4WD DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2218 of 5267

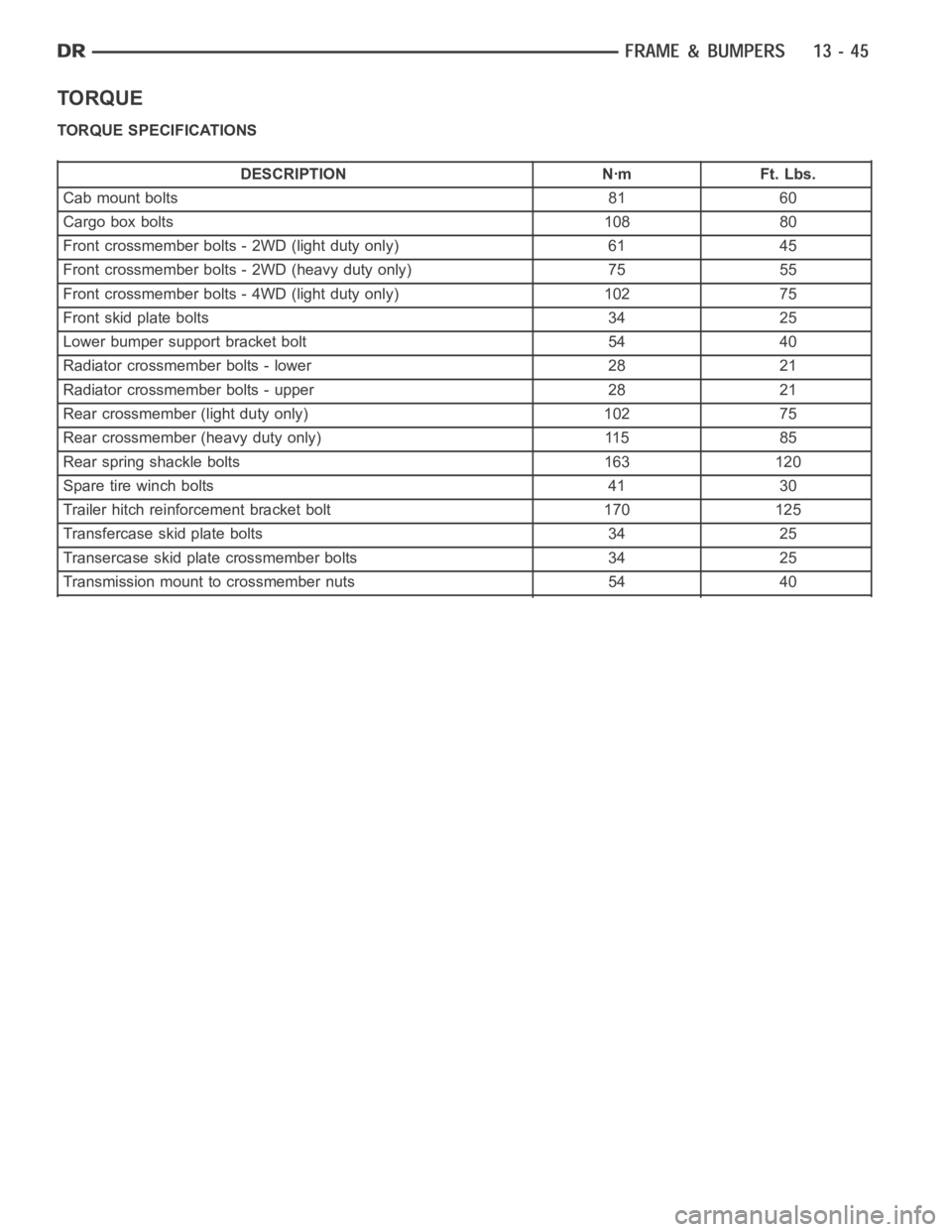

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs.

