key DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 425 of 5267

*5.7L INTERMITTENT NO CRANK CONDITION

For a complete wiring diagramRefer to Section 8W.

Possible Causes

ETC STARTER INHIBIT

Diagnostic Test

1.ETC STARTER INHIBIT

NOTE: This 5.7L engine will try to relearn ETC position when the key is left in the on position for an

extended period of time and will not allow the starter to crank during this procedure. This procedure can

take up to 2.5 seconds.

To verify the cause of the no crank condition or delayed crank use the scan tool, and read the ETC Starter Inhibit

mileage.

The controller will store the mileage at which the no start condition occurred because of the ETC testing procedure.

This is considered normal operation for a vehicle equipped with an Electronic Throttle Control System and no

repairs are necessary.

Is a mileage stored under the ETC Starter Inhibit?

Ye s>>

Te s t C o m p l e t e .

No>>

Refer to the appropriate diagnostic procedure for further assistance if any other DTC’s are set.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 433 of 5267

Possible Causes

NO START PRE-TEST

POWERTRAIN FUSES OPEN

SECONDARY INDICATORS PRESENT

ENGINE MECHANICAL

(K342) ASD RELAY OUTPUT CIRCUITS OPEN

FUEL CONTAMINATION

Diagnostic Test

1.NO START PRE-TEST

NOTE: The following list of items must be checked before continuing with any no start tests.

The battery must be fully charged and in good condition. A low charged battery may produce invalid test results. If

the battery is low, charge the battery and then attempt to start the vehicleby cranking the engine for 15 seconds,

3 consecutive times.

This will allow any DTCs to set that may have been erased due to a dead battery.

Try to communicate with PCM if not able to communicate check fuses.

Make sure the Powers and Ground to the PCM are OK.

Make sure the PCM communicates with the scan tool and that there are no DTCs stored in the PCM memory. If the

PCM reports a No Response condition, refer to section 8 Electrical Electronic Control Module Electrical Diagnostics

for the proper tests.

Read the PCM DTCs with the scan tool. If any DTCs are present, they must be repaired before continuing with any

other No Start diagnostic tests. Refer to the Table of Contents for the related P-code that is reported by the PCM.

Make sure that the Bus is functional. Attempt to communicate with the Instrument Cluster and VTSS, If you are

unable to establish communications refer to 8 Electrical Electronic Control Module Electrical Diagnostics for the

proper Diagnostic procedures.

The Sentry Key Immobilizer System mustbe operating properly. Check for proper communication with the scan tool

and check for DTCs that may be stored in the Sentry Key Immobilizer Module (SKIM). Repair the DTC(s) before

continuing.

If no DTCs are found, using the scan tool, select Clear PCM (BATT Disconnect).

Crank the engine several times. Using the scan tool, read DTCs. If a DTC is present perform the DTC diagnostics

before continuing.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.OPEN FUSE

Check for any open fuses in the IPM or Junction Block that may be related to theNoStartcondition.

Are any of the fuses open?

Ye s>>

Replace the open fuse and check the related circuit(s) for a short to ground.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 439 of 5267

3.EXCESSIVE RESISTANCE IN THE BATTERY CIRCUIT

Turn the ignition off.

Check the Battery Cables for excessive resistance using the service information procedure.

Did either Battery Cable have a voltage drop greater than 0.2 of a volt?

Ye s>>

Repair the excessive resistance in the Battery circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.STARTER RELAY

Turn ignition off.

Remove the Starter Relay from IPM.

CAUTION: The Parking Brake must be on and the Transmission must be in park for a vehicle equipped with

an automatic transmission.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Briefly connect a jumper wire from the Internal Fused B+ circuit to the (T750) Starter Relay Output circuit.

Did the Starter Motor crank the engine?

Ye s>>

Go To 5

No>>

Go To 7

5.(T751) FUSED IGNITION SWITCH OUTPUT CIRCUIT

Ignition on, engine not running.

Using a 12-volt test light, probe the (T751) Fused Ignition Switch Output circuit in the Starter Relay connector.

While observing 12-volt test light, hold ignition key in the start position.

Does the test light illuminate brightly?

