engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2342 of 5267

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM

WARNING: High-pressure fuel lines deliver diesel

fuel under extreme pressure from the injection

pump to the fuel injectors. This may be as high as

160,000 kpa (23,206 psi). Use extreme caution

when inspecting for high-pressure fuel leaks.

Inspect for high-pressure fuel leaks with a sheet of

cardboard. High fuel injection pressure can cause

personal injury if contact is made with the skin.

The fuel system used on the Cummins engine is an electronically controlled, Bosch HPCR (High-Pressure Common

Rail) system. The HPCR system consists of five main components:

Electric Fuel Transfer (lift) Pump Located in the Fuel Tank

Fuel Pump/Gear Pump (attached to fuel injection pump)

High-Pressure Fuel Injection Pump

Fuel Injection Rail

Fuel Injectors

Also to be considered as part of the overall fuel system are:

Accelerator Pedal

Air Cleaner Housing/Element

Check Valve Banjo Fitting at Rear of Cylinder Head

Fuel Connector Tubes

Fuel Drain Manifold (passage)

Fuel Drain Valve (at filter)

Fuel Filter/Water Separator

Fuel Heater

Fuel Heater Relay

Fuel Transfer Pump Relay

Fuel Level (gauge) Sending Unit

Fuel Pressure Limiting Valve

Fuel Tank

Fuel Tank Module (containing a fuel gauge sending unit, separate fuel filter located at bottom of tank module,

and fuel transfer pump)

Fuel Tank Filler/Vent Tube Assembly

Fuel Tank Filler Tube Cap

Fuel Tubes/Lines/Hoses

High-Pressure Fuel Injector Lines

In-Tank Fuel Filter (at bottom of fuel tank module)

Low-Pressure Fuel Supply Lines

Low-Pressure Fuel Return Lines

Overflow Valve

Quick-Connect Fuel Line Fittings

Accelerator Pedal Position Sensor (APPS) Located in Cab

Water Draining (maintenance)

Water-In-Fuel (WIF) Sensor

Screened Banjo Bolt (22)

The fuel injection pump supplies high pressure to the fuel rail independent of engine speed. This high pressure fuel

is then accumulated in the fuel rail. High pressure fuel is constantly supplied to the injectors by the fuel rail. The

Engine Control Module (ECM) controls the fueling and timing of the engine by actuating the injectors.

Page 2343 of 5267

Fuel enters the system from the electric fuel transfer (lift) pump, which is located inside of the fuel tank and attached

to the fuel tank module (the fuel transfer pump is no longer attached to the engine). Fuel is forced through the fuel

filter element and then enters the Fuel Pump/Gear Pump, which is attached to the rear of the fuel injection pump.

The Fuel Pump/Gear Pump is a low-pressure pump and produce pressures ranging from 551.5 kpa (80 psi) to 1241

kpa (180) psi. Fuel then enters the fuel injection pump. Low pressure fuel is then supplied to the FCA (Fuel Control

Actuator).

The FCA is an electronically controlled solenoid valve. The ECM controls the amount of fuel that enters the high-

pressure pumping chambers by opening and closing the FCA based on a demanded fuel pressure. The FPS (Fuel

Pressure Sensor) on the fuel rail monitors the actual fuel pressure and provides it as an input to the ECM. When

the actuator is opened, the maximum amount of fuel is being supplied to the fuel injection pump. Any fuel that does

not enter the injection pump is directed to the overflow valve. The overflow valve regulates how much excess fuel

is used for lubrication of the pump and how much is returned to the tank through the drain manifold.

Fuel entering the injection pump is pressurized to between 300-1600 bar (4351-23,206 psi) by three radial pumping

chambers. The pressurized fuel is then supplied to the fuel rail.

STANDARD PROCEDURE

WATER DRAINING AT FUEL FILTER

Refer to Fuel Filter/Water Separatorremoval/installation for procedures.

CLEANING FUEL SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.

FUEL SYSTEM PRIMING

A certain amount of air becomes trappedin the fuel system when fuel system components on the supply and/or

high-pressure side are serviced or replaced. Fuel system priming is accomplished using the electric fuel transfer (lift)

pump.

