DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1981 of 5267

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on out-

side diameter of seal to ease assembly.

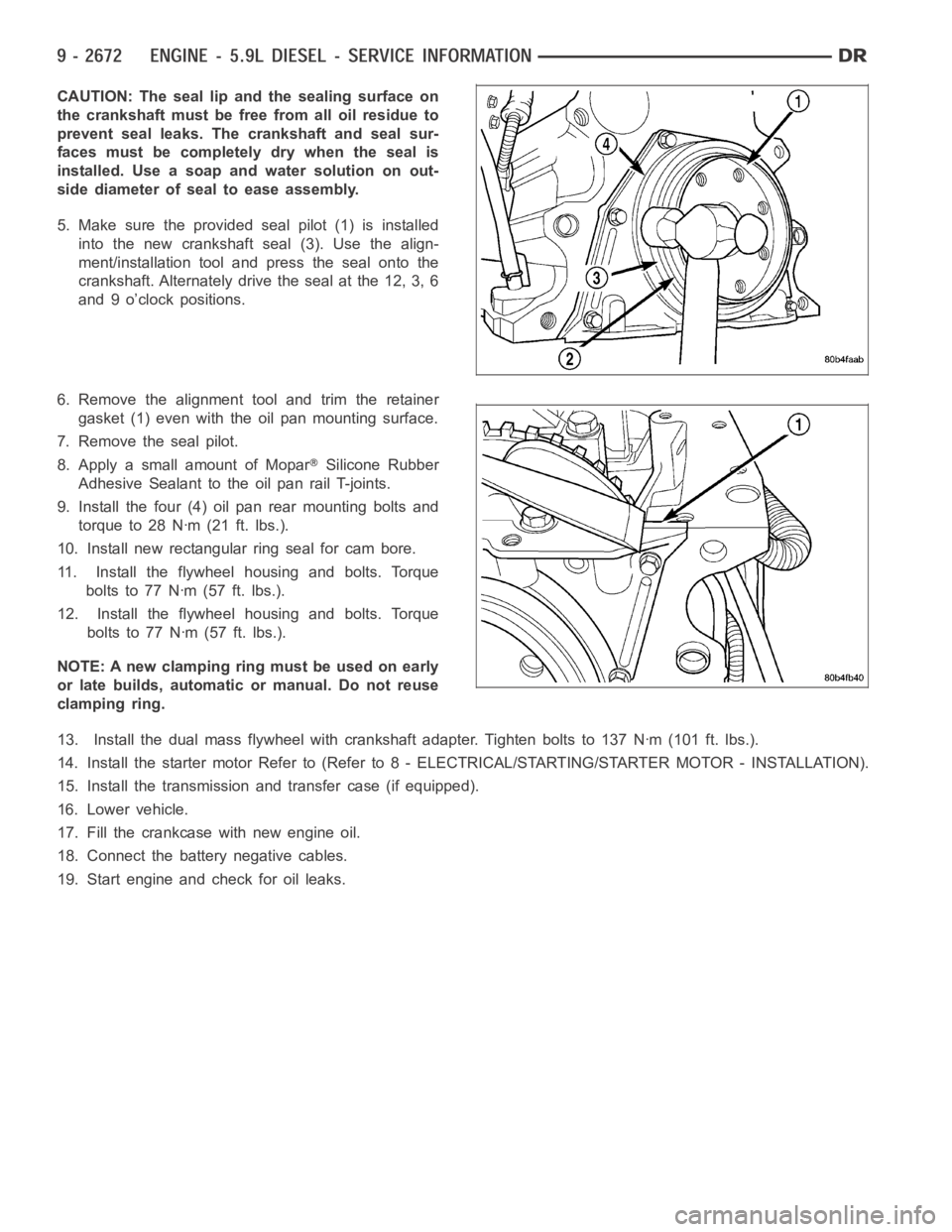

5. Make sure the provided seal pilot (1) is installed

into the new crankshaft seal (3). Use the align-

ment/installation tool and press the seal onto the

crankshaft. Alternately drive the seal at the 12, 3, 6

and 9 o’clock positions.

6. Remove the alignment tool and trim the retainer

gasket (1) even with the oil pan mounting surface.

7. Remove the seal pilot.

8. Apply a small amount of Mopar

Silicone Rubber

Adhesive Sealant to the oil pan rail T-joints.

9. Install the four (4) oil pan rear mounting bolts and

torque to 28 Nꞏm (21 ft. lbs.).

10. Install new rectangular ring seal for cam bore.

11. Install the flywheel housing and bolts. Torque

boltsto77Nꞏm(57ft.lbs.).

12. Install the flywheel housing and bolts. Torque

boltsto77Nꞏm(57ft.lbs.).

NOTE: A new clamping ring must be used on early

or late builds, automatic or manual. Do not reuse

clamping ring.

13. Install the dual mass flywheel with crankshaft adapter. Tighten boltsto 137 Nꞏm (101 ft. lbs.).

14. Install the starter motor Refer to (Refer to 8 - ELECTRICAL/STARTING/STA R T E R M O TO R - I N S TA L L AT I O N ) .

15. Install the transmission and transfer case (if equipped).

16. Lower vehicle.

17. Fill the crankcase with new engine oil.

18. Connect the battery negative cables.

19. Start engine and check for oil leaks.

Page 1982 of 5267

TAPPETS - VALVE

REMOVAL

NOTE: This procedure requires use of Miller Tool

8502 Tappet Replacement Kit.

1. Remove camshaft (Refer to 9 - ENGINE/ENGINE

BLOCK/CAMSHAFT & BEARINGS (IN BLOCK) -

REMOVAL).

