DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 121 of 5267

When Monitored:

Ignition on and vehicle moving. Brake pedal must not be applied.

Set Condition:

The PCM recognizes front axle speed is greater than rear axle speed. One tripfault.

Possible Causes

ACTIVE BUS OR COMMUNICATION DTCS

TIRE CIRCUMFERENCE

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: Check for any Bus Communication DTCs. If no Bus Communication DTCs are set, check for active

DTCs stored in the Ant-Lock Brake Module. Any Bus Communication DTCs or VSSDTCs in the Ant-Lock

Brake Module must be properly diagnosed before continuing.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: This code can set due to tire circumference differences and from the front or rear wheels being on

a slippery surface while the opposite tires are not.

This code may also set on a hard acceleration on loose gravel or during otheroff road driving conditions.

Check tire pressure of all the tires.

Checktirewearonallthetires.

Ask the customer what the road and driving conditions were like when the fault set.

Were any problems found?

Ye s>>

Repair as necessary. If the code set during a front OR rear wheel spin condition, no repair is necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 122 of 5267

3.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 123 of 5267

P1521–INCORRECT ENGINE OIL TYPE

When Monitored:

Engine Running.

Set Condition:

Using the oil pressure, oil temperature and other vital engine inputs the PCM can determine the engine oil

viscosity. Incorrect viscosity will effect the operation of the MDS by delaying cylinder activation.

Possible Causes

INCORRECT ENGINE OIL TYPE

ENGINE OIL CONTAMINATION

ENGINE OIL

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Review the customers oil change history. Make sure the customers is using the correct engine oil

viscosity. If the incorrect oil is being used, change the oil, using the correct engine oil viscosity.

Ignition on, engine off.

With the scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go to 2

No>>

Te s t C o m p l e t e .

2.ENGINE OIL

NOTE: If any engine oil pressure or oil temperature DTCs set along with P1521, repair them before continu-

ing with the P1521 diagnostics.

The following conditions must be checked.

OEM recommended oil viscosity is being used.

Customer is following the oil change schedule.

Check the engine oil for contamination. (i.e., fuel and/or engine coolant)

Internal engine condition that may effect oil pressure.

Were any of the above condition found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Change the engine oil using the correct oil viscosity.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 124 of 5267

