engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1509 of 5267

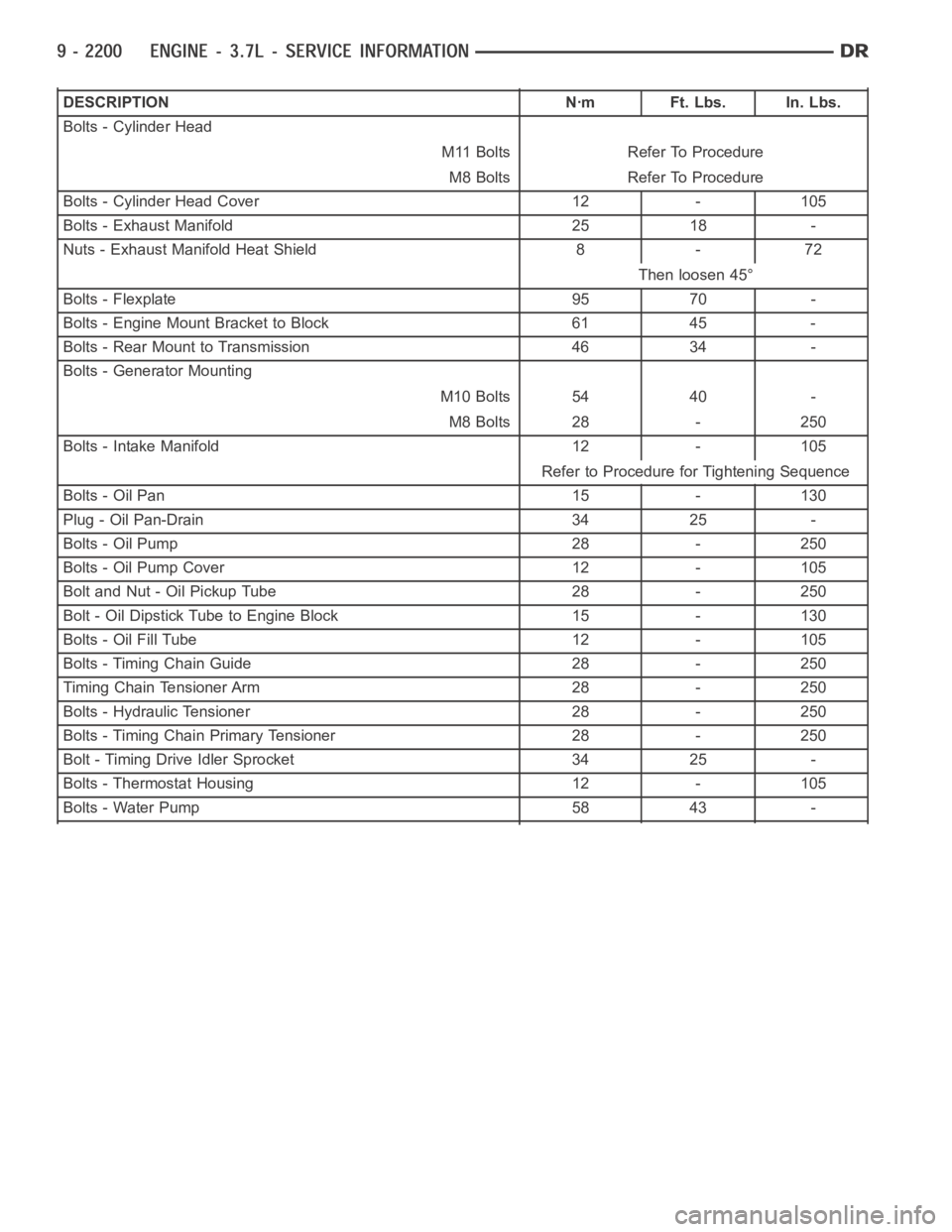

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Bolts - Cylinder Head

M11 Bolts Refer To Procedure

M8 Bolts Refer To Procedure

Bolts - Cylinder Head Cover 12 - 105

Bolts - Exhaust Manifold 25 18 -

Nuts - Exhaust Manifold Heat Shield 8 - 72

Then loosen 45°

Bolts - Flexplate 95 70 -

Bolts - Engine Mount Bracket to Block 61 45 -

Bolts - Rear Mount to Transmission 46 34 -

Bolts - Generator Mounting

M10 Bolts 54 40 -

M8 Bolts 28 - 250

Bolts - Intake Manifold 12 - 105

Refer to Procedure for Tightening Sequence

