belt DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2410 of 5267

FLOW AND PRESSURE TEST

1. Check the power steering belt to ensure it is in good condition and adjusted properly.

2. Connect pressure gauge hose from the Power Steering Analyzer to adapter6826.

3. Connect tube 6825A to Power Steering Analyzer test valve end.

4. Disconnect the high pressure hose from the power steering pump.

5. Connect the tube 6825A to the pump fitting.

6. Connect the power steering hose from the steering gear to the adapter 6826.

NOTE: If fluid leaked from the steering system, it should be filled to correct lervel prior to starting the

engine.

7. Open the test valve completely.

8. Start engine and let idle long enough to circulate power steering fluid through flow/pressure test gauge and to get

air out of the fluid. Then shut off engine.

9. Check fluid level, add fluid as necessary. Start engine again and let idle.

10. Gauge should read below 862 kPa (125 psi), if above, inspect the hoses for restrictions and repair as neces-

sary. The initial pressure reading should be in the range of 345-552 kPa (50-80 psi).

11. Increase the engine speed to 1500 RPM and read the flow meter. If the flowrate (GPM) is below specification,

(refer to pump specification chart for GPM) the pump should be replaced.

CAUTION: The following test procedure involves testing maximum pump pressure output and flow control

valve operation. Do not leave valve closed for more than three seconds as the pump could be damaged.

12. Close valve fully three times and record highest pressure indicated each time.All three readings must be

above specifications and within 345 kPa (50 psi) of each other.

Pressures above specifications but not within 345 kPa (50 psi) of each other, replace pump.

Pressures within 345 kPa (50 psi) of each other but below specifications, replace pump.

13. Open the test valve and turn the steering wheel to the extreme left and right positions three times against the

stops. Record the highest pressure reading at each position. Compare readings to the pump specifications

chart. If pressures readings are not within 50 psi of each other, the gear isleaking internally and must be

replaced.

CAUTION: Do not force the pump to operate against the stops for more than 2 to3 seconds at a time

because, pump damage will result.

PUMP SPECIFICATION

ENGINE RELIEF PRESSURE ± 65 FLOW RATE (GPM) AT 1500 RPM

1500 series 11032 kPa (1615 ± 65 psi) 3.1 - 3.5

2500 & 3500

series12400 kPa (1800 ± 50 psi) 3.5 - 4.0

Page 2482 of 5267

PUMP

DESCRIPTION

CAUTION: MOPARATF+4 is to be used in the power steering system. No other power steering or auto-

matic transmission fluid is to be used in the system. Damage may result to the power steering pump and

system if any other fluid is used, and do not overfill.

The pump is connected to the steering gear via the pressure hose and the return hose. The pump shaft has a

pressed-on pulley that is belt driven by the crankshaft pulley.

All vehicles are equipped with a power steering fluid cooler.

NOTE: Power steering pumps are not interchangeable with pumps installed on other vehicles.

OPERATION

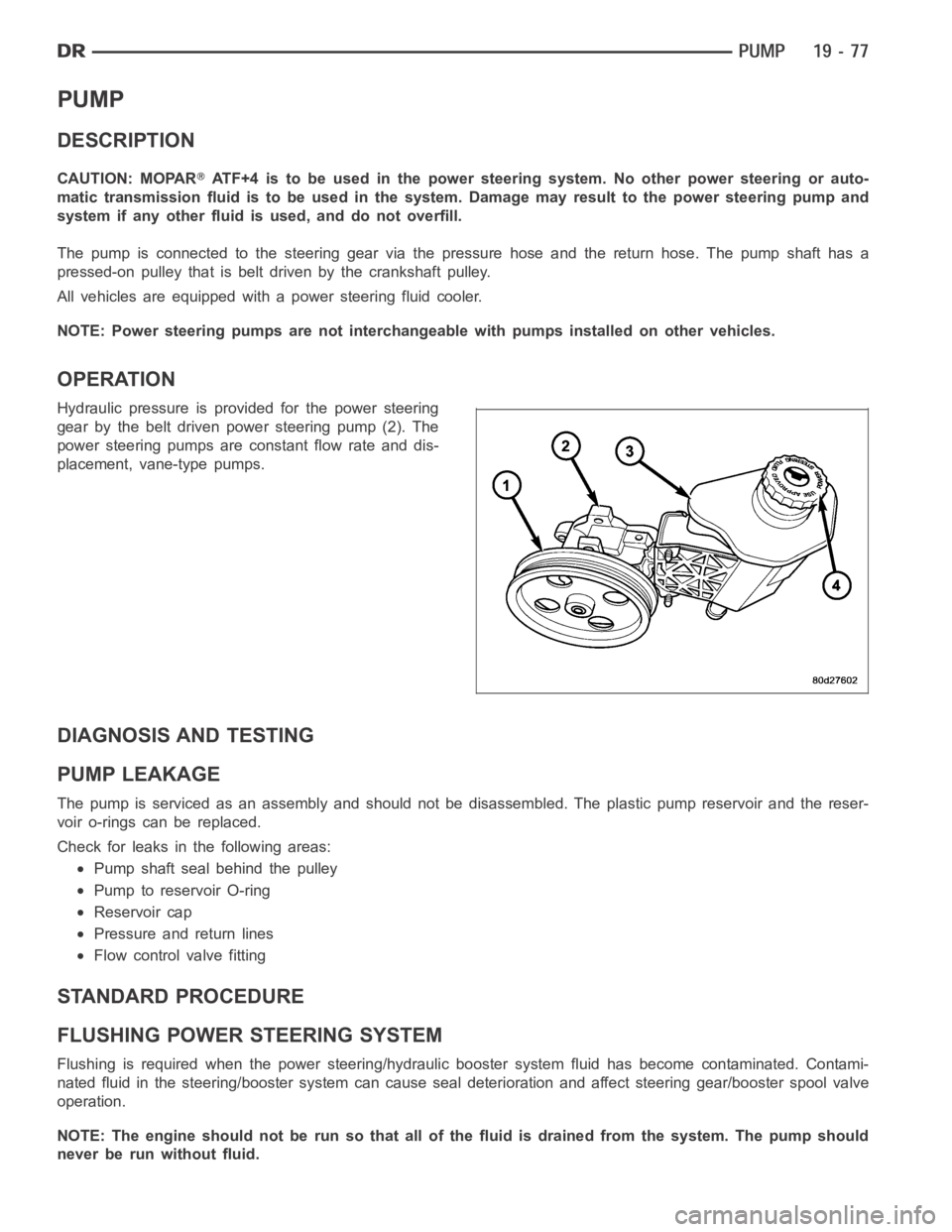

Hydraulic pressure is provided for the power steering

gear by the belt driven power steering pump (2). The

power steering pumps are constant flow rate and dis-

placement, vane-type pumps.

