charging DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1768 of 5267

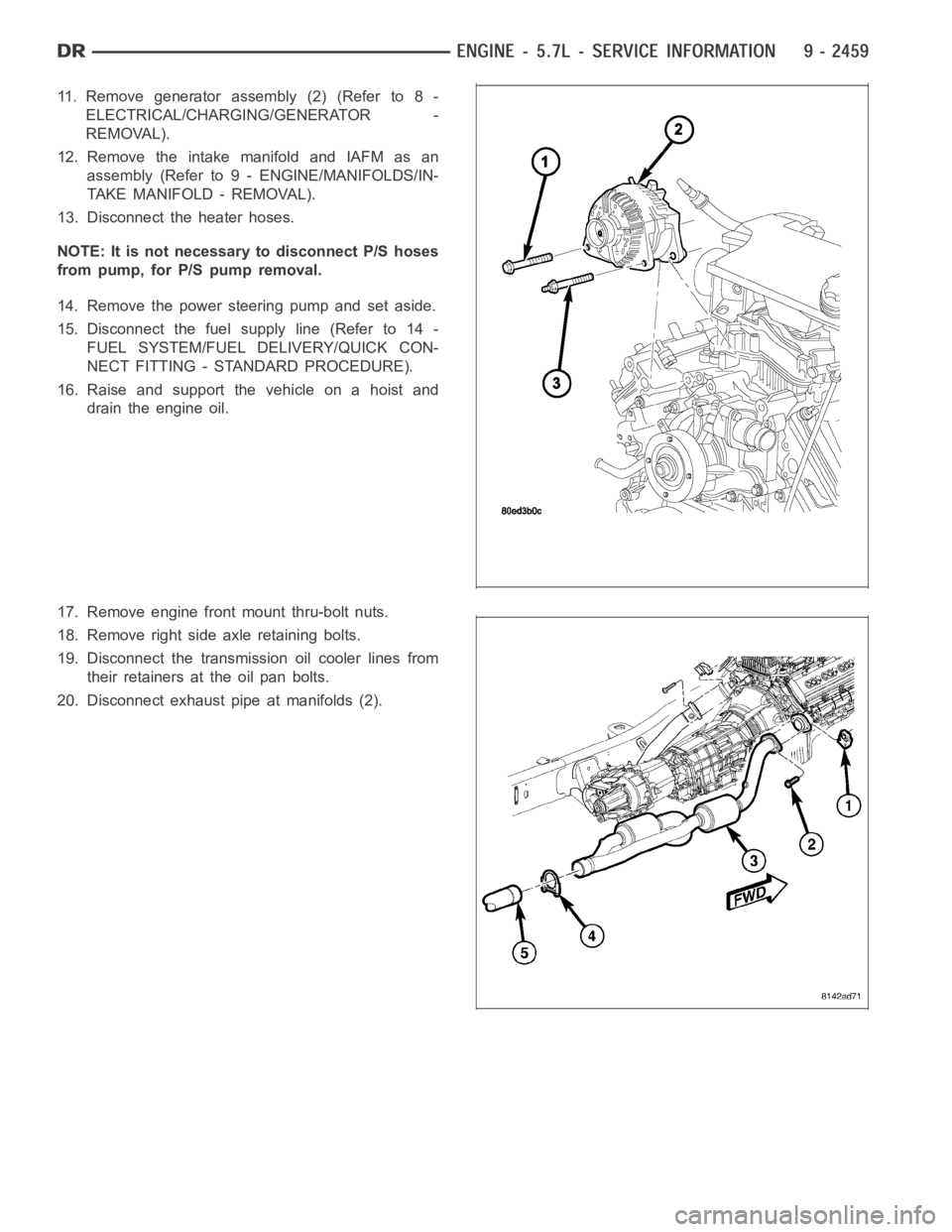

11. Remove generator assembly (2) (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

12. Remove the intake manifold and IAFM as an

assembly (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - REMOVAL).

13. Disconnect the heater hoses.

NOTE: It is not necessary to disconnect P/S hoses

from pump, for P/S pump removal.

14. Remove the power steering pump and set aside.

15. Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

16. Raise and support the vehicle on a hoist and

drain the engine oil.

