key DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 869 of 5267

When Monitored:

Continuous - key on or key off.

Set Condition:

Loss of voltage detected at the ECM for a calibrated amount of time.

Possible Causes

POOR CONNECTIONS AT THE BATTERIES

LOW BATTERY VOLTAGE

OPEN FUSED B+ TO ECM

OPEN GROUND CIRCUIT

BATTERY + SHORTED TO OTHER CIRCUITS

RETURN CIRCUIT SHORTED

BATTERY + SHORTED TO GROUND

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.POOR CONNECTIONS AT THE BATTERIES

Visually inspect the wiring at the battery for damaged wires, or corrosion.

Are the connections tight and free of corrosion?

Ye s>>

Go To 2

No>>

Repair the poor connections at the batteries.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

2.L O W B AT T E RY V O LTA G E

Measure the voltage between the positive and negative posts of the batteries.

Is the battery voltages both above 12 volts?

Ye s>>

Go To 3

No>>

Recharge or replace the battery (s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 909 of 5267

U1421-IMPLAUSIBLE IGNITION KEY OFF TIME RECEIVED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The fuel volume message the ECM is receiving is implausible. The circuit iscontinuously monitored. One Trip

fault.

Possible Causes

CAN B OPEN OR SHORTED

CLUSTER MODULE

FCM (TOTALLY INTEGRATED POWER MODULE)

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Theory of Operation

The Totally Integrated Power Module (TIPM) isn’t receiving a fuel volume signal over CAN B from the Cluster Mod-

ule. The TIPM has to send the PCM a fuel volume signal over CAN C. The signal the TIPM sends over CAN C is

implausible.

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.CAN B BUS HARDWARE DTCS ALSO ACTIVE

With a scan tool check for DTCs in the TIPM.

Are any CAN B Hardware related DTCs active at this time?

Ye s>>

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING) for the

appropriate diagnostic procedures.

Perform BODY VERIFICATION TEST – VER 1.

