light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2954 of 5267

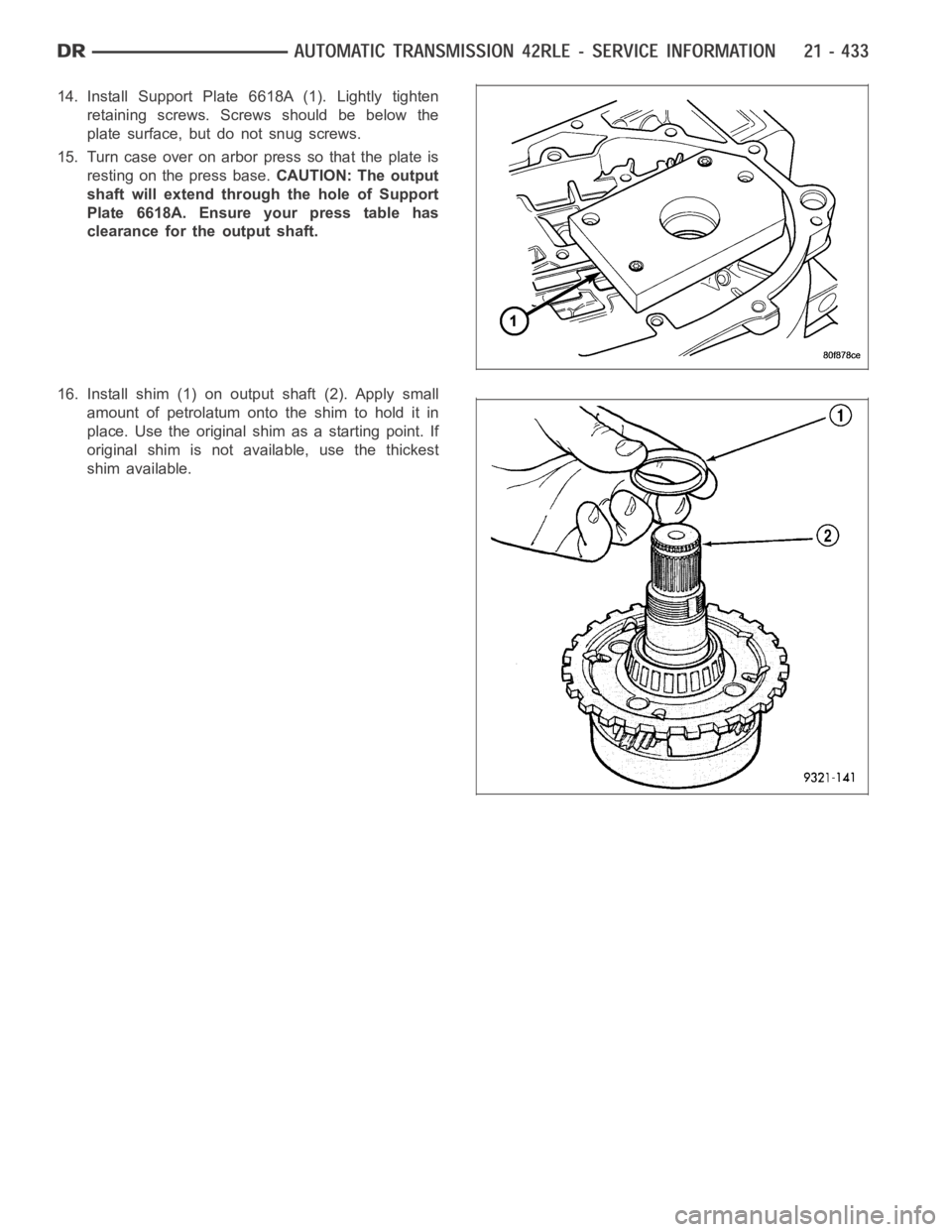

14. Install Support Plate 6618A (1). Lightly tighten

retaining screws. Screws should be below the

plate surface, but do not snug screws.

15. Turn case over on arbor press so that the plate is

resting on the press base.CAUTION: The output

shaft will extend through the hole of Support

Plate 6618A. Ensure your press table has

clearance for the output shaft.

16. Install shim (1) on output shaft (2). Apply small

amount of petrolatum onto the shim to hold it in

place. Use the original shim as a starting point. If

original shim is not available, use the thickest

shim available.