Servicing or replacing fuel system components will not require fuel systempriming.

The fuel transfer (lift) pump is self-priming: When the key is first turnedon (without cranking engine), the pump

operates for approximately 1 to 2 second and then shuts off (Note: When ambient temperatures are cold enough to

cause the intake air heaters to operate, the fuel lift pump will operate during the entire intake air pre-heat cycle).

The pump will also operate for up to 25 seconds after the starter is quickly engaged, and then disengaged without

allowing the engine to start. The pump shuts off immediately if the key is onand the engine stops running.

1. Turn key to CRANK position and quickly release key to ON position before engine starts. This will operate fuel

transfer pump for approximately 25 seconds.

2. Crank engine. If the engine does not start after 25 seconds, turn key to OFF position, and leave it off for at least

5 seconds. Repeat previous step until engine starts.

3. Fuel system priming is now completed.

4. Attempt to start engine. If engine will not start, proceed to following steps.When engine does start, it may run

erratically and be noisy for a few minutes. This is a normal condition.

CAUTION: Do not engage the starter motor for more than 30 seconds at a time. Allow two minutes between

cranking intervals.

5. Perform previous fuel priming procedure steps using fuel transfer pump. Be sure fuel is present at fuel tank.

6. Crank the engine for 30 seconds at a time to allow fuel system to prime.

Page 2344 of 5267

WARNING: The fuel injection pump supplies extremely high fuel pressure toeach individual injector

through the high-pressure lines. Fuel under this amount of pressure can penetrate the skin and cause per-

sonal injury. Wear safety goggles and adequate protective clothing. Do not loosen fuel fittings while engine

is running.

WARNING: Engine may start while cranking starter motor.

DRAINING FUEL TANK - DIESEL

Due to a one-way check valve installed into the fuel fill opening fitting atthe tank, the tank cannot be drained con-

ventionally at the fill cap.

1. Raise vehicle.

2. If vehicle is equipped with 4 doors and a 6 foot (short) box, remove left-rear tire/wheel.

3. Thoroughly clean area at top of fuel tank around fuel tank module.

4. Loosen clamp and disconnect rubber fuel fill hose at tank.

5. Drain fuel tank by attaching drain hose from an approved diesel fuel draining station to the fuel fill fitting of tank.