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 912 of 5267

P0355-IGNITION COIL #5 PRIMARY

CIRCUIT................................. 1948

P0420-1/1 CATALYTIC CONVERTER

EFFICIENCY............................. 1952

P0432-2/1 CATALYTIC CONVERTER

EFFICIENCY............................. 1955

P0441-EVAP PURGE FLOW MONITOR . . . . . 1958

P0442-EVAP LEAK MONITOR MEDIUM

(0.040) LEAK DETECTED.................. 1962

P0443-EVAP PURGE SOLENOID CIRCUIT . . 1968

P0455-EVAP LEAK MONITOR LARGE LEAK

DETECTED............................... 1972

P0460-FUEL LEVEL SENDING UNIT NO

CHANGE OVER MILES.................... 1978

P0462-FUEL LEVEL SENDING UNIT VOLTS

TOO LOW................................ 1979

P0463-FUEL LEVEL SENSOR 1 CIRCUIT

HIGH.................................... 1982

P0500-NO VEHICLE SPEED SIGNAL ....... 1986

P0505-IDLE AIR CONTROL MOTOR

CIRCUITS................................ 1989

P0513-INVALID SKREEM KEY ............. 1994

P0522-OIL PRESSURE CIRCUIT LOW ...... 1996

P0523-OIL PRESSURE CIRCUIT HIGH ..... 2000

P0601-PCM INTERNAL CONTROLLER

FAILURE................................. 2003

P0622-GENERATOR FIELD NOT

SWITCHING PROPERLY.................. 2004

P0645-A/C CLUTCH RELAY CIRCUIT . . ..... 2008

P0801-REVERSE GEAR LOCKOUT CIRCUIT

OPEN OR SHORTED...................... 2012

P1195-O2 SENSOR 1/1 SLOW DURING

CATALYST MONITOR..................... 2016

P1196-O2 SENSOR 2/1 SLOW DURING

CATALYST MONITOR..................... 2019

P126B-ASD CONTROL CIRCUIT 2 LOW .... 2022

P126C-ASD CONTROL CIRCUIT 2 HIGH .... 2026

P126D-ASD CONTROL CIRCUIT 2 OPEN . . . 2030

P126E-ASD CONTROL CIRCUIT

OVERCURRENT.......................... 2034

P1272-A/C CLUTCH CONTROL CIRCUIT 2

LOW..................................... 2038

P1273-A/C CLUTCH CONTROL CIRCUIT 2

HIGH.................................... 2041

P1274-A/C CLUTCH CONTROL CIRCUIT 2

OPEN.................................... 2045

P1275-A/C CLUTCH CONTROL CIRCUIT 2

OVERCURRENT.......................... 2049

P1277-STARTER CONTROL CIRCUIT 2 LOW

(TIPM)................................... 2052

P1278-STARTER CONTROL CIRCUIT 2

HIGH (TIPM).............................. 2055

P1279-STARTER CONTROL CIRCUIT 2

OPEN (TIPM)............................. 2058

P127A-STARTER CONTROL CIRCUIT 2

OVERCURRENT.......................... 2061

P127C-FUEL PUMP CONTROL CIRCUIT 2

LOW..................................... 2064P127D-FUEL PUMP CONTROL CIRCUIT 2

HIGH.................................... 2067

P127E-FUEL PUMP CONTROL CIRCUIT 2

OPEN (TIPM)............................. 2071

P0127F-FUEL PUMP CONTROL CIRCUIT 2

OVERCURRENT (TIPM)................... 2075

P1281-ENGINE IS COLD TOO LONG ....... 2078

P1282-FUEL PUMP/SYSTEM RELAY

CONTROL CIRCUIT....................... 2079

P1294-TARGET IDLE NOT REACHED ...... 2082

P1296-NO 5-VOLTS TO MAP SENSOR ..... 2085

P1297-NO CHANGE IN MAP FROM START

TO RUN.................................. 2089

P1388-AUTO SHUTDOWN RELAY CONTROL

CIRCUIT................................. 2094

P1389-NO ASD RELAY OUTPUT VOLTAGE

AT P C M.................................. 2097

P1391-INTERMITTENT LOSS OF CMP OR

CKP

..................................... 2100

P1398-MIS-FIRE ADAPTIVE NUMERATOR

AT L I M I T................................. 2104

P1486-EVAP LEAK MONITOR PINCHED

HOSE FOUND............................ 2106

P1492-AMBIENT/BATTERY TEMPERATURE

SENSOR VOLTAGE TOO HIGH............. 2110

P1493-AMBIENT/BATTERY TEMPERATURE

SENSOR VOLTAGE TOO LOW............. 2114

P1494-LEAK DETECTION PUMP SWITCH

OR MECHANICAL FAULT.................. 2117

P1495-LEAK DETECTION PUMP SOLENOID

CIRCUIT................................. 2121

P1499-HYDRAULIC FAN SOLENOID

CIRCUIT................................. 2126

P1594-CHARGING SYSTEM VOLTAGE TOO

HIGH.................................... 2130

P1598-A/C PRESSURE SENSOR VOLTAGE

TOO HIGH............................... 2133

P1599-A/C PRESSURE SENSOR VOLTAGE

TOO LOW................................ 2137

P1682-CHARGING SYSTEM VOLTAGE TOO

LOW..................................... 2141

P1687-NO CLUSTER BUS MESSAGE ...... 2146

P1695-BUS MESSAGE FROM BODY

CONTROL MODULE...................... 2148

P1696-PCM FAILURE EEPROM WRITE

DENIED.................................. 2151

*BRAKE SWITCH SENSE STATUS DOES

NOT CHANGE ON THE SCAN TOOL....... 2153

*CANNOT SHIFT INTO REVERSE .......... 2157

*CHECKING A/C SYSTEM OPERATION

WITH NO DTCS.......................... 2159

*CHECKING CHARGING SYSTEM

OPERATION WITH NO DTCS.............. 2163

*CHECKING RADIATOR FAN OPERATION . . 2167

*CHECKING THE PCM POWER AND

GROUNDS............................... 2169

B2277–CAN GATEWAY INTERNAL

(GATEWAY).............................. 2172

U0001–CAN C BUS CIRCUIT (GATEWAY) . . . 2172

Page 990 of 5267

When Monitored:

At a cold start, engine coolant below 98°F, Ambient/Battery Sensor readingwithin27°F,andEngineCoolant

Temperature above 170°F on the previous key off.