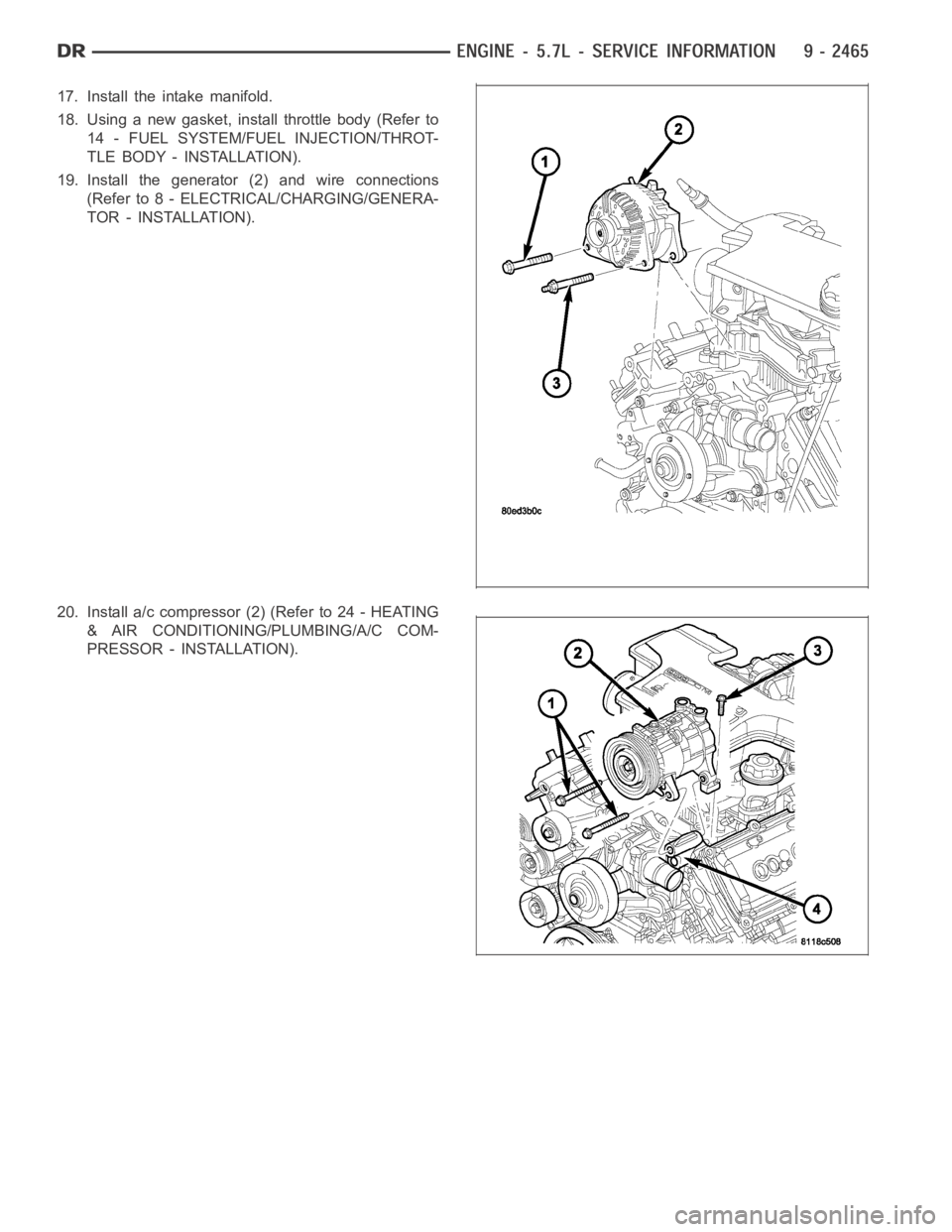

17. Remove engine front mount thru-bolt nuts.

18. Remove right side axle retaining bolts.

19. Disconnect the transmission oil cooler lines from

their retainers at the oil pan bolts.

20. Disconnect exhaust pipe at manifolds (2).

Page 1774 of 5267

17. Install the intake manifold.

18. Using a new gasket, install throttle body (Refer to

14 - FUEL SYSTEM/FUEL INJECTION/THROT-

TLE BODY - INSTALLATION).