Page 2972 of 5267

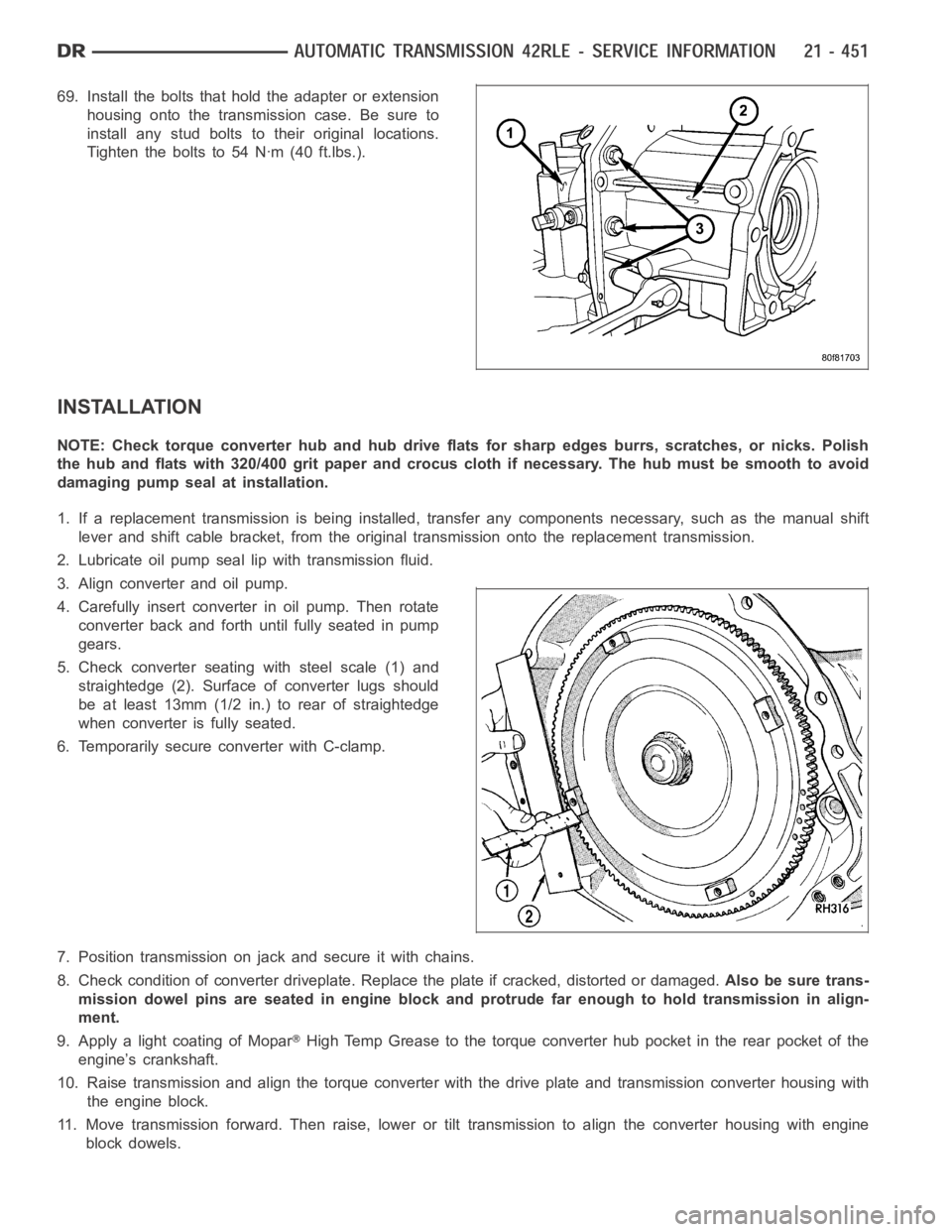

69. Install the bolts that hold the adapter or extension

housing onto the transmission case. Be sure to

install any stud bolts to their original locations.

Tighten the bolts to 54 Nꞏm (40 ft.lbs.).

INSTALLATION

NOTE: Check torque converter hub and hub drive flats for sharp edges burrs,scratches, or nicks. Polish

the hub and flats with 320/400 grit paper and crocus cloth if necessary. Thehub must be smooth to avoid

damaging pump seal at installation.

1. If a replacement transmission is being installed, transfer any components necessary, such as the manual shift

lever and shift cable bracket, from the original transmission onto the replacement transmission.

2. Lubricate oil pump seal lip with transmission fluid.

3. Align converter and oil pump.

4. Carefully insert converter in oil pump. Then rotate

converter back and forth until fully seated in pump

gears.

5. Check converter seating with steel scale (1) and

straightedge (2). Surface of converter lugs should

be at least 13mm (1/2 in.) to rear of straightedge

when converter is fully seated.