Ye s>>

Go To 6

No>>

Repair the excessive resistance in the(T751)FusedIgnitionSwitchOutput circuit. Inspect related fuses

and repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 448 of 5267

*START AND STALL CONDITION

For a complete wiring diagramRefer to Section 8W.

Possible Causes

CURRENT PCM DTCS

CURRENT SKIM DTCS

THROTTLE POSITION SENSOR SWEEP

TP SENSOR NO.1 VOLTAGE GREATER THAN 0.92 VOLTS WITH THROTTLE CLOSED

ECT SENSOR

OTHER POSSIBLE CAUSES FOR START AND STALL CONDITON

FUEL CONTAMINATION

Diagnostic Test

1.CHECKING DTCS

Ignition on, engine not running.

With a scan tool, read DTCs.

Are any DTCs present?

Ye s>>

Refer to the appropriate Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECKING SKREEM DTCS

NOTE: If you are unable to communicate with the SKIM/SKREEM, refer to the VEHICLE THEFT AND SECU-

RITY ELECTRICAL DIAGNOSTICS in Section 8 and perform the appropriate diagnostics.

With the scan tool, read the SKIM codes.

Are there any SKIM DTCs?

Ye s>>

Refer to the Sentry Key Vehicle Theft Security Electrical Diagnostics in Section 8.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.TP SENSOR SWEEP

Ignition on, engine not running.

With the scan tool read TP Sensor voltage.

While monitoring the scan tool, slowly open and close the Throttle on vehicles equipped with a 3.7L or 4.7L engine.

On vehicles equipped with a 5.7L engine, using a scan tool perform the pedalfollower test and monitor both TP

Sensor voltage readings.

Was the voltage change smooth?

Ye s>>

Go To 4

No>>

Replace the Throttle Position Sensor on a 3.7L and 4.7L engines or the Throttle Body Assembly on a

5.7L engine.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 451 of 5267

POWERTRAIN VERIFICATION TEST

For a complete wiring diagramRefer to Section 8W.

Diagnostic Test

1.SELECTING THE PROPER VERIFICATION TEST

The following verification test are for different repairs. Select the appropriate Verification test for the

repair that has been completed.

Speed Control repair

Go To 2

Charging System repair

Go To 3

NVLD System repair

Go To 4

All other repairs

Go To 5

2.POWERTRAIN VERIFICATION TEST 1

NOTE: 1. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 2. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 3. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 4. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

5. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected.

6. Connect the scan tool to the data link connector and erase all codes.

7. Turn the speed control ON (if equipped, cruise light will be on).

8. Depress and release the SET Switch when the vehicle speed is greater than35 MPH. The speed control should

engage and hold the selected speed.

9. Press and hold the RESUME/ACCEL Switch. The vehicle speed should increase by at least 2 MPH.

10. Press and hold the COAST switch. The vehicle speed should decrease.

11. Using caution, press and release the brake pedal. The speed control should disengage.

12. Bring the vehicle speed back up to 35 MPH.

13. Press the RESUME/ACCEL switch. The speed control should resume the previously set speed.

14. Hold down the SET switch. The vehicle should decelerate.

15. Make sure vehicle speed is greater than 35 mph and release the SET Switch. The vehicle should adjust and set

a new vehicle speed.

16. Press and release the CANCEL switch. The speed control should disengage.

17. Bring the vehicle speed back up above 35 mph and engage speed control.

18. Turn the Speed Control Off. (Cruise light will be off). The speed control should disengage.

NOTE: OVERSHOOT/UNDERSHOOT FOLLOWING SPEED CONTROL SET.

19. If the vehicle operator repeatedly presses and releases the SET buttonwith their foot off of the accelerator

(referred to as

lift foot set), the vehicle may accelerate and exceed the desired set speed by up to 5 mph (8km/h).

20. It may also decelerate to less than the desired set speed, before finally achieving the desired set speed.

21. The Speed Control System has an adaptive strategy that compensates forvehicle-to-vehicle variations in speed

control cable lengths.

22. When the speed control is set with the vehicles operators foot off of theaccelerator pedal, the speed control

thinks there is excessive speed control cable slack and adapts accordingly.

Page 452 of 5267

23. If thelift foot setsare continually used, a speed control overshoot/undershoot condition will develop.

24. To

unlearnthe overshoot/undershoot condition, the vehicle operator has to press and release the set button

while maintaining the desired set speedusing the accelerator pedal (not decelerating or accelerating).

