sensor DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5060 of 5267

page page

ACTUATOR-BLEND DOOR

DESCRIPTION ............................... 220

OPERATION ................................. 220

REMOVAL ................................... 221

INSTALLATION .............................. 222

ACTUATOR-MODE DOOR

DESCRIPTION ............................... 225

OPERATION ................................. 225

REMOVAL ................................... 226

INSTALLATION .............................. 227

ACTUATOR-RECIRCULATION DOOR

DESCRIPTION ............................... 229

OPERATION ................................. 229

REMOVAL ................................... 230

INSTALLATION .............................. 230

CLUTCH-A/C COMPRESSOR

DESCRIPTION ............................... 232

OPERATION ................................. 232

DIAGNOSIS AND TESTING

A/C COMPRESSOR CLUTCH COIL.......... 232

STANDARD PROCEDURE

A/C CLUTCH PLATE INSPECTION.......... 233

A/C CLUTCH BREAK-IN.................... 233

REMOVAL

DENSO A/C COMPRESSOR ................ 234

VISTEON A/C COMPRESSOR .............. 235INSTALLATION

DENSO A/C COMPRESSOR................ 238

VISTEON A/C COMPRESSOR.............. 240

CONTROL-A/C HEATER

DESCRIPTION

MANUAL SINGLE ZONE .................... 243

MANUAL DUAL ZONE ...................... 243

REMOVAL ................................... 244

INSTALLATION .............................. 244

RESISTOR-BLOWER MOTOR

DESCRIPTION ............................... 245

OPERATION ................................. 245

DIAGNOSIS AND TESTING

BLOWER MOTOR RESISTOR ............... 245

REMOVAL ................................... 246

INSTALLATION .............................. 247

SENSOR-EVAPORATOR TEMPERATURE

DESCRIPTION ............................... 248

OPERATION ................................. 248

REMOVAL ................................... 249

INSTALLATION .............................. 250

TRANSDUCER-A/C PRESSURE

DESCRIPTION ............................... 251

OPERATION ................................. 251

REMOVAL ................................... 251

INSTALLATION .............................. 252

Page 5089 of 5267

SENSOR-EVAPORATOR TEMPERATURE

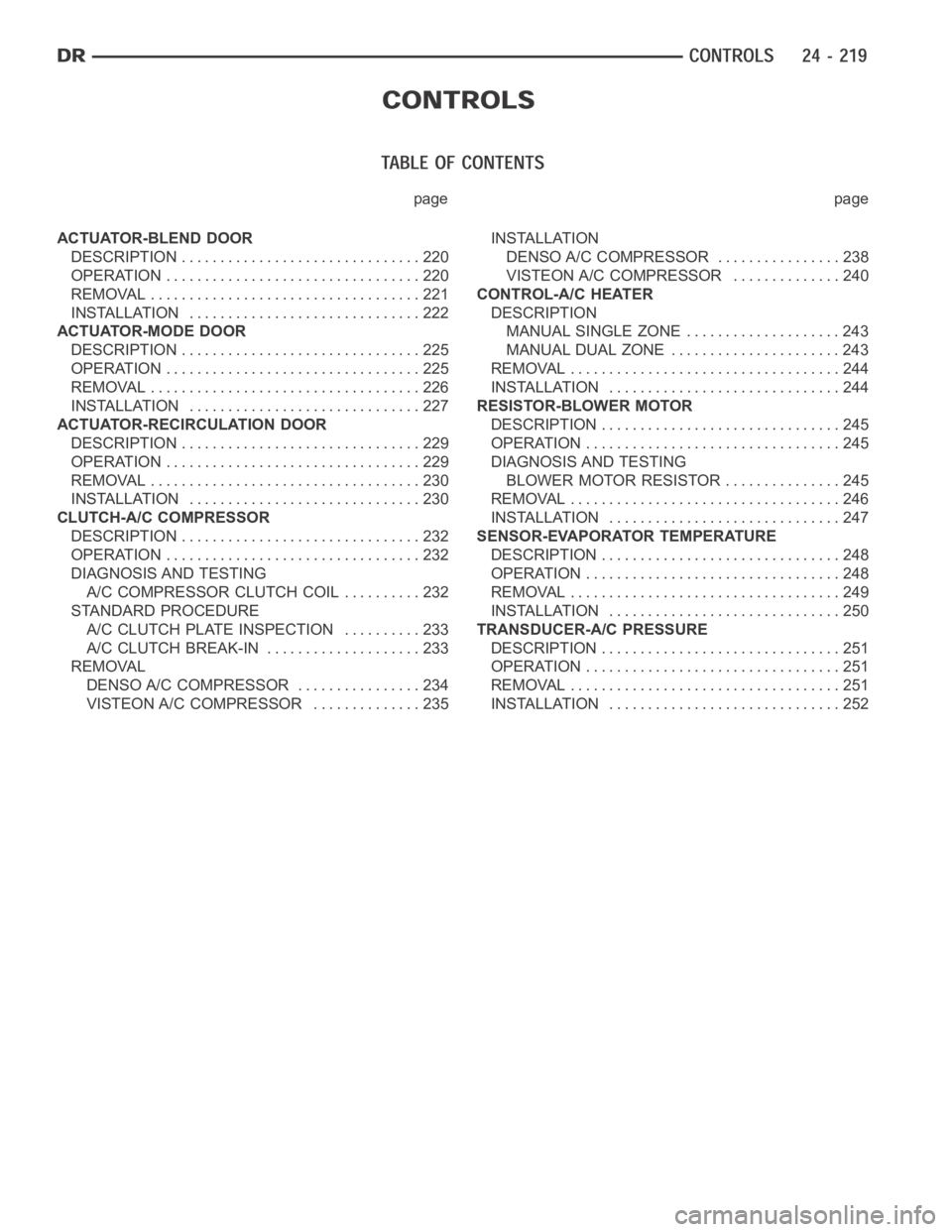

DESCRIPTION

The evaporator temperature sensor is a two-wire tem-

perature sensing element located at the coldest point

on the face of the A/C evaporator. The probe (1) for

evaporator temperature sensor is attached to the

evaporator coil fins. The wire lead (2) for evaporator

temperature sensor is routed through an opening at

the back of the HVAC housing and the connector (3)

is attached to the HVAC wire harness.