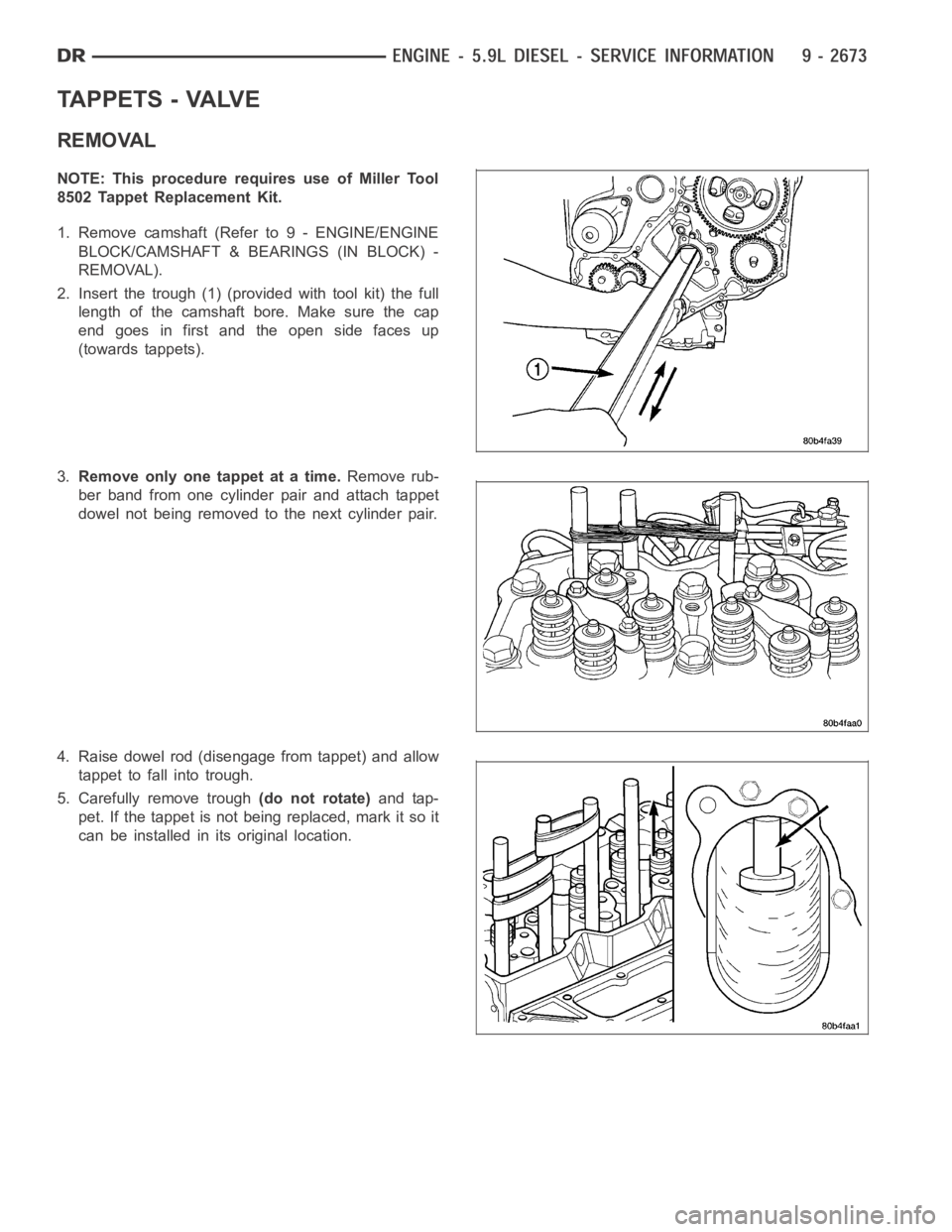

2. Insert the trough (1) (provided with tool kit) the full

length of the camshaft bore. Make sure the cap

end goes in first and the open side faces up

(towards tappets).

3.Remove only one tappet at a time.Remove rub-

ber band from one cylinder pair and attach tappet

dowel not being removed to the next cylinder pair.

4. Raise dowel rod (disengage from tappet) and allow

tappet to fall into trough.

5. Carefully remove trough(do not rotate)and tap-

pet. If the tappet is not being replaced, mark it so it

can be installed in its original location.

