lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1880 of 5267

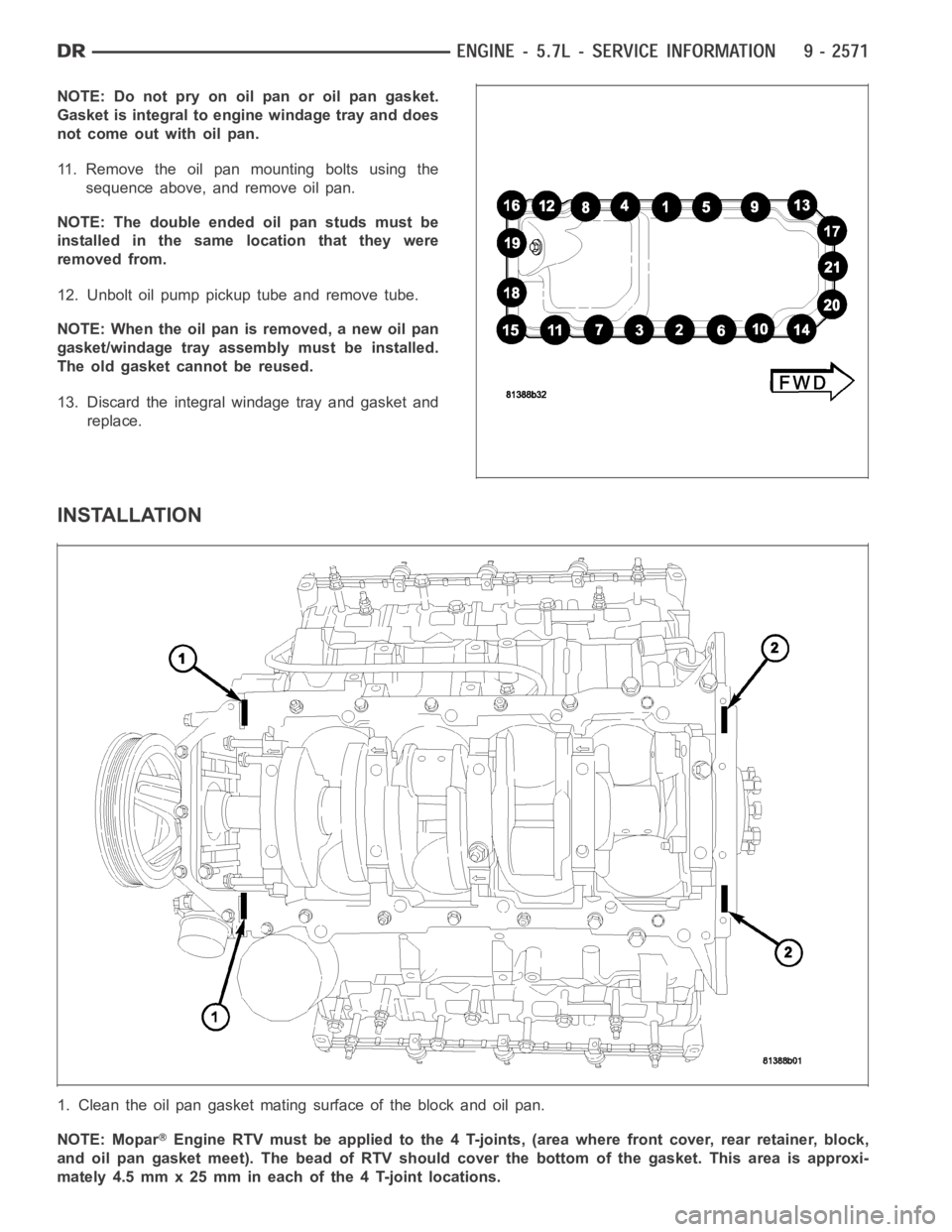

NOTE:Donotpryonoilpanoroilpangasket.

Gasket is integral to engine windage tray and does

not come out with oil pan.

11. Remove the oil pan mounting bolts using the

sequence above, and remove oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

12. Unbolt oil pump pickup tube and remove tube.

NOTE: When the oil pan is removed, a new oil pan

gasket/windage tray assembly must be installed.

The old gasket cannot be reused.

13. Discard the integral windage tray and gasket and

replace.

INSTALLATION

1. Clean the oil pan gasket mating surface of the block and oil pan.

NOTE: Mopar

Engine RTV must be applied to the 4 T-joints, (area where front cover, rear retainer, block,

and oil pan gasket meet). The bead of RTV should cover the bottom of the gasket. This area is approxi-

mately 4.5 mm x 25 mm in each of the 4 T-joint locations.