25. Then turn the cruise control switch to the OFF position (or press the CANCEL button if equipped) after waiting

10 seconds.

26. This procedure must be performed approximately 10-15 times to completely unlearn the overshoot/undershoot

condition.

Did the Speed Control pass the above test?

Ye s>>

Repair is complete.

No>>

Check for any related Technical Service Bulletins and/or refer to the appropriate Diagnostic Procedure.

3.POWERTRAIN VERIFICATION TEST 2

1. If this vehicle is equipped with an Electronic Throttle Control system,and the APP Sensors, PCM, or Throttle

Body Assembly has been replaced use a scan tool to perform the ETC RELEARN function.

NOTE: 2. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 3. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 4. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

5. Inspect the vehicle to make sure that all components related to the repair are properly installed and connected.

6. With the scan tool, clear DTCs.

7. Perform generator output test. Refer to the appropriate service information as necessary.

8. Start the engine and set engine speed to 2000 RPM for at least thirty seconds.

9. Cycle the ignition key off and on.

10. With the scan tool, read the DTCs.

Are any DTCs or symptoms remaining?

Ye s>>

Check for any Technical Service Bulletins and/or refer to the appropriateDiagnostic Procedure.

No>>

Repair is complete.

4.POWERTRAIN VERIFICATION TEST 3

1. Install the Miller Tool #8404 Evaporative Emission Leak Detector (EELD) according to the instructions in the pre-

vious DTC table.

2. Set the smoke/air control switch to AIR.

3. Insert the tester’s AIR supply tip (clear hose) into the appropriate calibration orifice on the tester’s control panel

(based on DTC leak size).

4. Press the remote smoke/air start button.

5. Position the red flag on the air flow meter so it is aligned with the indicator ball.

6. When the calibration is complete, release the remote button. The EELD flow meter is now calibrated in liters per

minute to the size of leak indicated by the DTC set in the PCM.

7. Install the service port adapter #8404-14 on the vehicle’s service port.

8. Connect the Air supply hose from the EELD to the vehicle.

9. Press the remote button to activate AIR flow.

NOTE: 10. Larger volume fuel tanks, lower fuel levels or if the vehicle is equipped with a Flow Management

Valve may indicate high flow and will require 4 to 5 minutes to fill.

11. Compare the flow meter indicator ball reading to the red flag.

12. ABOVE the red flag indicates a leak present.

13. BELOW the red flag indicates a sealed system.

Page 453 of 5267

NOTE: If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM, or

Throttle Body Assembly have been replaced, use the scan tool to perform theETC RELEARN function.

14. If the indicator ball shows a leak present, perform the smoke test indicated in the previous test and identify the

leak and repair. Perform this verification test when the repair is complete.

Didtheindicatorballindicatethealeakispresent?

Ye s>>

Repeat the DTC test to identify the leak and repair.

No>>

Repair is complete.

5.POWERTRAIN VERIFICATION TEST 4

NOTE: 1. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 2. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 3. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

NOTE: 4. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 5. When replacing an O2 Sensor, the PCM RAM memory must be cleared, either by disconnecting the

PCM C1 connector or momentarily disconnecting the Battery negative terminal.

6. The NGC learns the characteristics of each O2 heater element and these old values should be cleared when

installing a new O2 sensor. The customermay experience driveability issues if this is not performed.

7. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected. Reassemble

and reconnect components as necessary.

8. Connect the scan tool to the data link connector.

9. Make sure the fuel tank has at least a quarter tank of fuel. Turn off all accessories.

10. If the Catalyst was replaced, with the scan tool go to the MiscellaneousMenu Option

Catalyst Replacedand

press enter.

11. If a Comprehensive Component DTC was repaired, perform steps 12 - 14. Ifa Major OBDII Monitor DTC was

repaired skip those steps and continue verification.

12. After the ignition has been off for at least 10 seconds, restart the vehicle and run 2 minutes.

13. With the scan tool, monitor the appropriate pre-test enabling conditions until all conditions have been met. Once

the conditions have been met, switch screen to the appropriate OBDII monitor, (Audible beeps when the monitor is

running).