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL

1–5–3–6–2–4

TORQUE

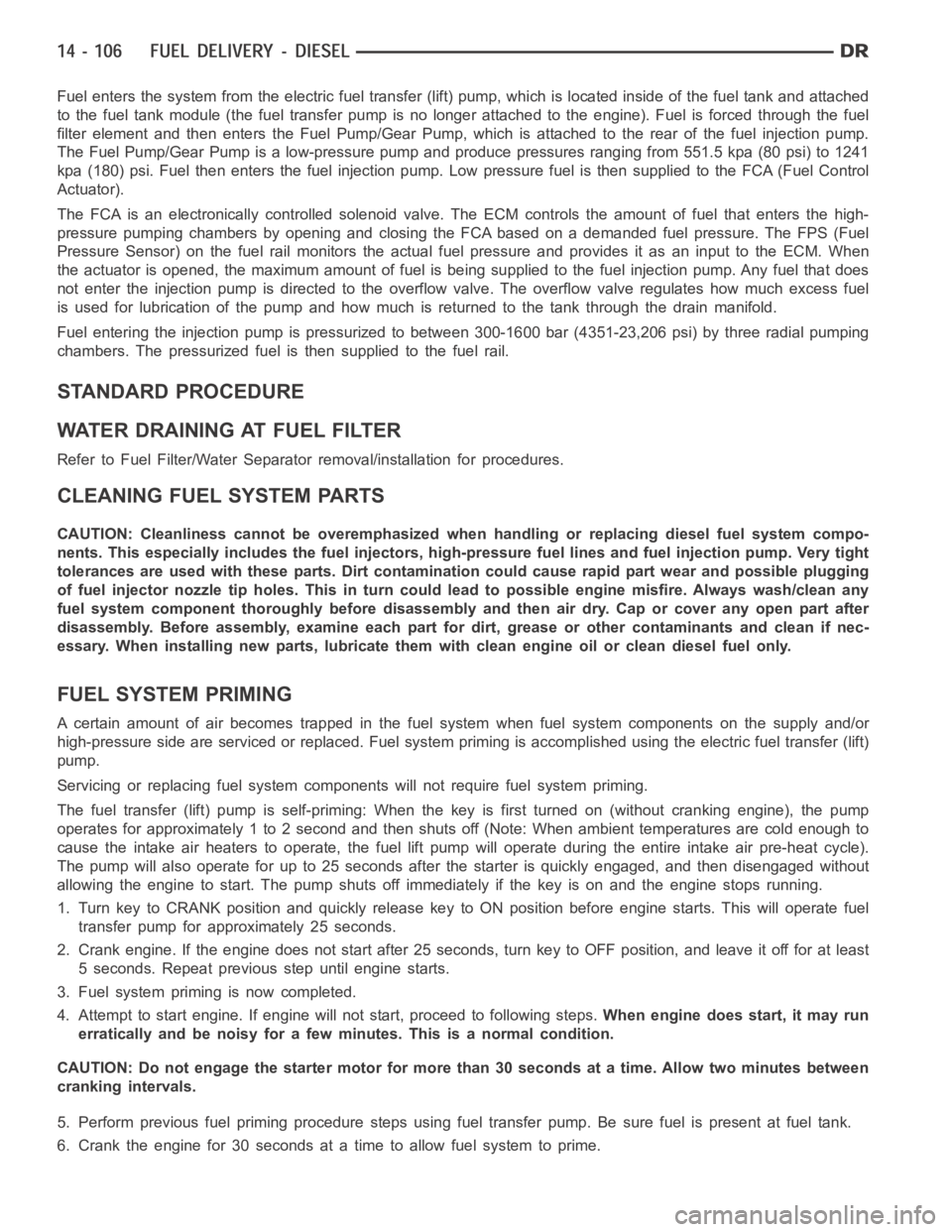

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Crankshaft Position

Sensor980

Camshaft Position Sensor 9 - 80

Engine Coolant

Temperature Sensor18 13 160

Rear Engine Lift Bracket

Bolts77 56 -

Fuel Connector Nut at

Cylinder Head50 37 -

Fuel Filler Hose Clamp at

Ta n k3-27

Fuel Filler Housing-to-

Body Screws2-17

Fuel Filter Lid 34 25 -

Fuel Filter Drain Valve

Screws1.5 - 14

Fuel Heater Element

Screws1.5 - 14

Fuel Line Banjo Fitting

Bolts24 18 -

Screened Banjo Bolt 24 18 -

Fuel Line Banjo Fitting

Bolts at Fuel Filter

Housing24 18 -

Page 2345 of 5267

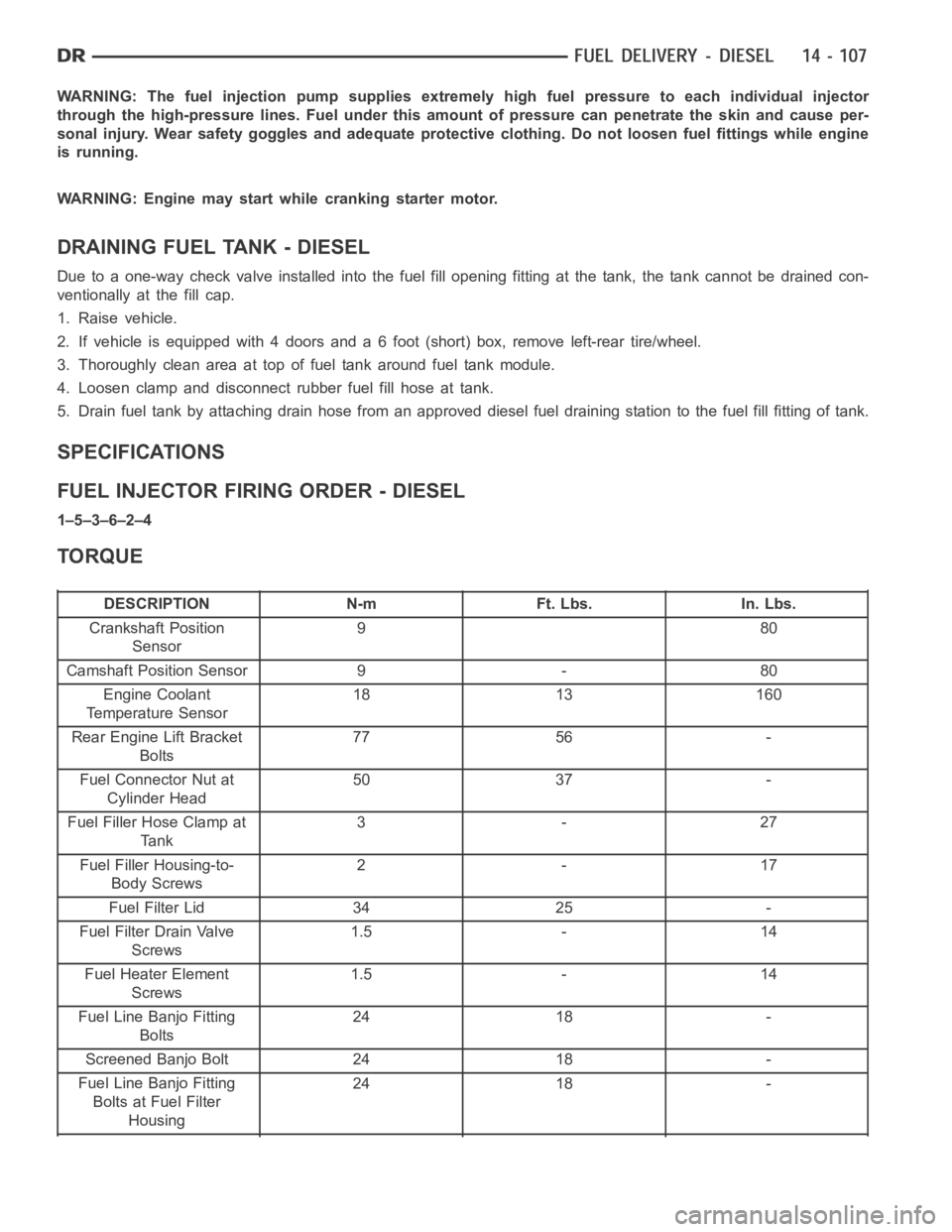

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Fuel Line Fittings

(High-Pressure - Pump to

Rail)37 27 -

Fuel Line Fittings

(High-Pressure - Cylinder

Head to Rail)30 22 -

#6 Fuel Line Shield Bolts 43 32 -

Fuel Injector Solenoid

Nuts1.25 - 11

Fuel Injection Pump-to-

Gear Shaft Nut105 77 -

Fuel Injection Pump

Mounting Nuts24 18 -

Fuel Line Brace-to-Intake

Manifold Cover Bolt

(High-Pressure)24 18 -

Fuel Pressure Sensor 70 52 -

Fuel Pressure Limiting

Valve(BanjoBolt)24 18 -

Fuel Pressure Limiting

Valve (In Fuel Rail)70 52 -

Fuel Rail Mounting Bolts 24 18 212

Fuel Tank Mounting Straps 41 30 -

Map Sensor Mounting

Screws1- 9

ECM-to-Engine Bracket

Mounting Bolts24 18 -

ECM Electrical Harness

Connector3-27

Water-In-Fuel Sensor 4.5 - 39

Page 2347 of 5267

ENGINE ROTATING (BARRING) TOOL - #7471B

(ALSOPARTOFKIT#6860)

Page 2348 of 5267

FILTER - FUEL / WATER SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located on left side of engineabove the starter motor. The assembly also

includes the fuel heater, Water-In-Fuel (WIF) sensor and a screened banjobolt attached at the bottom of the fuel

filter canister.

OPERATION

The fuel filter/water separator protects the fuel injection pump by removing water and contaminants from the fuel.