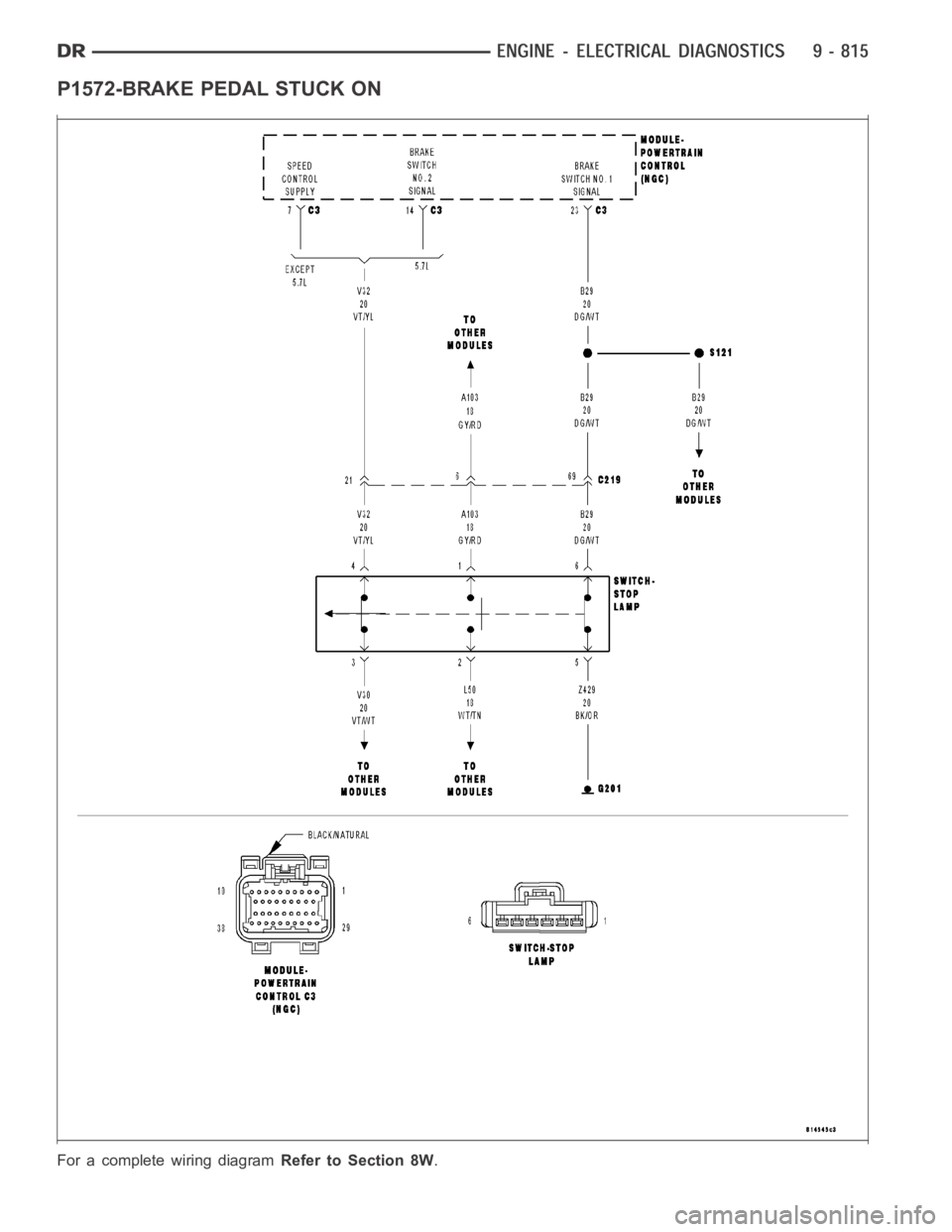

P1572-BRAKE PEDAL STUCK ON

For a complete wiring diagramRefer to Section 8W.

Page 125 of 5267

When Monitored:

Ignition on. In plant mode only.

Set Condition:

PCM recognizes the Brake Pedal couldnot electrically indicate the applied (On) position with both switch

inputs. One trip fault.

Possible Causes

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT OPEN

(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT OPEN

STOP LAMP SWITCH

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Make sure the Stop Lamp Switch is adjusted properly before continuing.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.STOP LAMP SWITCH OPERATION

Turn the ignition off.

Disconnect the Stop Lamp Switch harness connector.

Measure the resistance between the (Z429) Ground circuit terminal and the(B29) Brake Switch No.1 Signal terminal

in the Stop Lamp Switch.

Apply and release the brake pedal while monitoring the ohmmeter.

Does the resistance change from below 5.0 ohms to open circuit when pressingandreleasingthe

brake pedal switch?

Ye s>>

Go To 3

No>>

Replace the Stop Lamp Switch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

3.STOP LAMP SWITCH OPERATION

Measure the resistance between the (V30) Fused Ignition Switch Output terminal and the (V32) Brake Switch No.2

Signal circuit terminal in the Stop Lamp Switch.

Apply and release the brake pedal while monitoring the ohmmeter.

Does the resistance change from below 5.0 ohms to open circuit when pressingandreleasingtheStop

Lamp switch?

Ye s>>

Go To 4

No>>

Replace the Stop Lamp Switch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 126 of 5267