Cab mount bolts 81 60

Cargo box bolts 108 80

Front crossmember bolts - 2WD (light duty only) 61 45

Front crossmember bolts - 2WD (heavy duty only) 75 55

Front crossmember bolts - 4WD (light duty only) 102 75

Front skid plate bolts 34 25

Lower bumper support bracket bolt 54 40

Radiator crossmember bolts - lower 28 21

Radiator crossmember bolts - upper 28 21

Rear crossmember (light duty only) 102 75

Rear crossmember (heavy duty only) 115 85

Rear spring shackle bolts 163 120

Sparetirewinchbolts 41 30

Trailer hitch reinforcement bracket bolt 170 125

Transfercase skid plate bolts 34 25

Transercase skid plate crossmember bolts 34 25

Transmission mount to crossmember nuts 54 40

Page 2220 of 5267

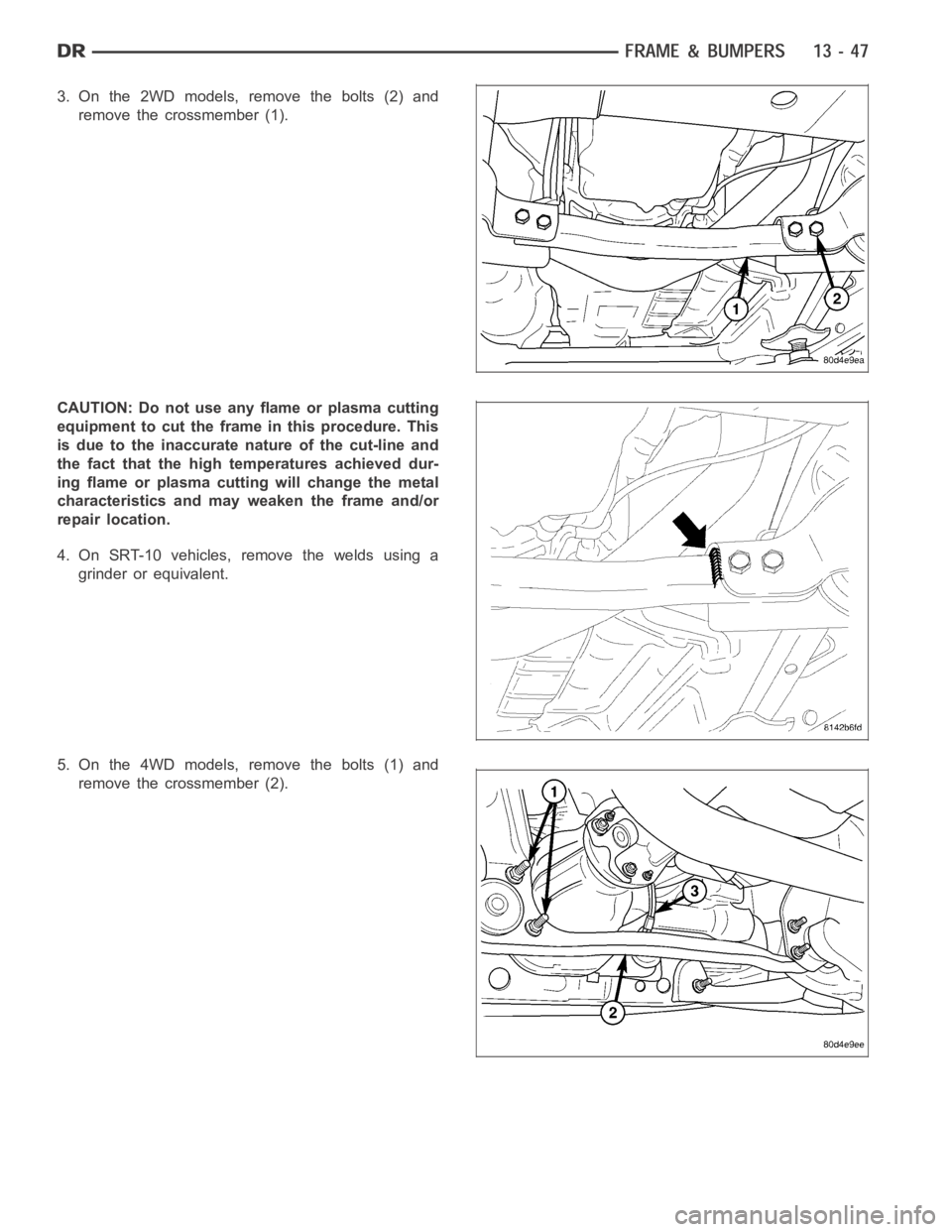

3. On the 2WD models, remove the bolts (2) and

remove the crossmember (1).

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. This

is due to the inaccurate nature of the cut-line and

the fact that the high temperatures achieved dur-

ing flame or plasma cutting will change the metal

characteristics and may weaken the frame and/or

repair location.

4. On SRT-10 vehicles, remove the welds using a

grinder or equivalent.

5. On the 4WD models, remove the bolts (1) and

remove the crossmember (2).

