lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1865 of 5267

COVER - STRUCTURAL

DESCRIPTION

The structural dust cover is made of die cast aluminum and joins the lower half of the transmission bell housing to

the engine.

OPERATION

The structural cover provides additional powertrain stiffness and reduces noise and vibration.

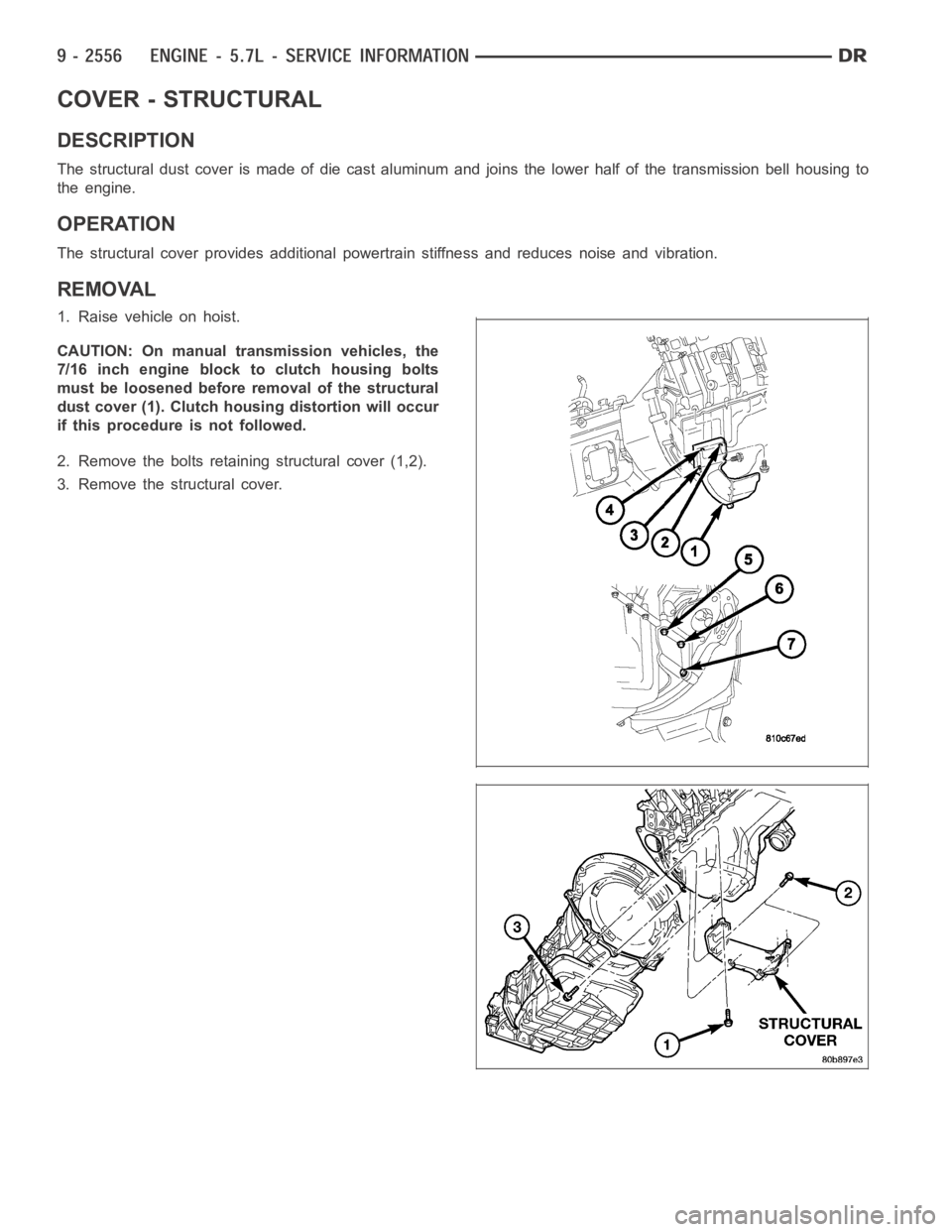

REMOVAL

1. Raise vehicle on hoist.

CAUTION: On manual transmission vehicles, the

7/16 inch engine block to clutch housing bolts

must be loosened before removal of the structural

dust cover (1). Clutch housing distortion will occur

if this procedure is not followed.