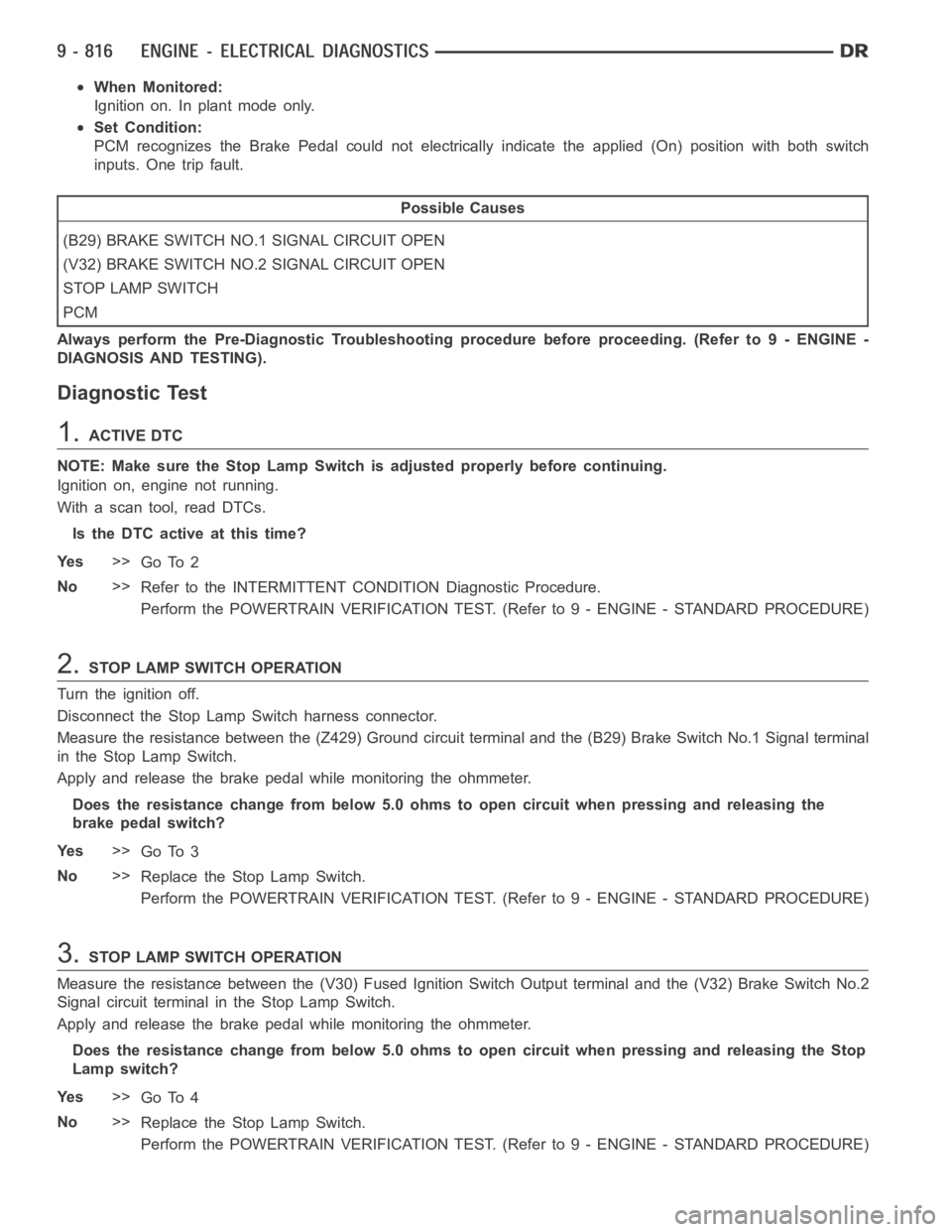

4.(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT OPEN

Disconnect the C3 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (B29) Brake Switch No.1 Signal circuit

from the Stop Lamp Switch harness connector to the appropriate termi-

nal of special tool #8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 5

No>>

Repair the open in the (B29) Brake Switch No.1 Signal cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

