belt DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1846 of 5267

SEAL - CRANKSHAFT OIL - FRONT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

4. Remove upper radiator hose.

5. Remove radiator shroud attaching fasteners.

6. Remove radiator cooling fan and shroud (Refer to

7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

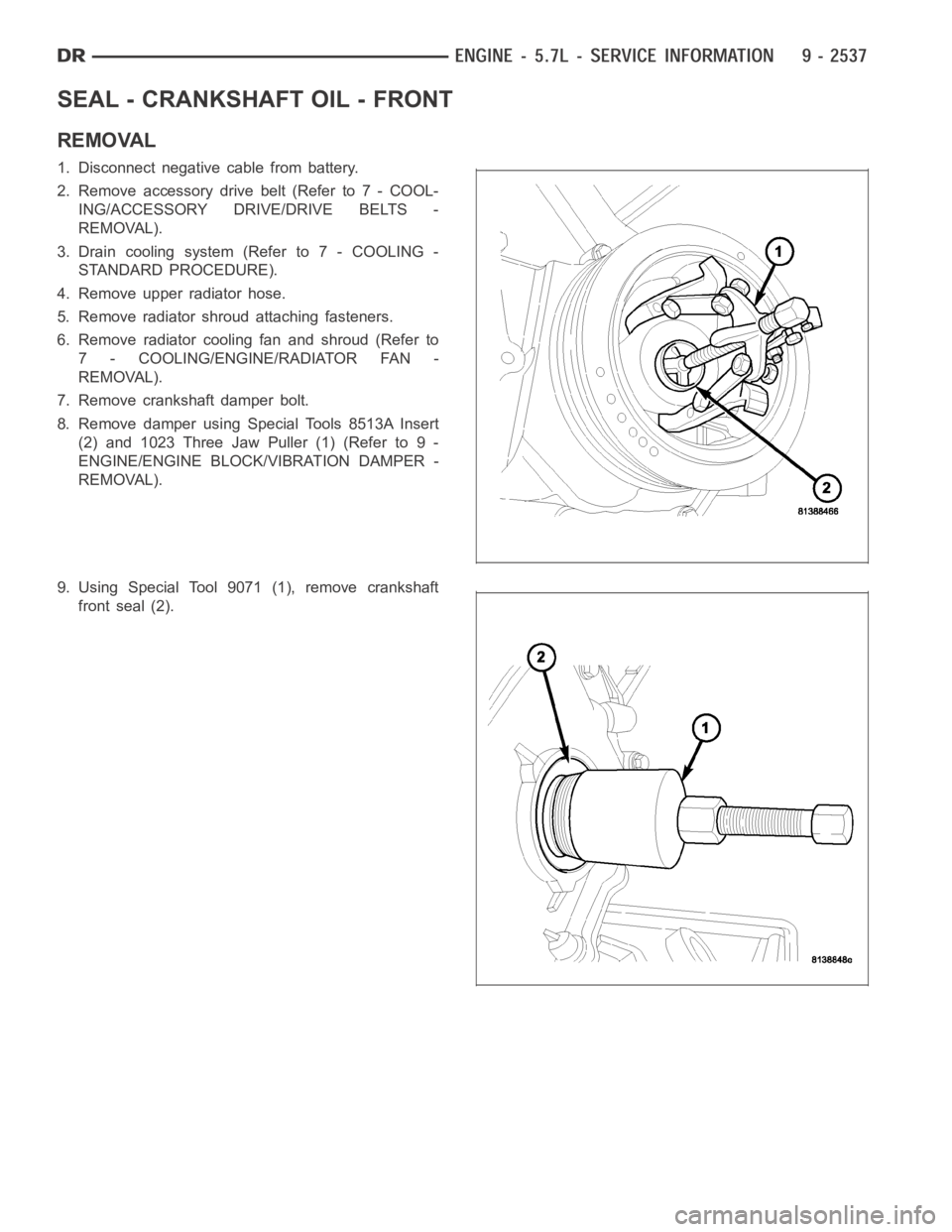

7. Remove crankshaft damper bolt.

8. Remove damper using Special Tools 8513A Insert

(2) and 1023 Three Jaw Puller (1) (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

