light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2267 of 5267

INSTALLATION

3.7L

1. If fuel injectors are to be installed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - INSTALLATION).

2. Clean out fuel injector machined bores in intake

manifold.

3. Apply a small amount of engine oil to each fuel

injector O-ring. This will helpin fuel rail installation.

4. Position fuel rail/fuel injector assembly to machined

injector openings in cylinder head.

5. Guide each injector into cylinder head. Be careful

not to tear injector O-rings.

6. Pushrightside of fuel rail down until fuel injectors

have bottomed on cylinder head shoulder. Push

leftfuel rail down until injectors have bottomed on

cylinder head shoulder.

7. Install 4 fuel rail mounting bolts and tighten. (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - SPECI-

FICATIONS)

8. Install 6 ignition coils. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL - INSTALLA-

TION)

9. Connect electrical connectors to throttle body.

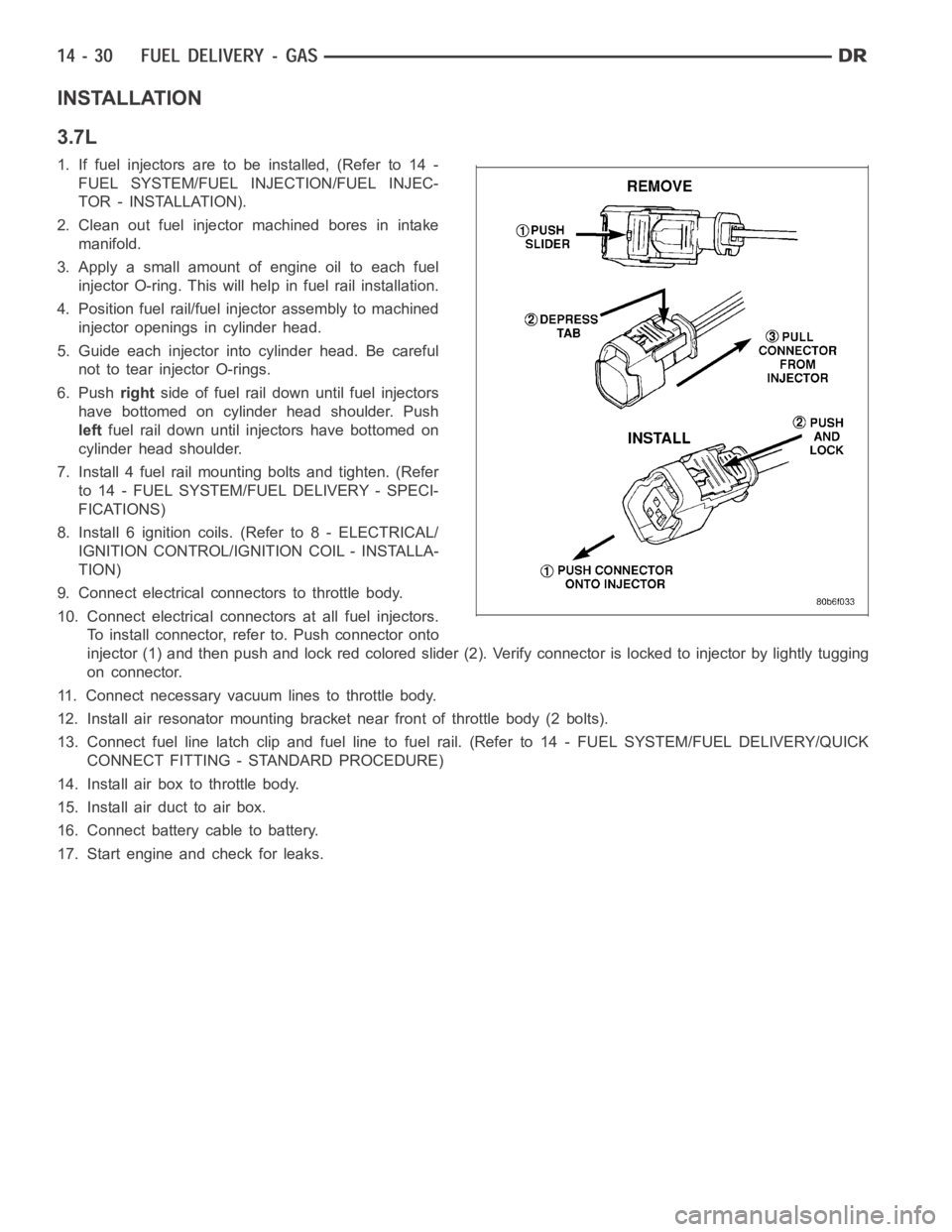

10. Connect electrical connectors at all fuel injectors.

To install connector, refer to. Push connector onto

injector (1) and then push and lock red colored slider (2). Verify connector is locked to injector by lightly tugging

on connector.

11. Connect necessary vacuum lines to throttle body.

12. Install air resonator mounting bracket near front of throttle body (2 bolts).

13. Connect fuel line latch clip and fuel line to fuel rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE)

14. Install air box to throttle body.

15. Install air duct to air box.

16. Connect battery cable to battery.

17. Start engine and check for leaks.

Page 2268 of 5267

4.7L

1. If fuel injectors are to be installed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - INSTALLATION).

2. Clean out fuel injector machined bores in intake

manifold.

3. Apply a small amount of engine oil to each fuel

injector O-ring. This will helpin fuel rail installation.

4. Position fuel rail/fuel injector assembly to machined

injector openings in cylinder head.

5. Guide each injector into cylinder head. Be careful

not to tear injector O-rings.

6. Pushrightside of fuel rail down until fuel injectors

have bottomed on cylinder head shoulder. Push

leftfuel rail down until injectors have bottomed on

cylinder head shoulder.