Page 2221 of 5267

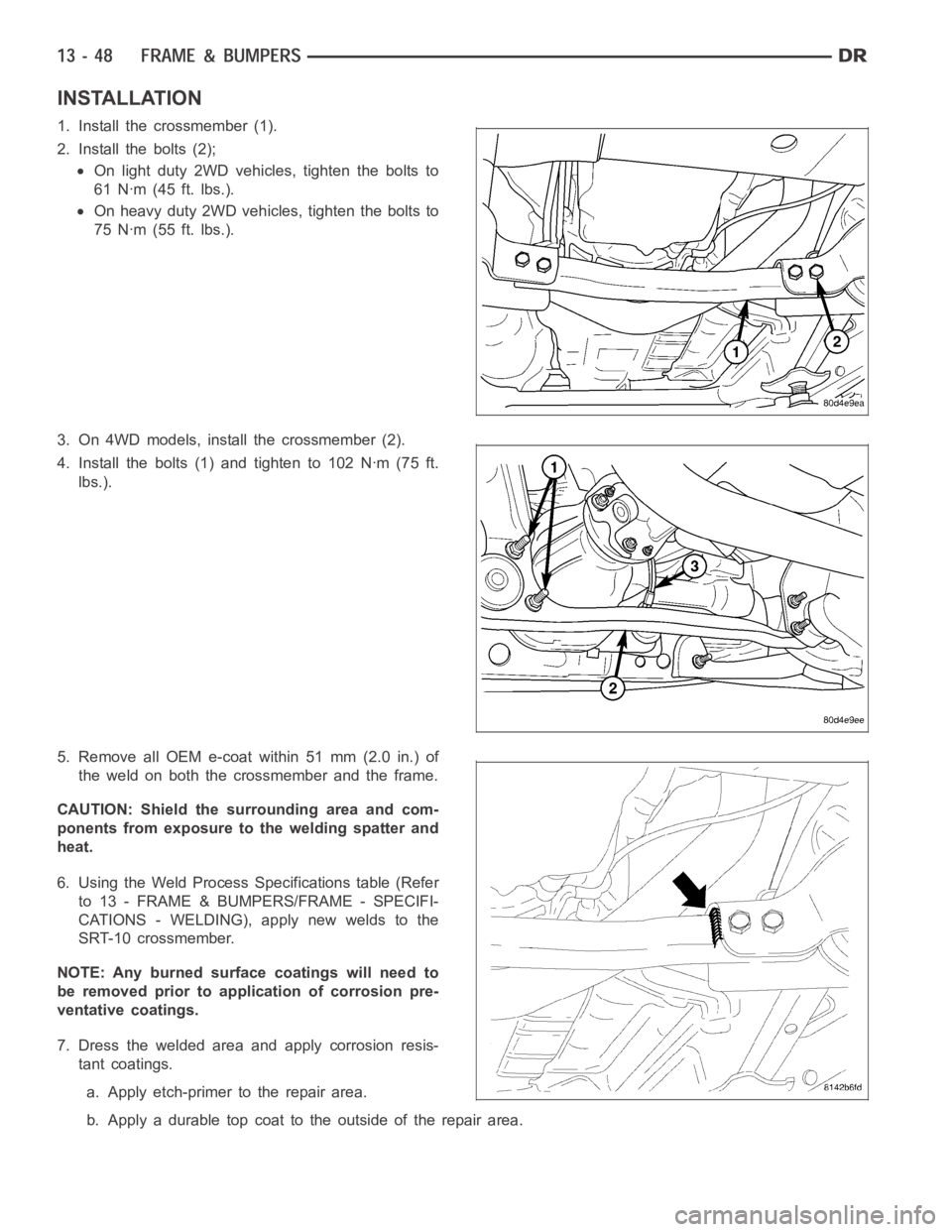

INSTALLATION

1. Install the crossmember (1).

2. Install the bolts (2);

On light duty 2WD vehicles, tighten the bolts to

61 Nꞏm (45 ft. lbs.).

On heavy duty 2WD vehicles, tighten the bolts to

75 Nꞏm (55 ft. lbs.).

3. On 4WD models, install the crossmember (2).

4. Install the bolts (1) and tighten to 102 Nꞏm (75 ft.

lbs.).

5. Remove all OEM e-coat within 51 mm (2.0 in.) of

the weld on both the crossmember and the frame.

CAUTION: Shield the surrounding area and com-

ponents from exposure to the welding spatter and

heat.

6. Using the Weld Process Specifications table (Refer

to 13 - FRAME & BUMPERS/FRAME - SPECIFI-

CATIONS - WELDING), apply new welds to the

SRT-10 crossmember.

NOTE: Any burned surface coatings will need to

be removed prior to application of corrosion pre-

ventative coatings.

7. Dress the welded area and apply corrosion resis-

tant coatings.

a. Apply etch-primer to the repair area.

b. Apply a durable top coat to the outside of the repair area.

Page 2228 of 5267

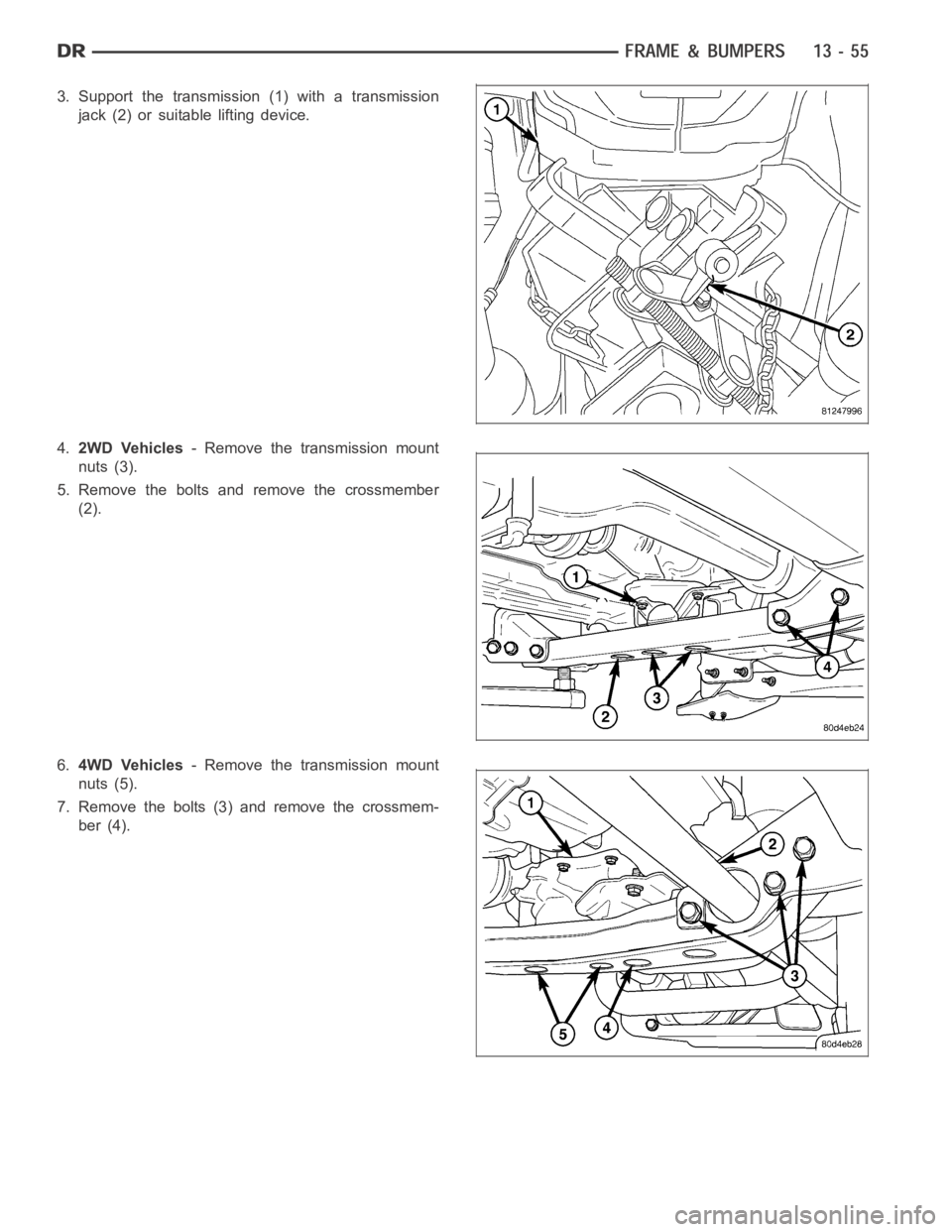

3. Support the transmission (1) with a transmission

jack (2) or suitable lifting device.