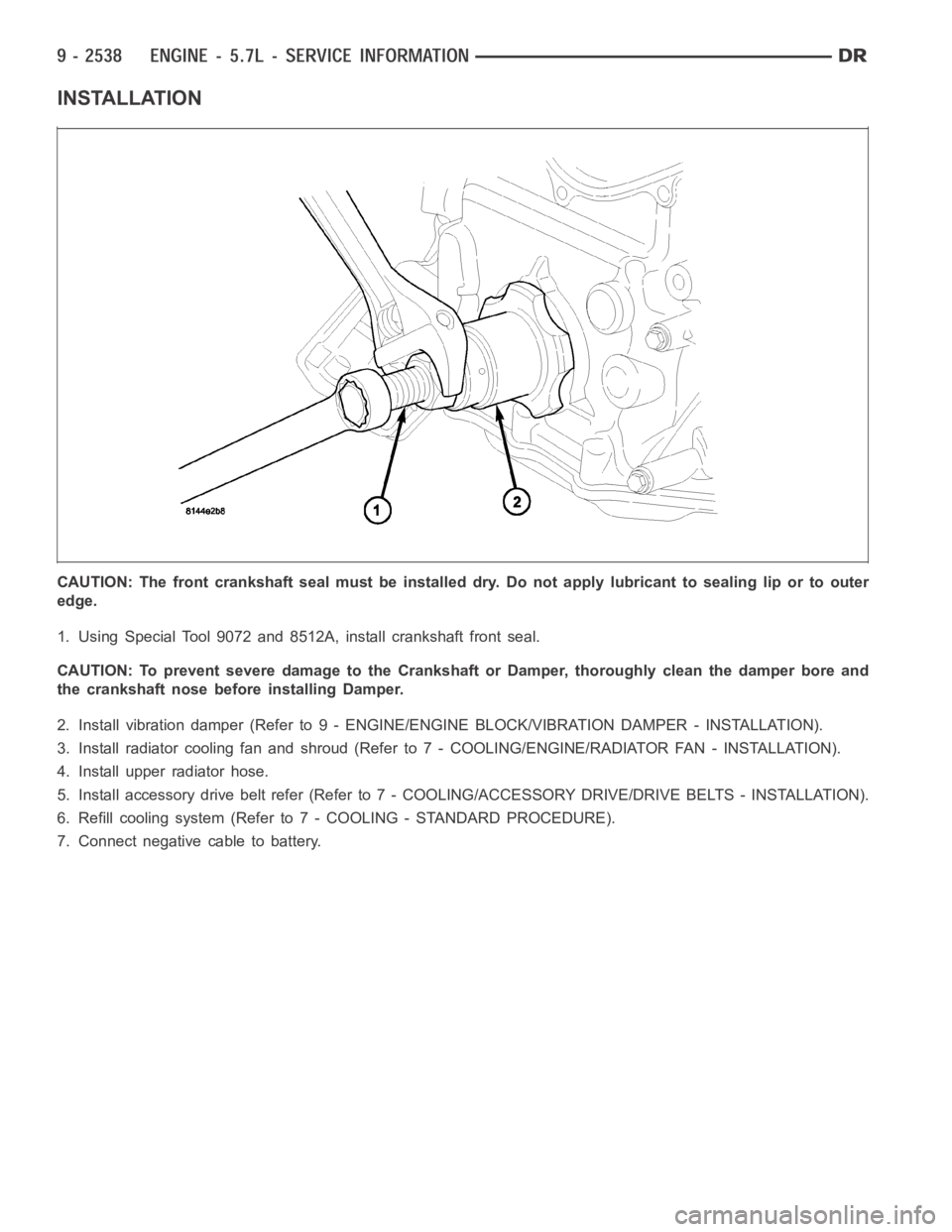

9. Using Special Tool 9071 (1), remove crankshaft

front seal (2).

Page 1847 of 5267

INSTALLATION

CAUTION: The front crankshaft seal must be installed dry. Do not apply lubricant to sealing lip or to outer

edge.

1. Using Special Tool 9072 and 8512A, install crankshaft front seal.

CAUTION: To prevent severe damage to the Crankshaft or Damper, thoroughlyclean the damper bore and

the crankshaft nose before installing Damper.