Bolts - Oil Pan 15 - 130

Plug - Oil Pan-Drain 34 25 -

Bolts - Oil Pump 28 - 250

Bolts - Oil Pump Cover 12 - 105

Bolt and Nut - Oil Pickup Tube 28 - 250

Bolt - Oil Dipstick Tube to Engine Block 15 - 130

Bolts - Oil Fill Tube 12 - 105

Bolts - Timing Chain Guide 28 - 250

Timing Chain Tensioner Arm 28 - 250

Bolts - Hydraulic Tensioner 28 - 250

Bolts - Timing Chain Primary Tensioner 28 - 250

Bolt - Timing Drive Idler Sprocket 34 25 -

Bolts - Thermostat Housing 12 - 105

Bolts - Water Pump 58 43 -

Page 1512 of 5267

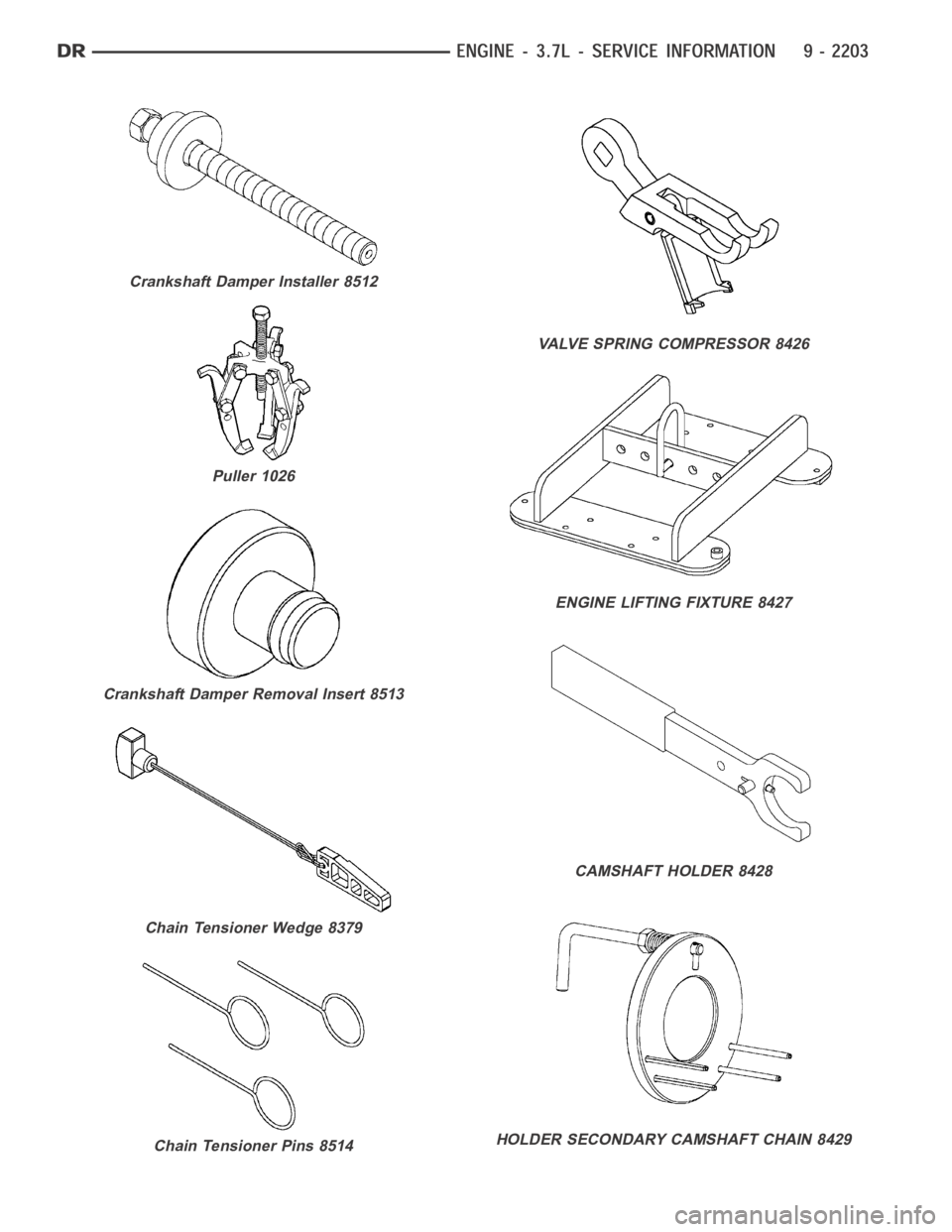

Crankshaft Damper Installer 8512

Puller 1026

Crankshaft Damper Removal Insert 8513

