charging DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1450 of 5267

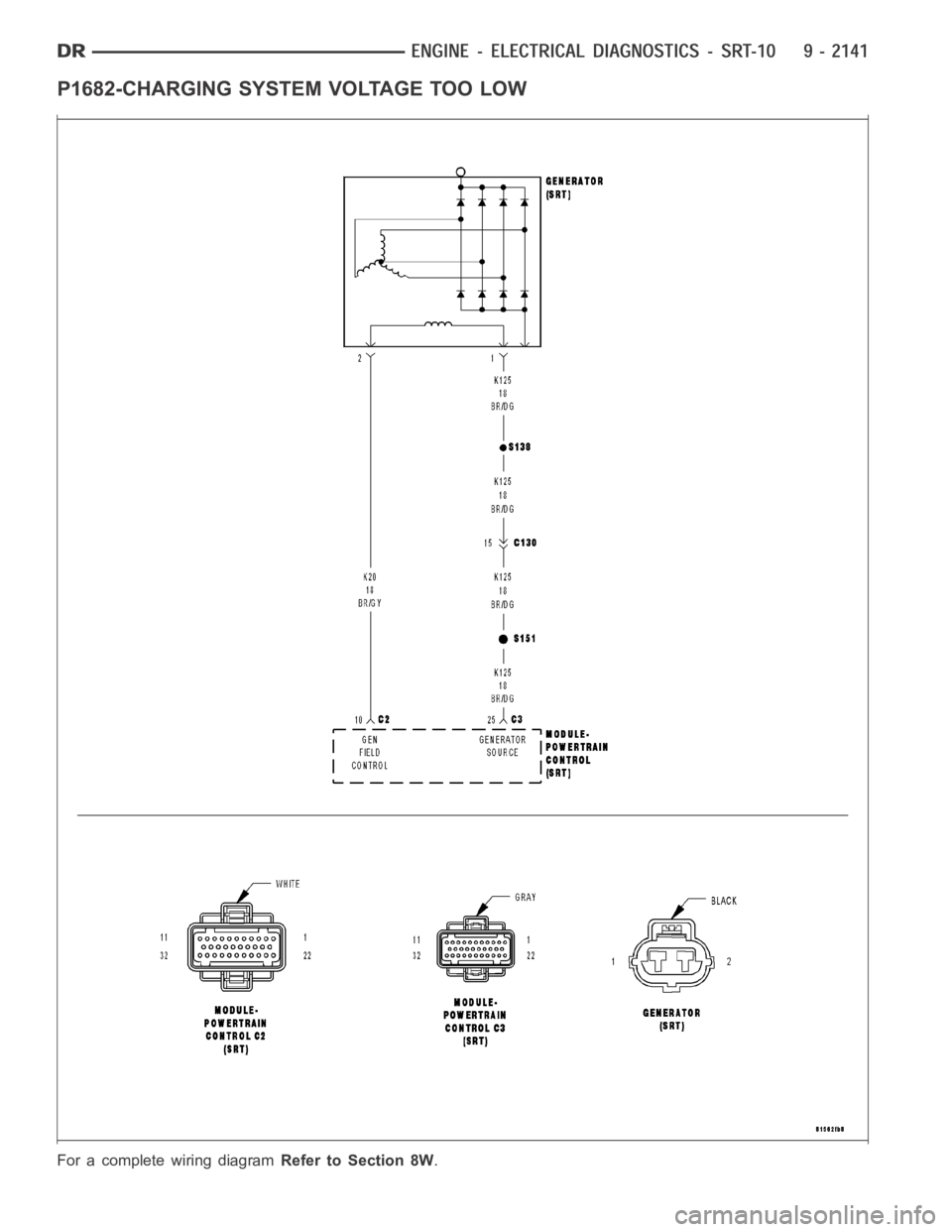

P1682-CHARGING SYSTEM VOLTAGE TOO LOW

For a complete wiring diagramRefer to Section 8W.

Page 1451 of 5267

When Monitored:

With the ignition key on and the engine running over 1500 RPM after 25 seconds.

Set Condition:

When the PCM regulates the generator field and there are no detected field problems, but the voltage output

does not increase.