14. If the repaired OBDII trouble code has reset or was seen in the monitor while on the road test, the repair is not

complete. Check for any related technical service bulletins or flash updates and return to Engine Electrical Diag-

nostic List.

15. If the conditions cannot be duplicated, erase all DTCs with the Scan tool.

16. If another DTC has set, return to the Engine Electrical Diagnostic Listand follow the path specified for that DTC.

Did the OBDII Monitor run successfully and has the Good Trip Counter changed to one or more?

Ye s>>

Repair is complete.

No>>

Check for any related Technical Service Bulletins and/or refer to the appropriate Diagnostic Procedure.

Page 455 of 5267

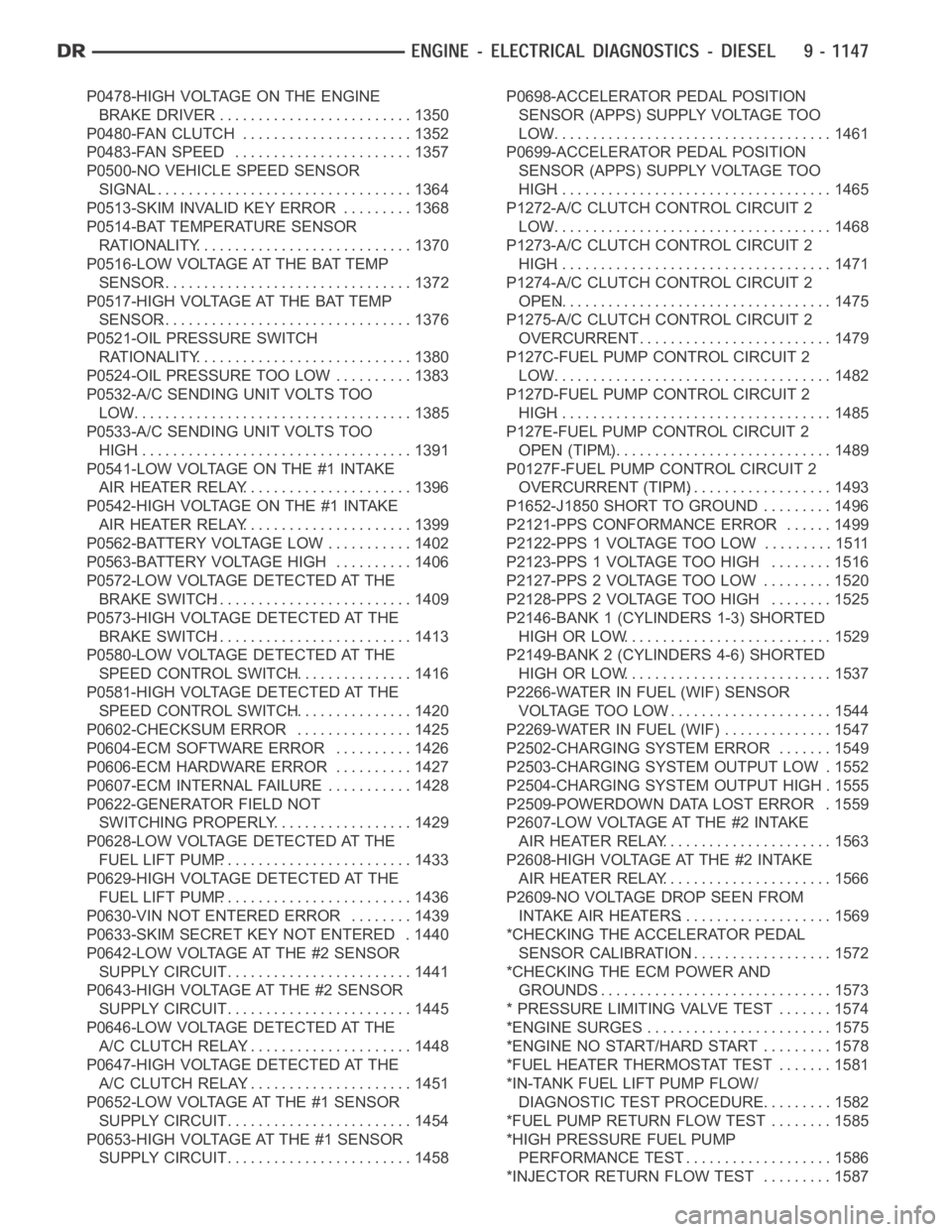

page page

ENGINE - ELECTRICAL DIAGNOSTICS -

DIESEL

DIAGNOSIS AND TESTING

PRE-DIAGNOSTIC TROUBLESHOOTING

PROCEDURE............................. 1150

POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL)................................. 1152