OPERATION

The evaporator temperature sensor monitors the surface temperature of A/C evaporator and supplies an input signal

to the A/C-heater control. The A/C-heater control uses the evaporator temperature sensor input signal to optimize

A/C system performance and to protect the A/C system from evaporator freezing. The evaporator temperature sen-

sor will change its internal resistance in response to the temperatures itmonitors and is connected to the A/C-heater

control through sensor ground circuit and a 5-volt reference signal circuit. As the temperature of the A/C evaporator

decreases, the internal resistance of the evaporator temperature sensordecreases.

The A/C-heater control uses the monitored voltage reading as an indication of evaporator temperature. The A/C-

heater control is programmed to respond to this input by requesting the powertrain control module (PCM) or the

engine control module (ECM) (depending on engine application) to cycle the A/C compressor clutch as necessary to

optimize A/C system performance and to protect the A/C system from evaporatorfreezing(Referto24-HEATING

& AIR CONDITIONING/CONTROLS/COIL-A/C COMPRESSOR CLUTCH - OPERATION formore information).

The evaporator temperature sensor is diagnosed using a scan tool (Refer to24 - HEATING & AIR CONDITIONING

- DIAGNOSIS AND TESTING and to 24 - HVAC Electrical Diagnostics for more information).

The evaporator temperature sensor cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

Page 5090 of 5267

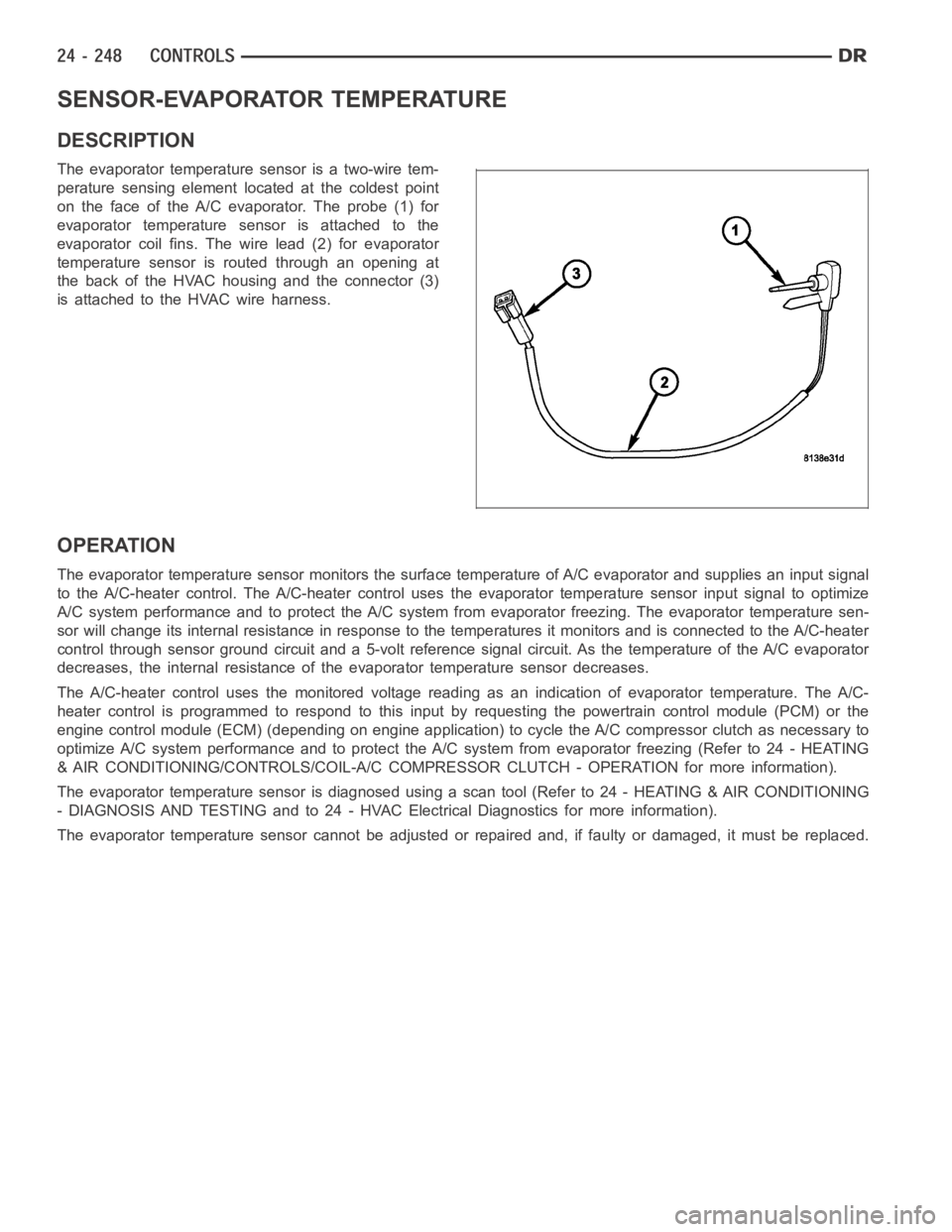

REMOVAL

1. RemovetheHVAChousingandplaceitonawork-

bench (Refer to 24 - HEATING & AIR CONDITION-

ING/DISTRIBUTION/HOUSING-HVAC -

REMOVAL).

2. Remove the wire lead for the evaporator tempera-

ture sensor (2) from the retainer located on the

HVAC housing (1) and disconnect the sensor con-

nector from the HVAC wire harness (3).

3. Remove the lower half of the HVAC housing from

the upper half of the HVAC housing to gain access

to the A/C evaporator (Refer to 24 - HEATING &

AIR CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - DISASSEMBLY).