DIAGNOSIS AND TESTING

PUMP LEAKAGE

The pump is serviced as an assembly and should not be disassembled. The plastic pump reservoir and the reser-

voir o-rings can be replaced.

Check for leaks in the following areas:

Pump shaft seal behind the pulley

Pump to reservoir O-ring

Reservoir cap

Pressure and return lines

Flow control valve fitting

STANDARD PROCEDURE

FLUSHING POWER STEERING SYSTEM

Flushing is required when the power steering/hydraulic booster system fluid has become contaminated. Contami-

nated fluid in the steering/booster system can cause seal deterioration and affect steering gear/booster spool valve

operation.

NOTE: The engine should not be run so that all of the fluid is drained from thesystem. The pump should

never be run without fluid.

Page 2484 of 5267

CAUTION: Do not run a vehicle with foamy fluid for an extended period. This may cause pump damage.

REMOVAL

GAS ENGINE

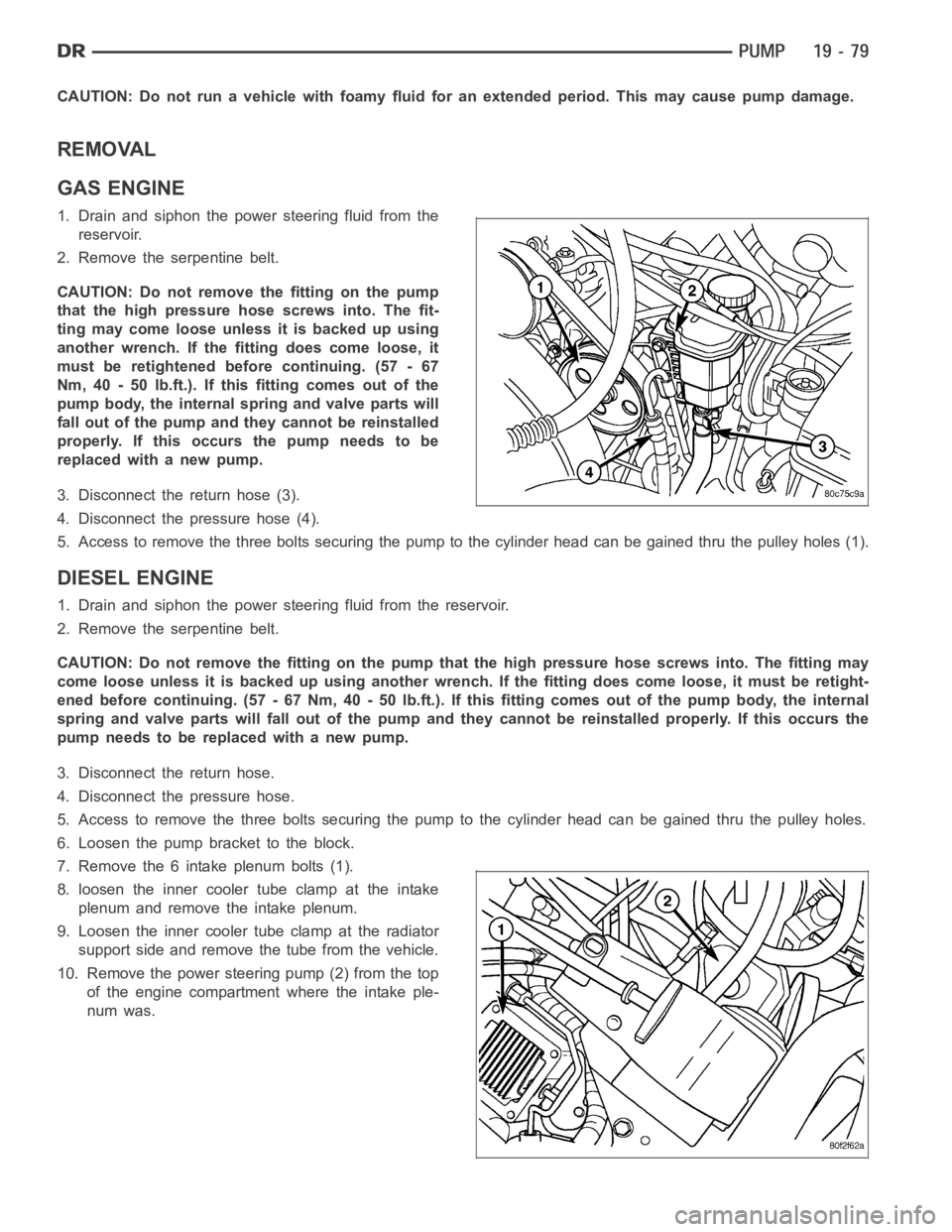

1. Drain and siphon the power steering fluid from the

reservoir.

2. Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump

that the high pressure hose screws into. The fit-

ting may come loose unless it is backed up using

another wrench. If the fitting does come loose, it

must be retightened before continuing. (57 - 67

Nm, 40 - 50 lb.ft.). If this fitting comes out of the

pump body, the internal spring and valve parts will

fall out of the pump and they cannot be reinstalled

properly. If this occurs the pump needs to be

replaced with a new pump.