Chain Tensioner Wedge 8379

Chain Tensioner Pins 8514

VALVE SPRING COMPRESSOR 8426

ENGINE LIFTING FIXTURE 8427

CAMSHAFT HOLDER 8428

HOLDER SECONDARY CAMSHAFT CHAIN 8429

Page 1514 of 5267

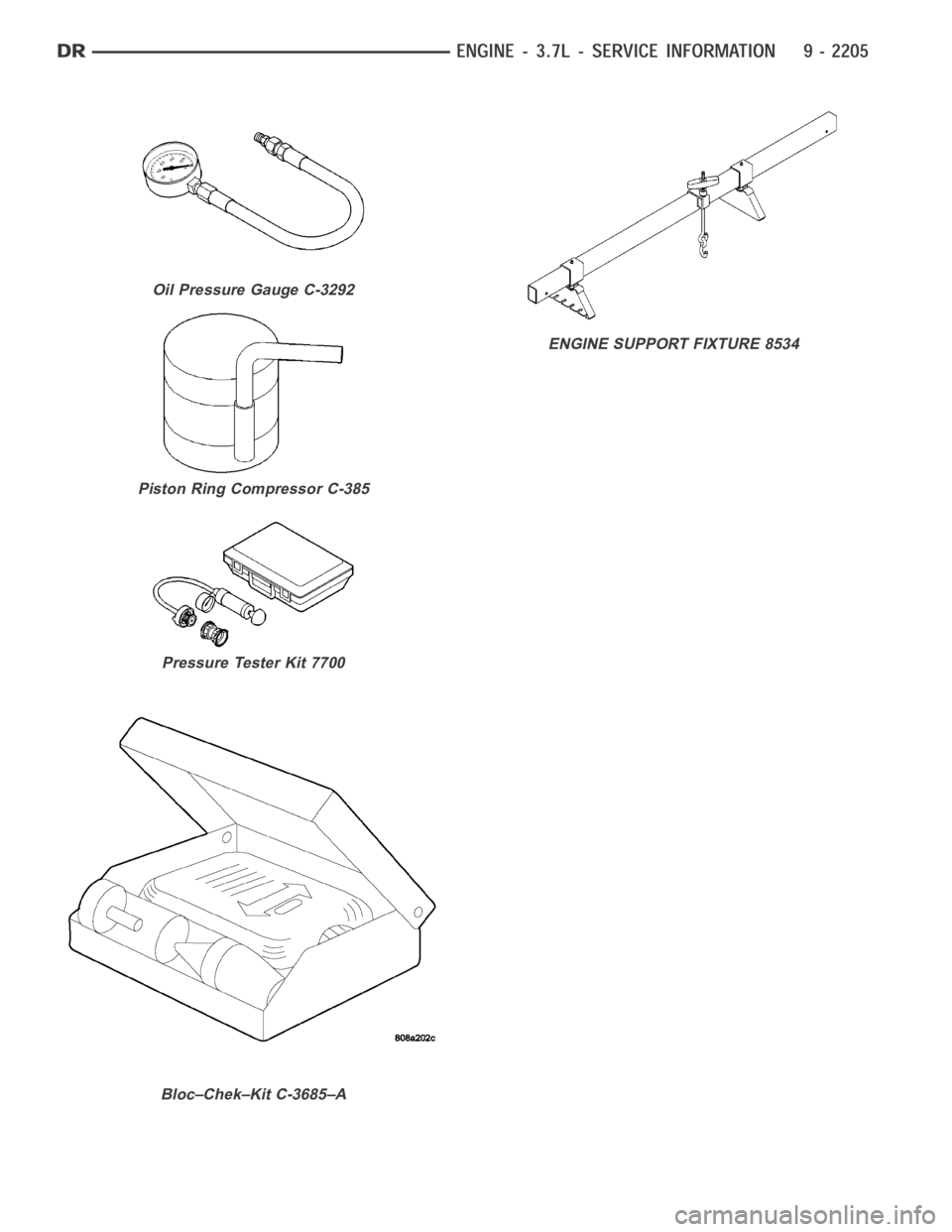

Oil Pressure Gauge C-3292

Piston Ring Compressor C-385

Pressure Tester Kit 7700

Bloc–Chek–Kit C-3685–A

ENGINE SUPPORT FIXTURE 8534

Page 1517 of 5267

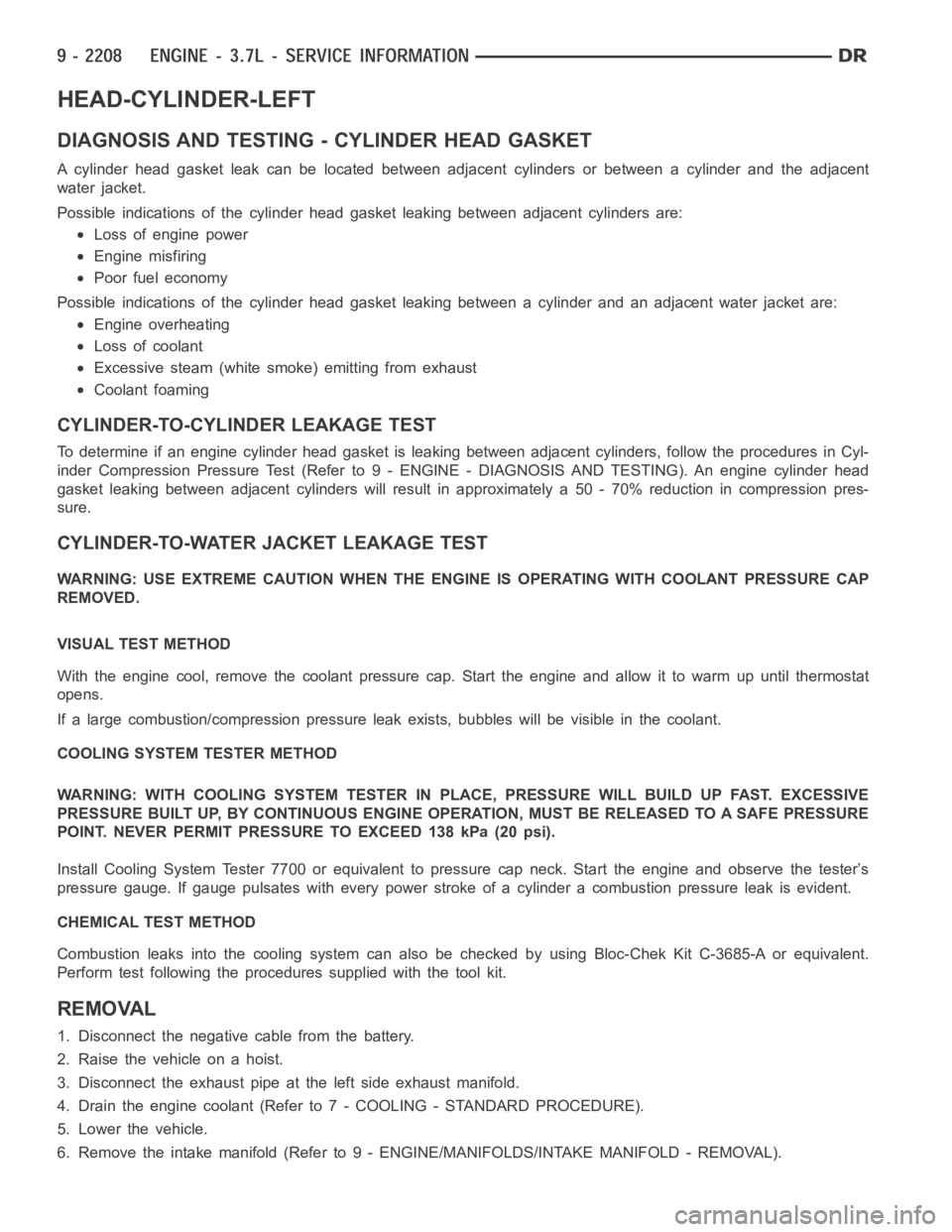

HEAD-CYLINDER-LEFT

DIAGNOSIS AND TESTING - CYLINDER HEAD GASKET

A cylinder head gasket leak can be located between adjacent cylinders or between a cylinder and the adjacent

water jacket.