Possible Causes

BATTERY TEMPERATURE SENSOR

RESISTANCE IN THE BATTERY POSITIVE CIRCUIT

(K125) GENERATOR FIELD SOURCE CIRCUIT OPEN

RESISTANCE IN THE GENERATOR GROUND

(K125) GENERATOR FIELD SOURCE CIRCUIT SHORTED TO GROUND

(K20) GENERATOR FIELD CONTROL CIRCUIT OPEN

RESISTANCE IN THE GENERATOR FIELD COIL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CHARGING VOLTAGE BELOW 15.1 VOLTS

Turn the ignition off.

NOTE: Battery must be fully charged and capable of passing a battery load test.

NOTE: Generator Belt tension and condition must be checked before continuing.

NOTE: Inspect the vehicle for any aftermarket accessories that may exceedthe maximum Generator output.

WARNING: When the engine is operating, do not stand in direct line of the fan. Do not put your hands near

the pulley, belts, or fan. Do no wear loose clothing.

Start the engine.

Record all DTCs and the related Freeze Frame data.

With the scan tool, read the target charging voltage.

Is the target charging voltage above 15.1 volts?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.BATTERY TEMPERATURE SENSOR

Turn the ignition off.

NOTE: Generator Belt tension and condition must be checked before continuing.

Start the engine.

Allow the engine to reach normal operating temperature.

With the scan tool in sensors, read the Battery Temp Sensor value.

Using a Thermometer, measure under hood temperature.

Is the temperature within 10° F of Battery temperature?

Ye s>>

Go To 3

No>>

Replace the Battery Temperature Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1472 of 5267