3. Disconnect the return hose (3).

4. Disconnect the pressure hose (4).

5. Access to remove the three bolts securing the pump to the cylinder head can be gained thru the pulley holes (1).

DIESEL ENGINE

1. Drain and siphon the power steering fluid from the reservoir.

2. Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump that the high pressure hose screws into. The fitting may

come loose unless it is backed up using another wrench. If the fitting does come loose, it must be retight-

ened before continuing. (57 - 67 Nm, 40 - 50 lb.ft.). If this fitting comes out of the pump body, the internal

spring and valve parts will fall out of the pump and they cannot be reinstalled properly. If this occurs the

pump needs to be replaced with a new pump.

3. Disconnect the return hose.

4. Disconnect the pressure hose.

5. Access to remove the three bolts securing the pump to the cylinder head can be gained thru the pulley holes.

6. Loosen the pump bracket to the block.

7. Remove the 6 intake plenum bolts (1).

8. loosen the inner cooler tube clamp at the intake

plenum and remove the intake plenum.

9. Loosen the inner cooler tube clamp at the radiator

support side and remove the tube from the vehicle.

10. Remove the power steering pump (2) from the top

of the engine compartment where the intake ple-

num was.

Page 2485 of 5267

INSTALLATION

GAS ENGINE

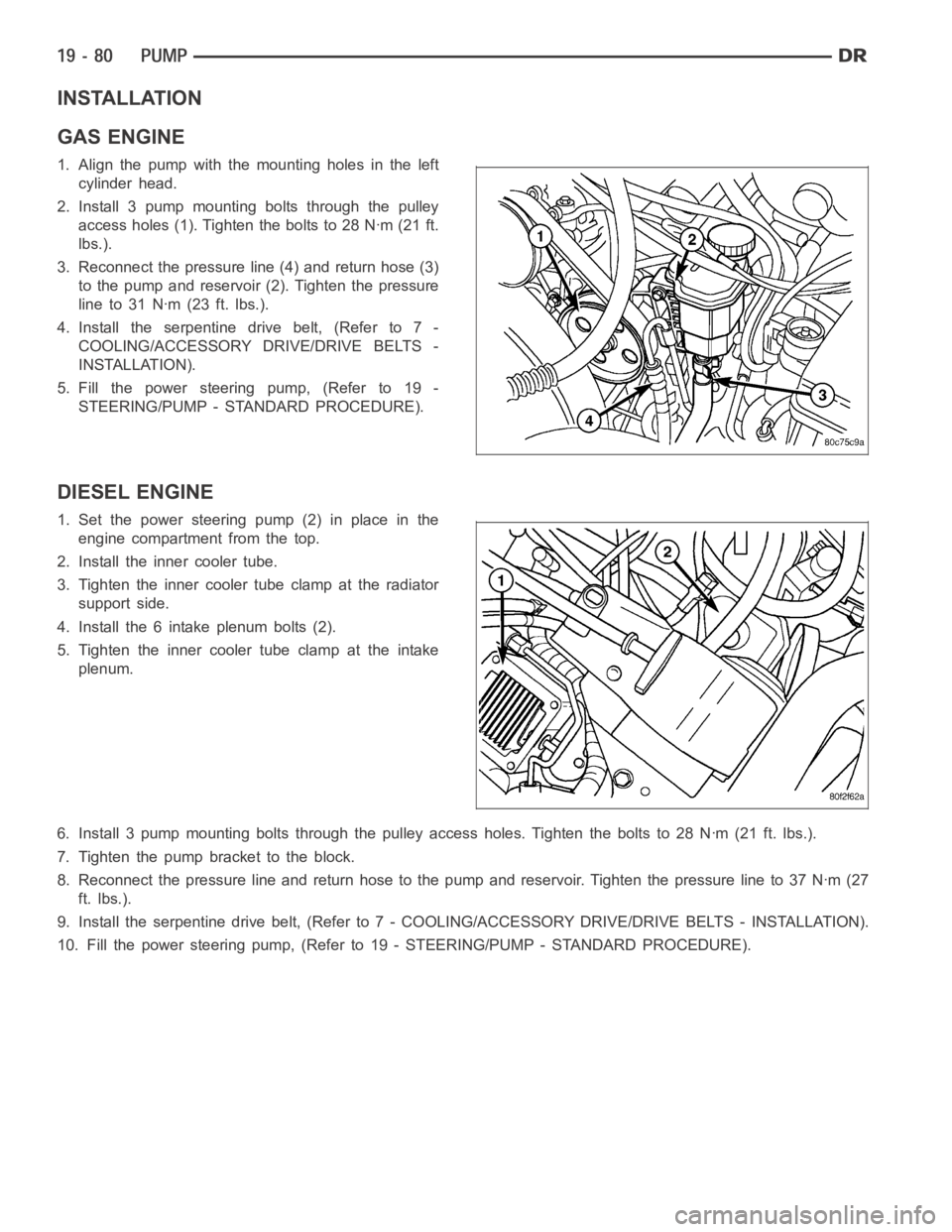

1. Align the pump with the mounting holes in the left

cylinder head.

2. Install 3 pump mounting bolts through the pulley

access holes (1). Tighten the bolts to 28 Nꞏm (21 ft.

lbs.).

3. Reconnect the pressure line (4) and return hose (3)

to the pump and reservoir (2). Tighten the pressure

line to 31 Nꞏm (23 ft. lbs.).

4. Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

5. Fill the power steering pump, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

DIESEL ENGINE

1. Set the power steering pump (2) in place in the

engine compartment from the top.

2. Install the inner cooler tube.

3. Tighten the inner cooler tube clamp at the radiator

support side.

4. Install the 6 intake plenum bolts (2).

5. Tighten the inner cooler tube clamp at the intake

plenum.

6. Install 3 pump mounting bolts through the pulley access holes. Tighten theboltsto28Nꞏm(21ft.lbs.).

7. Tighten the pump bracket to the block.

8. Reconnect the pressure line and return hose to the pump and reservoir. Tightenthepressurelineto37Nꞏm(27

ft. lbs.).