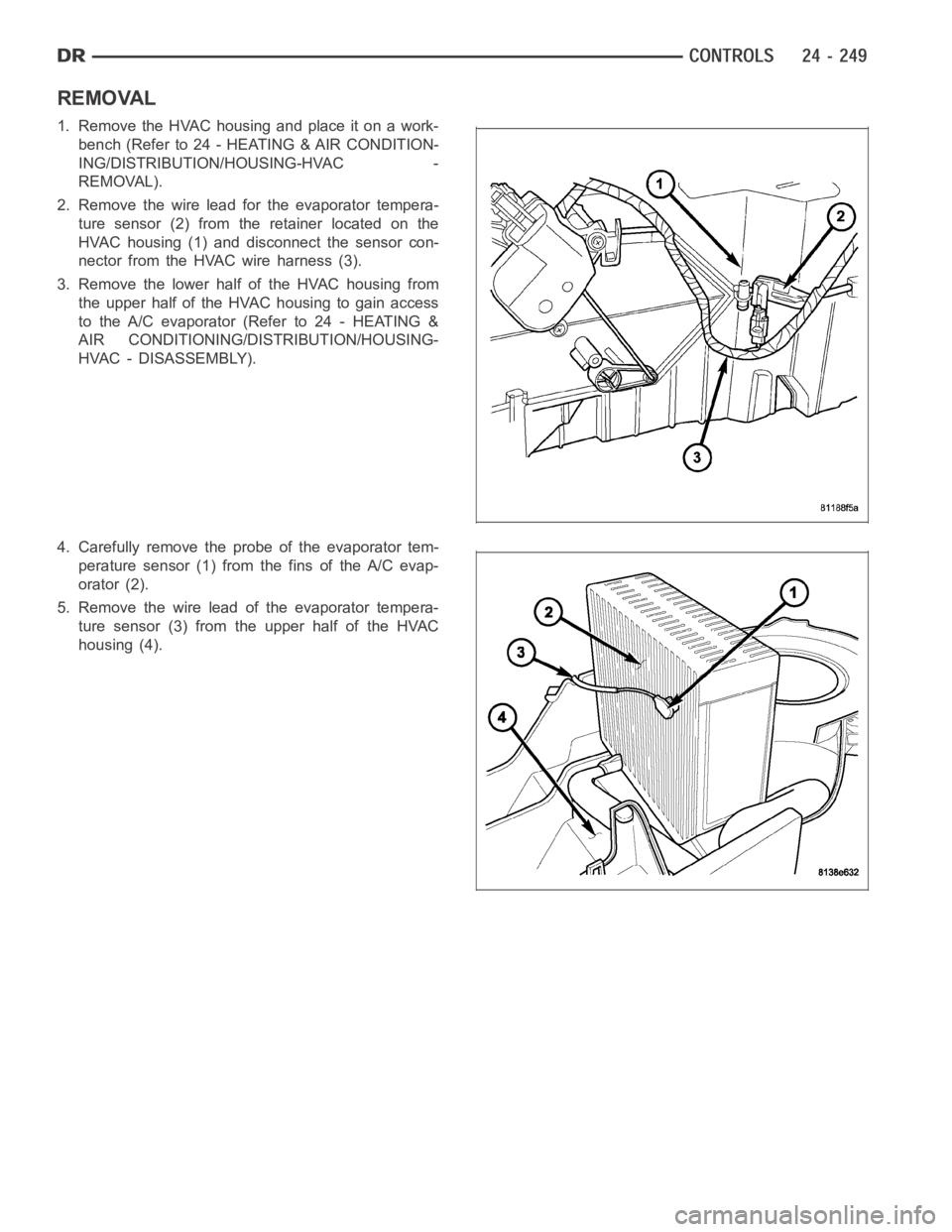

4. Carefully remove the probe of the evaporator tem-

perature sensor (1) from the fins of the A/C evap-

orator (2).

5. Remove the wire lead of the evaporator tempera-

ture sensor (3) from the upper half of the HVAC

housing (4).

Page 5091 of 5267

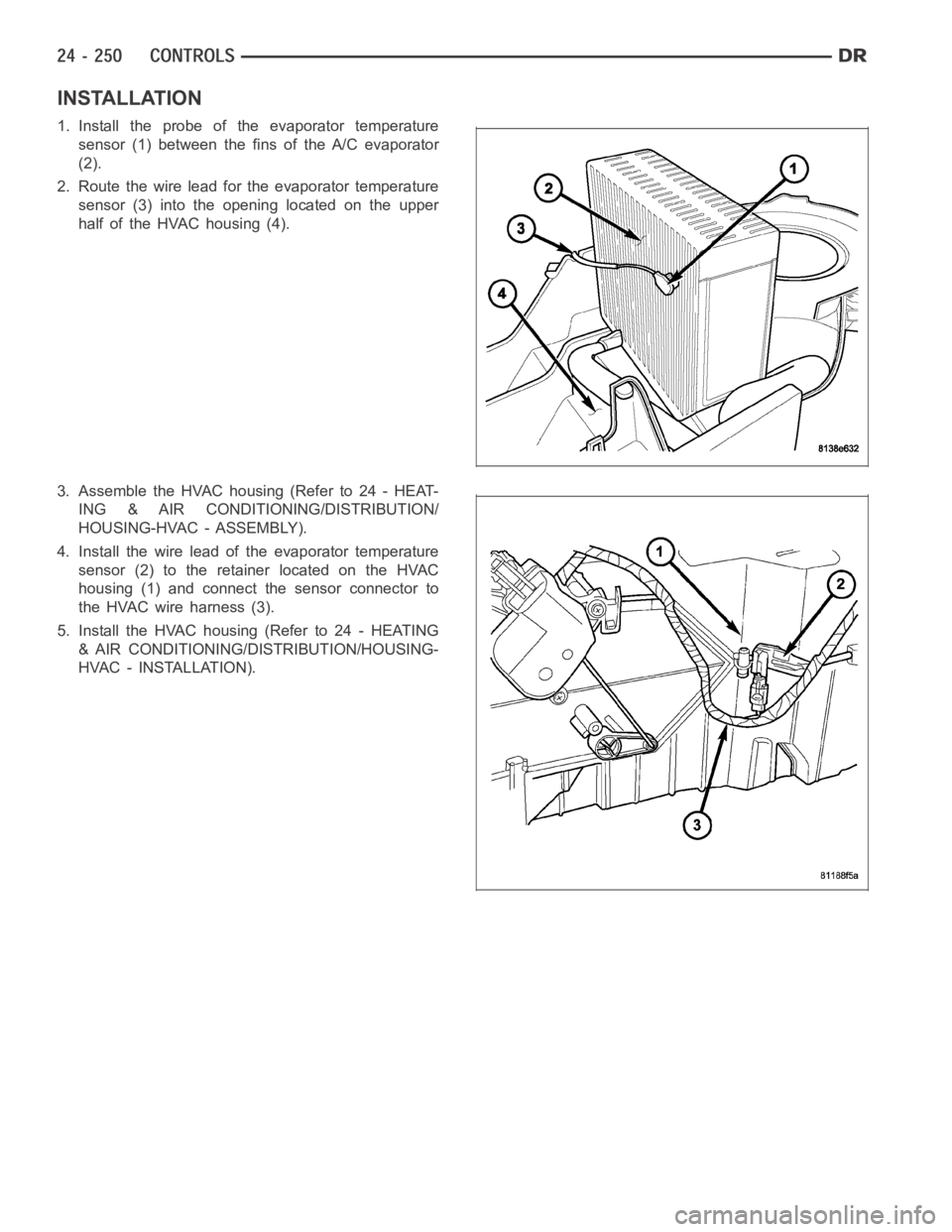

INSTALLATION

1. Install the probe of the evaporator temperature

sensor (1) between the fins of the A/C evaporator

(2).

