key DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 463 of 5267

POWERTRAIN VERIFICATION TEST VER - 4 (DIESEL)

1.POWERTRAIN VERIFICATION TEST VER - 4 (DIESEL)

1. Check if any of the following conditions exist.

2. The ECM has been disconnected or replace.

3. The Battery power has been disconnected.

4. Inspect the vehicle to ensure that all engine components are properly installed and connected. Reassemble and

reconnect components as necessary.

5. With the DRBIII

,eraseDTCs.

6. If the ECM has been replaced, perform steps 11 through 13, then continue with the verification.

7. If ECM has been changed and correct VIN and mileage have not been programmed, a DTC will be set in ABS

and Air bag modules. In addition, if vehicle is equipped with a Sentry Key Immobilizer Module (SKIM), Secret Key

data must be updated to enable start.

8. For ABS and Air Bag systems: Enter correct VIN and Mileage in ECM. Erase codes in ABS and Air Bag modules.

9. For SKIM theft alarm: Connect DRBIII

to data link conn. Go to Theft Alarm, SKIM, Misc. and place SKIM in

secured access mode, by using the appropriate PIN code for this vehicle. Select Update the Secret Key data. Data

will be transferred from SKIM to PCM

10. Turn the speed control ON (if equipped, cruise light will be on).

11. Depress and release the SET Switch. If the speed control did not engage,the repair is not complete. Check for

TSBs that pertain to speed control problem and then, if necessary, return to Symptom List.

12. Depress and hold the RESUME/ACCEL Switch. If the vehicle speed did not increase by at least 2 mph, the

repair is not complete. Check for TSBs that pertain to speed control problem and then, if necessary, return to Symp-

tom List.

13. Press and hold the COAST switch. The vehicle speed should decrease. If it did not decrease, the repair is not

complete. Check for TSBs that pertain to speed control problem and then, ifnecessary, return to Symptom List.

14. Using caution, depress and release the brake pedal. If the speed control did not disengage, the repair is not

complete. Check for TSBs that pertain to speed control problem and then, ifnecessary, return to Symptom List.

15. Bring the vehicle speed back up to 35 MPH.

16. Depress the RESUME/ACCEL switch. If the speed control did not resume the previously set speed, the repair

is not complete. Check for TSBs that pertain to speed control problem and then, if necessary, return to Symptom

List.

17. Hold down the SET switch. If the vehicle did not decelerate, the repair is not complete. Check for TSBs that

pertain to speed control problem and then, if necessary, return to SymptomList.

18. Ensure vehicle speed is greater than 35 mph and release the SET Switch. If vehicle did not adjust and set a

new vehicle speed, the repair is not complete. Check for TSBs that pertain to speed control problem and then, if

necessary, return to Symptom List.

19. Depress and release the CANCEL switch. If the speed control did not disengage, the repair is not complete.

Check for TSBs that pertain to speed control problem and then, if necessary, return to Symptom List.

20. Bring the vehicle speed back up above 35 mph and engage speed control.

21. Depress the OFF switch to turn OFF, (Cruise light will be off). If the speed control did not disengage, the repair

is not complete. Check for TSBs that pertain to speed control problem and then, if necessary, return to Symptom

List.

22. If the vehicle successfully passed all of the previous tests, the speedcontrol system is now functioning as

designed. The repair is now complete.

23. NOTE: OVERSHOOT/UNDERSHOOT FOLLOWING SPEED CONTROL SET.

24. If the vehicle operator repeatedly presses and releases the SET buttonwith their foot off of the accelerator

(referred to as

lift foot set), the vehicle may accelerate and exceed the desired set speed by up to 5 mph (8km/h).

25. It may also decelerate to less than the desired set speed, before finally achieving the desired set speed.

26. The Speed Control System has an adaptive strategy that compensates forvehicle-to-vehicle variations in speed

control cable lengths.

27. When the speed control is set with the vehicles operators foot off of theaccelerator pedal, the speed control

thinks there is excessive speed control cable slack and adapts accordingly.

28. If the

lift foot setsare continually used, a speed control overshoot/undershoot condition will develop.