19. Install the generator (2) and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

20. Install a/c compressor (2) (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

Page 2024 of 5267

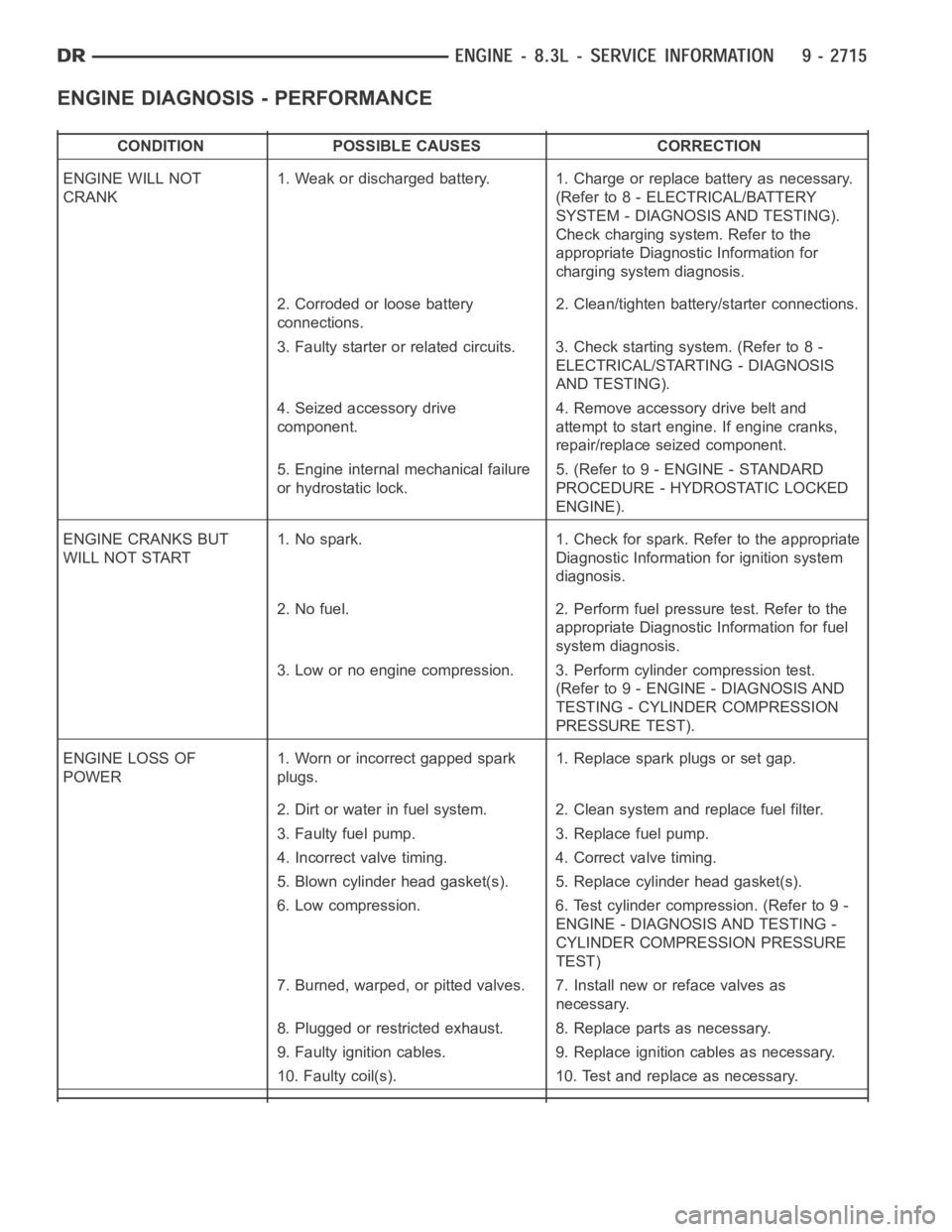

ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT

CRANK1. Weak or discharged battery. 1. Charge or replace battery as necessary.

(Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING).

Check charging system. Refer to the

appropriate Diagnostic Information for

charging system diagnosis.

2. Corroded or loose battery

connections.2. Clean/tighten battery/starter connections.

3. Faulty starter or related circuits. 3. Check starting system. (Refer to8-

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING).

4. Seized accessory drive

component.4. Remove accessory drive belt and

attempt to start engine. If engine cranks,

repair/replace seized component.

5. Engine internal mechanical failure

or hydrostatic lock.5. (Refer to 9 - ENGINE - STANDARD

PROCEDURE - HYDROSTATIC LOCKED

ENGINE).

ENGINE CRANKS BUT

WILL NOT START1. No spark. 1. Check for spark. Refer to the appropriate

Diagnostic Information for ignition system

diagnosis.

2. No fuel. 2. Perform fuel pressure test. Refer to the

appropriate Diagnostic Information for fuel

system diagnosis.

3. Low or no engine compression. 3. Perform cylinder compression test.

(Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING - CYLINDER COMPRESSION

PRESSURE TEST).

ENGINE LOSS OF

POWER1. Worn or incorrect gapped spark

plugs.1. Replace spark plugs or set gap.

2. Dirt or water in fuel system. 2. Clean system and replace fuel filter.

3. Faulty fuel pump. 3. Replace fuel pump.

4. Incorrect valve timing. 4. Correct valve timing.

5. Blown cylinder head gasket(s). 5. Replace cylinder head gasket(s).

6. Low compression. 6. Test cylinder compression. (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING -

CYLINDER COMPRESSION PRESSURE

TEST)

7. Burned, warped, or pitted valves. 7. Install new or reface valves as

necessary.

8. Plugged or restricted exhaust. 8. Replace parts as necessary.

9. Faulty ignition cables. 9. Replace ignition cables as necessary.

10. Faulty coil(s). 10. Test and replace as necessary.

Page 2080 of 5267

25. Remove A/C compressor mounting bolts. Reposi-

tion A/C compressor.Do notdisconnect A/C lines.

26. Disconnect the power steering line support

bracket at the radiator.

27. Lower the vehicle.

28. Remove the upper radiator hose and coolant

recovery container.

29. Remove the cooling fan module (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

30. Remove the upper idler pulley.

31. Remove power steering pump mounting bolts.

Reposition power steering pump aside.Do not

disconnect power steering lines.

32. Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

33. Disconnect the heater hose at the timing cover.

34. Disconnect the ground wire at the thermostat

housing.

NOTE: Do Not remove the camshaft position sensor from the timing cover.