7. Install 4 fuel rail mounting bolts and tighten. (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - SPECI-

FICATIONS)

8. Install 8 ignition coils. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL - INSTALLA-

TION)

9. Connect electrical connectors to throttle body.

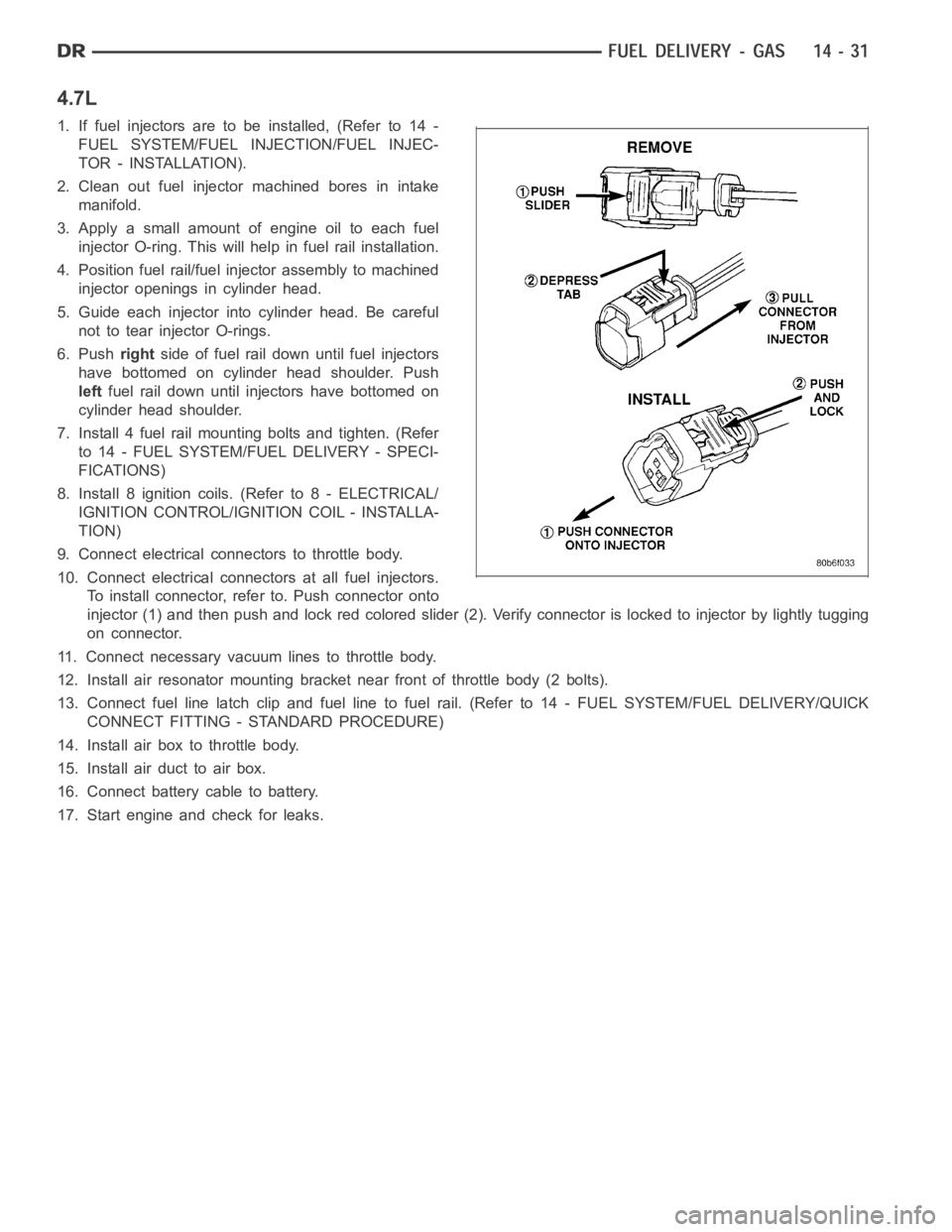

10. Connect electrical connectors at all fuel injectors.

To install connector, refer to. Push connector onto

injector (1) and then push and lock red colored slider (2). Verify connector is locked to injector by lightly tugging

on connector.

11. Connect necessary vacuum lines to throttle body.

12. Install air resonator mounting bracket near front of throttle body (2 bolts).

13. Connect fuel line latch clip and fuel line to fuel rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE)

14. Install air box to throttle body.

15. Install air duct to air box.

16. Connect battery cable to battery.

17. Start engine and check for leaks.

Page 2269 of 5267

5.7L

1. If fuel injectors are to be installed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - INSTALLATION).

2. Clean out fuel injector machined bores in intake

manifold.

3. Apply a small amount of engine oil to each fuel

injector O-ring. This will helpin fuel rail installation.

4. Position fuel rail/fuel injector assembly to machined

injector openings in intake manifold.

5. Guide each injector into intake manifold. Be careful

not to tear injector O-rings.

6. Pushrightside of fuel rail down until fuel injectors

have bottomed on shoulders. Pushleftfuel rail

down until injectors have bottomed on shoulders.