POWERTRAIN VERIFICATION TEST VER - 2

(DIESEL)................................. 1153

POWERTRAIN VERIFICATION TEST VER - 4

(DIESEL)................................. 1154

POWERTRAIN VERIFICATION TEST VER - 5

(DIESEL)................................. 1156

INTERMITTENT CONDITION ............... 1157

P0016-ENGINE SPEED SIGNAL MISMATCH . 1158

P0069-BOOST KEY ON RATIONALITY ...... 1160

P0071-INLET AIR TEMP SENSOR

RATIONALITY............................ 1163

P0072-INLET AIR TEMP SENSOR VOLTAGE

TOO LOW................................ 1165

P0073-INLET AIR TEMP SENSOR VOLTAGE

TOO HIGH............................... 1169

P0088-FUEL RAIL PRESSURE SIGNAL IS

ABOVE MAX LIMIT........................ 1174

P0106-INLET AIR PRESSURE SENSOR

RATIONALITY............................ 1176

P0107-INLET AIR PRESSURE SENSOR

VOLTAGE TOO LOW...................... 1178

P0108-INLET AIR PRESSURE SENSOR

VOLTAGE TOO HIGH...................... 1183

P0111-INTAKE AIR TEMPERATURE (IAT)

SENSOR RATIONALITY................... 1188

P0112-INTAKE AIR TEMPERATURE (IAT)

SENSOR VOLTAGE TOO LOW............. 1190

P0113-INTAKE AIR TEMPERATURE (IAT)

SENSOR VOLTAGE TOO HIGH............. 1195

P0116-ENGINE COOLANT TEMPERATURE

(ECT) SENSOR RATIONALITY............. 1200

P0117-ENGINE COOLANT TEMPERATURE

(ECT) SENSOR VOLTAGE TOO LOW....... 1202

P0118-ENGINE COOLANT TEMPERATURE

(ECT) SENSOR VOLTAGE TOO HIGH...... 1206

P0128-THERMOSTAT RATIONALITY ........ 1211

P0148-HIGH PRESSURE COMMON RAIL

(HPCR) CHECKSUM...................... 1212

P0169-WATER IN FUEL (WIF) LIGHT ON

TOO LONG............................... 1215

P0191-FUEL RAIL PRESSURE SENSOR

PERFORMANCE.......................... 1217

P0192-FUEL PRESSURE SENSOR

VOLTAGE TOO LOW...................... 1219P0193-FUEL PRESSURE SENSOR

VOLTAGE TOO HIGH...................... 1224

P0201-INJECTOR #1 CONTROL CIRCUIT . . . 1229

P0202-INJECTOR #2 CONTROL CIRCUIT . . . 1233

P0203-INJECTOR #3 CONTROL CIRCUIT . . . 1237

P0204-INJECTOR #4 CONTROL CIRCUIT . . . 1241

P0205-INJECTOR #5 CONTROL CIRCUIT . . . 1245

P0206-INJECTOR #6 CONTROL CIRCUIT . . . 1249

P0217-DECREASED ENGINE

PERFORMANCE DUE TO ENGINE

OVERHEAT CONDITION................... 1253

P0219-CRANKSHAFT POSITION SENSOR

OVER SPEED SIGNAL.................... 1255

P0234-TURBOCHARGER OVERBOOST

CONDITION.............................. 1257

P0236-MAP SENSOR TOO HIGH

TOO LONG............................... 1259

P0237-MAP SENSOR VOLTAGE TOO LOW . 1261

P0238-MAP SENSOR VOLTAGE TOO HIGH . 1266

P0243-WASTEGATE PRESSURE CONTROL

PWM.................................... 1271

P0251-CP3 PUMP REGULATOR CONTROL . 1277

P0299-BOOST IN RANGE LOW ............ 1283

P0300-MULTIPLE CYLINDER MISFIRE ..... 1286

P0301-CYLINDER # 1 MISFIRE ............ 1289

P0302-CYLINDER # 2 MISFIRE ............ 1292

P0303-CYLINDER # 3 MISFIRE ............ 1295

P0304-CYLINDER # 4 MISFIRE ............ 1298

P0305-CYLINDER # 5 MISFIRE ............ 1301

P0306-CYLINDER # 6 MISFIRE ............ 1304

P0335-CRANKSHAFT POSITION (CKP)