35. Disconnect the camshaft sensor wiring harness connector.

36. Disconnect engine coolant temperature (ECT) sensor connector.

37. Remove crankshaft pulley and damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

38. Remove the timing cover.

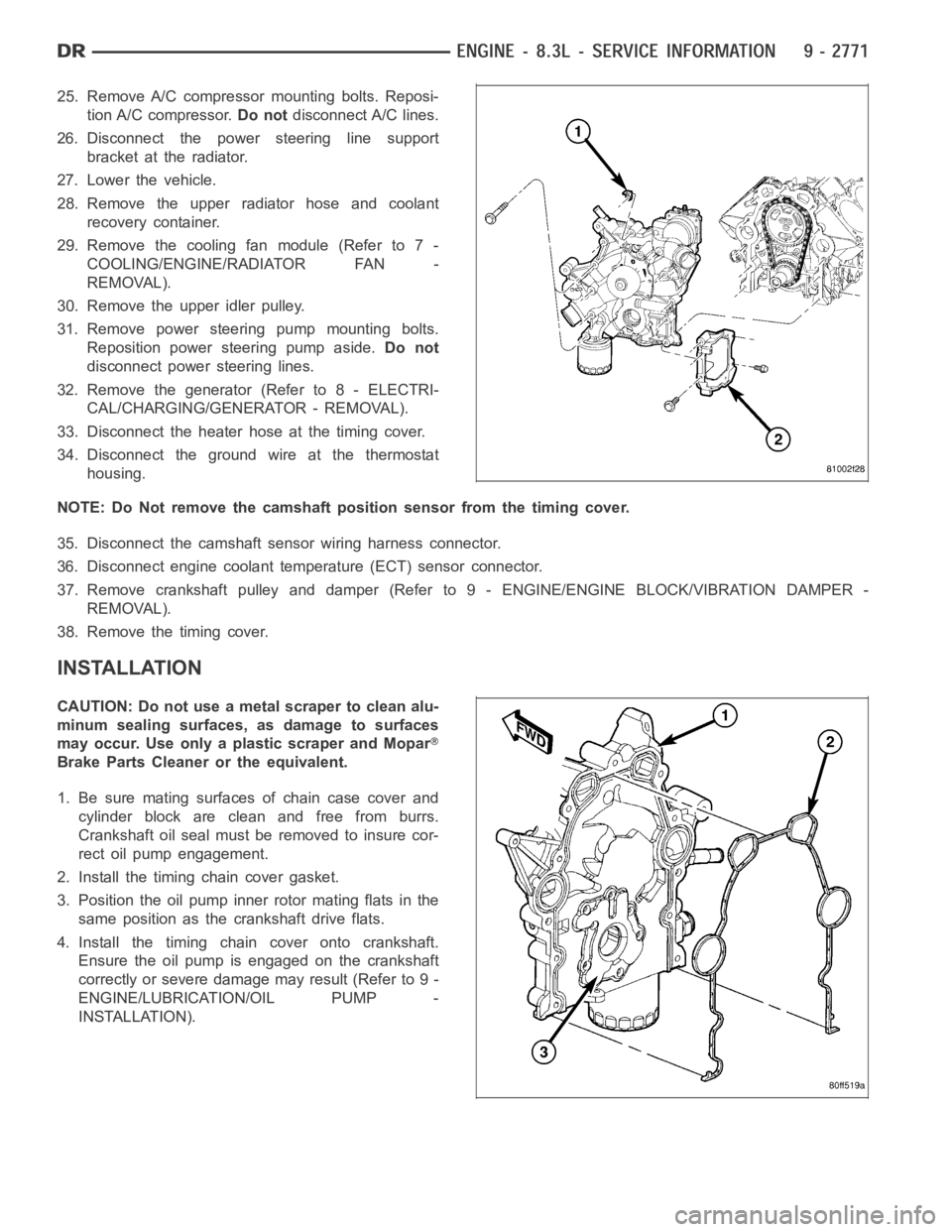

INSTALLATION

CAUTION: Do not use a metal scraper to clean alu-

minum sealing surfaces, as damage to surfaces

may occur. Use only a plastic scraper and Mopar

Brake Parts Cleaner or the equivalent.

1. Be sure mating surfaces of chain case cover and

cylinder block are clean and free from burrs.

Crankshaft oil seal must be removed to insure cor-

rect oil pump engagement.

2. Install the timing chain cover gasket.

3. Position the oil pump inner rotor mating flats in the

same position as the crankshaft drive flats.

4. Install the timing chain cover onto crankshaft.

Ensure the oil pump is engaged on the crankshaft

correctly or severe damage may result (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP -

INSTALLATION).

Page 2735 of 5267

When Monitored:

With the engine running and the PCM has closed the Transmission Control Relay.

Set Condition:

If the battery voltage of the Transmission Control Relay Output Sense circuit(s) to the PCM is less than 10.0

volts for the period of 15 seconds. Note: P0562 generally indicates a gradually falling battery voltage or a

resistive connection(s) to the PCM. The DTC will also set if the battery voltage sensed at the PCM is less than

6.5 volts for 200ms or when Transmission Control Relay Output circuits areless than 7.2 volts for 200ms.

