engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5213 of 5267

PUMP-NATURAL VAC LEAK DETECTION

DESCRIPTION

Vehicles equipped with an NGC Powertrain Control Module (PCM) use a Natural Vacuum Leak Detection (NVLD)

pump and system. Vehicles equipped with a JTEC PCM use an LDP (Leak Detection Pump). Refer to Leak Detec-

tion Pump (LDP) for additional information.

The NVLD pump is located in the same area as the leak detection pump. Refer toNVLD Removal / Installation for

additional information.

OPERATION

The Natural Vacuum Leak Detection (NVLD) system is the next generation evaporative leak detection system that

will first be used on vehicles equipped with the Next Generation Controller (NGC). This new system replaces the

leak detection pump as the method of evaporative system leak detection. This is to detect a leak equivalent to a

0.020

(0.5 mm) hole. This system has the capability to detect holes of this size very dependably.

The basic leak detection theory employed with NVLD is the

Gas Law. This is to say that the pressure in a sealed

vessel will change if the temperature of the gas in the vessel changes. The vessel will only see this effect if it is

indeed sealed. Even small leaks will allow the pressure in the vessel to come to equilibrium with the ambient pres-

sure. In addition to the detection of very small leaks, this system has the capability of detecting medium as well as

large evaporative system leaks.

A vent valve seals the canister vent during engine off conditions. If the vapor system has a leak of less than the

failure threshold, the evaporativesystem will be pulled into a vacuum, either due to the cool down from operating

temperature or diurnal ambient temperature cycling. The diurnal effect is considered one of the primary contributors

to the leak determination by this diagnostic. When the vacuum in the systemexceeds about 1

H2O (0.25 KPA), a

vacuum switch closes. The switch closure sends a signal to the NGC. The NGC,via appropriate logic strategies,

utilizes the switch signal, or lack thereof, to make a determination of whether a leak is present.

The NVLD device is designed with a normally open vacuum switch, a normally closed solenoid, and a seal, which

is actuated by both the solenoid and a diaphragm. The NVLD is located on the atmospheric vent side of the can-

ister. The NVLD assembly may be mounted on top of the canister outlet, or in-line between the canister and atmo-

spheric vent filter. The normally open vacuum switch will close with about1

H2O (0.25 KPA) vacuum in the

evaporative system. The diaphragm actuates the switch. This is above the opening point of the fuel inlet check valve

in the fill tube so cap off leaks can be detected. Submerged fill systems must have recirculation lines that do not

have the in-line normally closed check valve that protects the system fromfailednozzleliquidingestion,inorderto

detect cap off conditions.

The normally closed valve in the NVLD is intended to maintain the seal on theevaporative system during the engine

off condition. If vacuum in the evaporative system exceeds 3

to 6H2O (0.75 to 1.5 KPA), the valve will be pulled

off the seat, opening the seal. This will protect the system from excessivevacuum as well as allowing sufficient

purge flow in the event that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the canister vent while the engine is running. It also will be used to close

the vent during the medium and large leak tests and during the purge flow check. This solenoid requires an initial

1.5 amps of current to pull the valveopen, but after 100 mili-seconds, willbedutycycleddowntoanaverageof

about 150 mA for the remainder of the drive cycle.

Another feature in the device is a diaphragm that will open the seal in the NVLD with pressure in the evaporative

system. The device will

blow offat about 0.5H2O (0.12 KPA) pressure to permit the venting of vapors during

refueling. An added benefit to this is that it will also allow the tank to

breatheduring increasing temperatures, thus

limiting the pressure in the tank to this low level. This is beneficial because the induced vacuum during a subse-

quent declining temperature will achieve the switch closed (pass threshold) sooner than if the tank had to decay

from a built up pressure.

The device itself has 3 wires: Switch sense, solenoid driver and ground. Italso includes a resistor to protect the

switch from a short to battery or a short to ground. The NGC utilizes a high-side driver to energize and duty-cycle

the solenoid.