2. Remove the bolts retaining structural cover (1,2).

3. Remove the structural cover.

Page 1866 of 5267

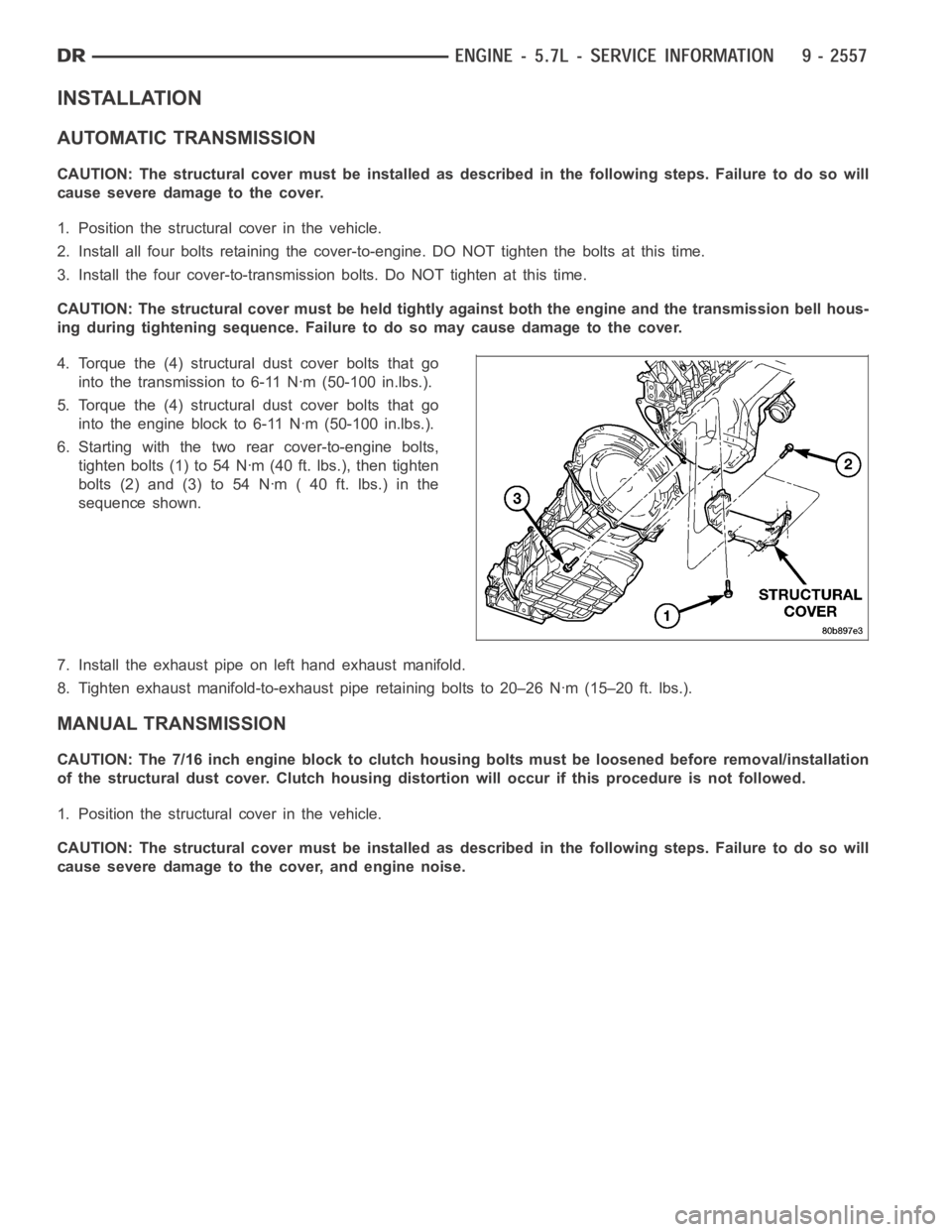

INSTALLATION

AUTOMATIC TRANSMISSION

CAUTION: The structural cover must be installed as described in the following steps. Failure to do so will

cause severe damage to the cover.

1. Position the structural cover in the vehicle.

2. Install all four bolts retaining the cover-to-engine. DO NOT tighten the bolts at this time.

3. Install the four cover-to-transmission bolts. Do NOT tighten at this time.

CAUTION: The structural cover must be held tightly against both the engineand the transmission bell hous-

ing during tightening sequence. Failure to do so may cause damage to the cover.

4. Torque the (4) structural dust cover bolts that go

intothetransmissionto6-11Nꞏm(50-100in.lbs.).

5. Torque the (4) structural dust cover bolts that go

into the engine block to 6-11 Nꞏm (50-100 in.lbs.).

6. Starting with the two rearcover-to-engine bolts,

tighten bolts (1) to 54 Nꞏm (40 ft. lbs.), then tighten

bolts(2)and(3)to54Nꞏm(40ft.lbs.)inthe

sequence shown.