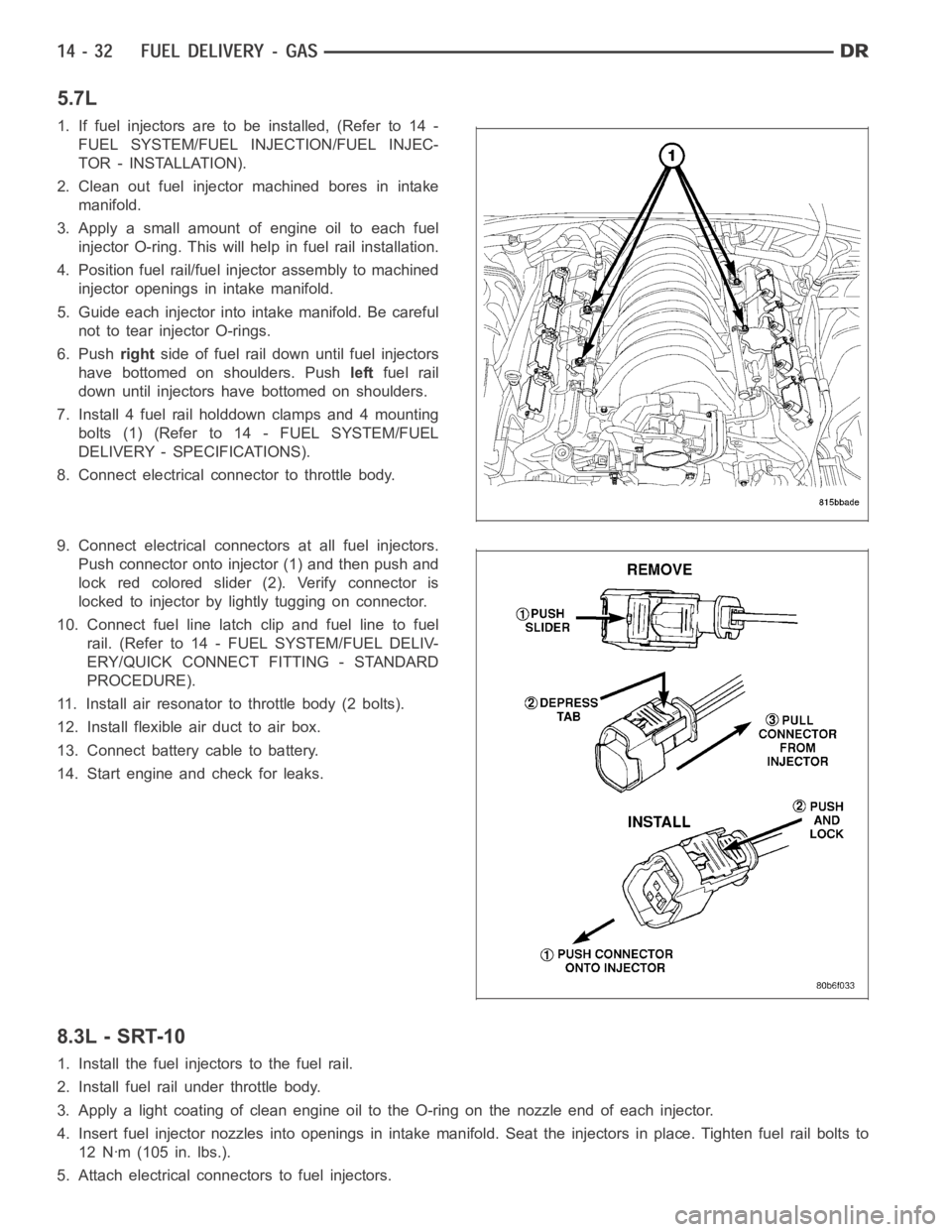

7. Install 4 fuel rail holddown clamps and 4 mounting

bolts (1) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - SPECIFICATIONS).

8. Connect electrical connector to throttle body.

9. Connect electrical connectors at all fuel injectors.

Push connector onto injector (1) and then push and

lock red colored slider (2). Verify connector is

locked to injector by lightly tugging on connector.

10. Connect fuel line latch clip and fuel line to fuel

rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY/QUICK CONNECT FITTING - STANDARD

PROCEDURE).

11. Install air resonator to throttle body (2 bolts).

12. Install flexible air duct to air box.

13. Connect battery cable to battery.

14. Start engine and check for leaks.

8.3L - SRT-10

1. Install the fuel injectors to the fuel rail.

2. Install fuel rail under throttle body.

3. Apply a light coating of clean engine oiltotheO-ringonthenozzleendofeach injector.

4. Insert fuel injector nozzles into openings in intake manifold. Seat theinjectors in place. Tighten fuel rail bolts to

12 Nꞏm (105 in. lbs.).

5. Attach electrical connectors to fuel injectors.

Page 2291 of 5267

1. Disconnect electrical connector from crankshaft

position sensor.

2. Remove sensor mounting bolt.

3. Pull sensor out. A light tap to top of sensor may

ease removal.