Page 1882 of 5267

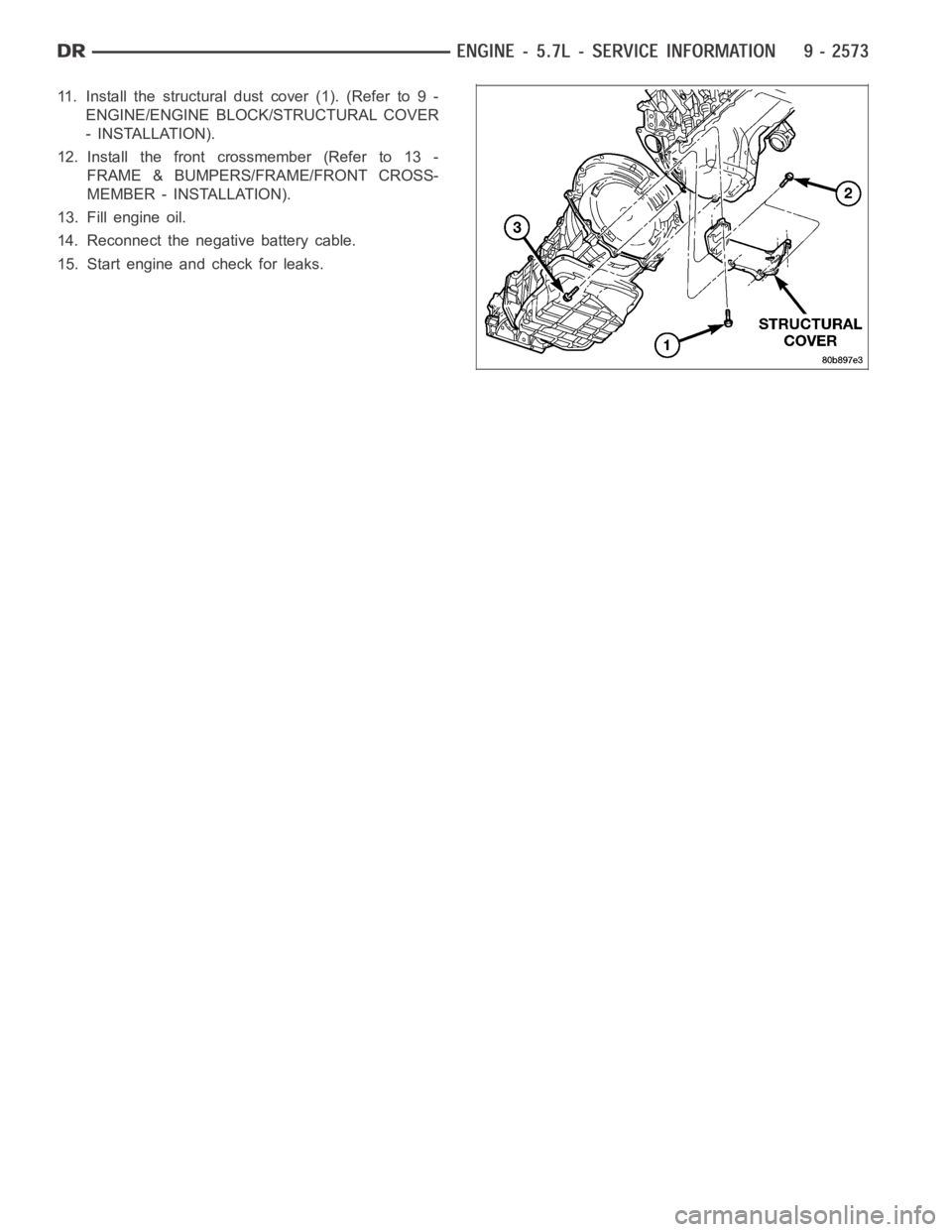

11. Install the structural dust cover (1). (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER

- INSTALLATION).

12. Install the front crossmember (Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

13. Fill engine oil.

14. Reconnect the negative battery cable.

15. Start engine and check for leaks.

Page 1888 of 5267

INSPECTION

1. Inspect the intake sealing surface for cracks, nicks and distortion.

2. Inspect the intake manifold vacuum hose fittings for looseness or blockage.

3. Inspect the manifold to throttlebody mating surface for cracks, nicks and distortion.

INSTALLATION

1. Install intake manifold seals.

2. Position intake manifold and IAFM.

3. Install intake manifold retaining bolts, and tighten in sequence from the middle bolts towards the outside in a

crisscross pattern. Torque fasteners to 12 Nꞏm (105 in. lbs.).

