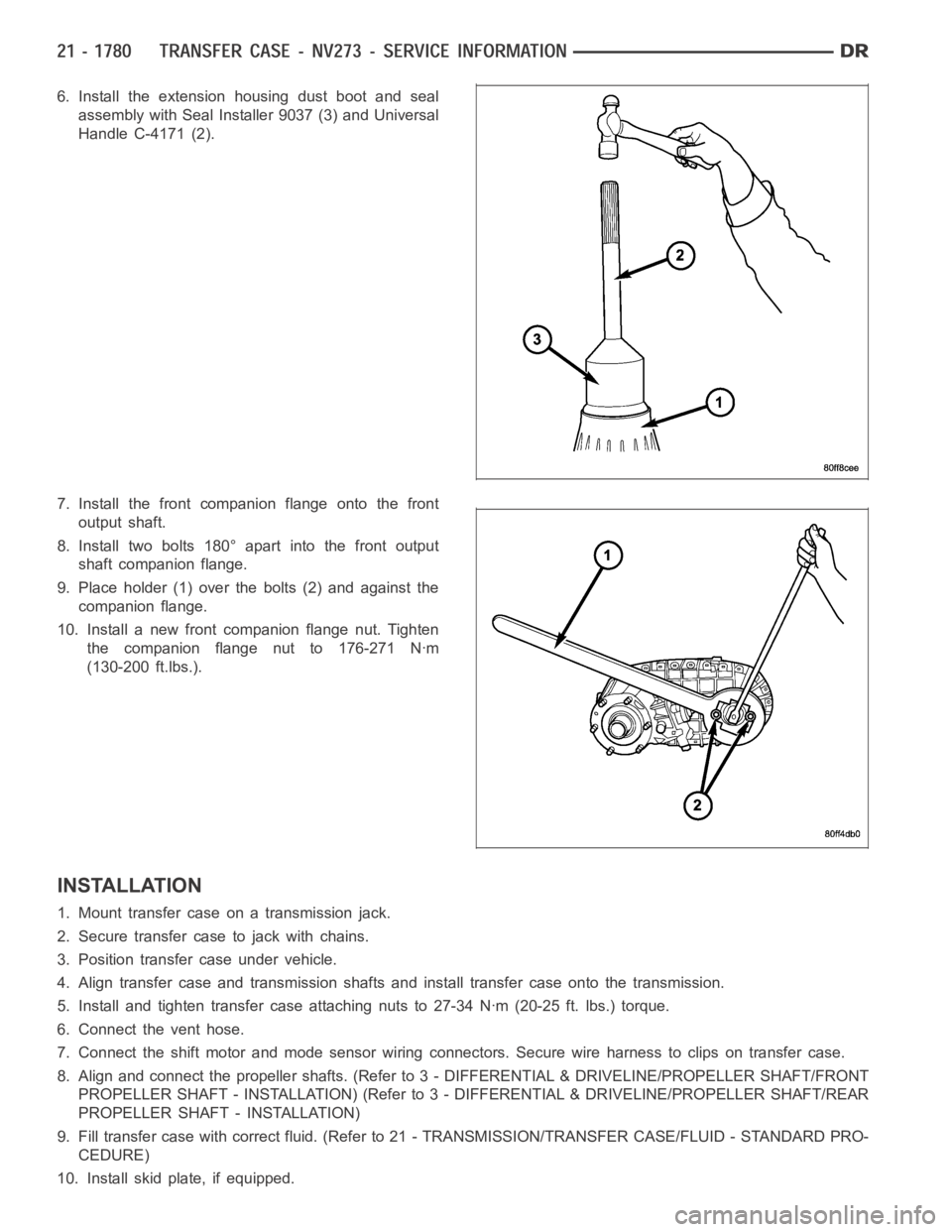

6. Install the extension housing dust boot and seal

assembly with Seal Installer 9037 (3) and Universal

Handle C-4171 (2).

7. Install the front companion flange onto the front

output shaft.

8. Install two bolts 180° apart into the front output

shaft companion flange.

9. Place holder (1) over the bolts (2) and against the

companion flange.

10. Install a new front companion flange nut. Tighten

the companion flange nut to 176-271 Nꞏm

(130-200 ft.lbs.).