Set Condition:

The Oxygen Sensor signal voltage is below 0.156 of a volt for 28 seconds after starting engine.

Possible Causes

(K41) O2 1/1 SIGNAL CIRCUIT SHORTED TO GROUND

(K41) O2 1/1 SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

O2 SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.O2 SENSOR BELOW 0.16 OF A VOLT

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Start the engine.

Allow the engine to idle for 4 to 5 minutes.

With the scan tool, read the O2 Sensor voltage.

Is the voltage below 0.16 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.O2 SENSOR OPERATION

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hands

near the pulleys, belts, or fan. Do no wear loose clothing.

Disconnect the O2 Sensor harness connector.

Start the engine.

With the scan tool, monitor the O2 Sensor voltage.

IstheO2Sensorvoltageabove0.16ofavolt?

Ye s>>

Replace the O2 Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1007 of 5267

When Monitored:

At a cold start, engine coolant below 98°F, Ambient/Battery Sensor readingwithin27°F,andEngineCoolant

Temperature above 170°F on the previous key off.

Set Condition:

The Oxygen Sensor signal voltage is below 0.156 of a volt for 28 seconds after starting engine.

Possible Causes

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT SHORTED TO GROUND

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

(K141) O2 SENSOR 2/1 SIGNAL SHORTED TO THE (Z1) HEATER GROUND CIRCUIT

O2 SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.O2 SENSOR BELOW 0.16 OF A VOLT

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Start the engine.

Allow the engine to idle for 4 to 5 minutes.

With the scan tool, read the O2 Sensor voltage.

Is the voltage below 0.16 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.O2 SENSOR OPERATION

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hands

near the pulleys, belts, or fan. Do not wear loose clothing.

Disconnect the O2 Sensor harness connector.

Start the engine.

With the scan tool, monitor the O2 Sensor voltage.

IstheO2Sensorvoltageabove0.16ofavolt?

Ye s>>

Replace the O2 Sensor

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1023 of 5267

When Monitored:

At a cold start, engine coolant below 98°F, Ambient/Battery Sensor readingwithin27°F,andEngineCoolant

Temperature above 170°F on the previous key off.

Set Condition:

The Oxygen Sensor signal voltage is below 0.156 of a volt for 28 seconds after starting engine.

Possible Causes

(K43) O2 2/1 SIGNAL CIRCUIT SHORTED TO GROUND

(K43) O2 2/1 SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

O2 SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.O2 SENSOR BELOW 0.16 OF A VOLT

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Start the engine.

Allow the engine to idle for 4 to 5 minutes.

With the scan tool, read the O2 Sensor voltage.

Is the voltage below 0.16 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.O2 SENSOR OPERATION

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hands

near the pulleys, belts, or fan. Do no wear loose clothing.

Disconnect the O2 Sensor harness connector.

Start the engine.

With the scan tool, monitor the O2 Sensor voltage.

IstheO2Sensorvoltageabove0.16ofavolt?

Ye s>>

Replace the O2 Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1038 of 5267

When Monitored:

At a cold start, engine coolant below 98°F, Ambient/Battery Sensor readingwithin27°F,andEngineCoolant

Temperature above 170°F on the previous key off.

Set Condition:

The Oxygen Sensor signal voltage is below 0.156 of a volt for 28 seconds after starting engine.

Possible Causes

(K243) O2 SENSOR 2/2 SIGNAL CIRCUIT SHORTED TO GROUND

(K243) O2 SENSOR 2/2 SIGNAL CIRCUIT SHORTED TO (K900) SENSOR GROUND CIRCUIT

(K243) O2 SENSOR 2/2 SIGNAL SHORTED TO THE (Z1) HEATER GROUND CIRCUIT

O2 SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.O2 SENSOR BELOW 0.16 OF A VOLT

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Start the engine.

Allow the engine to idle for 4 to 5 minutes.