INSTALLATION

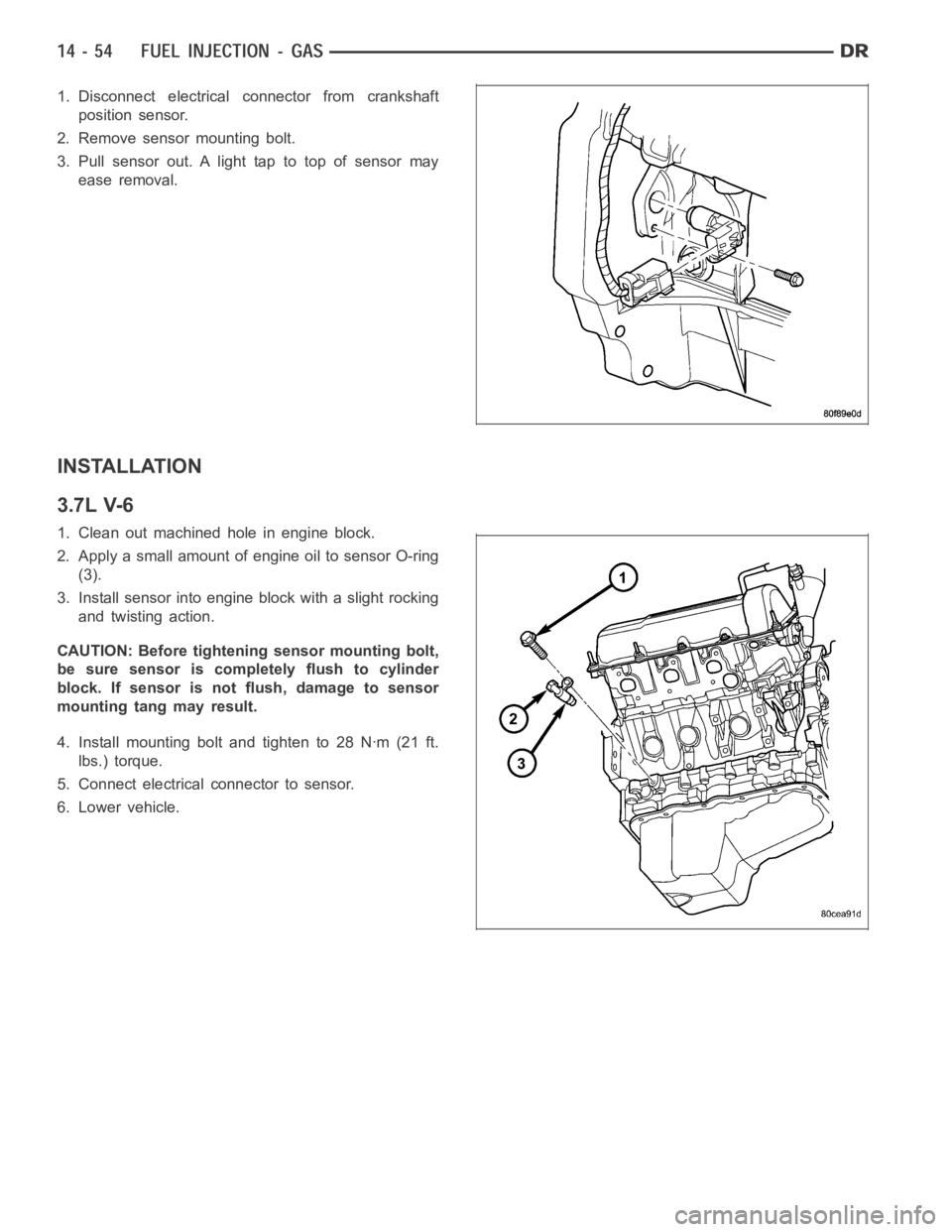

3.7L V-6

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor O-ring

(3).

3. Install sensor into engine block with a slight rocking

and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt and tighten to 28 Nꞏm (21 ft.

lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

Page 2292 of 5267

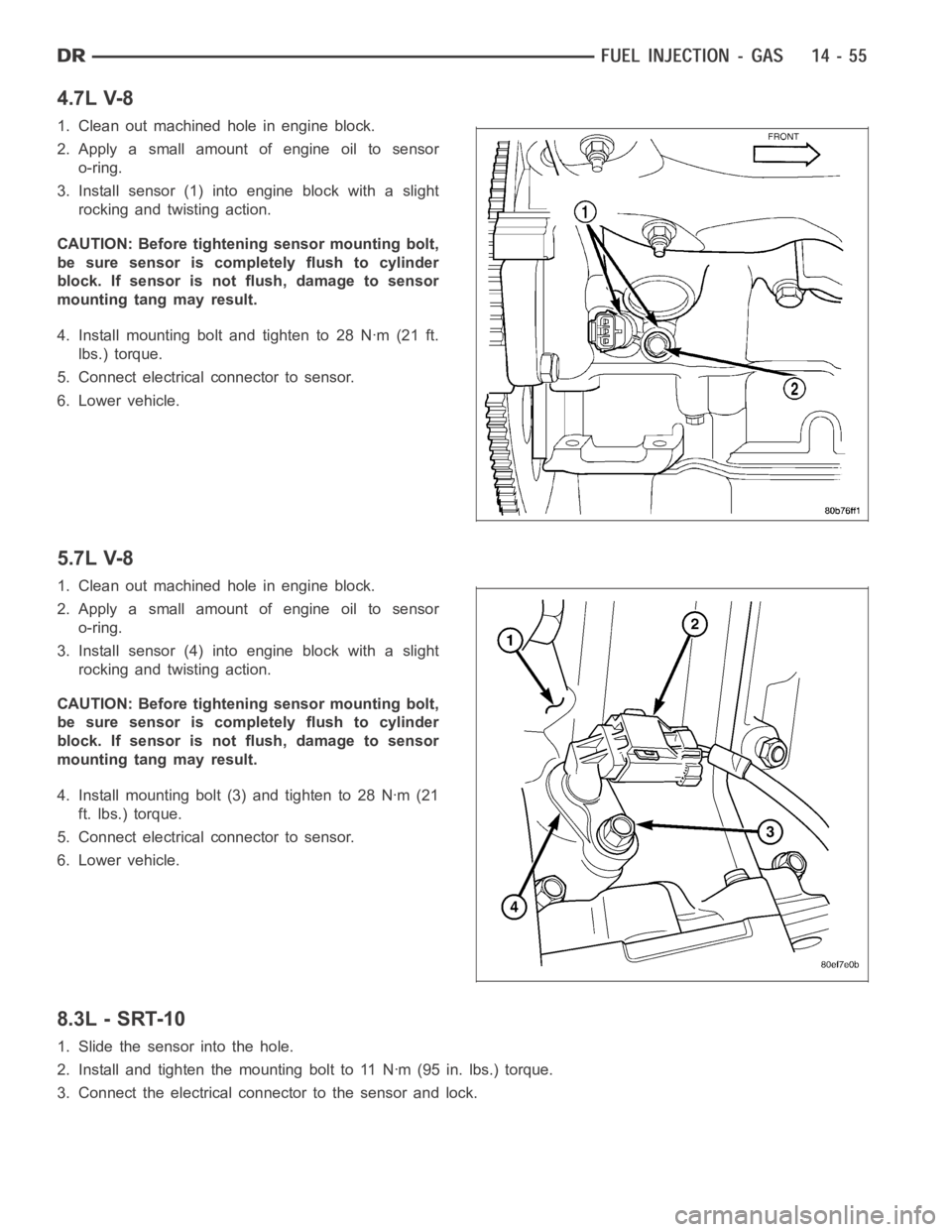

4.7L V-8

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor

o-ring.

3. Install sensor (1) into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt and tighten to 28 Nꞏm (21 ft.

lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

5.7L V-8

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor

o-ring.