The construction of the filter/separator allows fuel to pass through it, but helps prevent moisture (water) from doing

so. Moisture collects at the bottom of the canister.

Refer to the maintenance schedules in the owners manual for the recommended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel Filter/Water SeparatorRemoval/Installation section.

There is a screened banjo bolt that is attached at the bottom of the fuel filter canister. It provides additional filtering

for the high pressure fuel system components.

A Water-In-Fuel (WIF) sensor is attached to the side of fuel filter housing. Refer to Water-In-Fuel Sensor Descrip-

tion/Operation.

The fuel heater is installed into the top of the filter/separator housing.Refer to Fuel Heater Description/Operation.

REMOVAL

Refer to maintenance schedules in this manual, or the

Owner’s Manual for recommended fuel filter replace-

ment intervals.

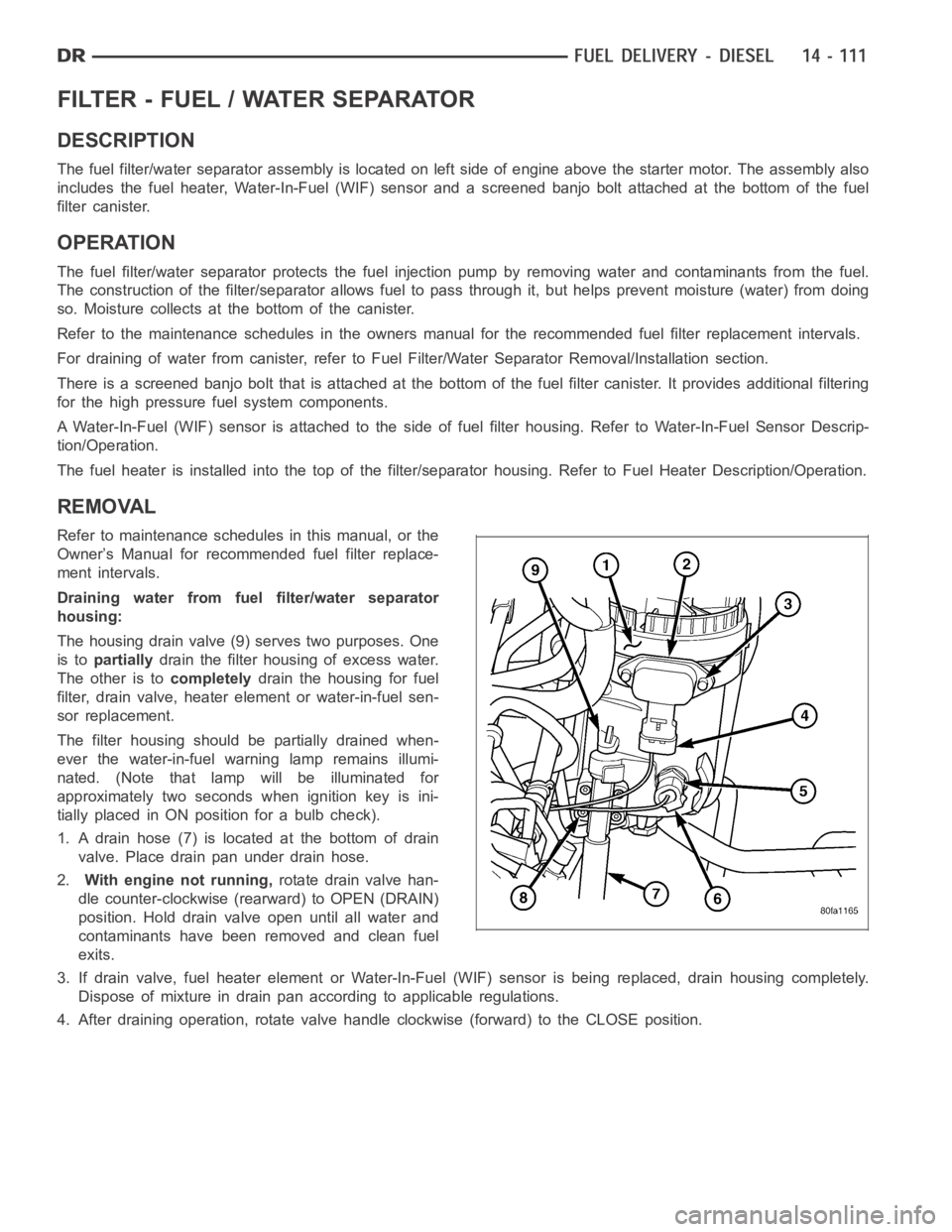

Draining water from fuel filter/water separator

housing:

The housing drain valve (9) serves two purposes. One

is topartiallydrain the filter housing of excess water.