9. Install the serpentine drive belt, (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

10. Fill the power steering pump, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2495 of 5267

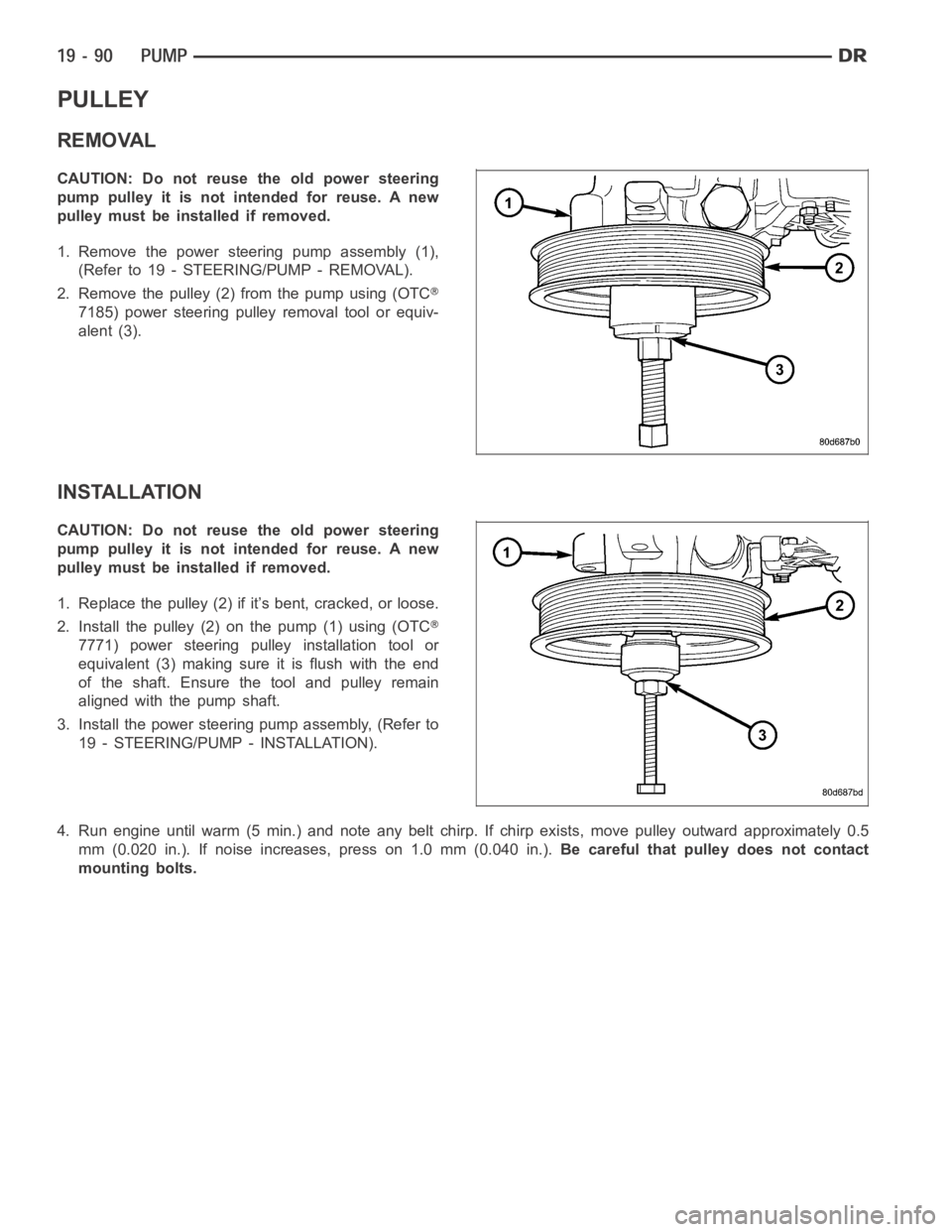

PULLEY

REMOVAL

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new

pulley must be installed if removed.

1. Remove the power steering pump assembly (1),

(Refer to 19 - STEERING/PUMP - REMOVAL).

2. Remove the pulley (2) from the pump using (OTC

7185) power steering pulley removal tool or equiv-

alent (3).