4.2WD Vehicles- Remove the transmission mount

nuts (3).

5. Remove the bolts and remove the crossmember

(2).

6.4WD Vehicles- Remove the transmission mount

nuts (5).

7. Remove the bolts (3) and remove the crossmem-

ber (4).

Page 2525 of 5267

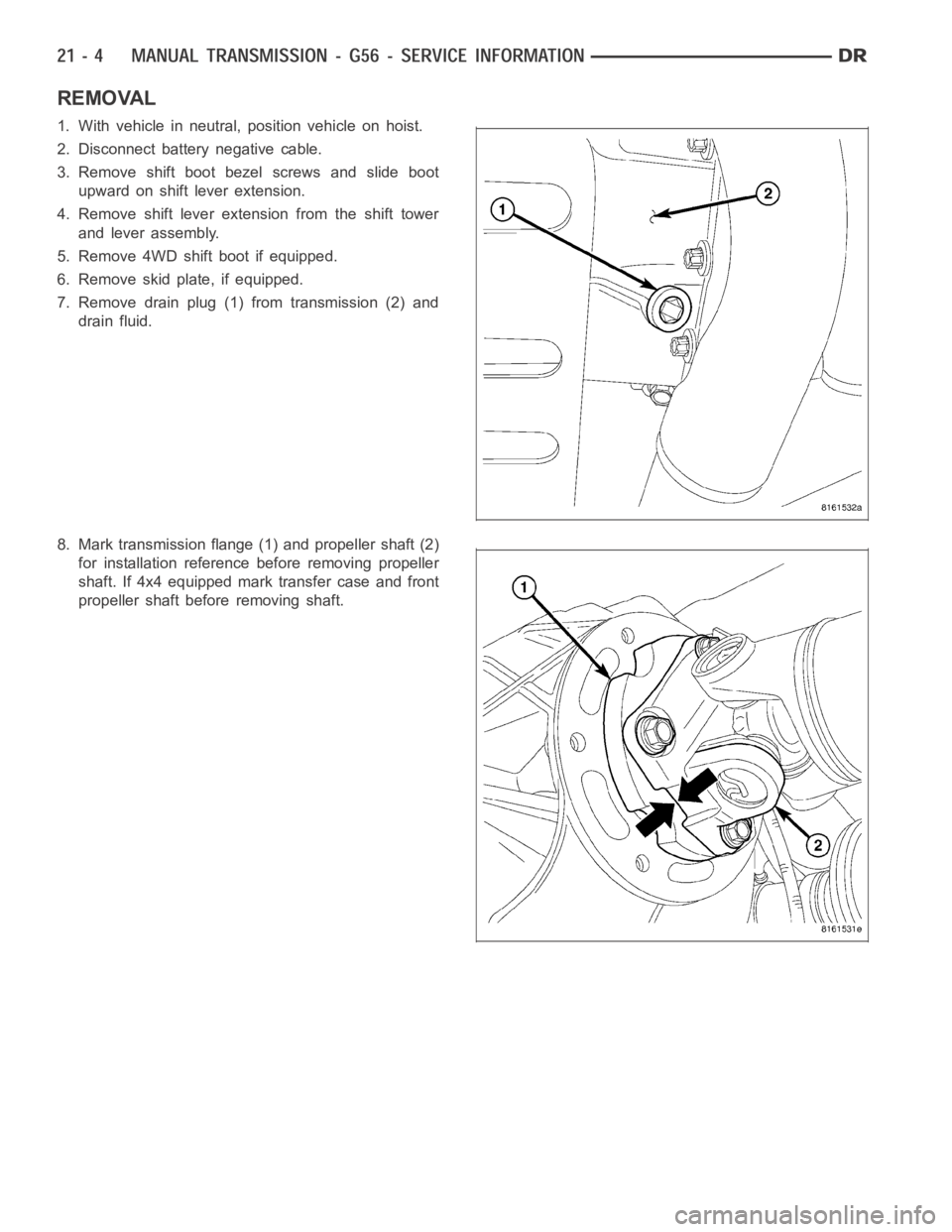

REMOVAL

1. With vehicle in neutral, position vehicle on hoist.

2. Disconnect battery negative cable.

3. Remove shift boot bezel screws and slide boot

upward on shift lever extension.

4. Remove shift lever extension from the shift tower

and lever assembly.

5. Remove 4WD shift boot if equipped.

6. Remove skid plate, if equipped.

7. Remove drain plug (1) from transmission (2) and

drain fluid.