4. Connect electrical connectors for the following components:

Manifold Absolute Pressure (MAP) Sensor

Intake Air Temperature (IAT) Sensor

Throttle Position (TPS) Sensor

Coolant Temperature (CTS) Sensor

Idle Air Control (IAC) Motor

5. Install generator.

6. Install A/C compressor.

7. Connect Brake booster hose and Positive crankcase ventilation (PCV) hose.

8. Install resonator assembly and air inlet hose.

9. Connect negative cable to battery.

Page 1892 of 5267

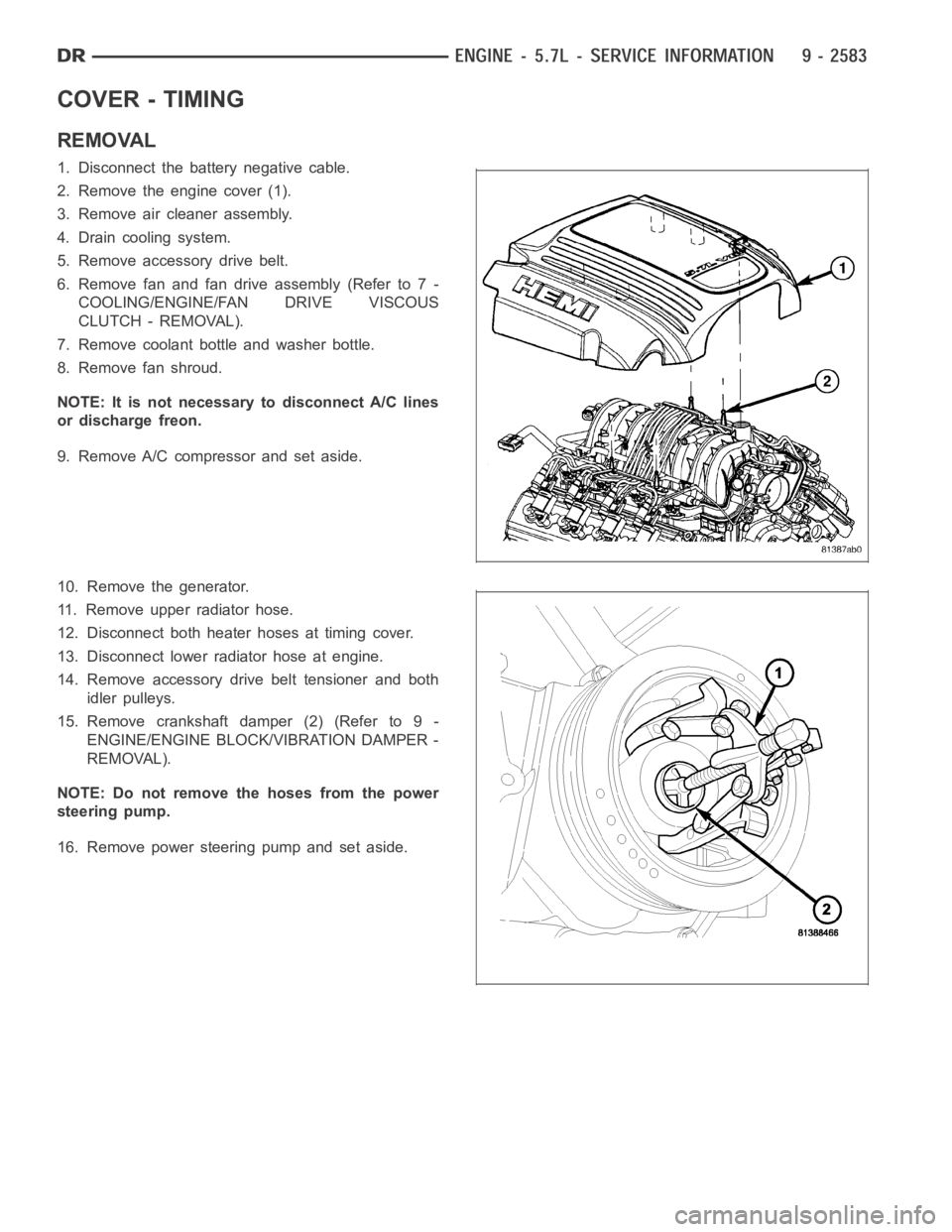

COVER - TIMING

REMOVAL

1. Disconnect the battery negative cable.

2. Remove the engine cover (1).

3. Remove air cleaner assembly.

4. Drain cooling system.

5. Remove accessory drive belt.

6. Remove fan and fan drive assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

7. Remove coolant bottle and washer bottle.

8. Remove fan shroud.

NOTE: It is not necessary to disconnect A/C lines

or discharge freon.

9. Remove A/C compressor and set aside.

10. Remove the generator.

11. Remove upper radiator hose.

12. Disconnect both heater hoses at timing cover.

13. Disconnect lower radiator hose at engine.

14. Remove accessory drive belt tensioner and both

idler pulleys.

15. Remove crankshaft damper (2) (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

NOTE: Do not remove the hoses from the power

steering pump.