The other is tocompletelydrain the housing for fuel

filter, drain valve, heater element or water-in-fuel sen-

sor replacement.

The filter housing should be partially drained when-

ever the water-in-fuel warning lamp remains illumi-

nated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).

1. A drain hose (7) is located at the bottom of drain

valve. Place drain pan under drain hose.

2.With engine not running,rotate drain valve han-

dle counter-clockwise (rearward) to OPEN (DRAIN)

position. Hold drain valve open until all water and

contaminants have been removed and clean fuel

exits.

3. If drain valve, fuel heater element or Water-In-Fuel (WIF) sensor is being replaced, drain housing completely.

Dispose of mixture in drain pan according to applicable regulations.

4. After draining operation, rotate valve handle clockwise (forward) to the CLOSE position.

Page 2350 of 5267

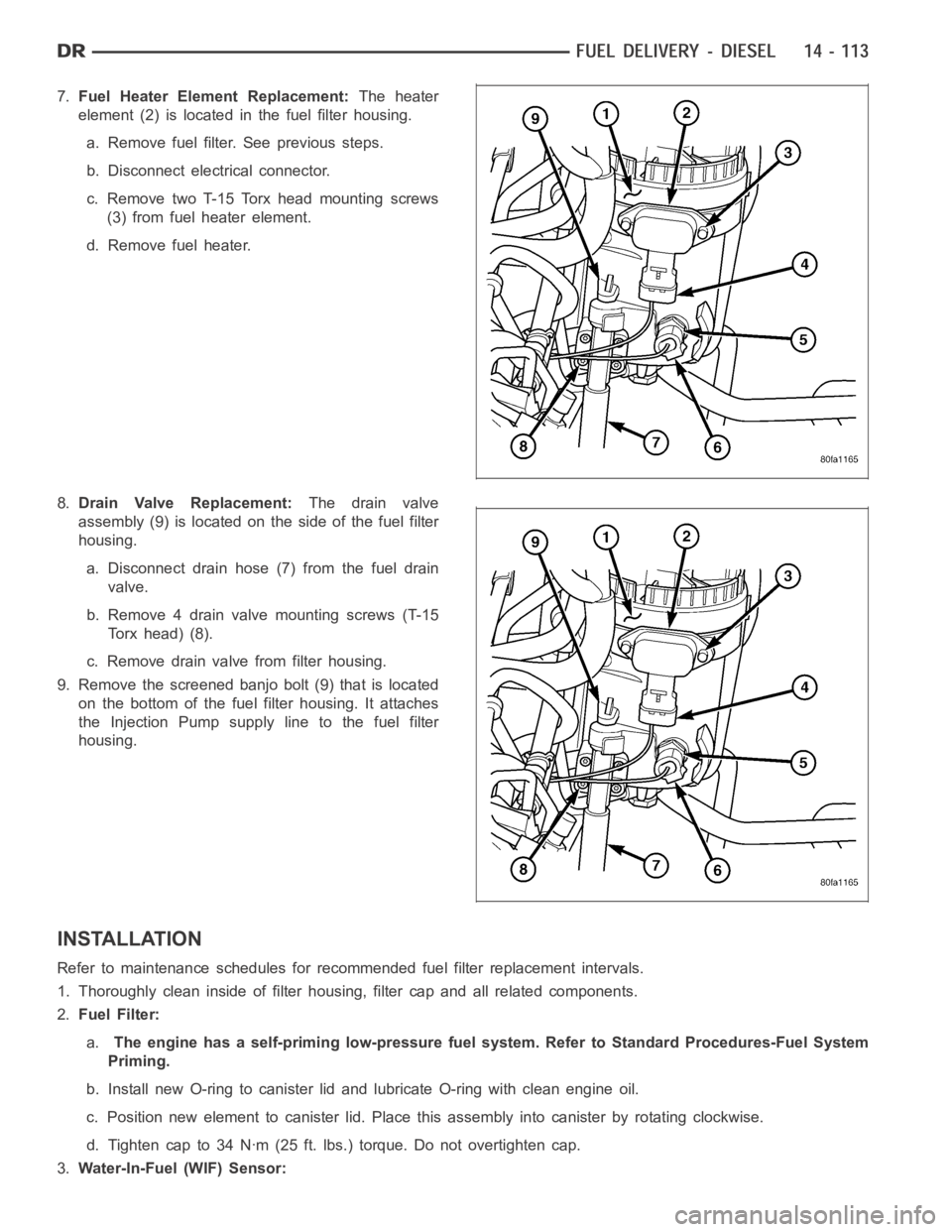

7.Fuel Heater Element Replacement:The heater

element (2) is located in the fuel filter housing.

a. Remove fuel filter. See previous steps.

b. Disconnect electrical connector.

c. Remove two T-15 Torx head mounting screws

(3) from fuel heater element.

d. Remove fuel heater.

8.Drain Valve Replacement:The drain valve

assembly (9) is located on the side of the fuel filter

housing.

a. Disconnect drain hose (7) from the fuel drain

valve.

b. Remove 4 drain valve mounting screws (T-15

Torx head) (8).

c. Remove drain valve from filter housing.

9. Remove the screened banjo bolt (9) that is located

on the bottom of the fuel filter housing. It attaches

the Injection Pump supply line to the fuel filter

housing.

INSTALLATION

Refer to maintenance schedules for recommended fuel filter replacement intervals.

1. Thoroughly clean inside of filter housing, filter cap and all related components.

2.Fuel Filter:

a.The engine has a self-priming low-pressure fuel system. Refer to StandardProcedures-Fuel System

Priming.

b. Install new O-ring to canister lid and lubricate O-ring with clean engine oil.

c. Position new element to canister lid. Place this assembly into canisterby rotating clockwise.

d. Tighten cap to 34 Nꞏm (25 ft. lbs.) torque. Do not overtighten cap.

3.Water-In-Fuel (WIF) Sensor:

Page 2351 of 5267

a. Install new o-ring seal to WIF sensor.

b. Apply a light film of clean oil to o-ring seal.

c. Install sensor into housing.

d. Tighten sensor to 2.5 Nꞏm (25 in. lbs.) torque.

e. Connect electrical connector to WIF sensor.

4.Fuel Heater Element:

a. Install fuel heater into fuel filter housing.

b. Install fuel heater thermostat onto the outside of the fuel filter housing.

c. Install fuel heater mounting screws and tighten to 1-1.5 Nꞏm (8 - 13 in. lbs.) torque.

d. Connect electrical connector to fuel heater thermostat.

e. Install new filter cover O-ring onto fuel filter housing cover and lubricate with clean engine oil.

f. Tighten fuel filter housing cover (lid) to 34 Nꞏm (25 ft. lbs.).

5.Drain Valve:

a. Install 2 new O-rings to valve.

b. Lubricate with silicon grease.

c. Installfueldrainvalve.

d. Install 4 mounting screws and tighten to 1–1.5 Nꞏm (8–13 in. lbs.) torque.

e. Connect drain hose to drain valve.

6. Install two new sealing washers to bolt.

7. Install screened banjo bolt Tighten to 24 Nꞏm (18 ft. lbs.)

8. Start engine and check for leaks.

Page 2352 of 5267

HEATER-FUEL

DESCRIPTION

The fuel heater assembly is located on the side of the fuel filter housing and internal to the fuel filter housing .

The heater/element assembly is equipped with a temperature sensor (thermostat) that senses fuel temperature. This

sensor is attached to the fuel heater/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from waxing during cold weather operation.