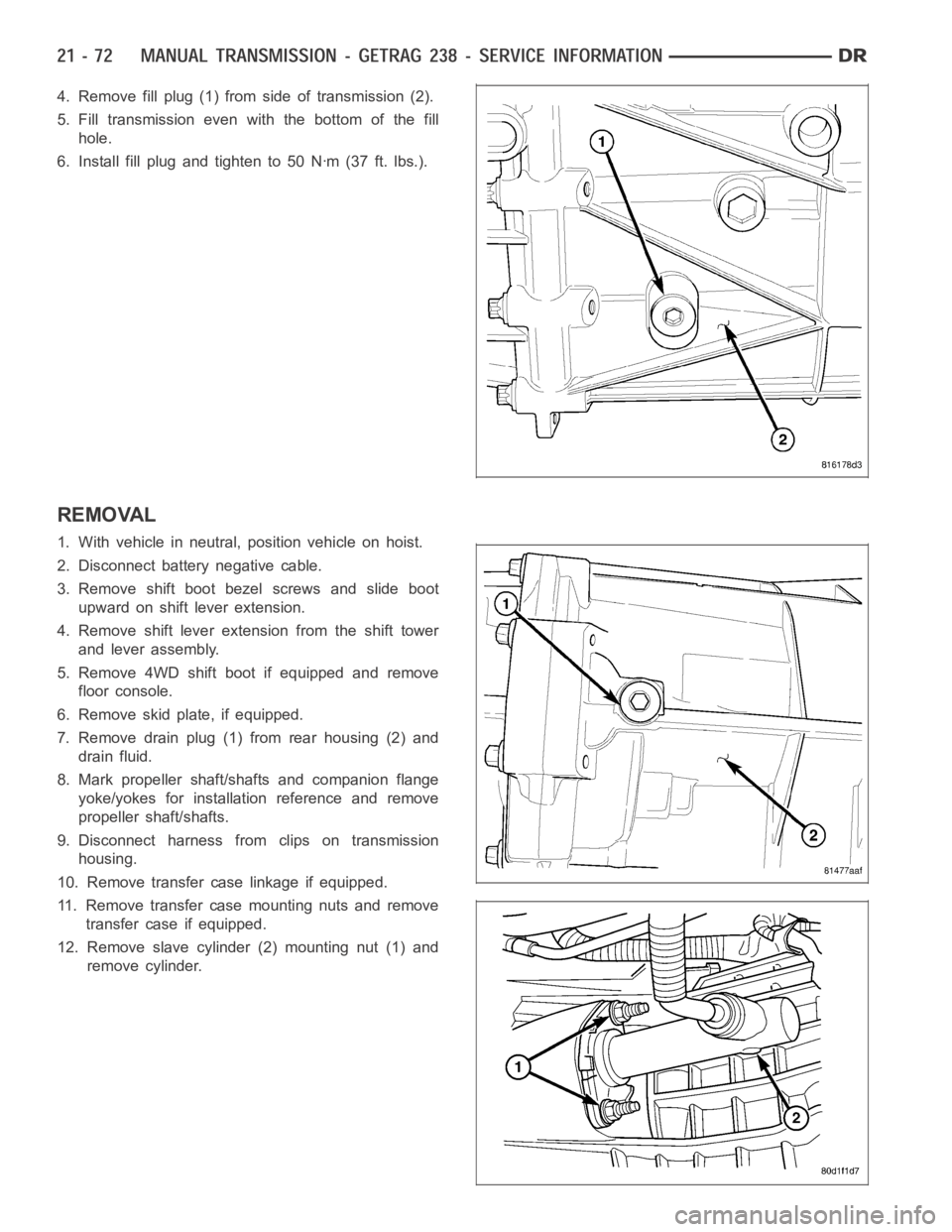

8. Mark transmission flange (1) and propeller shaft (2)

for installation reference before removing propeller

shaft. If 4x4 equipped mark transfer case and front

propeller shaft before removing shaft.