LOST.................................... 1307

P0336-CRANKSHAFT POSITION (CKP)

SENSOR SIGNAL......................... 1313

P0337-CRANKSHAFT POSITION (CKP)

SENSOR VOLTAGE TOO LOW............. 1319

P0338-CRANKSHAFT POSITION (CKP)

SENSOR VOLTAGE TOO HIGH............ 1322

P0340-CAMSHAFT POSITION (CMP) LOST . 1324

P0341-CAMSHAFT POSITION (CMP)

SENSOR SIGNAL......................... 1330

P0381-WAIT TO START LAMP

INOPERATIVE............................ 1336

P0461-FUEL LEVEL UNIT NO CHANGE

OVER TIME.............................. 1338

P0462-LOW VOLTAGE DETECTED AT THE

FUEL LEVEL SENSOR.................... 1341

P0463-HIGH VOLTAGE DETECTED AT THE

FUEL LEVEL SENSOR.................... 1345

P0477-LOW VOLTAGE ON THE ENGINE

BRAKE DRIVER.......................... 1348

Page 456 of 5267

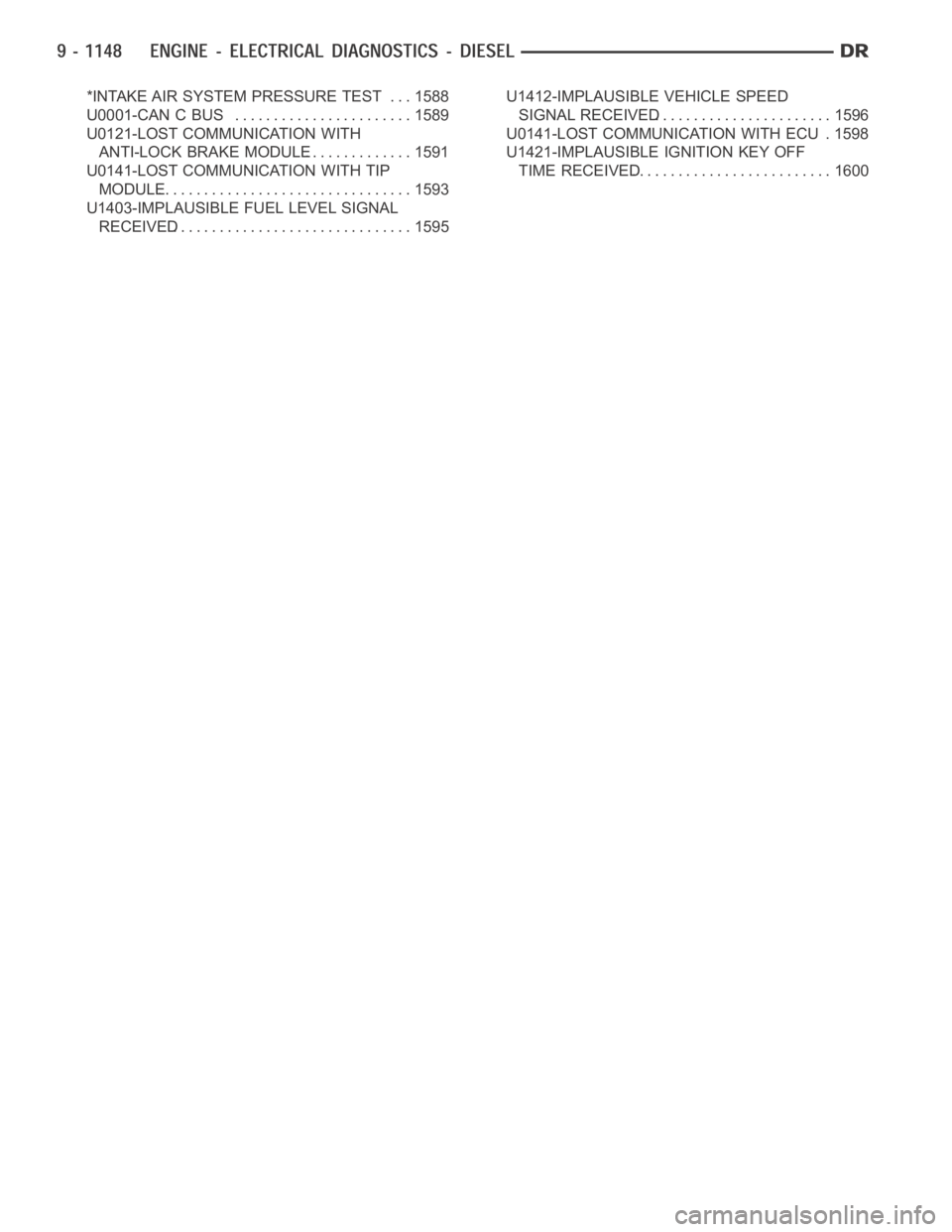

P0478-HIGH VOLTAGE ON THE ENGINE

BRAKE DRIVER.......................... 1350

P0480-FAN CLUTCH ...................... 1352

P0483-FAN SPEED ....................... 1357

P0500-NO VEHICLE SPEED SENSOR

SIGNAL.................................. 1364

P0513-SKIM INVALID KEY ERROR ......... 1368

P0514-BAT TEMPERATURE SENSOR

RATIONALITY............................ 1370

P0516-LOW VOLTAGE AT THE BAT TEMP

SENSOR................................. 1372

P0517-HIGH VOLTAGE AT THE BAT TEMP

SENSOR................................. 1376

P0521-OIL PRESSURE SWITCH

RATIONALITY............................ 1380

P0524-OIL PRESSURE TOO LOW .......... 1383

P0532-A/C SENDING UNIT VOLTS TOO

LOW..................................... 1385

P0533-A/C SENDING UNIT VOLTS TOO

HIGH.................................... 1391

P0541-LOW VOLTAGE ON THE #1 INTAKE

AIR HEATER RELAY...................... 1396

P0542-HIGH VOLTAGE ON THE #1 INTAKE

AIR HEATER RELAY...................... 1399

P0562-BATTERY VOLTAGE LOW ........... 1402

P0563-BATTERY VOLTAGE HIGH .......... 1406

P0572-LOW VOLTAGE DETECTED AT THE

BRAKE SWITCH.......................... 1409

P0573-HIGH VOLTAGE DETECTED AT THE

BRAKE SWITCH.......................... 1413