Possible indications of the cylinder head gasket leaking between adjacent cylinders are:

Loss of engine power

Engine misfiring

Poor fuel economy

Possible indications of the cylinder head gasket leaking between a cylinder and an adjacent water jacket are:

Engine overheating

Loss of coolant

Excessive steam (white smoke) emitting from exhaust

Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is leaking between adjacentcylinders, follow the procedures in Cyl-

inder Compression Pressure Test (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING). An engine cylinder head

gasket leaking between adjacent cylinders will result in approximately a50 - 70% reduction in compression pres-

sure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE ENGINE IS OPERATING WITH COOLANT PRESSURE CAP

REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure cap. Start the engine andallow it to warm up until thermostat

opens.

If a large combustion/compression pressure leak exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN PLACE, PRESSURE WILL BUILD UP FAST.EXCESSIVE

PRESSURE BUILT UP, BY CONTINUOUS ENGINE OPERATION, MUST BE RELEASED TO A SAFE PRESSURE

POINT. NEVER PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to pressure cap neck. Start the engine and observe the tester’s

pressure gauge. If gauge pulsates with every power stroke of a cylinder a combustion pressure leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also be checked by using Bloc-Chek Kit C-3685-A or equivalent.

Perform test following the procedures supplied with the tool kit.

REMOVAL

1. Disconnect the negative cable from the battery.

2. Raise the vehicle on a hoist.

3. Disconnect the exhaust pipe at the left side exhaust manifold.

4. Drain the engine coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

5. Lower the vehicle.

6. Remove the intake manifold (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

Page 1518 of 5267

7. Remove the master cylinder and booster assembly (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - REMOVAL).

8. Remove the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL).

9. Remove the fan shroud and fan blade assembly

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

10. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

11. Remove the power steering pump and set aside.

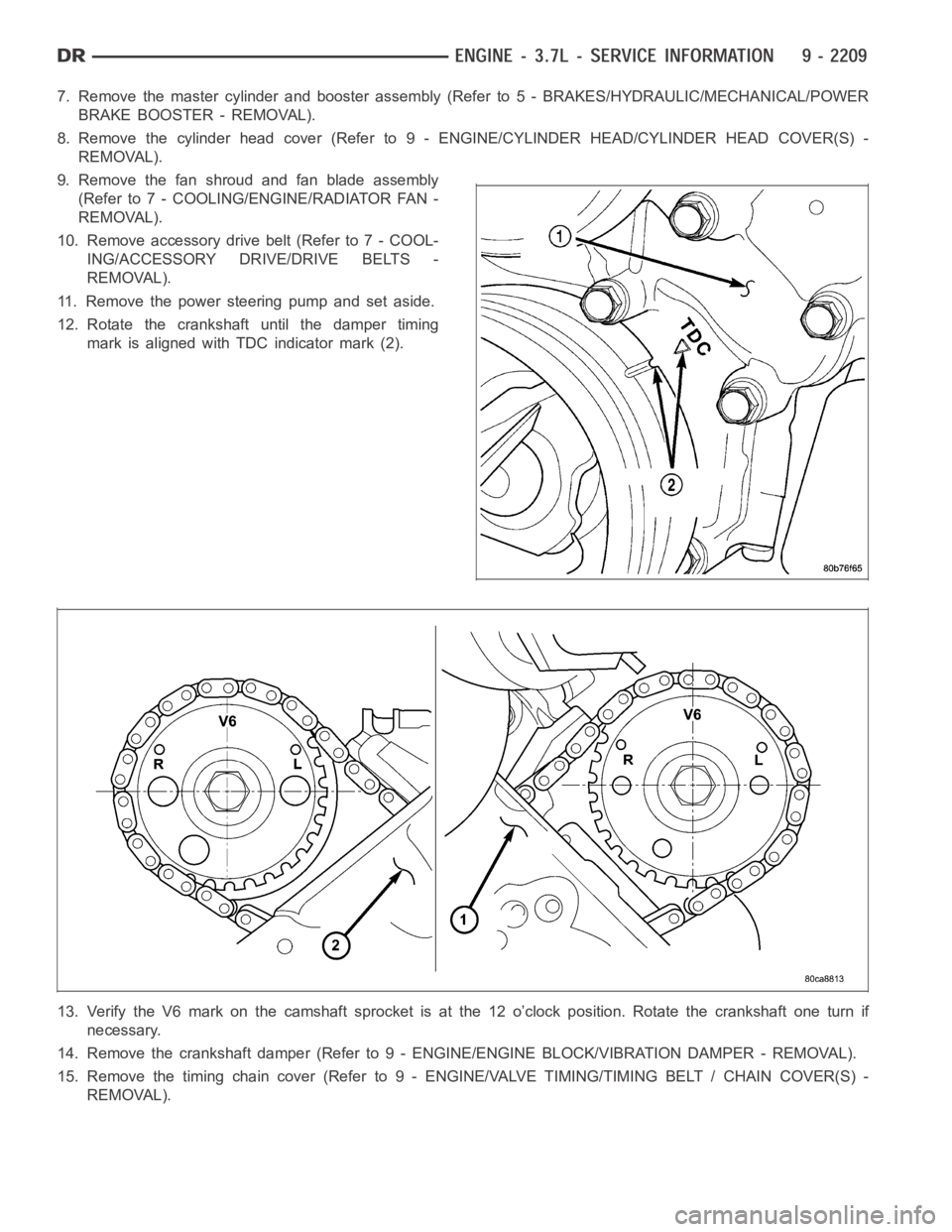

12. Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark (2).