Page 1983 of 5267

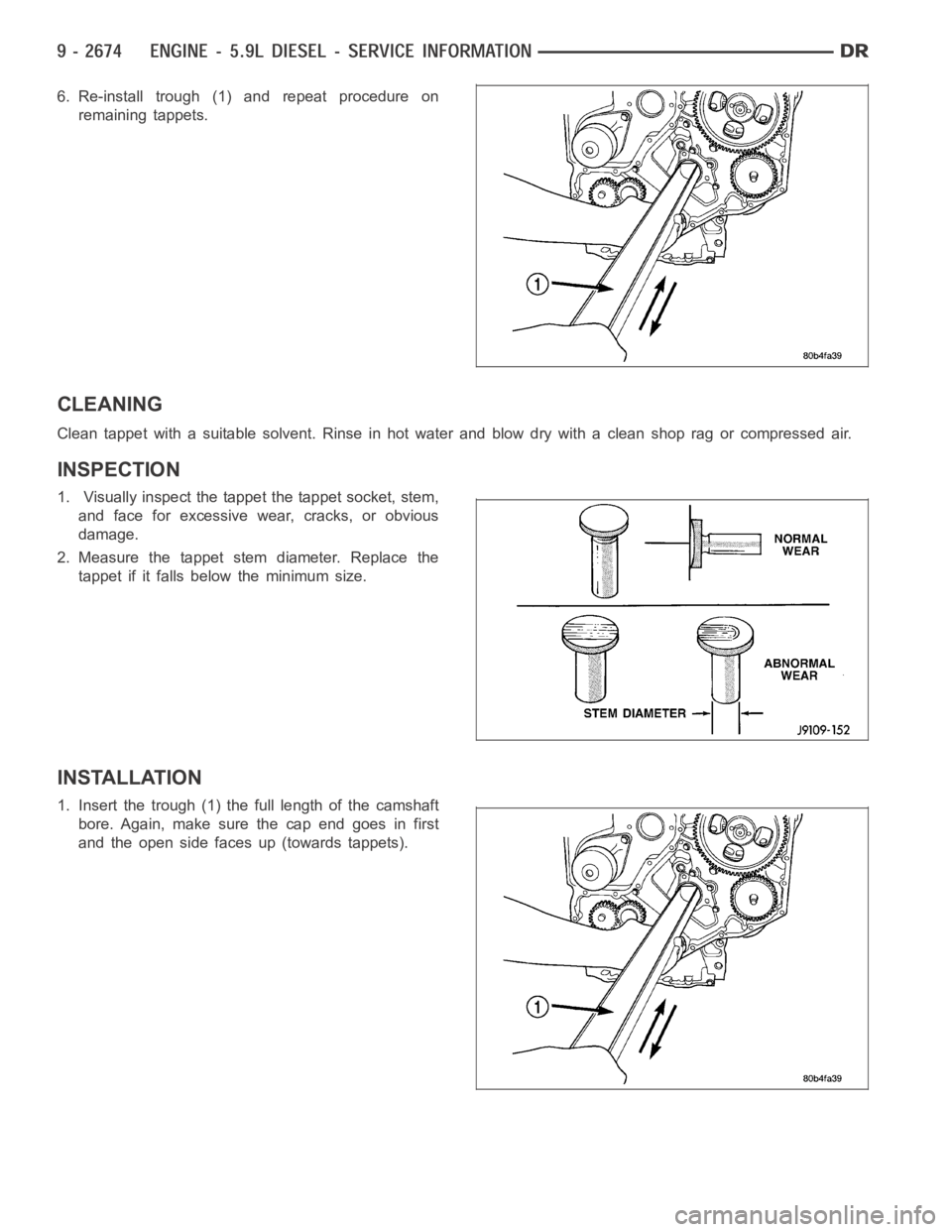

6. Re-install trough (1) and repeat procedure on

remaining tappets.

CLEANING

Clean tappet with a suitable solvent. Rinse in hot water and blow dry with a clean shop rag or compressed air.

INSPECTION

1. Visually inspect the tappet the tappet socket, stem,

and face for excessive wear, cracks, or obvious

damage.

2. Measure the tappet stem diameter. Replace the

tappet if it falls below the minimum size.

INSTALLATION

1. Insert the trough (1) the full length of the camshaft

bore. Again, make sure the cap end goes in first

and the open side faces up (towards tappets).

Page 1984 of 5267

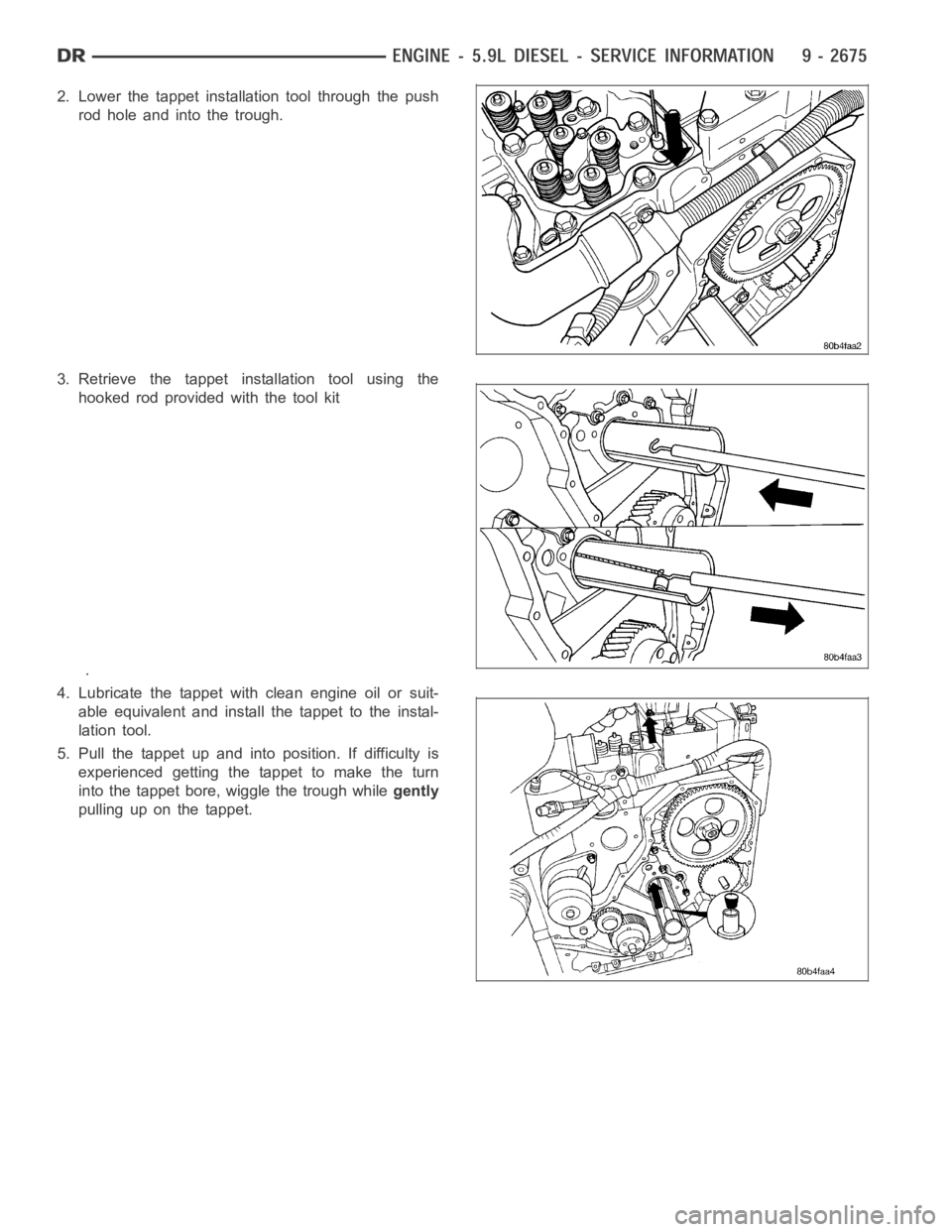

2. Lower the tappet installation tool through the push

rod hole and into the trough.

3. Retrieve the tappet installation tool using the

hooked rod provided with the tool kit

.

4. Lubricate the tappet with clean engine oil or suit-

able equivalent and install the tappet to the instal-

lation tool.

5. Pull the tappet up and into position. If difficulty is

experienced getting the tappet to make the turn

into the tappet bore, wiggle the trough whilegently

pulling up on the tappet.