INSTALLATION

1. Mount transfer case on a transmission jack.

2. Secure transfer case to jack with chains.

3. Position transfer case under vehicle.

4. Align transfer case and transmission shafts and install transfer case onto the transmission.

5. Install and tighten transfer case attaching nuts to 27-34 Nꞏm (20-25 ft.lbs.) torque.

6. Connect the vent hose.

7. Connect the shift motor and mode sensor wiring connectors. Secure wire harness to clips on transfer case.

8. Align and connect the propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/FRONT

PROPELLER SHAFT - INSTALLATION) (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/REAR

PROPELLER SHAFT - INSTALLATION)

9. Fill transfer case with correct fluid. (Refer to 21 - TRANSMISSION/TRANSFER CASE/FLUID - STANDARD PRO-

CEDURE)

10. Install skid plate, if equipped.

Page 4302 of 5267

11. Remove transmission jack and support stand.

12. Lower vehicle and verify transfer case shift operation.

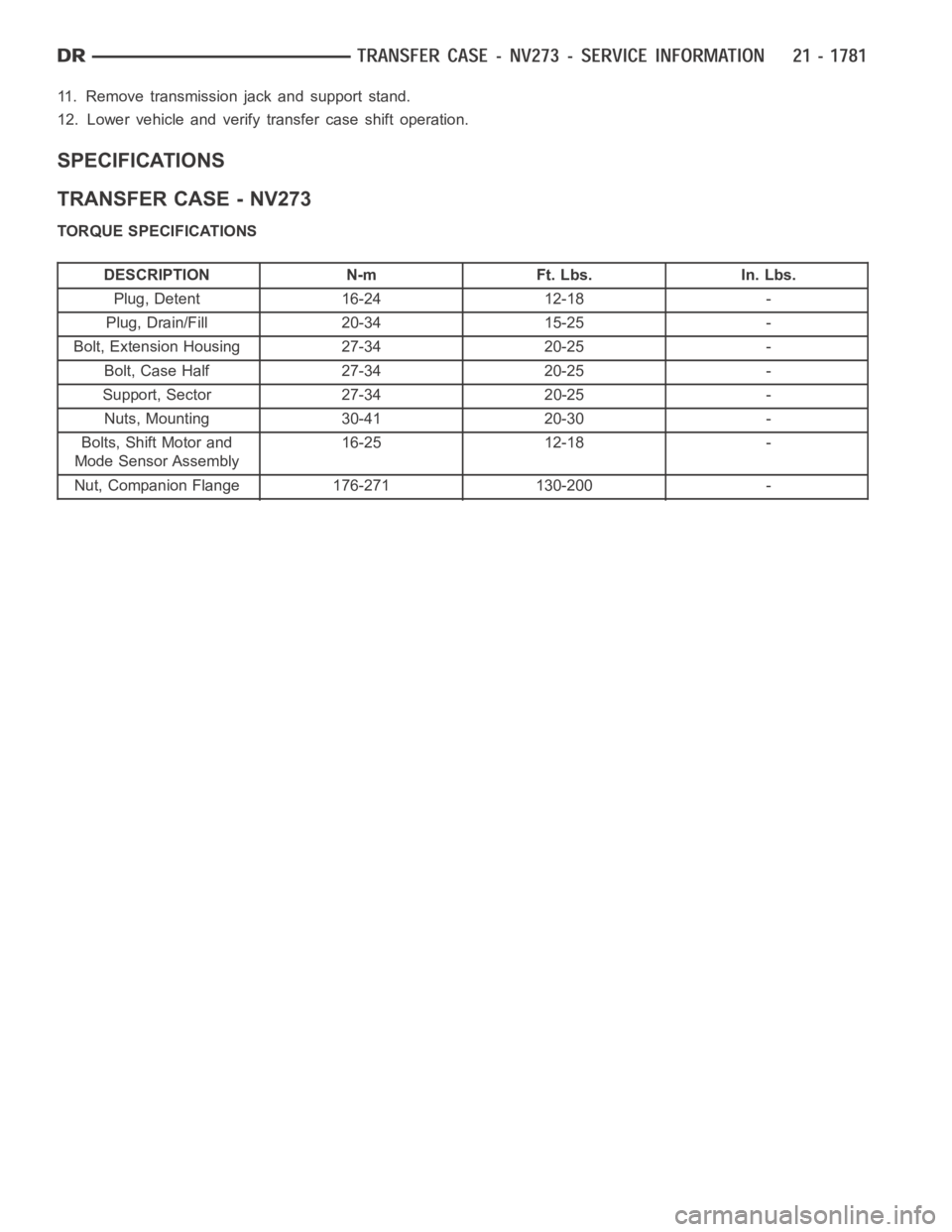

SPECIFICATIONS

TRANSFER CASE - NV273

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 27-34 20-25 -

Bolt, Case Half 27-34 20-25 -

Support, Sector 27-34 20-25 -

Nuts, Mounting 30-41 20-30 -

Bolts, Shift Motor and

Mode Sensor Assembly16-25 12-18 -

Nut, Companion Flange 176-271 130-200 -

Page 4308 of 5267

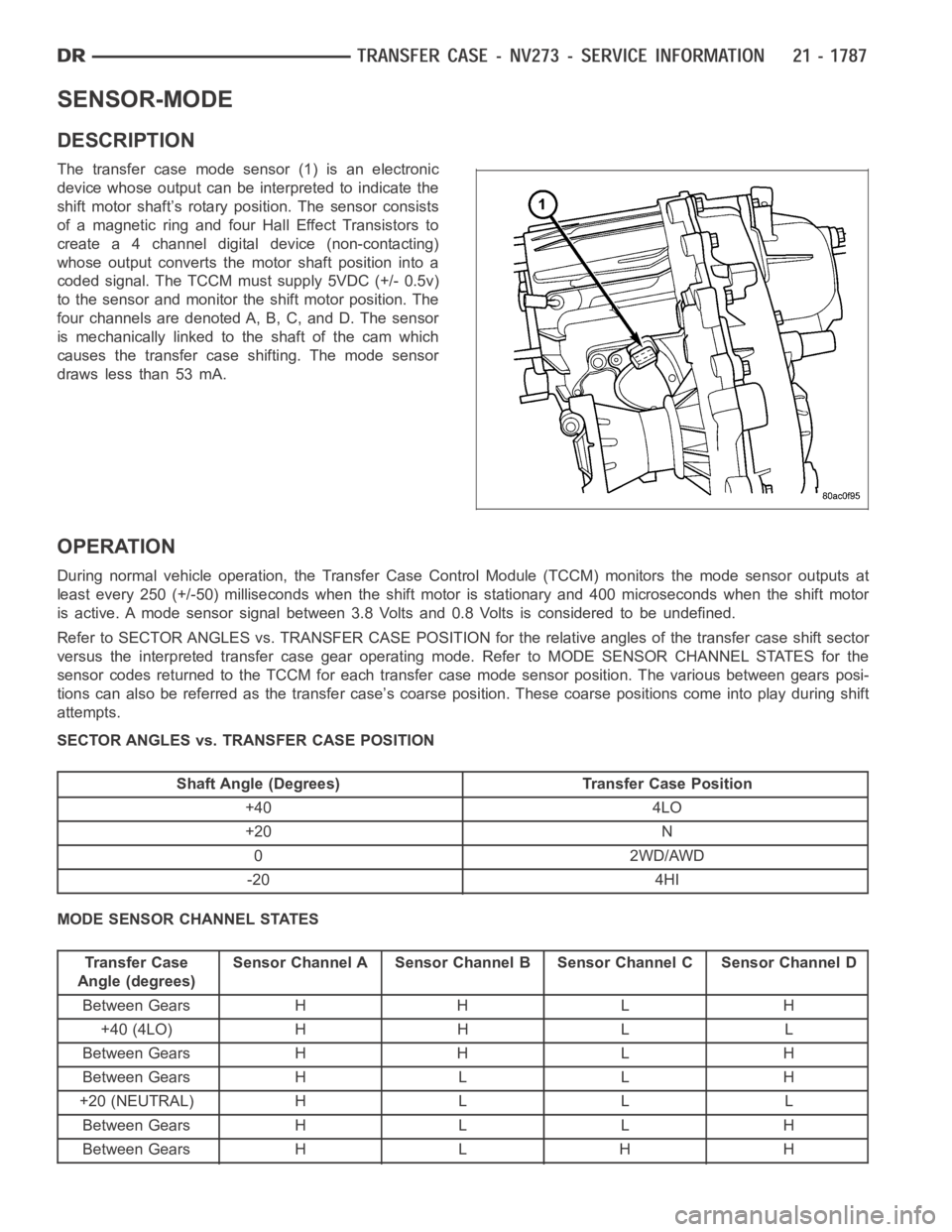

SENSOR-MODE

DESCRIPTION

The transfer case mode sensor (1) is an electronic

device whose output can be interpreted to indicate the

shift motor shaft’s rotary position. The sensor consists

of a magnetic ring and four Hall Effect Transistors to

create a 4 channel digital device (non-contacting)