With the scan tool, read the O2 Sensor voltage.

Is the voltage below 0.16 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.O2 SENSOR OPERATION

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hands

near the pulleys, belts, or fan. Do not wear loose clothing.

Disconnect the O2 Sensor harness connector.

Start the engine.

With the scan tool, monitor the O2 Sensor voltage.

IstheO2Sensorvoltageabove0.16ofavolt?

Ye s>>

Replace the O2 Sensor

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1278 of 5267

When Monitored:

Continuously after the ignition is turned on and the battery voltage is above 10.4 volts.

Set Condition:

Not powering down, not in limp-in and time since last solenoid activation is greater than 72 micro seconds. The

PCM will set a trouble code if the actual state of the solenoid does not matchthe intended state on two con-

secutive key cycles.

Possible Causes

(F202) FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

EVAP PURGE SOLENOID

(K70) EVAP PURGE SOLENOID CONTROL CIRCUIT OPEN

(K70) EVAP PURGE SOLENOID CONTROL CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.VEHICLE HISTORY AND SERVICE BULLETIN INVESTIGATION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data if any DTC(s) are present.

Whether or not any DTC(s) are present you will want to check the following items which may assist in repairing the

customer’s complaint successfully.

Check the vehicles repair history.

If the vehicle has a repair history that pertains to the customer’s currentcomplaint, review the repair.

Inspect the vehicle for any aftermarket accessories that may have been installed incorrectly.

Check for any service bulletin(s) related to the customer’s complaint or DTC(s).

If a service bulletin applies, follow the instructions per the service bulletin.

Choose the following scenario that best applies.

The service bulletin repaired the customer’s complaint.

Testing complete.

A DTC is present, no service bulletins apply, or the service bulletin didn’t repair the customer’s complaint.

Go To 2

2.ACTIVE DTC

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 3

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1303 of 5267

P0513-INVALID SKREEM KEY

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The Gateway detects that the Secret Key message is invalid or missing. One Trip Fault.

Possible Causes

WCM/SKREEM

POWERTRAIN CONTROL MODULE

GATEWAY MODULE

COMMUNICATION PROBLEM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With the scan tool, read the Gateway Module DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.COMMUNICATION (CAN BUS or J1850)

NOTE: For vehicle communication problems, use the scan tool to refer to theNetwork Review Screen. The

screen depicts a high level view of the vehicle network. Fault and problem areas appear in red. Selecting

any of the network components allows access to the source of the problem.

Does the scan tool display a Vehicle Network problem or NO RESPONSE condition?

Ye s>>

Refer to the appropriate BUS Communication test in the Section 8 ELECTRONIC CONTROL MODULE

- ELECTRICAL DIAGNOSTICS.

No>>

Go To 3

3.SKREEM/SKIM TROUBLE CODES SET

With the scan tool, check for SKREEM/SKIM DTCs.

Are any DTCs present in the SKREEM/SKIM?

Ye s>>

Refer to Section 8 - Electrical VEHICLE THEFT SECURITY - ELECTRICAL DIAGNOSTICS and perform

the appropriate Diagnostic Procedure.

No>>

Go To 4

Page 1314 of 5267

When Monitored:

With the ignition key on and the engine running.

Set Condition:

When the PCM tries to regulate the generator field with no result during monitoring.