3. Install sensor (4) into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt (3) and tighten to 28 Nꞏm (21

ft. lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

8.3L - SRT-10

1. Slide the sensor into the hole.

2. Install and tighten the mounting bolt to 11 Nꞏm (95 in. lbs.) torque.

3. Connect the electrical connector to the sensor and lock.

Page 2297 of 5267

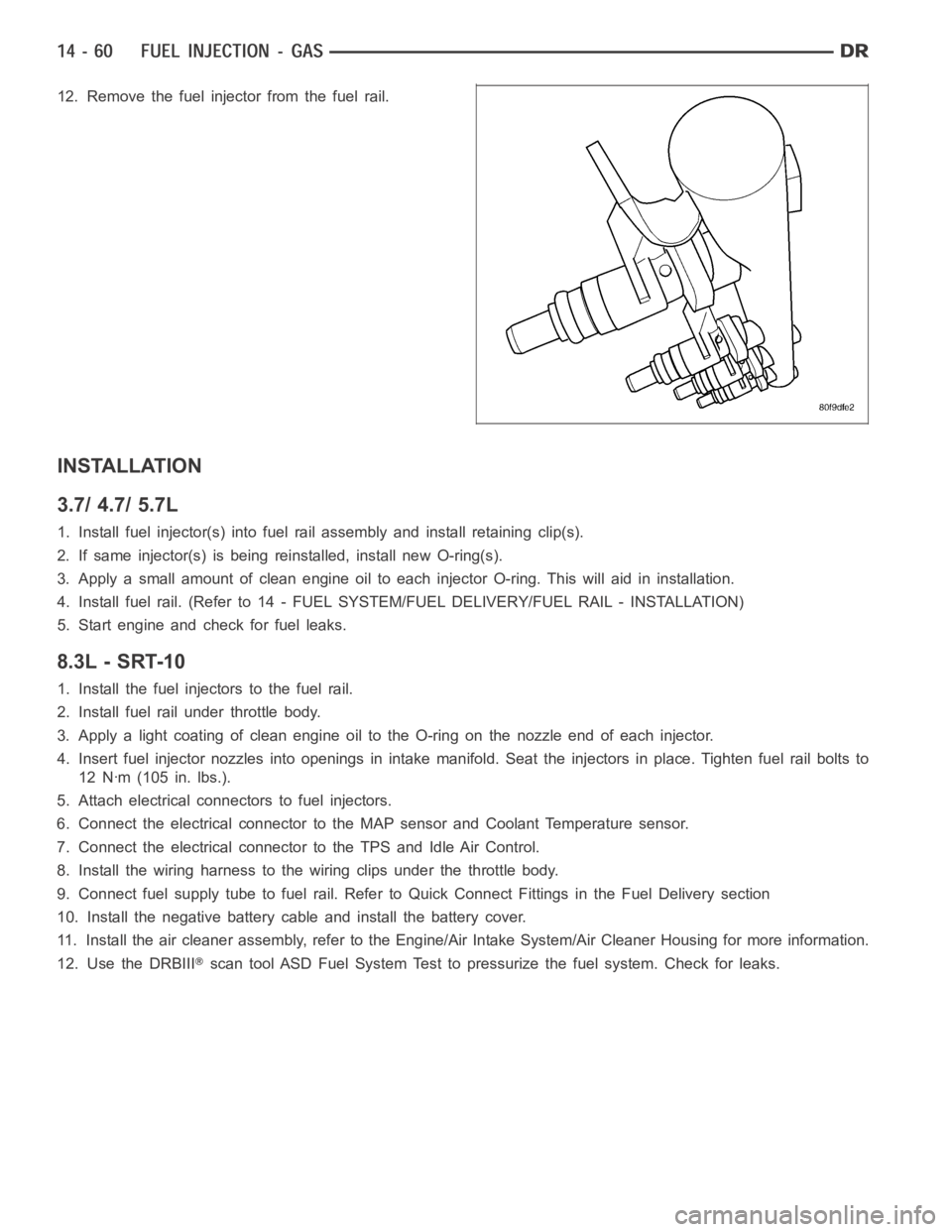

12. Remove the fuel injector from the fuel rail.

INSTALLATION

3.7/ 4.7/ 5.7L

1. Install fuel injector(s) into fuel rail assembly and install retainingclip(s).

2. If same injector(s) is being reinstalled, install new O-ring(s).

3. Apply a small amount of clean engine oil to each injector O-ring. This will aid in installation.

4. Install fuel rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL RAIL - INSTALLATION)

5. Start engine and check for fuel leaks.

8.3L - SRT-10

1. Install the fuel injectors to the fuel rail.

2. Install fuel rail under throttle body.

3. Apply a light coating of clean engine oiltotheO-ringonthenozzleendofeach injector.

4. Insert fuel injector nozzles into openings in intake manifold. Seat theinjectors in place. Tighten fuel rail bolts to

12 Nꞏm (105 in. lbs.).

5. Attach electrical connectors to fuel injectors.

6. Connect the electrical connector to the MAP sensor and Coolant Temperature sensor.

7. Connect the electrical connector to the TPS and Idle Air Control.

8. Install the wiring harness to the wiring clips under the throttle body.

9. Connect fuel supply tube to fuel rail. Refer to Quick Connect Fittings inthe Fuel Delivery section

10. Install the negative battery cable and install the battery cover.

11. Install the air cleaner assembly, refer to the Engine/Air Intake System/Air Cleaner Housing for more information.

12. Use the DRBIII

scan tool ASD Fuel System Test to pressurize the fuel system. Check for leaks.