2. Route the wire lead for the evaporator temperature

sensor (3) into the opening located on the upper

half of the HVAC housing (4).

3. Assemble the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - ASSEMBLY).

4. Install the wire lead of the evaporator temperature

sensor (2) to the retainer located on the HVAC

housing (1) and connect the sensor connector to

theHVACwireharness(3).

5. Install the HVAC housing (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - INSTALLATION).

Page 5092 of 5267

TRANSDUCER-A/C PRESSURE

DESCRIPTION

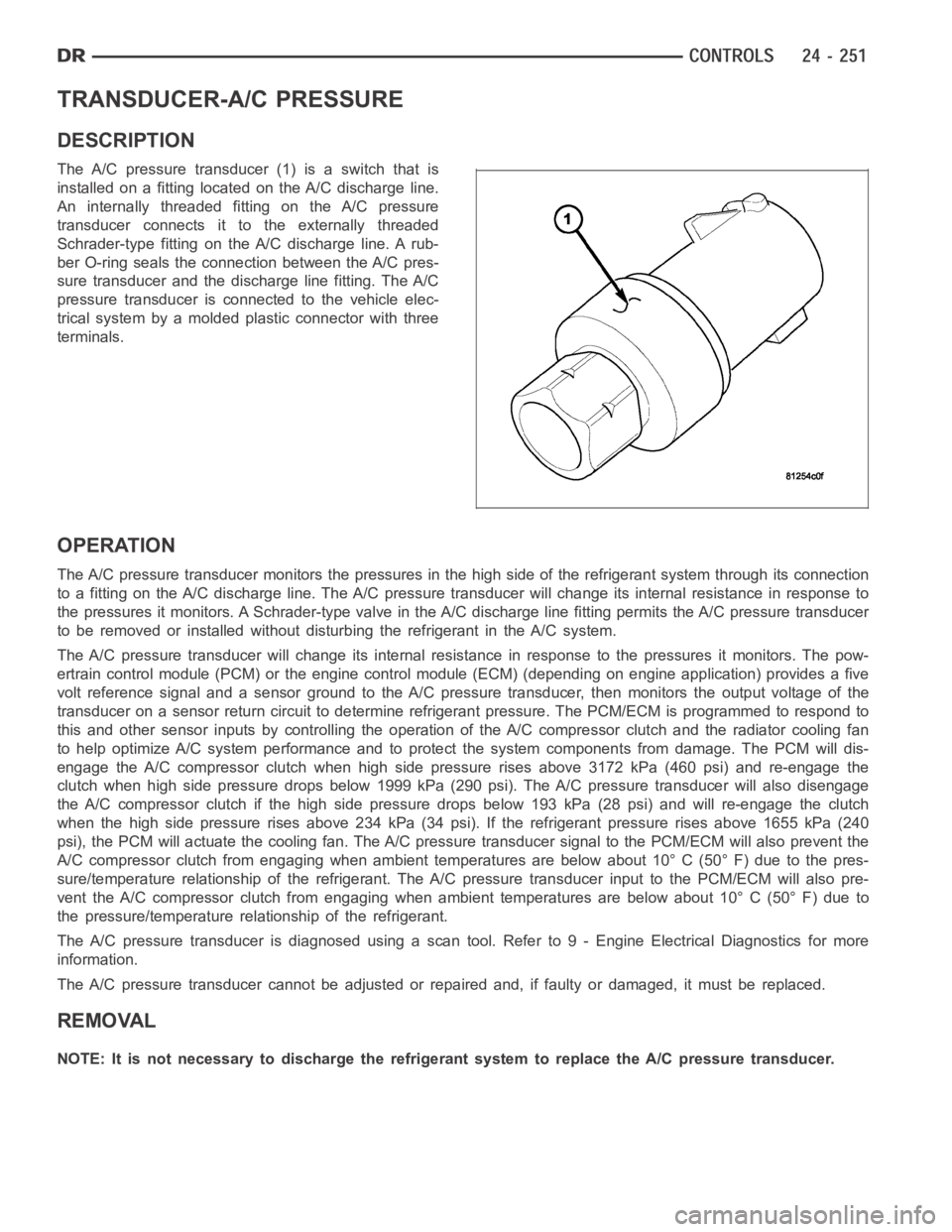

The A/C pressure transducer (1) is a switch that is

installed on a fitting located on the A/C discharge line.

An internally threaded fitting on the A/C pressure

transducer connects it to the externally threaded

Schrader-type fitting on the A/C discharge line. A rub-

ber O-ring seals the connection between the A/C pres-

sure transducer and the discharge line fitting. The A/C

pressure transducer is connected to the vehicle elec-

trical system by a molded plastic connector with three

terminals.

OPERATION

The A/C pressure transducer monitors the pressures in the high side of the refrigerant system through its connection

to a fitting on the A/C discharge line. The A/C pressure transducer will change its internal resistance in response to

the pressures it monitors. A Schrader-type valve in the A/C discharge linefitting permits the A/C pressure transducer

to be removed or installed without disturbing the refrigerant in the A/C system.

The A/C pressure transducer will change its internal resistance in response to the pressures it monitors. The pow-

ertrain control module (PCM) or the engine control module (ECM) (depending on engine application) provides a five

volt reference signal and a sensor ground to the A/C pressure transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine refrigerant pressure.The PCM/ECM is programmed to respond to

this and other sensor inputs by controlling the operation of the A/C compressor clutch and the radiator cooling fan

to help optimize A/C system performance and to protect the system components from damage. The PCM will dis-

engagetheA/Ccompressorclutchwhenhighsidepressurerisesabove3172kPa (460 psi) and re-engage the

clutch when high side pressure drops below 1999 kPa (290 psi). The A/C pressure transducer will also disengage

the A/C compressor clutch if the high side pressure drops below 193 kPa (28 psi) and will re-engage the clutch

when the high side pressure rises above 234 kPa (34 psi). If the refrigerantpressure rises above 1655 kPa (240

psi), the PCM will actuate the cooling fan. The A/C pressure transducer signal to the PCM/ECM will also prevent the

A/C compressor clutch from engaging when ambient temperatures are below about 10° C (50° F) due to the pres-

sure/temperature relationship of the refrigerant. The A/C pressure transducer input to the PCM/ECM will also pre-

vent the A/C compressor clutch from engaging when ambient temperatures are below about 10° C (50° F) due to

the pressure/temperature relationship of the refrigerant.