Page 5221 of 5267

VA LV E - P C V

DESCRIPTION

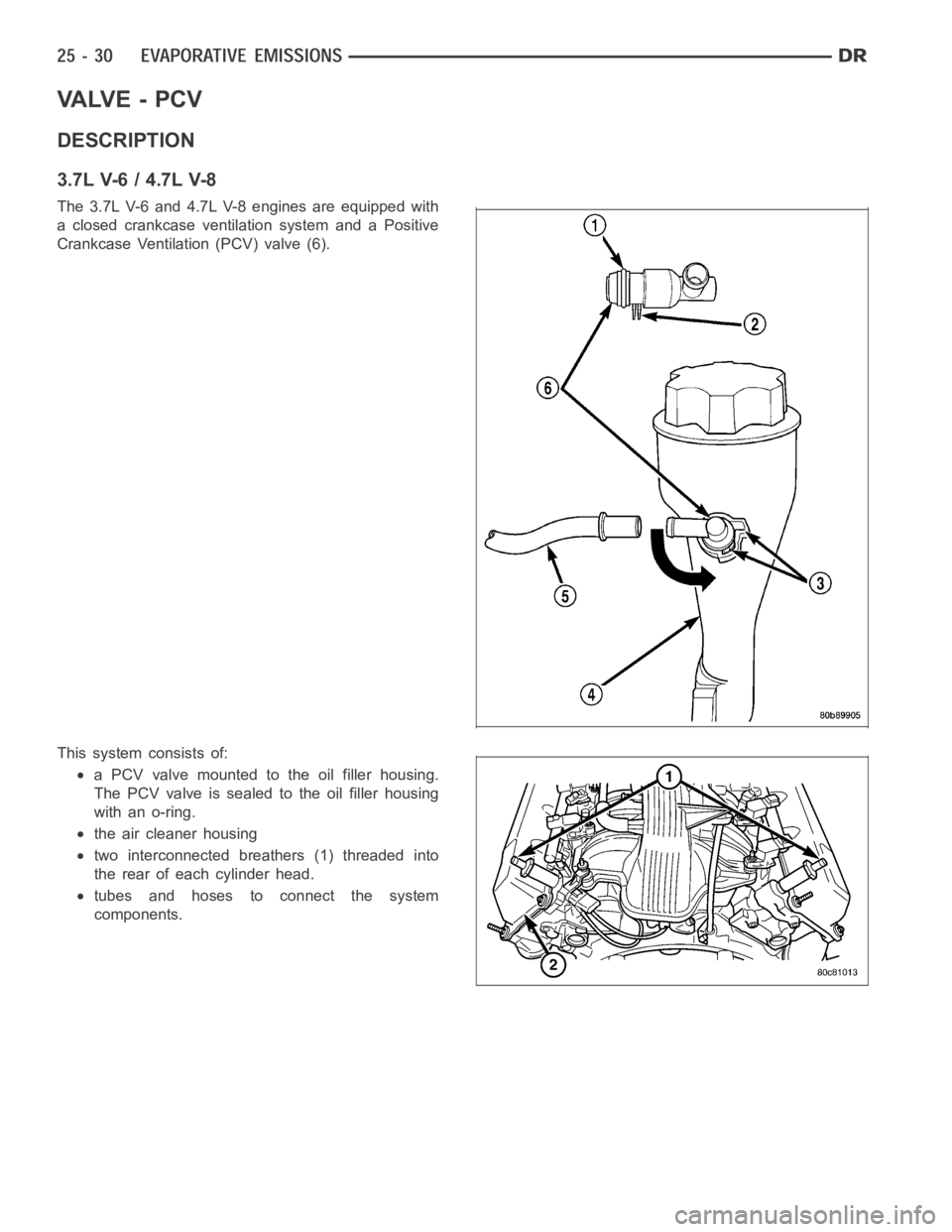

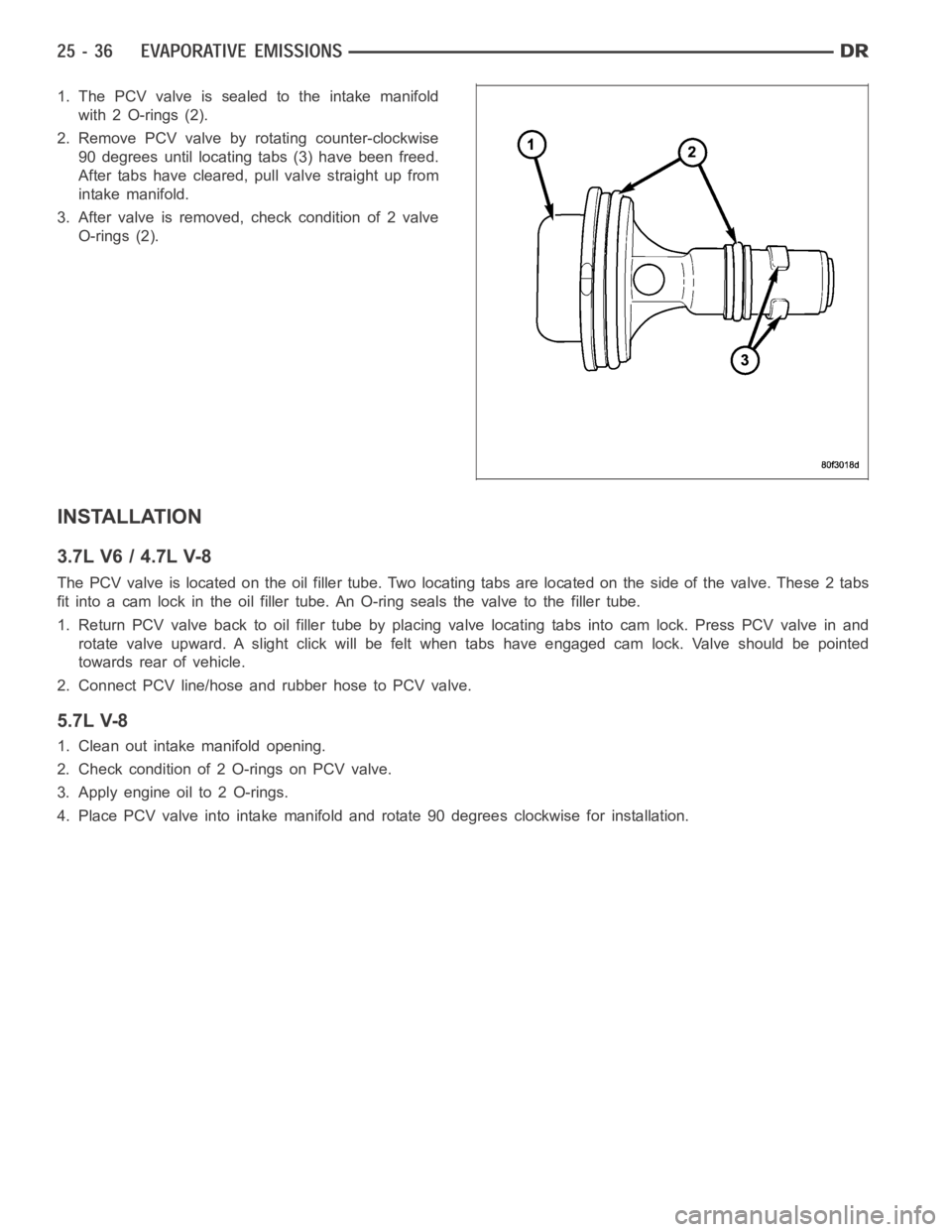

3.7L V-6 / 4.7L V-8

The 3.7L V-6 and 4.7L V-8 engines are equipped with

a closed crankcase ventilation system and a Positive

Crankcase Ventilation (PCV) valve (6).

This system consists of:

a PCV valve mounted to the oil filler housing.

The PCV valve is sealed to the oil filler housing