2. Install vibration damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTALLATION).

3. Install radiator cooling fan and shroud (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

4. Install upper radiator hose.

5. Install accessory drive belt refer (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

6. Refill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

7. Connect negative cable to battery.

Page 1856 of 5267

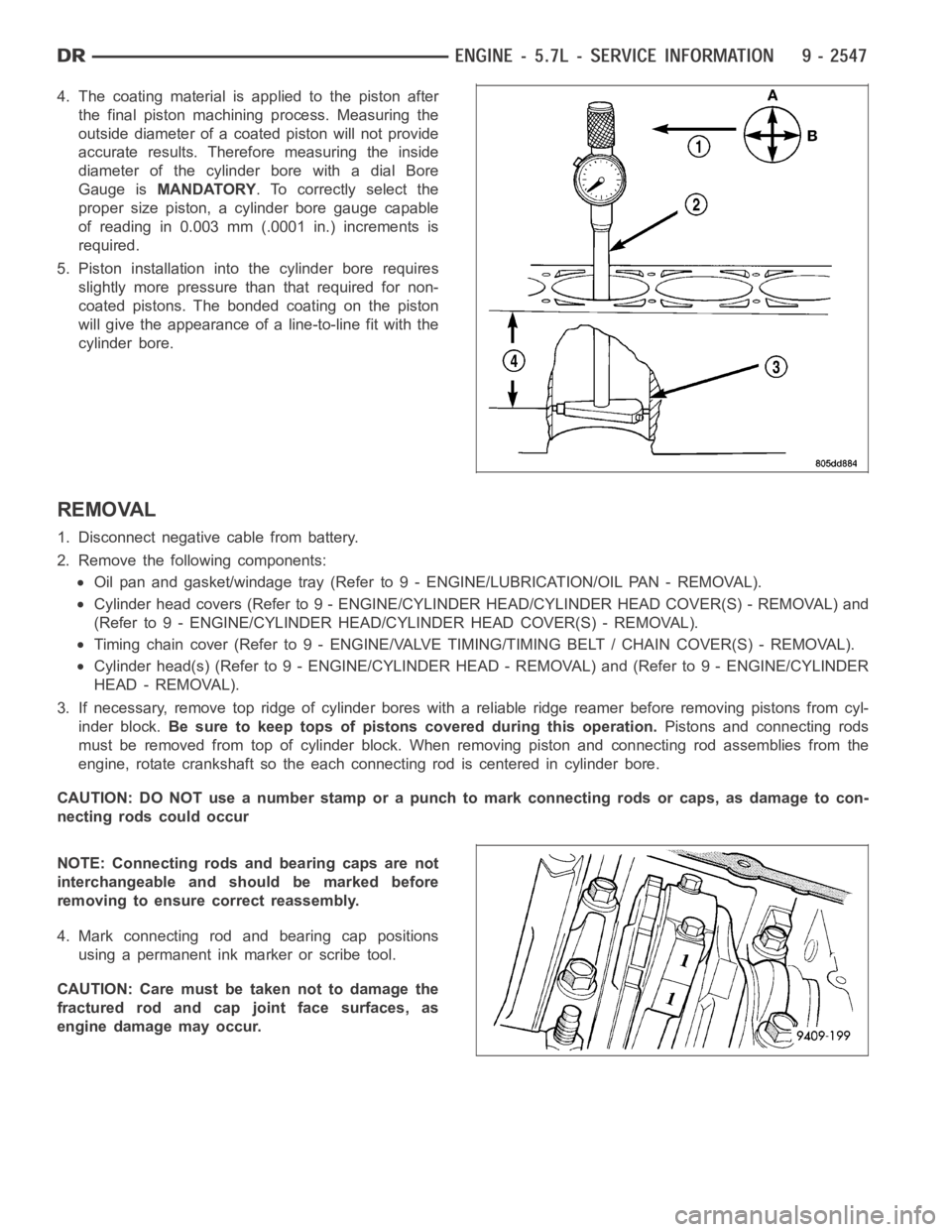

4. The coating material is applied to the piston after

the final piston machining process. Measuring the

outside diameter of a coated piston will not provide

accurate results. Therefore measuring the inside

diameter of the cylinder bore with a dial Bore

Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable

of reading in 0.003 mm (.0001 in.) increments is

required.

5. Piston installation intothe cylinder bore requires

slightly more pressure than that required for non-

coated pistons. The bonded coating on the piston

will give the appearance of a line-to-line fit with the

cylinder bore.

REMOVAL

1. Disconnect negative cable from battery.

2. Remove the following components:

Oil pan and gasket/windage tray (Refer to 9 - ENGINE/LUBRICATION/OIL PAN -REMOVAL).

Cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL) and

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

Timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) - REMOVAL).

Cylinder head(s) (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD - REMOVAL).

3. If necessary, remove top ridge of cylinder bores with a reliable ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons covered during this operation.Pistons and connecting rods

must be removed from top of cylinder block. When removing piston and connecting rod assemblies from the

engine, rotate crankshaft so the each connecting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch to mark connecting rods or caps,as damage to con-

necting rods could occur

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

4. Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as

engine damage may occur.

Page 1863 of 5267

DAMPER - CRANKSHAFT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

3. Drain cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

4. Remove radiator upper hose.

5. Removefanshroud(Referto7-COOLING/ENGINE/RADIATOR FAN - REMOVAL).

6. Remove crankshaft damper bolt.

7. Remove damper using Special Tools 8513A Insert

and 1023 Three Jaw Puller.