Page 1985 of 5267

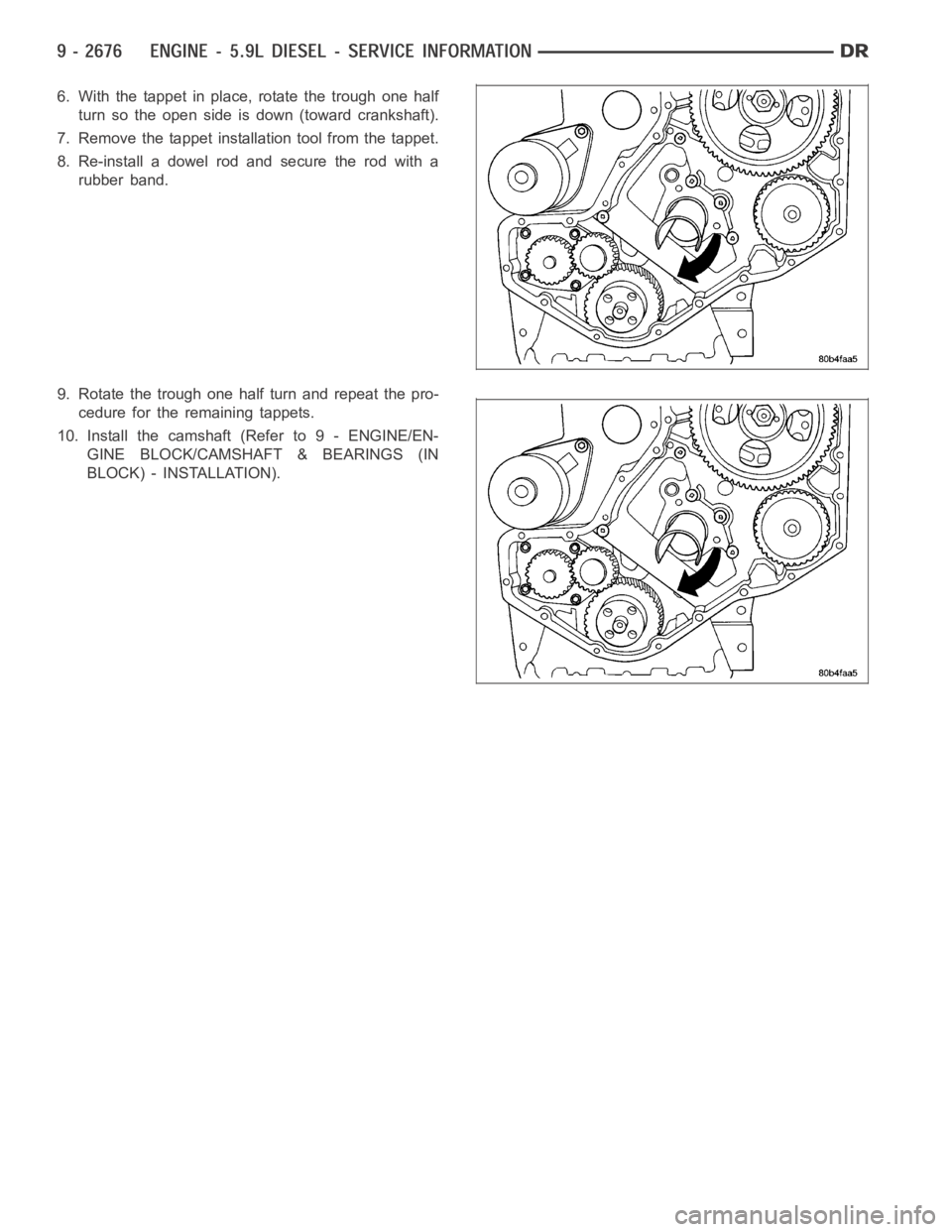

6. With the tappet in place, rotate the trough one half

turn so the open side is down (toward crankshaft).

7. Remove the tappet installation tool from the tappet.

8. Re-install a dowel rod and secure the rod with a

rubber band.

9. Rotate the trough one half turn and repeat the pro-

cedure for the remaining tappets.