7. Install the exhaust pipe on left hand exhaust manifold.

8. Tighten exhaust manifold-to-exhaust pipe retaining bolts to 20–26 Nꞏm(15–20 ft. lbs.).

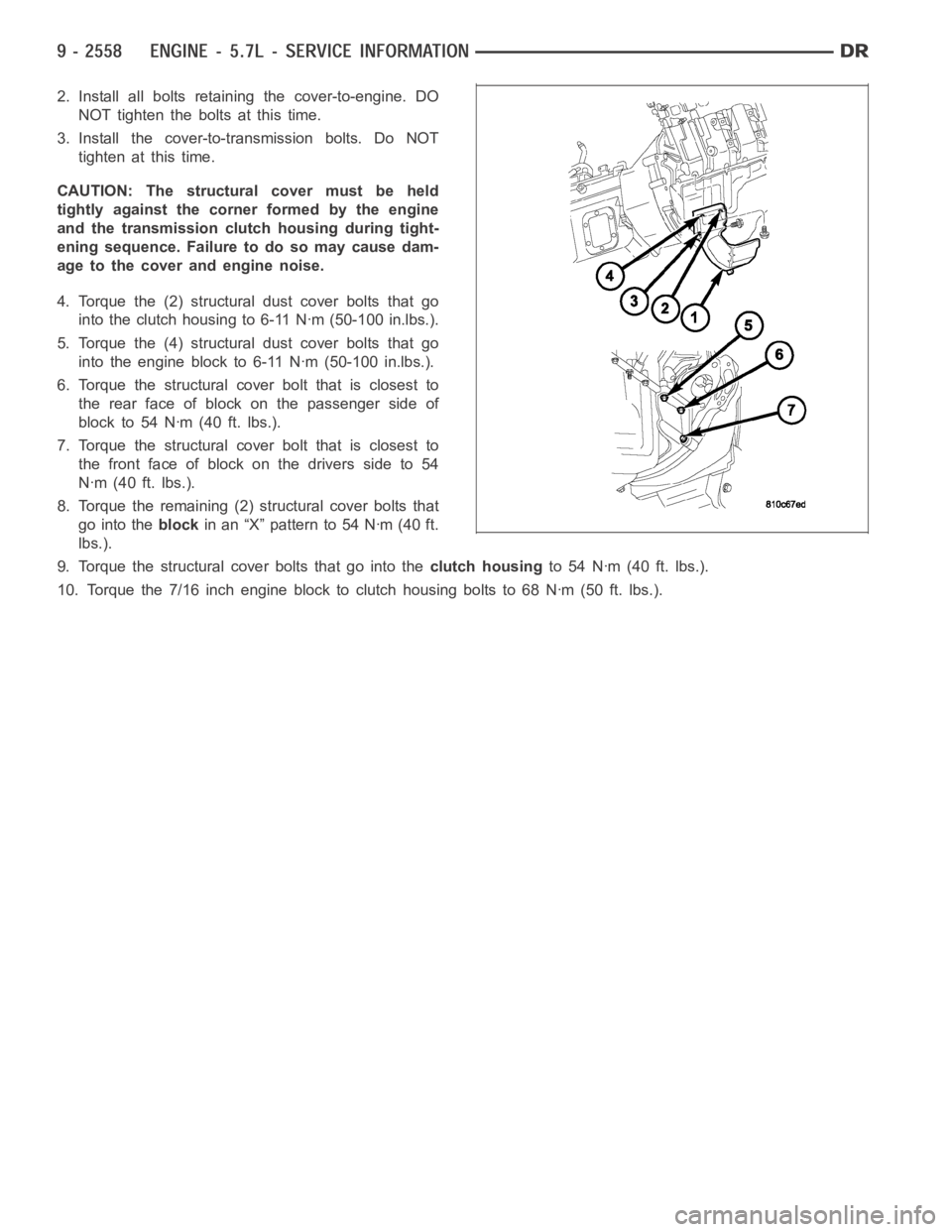

MANUAL TRANSMISSION

CAUTION: The 7/16 inch engine block to clutch housing bolts must be loosened before removal/installation

of the structural dust cover. Clutch housing distortion will occur if thisprocedure is not followed.

1. Position the structural cover in the vehicle.

CAUTION: The structural cover must be installed as described in the following steps. Failure to do so will

cause severe damage to the cover, and engine noise.

Page 1867 of 5267

2. Install all bolts retaining the cover-to-engine. DO

NOT tighten the bolts at this time.

3. Install the cover-to-transmission bolts. Do NOT

tighten at this time.

CAUTION: The structural cover must be held

tightly against the corner formed by the engine

and the transmission clutch housing during tight-

ening sequence. Failure to do so may cause dam-

age to the cover and engine noise.

4. Torque the (2) structural dust cover bolts that go

into the clutch housing to 6-11 Nꞏm (50-100 in.lbs.).

5. Torque the (4) structural dust cover bolts that go

into the engine block to 6-11 Nꞏm (50-100 in.lbs.).

6. Torque the structural cover bolt that is closest to

the rear face of block on the passenger side of

blockto54Nꞏm(40ft.lbs.).

7. Torque the structural cover bolt that is closest to

the front face of block on the drivers side to 54

Nꞏm (40 ft. lbs.).

8. Torque the remaining (2) structural cover bolts that

go into theblockin an “X” pattern to 54 Nꞏm (40 ft.

lbs.).