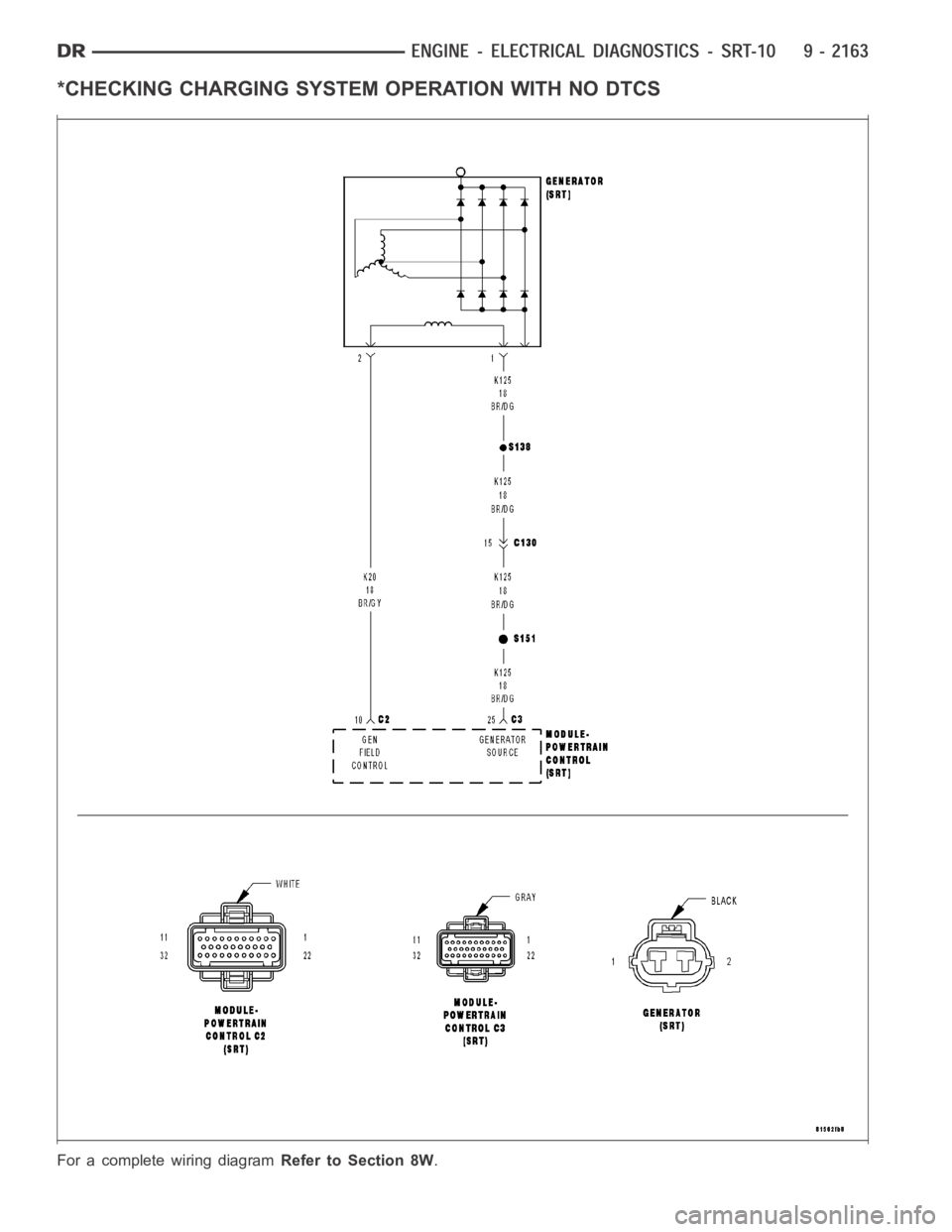

*CHECKING CHARGING SYSTEM OPERATION WITH NO DTCS

For a complete wiring diagramRefer to Section 8W.

Page 1473 of 5267

Possible Causes

GENERATOR BELT CONDITION

RESISTANCE IN THE BATTERY POSITIVE CIRCUIT

(K125) GENERATOR FIELD SOURCE CIRCUIT OPEN

GENERATOR FIELD COIL HIGH RESISTANCE

(K20) GEN FIELD CONTROL CIRCUIT OPEN

RESISTANCE IN THE GENERATOR GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.TARGET CHARGING DIFFERS FROM ACTUAL CHARGING BY 1 VOLT

NOTE: Verify that the Battery is able to pass a load test before continuing.

Ignition on, engine not running.

With the scan tool, read the Battery voltage and record the results.

Measure Battery voltage between the Battery Positive and Negative Terminals and record the results.

Compare the two voltage readings.

Is the voltage difference less than one volt?

Ye s>>

Go To 2

No>>

Go To 8

2.RESISTANCE IN THE BATTERY POSITIVE CIRCUIT

Ignition on, engine not running.

Measure the voltage between the Generator B+ Terminal and the Battery+ Post.

CAUTION: Make sure all wires are clear of the engine’s moving parts.

Start the engine.

Is the voltage above 0.4 of a volt?

Ye s>>

Repair the excessive resistance in the Battery Positive circuit between the Generator and Battery.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.(K125) GEN FIELD SOURCE CIRCUIT OPEN

Ignition on, engine not running.

Record all DTCs and freeze frame data, now erase Codes.

Carefully inspect all connectors for corrosion or spread terminals before continuing.

With the scan tool, actuate the Generator Field Driver.

Measure the voltage of the (K125) Generator Field Source circuit by backprobing the back of Generator Field har-

ness connector.

Is the voltage above 10.0 volts?

Ye s>>

Go To 4

No>>

Repair the (K125) Generator Field Source circuit for an open or short to ground.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1475 of 5267

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

8.GENERATOR BELT CONDITION

Turn the ignition off.

NOTE: Battery condition must be verified prior to this test.

Inspect the Generator Belt tension and condition.

Is the Generator Belt OK?

Ye s>>

Go To 9

No>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

9.ACTIVE DTC SET

Start the engine.

Turn on all accessories.

Raise engine speed to 2000 RPM for 30 seconds then return to idle.

With the scan tool, read DTCs.

Are there any

Charging SystemTrouble Codes?

Ye s>>

Refer to DTC list for the related Charging DTCs.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 10

10.WIRE HARNESS INSPECTION

Ignition on, engine not running.

With the scan tool, actuate the Generator Field Driver.

Using a 12-volt test light, backprobe the Generator Field Driver Terminalat the back of the Generator.

NOTE: The test light should blink On and Off every 1.4 seconds.