Possible Causes

(K125) GEN FIELD SOURCE CIRCUIT OPEN

(K20) GEN FIELD CONTROL CIRCUIT OPEN

(K20) GEN FIELD CONTROL CIRCUIT SHORTED TO GROUND

GENERATOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

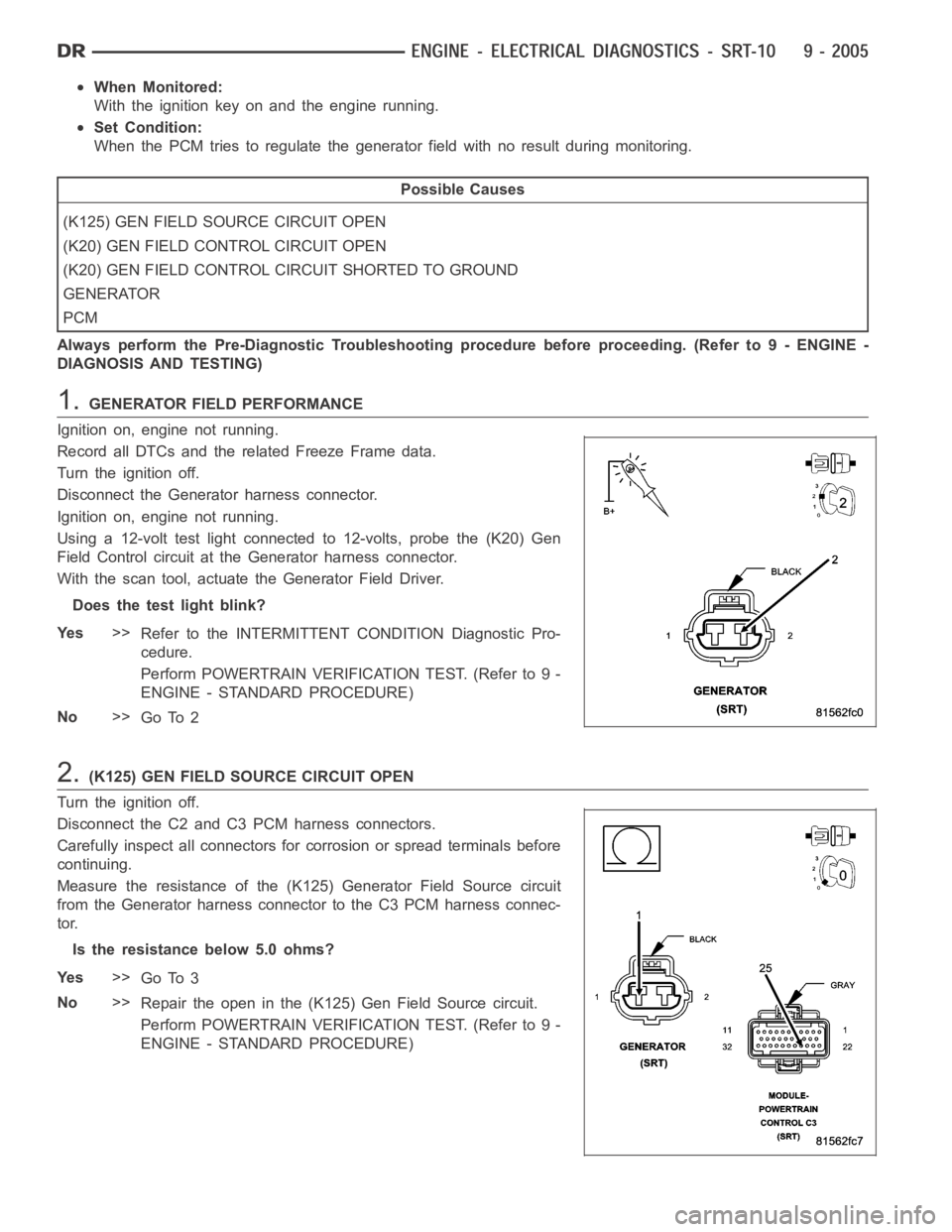

1.GENERATOR FIELD PERFORMANCE

Ignition on, engine not running.

Record all DTCs and the related Freeze Frame data.

Turn the ignition off.

Disconnect the Generator harness connector.

Ignition on, engine not running.

Using a 12-volt test light connected to 12-volts, probe the (K20) Gen

Field Control circuit at the Generator harness connector.

With the scan tool, actuate the Generator Field Driver.

Does the test light blink?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Pro-

cedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.(K125) GEN FIELD SOURCE CIRCUIT OPEN

Turn the ignition off.

Disconnect the C2 and C3 PCM harness connectors.

Carefully inspect all connectors for corrosion or spread terminals before

continuing.

Measure the resistance of the (K125) Generator Field Source circuit

from the Generator harness connector to the C3 PCM harness connec-

tor.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 3

No>>

Repair the open in the (K125) Gen Field Source circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)