6. Temporarily secure converter with C-clamp.

7. Position transmission on jack and secure it with chains.

8. Check condition of converter driveplate. Replace the plate if cracked,distorted or damaged.Also be sure trans-

mission dowel pins are seated in engine block and protrude far enough to holdtransmissioninalign-

ment.

9. Apply a light coating of Mopar

High Temp Grease to the torque converter hub pocket in the rear pocket of the

engine’s crankshaft.

10. Raise transmission and align the torque converter with the drive plateand transmission converter housing with

the engine block.

11. Move transmission forward. Then raise, lower or tilt transmission to align the converter housing with engine

block dowels.

Page 3054 of 5267

SEAL-OIL PUMP

REMOVAL

1. Remove the transmission from the vehicle (Refer to 21 - TRANSMISSION/AUTOMATIC - 42RLE - REMOVAL).

2. Remove the torque converter from the transmission bellhousing.

3. Use a screw mounted in a slide hammer to remove oil pump seal.

INSTALLATION

1. Clean and inspect oil pump seal seat. Then install seal using Seal Installer C-4193-A.

2. Clean and inspect torque converter hub. If nicks, scratches or hub wear are found, torque converter replacement

will be required.

CAUTION: If the torque converter isbeing replaced, apply a light coating of grease to the crankshaft pilot

hole. Also inspect the engine drive plate for cracks. If any cracks are found replace the drive plate. Do not

attempt to repair a cracked drive plate. Always use new torque converter todrive plate bolts.

3. Apply a light film of transmission oil to the torque converter hub and oilseal lips. Then install torque converter

into transmission. Be sure that the hub lugs mesh with the front pump lugs when installing.

4. Reinstall the transmission into the vehicle. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE -

INSTALLATION)