While monitoring the 12-volt test light, wiggle the Field Terminals back to the PCM and ASD Relay.

Was there any interruption in the normal cycle of the test light?

Ye s>>

Repair the wire or connector where the wiggling interrupted the voltage cycle.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1483 of 5267

POWERTRAIN VERIFICATION TEST

For a complete wiring diagramRefer to Section 8W.

Diagnostic Test

1.SELECTING THE PROPER VERIFICATION TEST

The following verification test are for different repairs. Select the appropriate Verification test for the

repair that has been completed.

Speed Control repair

Go To 2

Charging System repair

Go To 3

NVLD System repair

Go To 4

All other repairs

Go To 5

2.POWERTRAIN VERIFICATION TEST 1

NOTE: 1. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 2. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 3. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 4. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

5. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected.

6. Connect the scan tool to the data link connector and erase all codes.

7. Turn the speed control ON (if equipped, cruise light will be on).

8. Depress and release the SET Switch when the vehicle speed is greater than35 MPH. The speed control should

engage and hold the selected speed.

9. Press and hold the RESUME/ACCEL Switch. The vehicle speed should increase by at least 2 MPH.

10. Press and hold the COAST switch. The vehicle speed should decrease.

11. Using caution, press and release the brake pedal. The speed control should disengage.

12. Bring the vehicle speed back up to 35 MPH.

13. Press the RESUME/ACCEL switch. The speed control should resume the previously set speed.

14. Hold down the SET switch. The vehicle should decelerate.

15. Make sure vehicle speed is greater than 35 mph and release the SET Switch. The vehicle should adjust and set

a new vehicle speed.

16. Press and release the CANCEL switch. The speed control should disengage.

17. Bring the vehicle speed back up above 35 mph and engage speed control.

18. Turn the Speed Control Off. (Cruise light will be off). The speed control should disengage.

NOTE: OVERSHOOT/UNDERSHOOT FOLLOWING SPEED CONTROL SET.

19. If the vehicle operator repeatedly presses and releases the SET buttonwith their foot off of the accelerator

(referred to as

lift foot set), the vehicle may accelerate and exceed the desired set speed by up to 5 mph (8km/h).

20. It may also decelerate to less than the desired set speed, before finally achieving the desired set speed.

21. The Speed Control System has an adaptive strategy that compensates forvehicle-to-vehicle variations in speed

control cable lengths.

22. When the speed control is set with the vehicles operators foot off of theaccelerator pedal, the speed control

thinks there is excessive speed control cable slack and adapts accordingly.