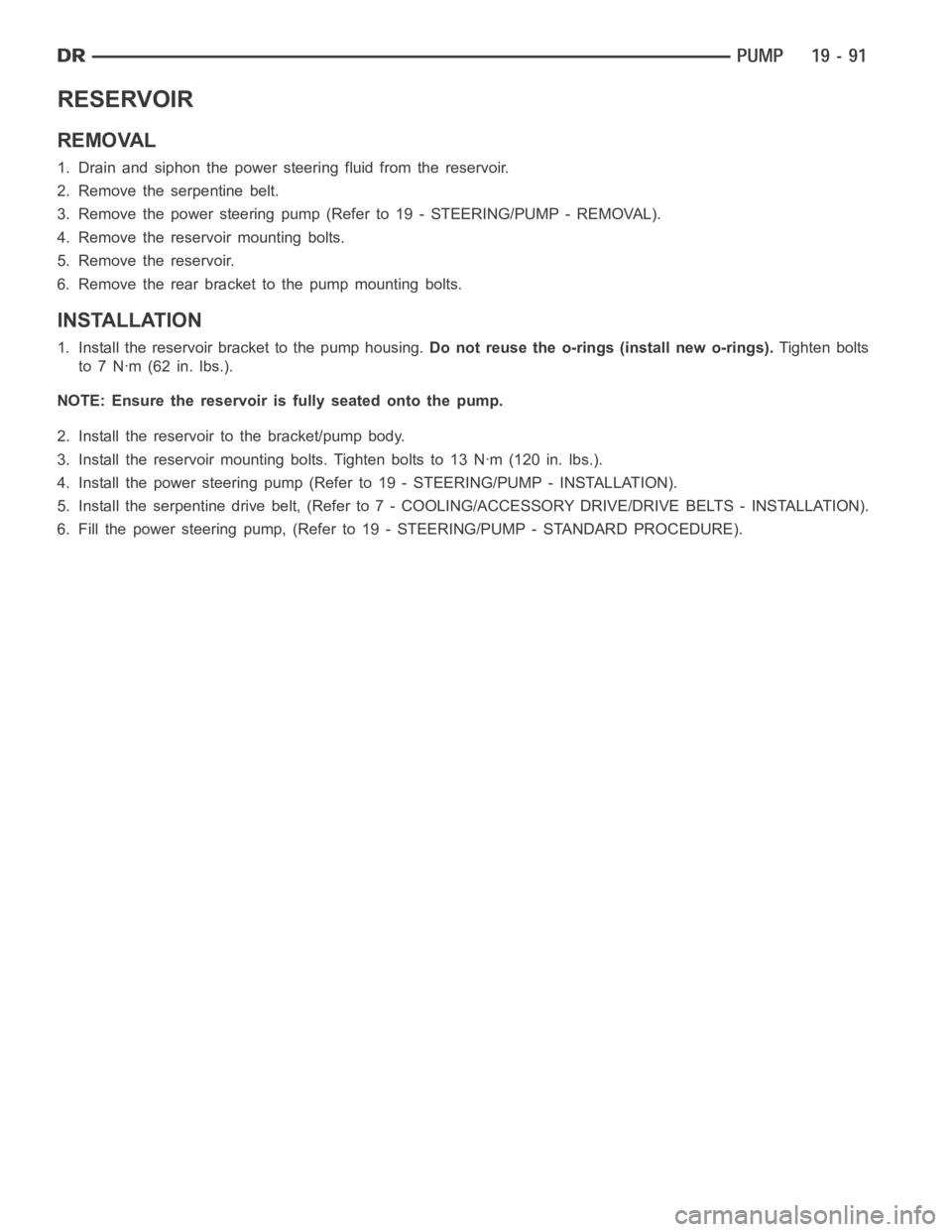

INSTALLATION

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new

pulley must be installed if removed.

1. Replace the pulley (2) if it’s bent, cracked, or loose.

2. Install the pulley (2) on the pump (1) using (OTC

7771) power steering pulley installation tool or

equivalent (3) making sure it is flush with the end

of the shaft. Ensure the tool and pulley remain

aligned with the pump shaft.

3. Install the power steering pump assembly, (Refer to

19 - STEERING/PUMP - INSTALLATION).

4. Run engine until warm (5 min.) and note any belt chirp. If chirp exists, move pulley outward approximately 0.5

mm (0.020 in.). If noise increases, press on 1.0 mm (0.040 in.).Be careful that pulley does not contact

mounting bolts.

Page 2496 of 5267

RESERVOIR

REMOVAL

1. Drain and siphon the power steering fluid from the reservoir.

2. Remove the serpentine belt.

3. Remove the power steering pump (Refer to 19 - STEERING/PUMP - REMOVAL).

4. Remove the reservoir mounting bolts.

5. Remove the reservoir.

6. Remove the rear bracket to the pump mounting bolts.

INSTALLATION

1. Install the reservoir bracket to the pump housing.Do not reuse the o-rings (install new o-rings).Tighten bolts

to7Nꞏm(62in.lbs.).

NOTE: Ensure the reservoir is fully seated onto the pump.