10. Install the camshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - INSTALLATION).

Page 1986 of 5267

PISTON & CONNECTING ROD

DESCRIPTION

PISTONS

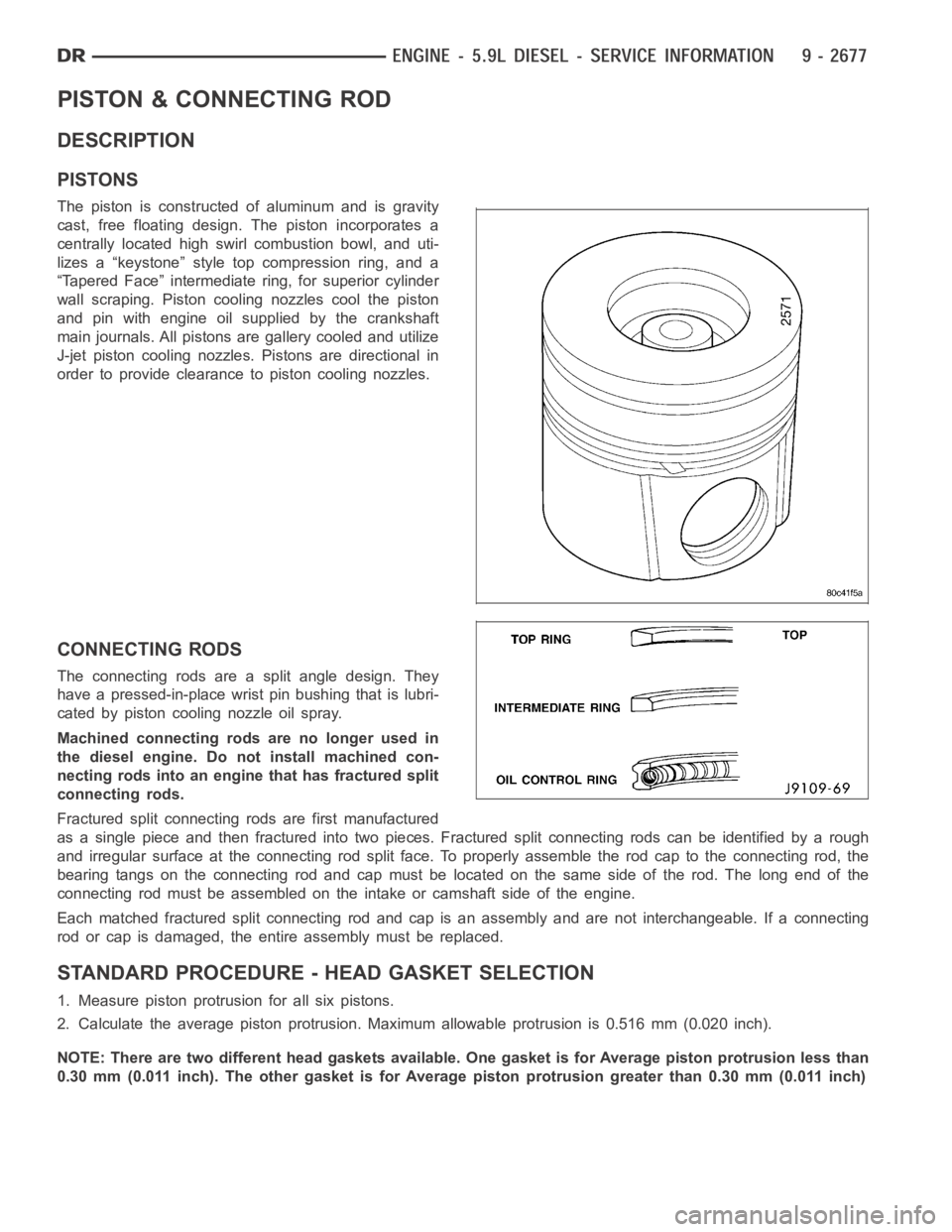

The piston is constructed of aluminum and is gravity

cast, free floating design. The piston incorporates a

centrally located high swirl combustion bowl, and uti-

lizes a “keystone” style top compression ring, and a

“Tapered Face” intermediate ring, for superior cylinder

wall scraping. Piston cooling nozzles cool the piston

and pin with engine oil supplied by the crankshaft

main journals. All pistons are gallery cooled and utilize

J-jet piston cooling nozzles. Pistons are directional in

order to provide clearance to piston cooling nozzles.

CONNECTING RODS

The connecting rods are a split angle design. They

have a pressed-in-place wrist pin bushing that is lubri-

cated by piston cooling nozzle oil spray.

Machined connecting rods are no longer used in

the diesel engine. Do not install machined con-

necting rods into an engine that has fractured split

connecting rods.

Fractured split connecting rods are first manufactured

asasinglepieceandthenfracturedintotwopieces.Fracturedsplitconnecting rods can be identified by a rough

and irregular surface at the connecting rod split face. To properly assemble the rod cap to the connecting rod, the

bearing tangs on the connecting rod and cap must be located on the same side of the rod. The long end of the

connecting rod must be assembled on theintake or camshaft side of the engine.

Each matched fractured split connecting rod and cap is an assembly and are not interchangeable. If a connecting

rod or cap is damaged, the entire assembly must be replaced.

STANDARD PROCEDURE - HEAD GASKET SELECTION

1. Measure piston protrusion for all six pistons.

2. Calculate the average piston protrusion. Maximum allowable protrusion is 0.516 mm (0.020 inch).

NOTE: There are two different head gaskets available. One gasket is for Average piston protrusion less than

0.30 mm (0.011 inch). The other gasket is for Average piston protrusion greater than 0.30 mm (0.011 inch)

Page 1987 of 5267

REMOVAL

1. Disconnect the battery cables.

2. Remove the cylinder head (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL).

3. Remove the oil pan and suction tube (Refer to 9 - ENGINE/LUBRICATION/OILPA N - R E M O VA L ) .

4. Remove bolts and the block stiffener.

5. Using Miller Tool 7471-B crankshaft barring tool, rotate the crankshaft so all of the pistons are below TDC.

6. Before removing the piston(s) from the bore(s):

a. Remove any carbon ridge formations or deposits at the top of the bore witha dull scraper or soft wire brush.

b. If cylinder bore wear ridges are found, use a ridge reamer to cut the ridgefrom the bore. DO NOT remove

more metal than necessaryto remove the ridge.

7. Remove the J-jet cooling nozzles.

NOTE: If cylinders have ridges, the cylinders are oversize and will more than likely need boring.

8. Using a hammer and steel stamp, stamp the cylinder number in the top of eachpiston.Thefrontofthepiston

is identified by a stamping on the top of the piston. DO NOT stamp in the outside 5 mm (.197 in.) of the piston

diameter. DO NOT stamp over the piston pin.

9. Mark the connecting rod and cap with the corresponding cylinder numbers.

10. Remove the connecting rod bolts and rod caps. Use care so the cylinder bores and connecting rods are not

damaged.

11. Use a hammer handle or similar object to push the piston and connecting rod through the cylinder bore.

12. Store the piston/rod assemblies in a rack.

CLEANING—PISTON AND CONNECTING ROD

CAUTION: DO NOT use bead blast to clean the pistons. DO NOT clean the pistonsandrodsinanacidtank.

PISTON

Clean the pistons and pins in a suitable solvent, rinse in hot water and blowdry with compressed air. Soaking the

pistons over night will loosen most of the carbon build up. De-carbon the ringgrooveswithabrokenpistonringand

again clean the pistons in solvent. Rinse in hot water and blow dry with compressed air.

CONNECTING ROD

Clean the connecting rods in a suitable solvent, rinse in hot water and blowdry with compressed air.

INSPECTION

INSPECTION - PISTONS

PISTON SKIRT DIAMETER (MIN.)

101.775 mm (4.006 in. )

Inspect the pistons for damage and excessive wear. Check top of the piston,ring grooves, skirt and pin bore. Mea-

sure the piston skirt diameter. If the piston is out of limits, replace the piston.