Possible Causes

RELATED CHARGING SYSTEM DTC’S

(Z908) OR (Z977) GROUND CIRCUIT OPEN OR HIGH RESISTANCE

(A104) FUSED B(+) CIRCUIT OPEN OR HIGH RESISTANCE

(T16) TRANSMISSION CONTROL OUTPUT TO TCM OPEN OR HIGH RESISTANCE

TOTALLY INTEGRATED POWER MODULE (TIPM)

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Transmission damage may occur if there is insufficient supply voltage to properly control the solenoids. To prevent

this possibility, the battery voltage is monitored and the system is placed in logical limp-in if the battery voltage

drops below the limit.

Diagnostic Test

1.CHECK FOR RELATED CHARGING SYSTEM DTC’S

With the scan tool, read the Engine DTC’s.

Are there any Charging System related DTCs present?

Ye s>>

Refer to the Charging System category and repair any Charging System DTCs before proceeding. After

repairing the Charging System DTCs, perform the Transmission Verification test to verify the transmis-

sion and or controller was not damaged.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK FOR TIPM DTCS

NOTE: Generator, battery, and charging system must be fully functional before performing this test.

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 3

Page 3111 of 5267

When Monitored:

With the engine running and the PCM has closed the Transmission Control Relay.

Set Condition:

If the battery voltage of the Transmission Output circuit(s) to the PCM is less than 10.0 volts for the period of

15 seconds. Note: P0562 generally indicates a gradually falling battery voltage or a resistive connection(s) to

the PCM. The DTC will also set if the battery voltage sensed at the PCM is lessthan 6.5-volts for 200ms or

where the Transmission Output circuits are less than 7.2-volts for 200ms.

Possible Causes

RELATED CHARGING SYSTEM DTC’S

(Z904, Z908, Z977) GROUND CIRCUITS OPEN OR HIGH RESISTANCE

(T16) TIPM OUTPUT CIRCUIT OPEN OR HIGH RESISTANCE

TOTALLY INTEGRATED POWER MODULE (TIPM)

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Friction element distress could result from an insufficient supply voltage to properly control the solenoids. To prevent

this possibility, the battery voltage is monitored and the system is placed in logical limp-in if the battery voltage

drops below the limit.

Diagnostic Test

1.RELATED CHARGING SYSTEM DTCS

With the scan tool, read the Engine DTCs.

Are there any related Charging System DTCs also present?

Ye s>>

Refer to the Charging System category and repair any Engine Charging System DTCs, before testing

DTC P0562. NOTE: After repairing the Engine Charging System DTC’s, perform the Transmission Ver-

ification test to verify the transmission control systemwas not damaged.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK FOR TIPM DTCS

NOTE: Generator, battery, and charging system must be fully functional before performing this test.

With the scan tool, read TIPM DTCs.

Are there any TCM TIPM DTCs present.

Ye s>>

Refer to the Transmission category and perform the appropriate symptom. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - DIAGNOSIS AND TESTING)

No>>

Go To 3

Page 4658 of 5267

WINCH

DESCRIPTION

The winch uses the electrical power from the vehicle charging system to power a motor that winds wire rope into

the winch drum by means of planetary gear reduction.

The winch assembly includes the following:

Motor:The winch motor is powered by the vehicle electrical system and features a thermal protection switch

that automatically stops the motor function in the power-in direction if the motor gets too hot.

Winch Drum:The winch drum allows the wire rope to be stored on the winch and transmits forcetothewire

rope.

Wire Rope:The wire rope allows the winch to be connected to an anchor to provide a pulling force.

Fairlead:The fairlead consists of four rollers and acts as guide for the wire rope andminimizes damage to the

rope.

Automatic Brake:The winch is equipped with an automatic brake that will stop rotation of thewinch drum if

the winch motor is stopped.

Clutch Lever:The clutch lever allows the winch drum to be disconnected from the winch motor to allow the

wire rope to be pulled from the winch by hand.

Remote Socket:The remote socket allows the remote control to be attached to the control pack to allow the

winchtofunction.

Remote Control:The remote control provides the interface between the winch operator and the winch. The

remote control provides the ability to power the winch in, out, and stop thewinch.

OPERATION

Winch:The winch uses the electrical power from the vehicle charging system to power a motor that winds wire rope

into the winch drum via planetary gear reduction. By nature, a winch is capable of generating very high forces and

should be used with care. Do not operate the winch without reading and understanding the complete winch owner’s

manual.

Low Voltage Interrupt:The winch is equipped with a device that will interrupt winch function if the vehicle charging

system voltage drops to a low level. The winch will not power-in or out for 30seconds if this device is tripped. If the

interrupt is tripped, the vehicle should be operated at high idle for a few minutes to allow the vehicle charging sys-

tem to recover before continuing to winch.

Winch Motor Thermal Protection:The winch is equipped with athermalprotectiondeviceinthemotor.Ifthe

winch is operated for an excessive duration, the device may interrupt motor function to protect the winch motor.

During this time the winch will power-out but will not power-in. Allow the winch motor to cool for a few minutes

before continuing operation of the winch. The winch will resume normal function once the motor cools.

Remote Control:Tooperatethewinch,thetoggleswitchispresseddowntopowerthewinchinand up to power

the winch out. The winch will stop if the switch is left in the neutral (center) position.

Clutch Lever:The clutch lever is used to allow free spooling of the winch drum. Rotate theclutch lever on the

winch to disengage the clutch.