with an o-ring.

the air cleaner housing

two interconnected breathers (1) threaded into

the rear of each cylinder head.

tubes and hoses to connect the system

components.

Page 5222 of 5267

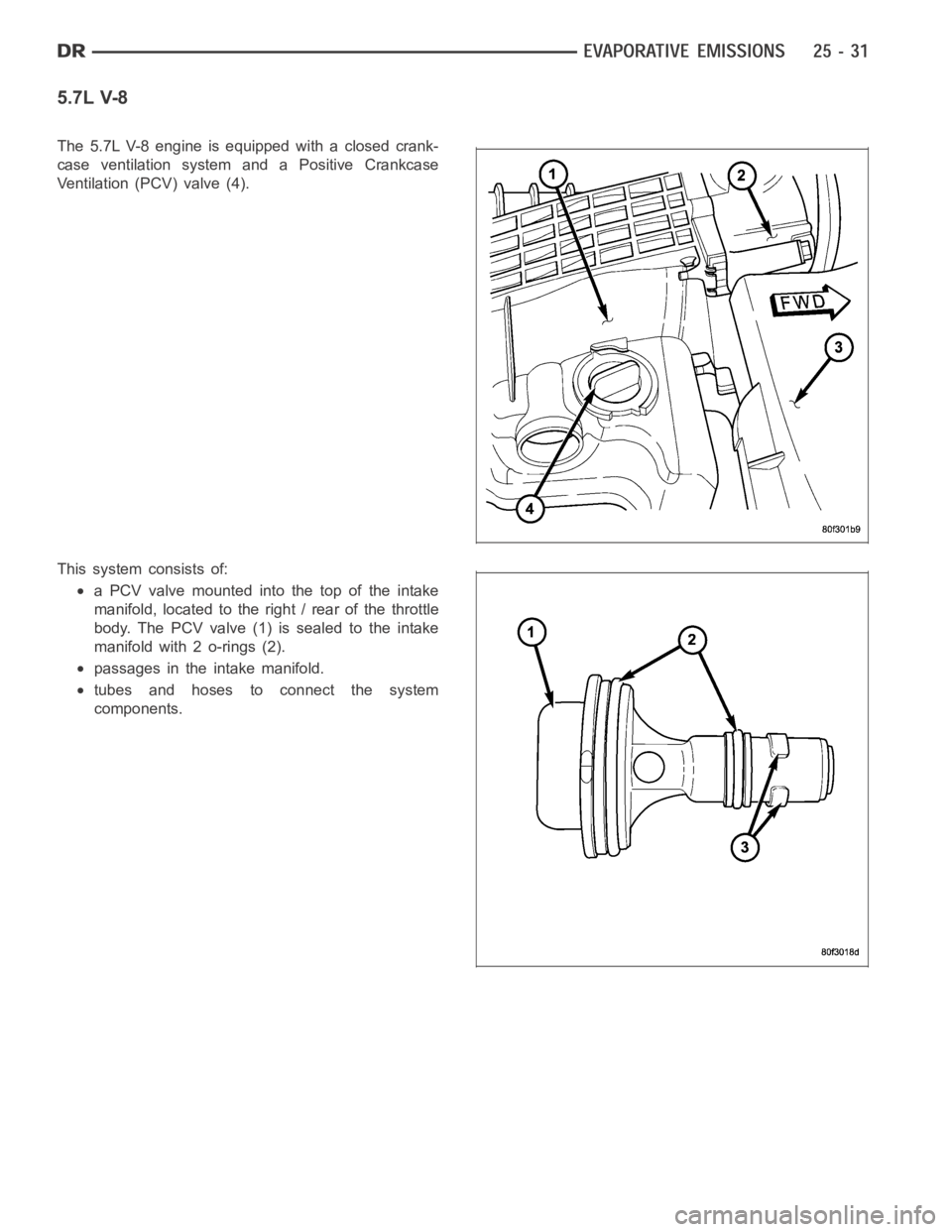

5.7L V-8

The 5.7L V-8 engine is equipped with a closed crank-

case ventilation system and a Positive Crankcase

Ventilation (PCV) valve (4).