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512–A, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

1. Slide damper onto crankshaft slightly.

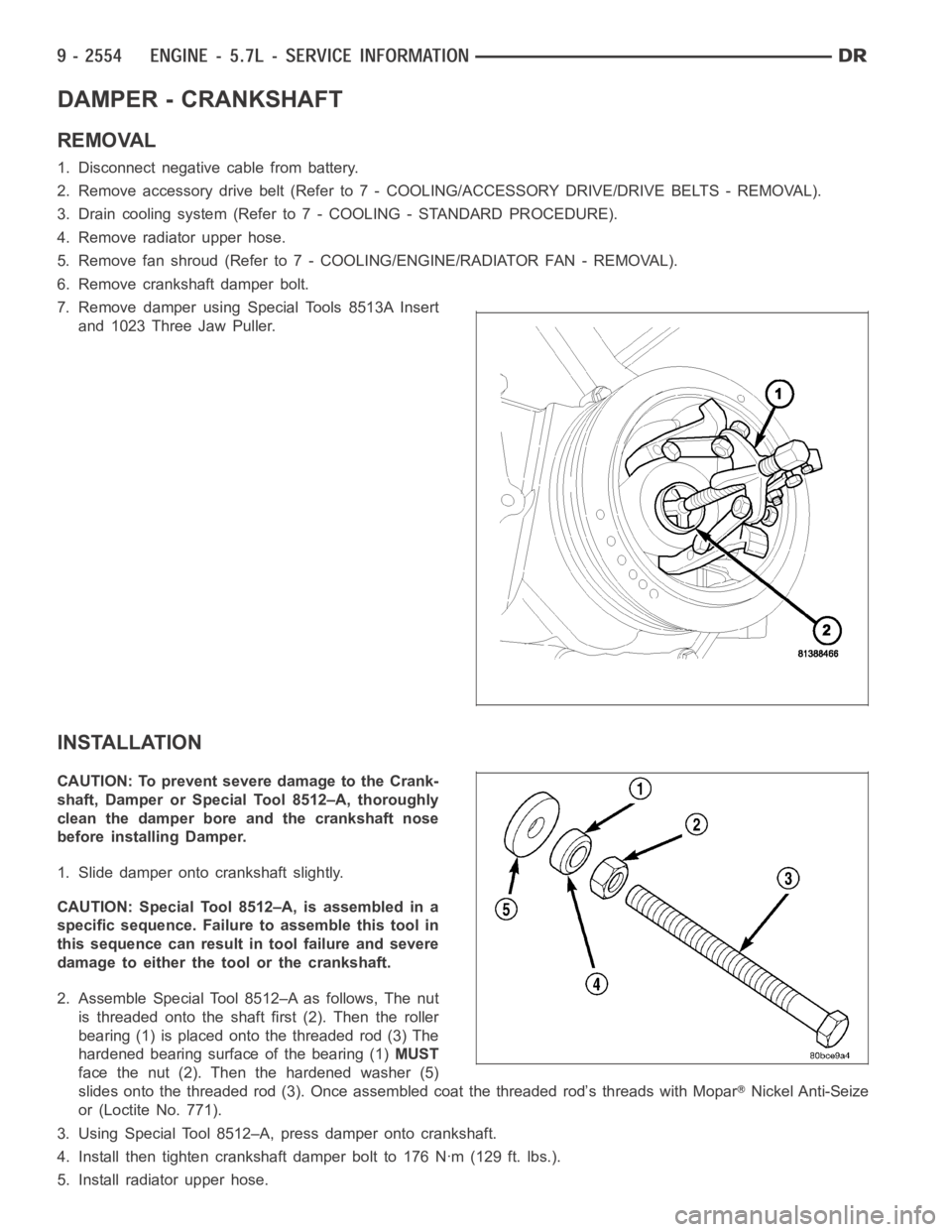

CAUTION: Special Tool 8512–A, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.

2. Assemble Special Tool 8512–A as follows, The nut

is threaded onto the shaft first (2). Then the roller

bearing (1) is placed onto the threaded rod (3) The

hardened bearing surface of the bearing (1)MUST

face the nut (2). Then the hardened washer (5)

slides onto the threaded rod (3). Once assembled coat the threaded rod’s threads with Mopar

Nickel Anti-Seize

or (Loctite No. 771).