9. Torque the structural cover bolts that go into theclutch housingto 54 Nꞏm (40 ft. lbs.).

10. Torque the 7/16 inch engine block to clutch housing bolts to 68 Nꞏm (50 ft.lbs.).

Page 1869 of 5267

REMOVAL

1. Disconnect the negative battery cable.

2. Remove the intake manifold. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

3. Remove wiring harness connectors from the MDS solenoids.

4. Remove hold down bolt from MDS solenoid.

5. Remove MDS solenoid.

INSTALLATION

1. Verify that MDS bores are free of debris, before solenoid installation.

2. Install MDS solenoid fully into block.

3. Install hold down bolt and torque to 11 Nꞏm (97 in. lbs.).

4. Reconnect the MDS wiring harness to the solenoids.

5. Install the intake manifold. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

Page 1872 of 5267

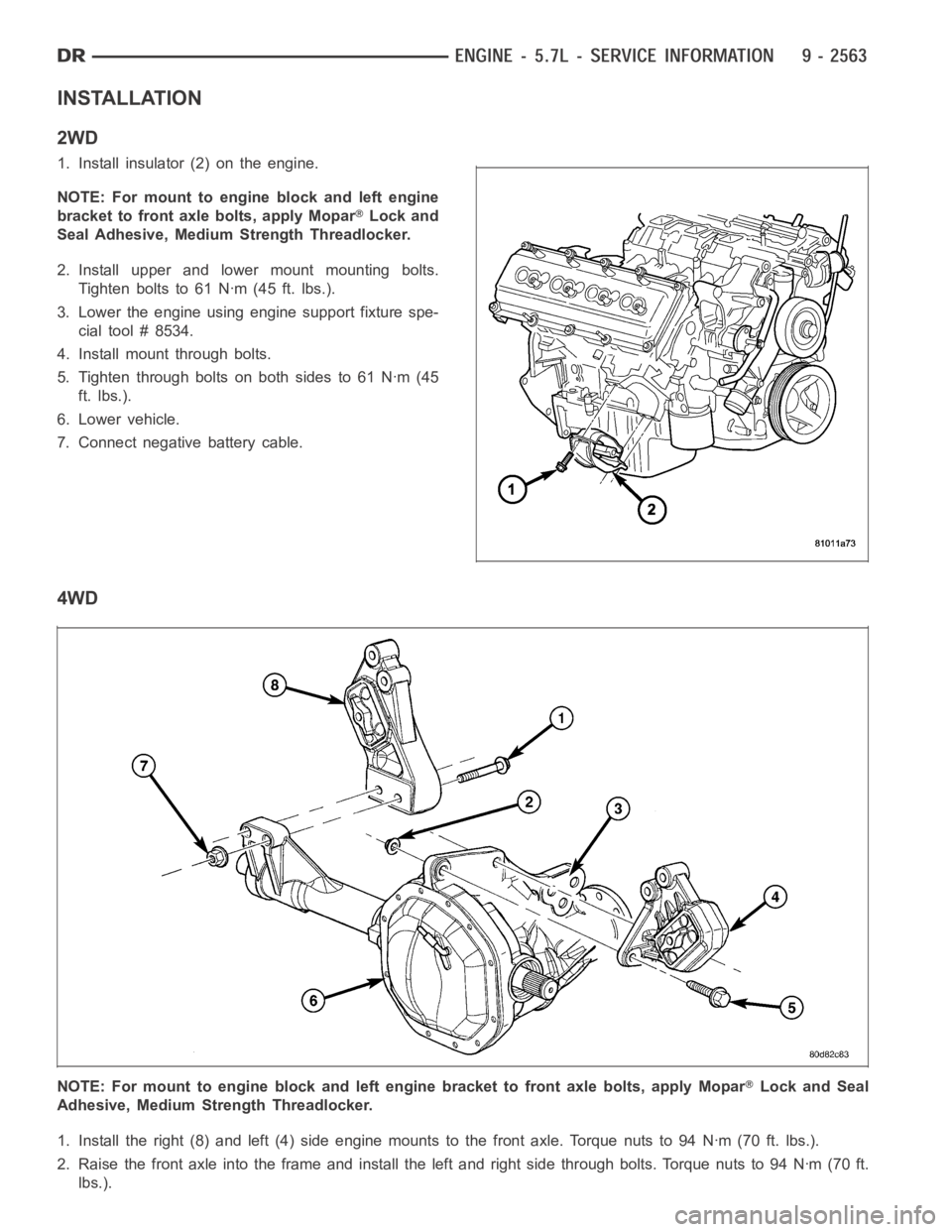

INSTALLATION

2WD

1. Install insulator (2) on the engine.

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply Mopar

Lock and

Seal Adhesive, Medium Strength Threadlocker.

2. Install upper and lower mount mounting bolts.

Tighten bolts to 61 Nꞏm (45 ft. lbs.).

3. Lower the engine using engine support fixture spe-

cial tool # 8534.

4. Install mount through bolts.

5. Tighten through bolts on both sides to 61 Nꞏm (45

ft. lbs.).