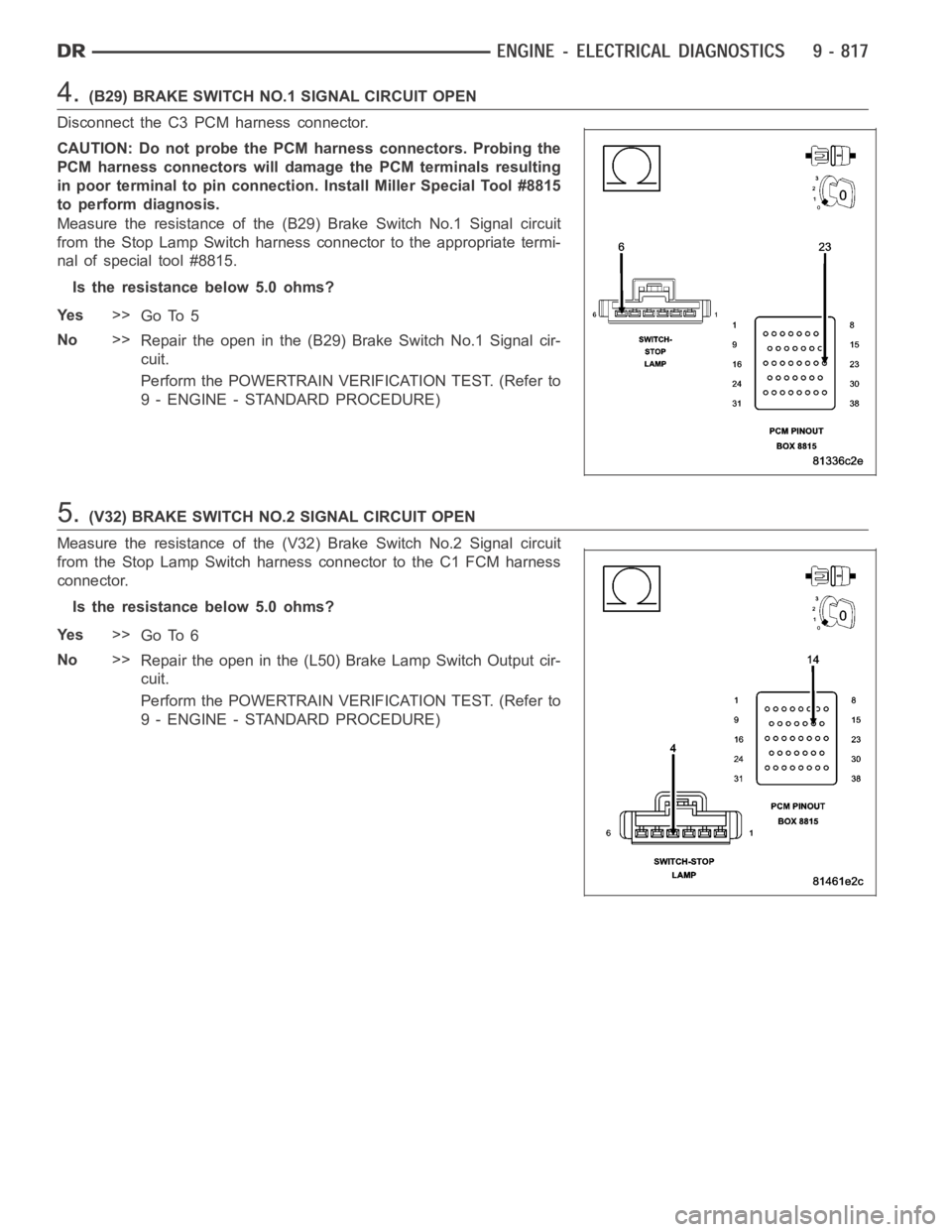

5.(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT OPEN

Measure the resistance of the (V32) Brake Switch No.2 Signal circuit

from the Stop Lamp Switch harness connector to the C1 FCM harness

connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the (L50) Brake Lamp Switch Output cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 127 of 5267