3. Using Special Tool 8512–A, press damper onto crankshaft.

4. Install then tighten crankshaft damper bolt to 176 Nꞏm (129 ft. lbs.).

5. Install radiator upper hose.

Page 1864 of 5267

6. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

7. Refill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

8. Connect negative cable to battery.

Page 1884 of 5267

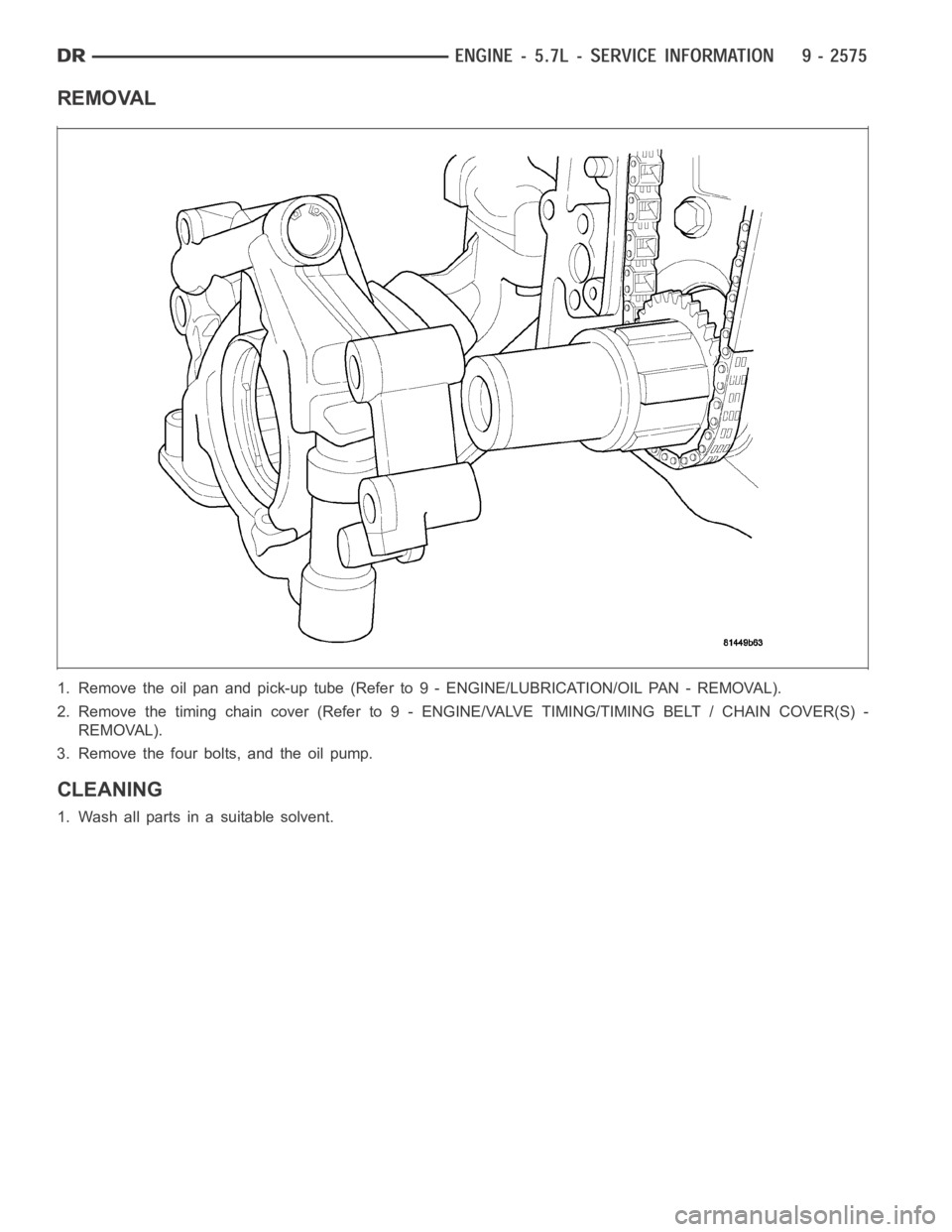

REMOVAL

1. Remove the oil pan and pick-up tube (Refer to 9 - ENGINE/LUBRICATION/OILPA N - R E M O VA L ) .

2. Remove the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) -

REMOVAL).