29. To

unlearnthe overshoot/undershoot condition, the vehicle operator has to press and release the set button

Page 465 of 5267

POWERTRAIN VERIFICATION TEST VER - 5 (DIESEL)

Diagnostic Test

1.POWERTRAIN VERIFICATION TEST VER - 5 (DIESEL)

1. Check if any of the following conditions exist.

2. The ECM has been disconnected or replace.

3. The Battery power has been disconnected.

4. Inspect the vehicle to ensure that all engine components are properly installed and connected. Reassemble and

reconnect components as necessary.

5. If any existing diagnostic trouble codes have not been repaired, go to Symptom List and follow path specified.

6. Connect the scan tool to the data link connector.

7. Ensure the fuel tank has at least a quarter tank of fuel. Turn off all accessories.

8. Perform steps 15 through 17 if the PCM has been replaced. Then proceed with the verification. If the ECM has

not been replaced skip those steps and continue verification.

9. If ECM has been changed and correct VIN and mileage have not been programmed, a DTC will be set in ABS

and Air bag modules. In addition, if vehicle is equipped with a Sentry Key Immobilizer Module (SKIM), Secret Key

data must be updated to enable start.

10. For ABS and Air Bag systems: Enter correct VIN and Mileage in ECM. Erase codes in ABS and Air Bag mod-

ules.

11. For SKIM theft alarm: Connect scan tool to data link connector to Theft Alarm, SKIM, Misc. and place SKIM in

secured access mode by using appropriate PIN code for this vehicle. SelectUpdate the Secret Key data. Data will

be transferred from SKIM to PCM.

12. If a Comprehensive Component DTC was repaired, perform steps 10-13. Ifa Major OBDII Monitor DTC was

repaired skip those steps and continue verification.

13. After the ignition has been off for at least 10 seconds, restart the vehicle and run 2 minutes.

14. If there are no new DTC’s, the repair was successful and is now complete.Erase DTC’s and disconnect the

scan tool.

15. If the repaired DTC has reset, the repair is not complete. Check for any related TSB’s or flash updates and

return to the Symptom list.

16. If another DTC has set, return to the Symptom List and follow the path specified for that DTC.

17. With the scan tool, monitor the appropriate pre-test enabling conditions until all conditions have been met. Once

the conditions have been met, switch screen to the appropriate OBDII monitor, (Audible beeps when the monitor is

running).

18. If the monitor ran, the repair was successful and is now complete. EraseDTC’s and disconnect the scan tool.

19. If the repaired OBDII trouble code has reset or was seen in the monitor while on the road test, the repair is not

complete. Check for any related technical service bulletins or flash updates and return to Symptom List.

20. If another DTC has set, return to the Symptom List and follow the path specified for that DTC.

Is any DTC(s) present?

Ye s>>

Repair is not complete, refer to appropriate symptom.

No>>

Repair is complete.