P0580-LOW VOLTAGE DETECTED AT THE

SPEED CONTROL SWITCH................ 1416

P0581-HIGH VOLTAGE DETECTED AT THE

SPEED CONTROL SWITCH................ 1420

P0602-CHECKSUM ERROR ............... 1425

P0604-ECM SOFTWARE ERROR .......... 1426

P0606-ECM HARDWARE ERROR .......... 1427

P0607-ECM INTERNAL FAILURE ........... 1428

P0622-GENERATOR FIELD NOT

SWITCHING PROPERLY.................. 1429

P0628-LOW VOLTAGE DETECTED AT THE

FUEL LIFT PUMP......................... 1433

P0629-HIGH VOLTAGE DETECTED AT THE

FUEL LIFT PUMP......................... 1436

P0630-VIN NOT ENTERED ERROR ........ 1439

P0633-SKIM SECRET KEY NOT ENTERED . 1440

P0642-LOW VOLTAGE AT THE #2 SENSOR

SUPPLY CIRCUIT......................... 1441

P0643-HIGH VOLTAGE AT THE #2 SENSOR

SUPPLY CIRCUIT......................... 1445

P0646-LOW VOLTAGE DETECTED AT THE

A/C CLUTCH RELAY...................... 1448

P0647-HIGH VOLTAGE DETECTED AT THE

A/C CLUTCH RELAY...................... 1451

P0652-LOW VOLTAGE AT THE #1 SENSOR

SUPPLY CIRCUIT......................... 1454

P0653-HIGH VOLTAGE AT THE #1 SENSOR

SUPPLY CIRCUIT......................... 1458P0698-ACCELERATOR PEDAL POSITION

SENSOR (APPS) SUPPLY VOLTAGE TOO

LOW..................................... 1461

P0699-ACCELERATOR PEDAL POSITION

SENSOR (APPS) SUPPLY VOLTAGE TOO

HIGH.................................... 1465

P1272-A/C CLUTCH CONTROL CIRCUIT 2

LOW..................................... 1468

P1273-A/C CLUTCH CONTROL CIRCUIT 2

HIGH.................................... 1471

P1274-A/C CLUTCH CONTROL CIRCUIT 2

OPEN.................................... 1475

P1275-A/C CLUTCH CONTROL CIRCUIT 2

OVERCURRENT.......................... 1479

P127C-FUEL PUMP CONTROL CIRCUIT 2

LOW..................................... 1482

P127D-FUEL PUMP CONTROL CIRCUIT 2

HIGH.................................... 1485

P127E-FUEL PUMP CONTROL CIRCUIT 2

OPEN (TIPM)............................. 1489

P0127F-FUEL PUMP CONTROL CIRCUIT 2

OVERCURRENT (TIPM)

................... 1493