Page 1988 of 5267

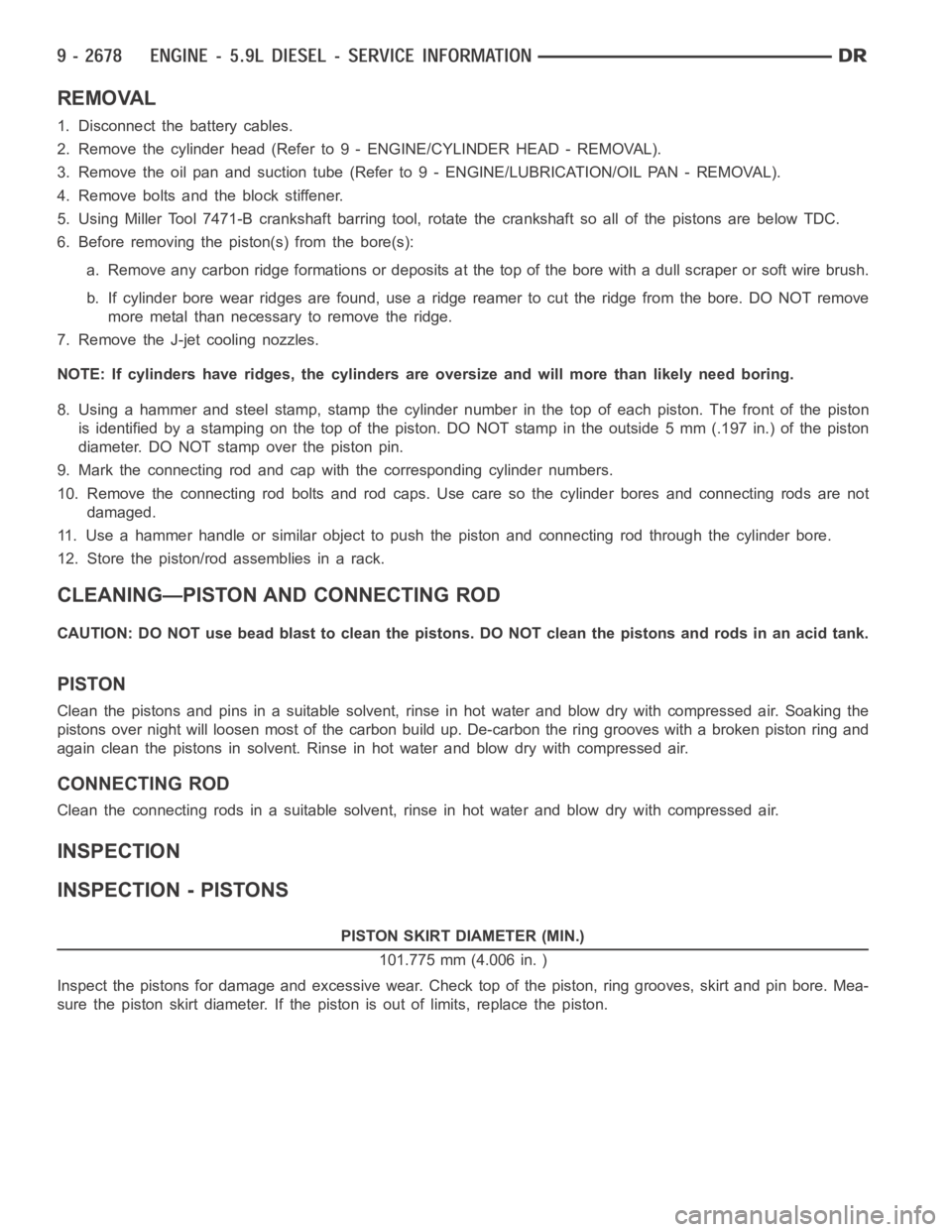

The upper groove only needs to be inspected for dam-

age. Use a new piston ring (2) to measure the clear-

ance in the intermediate ring groove. Minimum

clearance is 0.045 mm (0.0018 inch), maximum clear-

ance is 0.095 mm (.0037 inch). If the clearance of the

intermediate ring exceeds specifications, replace the

piston (3).

Use a new oil ring to measure the clearance in the oil

groove. Minimum clearance is 0.040 mm (0.0016

inch), maximum clearance is 0.085 mm (.0033 inch). If

the clearance exceeds specifications, replace the

piston.

Measure the pin bore (2). The maximum diameter is

40.012 mm (1.5753 inch), Minimum is 40.006 mm

(1.575 inch). If the bore is over limits, replace the pis-

ton (1).