Page 469 of 5267

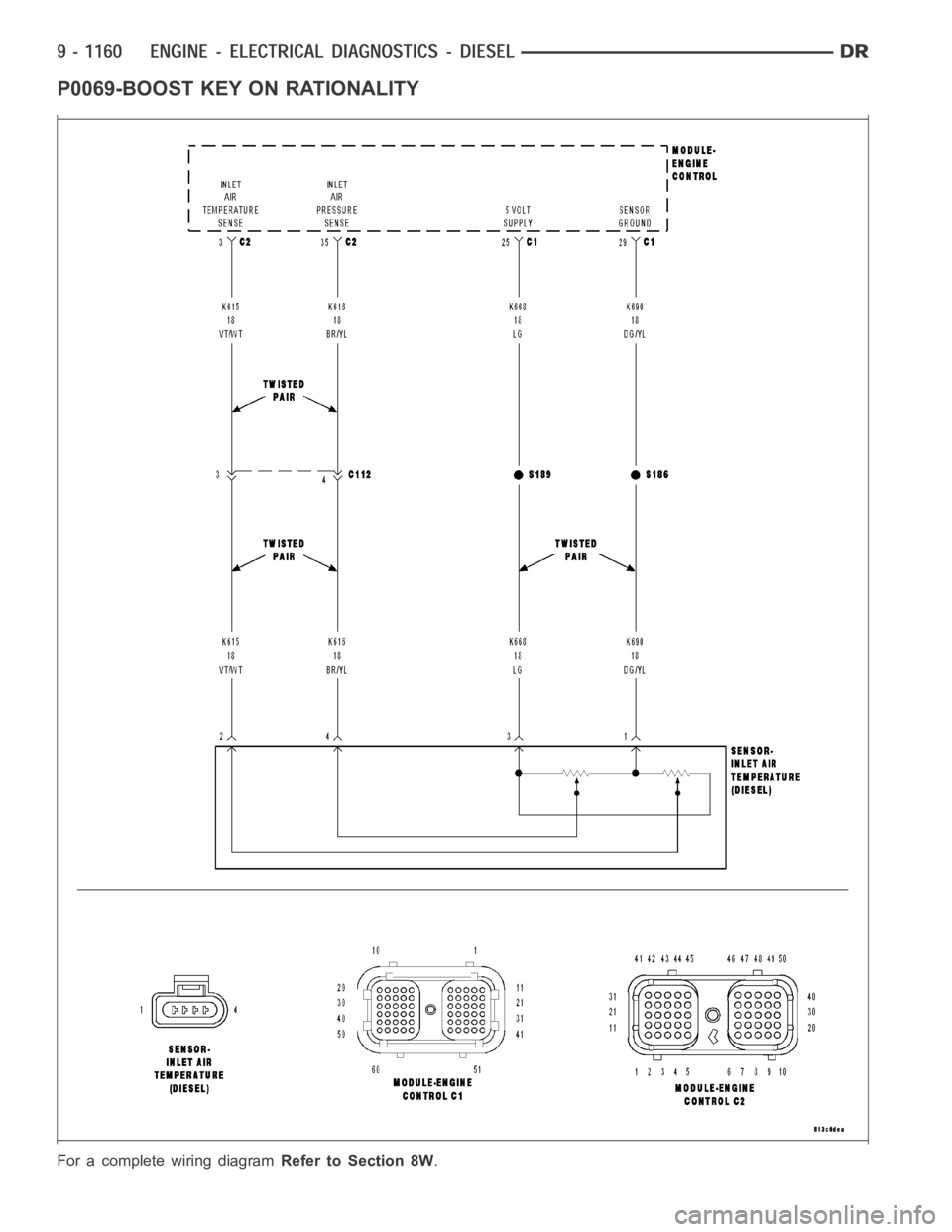

P0069-BOOST KEY ON RATIONALITY

For a complete wiring diagramRefer to Section 8W.

Page 470 of 5267

When Monitored:

Whilethekeyison.

Set Condition:

The boost pressure recorded at key on is not within a calibrated range from the inlet air pressure sensor.

Possible Causes

OTHER DTC’S PRESENT

INLET AIR PRESSURE SENSOR

BOOST PRESSURE SENSOR

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S PRESENT

With the scan tool, read DTCs.

Are any DTC’s present for Inlet air pressure or boost pressure?

Ye s>>

Repair other DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 9 - ENGINE- DIAGNOSIS

AND TESTING)

No>>

Go To 2

2.COMPARE THE INLET AIR PRESSURE

Using the scan tool, compare the inlet air pressure (barometric pressure)sensor reading to the boost pressure sen-

sor reading.

Are the pressure readings within 6 in hg of each other?

Ye s>>

Go To 5

No>>

Go To 3

3.INLET AIR PRESSURE SENSOR

Turn the ignition on, engine off.

Using the scan tool, read the inlet air pressure sensor value.

Is the inlet air pressure sensor reading consistent with the barometric pressure for the geographic

region?

Ye s>>

Go To 4

No>>

Relace the inlet air pressure sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 9 - ENGINE- DIAGNOSIS

AND TESTING)

Page 527 of 5267

When Monitored:

At key on.

Set Condition:

The fuel pressure sensor reading at key on does not match the expected fuel pressure reading at key on.

Possible Causes

OTHER DTC’S PRESENT

FUEL RAIL PRESSURE SENSOR

FUEL SYSTEM TAMPERING

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S PRESENT

With the scan tool, read DTCs.