Page 1614 of 5267

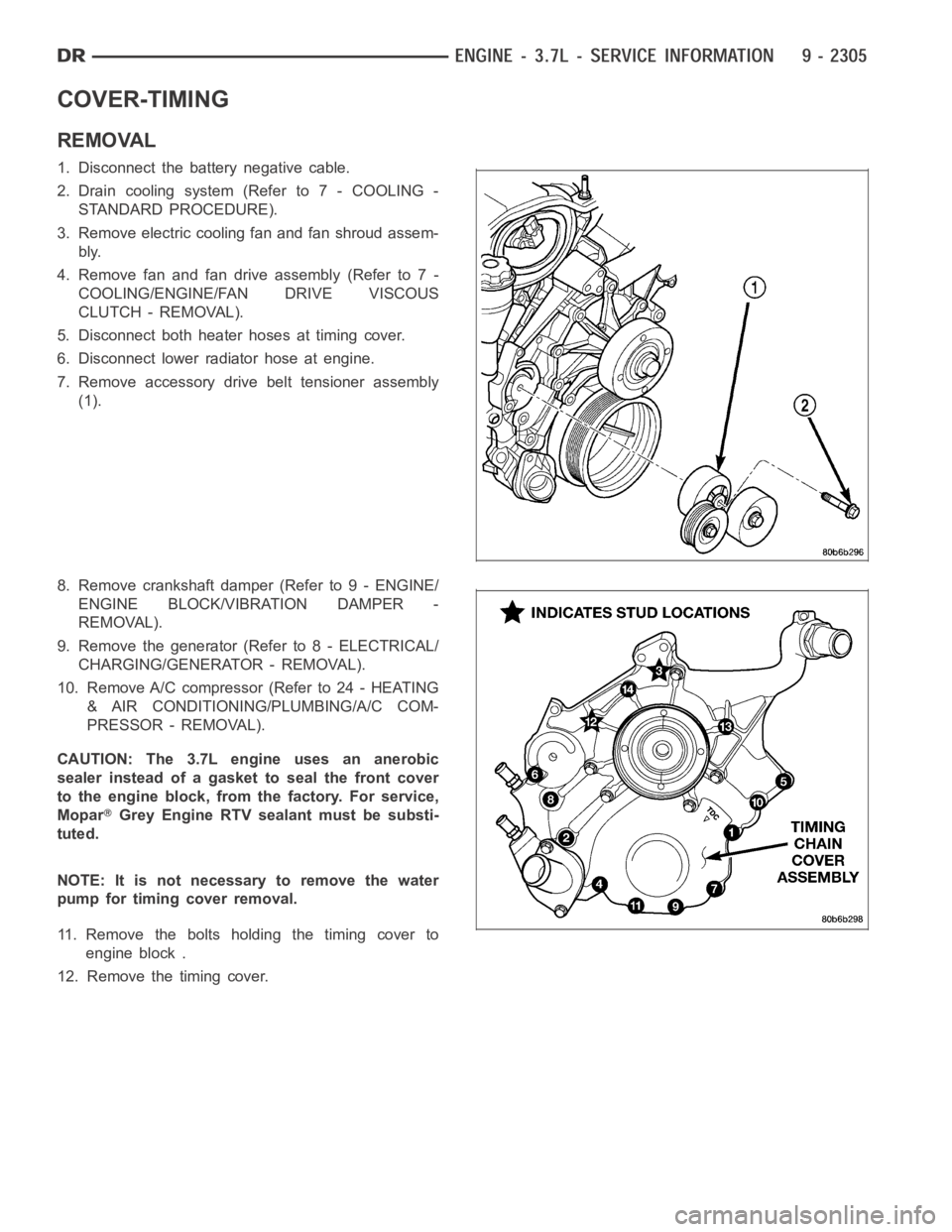

COVER-TIMING

REMOVAL

1. Disconnect the battery negative cable.

2. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

3. Remove electric cooling fan and fan shroud assem-

bly.

4. Remove fan and fan drive assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

5. Disconnect both heater hoses at timing cover.

6. Disconnect lower radiator hose at engine.

7. Remove accessory drive belt tensioner assembly

(1).

8. Remove crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

9. Remove the generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

10. Remove A/C compressor (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

CAUTION: The 3.7L engine uses an anerobic

sealer instead of a gasket to seal the front cover

to the engine block, from the factory. For service,

Mopar

Grey Engine RTV sealant must be substi-

tuted.

NOTE: It is not necessary to remove the water

pump for timing cover removal.

11. Remove the bolts holding the timing cover to

engine block .