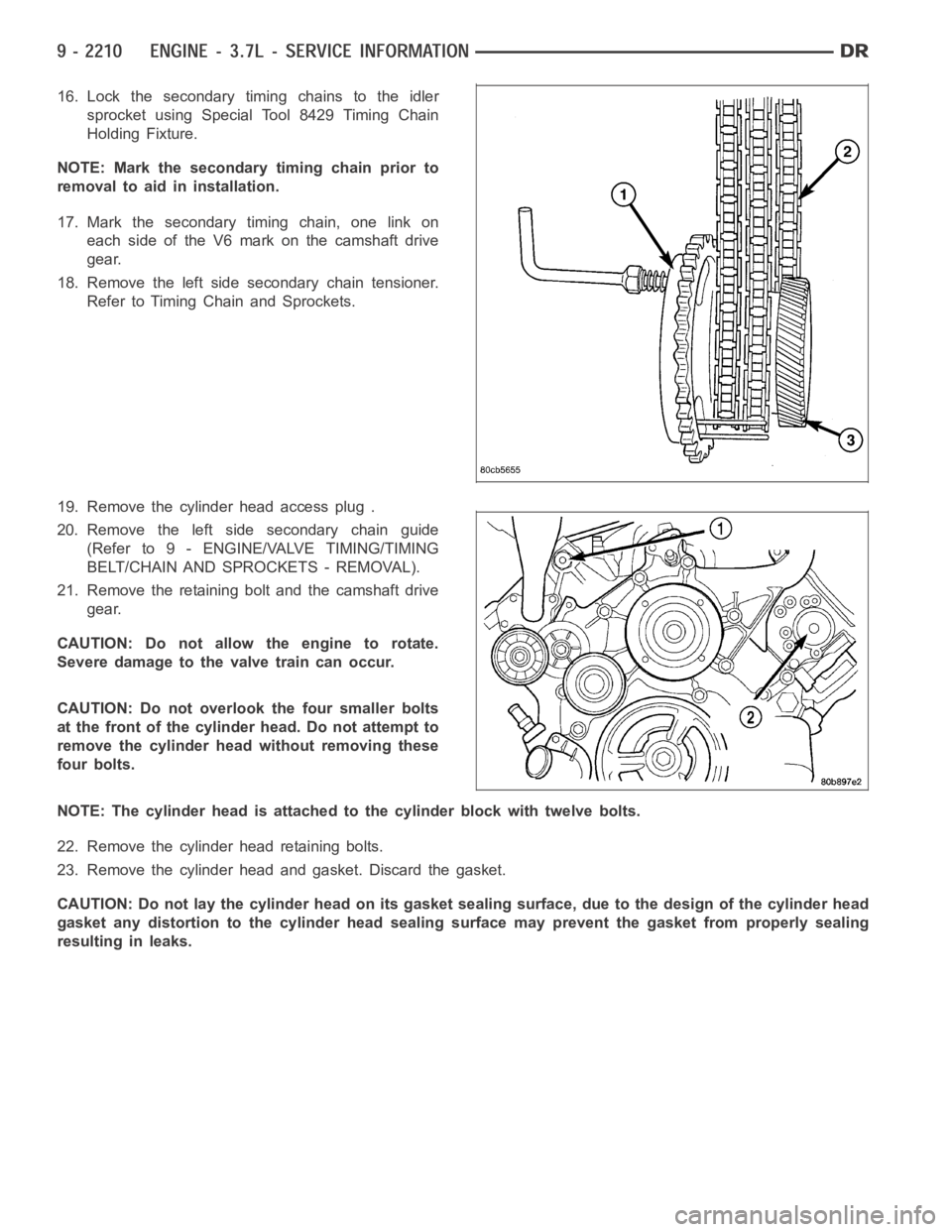

13. Verify the V6 mark on the camshaft sprocket is at the 12 o’clock position. Rotate the crankshaft one turn if

necessary.

14. Remove the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - REMOVAL).

15. Remove the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMINGBELT / CHAIN COVER(S) -

REMOVAL).

Page 1519 of 5267

16. Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain

Holding Fixture.

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

17. Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive

gear.

18. Remove the left side secondary chain tensioner.

Refer to Timing Chain and Sprockets.

19. Remove the cylinder head access plug .

20. Remove the left side secondary chain guide

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

21. Remove the retaining bolt and the camshaft drive

gear.

CAUTION: Do not allow the engine to rotate.

Severe damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts

at the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

NOTE: The cylinder head is attached to the cylinder block with twelve bolts.

22. Remove the cylinder head retaining bolts.

23. Remove the cylinder head and gasket. Discard the gasket.

CAUTION: Do not lay the cylinder head on its gasket sealing surface, due to the design of the cylinder head

gasket any distortion to the cylinder head sealing surface may prevent thegasket from properly sealing

resulting in leaks.