This system consists of:

a PCV valve mounted into the top of the intake

manifold, located to the right / rear of the throttle

body. The PCV valve (1) is sealed to the intake

manifold with 2 o-rings (2).

passages in the intake manifold.

tubes and hoses to connect the system

components.

Page 5223 of 5267

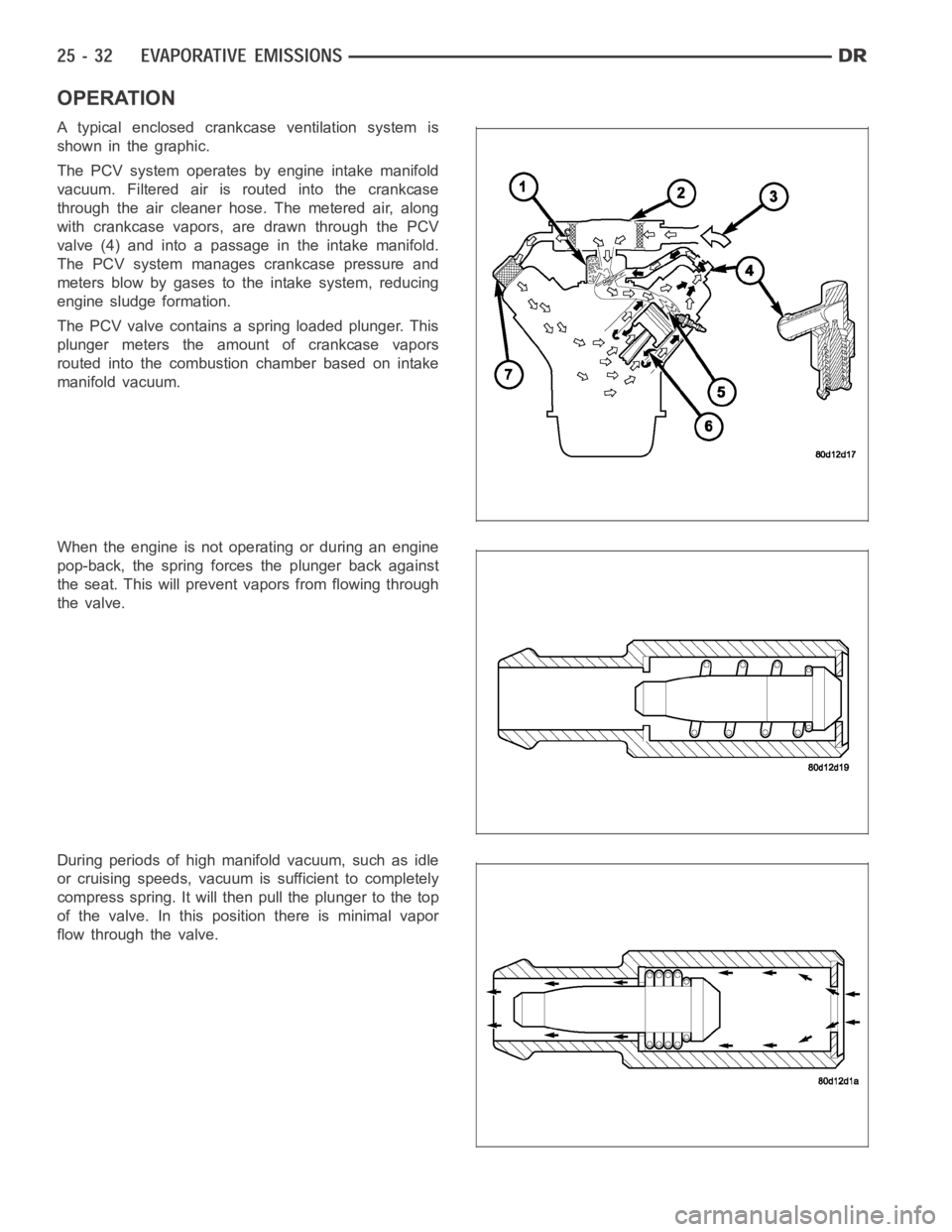

OPERATION

A typical enclosed crankcase ventilation system is

shown in the graphic.

The PCV system operates by engine intake manifold

vacuum. Filtered air is routed into the crankcase

through the air cleaner hose. The metered air, along

with crankcase vapors, are drawn through the PCV

valve (4) and into a passage in the intake manifold.