6. Lower vehicle.

7. Connect negative battery cable.

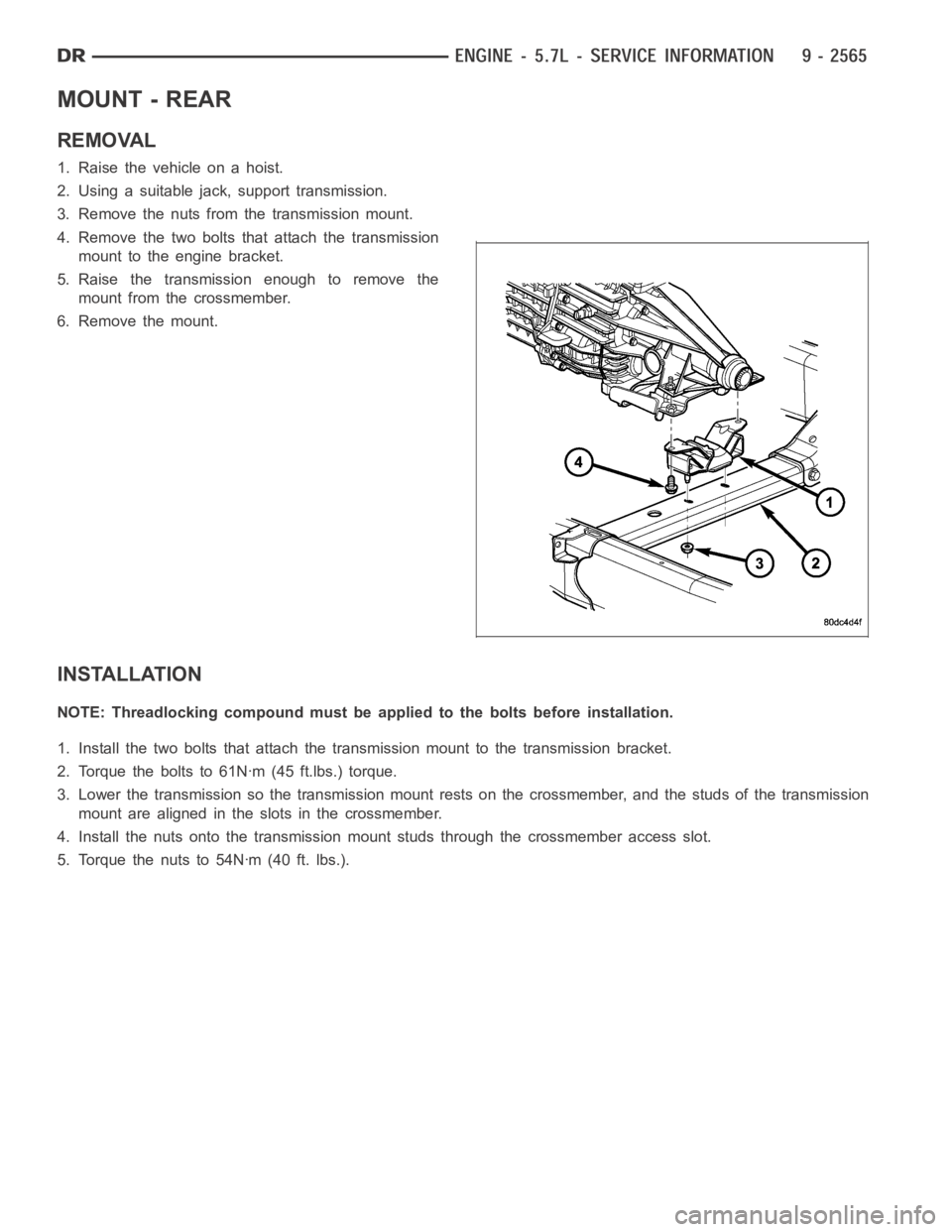

4WD

NOTE: For mount to engine block and left engine bracket to front axle bolts,apply MoparLock and Seal

Adhesive, Medium Strength Threadlocker.

1. Install the right (8) and left (4) side engine mounts to the front axle. Torque nuts to 94 Nꞏm (70 ft. lbs.).

2. Raise the front axle into the frame and install the left and right side through bolts. Torque nuts to 94 Nꞏm (70 ft.

lbs.).