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 128 of 5267

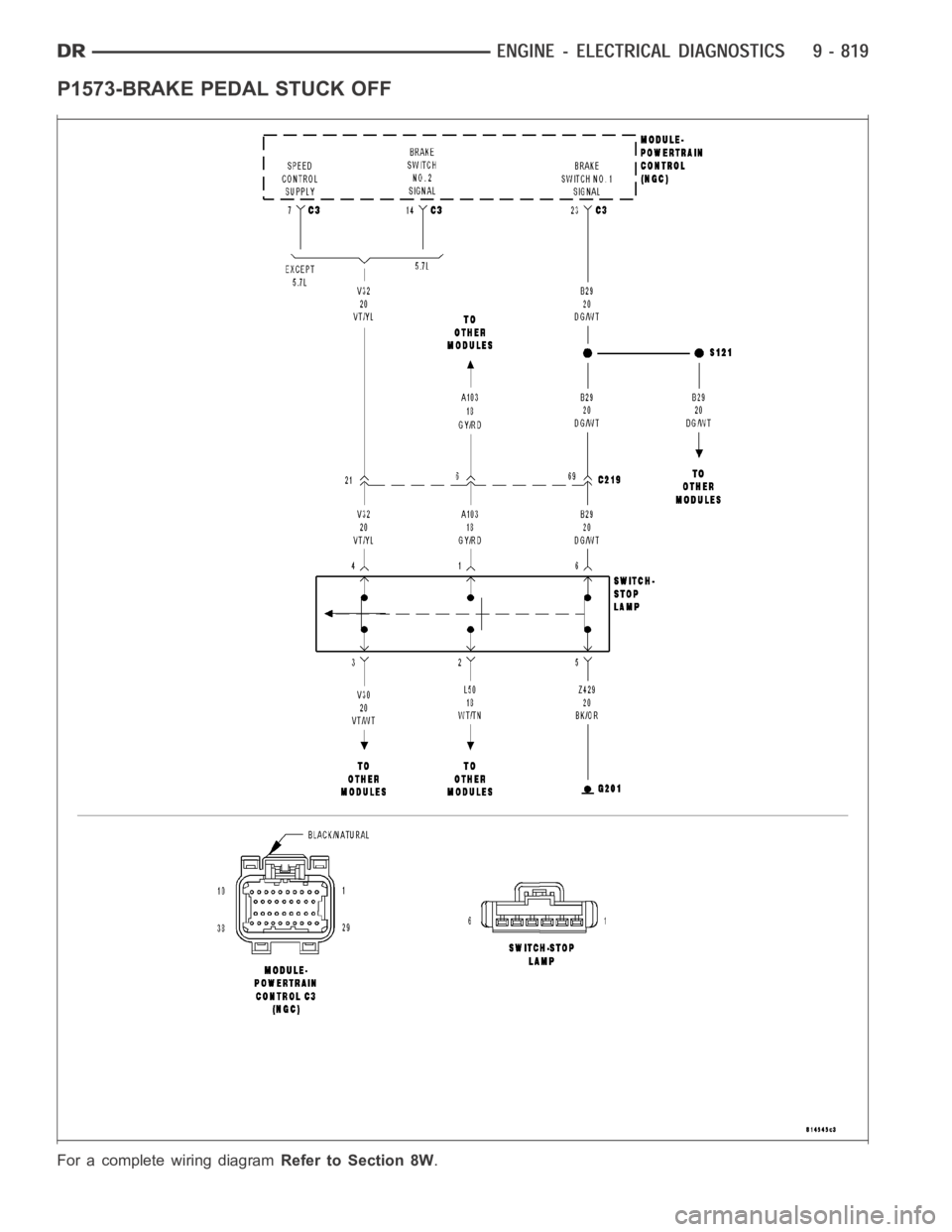

P1573-BRAKE PEDAL STUCK OFF

For a complete wiring diagramRefer to Section 8W.

Page 129 of 5267

When Monitored:

Ignition on, In plant mode passed the Applied test.

Set Condition:

PCM recognizes the Brake Pedal could not electronically indicate the released (Off) position with both

switches. If P1572 sets, P1573 will also set. One trip fault.

Possible Causes

(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

STOP LAMP SWITCH

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Make sure the Stop Lamp Switch is adjusted properly before continuing.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.STOP LAMP SWITCH OPERATION

Turn the ignition off.

Disconnect the Stop Lamp Switch harness connectors.

Measure the resistance between the (Z429) Ground circuit terminal and the(B29) Brake Switch No.1 Signal terminal

in the Stop Lamp Switch.

Apply and release the brake pedal while monitoring the ohmmeter.

Does the resistance change from below 5.0 ohms to an open circuit when pressing and releasing the

brake switch?

Ye s>>

Go To 3

No>>

Replace the Stop Lamp Switch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

3.STOP LAMP SWITCH OPERATION

Measure the resistance between the (V30) Fused Ignition Switch Output circuit terminal and the (V32) Brake Switch

No.2 Signal terminal in the Stop Lamp Switch.

Apply and release the brake pedal while monitoring the ohmmeter.