When the fuel temperature is below 45° ±8 F (7°C), the temperature sensor allows current to flow to the heater

element warming the fuel. When the fuel temperature is above 75° ±8 F (24°C), the sensor stops current flow to the

heater element.

Battery voltage to operate the fuel heater element is supplied from the ignition switch and through a solid stated

device in the IPM.The fuel heater element and

solid state device in IPMinstead offuel heater relayare not

computer controlled.

The heater element operates on 12 volts, 300 watts at 0° F (-18° C).

DIAGNOSIS AND TESTING

FUEL HEATER

The fuel heater is used to prevent diesel fuel from waxing during cold weather operation.

NOTE: The fuel heater element,

solid state device in IPMinstead offuel heater relayand fuel heater tem-

perature sensor are not controlled by the Engine Control Module (ECM).

A malfunctioning fuel heater can cause a wax build-up in the fuel filter/water separator. Wax build-up in the filter/

separator can cause engine starting problems and prevent the engine from revving up. It can also cause blue or

white fog-like exhaust. If the heater is not operating in cold temperatures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of fuel filter housing and internal to the fuel filter housing.

The heater assembly is equipped with a built-in fuel temperature sensor (thermostat) that senses fuel temperature.

When fuel temperature drops below 45° ± 8° F (7° C), the sensor allows current to flow to built-in heater element

to warm fuel. When fuel temperature rises above 75 °± 8° F (24° C), the sensorstops current flow to heater ele-

ment (circuit is open).

Voltage to operate fuel heater element is supplied from ignition switch, through

solid state device in IPM,tofuel

temperature sensor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts at 0 °F (-18° C). As temperature increases, power requirements

decrease.

A minimum of 7 volts is required to operate the fuel heater. The resistance value of the heater element is less than

1 ohm (cold) and up to 1000 ohms warm.

TESTING

1. Disconnect electrical connector from thermostat.

Ambient temperature must be below the circuit close temperature. If necessary, induce this ambient temperature by

placing ice packs on thermostat to produce an effective ambient temperature below circuit close temperature.

Measure resistance across two pins. Operating range is 0.3 - 0.45 Ohms.

2. If resistance is out of range, remove thermostat and check resistance across terminal connections of heater. The

heater can be checked at room temperature. Operating range is 0.3 - 0.45 Ohms.

3. Replace heater if resistance is not within operating range.

4. If heater is within operating range, replace heater thermostat.

Page 2354 of 5267

PUMP - FUEL INJECTION

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump is used. The pump is attached to the back of the timing gear

housing at the left /front side of the engine.

OPERATION

The fuel injection pump supplies high pressure to the fuel rail independent of engine speed. This high pressure is

then accumulated in the fuel rail. High pressure fuel is constantly supplied to the injectors by the fuel rail. The

Engine Control Module (ECM) controls the fueling and timing of the engine by actuating the injectors.

Fuel enters the system from the electric fuel transfer (lift) pump, which is located in the fuel tank. Fuel is forced

through the fuel filter element and then enters the Fuel Pump/Gear Pump, which is attached to the rear of the fuel

injection pump. The Fuel Pump/Gear Pump is a low-pressure pump and producepressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the fuel injection pump. Lowpressure fuel is then supplied to the

FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid valve. The ECM controls the amount of fuel that enters the high-

pressure pumping chambers by opening and closing the FCA based on a demanded fuel pressure. The FPS (Fuel

Pressure Sensor) on the fuel rail provides the actual fuel pressure. When the actuator is opened, the maximum

amount of fuel is being supplied to the fuel injection pump. Any fuel that does not enter the injection pump is

directed to the cascade overflow valve. The cascade overflow valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to the tank through the drain manifold.

Fuel entering the injection pump is pressurized to between 300-1600 bar (4351-23206 psi) by three radial pumping

chambers. The pressurized fuel is then supplied to the fuel rail.

DIAGNOSIS AND TESTING

FUEL INJECTION PUMP TIMING

With the Bosch injection pump, there are no mechanical adjustments neededor necessary to accomplish fuel injec-

tion timing. All timing and fuel adjustments are electrically made by the engine mounted Engine Control Module

(ECM).

REMOVAL

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.