Are any DTC’s present?

Ye s>>

Repair other DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.FUEL PRESSURE READING

Using the scan tool, monitor the actual fuel pressure reading while the keyis on and engine is not running.

Is the actual fuel pressure reading greater than 870 psi?

Ye s>>

Go To 3

No>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

3.FUEL RAIL PRESSURE SENSOR

Visually inspect the fuel system components for signs of tampering, pay particular attention to the fuel pressure

sensor on the fuel rail and the fuel pressure sensor wiring harness.

Were any signs of tampering discovered?

No>>

Replace the Fuel rail pressure sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Ye s>>

Restore Fuel system to original condition.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 623 of 5267

When Monitored:

With the key on.

Set Condition:

The voltage detected at the Crankshaft position sensor is below a calibrated value.

Possible Causes

CKP SENSOR

(K24) SIGNAL CIRCUIT OPEN

(K853) 5-VOLT SUPPLY CIRCUIT OPEN

(K975) RETURN CIRCUIT OPEN

(K24) SIGNAL CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

(K24) SIGNAL CIRCUIT SHORTED TO(K853) 5-VOLT SUPPLY CIRCUIT

(K24) SIGNAL CIRCUIT SHORTED TO GROUND

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY NEGATIVE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CKP SENSOR

Disconnect the CKP sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the (K24) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 2

No>>

Replace the CKP sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 629 of 5267

When Monitored:

With the key on.

Set Condition:

Voltage detected at the CKP is below acalibrated value for a calibrated amountoftime.

Possible Causes

CKP SENSOR

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED BATTERY NEGATIVE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CKP SENSOR

Disconnect the CKP sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the (K24) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 2