16. Remove power steering pump and set aside.

Page 1894 of 5267

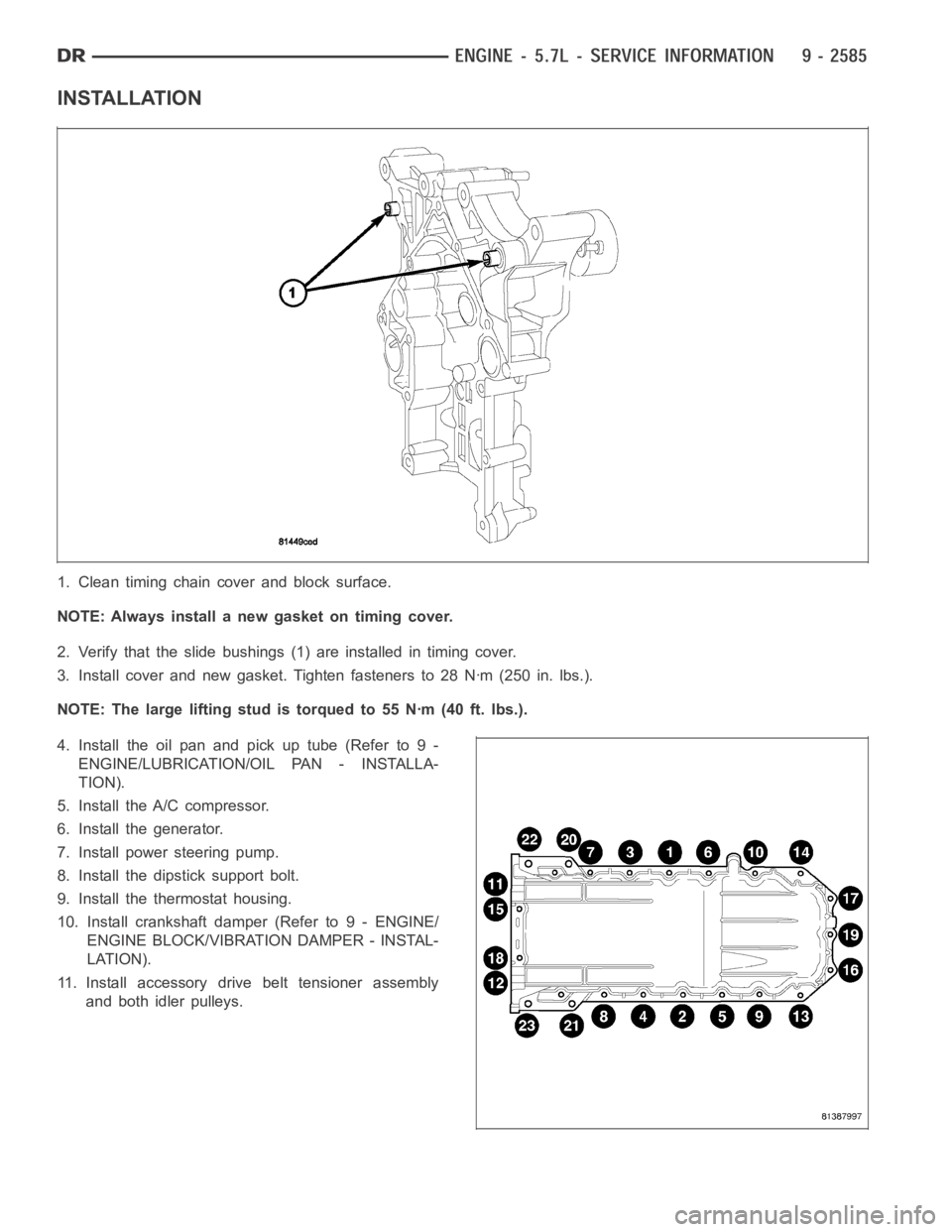

INSTALLATION

1. Clean timing chain cover and block surface.

NOTE: Always install a new gasket on timing cover.

2. Verify that the slide bushings (1) are installed in timing cover.

3. Install cover and new gasket. Tighten fasteners to 28 Nꞏm (250 in. lbs.).

NOTE: The large lifting stud is torqued to 55 Nꞏm (40 ft. lbs.).

4. Install the oil pan and pick up tube (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

5. Install the A/C compressor.

6. Install the generator.

7. Install power steering pump.

8. Install the dipstick support bolt.

9. Install the thermostat housing.

10. Install crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

11. Install accessory drive belt tensioner assembly

and both idler pulleys.