WARNING

WARNING: Disconnect and isolate battery negative cable before attempting any troubleshooting or repairs.

Do not disengage the clutch if the winch is under a load or wire rope is under tension.

Do not route electrical cables across sharp edges.

Do not route electrical cables through or near moving parts.

Always wear heavy leather gloves when handling a wire rope.

Never let wire rope slip through your hands.

Always keep hands clear of wire rope, hook loop, hook and fairlead opening during installation, opera-

tion, and when spooling in or out.

Always use supplied hook strap whenever spooling wire rope in or out, during installation or operation.

Failure to follow these instructions may result in personal injury.

Page 4687 of 5267

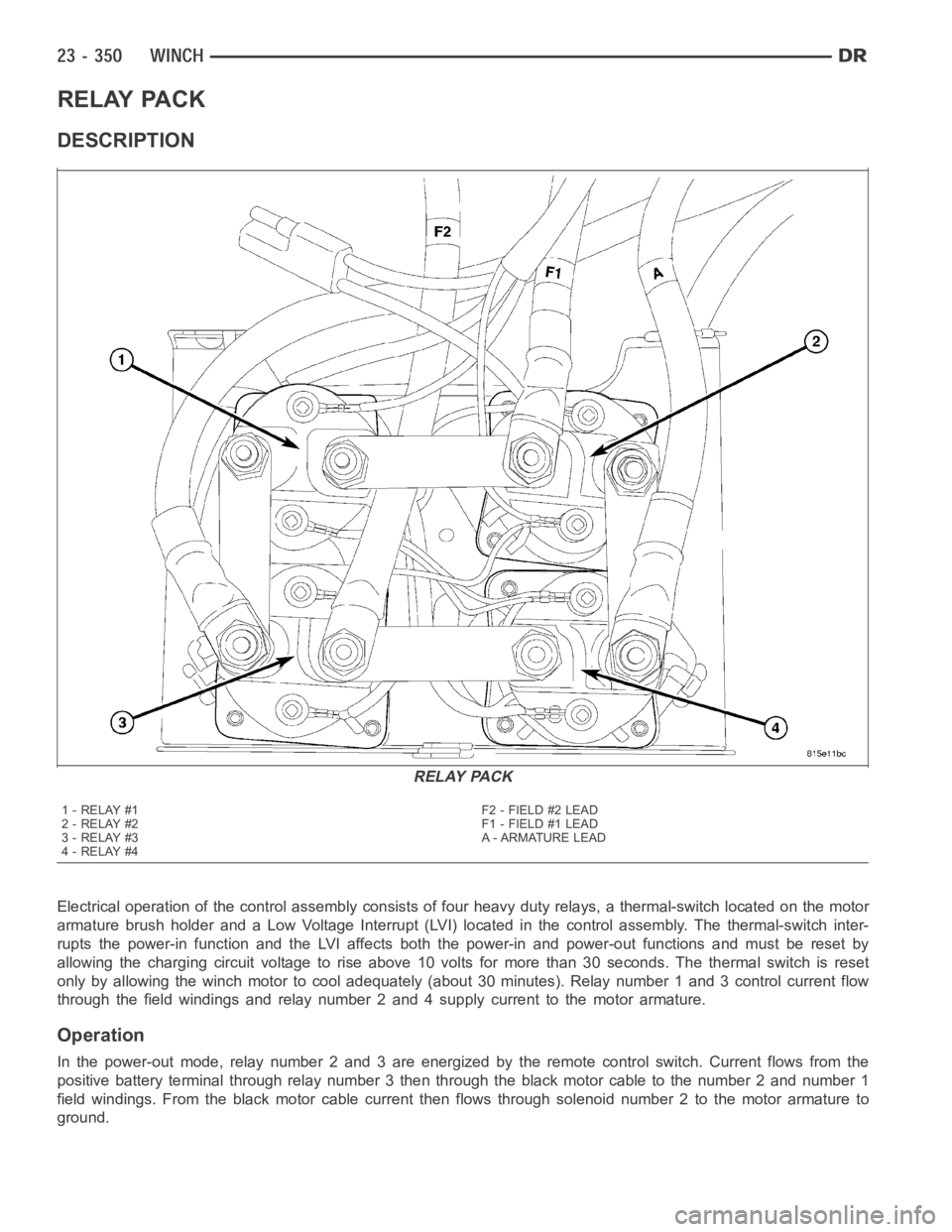

RELAY PACK

DESCRIPTION

Electrical operation of the control assembly consists of four heavy duty relays, a thermal-switch located on the motor

armature brush holder and a Low Voltage Interrupt (LVI) located in the control assembly. The thermal-switch inter-

rupts the power-in function and the LVI affects both the power-in and power-out functions and must be reset by

allowing the charging circuit voltage to rise above 10 volts for more than 30 seconds. The thermal switch is reset

only by allowing the winch motor to cool adequately (about 30 minutes). Relay number 1 and 3 control current flow

through the field windings and relay number 2 and 4 supply current to the motor armature.