Page 1521 of 5267

2. Position the new cylinder head gasket on the locat-

ing dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

3. Position the cylinder head onto the cylinder block.

Make sure the cylinder head seats fully over the

locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

4. Lubricate the cylinder head bolt threads with clean

engine oil and install the eight M11 bolts.

5. Coat the four M8 cylinder head bolts withMopar

Lock and Seal Adhesivethen install the bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

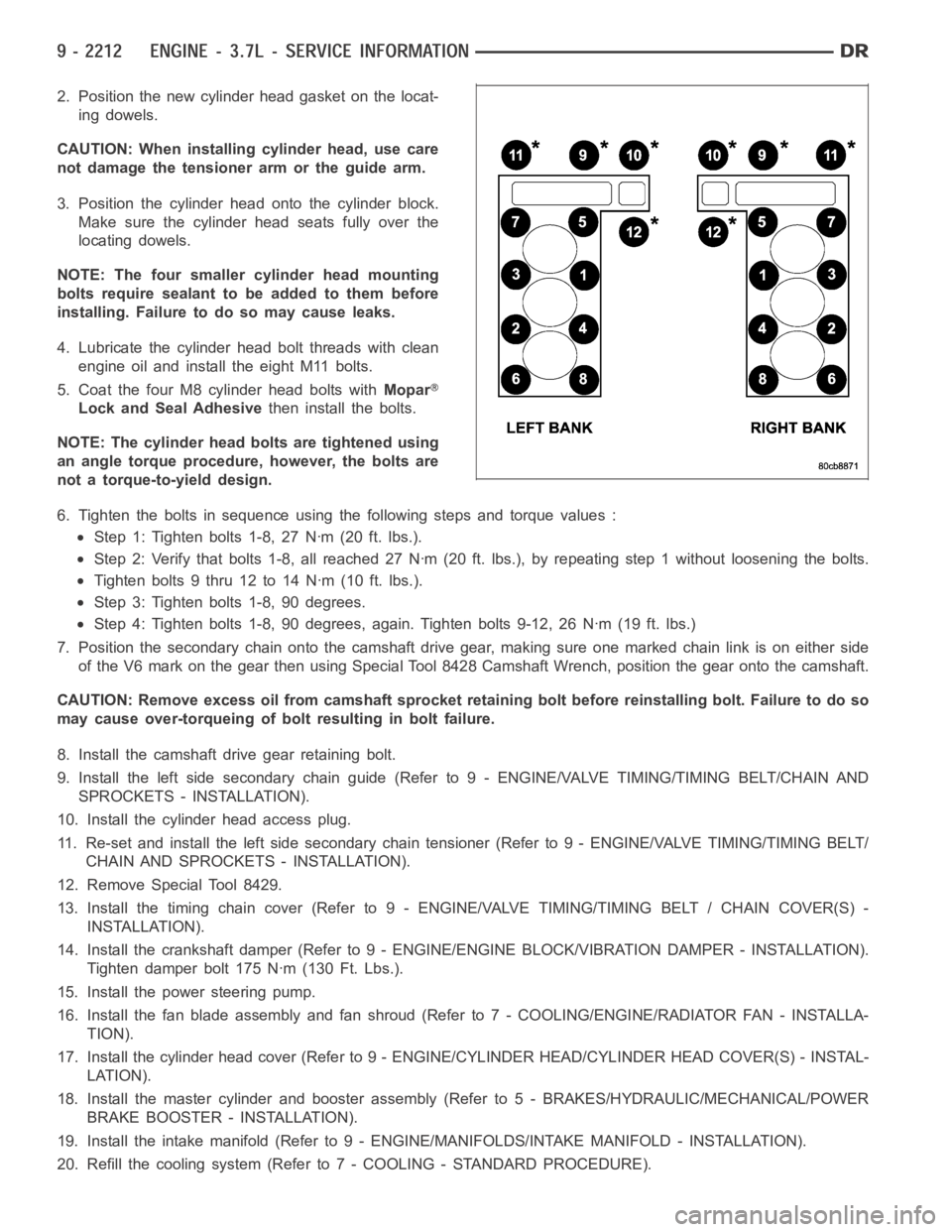

6. Tighten the bolts in sequence using the following steps and torque values:

Step 1: Tighten bolts 1-8, 27 Nꞏm (20 ft. lbs.).

Step 2: Verify that bolts 1-8, all reached 27 Nꞏm (20 ft. lbs.), by repeatingstep 1 without loosening the bolts.

Tightenbolts9thru12to14Nꞏm(10ft.lbs.).

Step 3: Tighten bolts 1-8, 90 degrees.

Step 4: Tighten bolts 1-8, 90 degrees, again. Tighten bolts 9-12, 26 Nꞏm (19ft. lbs.)

7. Position the secondary chain onto the camshaft drive gear, making sure one marked chain link is on either side

of the V6 mark on the gear then using Special Tool 8428 Camshaft Wrench, position the gear onto the camshaft.

CAUTION: Remove excess oil from camshaft sprocket retaining bolt before reinstalling bolt. Failure to do so

may cause over-torqueing of bolt resulting in bolt failure.

8. Install the camshaft drive gear retaining bolt.

9. Install the left side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

10. Install the cylinder head access plug.

11. Re-set and install the left side secondary chain tensioner (Refer to 9 -ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - INSTALLATION).

12. Remove Special Tool 8429.

13. Install the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) -

INSTALLATION).

14. Install the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTALLATION).

Tighten damper bolt 175 Nꞏm (130 Ft. Lbs.).

15. Install the power steering pump.

16. Install the fan blade assembly and fan shroud (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

17. Install the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTAL-

LATION).