Page 1896 of 5267

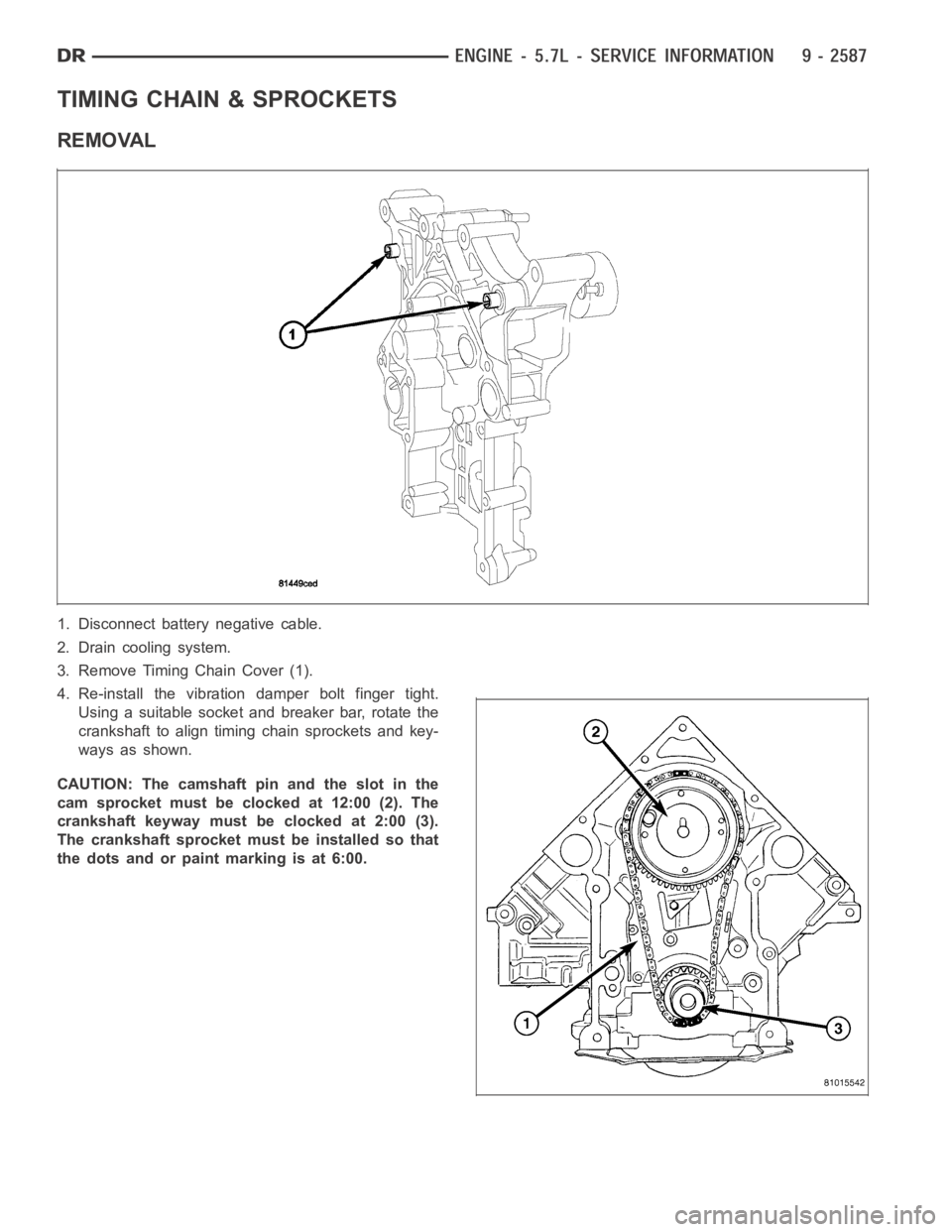

TIMING CHAIN & SPROCKETS

REMOVAL

1. Disconnect battery negative cable.

2. Drain cooling system.

3. Remove Timing Chain Cover (1).

4. Re-install the vibration damper bolt finger tight.

Using a suitable socket and breaker bar, rotate the

crankshaft to align timing chain sprockets and key-

ways as shown.

CAUTION: The camshaft pin and the slot in the

cam sprocket must be clocked at 12:00 (2). The

crankshaft keyway must be clocked at 2:00 (3).

The crankshaft sprocket must be installed so that

the dots and or paint marking is at 6:00.