Page 3068 of 5267

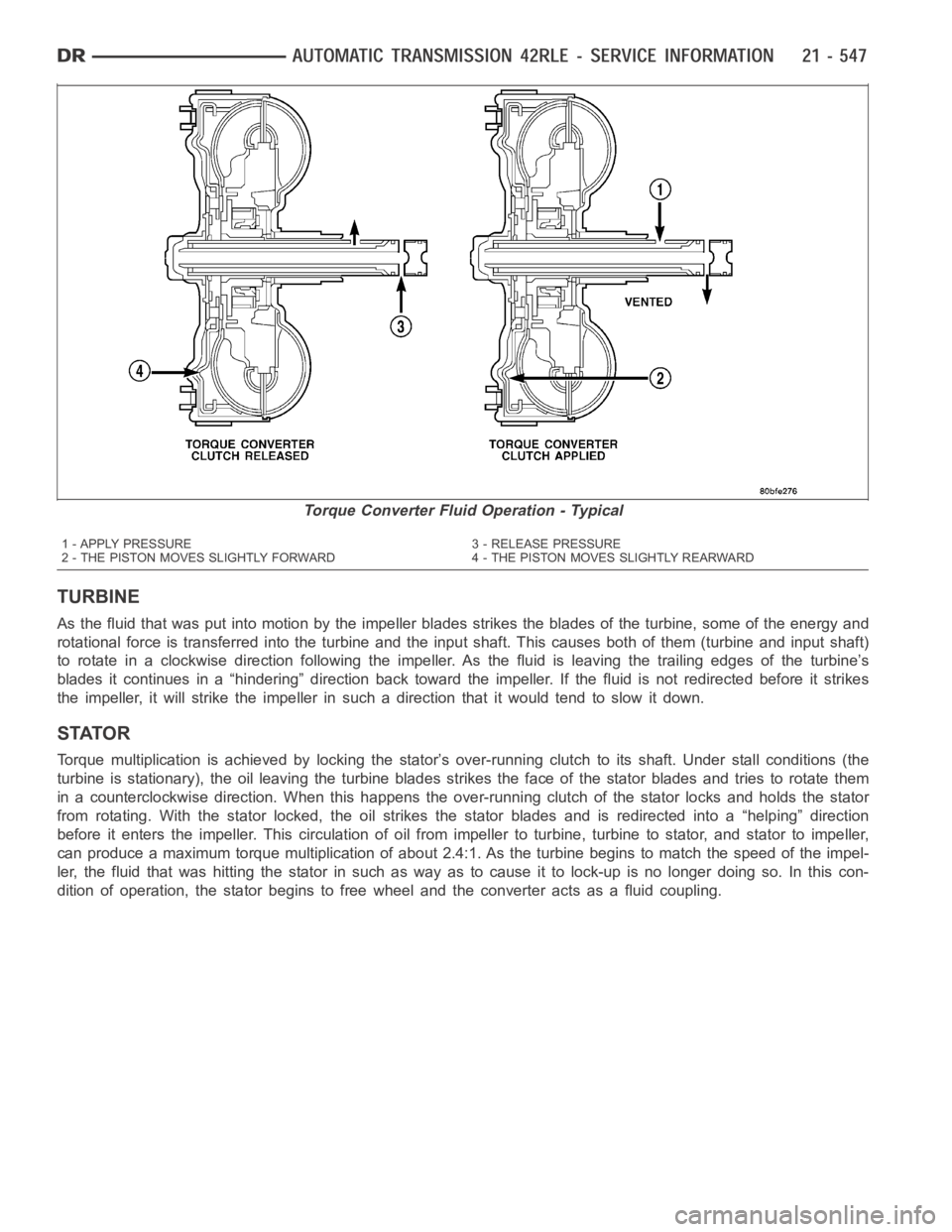

TURBINE

As the fluid that was put into motion bythe impeller blades strikes the blades of the turbine, some of the energy and

rotational force is transferred into the turbine and the input shaft. Thiscauses both of them (turbine and input shaft)

to rotate in a clockwise direction following the impeller. As the fluid is leaving the trailing edges of the turbine’s

blades it continues in a “hindering” direction back toward the impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a direction that it would tend to slow it down.