Page 2300 of 5267

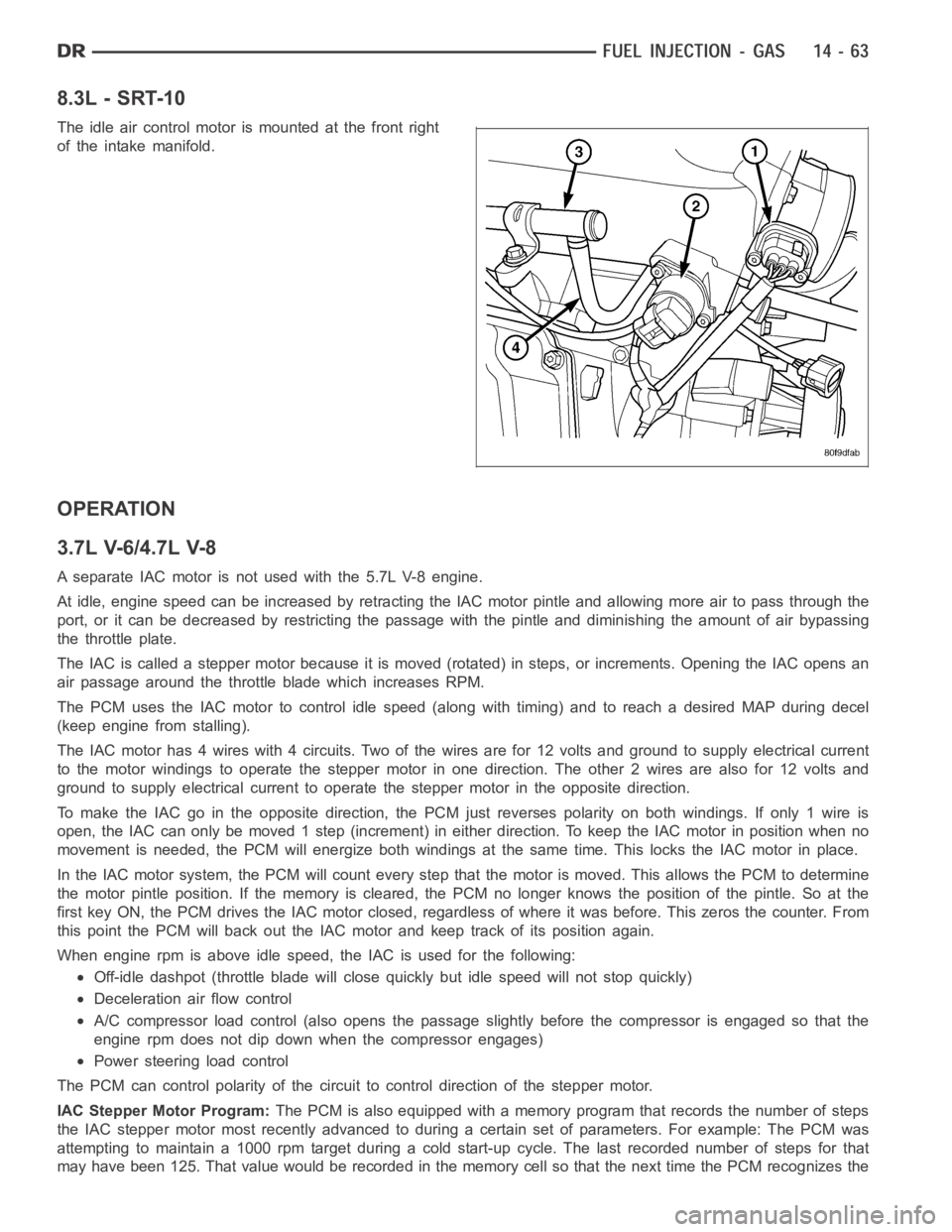

8.3L - SRT-10

The idle air control motor is mounted at the front right

of the intake manifold.

OPERATION

3.7L V-6/4.7L V-8

A separate IAC motor is not used with the 5.7L V-8 engine.

At idle, engine speed can be increased by retracting the IAC motor pintle and allowing more air to pass through the

port, or it can be decreased by restricting the passage with the pintle and diminishing the amount of air bypassing

the throttle plate.

The IAC is called a stepper motor because it is moved (rotated) in steps, or increments. Opening the IAC opens an

air passage around the throttle blade which increases RPM.

The PCM uses the IAC motor to control idle speed (along with timing) and to reach a desired MAP during decel

(keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of the wires are for 12 volts andground to supply electrical current

to the motor windings to operate the stepper motor in one direction. The other2wiresarealsofor12voltsand

ground to supply electrical current to operate the stepper motor in the opposite direction.

To make the IAC go in the opposite direction, the PCM just reverses polarityon both windings. If only 1 wire is

open, the IAC can only be moved 1 step (increment) in either direction. To keeptheIACmotorinpositionwhenno

movement is needed, the PCM will energize both windings at the same time. This locks the IAC motor in place.

In the IAC motor system, the PCM will count every step that the motor is moved. This allows the PCM to determine

the motor pintle position. If the memory is cleared, the PCM no longer knowsthe position of the pintle. So at the

first key ON, the PCM drives the IAC motor closed, regardless of where it wasbefore. This zeros the counter. From

this point the PCM will back out the IAC motor and keep track of its position again.

When engine rpm is above idle speed, the IAC is used for the following:

Off-idle dashpot (throttle blade will close quickly but idle speed will notstopquickly)

Deceleration air flow control

A/C compressor load control (also opens the passage slightly before the compressor is engaged so that the

engine rpm does not dip down when the compressor engages)

Power steering load control

The PCM can control polarity of the circuit to control direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also equipped with a memory program that records the number of steps

the IAC stepper motor most recently advanced to during a certain set of parameters. For example: The PCM was

attempting to maintain a 1000 rpm target during a cold start-up cycle. The last recorded number of steps for that

may have been 125. That value would be recorded in the memory cell so that thenext time the PCM recognizes the