3. Remove the four bolts, and the oil pump.

CLEANING

1. Wash all parts in a suitable solvent.

Page 1886 of 5267

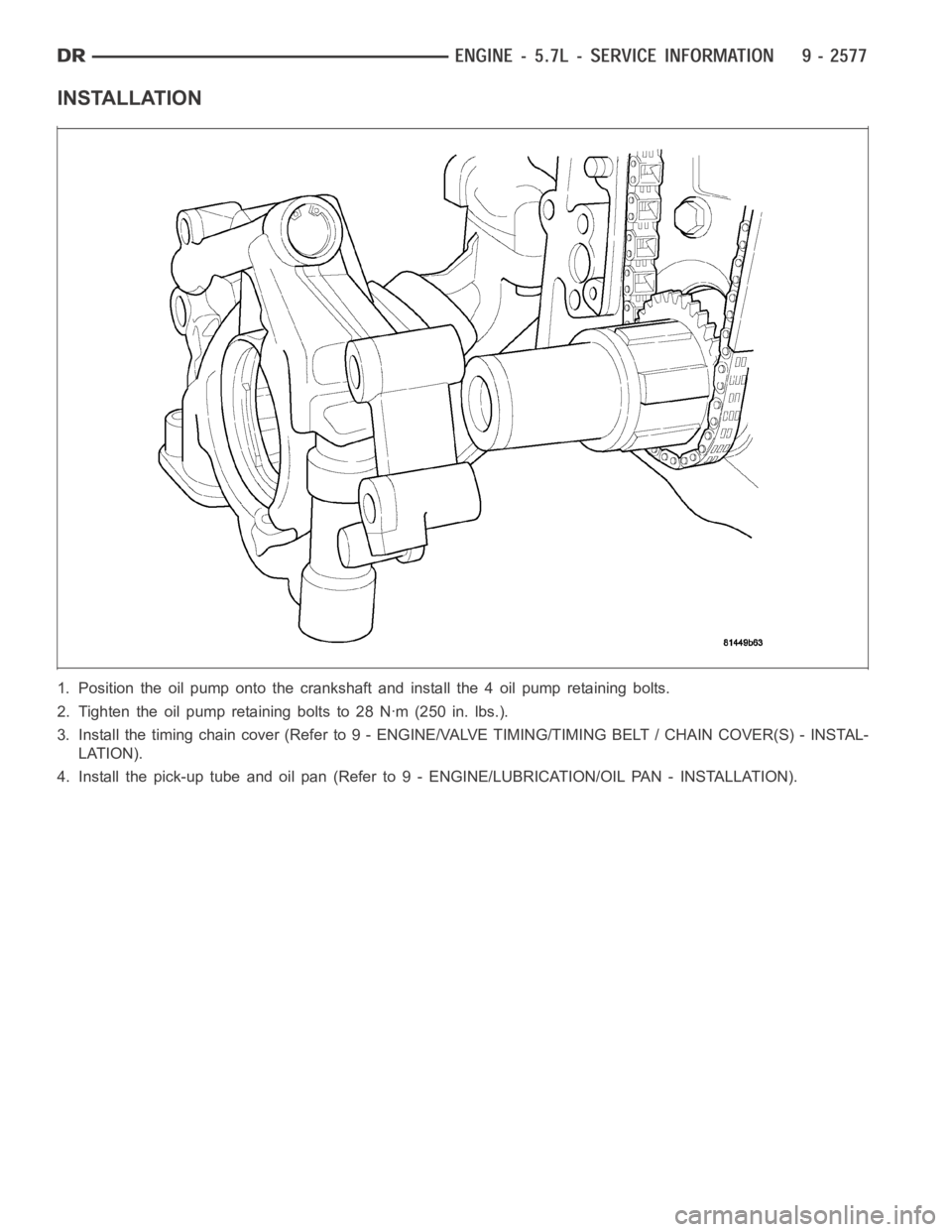

INSTALLATION

1. Position the oil pump onto the crankshaft and install the 4 oil pump retaining bolts.

2. Tighten the oil pump retaining bolts to 28 Nꞏm (250 in. lbs.).

3. Install the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMINGBELT / CHAIN COVER(S) - INSTAL-

LATION).

4. Install the pick-up tube and oil pan (Refer to 9 - ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

Page 1887 of 5267

MANIFOLD - INTAKE

DESCRIPTION

The intake manifold is made of a composite material and features long runners which maximizes low end torque.

The intake manifold uses single plane sealing which consist of eight individual press in place port gaskets to prevent

leaks.

DIAGNOSIS AND TESTING - INTAKE MANIFOLD LEAKAGE

An intake manifold air leak is characterized by lower than normal manifoldvacuum. Also, one or more cylinders may

not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE ENGINE IS OPERATING. DO NOT STAND IN ADIRECT LINE

WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR THE FAN. DO NOT WEAR

LOOSE CLOTHING.

1. Start the engine.

2. Spray a small stream of water at the suspected leak area.

3. If a change in RPM is observed the area of the suspected leak has been found.

4. Repair as required.

REMOVAL

1. Disconnect negative cable from battery.

2. Remove resonator assembly and air inlet hose.

3. Disconnect electrical connectors for the following components:

Manifold Absolute Pressure (MAP) Sensor

Intake Air Temperature (IAT) Sensor

Throttle Position (TPS) Sensor

Coolant Temperature (CTS) Sensor

4. Disconnect brake booster hose and positive crankcase ventilation (PCV)hose.

5. Remove generator and set aside.

NOTE: It is not necessary to remove lines or remove freon from A/C compressor.

6. Remove air conditioning compressor and set aside..

7. Bleed fuel system (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - STANDARD PROCEDURE).

8. Remove intake manifold retaining fasteners in a crisscross pattern starting from the outside bolts and ending at

themiddlebolts.