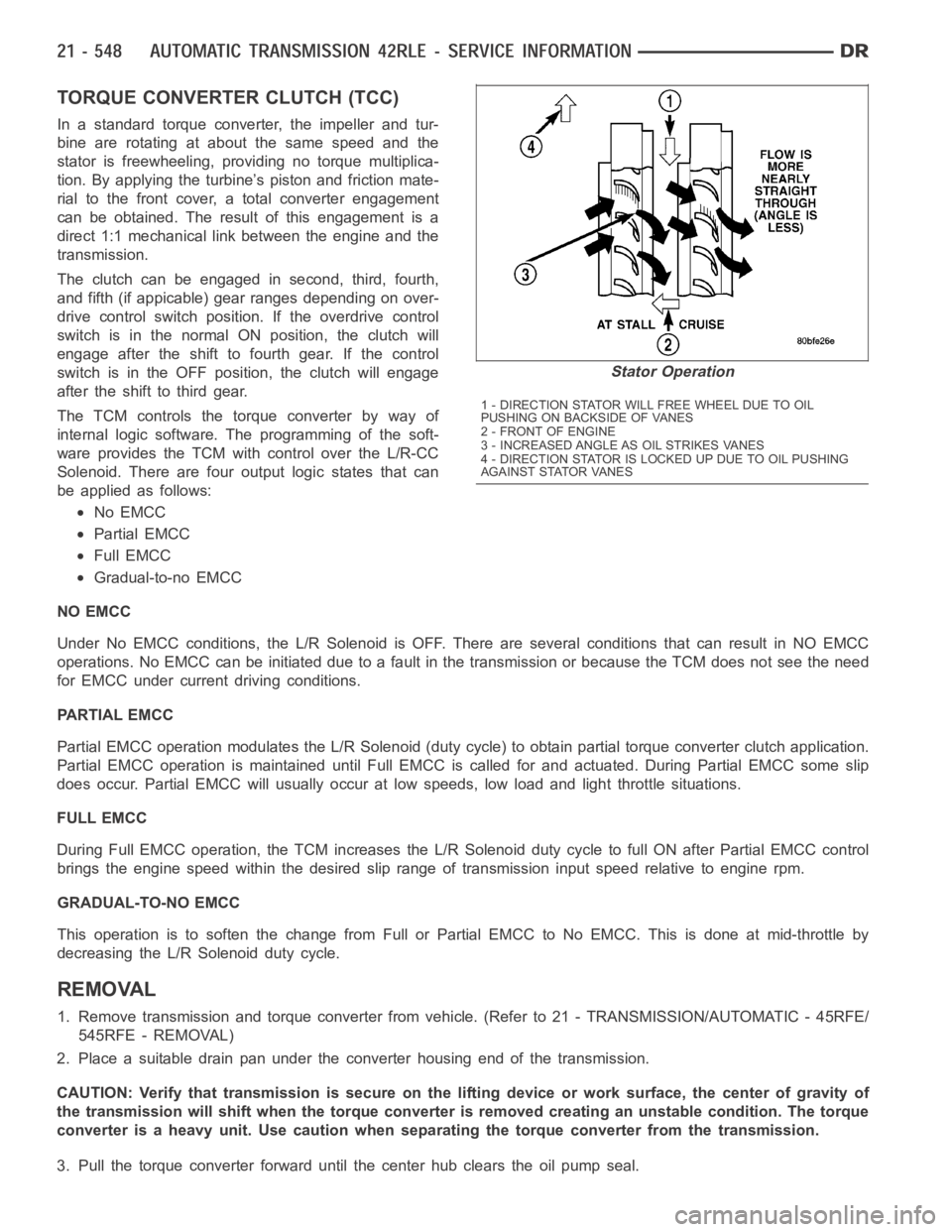

STATOR

Torque multiplication is achieved by locking the stator’s over-running clutch to its shaft. Under stall conditions (the

turbine is stationary), the oil leaving the turbine blades strikes the face of the stator blades and tries to rotate them

in a counterclockwise direction. When this happens the over-running clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes the stator blades and is redirected into a “helping” direction

before it enters the impeller. This circulation of oil from impeller to turbine, turbine to stator, and stator to impeller,

can produce a maximum torque multiplicationofabout2.4:1.Astheturbinebegins to match the speed of the impel-

ler, the fluid that was hitting the stator in such as way as to cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel and the converter actsas a fluid coupling.

Torque Converter Fluid Operation - Typical

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Page 3069 of 5267

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and tur-

bine are rotating at about the same speed and the

stator is freewheeling, providing no torque multiplica-

tion. By applying the turbine’s piston and friction mate-

rial to the front cover, a total converter engagement

can be obtained. The result of this engagement is a

direct 1:1 mechanical link between the engine and the

transmission.

The clutch can be engaged in second, third, fourth,

and fifth (if appicable) gear ranges depending on over-

drive control switch position. If the overdrive control

switch is in the normal ON position, the clutch will

engage after the shift to fourth gear. If the control

switch is in the OFF position, the clutch will engage

after the shift to third gear.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

No EMCC

Partial EMCC

Full EMCC

Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is OFF. There are several conditions that can result in NO EMCC

operations. No EMCC can be initiated due to a fault in the transmission or because the TCM does not see the need

for EMCC under current driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Solenoid (duty cycle) to obtain partial torque converter clutch application.

Partial EMCC operation is maintaineduntil Full EMCC is called for and actuated. During Partial EMCC some slip

does occur. Partial EMCC will usually occur at low speeds, low load and light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases the L/R Solenoid duty cycle to full ON after Partial EMCC control

brings the engine speed within the desired slip range of transmission input speed relative to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or Partial EMCC to No EMCC. This is done at mid-throttle by

decreasing the L/R Solenoid duty cycle.

REMOVAL

1. Remove transmission and torque converter from vehicle. (Refer to 21 - TRANSMISSION/AUTOMATIC - 45RFE/

545RFE - REMOVAL)

2. Place a suitable drain pan under the converter housing end of the transmission.

CAUTION: Verify that transmission is secure on the lifting device or work surface, the center of gravity of

the transmission will shift when the torque converter is removed creatingan unstable condition. The torque

converter is a heavy unit. Use caution when separating the torque converter from the transmission.

3. Pull the torque converter forward until the center hub clears the oil pumpseal.

Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2-FRONTOFENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