Page 1874 of 5267

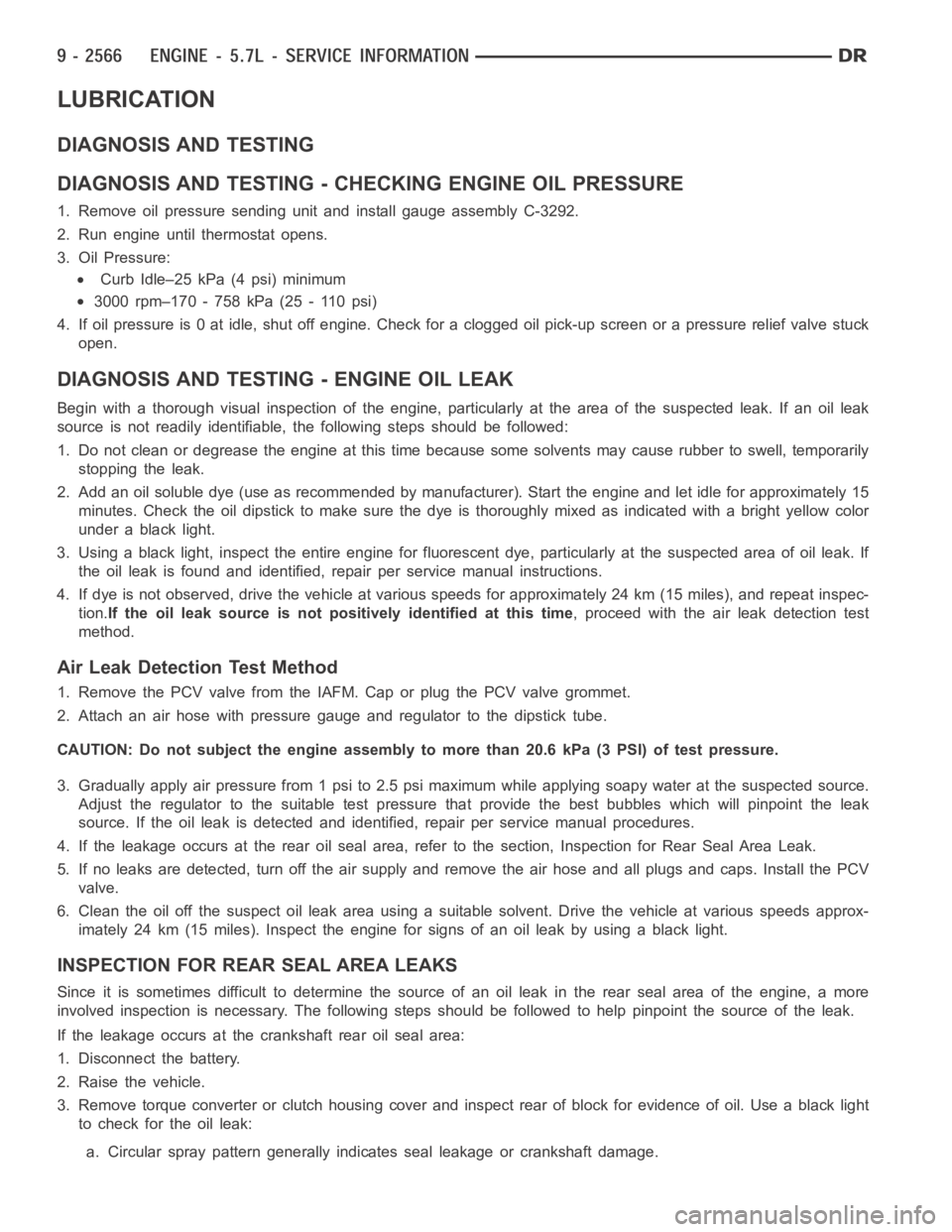

MOUNT - REAR

REMOVAL

1. Raise the vehicle on a hoist.

2. Using a suitable jack, support transmission.

3. Remove the nuts from the transmission mount.

4. Remove the two bolts that attach the transmission

mount to the engine bracket.

5. Raise the transmission enough to remove the

mount from the crossmember.

6. Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to the bolts before installation.

1. Install the two bolts that attach the transmission mount to the transmission bracket.

2. Torque the bolts to 61Nꞏm (45 ft.lbs.) torque.

3. Lower the transmission so the transmission mount rests on the crossmember, and the studs of the transmission

mount are aligned in the slots in the crossmember.

4. Install the nuts onto the transmission mount studs through the crossmember access slot.

5. Torque the nuts to 54Nꞏm (40 ft. lbs.).

Page 1875 of 5267

LUBRICATION

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHECKING ENGINE OIL PRESSURE

1. Remove oil pressure sending unit and install gauge assembly C-3292.

2. Run engine until thermostat opens.

3. Oil Pressure:

Curb Idle–25 kPa (4 psi) minimum

3000 rpm–170 - 758 kPa (25 - 110 psi)

4. If oil pressure is 0 at idle, shut off engine. Check for a clogged oil pick-up screen or a pressure relief valve stuck

open.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the engine, particularly at thearea of the suspected leak. If an oil leak

source is not readily identifiable, thefollowingstepsshouldbefollowed:

1. Do not clean or degrease the engine at this time because some solvents maycause rubber to swell, temporarily

stopping the leak.

2. Add an oil soluble dye (use as recommended by manufacturer). Start the engine and let idle for approximately 15

minutes. Check the oil dipstick to make sure the dye is thoroughly mixed as indicated with a bright yellow color

under a black light.

3. Using a black light, inspect the entire engine for fluorescent dye, particularly at the suspected area of oil leak. If

the oil leak is found and identified, repair per service manual instructions.

4. If dye is not observed, drive the vehicle at various speeds for approximately 24 km (15 miles), and repeat inspec-

tion.If the oil leak source is not positively identified at this time, proceed with the air leak detection test

method.

Air Leak Detection Test Method

1. Remove the PCV valve from the IAFM. Cap or plug the PCV valve grommet.

2. Attach an air hose with pressure gauge and regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to more than 20.6 kPa (3 PSI) of test pressure.

3. Gradually apply air pressure from 1 psi to 2.5 psi maximum while applyingsoapy water at the suspected source.

Adjust the regulator to the suitable test pressure that provide the best bubbles which will pinpoint the leak

source. If the oil leak is detected and identified, repair per service manual procedures.