The A/C pressure transducer is diagnosed using a scan tool. Refer to 9 - Engine Electrical Diagnostics for more

information.

The A/C pressure transducer cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

REMOVAL

NOTE: It is not necessary to discharge the refrigerant system to replace the A/C pressure transducer.

Page 5103 of 5267

HOUSING-HVAC

DESCRIPTION

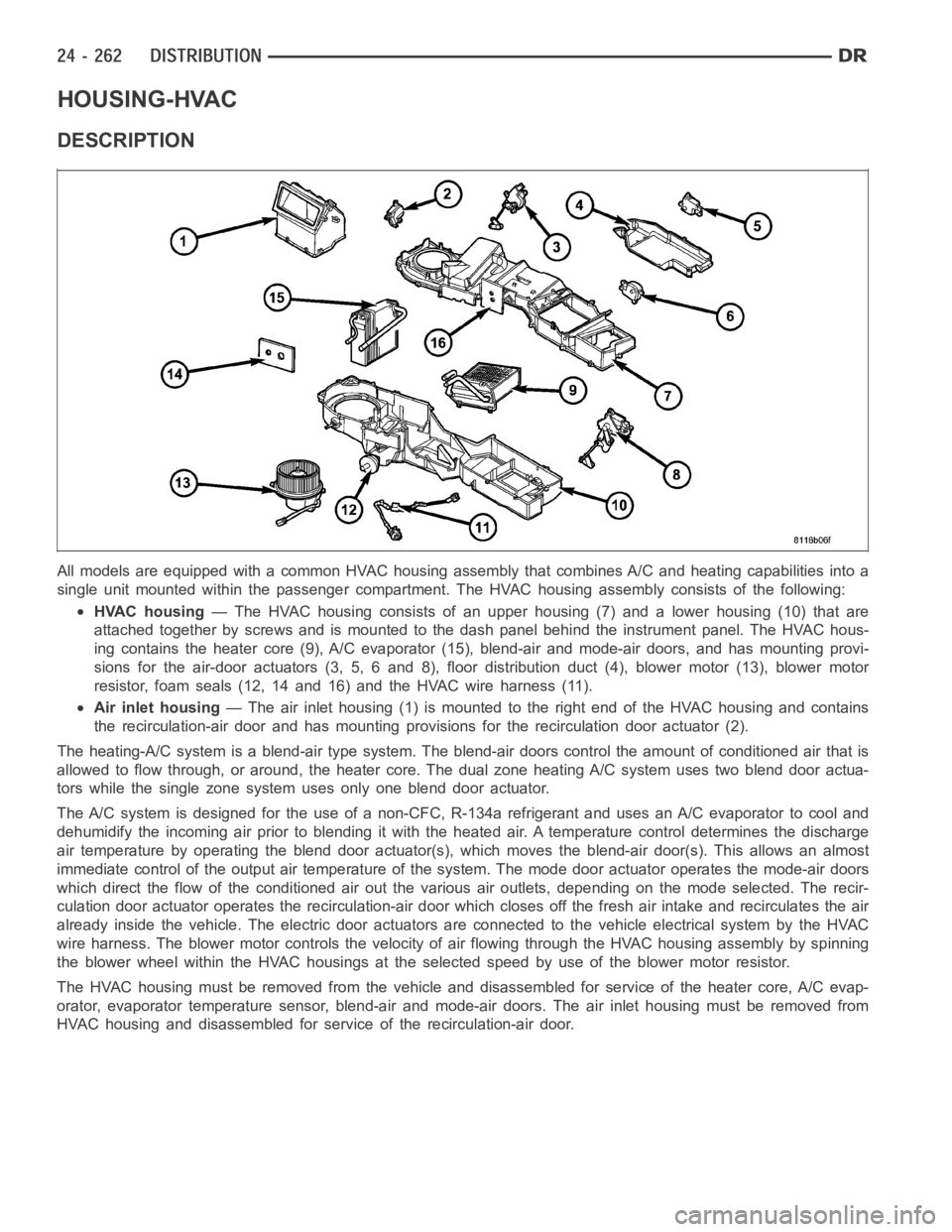

All models are equipped with a common HVAC housing assembly that combines A/C and heating capabilities into a

single unit mounted within the passenger compartment. The HVAC housing assembly consists of the following:

HVAC housing— The HVAC housing consists of an upper housing (7) and a lower housing (10) that are

attached together by screws and is mounted to the dash panel behind the instrument panel. The HVAC hous-

ing contains the heater core (9), A/C evaporator (15), blend-air and mode-air doors, and has mounting provi-

sions for the air-door actuators (3, 5, 6 and 8), floor distribution duct (4), blower motor (13), blower motor

resistor, foam seals (12, 14 and 16) and the HVAC wire harness (11).

Air inlet housing— The air inlet housing (1) is mounted to the right end of the HVAC housing andcontains

the recirculation-air door and has mounting provisions for the recirculation door actuator (2).

The heating-A/C system is a blend-air type system. The blend-air doors control the amount of conditioned air that is

allowed to flow through, or around, the heater core. The dual zone heating A/C system uses two blend door actua-

tors while the single zone system uses only one blend door actuator.

The A/C system is designed for the use of a non-CFC, R-134a refrigerant and uses an A/C evaporator to cool and

dehumidify the incoming air prior to blending it with the heated air. A temperature control determines the discharge

air temperature by operating the blend door actuator(s), which moves the blend-air door(s). This allows an almost

immediate control of the output air temperature of the system. The mode door actuator operates the mode-air doors

which direct the flow of the conditioned air out the various air outlets, depending on the mode selected. The recir-

culation door actuator operates the recirculation-air door which closesoff the fresh air intake and recirculates the air

already inside the vehicle. The electric door actuators are connected to the vehicle electrical system by the HVAC

wire harness. The blower motor controls the velocity of air flowing through the HVAC housing assembly by spinning

the blower wheel within the HVAC housings at the selected speed by use of theblower motor resistor.