Operation

In the power-out mode, relay number 2 and 3 are energized by the remote control switch. Current flows from the

positive battery terminal through relay number 3 then through the black motor cable to the number 2 and number 1

field windings. From the black motor cable current then flows through solenoid number 2 to the motor armature to

ground.

RELAY PACK

1-RELAY#1

2-RELAY#2

3-RELAY#3

4-RELAY#4F2 - FIELD #2 LEAD

F1 - FIELD #1 LEAD

A - ARMATURE LEAD

Page 5054 of 5267

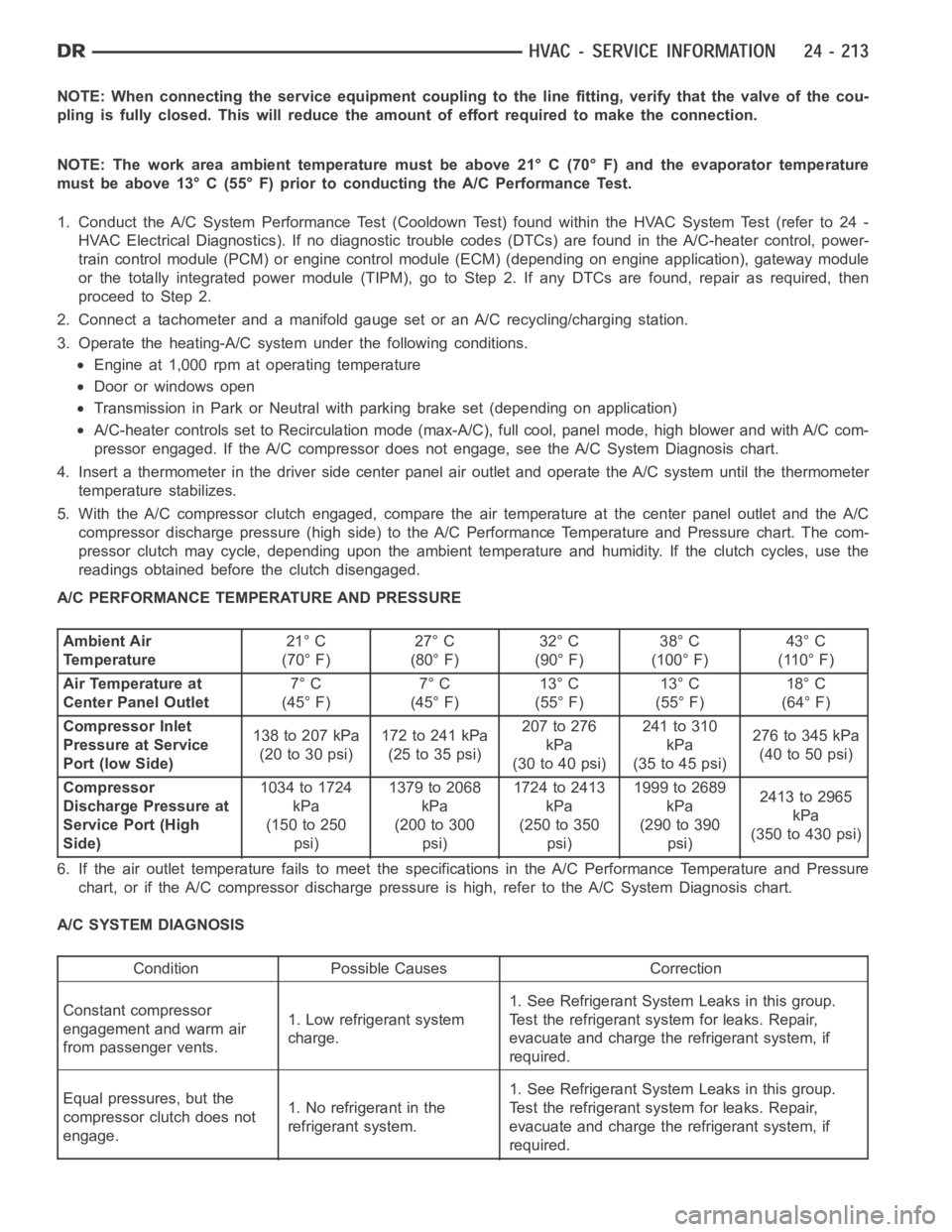

NOTE: When connecting the service equipment coupling to the line fitting,verify that the valve of the cou-

pling is fully closed. This will reduce the amount of effort required to make the connection.

NOTE: The work area ambient temperature must be above 21° C (70° F) and the evaporator temperature

must be above 13° C (55° F) prior to conducting the A/C Performance Test.

1. Conduct the A/C System Performance Test (Cooldown Test) found within the HVAC System Test (refer to 24 -

HVAC Electrical Diagnostics). If no diagnostic trouble codes (DTCs) are found in the A/C-heater control, power-

train control module (PCM) or engine control module (ECM) (depending on engine application), gateway module

or the totally integrated power module (TIPM), go to Step 2. If any DTCs are found, repair as required, then

proceedtoStep2.