whose output converts the motor shaft position into a

coded signal. The TCCM must supply 5VDC (+/- 0.5v)

to the sensor and monitor the shift motor position. The

four channels are denoted A, B, C, and D. The sensor

is mechanically linked to the shaft of the cam which

causes the transfer case shifting. The mode sensor

draws less than 53 mA.

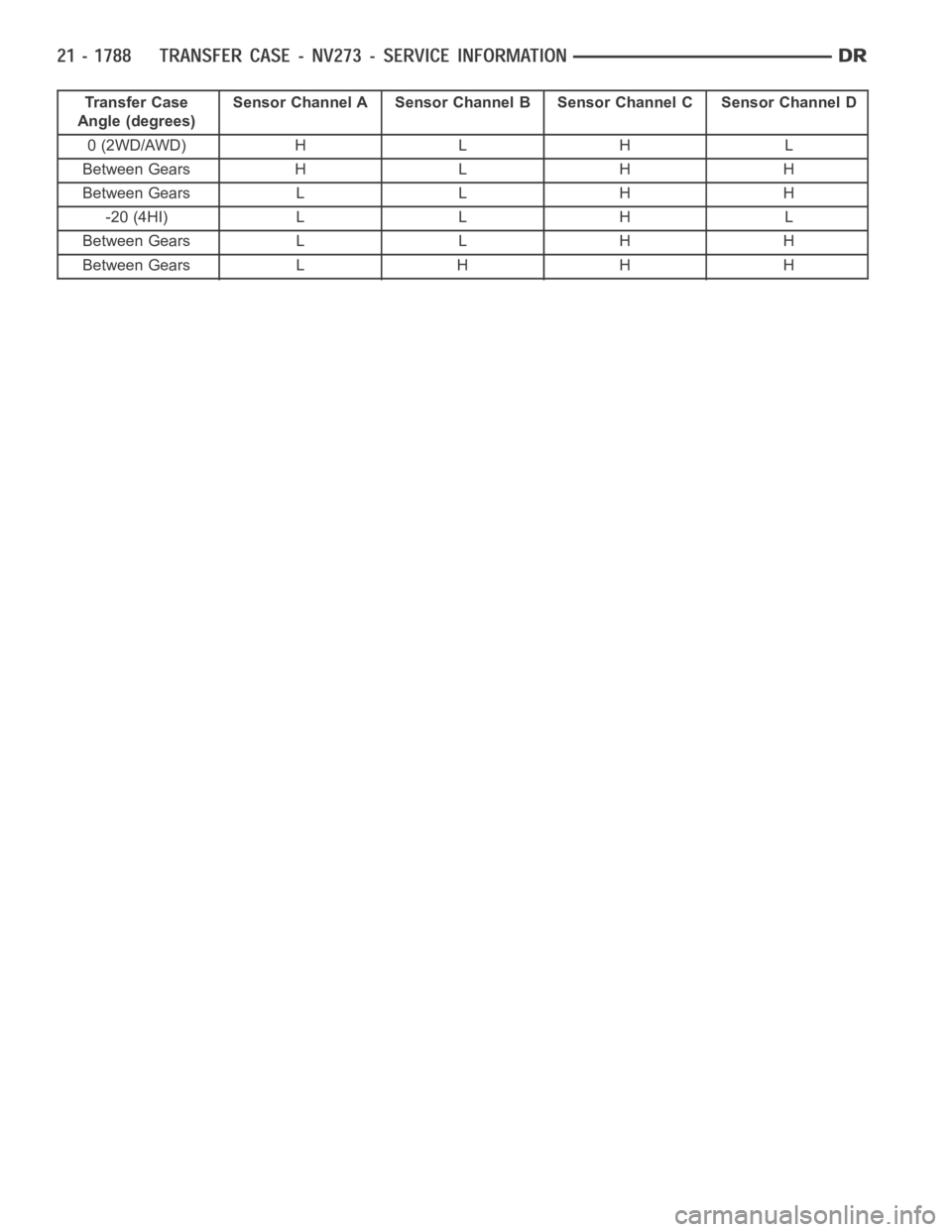

OPERATION

During normal vehicle operation, the Transfer Case Control Module (TCCM)monitors the mode sensor outputs at