12. Remove the timing cover.

Page 1615 of 5267

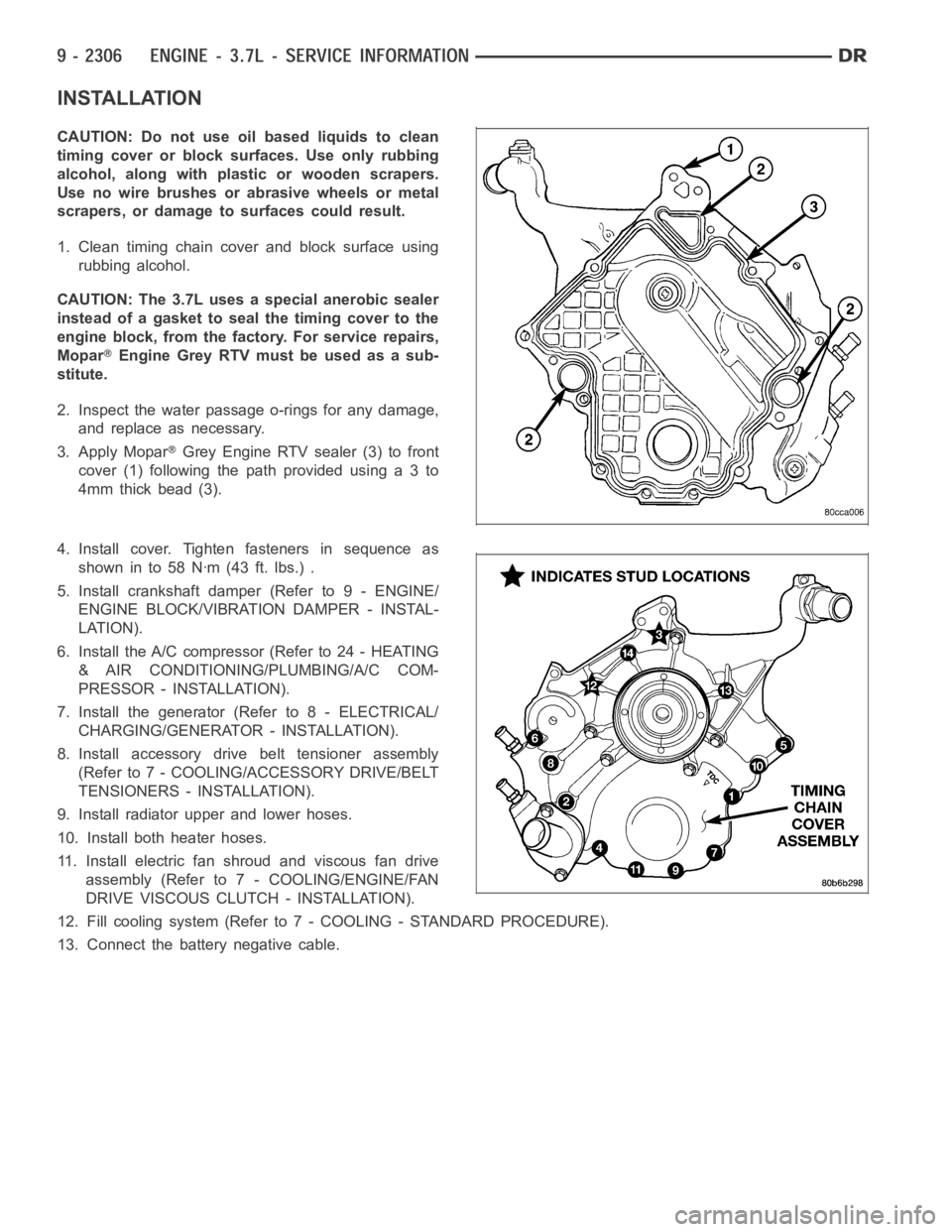

INSTALLATION

CAUTION: Do not use oil based liquids to clean

timing cover or block surfaces. Use only rubbing

alcohol, along with plastic or wooden scrapers.

Use no wire brushes or abrasive wheels or metal

scrapers, or damage to surfaces could result.

1. Clean timing chain cover and block surface using

rubbing alcohol.

CAUTION: The 3.7L uses a special anerobic sealer

instead of a gasket to seal the timing cover to the

engine block, from the factory. For service repairs,

Mopar

Engine Grey RTV must be used as a sub-

stitute.

2. Inspect the water passage o-rings for any damage,

and replace as necessary.

3. Apply Mopar

Grey Engine RTV sealer (3) to front

cover(1)followingthepathprovidedusinga3to

4mm thick bead (3).

4. Install cover. Tighten fasteners in sequence as

showninto58Nꞏm(43ft.lbs.).

5. Install crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

6. Install the A/C compressor (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

7. Install the generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

8. Install accessory drive belt tensioner assembly

(Refer to 7 - COOLING/ACCESSORY DRIVE/BELT

TENSIONERS - INSTALLATION).

9. Install radiator upper and lower hoses.

10. Install both heater hoses.

11. Install electric fan shroud and viscous fan drive

assembly (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH - INSTALLATION).