9. Remove intake manifold and IAFM as an assembly.

CLEANING

NOTE: There is NO approved repair procedure for the intake manifold. If severe damage is found during

inspection, the intake manifold must be replaced.

Before installing the intake manifoldthoroughly clean the mating surfaces. Use a suitable cleaning solvent, then air

dry.

Page 1892 of 5267

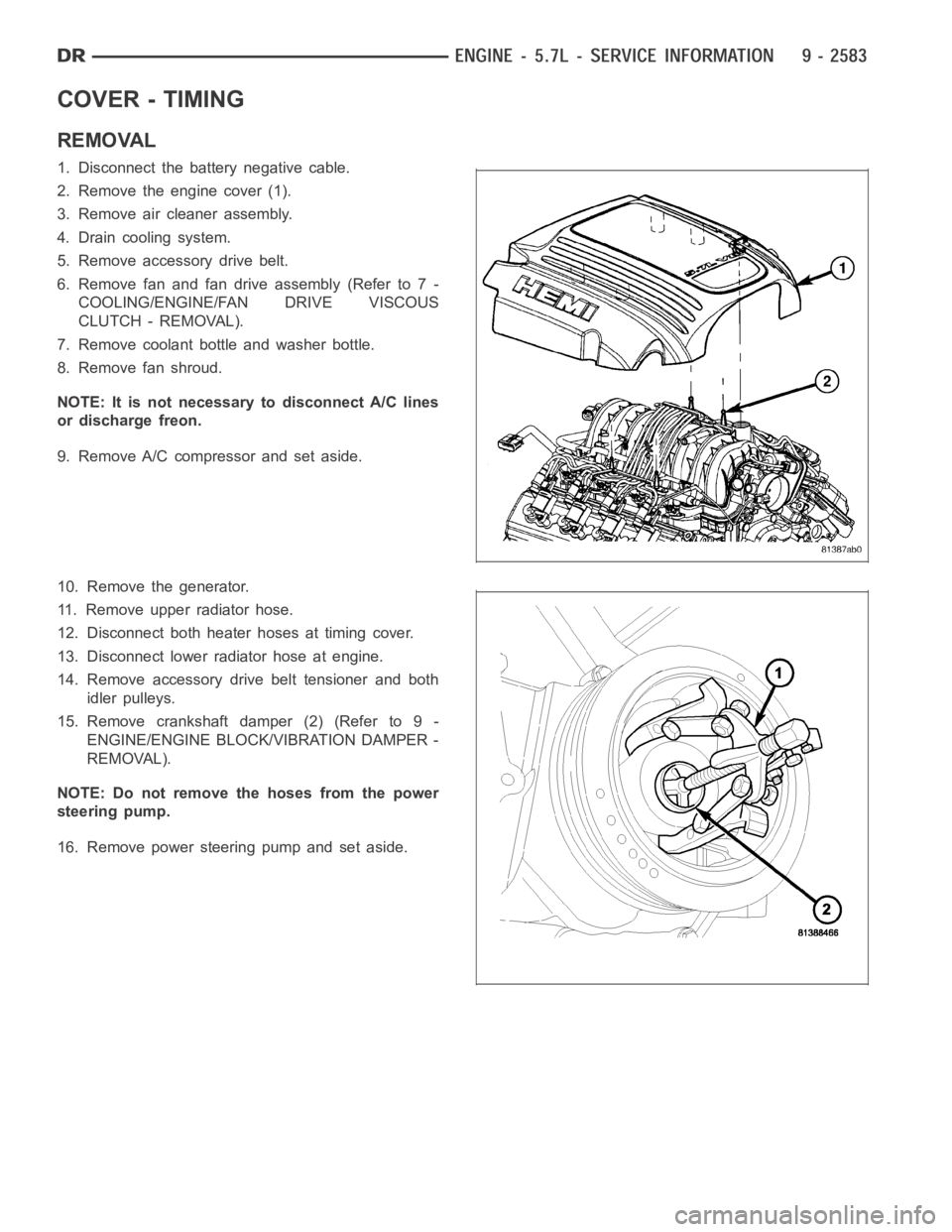

COVER - TIMING

REMOVAL

1. Disconnect the battery negative cable.

2. Remove the engine cover (1).

3. Remove air cleaner assembly.

4. Drain cooling system.

5. Remove accessory drive belt.

6. Remove fan and fan drive assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

7. Remove coolant bottle and washer bottle.

8. Remove fan shroud.

NOTE: It is not necessary to disconnect A/C lines

or discharge freon.

9. Remove A/C compressor and set aside.

10. Remove the generator.

11. Remove upper radiator hose.

12. Disconnect both heater hoses at timing cover.

13. Disconnect lower radiator hose at engine.

14. Remove accessory drive belt tensioner and both

idler pulleys.