18. Install the master cylinder and booster assembly (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - INSTALLATION).

19. Install the intake manifold (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

20. Refill the cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

Page 1522 of 5267

21. Raise the vehicle.

22. Install the exhaust pipe onto the left exhaust manifold.

23. Lower the vehicle.

24. Connect the negative cable to the battery.

25. Start the engine and check for leaks.

Page 1523 of 5267

CAMSHAFT

DESCRIPTION

The camshafts consist of powdered metal steel lobes which are sinter-bonded to a steel tube. Four bearing journals

are machined into the camshaft. Camshaft end play is controlled by two thrust walls that border the nose piece

journal.

REMOVAL

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT forcefully

rotate the camshafts or crankshaft independently of each other. Severe valve and/or piston damage can

occur.

CAUTION: When removing the cam sprocket, timing chains or camshaft, Failure to use Special Tool 8379

will result in hydraulic tensioner ratchet over extension, requiring timing chain cover removal to reset the

tensioner ratchet.

1. Remove cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDERHEAD COVER(S) -

REMOVAL).

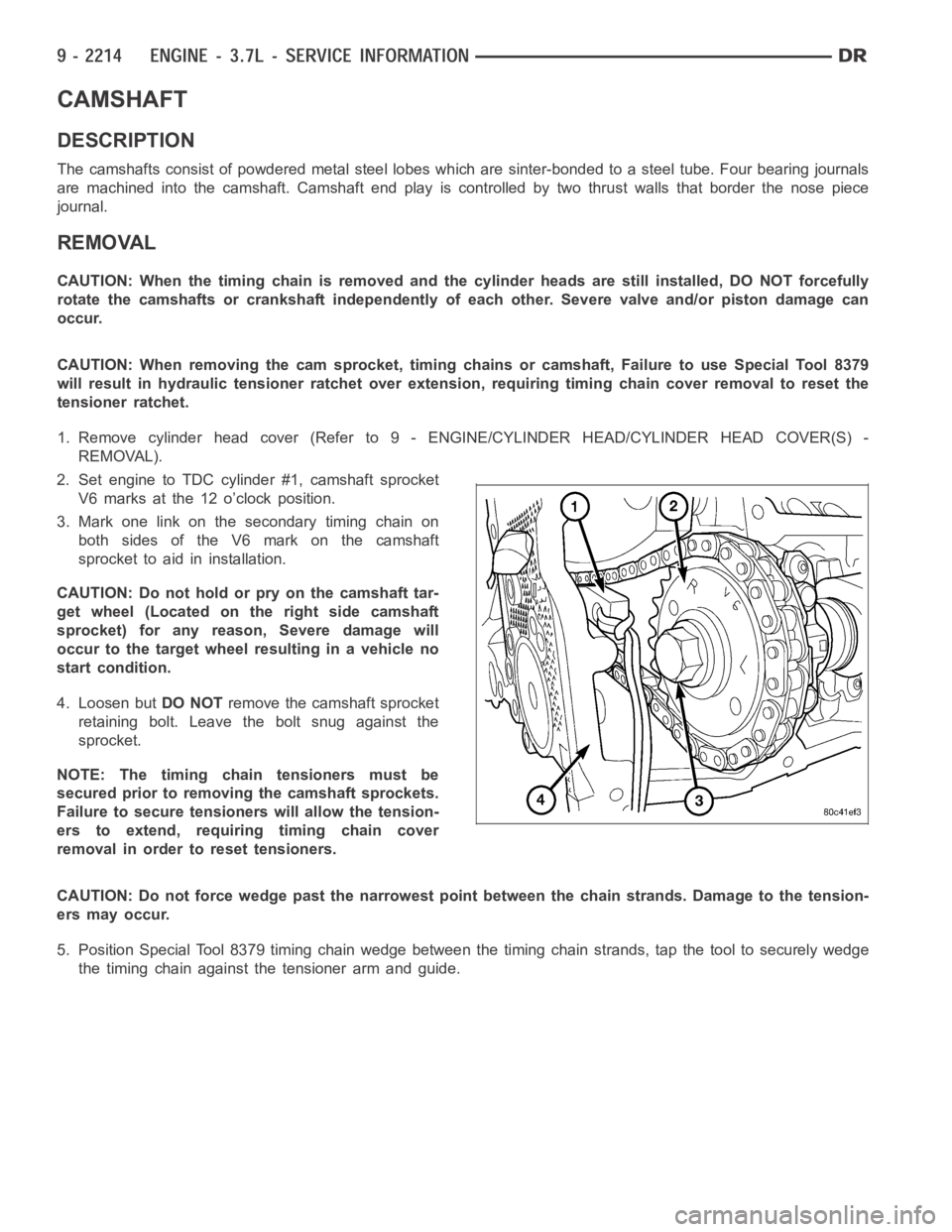

2. Set engine to TDC cylinder #1, camshaft sprocket

V6 marks at the 12 o’clock position.

3. Mark one link on the secondary timing chain on

both sides of the V6 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel (Located on the right side camshaft

sprocket) for any reason, Severe damage will

occur to the target wheel resulting in a vehicle no

start condition.

4. Loosen butDO NOTremove the camshaft sprocket

retaining bolt. Leave the bolt snug against the

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

erstoextend,requiringtimingchaincover

removal in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest point between the chain strands. Damage to the tension-

ers may occur.

5. Position Special Tool 8379 timing chain wedge between the timing chain strands, tap the tool to securely wedge

the timing chain against the tensioner arm and guide.