4. If the leakage occurs at the rear oil seal area, refer to the section, Inspection for Rear Seal Area Leak.

5. If no leaks are detected, turn off the air supply and remove the air hose and all plugs and caps. Install the PCV

valve.

6. Clean the oil off the suspect oil leak area using a suitable solvent. Drive the vehicle at various speeds approx-

imately 24 km (15 miles). Inspect the engine for signs of an oil leak by usinga black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

Page 1876 of 5267

b. Where leakage tends to run straight down, possible causes are a porous block, distributor seal, camshaft

bore cup plugs oil galley pipe plugs, oil filter runoff, and main bearing cap to cylinder block mating surfaces.

4. If no leaks are detected, pressurize the crankcase as outlined in the, Inspection (Engine oil Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled.

Page 1878 of 5267

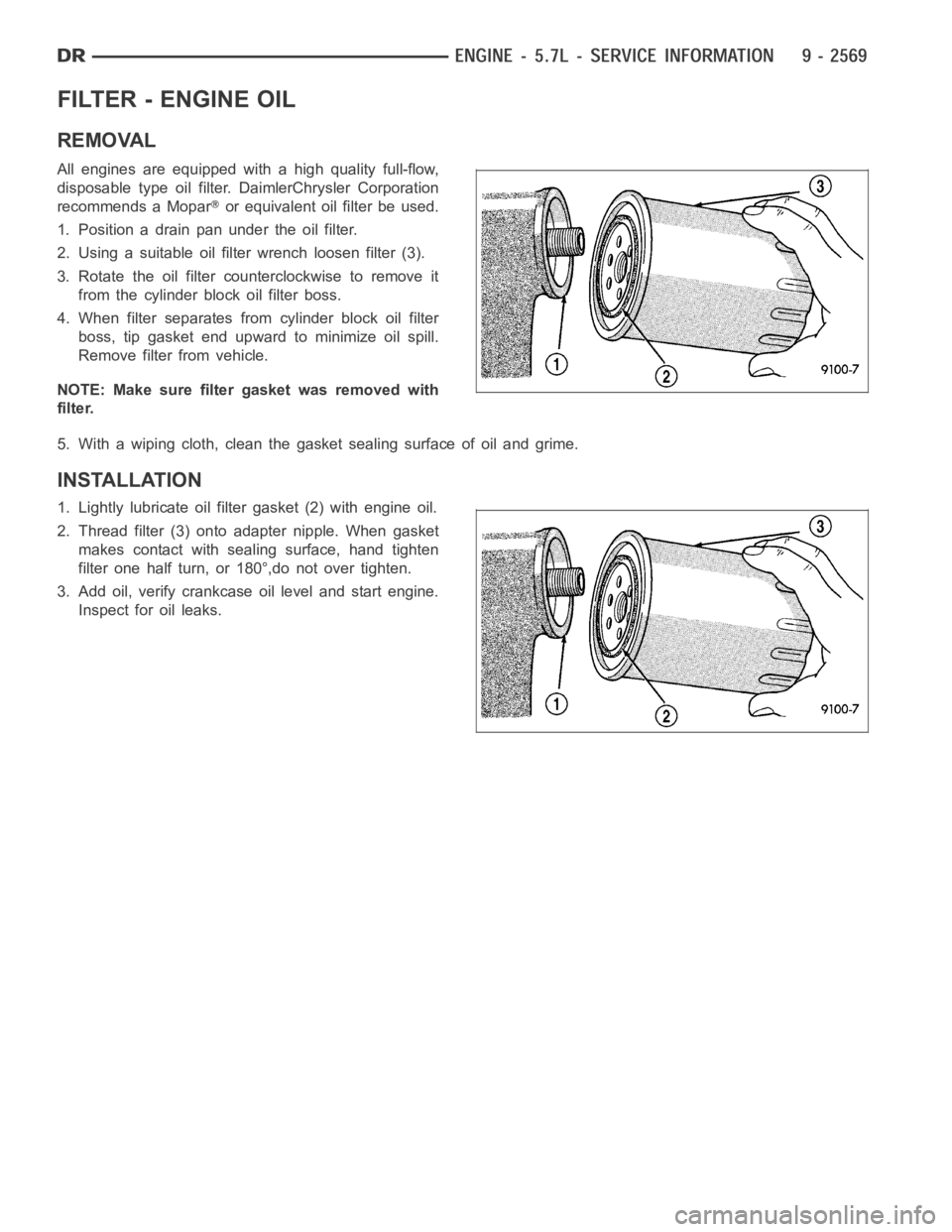

FILTER - ENGINE OIL

REMOVAL

All engines are equipped with a high quality full-flow,

disposable type oil filter. DaimlerChrysler Corporation

recommends a Mopar

or equivalent oil filter be used.

1. Position a drain pan under the oil filter.

2. Using a suitable oil filter wrench loosen filter (3).

3. Rotate the oil filter counterclockwise to remove it

from the cylinder block oil filter boss.

4. When filter separates from cylinder block oil filter

boss, tip gasket end upward to minimize oil spill.

Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with

filter.