2. Install the reservoir to the bracket/pump body.

3. Install the reservoir mounting bolts. Tighten bolts to 13 Nꞏm (120 in. lbs.).

4. Install the power steering pump (Refer to 19 - STEERING/PUMP - INSTALLATION).

5. Install the serpentine drive belt, (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

6. Fill the power steering pump, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2498 of 5267

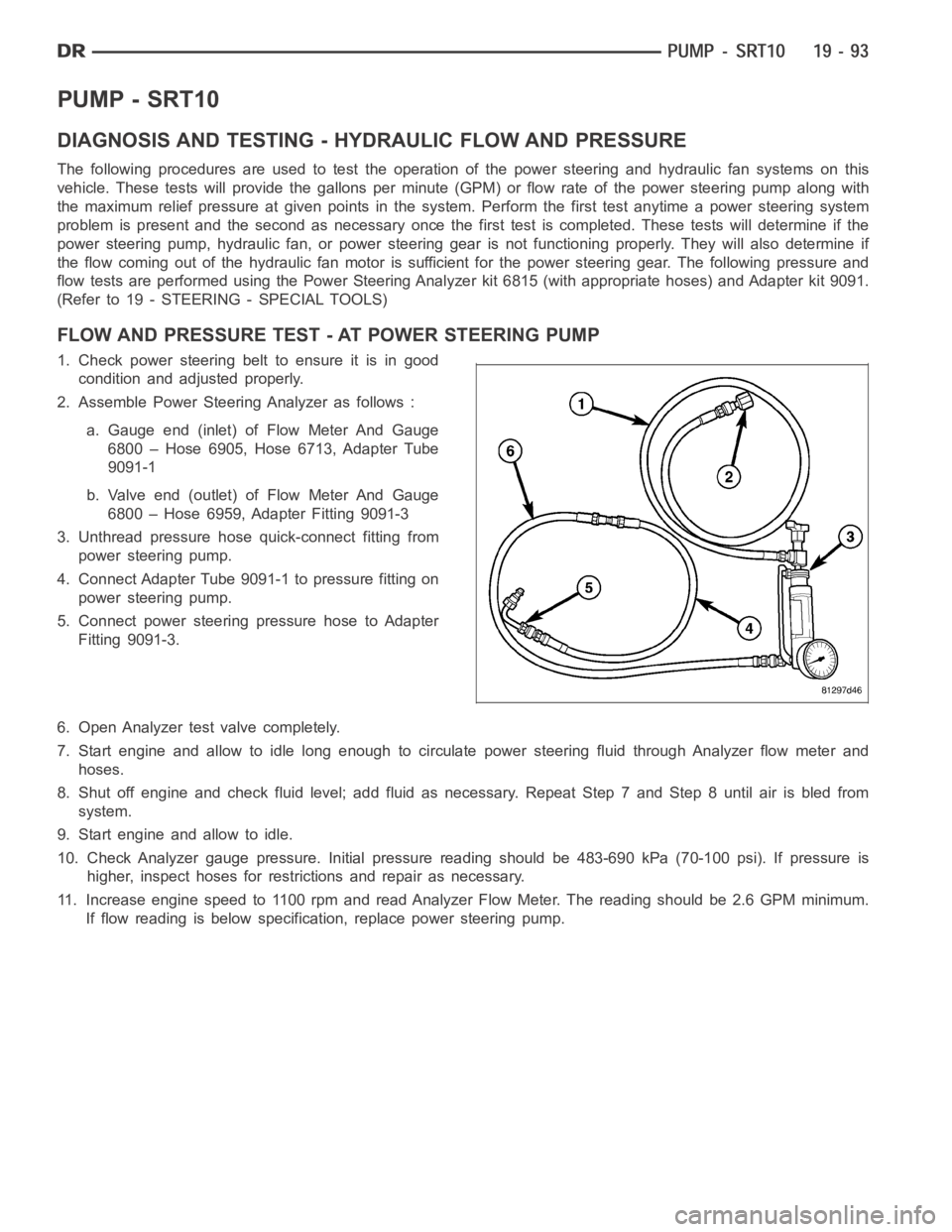

PUMP - SRT10

DIAGNOSIS AND TESTING - HYDRAULIC FLOW AND PRESSURE

The following procedures are used to test the operation of the power steering and hydraulic fan systems on this

vehicle. These tests will provide the gallons per minute (GPM) or flow rateof the power steering pump along with

the maximum relief pressure at given points in the system. Perform the first test anytime a power steering system

problem is present and the second as necessary once the first test is completed. These tests will determine if the

power steering pump, hydraulic fan, or power steering gear is not functioning properly. They will also determine if

the flow coming out of the hydraulic fan motor is sufficient for the power steering gear. The following pressure and

flow tests are performed using the Power Steering Analyzer kit 6815 (with appropriate hoses) and Adapter kit 9091.

(Refer to 19 - STEERING - SPECIAL TOOLS)

FLOW AND PRESSURE TEST - AT POWER STEERING PUMP

1. Check power steering belt to ensure it is in good

condition and adjusted properly.

2. Assemble Power Steering Analyzer as follows :

a. Gauge end (inlet) of Flow Meter And Gauge

6800 – Hose 6905, Hose 6713, Adapter Tube

9091-1

b. Valve end (outlet) of Flow Meter And Gauge

6800 – Hose 6959, Adapter Fitting 9091-3

3. Unthread pressure hose quick-connect fitting from

power steering pump.

4. Connect Adapter Tube 9091-1 to pressure fitting on

power steering pump.

5. Connect power steering pressure hose to Adapter

Fitting 9091-3.

6. Open Analyzer test valve completely.

7. Start engine and allow to idle long enough to circulate power steering fluid through Analyzer flow meter and

hoses.

8. Shut off engine and check fluid level; add fluid as necessary. Repeat Step7andStep8untilairisbledfrom

system.

9. Start engine and allow to idle.

10. Check Analyzer gauge pressure. Initial pressure reading should be 483-690 kPa (70-100 psi). If pressure is

higher, inspect hoses for restrictions and repair as necessary.

11. Increase engine speed to 1100 rpm and read Analyzer Flow Meter. The reading should be 2.6 GPM minimum.

If flow reading is below specification, replace power steering pump.