Page 2593 of 5267

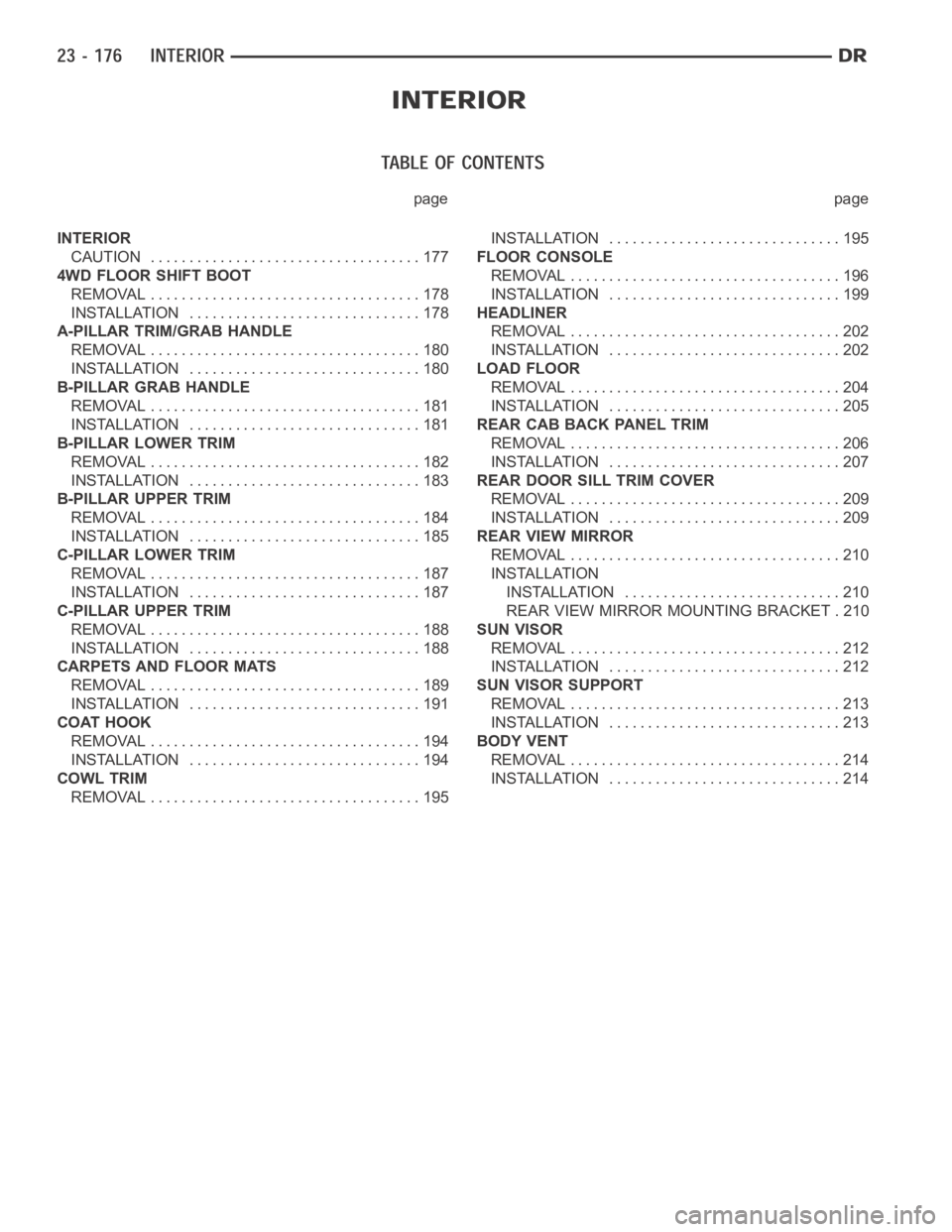

4. Remove fill plug (1) from side of transmission (2).

5. Fill transmission even with the bottom of the fill

hole.

6. Install fill plug and tighten to 50 Nꞏm (37 ft. lbs.).

REMOVAL

1. With vehicle in neutral, position vehicle on hoist.

2. Disconnect battery negative cable.

3. Remove shift boot bezel screws and slide boot

upward on shift lever extension.

4. Remove shift lever extension from the shift tower

and lever assembly.

5. Remove 4WD shift boot if equipped and remove

floor console.

6. Remove skid plate, if equipped.

7. Remove drain plug (1) from rear housing (2) and

drain fluid.

8. Mark propeller shaft/shafts and companion flange

yoke/yokes for installation reference and remove

propeller shaft/shafts.

9. Disconnect harness from clips on transmission

housing.

10. Remove transfer case linkage if equipped.

11. Remove transfer case mounting nuts and remove

transfer case if equipped.

12. Remove slave cylinder (2) mounting nut (1) and

remove cylinder.