No>>

Replace the CKP sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

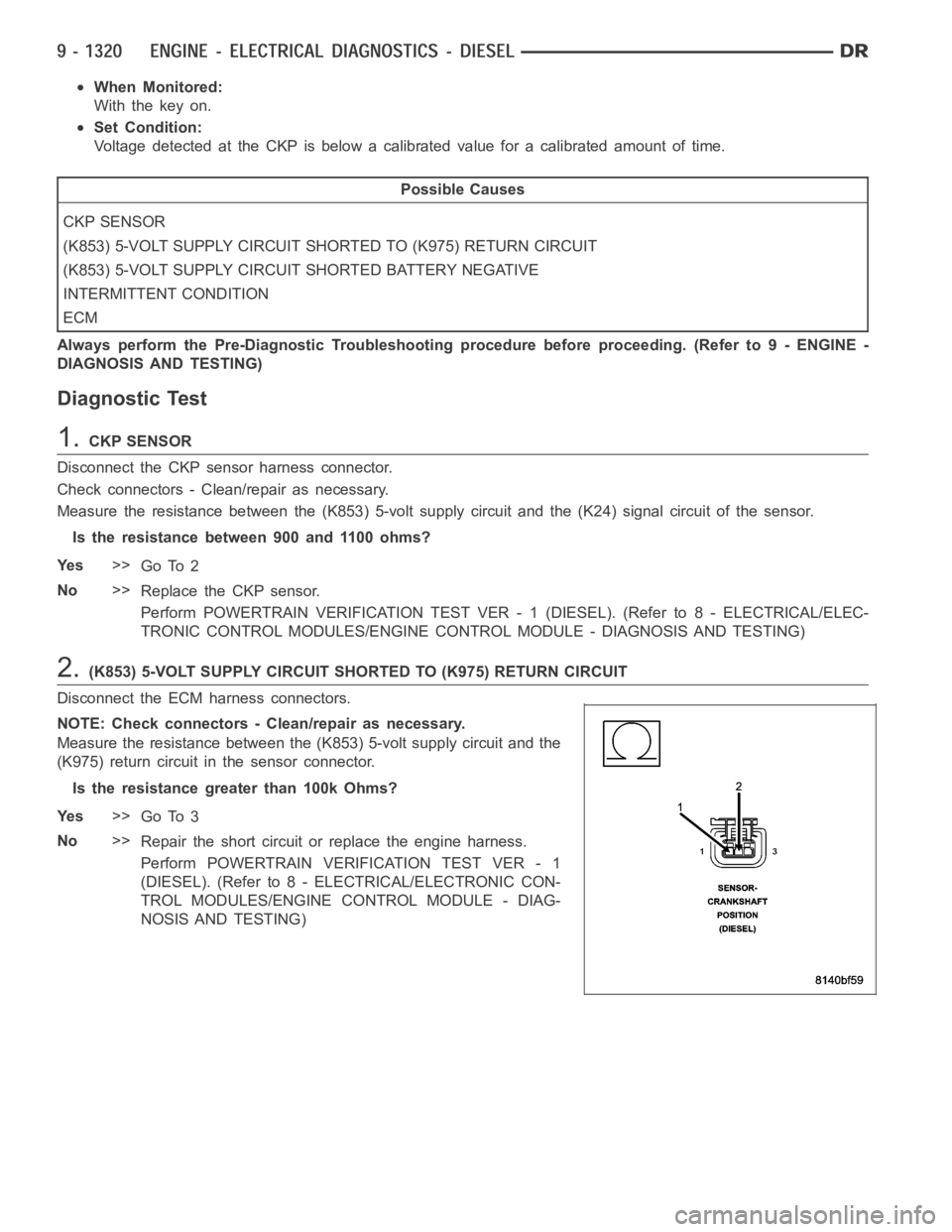

2.(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the

(K975) return circuit in the sensor connector.

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 3

No>>

Repair the short circuit or replace the engine harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 632 of 5267

When Monitored:

With the key on.

Set Condition:

Voltage detected at the CKP is above a calibrated value for a calibrated amount of time.