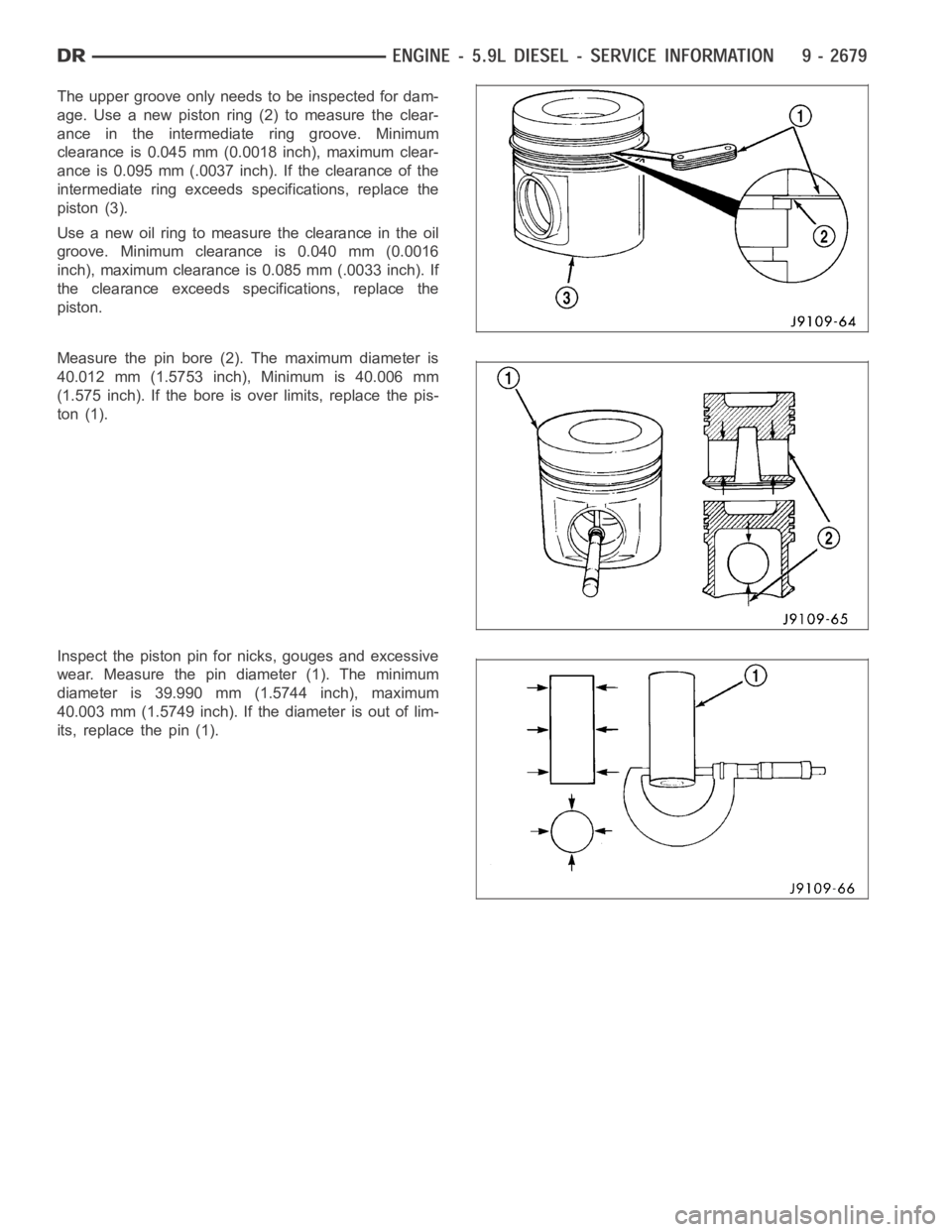

Inspect the piston pin for nicks, gouges and excessive

wear. Measure the pin diameter (1). The minimum

diameter is 39.990 mm (1.5744 inch), maximum

40.003 mm (1.5749 inch). If the diameter is out of lim-

its, replace the pin (1).

Page 1989 of 5267

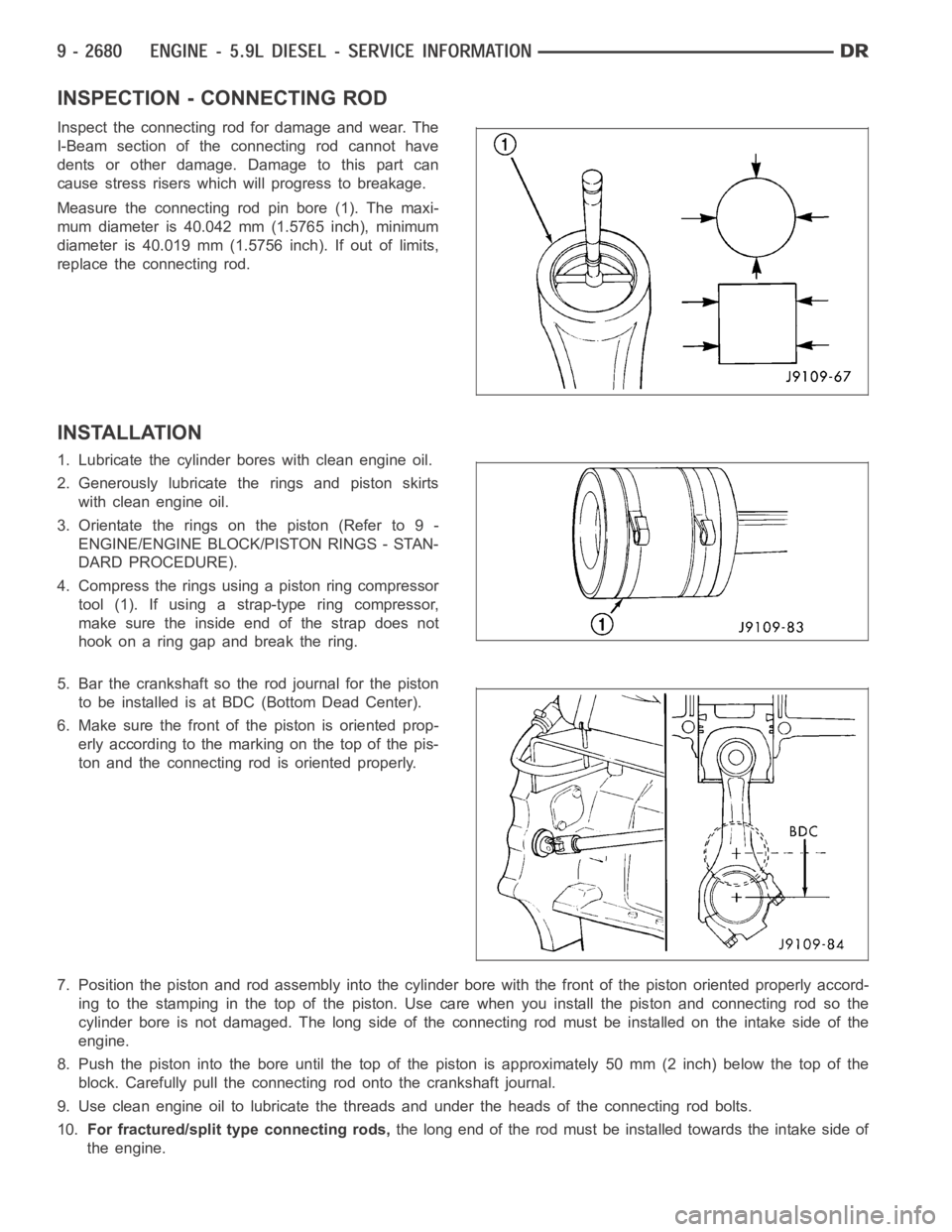

INSPECTION - CONNECTING ROD

Inspect the connecting rod for damage and wear. The

I-Beam section of the connecting rod cannot have

dents or other damage. Damage to this part can

cause stress risers which will progress to breakage.

Measure the connecting rod pin bore (1). The maxi-

mum diameter is 40.042 mm (1.5765 inch), minimum

diameter is 40.019 mm (1.5756 inch). If out of limits,

replace the connecting rod.