Page 1898 of 5267

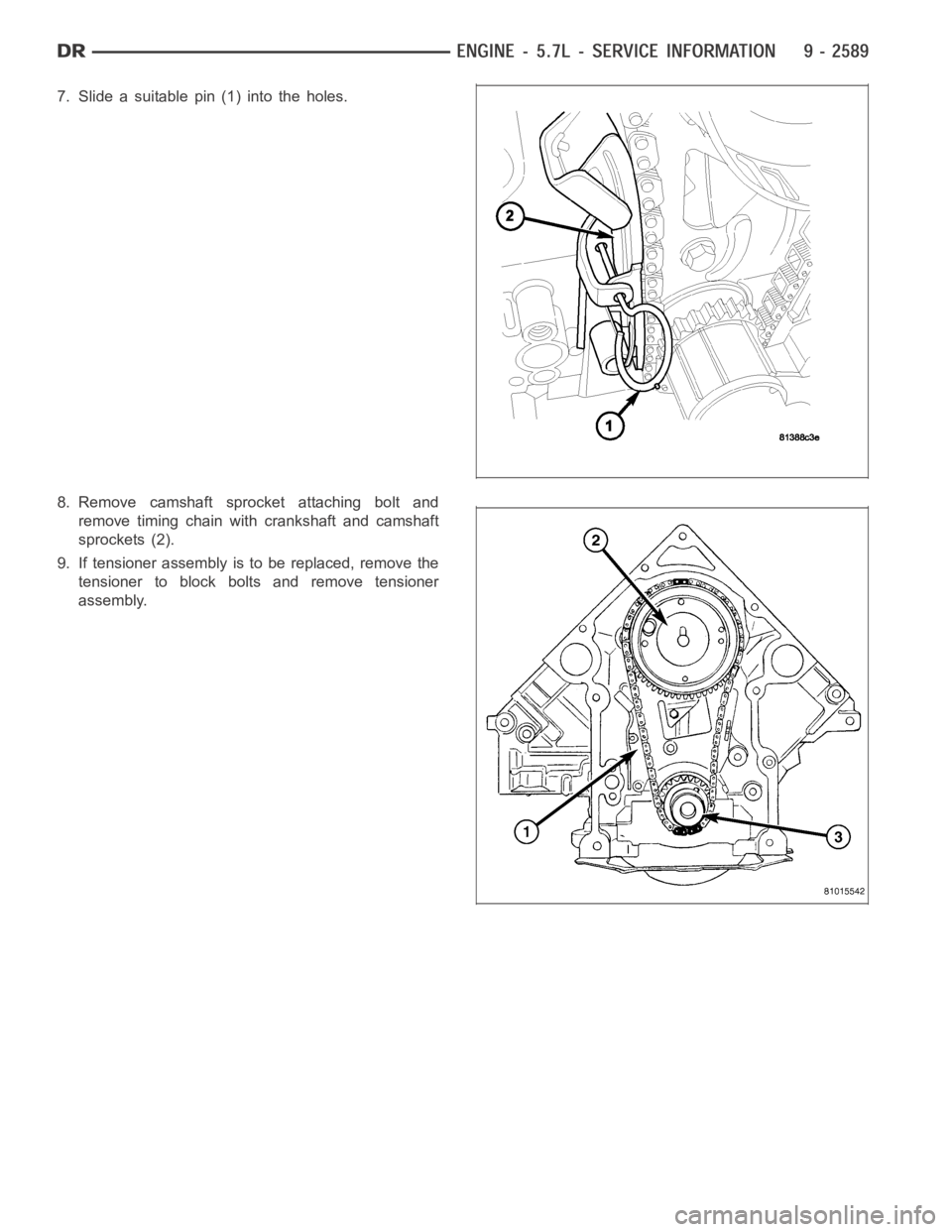

7. Slide a suitable pin (1) into the holes.

8. Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets (2).

9. If tensioner assembly is to be replaced, remove the

tensioner to block bolts and remove tensioner

assembly.