Possible Causes

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

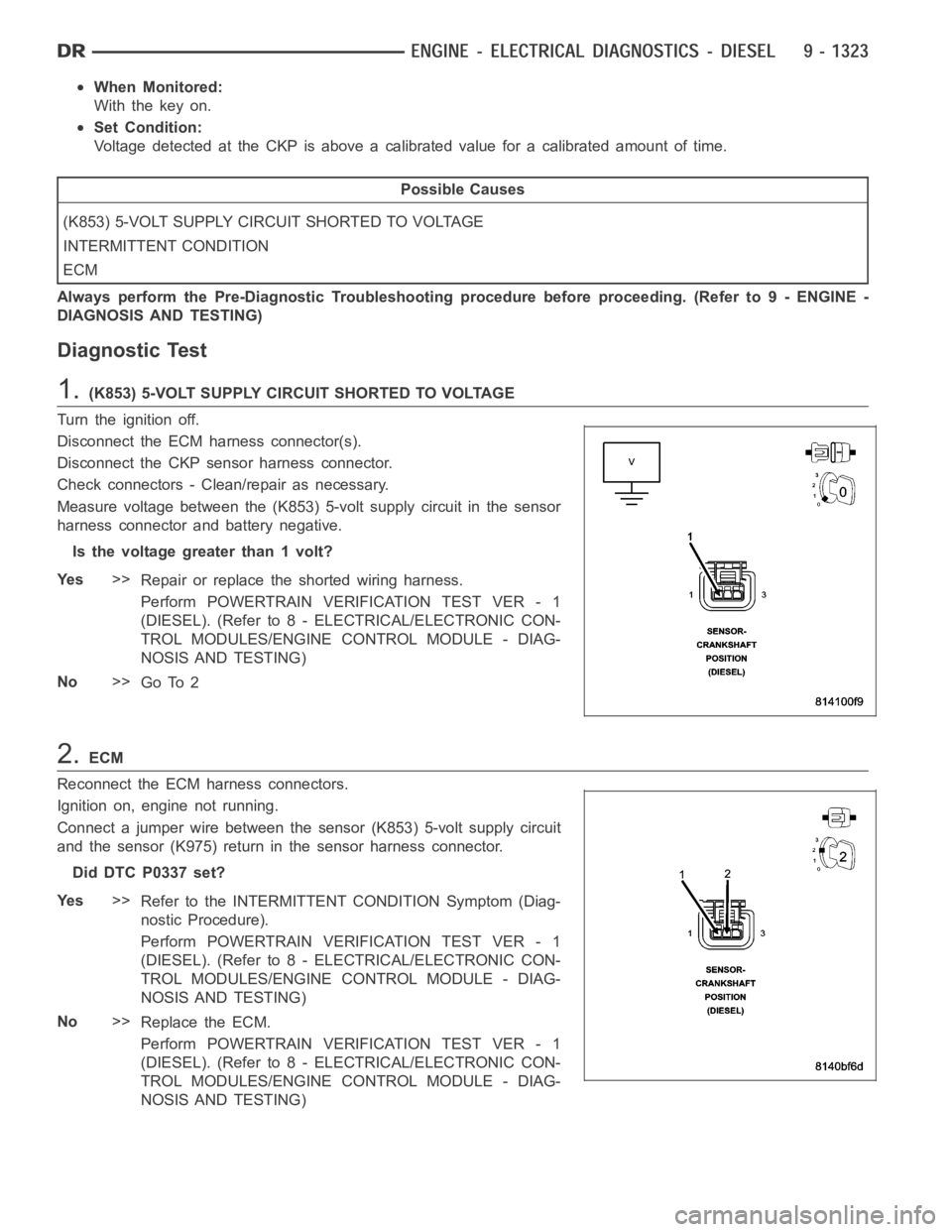

1.(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off.

Disconnect the ECM harness connector(s).

Disconnect the CKP sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure voltage between the (K853) 5-volt supply circuit in the sensor

harness connector and battery negative.

Is the voltage greater than 1 volt?

Ye s>>

Repair or replace the shorted wiring harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 2

2.ECM

Reconnect the ECM harness connectors.

Ignition on, engine not running.

Connect a jumper wire between the sensor (K853) 5-volt supply circuit

and the sensor (K975) return in the sensor harness connector.

Did DTC P0337 set?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure).

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 645 of 5267

P0381-WAIT TO START LAMP INOPERATIVE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The cluster sends a signal to the ECM that it has detected a failed wait to start lamp.

Possible Causes

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

WAIT-TO-START LIGHT BULB

WIRING/CONNECTOR PROBLEM

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.WAIT-TO-START LAMP DOES NOT COME ON

Turn the ignition off.

While watching the wait-to-start lamp, turn the ignition key on.

Did the wait-to-start lamp light?

Ye s>>

Go To 2

No>>

Go To 3

2.WAIT-TO-START LAMP STAYS ON ALL THE TIME

Turn the ignition off.

While watching the wait-to-start lamp, turn the ignition key on.

Does the wait-to-start lamp stay on all the time?

Ye s>>

Go To 3

No>>

Wait-to-start Lamp operating normally. Test passed.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 677 of 5267

P0513-SKIM INVALID KEY ERROR

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Key on

Set Condition:

Invalid Key Code received from SKIM Module

Possible Causes

GENERAL NETWORK ERROR

KEY NOT PROGRAMMED

INCORRECT KEY

INCORRECT VIN IN ECM ORSKIM

LOSSS OF COMMUNICATION BETWEEN ECM AND SKIM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With the scan tool, read the ECM DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Go To 6

2.NO COMMUNICATION WITH SKIM

With the scan tool, attempt to communicate with the SKIM.

Can the scan tool communicate with the SKIM?

Ye s>>

Go To 3

No>>

Refer to Section 8 - Electrical VEHICLE THEFT SECURITY - ELECTRICAL DIAGNOSTICS and perform

the appropriate Diagnostic Procedure.

Perform SKIM VERIFICATION. (Refer to 8 - ELECTRICAL/VEHICLE THEFT SECURITY - STANDARD

PROCEDURE)

3.SKIM TROUBLE CODES SET

With the scan tool, check for SKIM DTCs.

Are any DTCs present in the SKIM?

Ye s>>

Refer to Section 8 - Electrical VEHICLE THEFT SECURITY - ELECTRICAL DIAGNOSTICS and perform

the appropriate Diagnostic Procedure.

Perform SKIM VERIFICATION. (Refer to 8 - ELECTRICAL/VEHICLE THEFT SECURITY - STANDARD

PROCEDURE)

No>>

Go To 4