The PCV system manages crankcase pressure and

meters blow by gases to the intake system, reducing

engine sludge formation.

The PCV valve contains a spring loaded plunger. This

plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

When the engine is not operating or during an engine

pop-back, the spring forces the plunger back against

the seat. This will prevent vapors from flowing through

the valve.

During periods of high manifold vacuum, such as idle

or cruising speeds, vacuum is sufficient to completely

compress spring. It will then pull the plunger to the top

of the valve. In this position there is minimal vapor

flow through the valve.

Page 5224 of 5267

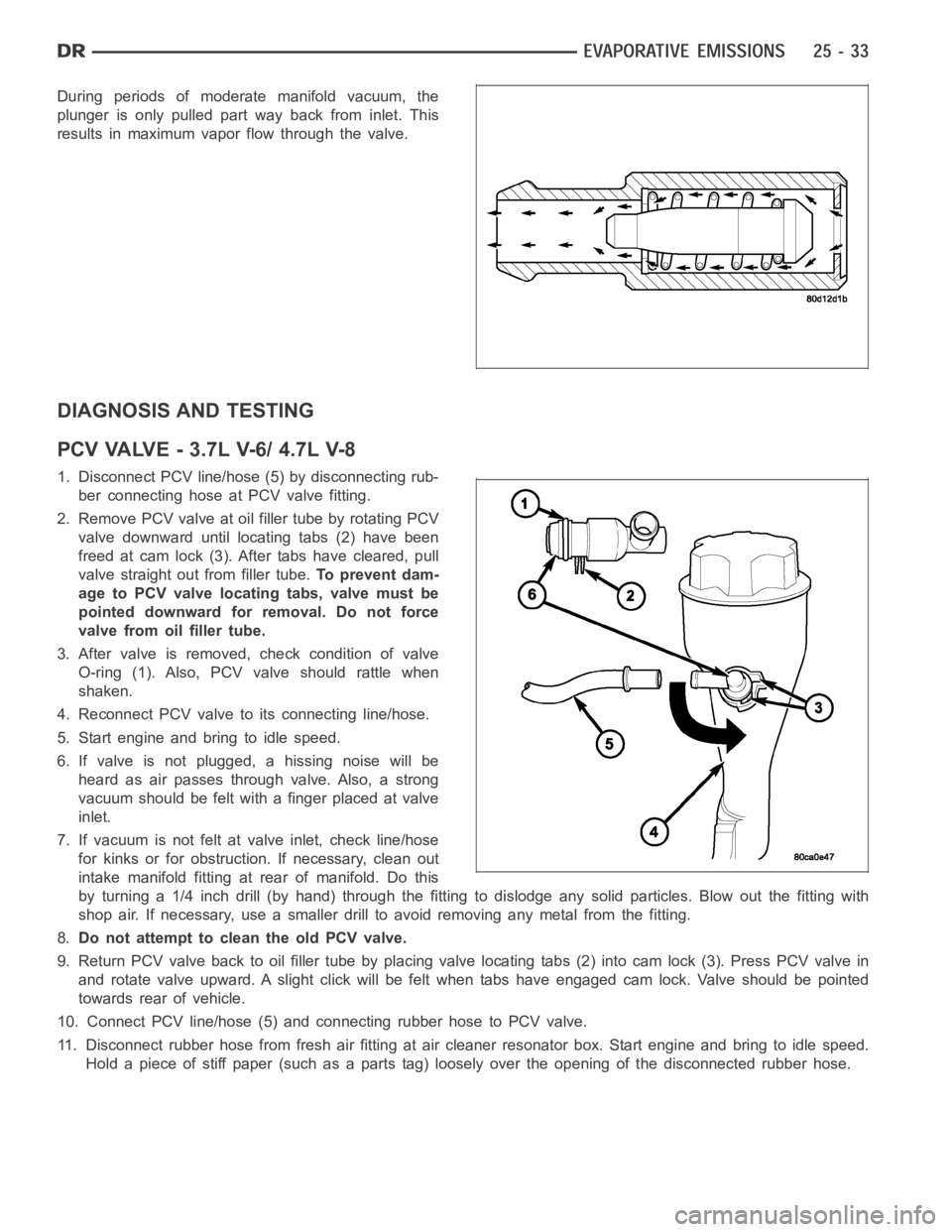

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve.

DIAGNOSIS AND TESTING

PCVVALVE-3.7LV-6/4.7LV-8

1. Disconnect PCV line/hose (5) by disconnecting rub-

ber connecting hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward until locating tabs (2) have been

freed at cam lock (3). After tabs have cleared, pull

valve straight out from filler tube.To prevent dam-

age to PCV valve locating tabs, valve must be

pointed downward for removal. Do not force

valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1). Also, PCV valve should rattle when

shaken.

4. Reconnect PCV valve to its connecting line/hose.

5. Start engine and bring to idle speed.

6. If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong

vacuum should be felt with a finger placed at valve

inlet.

7. If vacuum is not felt at valve inlet, check line/hose

for kinks or for obstruction. If necessary, clean out

intake manifold fitting at rear of manifold. Do this

byturninga1/4inchdrill(byhand)throughthefittingtodislodgeanysolid particles. Blow out the fitting with

shop air. If necessary, use a smaller drill to avoid removing any metal fromthe fitting.