Page 4513 of 5267

page page

INTERIOR

CAUTION ................................... 177

4WD FLOOR SHIFT BOOT

REMOVAL ................................... 178

INSTALLATION .............................. 178

A-PILLAR TRIM/GRAB HANDLE

REMOVAL ................................... 180

INSTALLATION .............................. 180

B-PILLAR GRAB HANDLE

REMOVAL ................................... 181

INSTALLATION .............................. 181

B-PILLAR LOWER TRIM

REMOVAL ................................... 182

INSTALLATION .............................. 183

B-PILLAR UPPER TRIM

REMOVAL ................................... 184

INSTALLATION .............................. 185

C-PILLAR LOWER TRIM

REMOVAL ................................... 187

INSTALLATION .............................. 187

C-PILLAR UPPER TRIM

REMOVAL ................................... 188

INSTALLATION .............................. 188

CARPETS AND FLOOR MATS

REMOVAL ................................... 189

INSTALLATION .............................. 191

COAT HOOK

REMOVAL ................................... 194

INSTALLATION .............................. 194

COWL TRIM

REMOVAL ................................... 195INSTALLATION .............................. 195

FLOOR CONSOLE

REMOVAL ................................... 196

INSTALLATION .............................. 199

HEADLINER

REMOVAL ................................... 202

INSTALLATION .............................. 202

LOAD FLOOR

REMOVAL ................................... 204

INSTALLATION .............................. 205

REAR CAB BACK PANEL TRIM

REMOVAL ................................... 206

INSTALLATION .............................. 207

REAR DOOR SILL TRIM COVER

REMOVAL ................................... 209

INSTALLATION .............................. 209

REAR VIEW MIRROR

REMOVAL ................................... 210

INSTALLATION

INSTALLATION ............................ 210

REAR VIEW MIRROR MOUNTING BRACKET . 210

SUN VISOR

REMOVAL ................................... 212

INSTALLATION .............................. 212

SUN VISOR SUPPORT

REMOVAL ................................... 213

INSTALLATION .............................. 213

BODY VENT

REMOVAL ................................... 214

INSTALLATION .............................. 214

Page 4515 of 5267

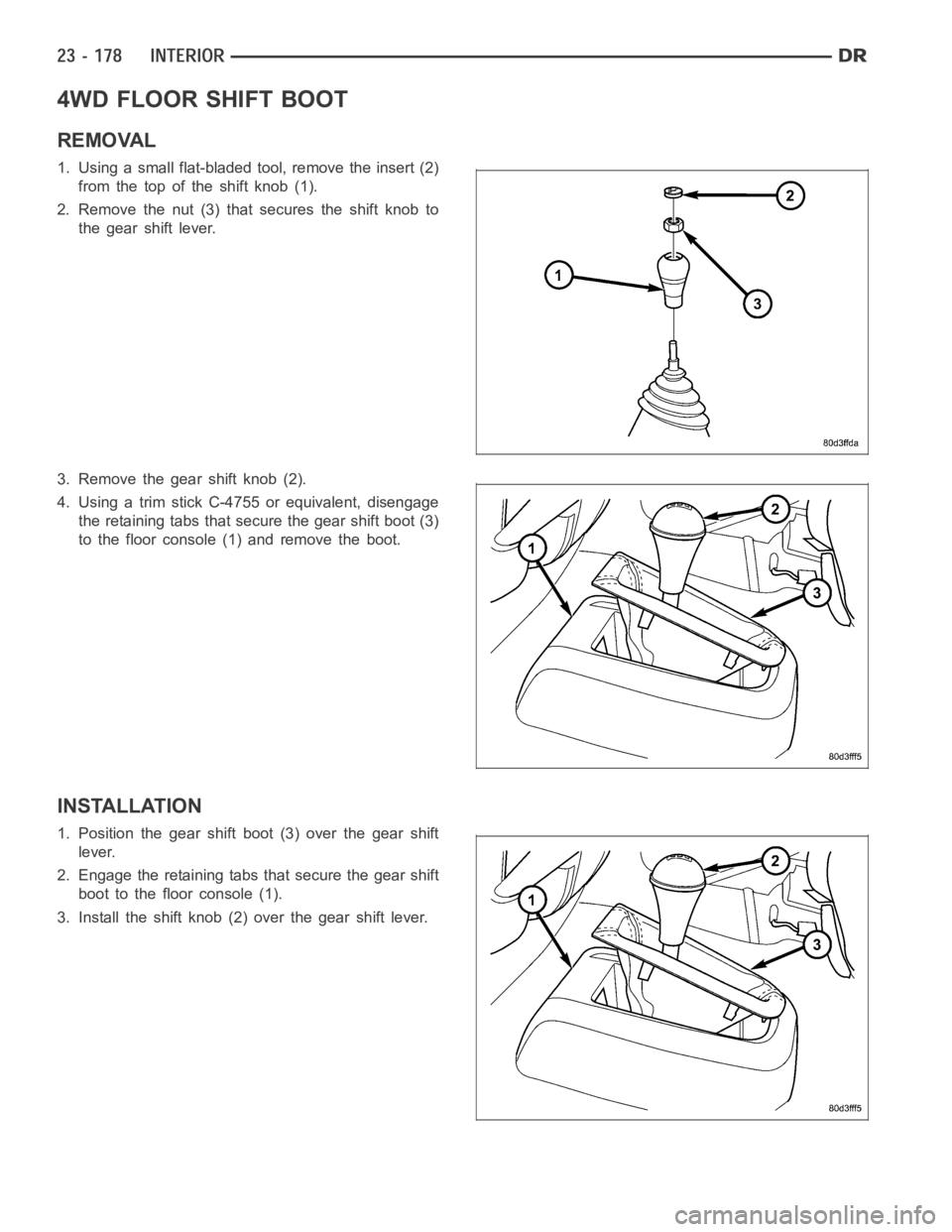

4WD FLOOR SHIFT BOOT

REMOVAL

1. Using a small flat-bladed tool, remove the insert (2)

from the top of the shift knob (1).

2. Remove the nut (3) that secures the shift knob to

the gear shift lever.

3. Remove the gear shift knob (2).

4. Using a trim stick C-4755 or equivalent, disengage

the retaining tabs that secure the gear shift boot (3)

to the floor console (1) and remove the boot.

INSTALLATION

1. Position the gear shift boot (3) over the gear shift

lever.

2. Engage the retaining tabs that secure the gear shift

boot to the floor console (1).