Does the resistance change from below 5.0 ohms to an open circuit when pressing and releasing the

Stop Lamp switch?

Ye s>>

Go To 4

No>>

Replace the Stop Lamp Switch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 130 of 5267

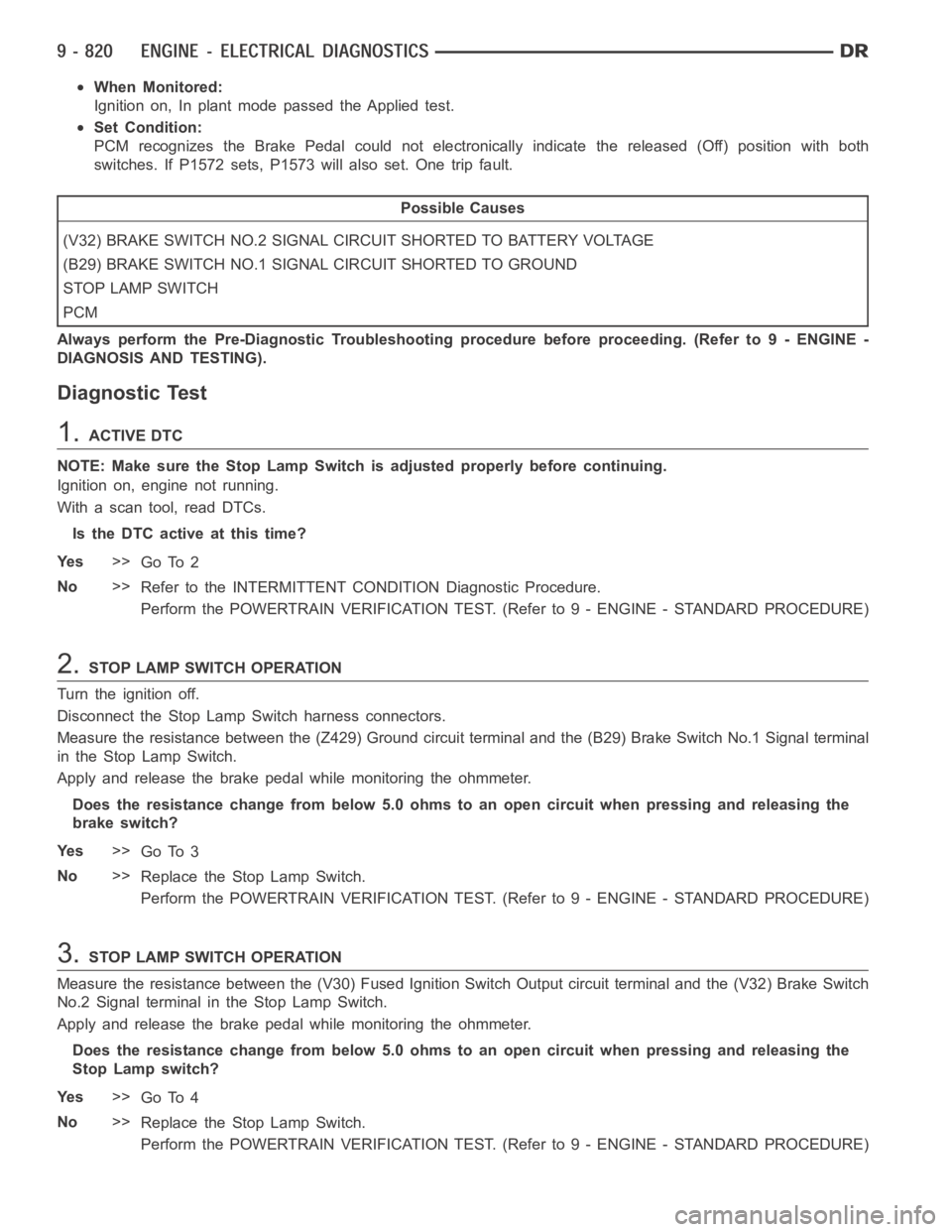

4.(V32) BRAKE SWITCH NO.2 SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

Disconnect the C2 PCM harness connector.

Ignition on, engine not running.