Page 1899 of 5267

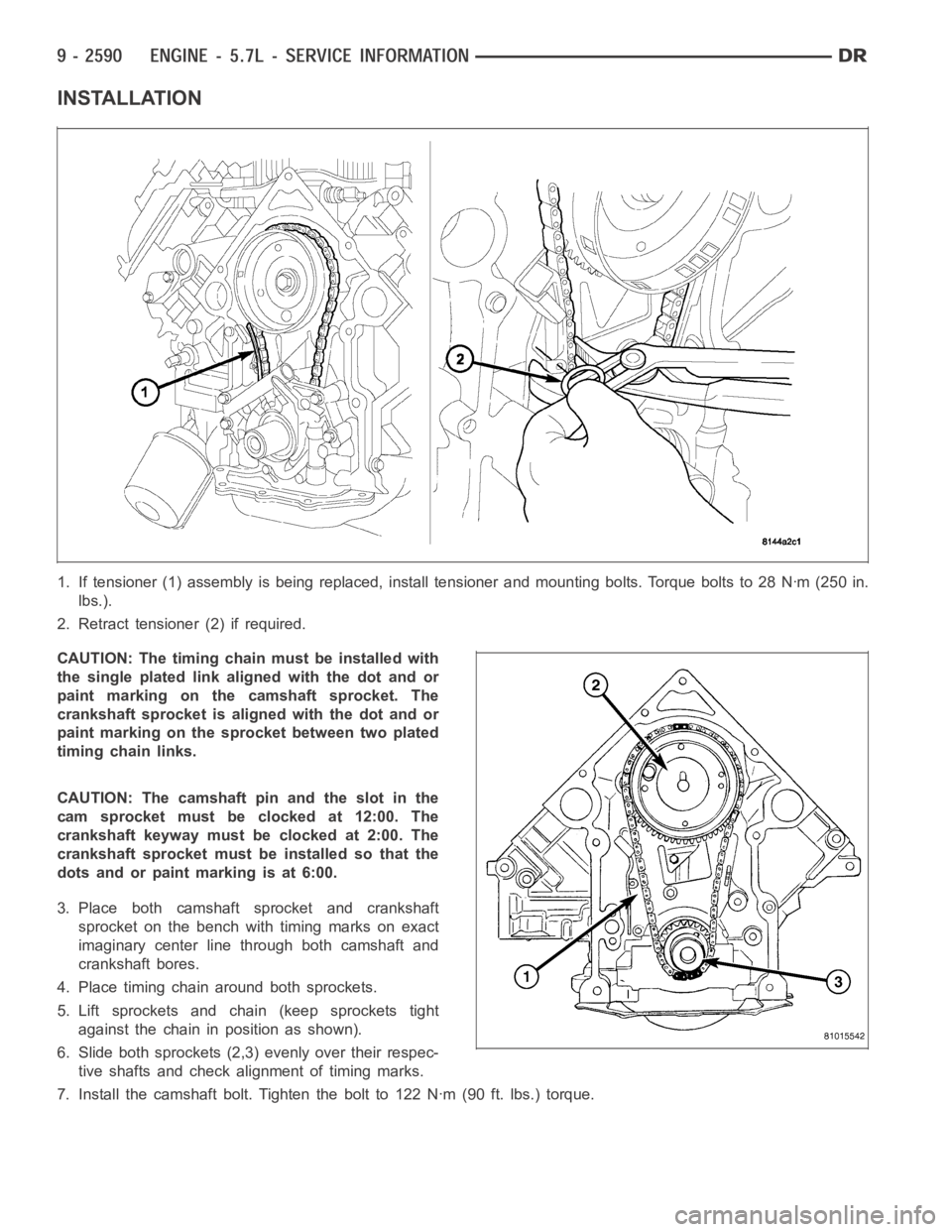

INSTALLATION

1. If tensioner (1) assembly is being replaced, install tensioner and mounting bolts. Torque bolts to 28 Nꞏm (250 in.

lbs.).

2. Retract tensioner (2) if required.

CAUTION: The timing chainmust be installed with

the single plated link aligned with the dot and or

paint marking on the camshaft sprocket. The

crankshaft sprocket is aligned with the dot and or

paint marking on the sprocket between two plated

timing chain links.

CAUTION: The camshaft pin and the slot in the

cam sprocket must be clocked at 12:00. The

crankshaft keyway must be clocked at 2:00. The

crankshaft sprocket must be installed so that the

dots and or paint marking is at 6:00.

3. Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

4. Place timing chain around both sprockets.

5. Lift sprockets and chain (keep sprockets tight

against the chain in position as shown).

6. Slide both sprockets (2,3) evenly over their respec-

tive shafts and check alignment of timing marks.

7. Install the camshaft bolt. Tighten the bolt to 122 Nꞏm (90 ft. lbs.) torque.

Page 1903 of 5267

page page

ENGINE - 5.9L DIESEL - SERVICE

INFORMATION

DESCRIPTION

DESCRIPTION - 5.9L DIESEL .............. 2596

DESCRIPTION - CRANKCASE BREATHER . . 2597

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............... 2597

DIAGNOSIS AND TESTING - SMOKE

DIAGNOSIS CHARTS..................... 2599

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS......... 2602

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.......... 2603

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS.......... 2604

STANDARD PROCEDURE—HYDROSTATIC

LOCK.................................... 2604

REMOVAL - ENGINE ........................ 2605

INSTALLATION - ENGINE ................... 2610

SPECIFICATIONS

SPECIFICATIONS - 5.9L DIESEL ........... 2615

TORQUE ................................. 2617

SPECIAL TOOLS

5.9L DIESEL ENGINE ..................... 2619

ENGINE DATA PLATE

DESCRIPTION ............................. 2621

AIR CLEANER ELEMENT

REMOVAL ................................. 2622

INSTALLATION ............................. 2623

CYLINDER HEAD

DESCRIPTION ............................. 2624

REMOVAL ................................. 2624

CLEANING

CLEANING ............................... 2626

CLEANING—CROSSHEADS ............... 2626

CLEANING—PUSHRODS .................. 2626

INSPECTION

INSPECTION............................. 2627

INSPECTION - CROSSHEADS . . ........... 2627

INSPECTION—PUSHRODS................ 2628

INSTALLATION ............................. 2628

COVER - CYLINDER HEAD

REMOVAL

REMOVAL - ROCKER HOUSING ........... 2632

REMOVAL - CYL HEAD COVER ............ 2632

REMOVAL - CYL HEAD COVER GASKET . . . 2634

CLEANING

CLEANING CYLINDER HEAD COVER ...... 2634

INSPECTION - CYLINDER HEAD COVER ..... 2634INSTALLATION

INSTALLATION - ROCKER HOUSING ....... 2634

INSTALLATION - CYL HEAD COVER ....... 2635

INSTALLATION - CYL HEAD COVER

GASKET................................. 2636

VALVES & SEATS - INTAKE/EXHAUST

DESCRIPTION ............................. 2638

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES,

GUIDES AND SPRINGS................... 2638

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION......... 2643

REMOVAL ................................. 2644

INSTALLATION ............................. 2646

ROCKER ARM

DESCRIPTION ............................. 2647

REMOVAL ................................. 2647

CLEANING ................................. 2648

INSPECTION............................... 2648

INSTALLATION ............................. 2649

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER

BLOCK REFACING........................ 2651

STANDARD PROCEDURE - CYLINDER

BORE - DE-GLAZE........................ 2651

STANDARD PROCEDURE—CYLINDER

BORE REPAIR............................ 2652

STANDARD PROCEDURE - CAM BORE

REPAIR.................................. 2655

INSPECTION............................... 2655

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

CAMSHAFT BEARINGS................... 2657

CAMSHAFT .............................. 2657

INSPECTION

............................... 2659

INSTALLATION

CAMSHAFT BEARINGS................... 2661

CAMSHAFT .............................. 2661

BEARINGS - CONNECTING ROD

STANDARD PROCEDURE - CONNECTING

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE................... 2663

CRANKSHAFT & GEAR

DESCRIPTION ............................. 2664

REMOVAL - GEAR .......................... 2664

INSTALLATION - GEAR ..................... 2664

BEARINGS - CRANKSHAFT MAIN

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE ............................. 2665