Page 2502 of 5267

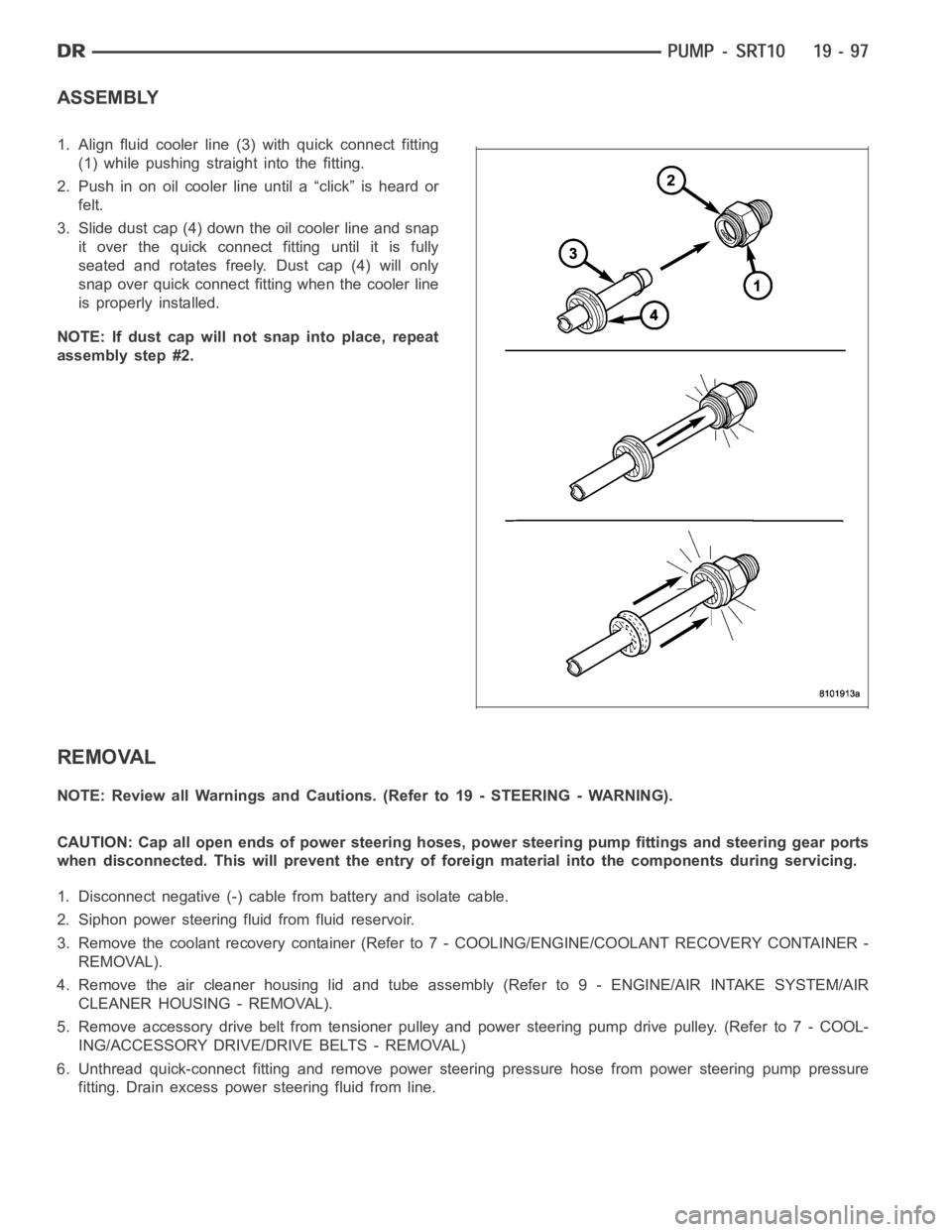

ASSEMBLY

1. Align fluid cooler line (3) with quick connect fitting

(1) while pushing straight into the fitting.

2. Push in on oil cooler line until a “click” is heard or

felt.

3. Slide dust cap (4) down the oil cooler line and snap

it over the quick connect fitting until it is fully

seated and rotates freely. Dust cap (4) will only

snap over quick connect fitting when the cooler line

is properly installed.

NOTE: If dust cap will not snap into place, repeat

assembly step #2.

REMOVAL

NOTE: Review all Warnings and Cautions. (Refer to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering hoses, power steering pump fittings and steering gear ports

when disconnected. This will prevent the entry of foreign material into the components during servicing.

1. Disconnect negative (-) cable from battery and isolate cable.

2. Siphon power steering fluid from fluid reservoir.

3. Remove the coolant recovery container (Refer to 7 - COOLING/ENGINE/COOLANT RECOVERY CONTAINER -

REMOVAL).

4. Remove the air cleaner housing lid and tube assembly (Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR

CLEANER HOUSING - REMOVAL).

5. Remove accessory drive belt from tensioner pulley and power steering pump drive pulley. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

6. Unthread quick-connect fitting and remove power steering pressure hose from power steering pump pressure

fitting. Drain excess power steering fluid from line.

Page 2504 of 5267

INSTALLATION

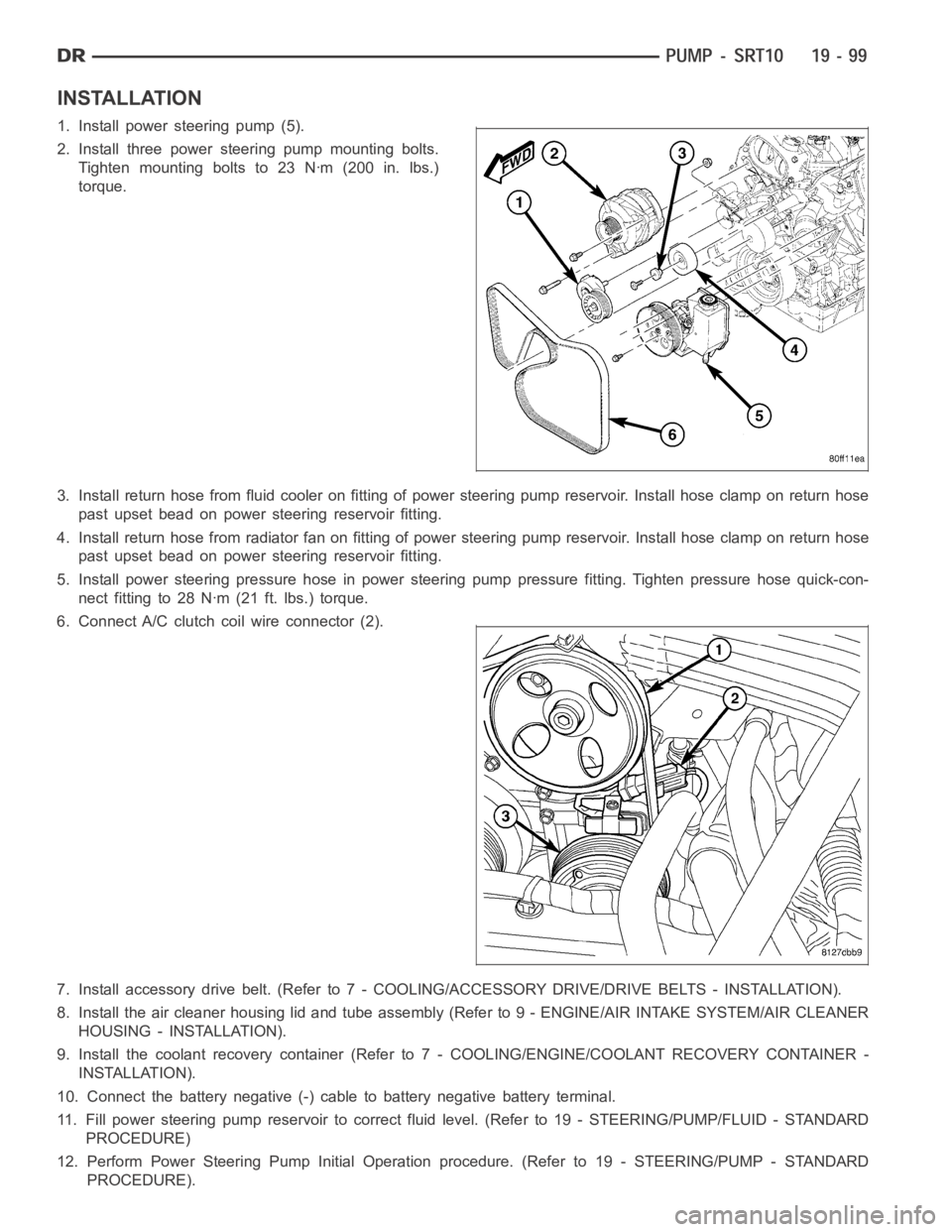

1. Install power steering pump (5).

2. Install three power steering pump mounting bolts.

Tighten mounting bolts to 23 Nꞏm (200 in. lbs.)

torque.