Measure the voltage on the (V32) Brake Switch No.2 Signal circuit in

the Stop Lamp Switch harness connector.

Is the voltage above 1.0 volt?

Ye s>>

Repair the short to battery voltage in the (V32) Brake

Switch No.2 Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

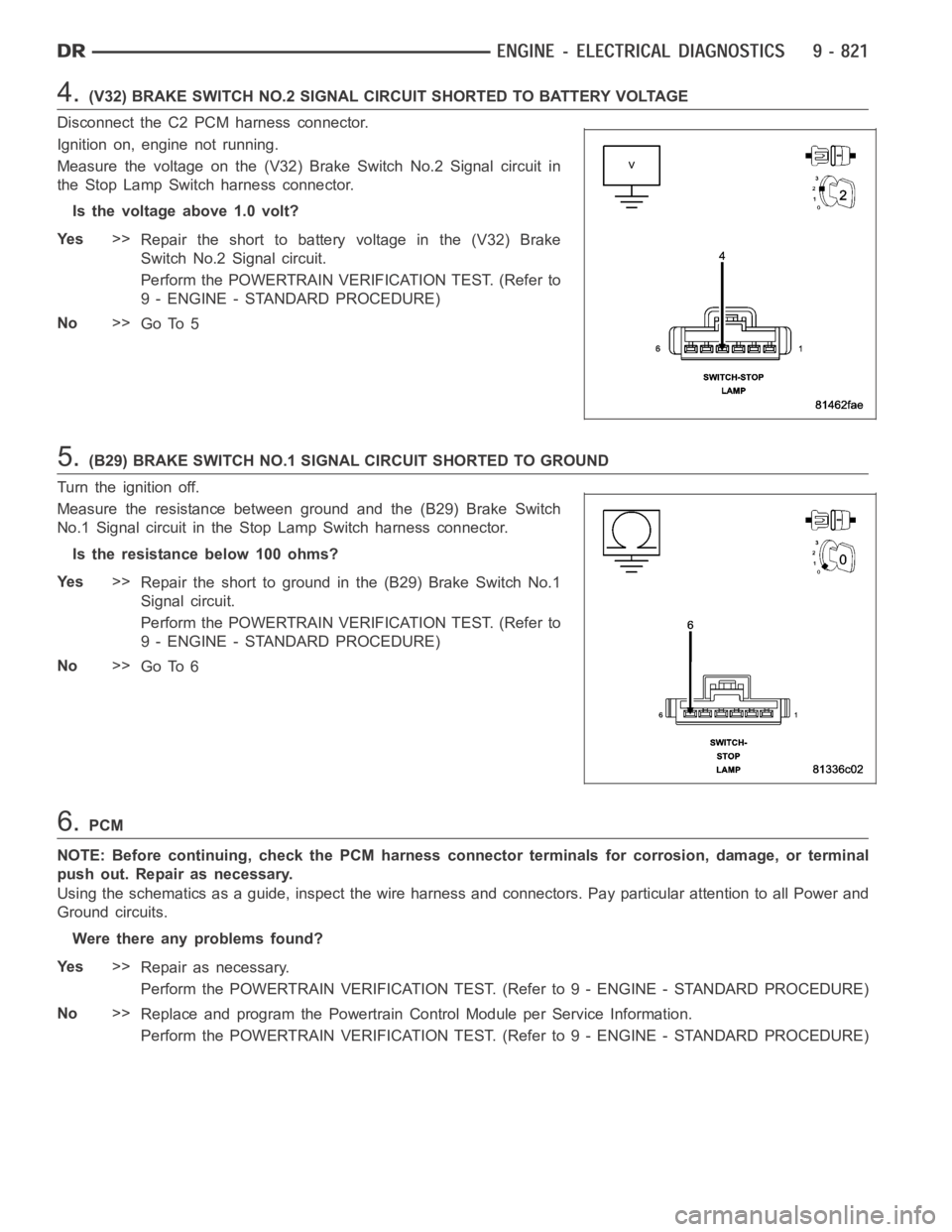

5.(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Measure the resistance between ground and the (B29) Brake Switch

No.1 Signal circuit in the Stop Lamp Switch harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (B29) Brake Switch No.1

Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)