5. With a wiping cloth, clean the gasket sealing surface of oil and grime.

INSTALLATION

1. Lightly lubricate oil filter gasket (2) with engine oil.

2. Thread filter (3) onto adapter nipple. When gasket

makes contact with sealing surface, hand tighten

filter one half turn, or 180°,do not over tighten.

3. Add oil, verify crankcase oil level and start engine.

Inspect for oil leaks.

Page 1879 of 5267

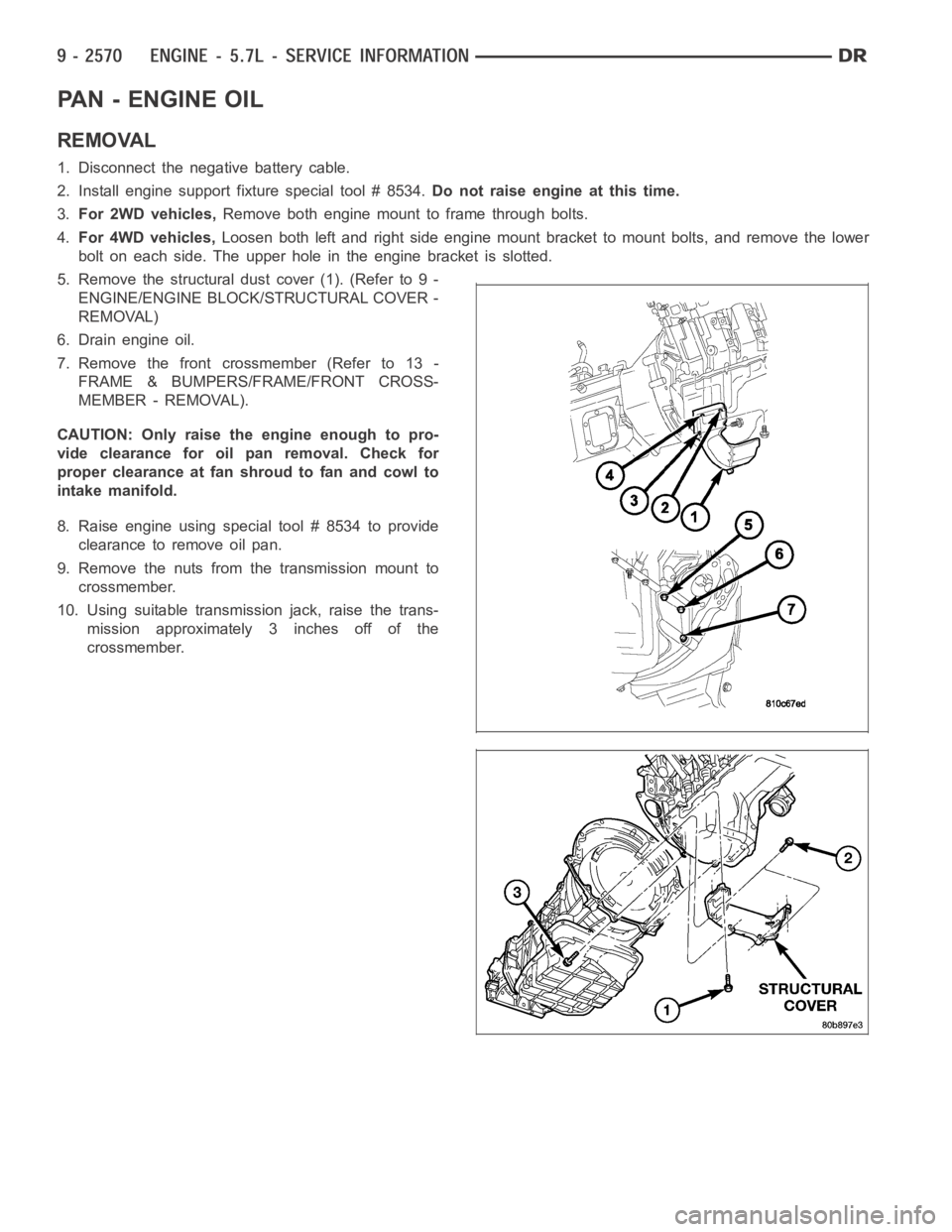

PA N - E N G I N E O I L

REMOVAL

1. Disconnect the negative battery cable.

2. Install engine support fixture special tool # 8534.Do not raise engine at this time.

3.For 2WD vehicles,Remove both engine mount to frame through bolts.

4.For 4WD vehicles,Loosen both left and right side engine mount bracket to mount bolts, and remove the lower

bolt on each side. The upper hole in the engine bracket is slotted.

5. Remove the structural dust cover (1). (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

6. Drain engine oil.

7. Remove the front crossmember (Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to pro-

vide clearance for oil pan removal. Check for

proper clearance at fan shroud to fan and cowl to

intake manifold.

8. Raise engine using special tool # 8534 to provide

clearance to remove oil pan.

9. Remove the nuts from the transmission mount to

crossmember.

10. Using suitable transmission jack, raise the trans-

mission approximately 3 inches off of the

crossmember.