3. Install the shift knob (2) over the gear shift lever.

Page 4533 of 5267

FLOOR CONSOLE

REMOVAL

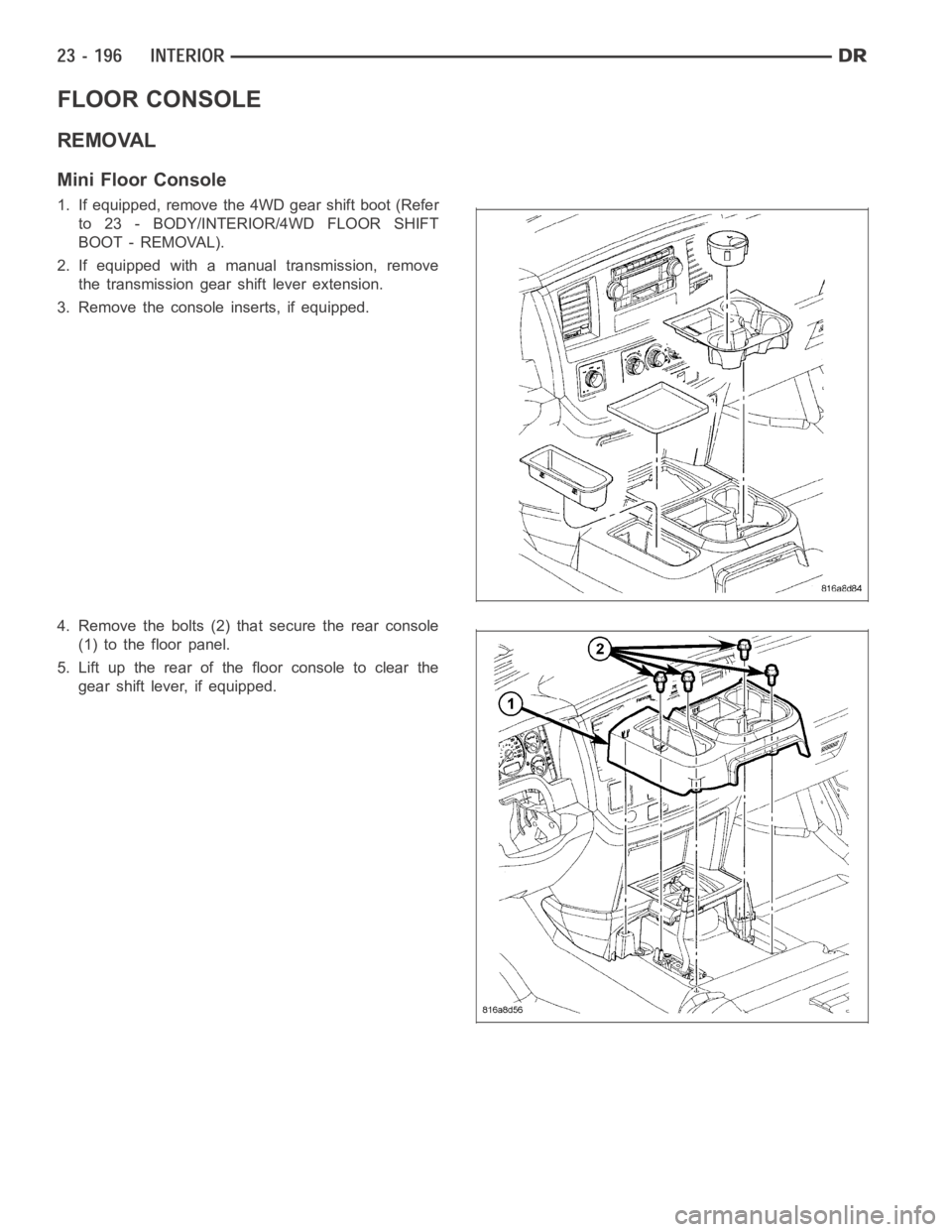

Mini Floor Console

1. If equipped, remove the 4WD gear shift boot (Refer

to 23 - BODY/INTERIOR/4WD FLOOR SHIFT

BOOT - REMOVAL).

2. If equipped with a manual transmission, remove

the transmission gear shift lever extension.

3. Remove the console inserts, if equipped.

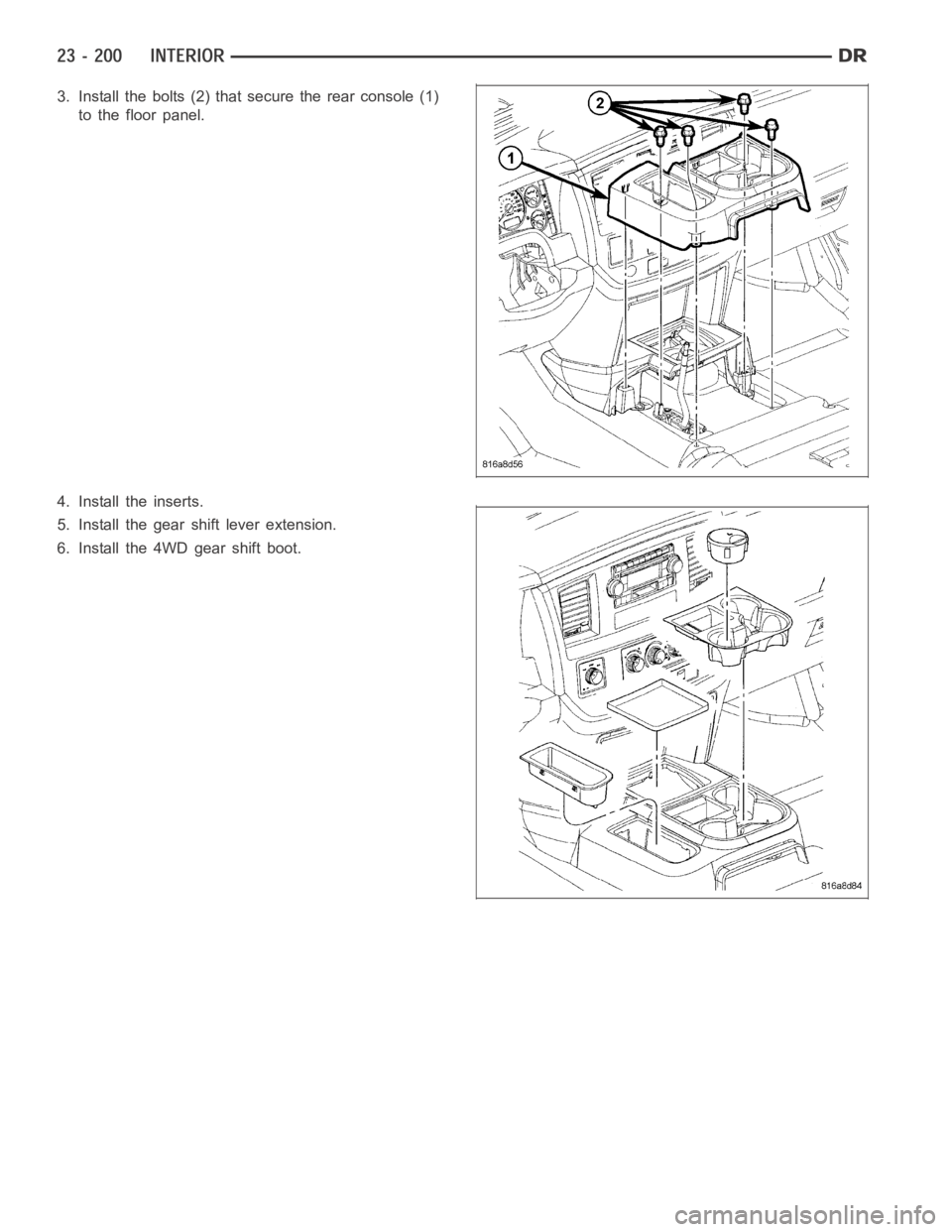

4. Remove the bolts (2) that secure the rear console

(1) to the floor panel.

5. Lift up the rear of the floor console to clear the

gear shift lever, if equipped.

Page 4537 of 5267

3. Install the bolts (2) that secure the rear console (1)

to the floor panel.

4. Install the inserts.

5. Install the gear shift lever extension.

6. Install the 4WD gear shift boot.