least every 250 (+/-50) milliseconds when the shift motor is stationary and 400 microseconds when the shift motor

is active. A mode sensor signal between 3.8 Volts and 0.8 Volts is considered to be undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE POSITION for the relative angles of the transfer case shift sector

versus the interpreted transfer case gear operating mode. Refer to MODE SENSOR CHANNEL STATES for the

sensor codes returned to the TCCM for each transfer case mode sensor position. The various between gears posi-

tions can also be referred as the transfer case’s coarse position. These coarse positions come into play during shift

attempts.

SECTOR ANGLES vs. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

+20 (NEUTRAL) H L L L

Between Gears H L L H

Between Gears H L H H

Page 4309 of 5267

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

0 (2WD/AWD) H L H L

Between Gears H L H H

Between Gears L L H H

-20 (4HI) L L H L

Between Gears L L H H

Between Gears L H H H

Page 4310 of 5267

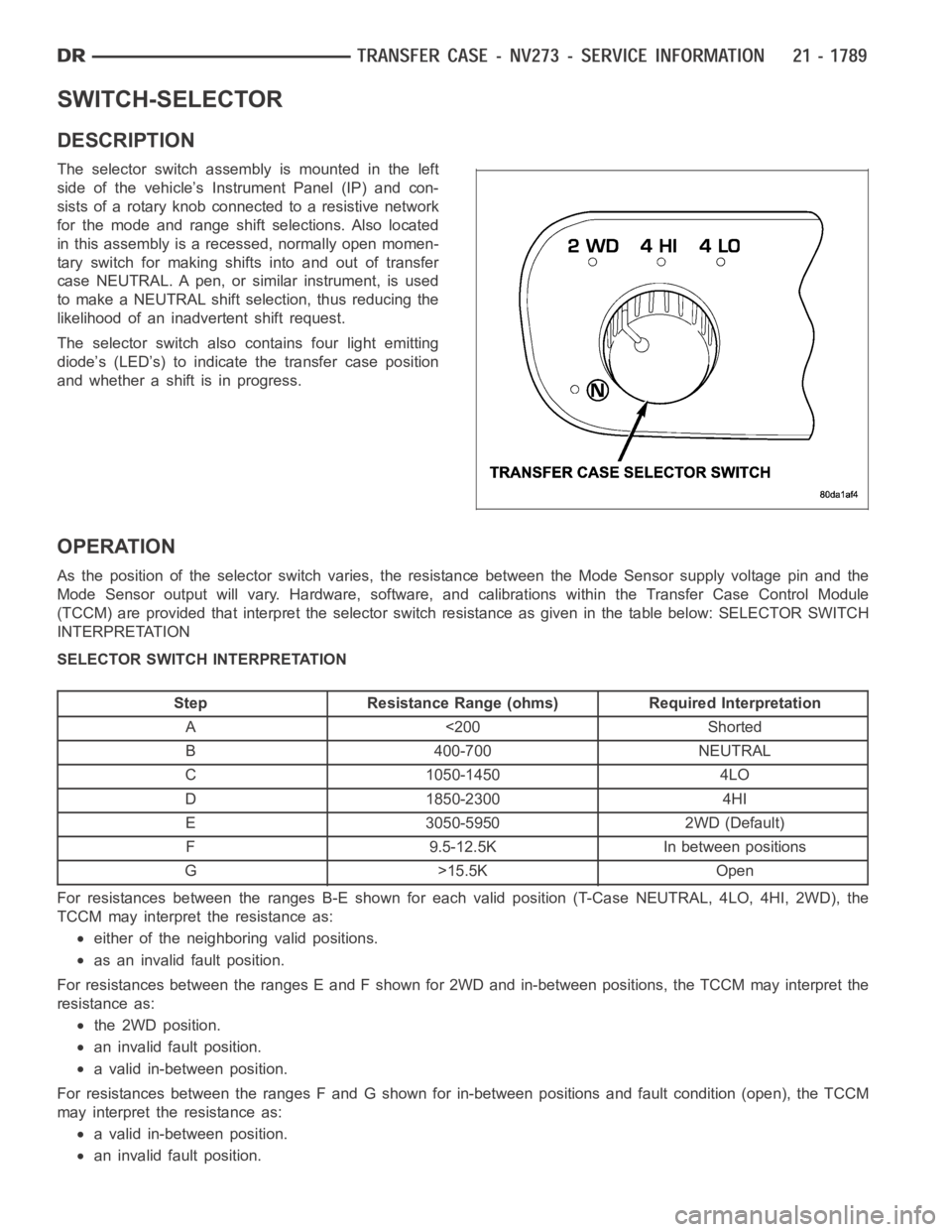

SWITCH-SELECTOR

DESCRIPTION

The selector switch assembly is mounted in the left

side of the vehicle’s Instrument Panel (IP) and con-

sists of a rotary knob connected to a resistive network

for the mode and range shift selections. Also located

in this assembly is a recessed, normally open momen-

tary switch for making shifts into and out of transfer

case NEUTRAL. A pen, or similar instrument, is used

to make a NEUTRAL shift selection, thus reducing the

likelihood of an inadvertent shift request.

The selector switch also contains four light emitting

diode’s (LED’s) to indicate the transfer case position

and whether a shift is in progress.

OPERATION

As the position of the selector switchvaries, the resistance between the Mode Sensor supply voltage pin and the

Mode Sensor output will vary. Hardware, software, and calibrations within the Transfer Case Control Module

(TCCM) are provided that interpret the selector switch resistance as giveninthetablebelow:SELECTORSWITCH

INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance Range (ohms) Required Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4HI

E 3050-5950 2WD (Default)

F 9.5-12.5K In between positions

G>15.5KOpen

For resistances between the ranges B-E shown for each valid position (T-Case NEUTRAL, 4LO, 4HI, 2WD), the

TCCM may interpret the resistance as:

either of the neighboring valid positions.

as an invalid fault position.

For resistances between the ranges E and F shown for 2WD and in-between positions, the TCCM may interpret the

resistance as:

the 2WD position.

an invalid fault position.

a valid in-between position.

For resistances between the ranges F and G shown for in-between positions and fault condition (open), the TCCM

may interpret the resistance as:

a valid in-between position.

an invalid fault position.