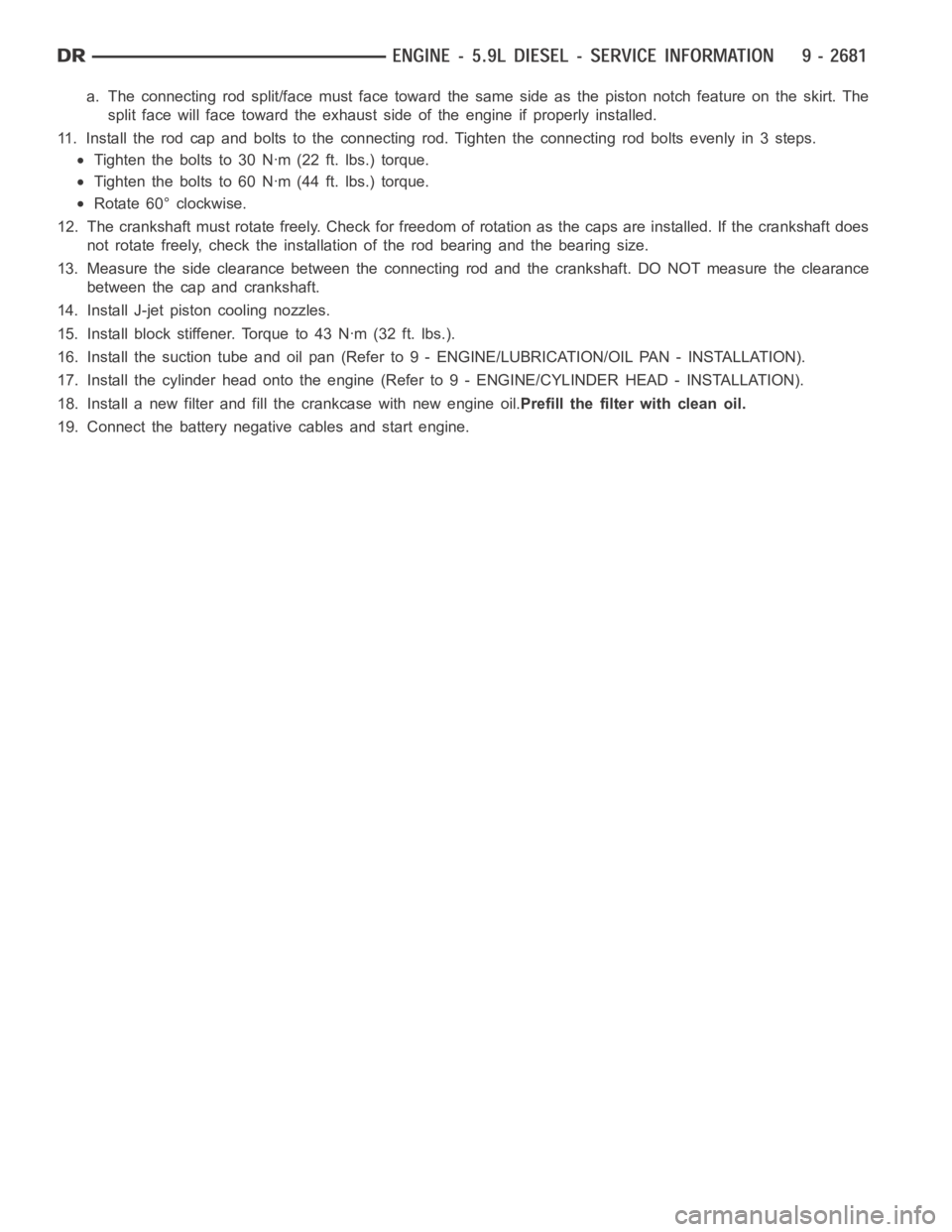

INSTALLATION

1. Lubricate the cylinder bores with clean engine oil.

2. Generously lubricate the rings and piston skirts

with clean engine oil.

3. Orientate the rings on the piston (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON RINGS - STAN-

DARD PROCEDURE).

4. Compress the rings using a piston ring compressor

tool(1).Ifusingastrap-typeringcompressor,

make sure the inside end of the strap does not

hook on a ring gap and break the ring.

5. Bar the crankshaft so the rod journal for the piston

to be installed is at BDC(Bottom Dead Center).

6. Make sure the front of the piston is oriented prop-

erly according to the marking on the top of the pis-

ton and the connecting rod is oriented properly.

7. Position the piston and rod assemblyinto the cylinder bore with the front of the piston oriented properly accord-

ing to the stamping in the top of the piston. Use care when you install the piston and connecting rod so the

cylinder bore is not damaged. The long side of the connecting rod must be installed on the intake side of the

engine.

8. Push the piston into the bore until the top of the piston is approximately50 mm (2 inch) below the top of the

block. Carefully pull the connecting rod onto the crankshaft journal.

9. Use clean engine oil to lubricate the threads and under the heads of the connecting rod bolts.

10.For fractured/split type connecting rods,thelongendoftherodmustbeinstalledtowardstheintakesideof

the engine.

Page 1990 of 5267

a. The connecting rod split/face mustface toward the same side as the piston notch feature on the skirt. The

split face will face toward the exhaust side of the engine if properly installed.

11. Install the rod cap and bolts to the connecting rod. Tighten the connecting rod bolts evenly in 3 steps.

Tighten the bolts to 30 Nꞏm (22 ft. lbs.) torque.

Tighten the bolts to 60 Nꞏm (44 ft. lbs.) torque.

Rotate 60° clockwise.

12. The crankshaft must rotate freely. Check for freedom of rotation as thecaps are installed. If the crankshaft does

not rotate freely, check the installation of the rod bearing and the bearingsize.

13. Measure the side clearance between the connecting rod and the crankshaft. DO NOT measure the clearance

between the cap and crankshaft.

14. Install J-jet piston cooling nozzles.

15. Install block stiffener. Torque to 43 Nꞏm (32 ft. lbs.).

16. Install the suction tube and oil pan (Refer to 9 - ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

17. Install the cylinder head onto the engine (Refer to 9 - ENGINE/CYLINDERHEAD - INSTALLATION).

18. Install a new filter and fill the crankcase with new engine oil.Prefill the filter with clean oil.

19. Connect the battery negative cables and start engine.