The HVAC housing must be removed from the vehicle and disassembled for service of the heater core, A/C evap-

orator, evaporator temperature sensor, blend-air and mode-air doors. The air inlet housing must be removed from

HVAC housing and disassembled for service of the recirculation-air door.

Page 5104 of 5267

REMOVAL

HVAC HOUSING ASSEMBLY

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

negative battery (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in accidental airbag deploymentand possible personal injury or

death.

NOTE: The HVAC housing must be removedfrom the vehicle and disassembled for service of the A/C evap-

orator, evaporator temperature sensor, mode-air and blend-air doors.

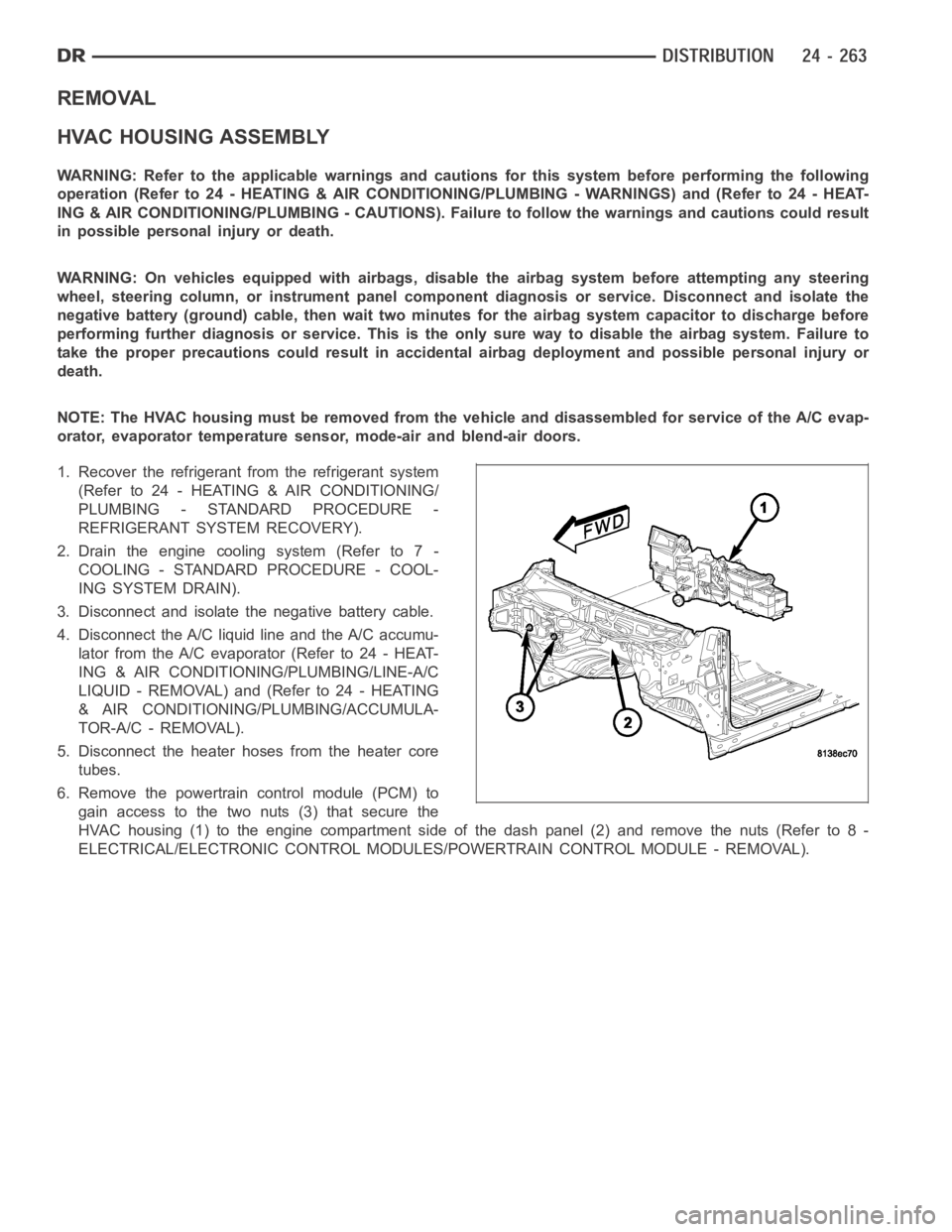

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOL-

ING SYSTEM DRAIN).

3. Disconnect and isolate the negative battery cable.

4. Disconnect the A/C liquid line and the A/C accumu-

lator from the A/C evaporator (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/LINE-A/C

LIQUID - REMOVAL) and (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/ACCUMULA-

TOR-A/C - REMOVAL).

5. Disconnect the heater hoses from the heater core

tubes.

6. Remove the powertrain control module (PCM) to

gain access to the two nuts (3) that secure the

HVAC housing (1) to the engine compartment side of the dash panel (2) and remove the nuts (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/POWERTRAIN CONTROL MODULE - REMOVAL).