Page 4312 of 5267

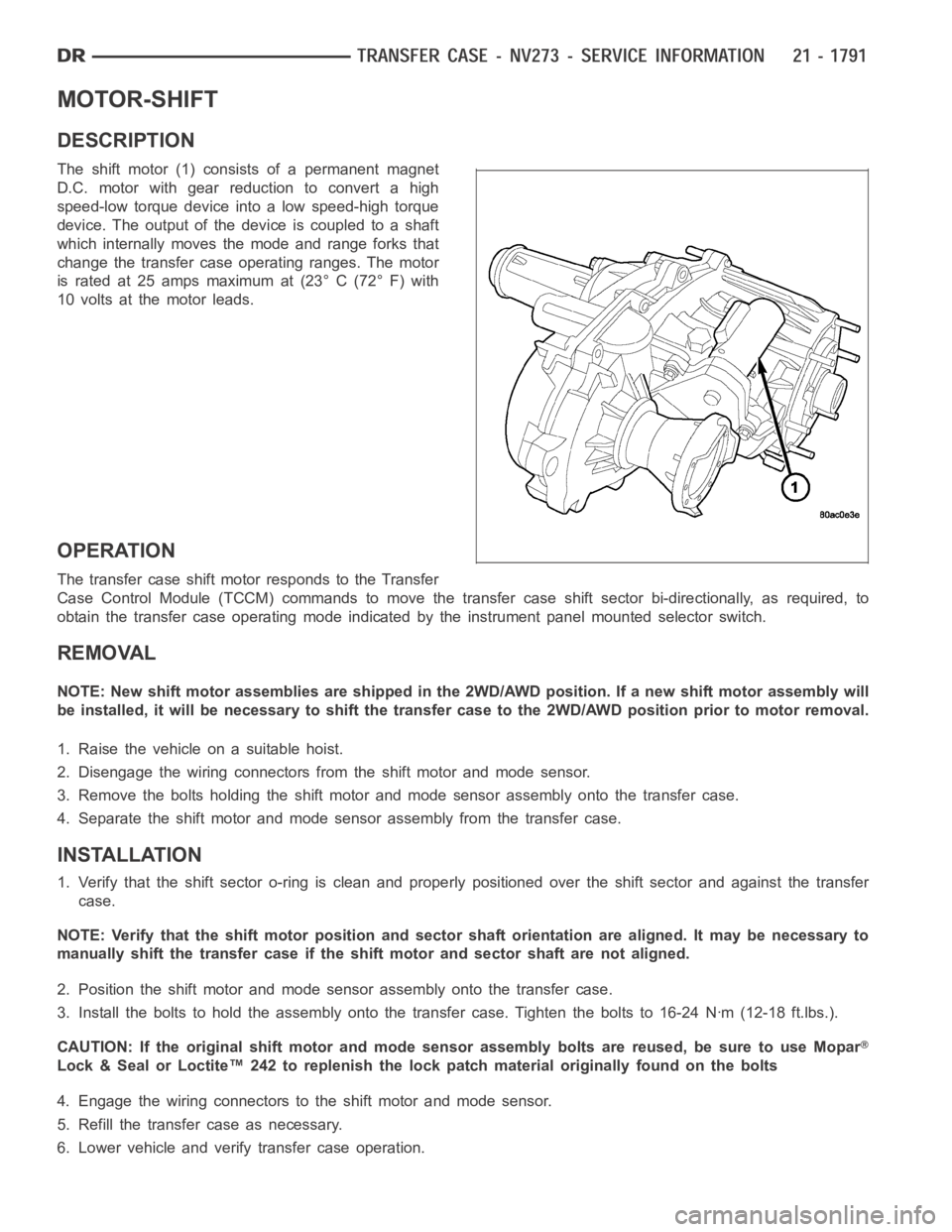

MOTOR-SHIFT

DESCRIPTION

The shift motor (1) consists of a permanent magnet

D.C. motor with gear reduction to convert a high

speed-low torque device into a low speed-high torque

device. The output of the device is coupled to a shaft

which internally moves the mode and range forks that

change the transfer case operating ranges. The motor

is rated at 25 amps maximum at (23° C (72° F) with

10 volts at the motor leads.

OPERATION

The transfer case shift motor responds to the Transfer

Case Control Module (TCCM) commands to move the transfer case shift sectorbi-directionally, as required, to

obtain the transfer case operating mode indicated by the instrument panelmounted selector switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in the 2WD/AWD position. If a new shift motor assembly will

be installed, it will be necessary to shift the transfer case to the 2WD/AWDposition prior to motor removal.

1. Raise the vehicle on a suitable hoist.

2. Disengage the wiring connectors from the shift motor and mode sensor.

3. Remove the bolts holding the shift motor and mode sensor assembly onto the transfer case.

4. Separate the shift motor and mode sensor assembly from the transfer case.

INSTALLATION

1. Verify that the shift sector o-ring is clean and properly positioned over the shift sector and against the transfer

case.

NOTE: Verify that the shift motor position and sector shaft orientation are aligned. It may be necessary to

manually shift the transfer case if the shift motor and sector shaft are notaligned.

2. Position the shift motor and mode sensor assembly onto the transfer case.

3. Install the bolts to hold the assembly onto the transfer case. Tighten the bolts to 16-24 Nꞏm (12-18 ft.lbs.).

CAUTION: If the original shift motor and mode sensor assembly bolts are reused, be sure to use Mopar

Lock & Seal or Loctite™ 242 to replenish the lock patch material originallyfound on the bolts