Page 2338 of 5267

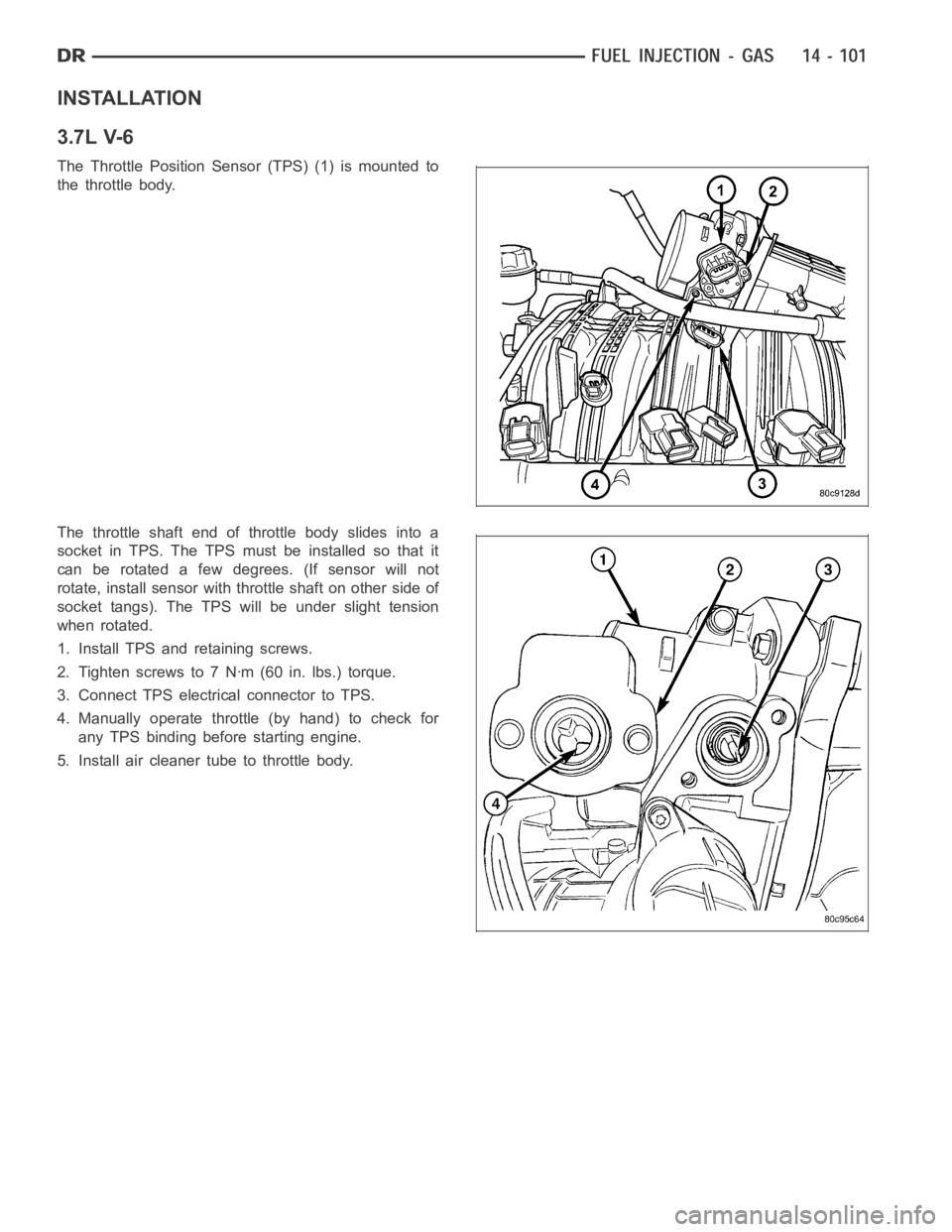

INSTALLATION

3.7L V-6

The Throttle Position Sensor (TPS) (1) is mounted to

the throttle body.

The throttle shaft end of throttle body slides into a

socket in TPS. The TPS must be installed so that it

can be rotated a few degrees. (If sensor will not

rotate, install sensor with throttle shaft on other side of

socket tangs). The TPS will be under slight tension

when rotated.

1. Install TPS and retaining screws.

2. Tighten screws to 7 Nꞏm (60 in. lbs.) torque.

3. Connect TPS electrical connector to TPS.

4. Manually operate throttle (by hand) to check for

any TPS binding before starting engine.