Page 3071 of 5267

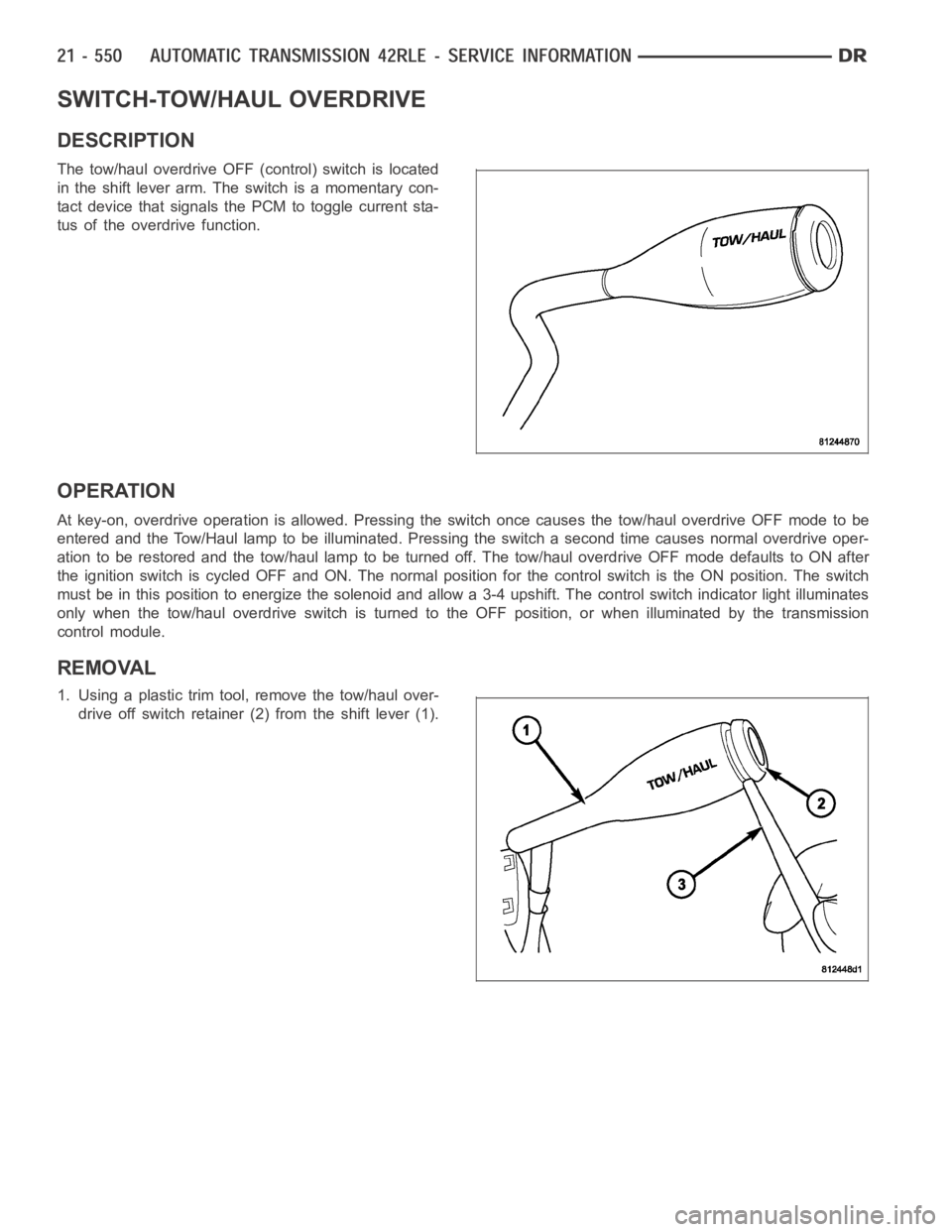

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION

The tow/haul overdrive OFF (control) switch is located

in the shift lever arm. The switch is a momentary con-

tact device that signals the PCM to toggle current sta-

tus of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing the switch once causes the tow/haul overdrive OFF mode to be

entered and the Tow/Haul lamp to be illuminated. Pressing the switch a second time causes normal overdrive oper-

ationtoberestoredandthetow/haullamptobeturnedoff.Thetow/hauloverdrive OFF mode defaults to ON after

the ignition switch is cycled OFF and ON. The normal position for the control switch is the ON position. The switch

must be in this position to energize the solenoid and allow a 3-4 upshift. The control switch indicator light illuminates

only when the tow/haul overdrive switch is turned to the OFF position, or when illuminated by the transmission

control module.

REMOVAL

1. Using a plastic trim tool, remove the tow/haul over-

drive off switch retainer (2) from the shift lever (1).