2. Connect a tachometer and a manifold gauge set or an A/C recycling/charging station.

3. Operate the heating-A/C system under the following conditions.

Engine at 1,000 rpm at operating temperature

Door or windows open

Transmission in Park or Neutral with parking brake set (depending on application)

A/C-heater controls set to Recirculation mode (max-A/C), full cool, panel mode, high blower and with A/C com-

pressor engaged. If the A/C compressor does not engage, see the A/C System Diagnosis chart.

4. Insert a thermometer in the driver side center panel air outlet and operate the A/C system until the thermometer

temperature stabilizes.

5. With the A/C compressor clutch engaged, compare the air temperature at the center panel outlet and the A/C

compressor discharge pressure (high side) to the A/C Performance Temperature and Pressure chart. The com-

pressor clutch may cycle, depending upon the ambient temperature and humidity. If the clutch cycles, use the

readings obtained before the clutch disengaged.

A/C PERFORMANCE TEMPERATURE AND PRESSURE

Ambient Air

Temperature21° C

(70° F)27° C

(80° F)32° C

(90° F)38° C

(100° F)43° C

(110° F)

Air Temperature at

Center Panel Outlet7° C

(45° F)7° C

(45° F)13° C

(55° F)13° C

(55° F)18° C

(64° F)

Compressor Inlet

Pressure at Service

Port (low Side)138 to 207 kPa

(20to30psi)172to241kPa

(25to35psi)207 to 276

kPa

(30to40psi)241 to 310

kPa

(35to45psi)276to345kPa

(40to50psi)

Compressor

Discharge Pressure at

Service Port (High

Side)1034 to 1724

kPa

(150 to 250

psi)1379to2068

kPa

(200 to 300

psi)1724to2413

kPa

(250 to 350

psi)1999 to 2689

kPa

(290 to 390

psi)2413to2965

kPa

(350 to 430 psi)

6. If the air outlet temperature fails to meet the specifications in the A/CPerformance Temperature and Pressure

chart, or if the A/C compressor discharge pressure is high, refer to the A/CSystem Diagnosis chart.

A/C SYSTEM DIAGNOSIS

Condition Possible Causes Correction

Constant compressor

engagement and warm air

from passenger vents.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

Page 5128 of 5267

WARNING: The engine cooling system is designed to develop internal pressures up to 145 kilopascals (21

pounds per square inch). Do not remove or loosen the coolant pressure cap, cylinder block drain plugs,

radiator drain, radiator hoses, heater hoses, or hose clamps while the engine cooling system is hot and

under pressure. Allow the vehicle to cool for a minimum of 15 minutes beforeopening the cooling system

for service. Failure to observe this warning can result in serious burns from the heated engine coolant.

CAUTION

CAUTION: Never add R-12 to a refrigerant system designed to use R-134a. Do not use R-12 equipment or

parts on an R-134a A/C system. These refrigerants are not compatible and damage to the A/C system will

result.

CAUTION: Never use R-12 refrigerant oil in a A/C system designed to use R-134a refrigerant oil. These

refrigerant oils are not compatible and damage to the A/C system will result.

CAUTION: The use of A/C system sealers may result in damage to A/C refrigerant recovery/evacuation/re-

charging equipment and/or A/C system. Many federal, state/provincial and local regulations prohibit the

recharge of A/C systems with known leaks. DaimlerChrysler recommends thedetection of A/C system leaks

through the use of approved leak detectors and fluorescent leak detectiondyes. Vehicles found with A/C

system sealers should be treated as contaminated and replacement of the entire A/C refrigerant system is

recommended. A/C systems found to be contaminated with A/C system sealers, A/C stop-leak products or

seal conditioners voids the warranty for the A/C system.

CAUTION: Recover the refrigerant before opening any fitting or connection. Open the fittings with caution,

even after the system has been discharged. Never open or loosen a connection before recovering the refrig-

erant.

CAUTION: If equipped, do not remove the secondary retention clip from any spring-lock coupler connection

while the refrigerant system is under pressure. Recover the refrigerant before removing the secondary

retention clip. Open the fittings with caution, even after the system has been discharged. Never open or

loosen a connection before recovering the refrigerant.

CAUTION: The internal parts of the A/C system will remain stable as long as moisture-free refrigerant and

refrigerant oil is used. Abnormal amounts of dirt, moisture or air can upset the chemical stability. This may

cause operational troubles or even serious damage if present in more than very small quantities. Before

disconnecting a component, clean the outside of the fittings thoroughly to prevent contamination from

entering the refrigerant system. Keep service tools and the work area clean. Do not open the refrigerant

system or uncap a replacement component until you are ready to service the system. Immediately after

disconnecting a component from the refrigerant system, seal the open fittings with a cap or plug. This will

prevent contamination from entering the A/C system.

CAUTION: Refrigerant oil will absorb moisture from the atmosphere if leftuncapped. Do not open a con-

tainer of refrigerant oil until you are ready to use it. Replace the cap on the oil container immediately after

using. Store refrigerant oil only in a clean, airtight, and moisture-freecontainer.

CAUTION: Do not overcharge the refrigerant system. Overcharging will cause excessive compressor head

pressure and can cause compressor noise and A/C system failure.