Page 1524 of 5267

6. Hold the camshaft with Special Tool 8428 Camshaft

Wrench , while removing the camshaft sprocket

bolt and sprocket.

7. Using Special Tool 8428 Camshaft Wrench, gently

allow the camshaft to rotate 5° clockwise until the

camshaft is in the neutral position (no valve load).

8. Starting at the outside working inward, loosen the

camshaft bearing cap retaining bolts 1/2 turn at a

time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

9. Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

1. Lubricate camshaft journals with clean engine oil.

NOTE: Position the left side camshaft so that the

camshaft sprocket dowel is near the 1 o’clock

position, This will place the camshaft at the neu-

tral position easing the installation of the camshaft

bearing caps.

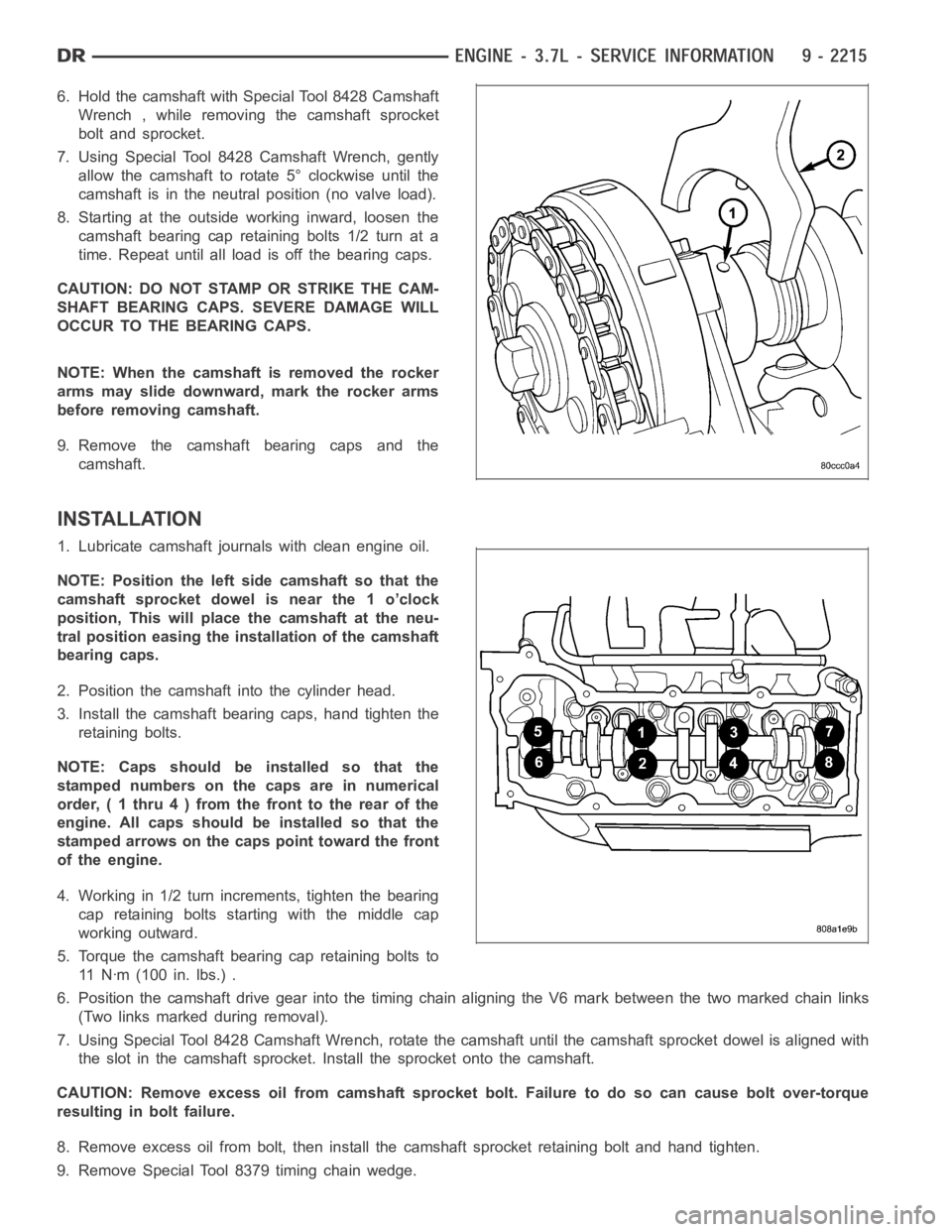

2. Position the camshaft into the cylinder head.

3. Install the camshaft bearing caps, hand tighten the

retaining bolts.

NOTE: Caps should be installed so that the

stamped numbers on the caps are in numerical

order, ( 1 thru 4 ) from the front to the rear of the

engine. All caps should be installed so that the

stamped arrows on the caps point toward the front

of the engine.

4. Working in 1/2 turn increments, tighten the bearing

cap retaining bolts starting with the middle cap

working outward.

5. Torque the camshaft bearing cap retaining bolts to

11 N ꞏm ( 1 0 0 i n . l b s . ) .

6. Position the camshaft drive gear into the timing chain aligning the V6 mark between the two marked chain links

(Two links marked during removal).

7. Using Special Tool 8428 Camshaft Wrench, rotate the camshaft until the camshaft sprocket dowel is aligned with

the slot in the camshaft sprocket. Install the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft sprocket bolt. Failure to do so can cause bolt over-torque

resulting in bolt failure.

8. Remove excess oil from bolt, then install the camshaft sprocket retaining bolt and hand tighten.

9. Remove Special Tool 8379 timing chain wedge.