8.Do not attempt to clean the old PCV valve.

9. Return PCV valve back to oil filler tube by placing valve locating tabs (2) into cam lock (3). Press PCV valve in

and rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

10. Connect PCV line/hose (5) and connecting rubber hose to PCV valve.

11. Disconnect rubber hose from fresh air fitting at air cleaner resonatorbox. Start engine and bring to idle speed.

Hold a piece of stiff paper (such as a parts tag) loosely over the opening of the disconnected rubber hose.

Page 5227 of 5267

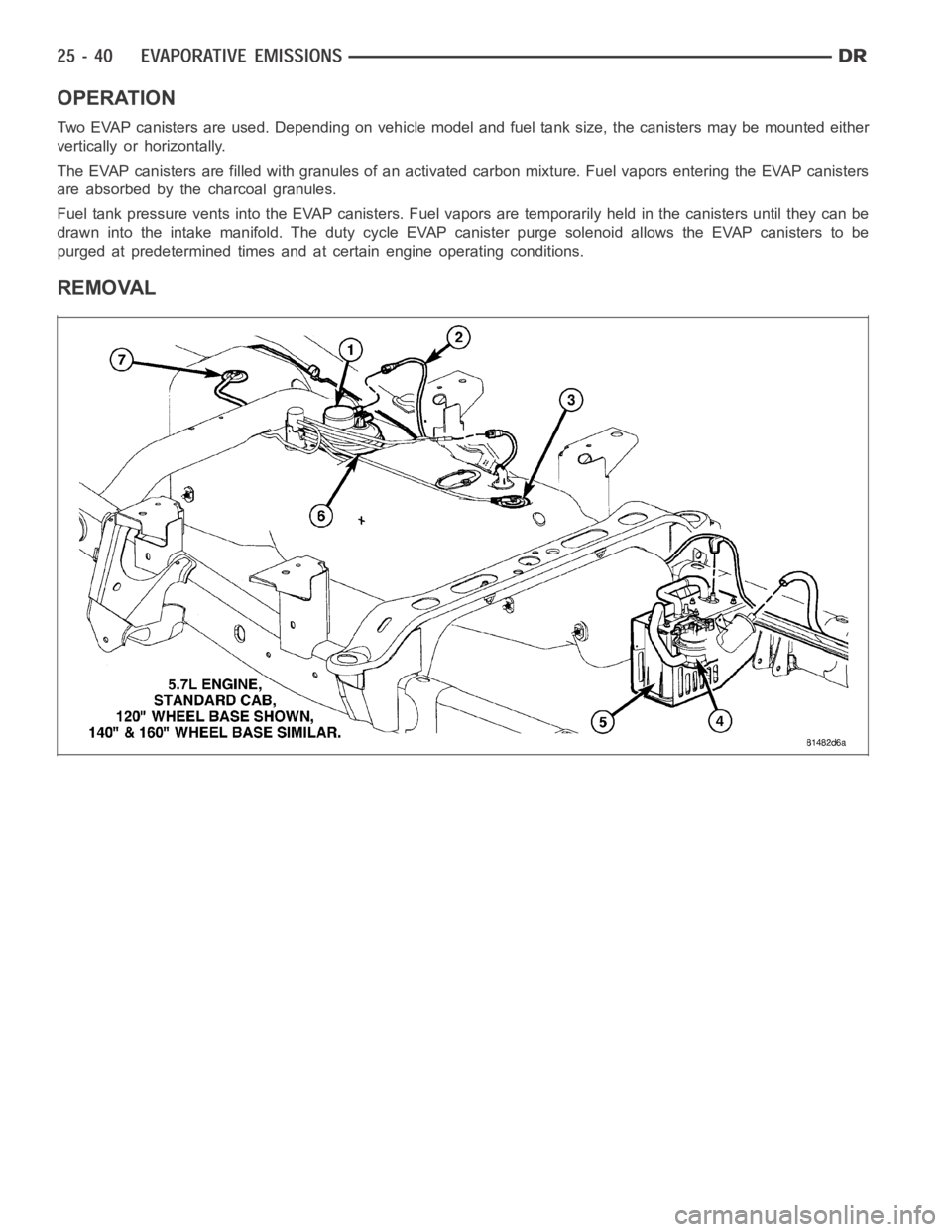

1. The PCV valve is sealed to the intake manifold

with 2 O-rings (2).

2. Remove PCV valve by rotating counter-clockwise

90 degrees until locating tabs (3) have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

3. After valve is removed, check condition of 2 valve

O-rings (2).

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two locating tabs are locatedonthesideofthevalve.These2tabs

fit into a cam lock in the oil filler tube.An O-ring seals the valve to the filler tube.