Page 3083 of 5267

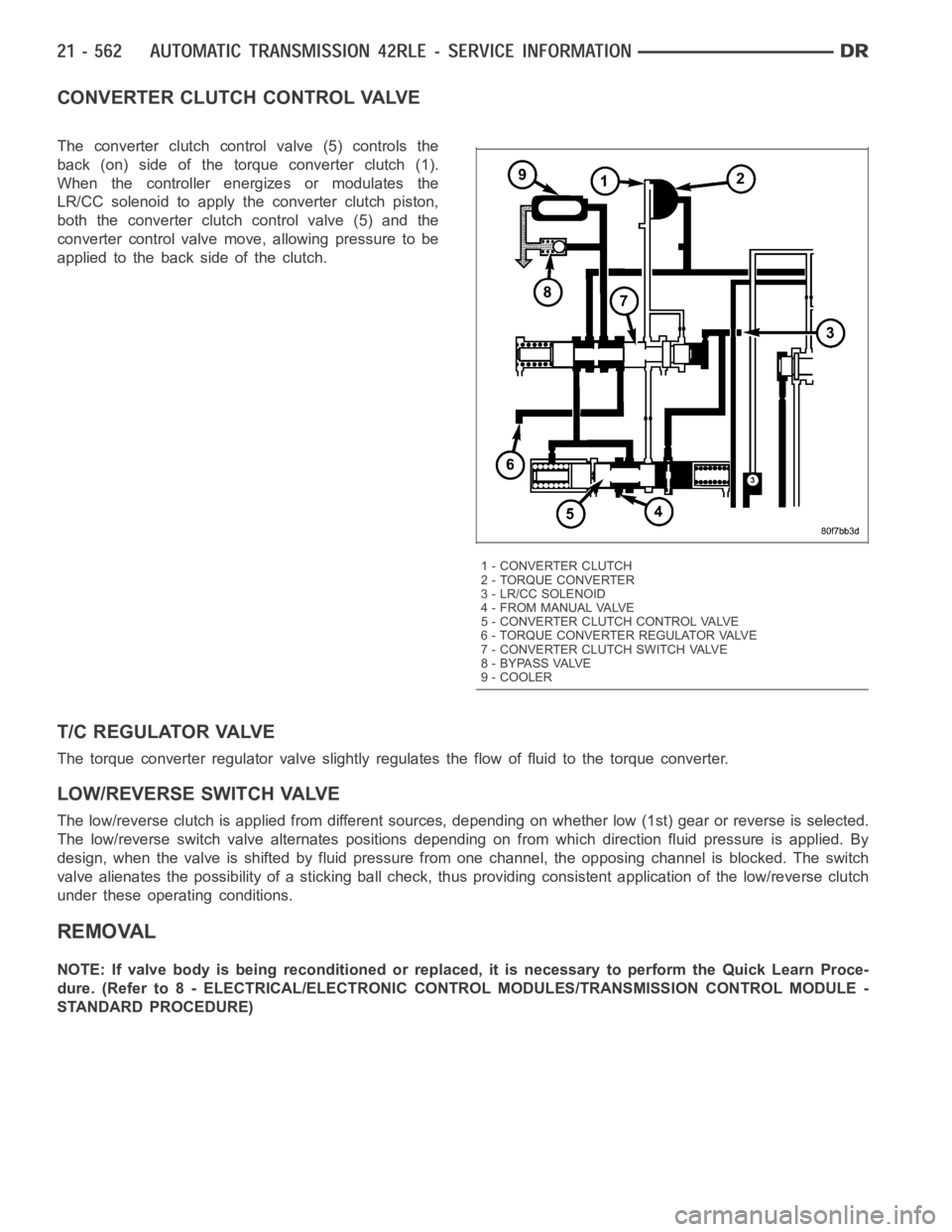

CONVERTER CLUTCH CONTROL VALVE

The converter clutch control valve (5) controls the

back (on) side of the torque converter clutch (1).

When the controller energizes or modulates the

LR/CC solenoid to apply the converter clutch piston,

both the converter clutch control valve (5) and the

converter control valve move, allowing pressure to be

applied to the back side of the clutch.

T/C REGULATOR VALVE

The torque converter regulator valve slightly regulates the flow of fluidto the torque converter.

LOW/REVERSE SWITCH VALVE

The low/reverse clutch is applied from different sources, depending on whether low (1st) gear or reverse is selected.

The low/reverse switch valve alternates positions depending on from which direction fluid pressure is applied. By

design, when the valve is shifted by fluid pressure from one channel, the opposing channel is blocked. The switch

valve alienates the possibility of a sticking ball check, thus providing consistent application of the low/reverse clutch

under these operating conditions.

REMOVAL

NOTE: If valve body is being reconditioned or replaced, it is necessary to perform the Quick Learn Proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/TRANSMISSIONCONTROL MODULE -

STANDARD PROCEDURE)

1 - CONVERTER CLUTCH

2 - TORQUE CONVERTER

3 - LR/CC SOLENOID

4 - FROM MANUAL VALVE

5 - CONVERTER CLUTCH CONTROL VALVE

6 - TORQUE CONVERTER REGULATOR VALVE

7 - CONVERTER CLUTCH SWITCH VALVE

8 - BYPASS VALVE

9 - COOLER

Page 3112 of 5267

3.CONDITION P0562 PRESENT

With the scan tool, read Transmission DTCs.