P1652-J1850 SHORT TO GROUND ......... 1496

P2121-PPS CONFORMANCE ERROR ...... 1499

P2122-PPS 1 VOLTAGE TOO LOW ......... 1511

P2123-PPS 1 VOLTAGE TOO HIGH ........ 1516

P2127-PPS 2 VOLTAGE TOO LOW ......... 1520

P2128-PPS 2 VOLTAGE TOO HIGH ........ 1525

P2146-BANK 1 (CYLINDERS 1-3) SHORTED

HIGH OR LOW........................... 1529

P2149-BANK 2 (CYLINDERS 4-6) SHORTED

HIGH OR LOW........................... 1537

P2266-WATER IN FUEL (WIF) SENSOR

VOLTAGE TOO LOW...................... 1544

P2269-WATER IN FUEL (WIF) .............. 1547

P2502-CHARGING SYSTEM ERROR ....... 1549

P2503-CHARGING SYSTEM OUTPUT LOW . 1552

P2504-CHARGING SYSTEM OUTPUT HIGH . 1555

P2509-POWERDOWN DATA LOST ERROR . 1559

P2607-LOW VOLTAGE AT THE #2 INTAKE

AIR HEATER RELAY...................... 1563

P2608-HIGH VOLTAGE AT THE #2 INTAKE

AIR HEATER RELAY...................... 1566

P2609-NO VOLTAGE DROP SEEN FROM

INTAKE AIR HEATERS.................... 1569

*CHECKING THE ACCELERATOR PEDAL

SENSOR CALIBRATION................... 1572

*CHECKING THE ECM POWER AND

GROUNDS............................... 1573

* PRESSURE LIMITING VALVE TEST ....... 1574

*ENGINE SURGES ........................ 1575

*ENGINE NO START/HARD START ......... 1578

*FUEL HEATER THERMOSTAT TEST ....... 1581

*IN-TANK FUEL LIFT PUMP FLOW/

DIAGNOSTIC TEST PROCEDURE.......... 1582

*FUEL PUMP RETURN FLOW TEST ........ 1585

*HIGH PRESSURE FUEL PUMP

PERFORMANCE TEST.................... 1586

*INJECTOR RETURN FLOW TEST ......... 1587

Page 457 of 5267

*INTAKE AIR SYSTEM PRESSURE TEST . . . 1588

U0001-CAN C BUS ....................... 1589

U0121-LOST COMMUNICATION WITH

ANTI-LOCK BRAKE MODULE.............. 1591

U0141-LOST COMMUNICATION WITH TIP

MODULE................................. 1593

U1403-IMPLAUSIBLE FUEL LEVEL SIGNAL

RECEIVED............................... 1595U1412-IMPLAUSIBLE VEHICLE SPEED

SIGNAL RECEIVED....................... 1596

U0141-LOST COMMUNICATION WITH ECU . 1598

U1421-IMPLAUSIBLE IGNITION KEY OFF

TIME RECEIVED.......................... 1600