1. Return PCV valve back to oil filler tube by placing valve locating tabs into cam lock. Press PCV valve in and

rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

2. Connect PCV line/hose and rubber hose to PCV valve.

5.7L V-8

1. Clean out intake manifold opening.

2. Check condition of 2 O-rings on PCV valve.

3. Apply engine oil to 2 O-rings.

4. Place PCV valve into intake manifold and rotate 90 degrees clockwise forinstallation.

Page 5231 of 5267

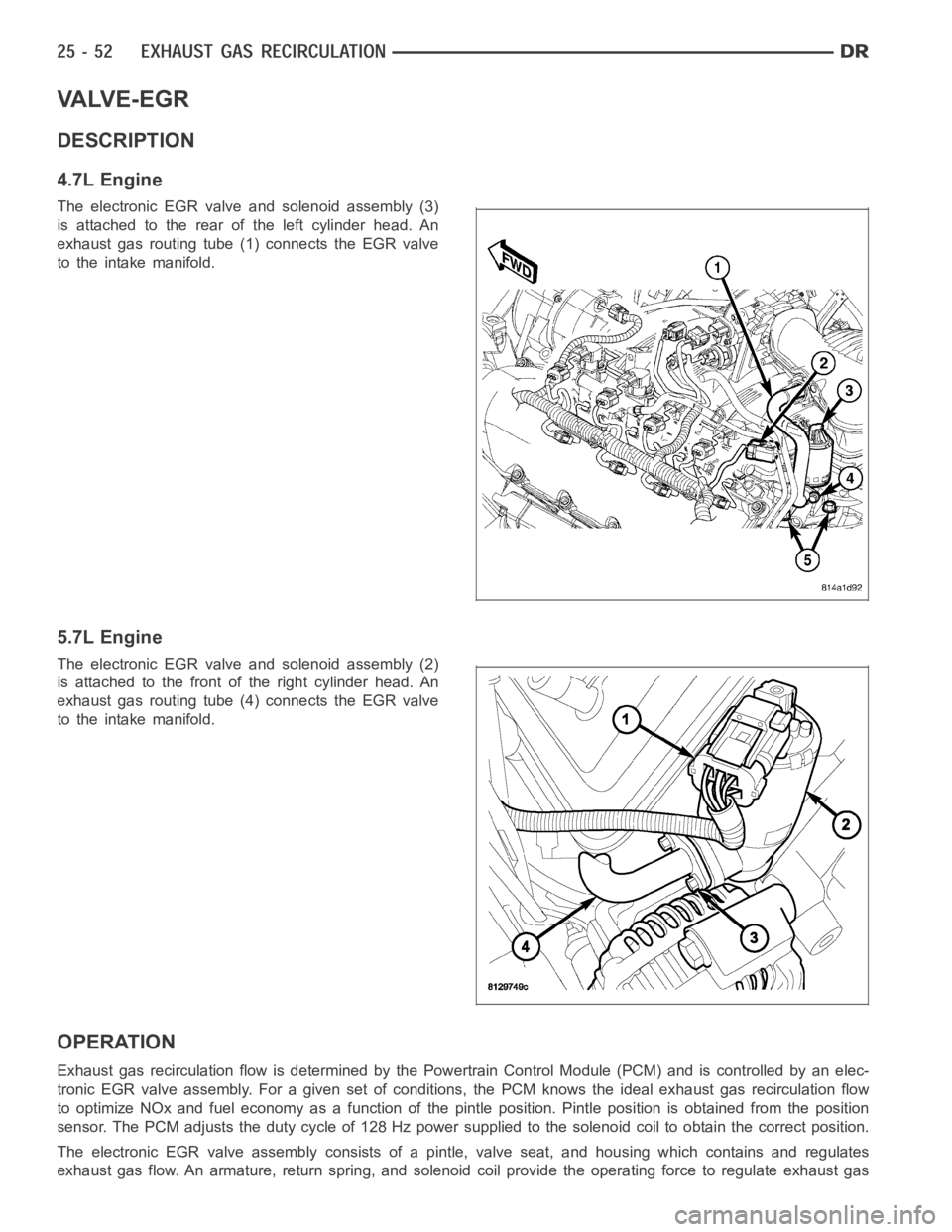

OPERATION

Two EVAP canisters are used. Depending on vehicle model and fuel tank size,the canisters may be mounted either

vertically or horizontally.

The EVAP canisters are filled with granules of an activated carbon mixture. Fuel vapors entering the EVAP canisters

are absorbed by the charcoal granules.

Fuel tank pressure vents into the EVAP canisters. Fuel vapors are temporarily held in the canisters until they can be

drawn into the intake manifold. The duty cycle EVAP canister purge solenoid allows the EVAP canisters to be

purged at predetermined times and at certain engine operating conditions.

REMOVAL

Page 5243 of 5267

VALVE-EGR

DESCRIPTION

4.7L Engine

The electronic EGR valve and solenoid assembly (3)

is attached to the rear of the left cylinder head. An

exhaust gas routing tube (1) connects the EGR valve

to the intake manifold.

5.7L Engine

The electronic EGR valve and solenoid assembly (2)

is attached to the front of the right cylinder head. An

exhaust gas routing tube (4) connects the EGR valve

to the intake manifold.