3. Install return hose from fluid cooler on fitting of power steering pump reservoir. Install hose clamp on return hose

past upset bead on power steering reservoir fitting.

4. Install return hose from radiator fan on fitting of power steering pump reservoir. Install hose clamp on return hose

past upset bead on power steering reservoir fitting.

5. Install power steering pressure hose in power steering pump pressure fitting. Tighten pressure hose quick-con-

nect fitting to 28 Nꞏm (21 ft. lbs.) torque.

6. Connect A/C clutch coil wire connector (2).

7. Install accessory drive belt. (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

8. Install the air cleaner housing lid and tube assembly (Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

9. Install the coolant recovery container (Refer to 7 - COOLING/ENGINE/COOLANT RECOVERY CONTAINER -

INSTALLATION).

10. Connect the battery negative (-) cable to battery negative battery terminal.

11. Fill power steering pump reservoir to correct fluid level. (Refer to 19- STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

12. Perform Power Steering Pump Initial Operation procedure. (Refer to 19- STEERING/PUMP - STANDARD

PROCEDURE).

Page 2515 of 5267

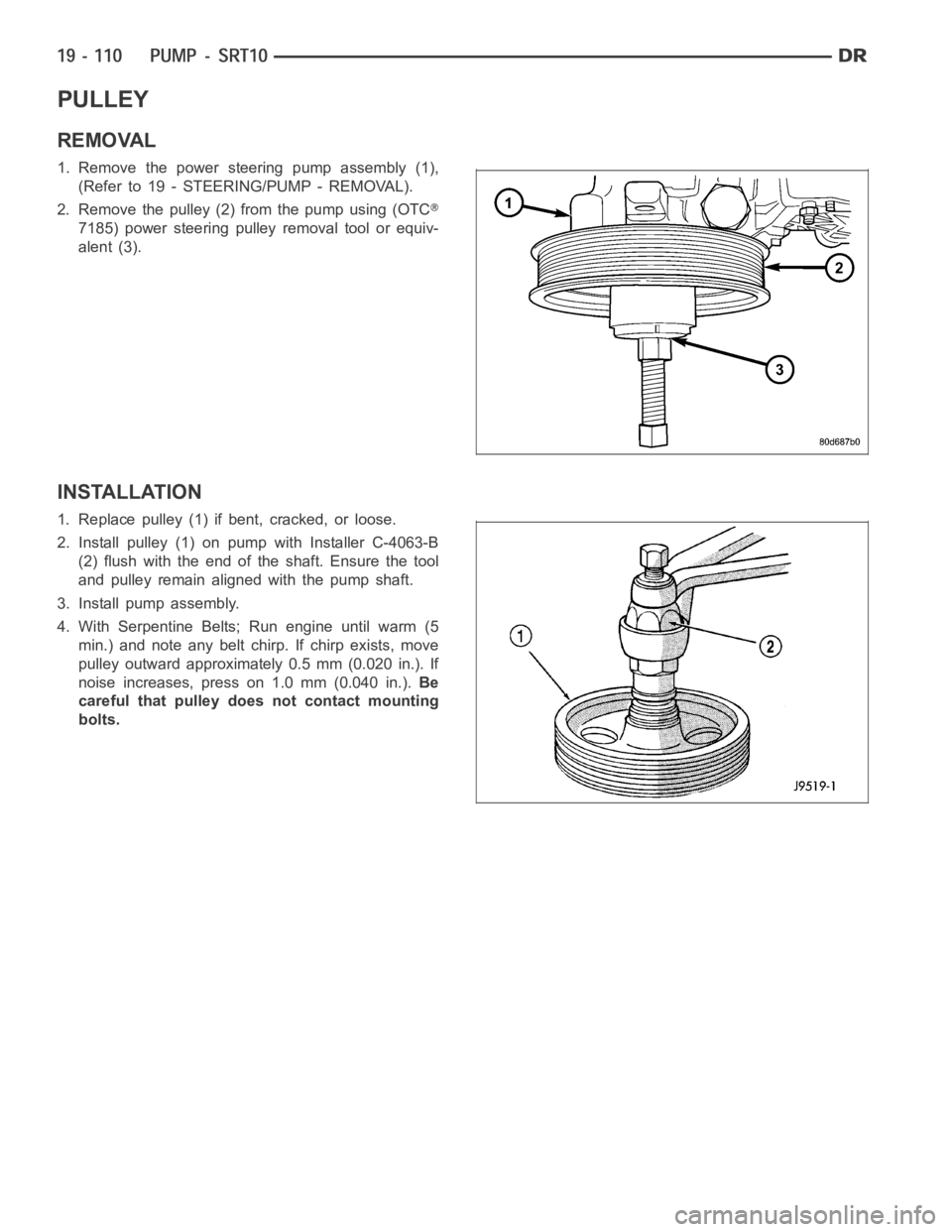

PULLEY

REMOVAL

1. Remove the power steering pump assembly (1),

(Refer to 19 - STEERING/PUMP - REMOVAL).

2. Remove the pulley (2) from the pump using (OTC

7185) power steering pulley removal tool or equiv-

alent (3).

INSTALLATION

1. Replace pulley (1) if bent, cracked, or loose.

2. Install pulley (1) on pump with Installer C-4063-B

(2) flush with the end of the shaft. Ensure the tool

and pulley remain aligned with the pump shaft.

3. Install pump assembly.

4. With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.