Page 5106 of 5267

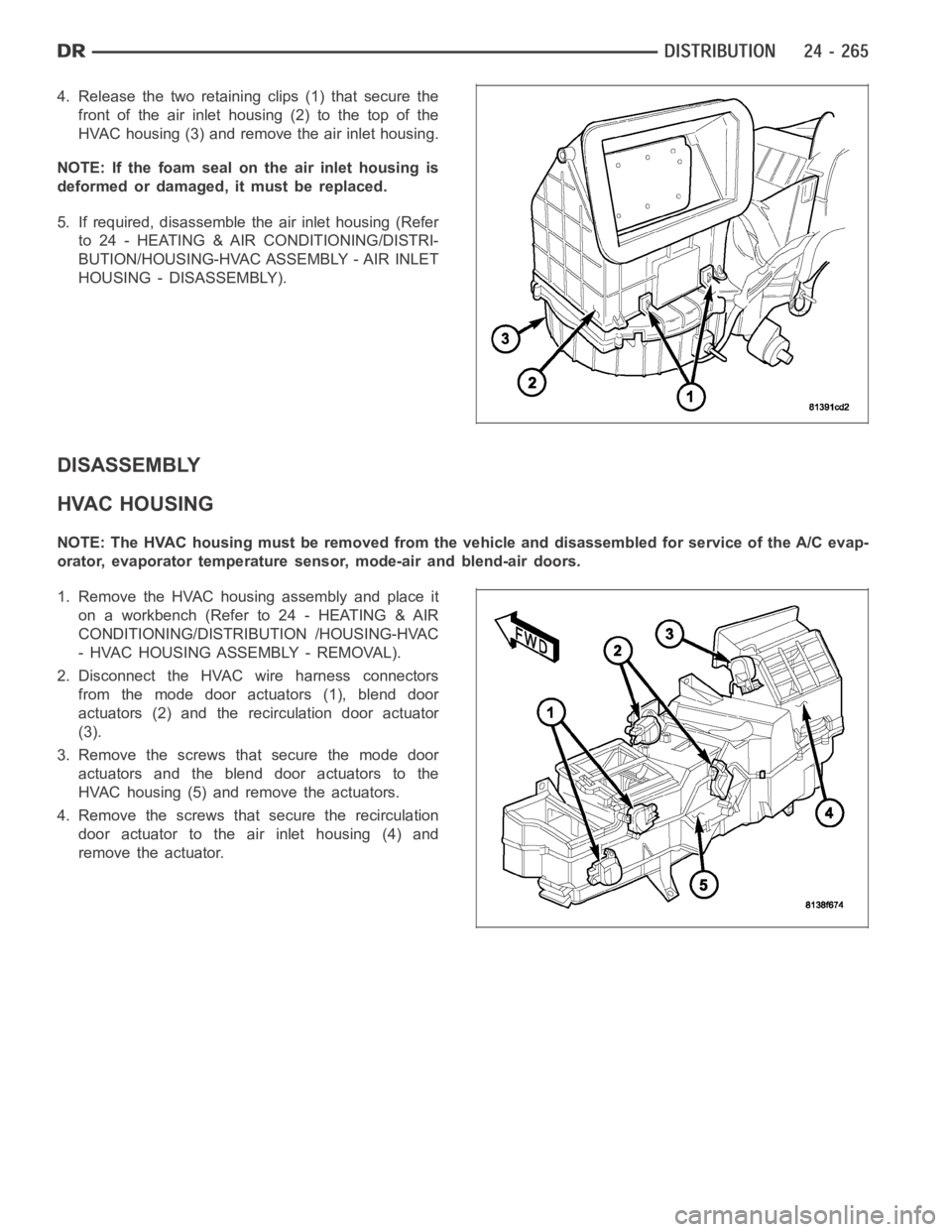

4. Release the two retaining clips (1) that secure the

front of the air inlet housing (2) to the top of the

HVAC housing (3) and remove the air inlet housing.

NOTE: If the foam seal on the air inlet housing is

deformed or damaged, it must be replaced.

5. If required, disassemblethe air inlet housing (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HOUSING-HVAC ASSEMBLY - AIR INLET

HOUSING - DISASSEMBLY).

DISASSEMBLY

HVAC HOUSING

NOTE: The HVAC housing must be removedfrom the vehicle and disassembled for service of the A/C evap-

orator, evaporator temperature sensor, mode-air and blend-air doors.

1. Remove the HVAC housing assembly and place it

on a workbench (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION /HOUSING-HVAC

- HVAC HOUSING ASSEMBLY - REMOVAL).

2. Disconnect the HVAC wire harness connectors

from the mode door actuators (1), blend door

actuators (2) and the recirculation door actuator

(3).

3. Remove the screws that secure the mode door

actuators and the blend door actuators to the

HVAC housing (5) and remove the actuators.

4. Remove the screws that secure the recirculation

door actuator to the air inlet housing (4) and

remove the actuator.

Page 5107 of 5267

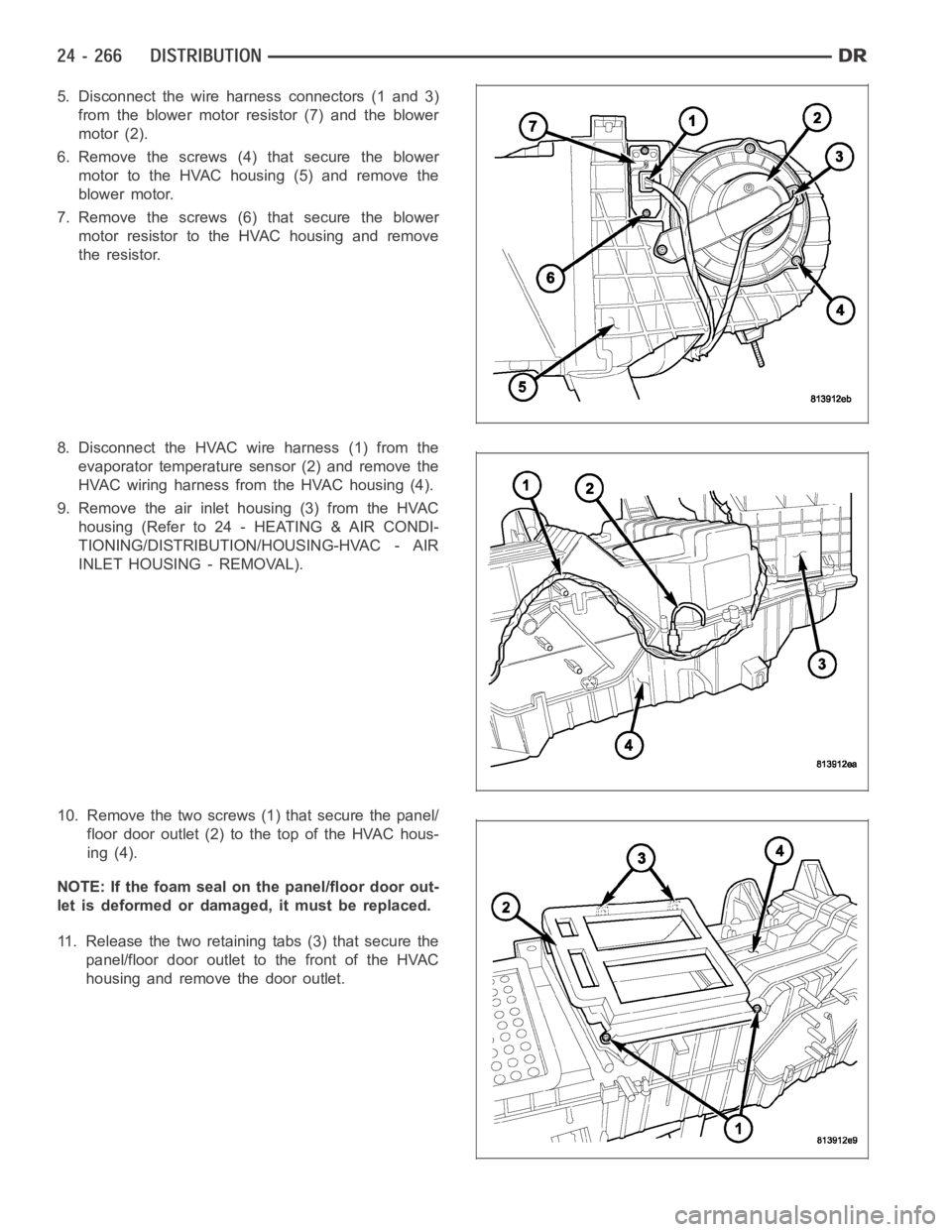

5. Disconnect the wire harness connectors (1 and 3)

from the blower motor resistor (7) and the blower

motor (2).