OPERATION

Exhaust gas recirculation flow is determined by the Powertrain Control Module (PCM) and is controlled by an elec-

tronic EGR valve assembly. For a given set of conditions, the PCM knows the ideal exhaust gas recirculation flow

to optimize NOx and fuel economy as a function of the pintle position. Pintle position is obtained from the position

sensor. The PCM adjusts the duty cycle of 128 Hz power supplied to the solenoid coil to obtain the correct position.

The electronic EGR valve assembly consists of a pintle, valve seat, and housing which contains and regulates

exhaust gas flow. An armature, return spring, and solenoid coil provide the operating force to regulate exhaust gas

Page 5244 of 5267

flow by changing the pintle position. The solenoid coil assembly is wired in parallel with a diode that connects two

internal connectors.

REMOVAL

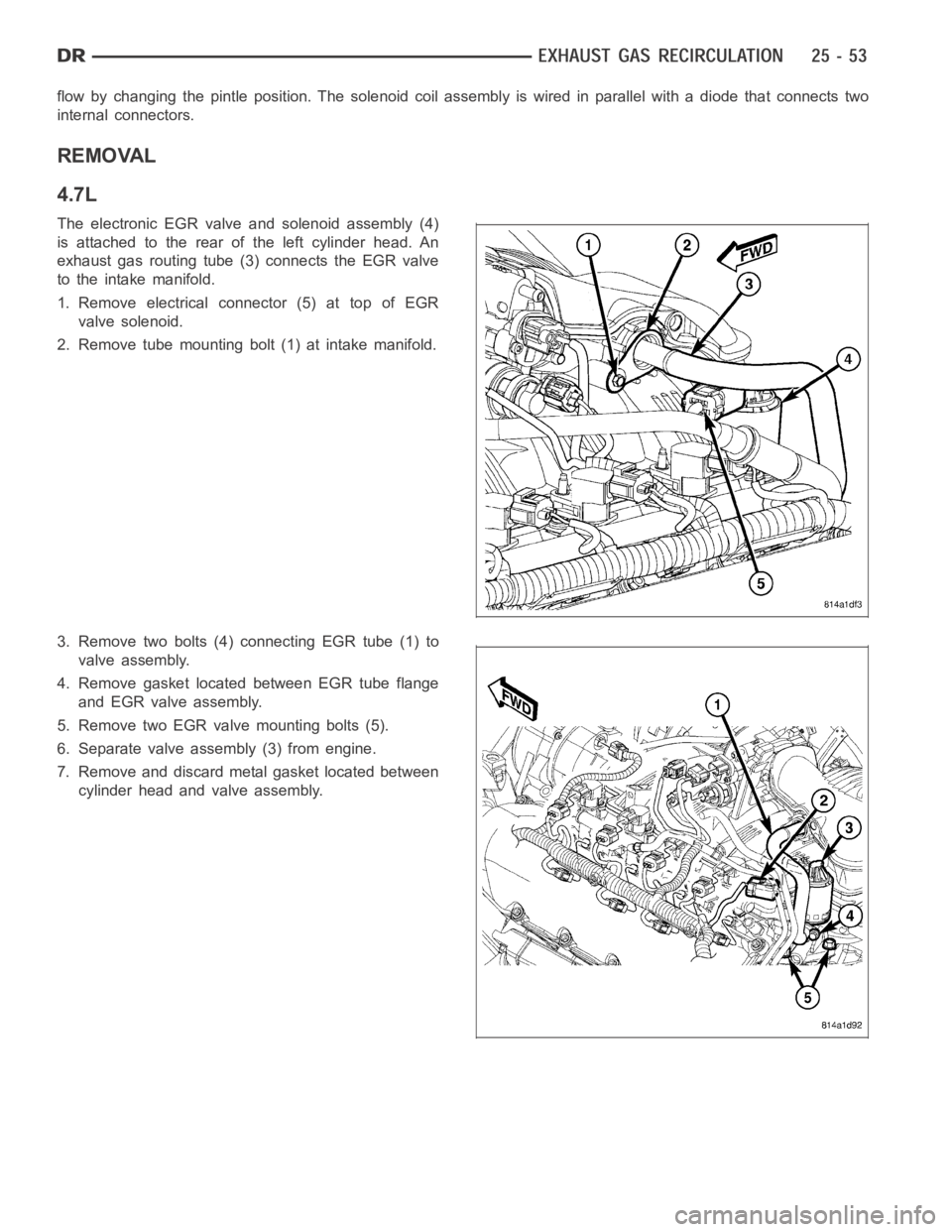

4.7L

The electronic EGR valve and solenoid assembly (4)

is attached to the rear of the left cylinder head. An

exhaust gas routing tube (3) connects the EGR valve

to the intake manifold.

1. Remove electrical connector (5) at top of EGR

valve solenoid.

2. Remove tube mounting bolt (1) at intake manifold.

3. Remove two bolts (4) connecting EGR tube (1) to

valve assembly.

4. Remove gasket located between EGR tube flange

and EGR valve assembly.

5. Remove two EGR valve mounting bolts (5).

6. Separate valve assembly (3) from engine.

7. Remove and discard metal gasket located between

cylinder head and valve assembly.