Page 1905 of 5267

ENGINE - 5.9L DIESEL - SERVICE INFORMATION

DESCRIPTION

DESCRIPTION - 5.9L DIESEL

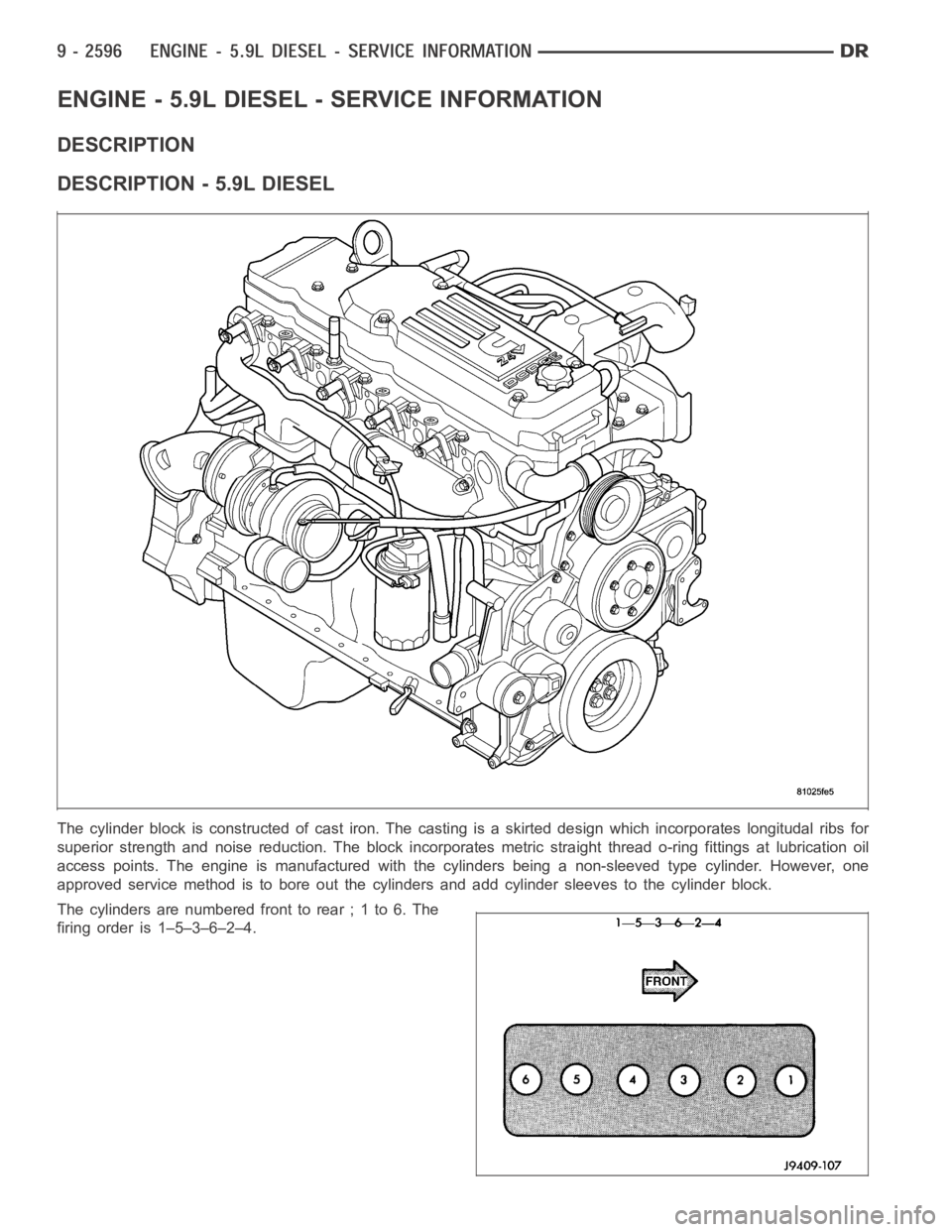

The cylinder block is constructed of cast iron. The casting is a skirted design which incorporates longitudal ribs for

superior strength and noise reduction. The block incorporates metric straight thread o-ring fittings at lubrication oil

access points. The engine is manufactured with the cylinders being a non-sleeved type cylinder. However, one

approved service method is to bore out the cylinders and add cylinder sleeves to the cylinder block.

The cylinders are numbered front to rear ; 1 to 6. The

firing order is 1–5–3–6–2–4.