6. Remove the screws (4)that secure the blower

motor to the HVAC housing (5) and remove the

blower motor.

7. Remove the screws (6)that secure the blower

motor resistor to the HVAC housing and remove

the resistor.

8. Disconnect the HVAC wire harness (1) from the

evaporator temperature sensor (2) and remove the

HVAC wiring harness from the HVAC housing (4).

9. Remove the air inlet housing (3) from the HVAC

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HOUSING-HVAC - AIR

INLET HOUSING - REMOVAL).

10. Remove the two screws (1) that secure the panel/

floor door outlet (2) to the top of the HVAC hous-

ing (4).

NOTE: If the foam seal on the panel/floor door out-

let is deformed or damaged, it must be replaced.

11. Release the two retaining tabs (3) that secure the

panel/floor door outlet to the front of the HVAC

housing and remove the door outlet.

Page 5111 of 5267

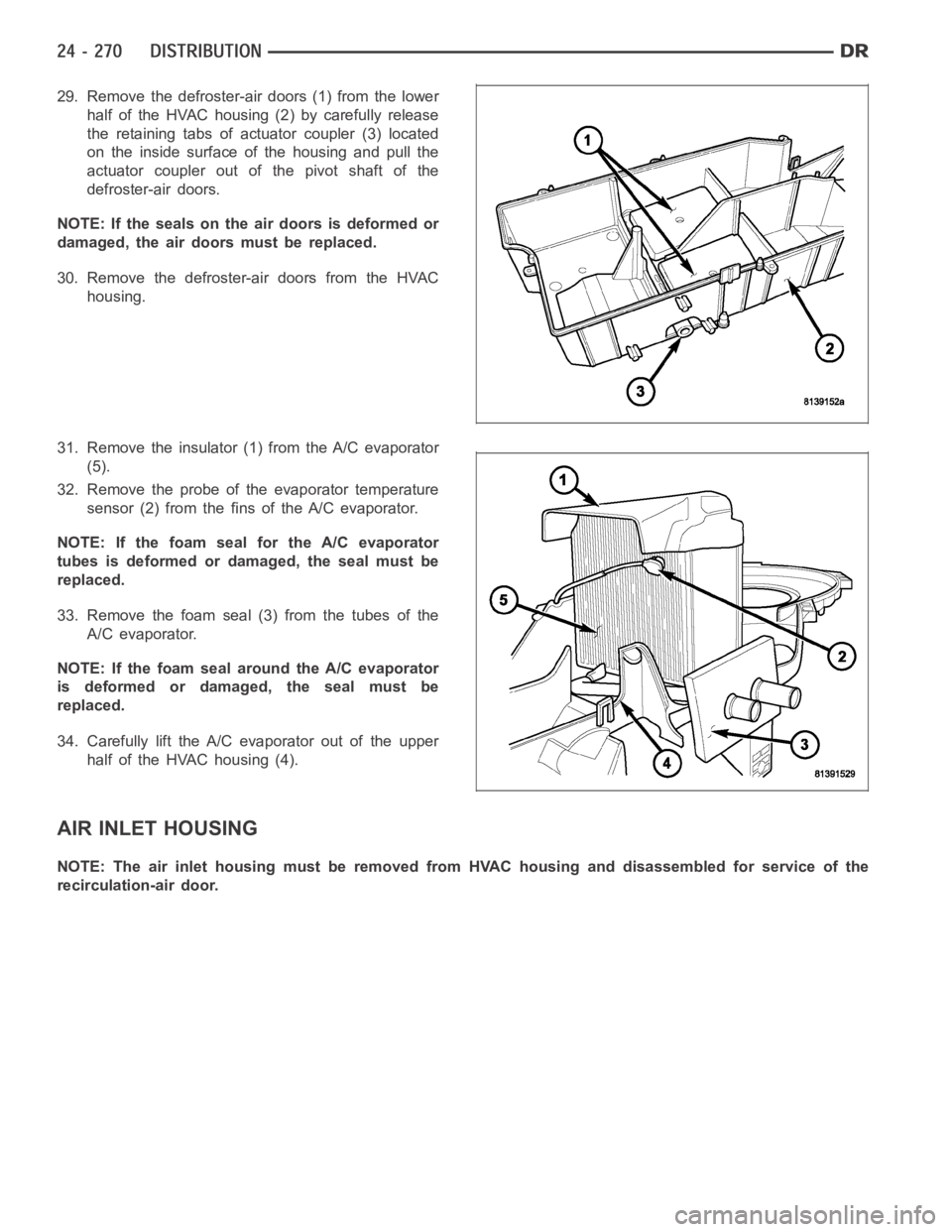

29. Remove the defroster-air doors (1) from the lower

half of the HVAC housing (2) by carefully release

the retaining tabs of actuator coupler (3) located

on the inside surface of the housing and pull the

actuator coupler out of the pivot shaft of the

defroster-air doors.

NOTE: If the seals on the air doors is deformed or

damaged, the air doors must be replaced.

30. Remove the defroster-air doors from the HVAC

housing.

31. Remove the insulator (1) from the A/C evaporator

(5).

32. Remove the probe of the evaporator temperature

sensor (2) from the fins of the A/C evaporator.

NOTE: If the foam seal for the A/C evaporator

tubes is deformed or damaged, the seal must be

replaced.

33. Remove the foam seal (3) from the tubes of the

A/C evaporator.

NOTE: If the foam seal around the A/C evaporator

is deformed or damaged, the seal must be

replaced.

34. Carefully lift the A/C evaporator out of the upper

half of the HVAC housing (4).

AIR INLET HOUSING

NOTE: The air inlet housing must be removed from HVAC housing and disassembled for service of the

recirculation-air door.