12. Fill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

13. Connect the battery negative cable.

Page 1633 of 5267

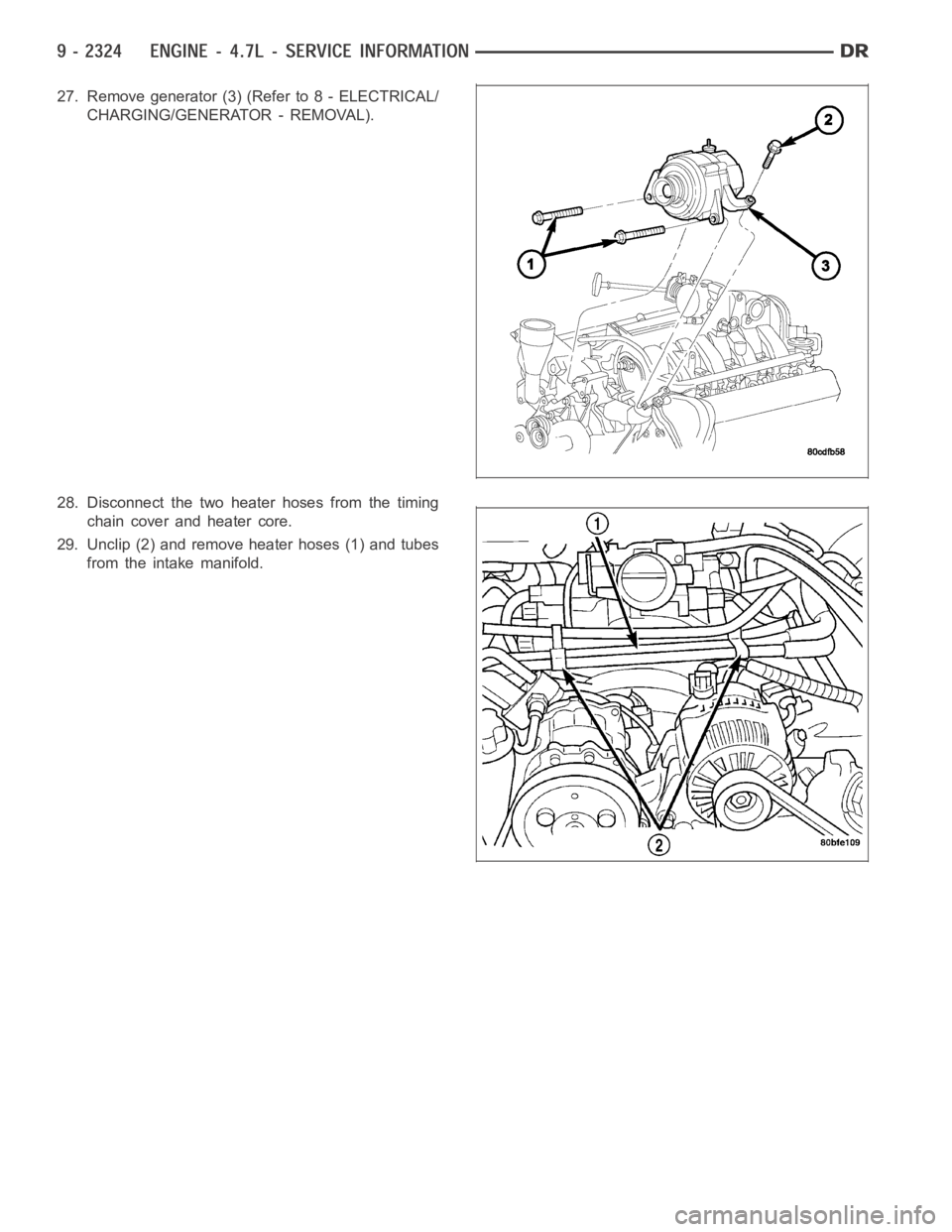

27. Remove generator (3) (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

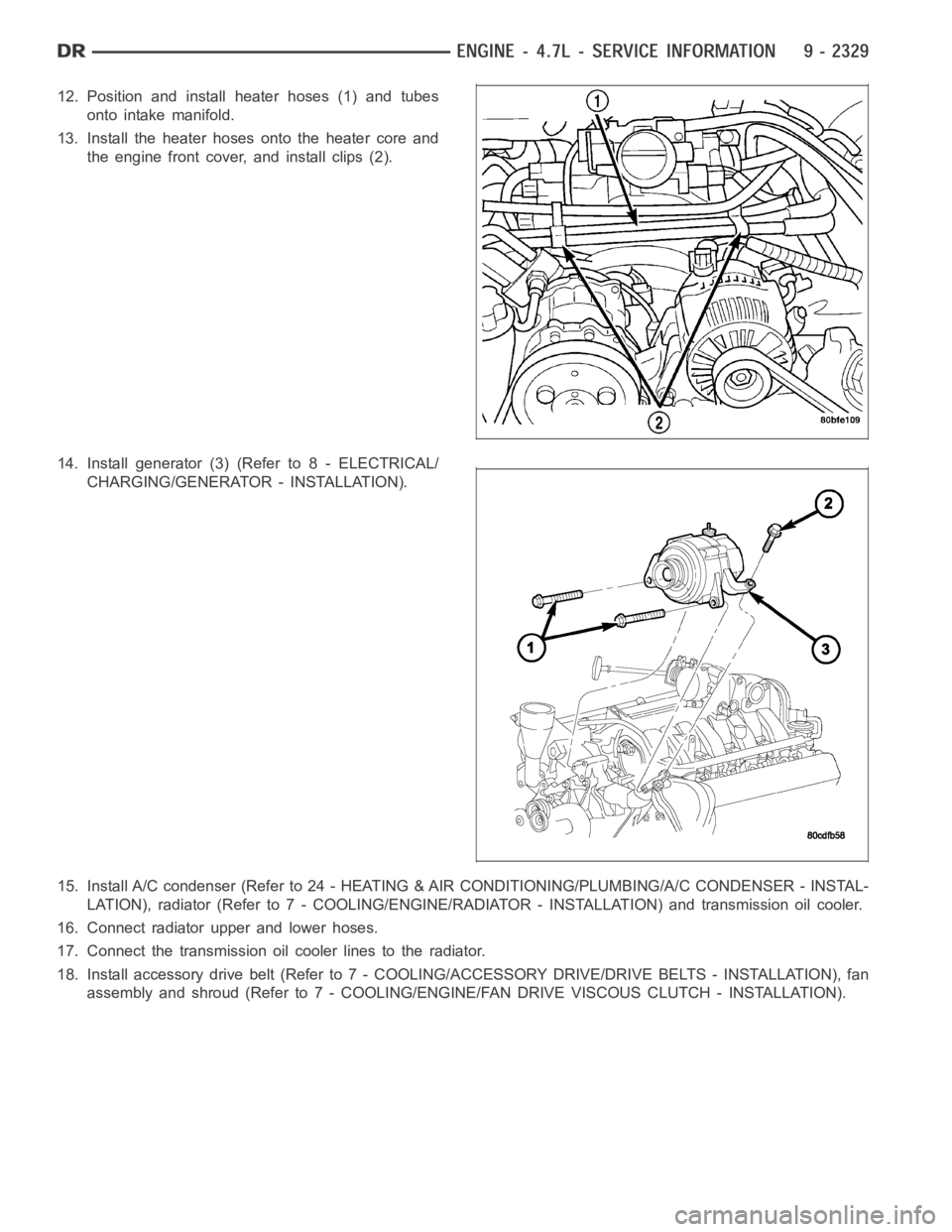

28. Disconnect the two heater hoses from the timing

chain cover and heater core.

29. Unclip (2) and remove heater hoses (1) and tubes

from the intake manifold.

Page 1638 of 5267

12. Position and install heater hoses (1) and tubes

onto intake manifold.

13. Install the heater hoses onto the heater core and

the engine front cover, and install clips (2).

14. Install generator (3) (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

15. Install A/C condenser (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/A/C CONDENSER - INSTAL-

LATION), radiator (Refer to 7 - COOLING/ENGINE/RADIATOR - INSTALLATION)and transmission oil cooler.

16. Connect radiator upper and lower hoses.

17. Connect the transmission oil cooler lines to the radiator.

18. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION), fan

assembly and shroud (Refer to 7 - COOLING/ENGINE/FAN DRIVE VISCOUS CLUTCH- INSTALLATION).