5. Install air cleaner tube to throttle body.

Page 2339 of 5267

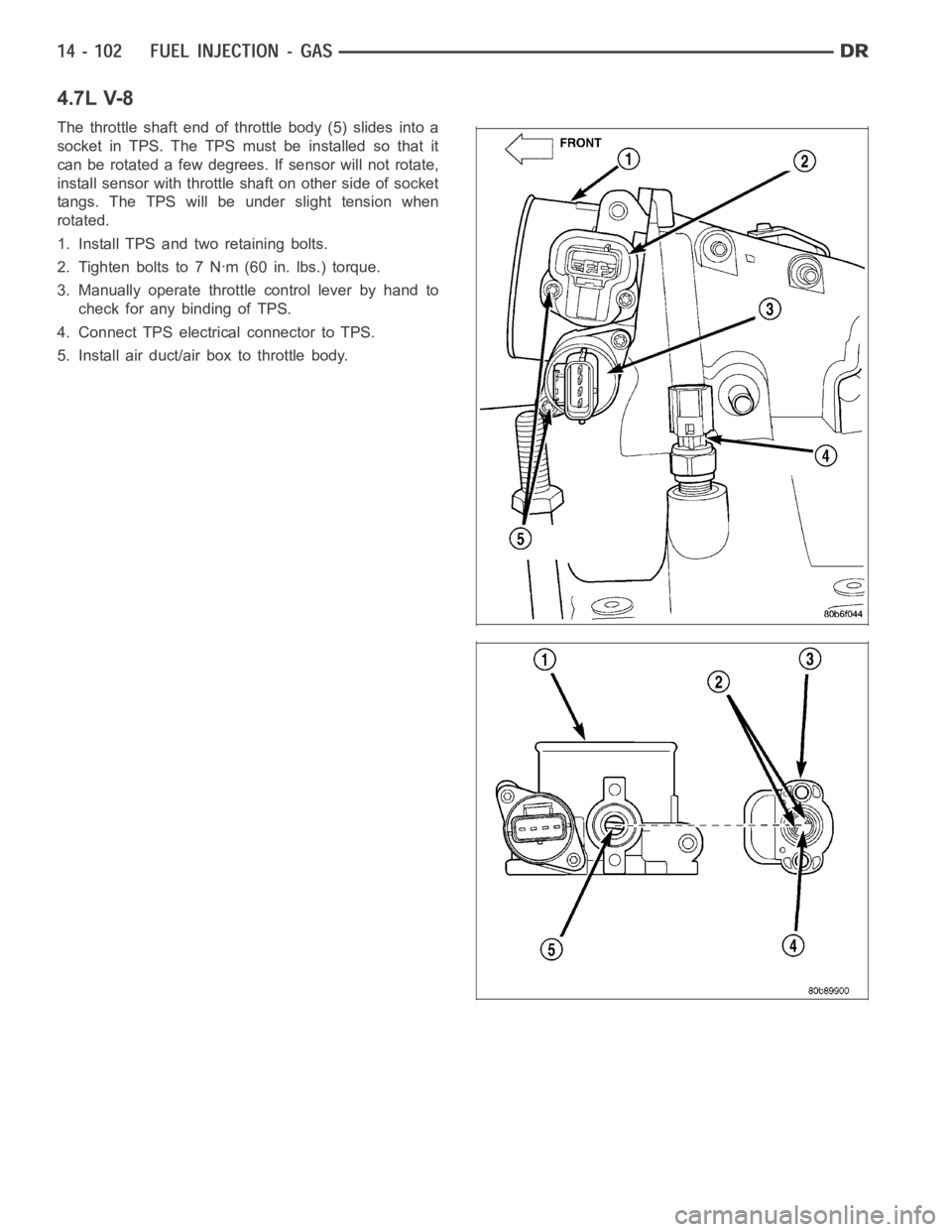

4.7L V-8

The throttle shaft end of throttle body (5) slides into a

socket in TPS. The TPS must be installed so that it

can be rotated a few degrees. If sensor will not rotate,

install sensor with throttle shaft on other side of socket

tangs. The TPS will be under slight tension when

rotated.

1. Install TPS and two retaining bolts.

2. Tighten bolts to 7 Nꞏm (60 in. lbs.) torque.

3. Manually operate throttle control lever by hand to

check for any binding of TPS.

4. Connect TPS electrical connector to TPS.

5. Install air duct/air box to throttle body.

Page 2340 of 5267

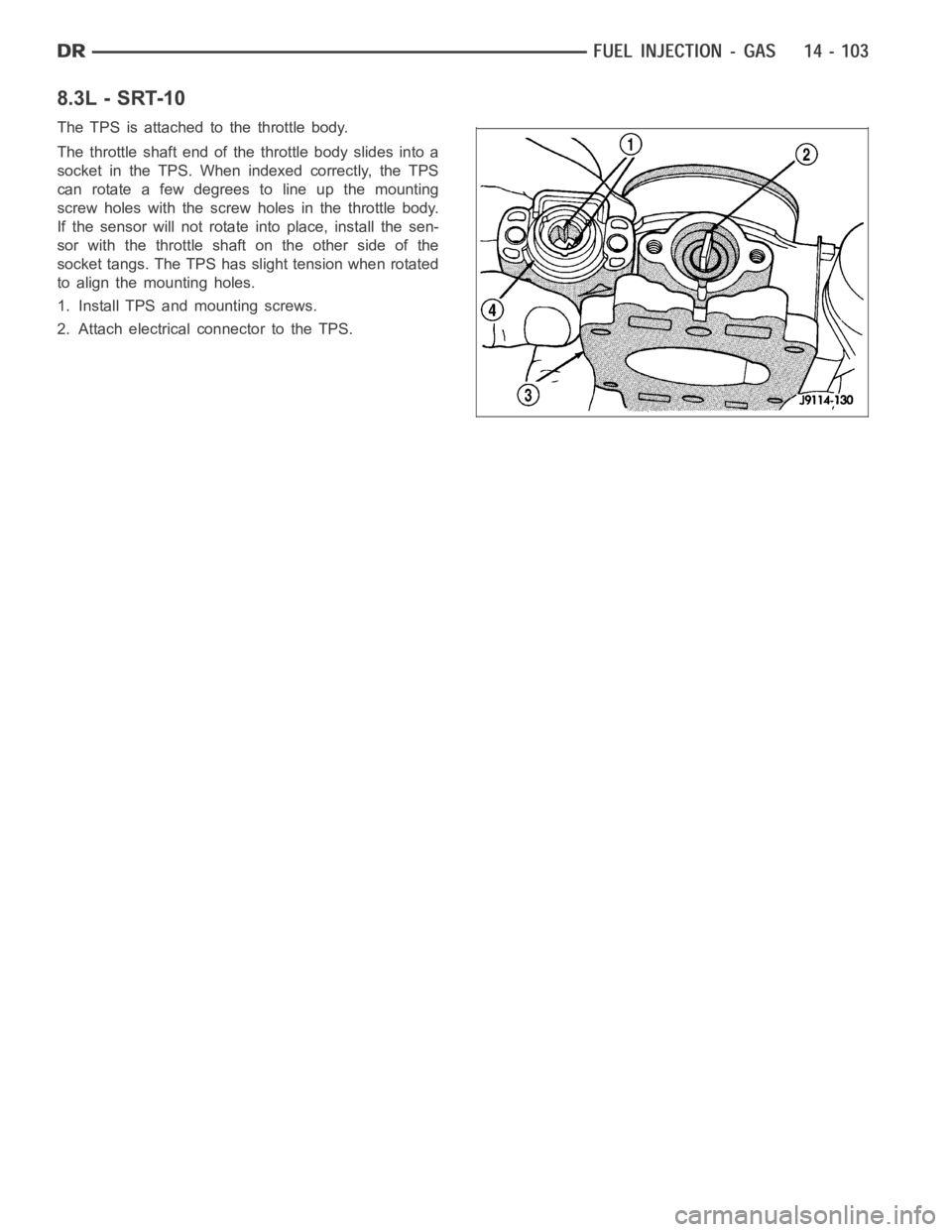

8.3L - SRT-10

The TPS is attached to the throttle body.

The throttle shaft end of the throttle body slides into a

socket in the TPS. When indexed correctly, the TPS

can rotate a few degrees to line up the mounting

screw holes with the screw holes in the throttle body.

If the sensor will not rotate into place, install the sen-

sor with the throttle shaft on the other side of the

socket tangs. The TPS has slight tension when rotated

to align the mounting holes.

1. Install TPS and mounting screws.

2. Attach electrical connector to the TPS.