4. Engage the wiring connectors to the shift motor and mode sensor.

5. Refill the transfer case as necessary.

6. Lower vehicle and verify transfer case operation.

Page 4333 of 5267

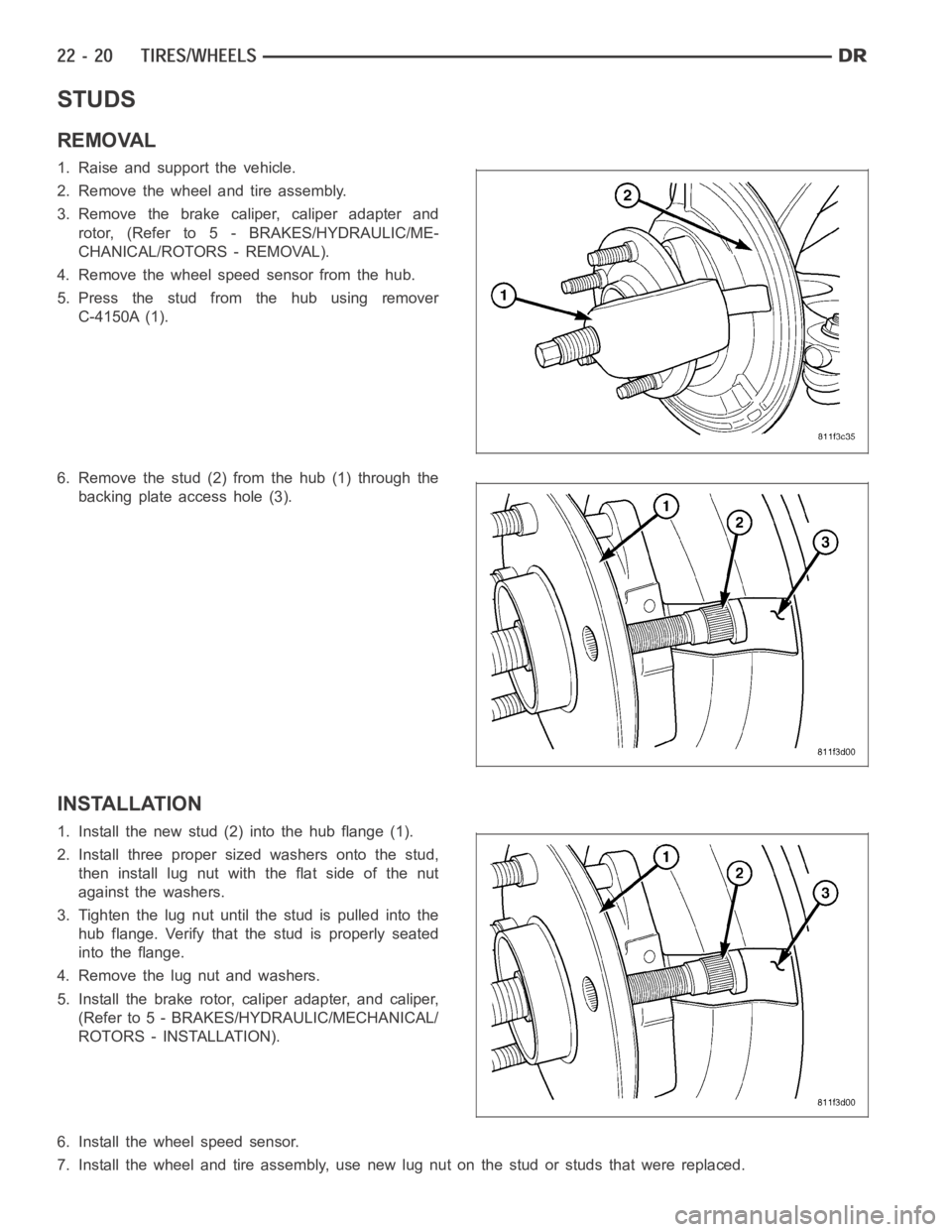

STUDS

REMOVAL

1. Raise and support the vehicle.

2. Remove the wheel and tire assembly.

3. Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/ROTORS - REMOVAL).

4. Remove the wheel speed sensor from the hub.

5. Press the stud from the hub using remover

C-4150A (1).

6. Remove the stud (2) from the hub (1) through the

backing plate access hole (3).

INSTALLATION

1. Install the new stud (2) into the hub flange (1).

2. Install three proper sized washers onto the stud,

then install lug nut with the flat side of the nut

against the washers.

3. Tighten the lug nut until the stud is pulled into the

hub flange. Verify that the stud is properly seated

into the flange.

4. Remove the lug nut and washers.

5. Install the brake rotor, caliper adapter, and caliper,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

ROTORS - INSTALLATION).

6. Install the wheel speed sensor.

7. Install the wheel and tire assembly, use new lug nut on the stud or studs that were replaced.