15. Remove crankshaft damper (2) (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

NOTE: Do not remove the hoses from the power

steering pump.

16. Remove power steering pump and set aside.

Page 1894 of 5267

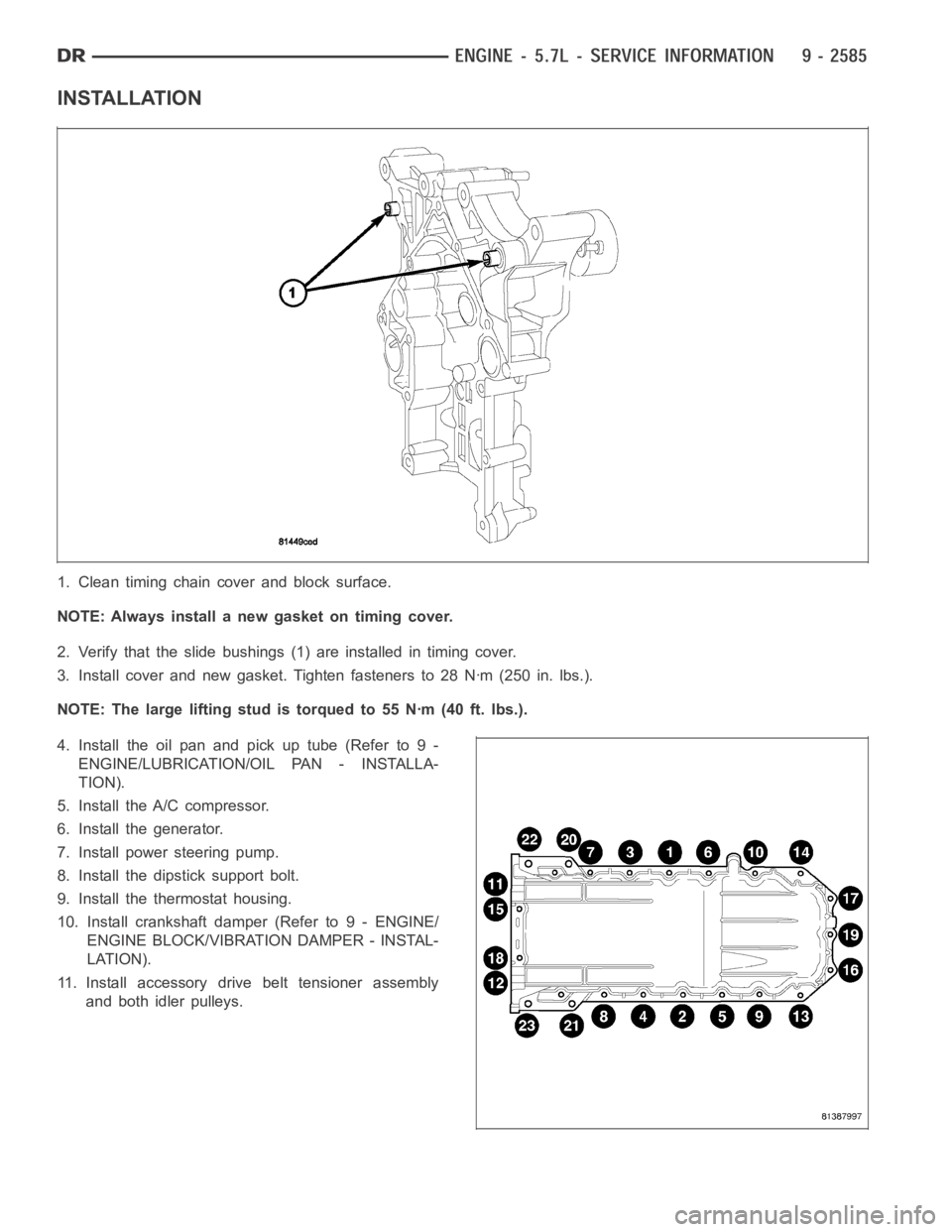

INSTALLATION

1. Clean timing chain cover and block surface.

NOTE: Always install a new gasket on timing cover.

2. Verify that the slide bushings (1) are installed in timing cover.

3. Install cover and new gasket. Tighten fasteners to 28 Nꞏm (250 in. lbs.).

NOTE: The large lifting stud is torqued to 55 Nꞏm (40 ft. lbs.).

4. Install the oil pan and pick up tube (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

5. Install the A/C compressor.

6. Install the generator.

7. Install power steering pump.

8. Install the dipstick support bolt.

9. Install the thermostat housing.

10. Install crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

11. Install accessory drive belt tensioner assembly

and both idler pulleys.