With the scan tool, Check the STARTS SINCE SET counter for P0562.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter set at 0?

Ye s>>

Go To 4

No>>

Go To 7

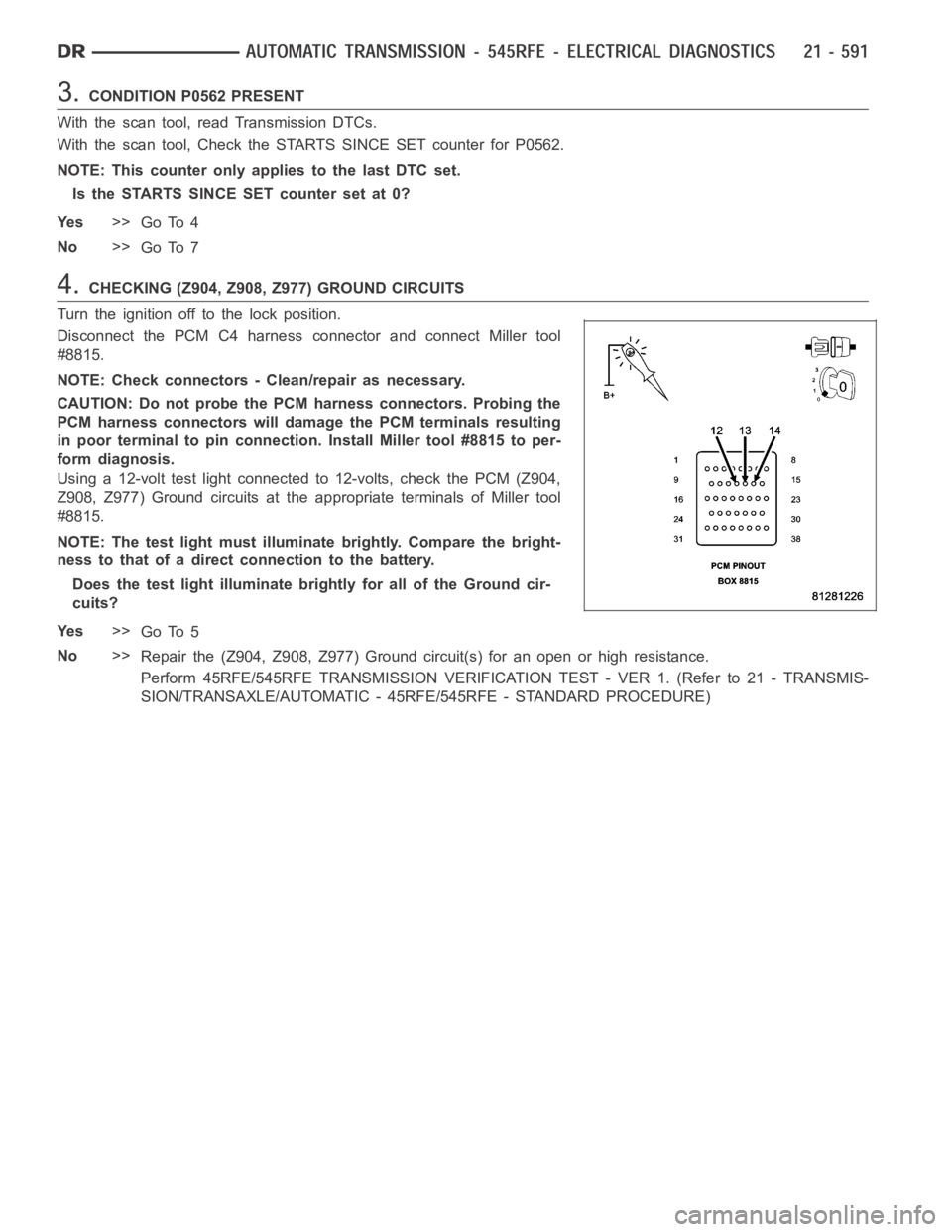

4.CHECKING (Z904, Z908, Z977) GROUND CIRCUITS

Turn the ignition off to the lock position.

Disconnect the PCM C4 harness connector and connect Miller tool

#8815.

NOTE: Check connectors - Clean/repair as necessary.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Using a 12-volt test light connected to 12-volts, check the PCM (Z904,

Z908, Z977) Ground circuits at the appropriate terminals of Miller tool

#8815.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly for all of the Ground cir-

cuits?

Ye s>>

Go To 5

No>>

Repair the (Z904, Z908, Z977) Ground circuit(s) for an open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3113 of 5267

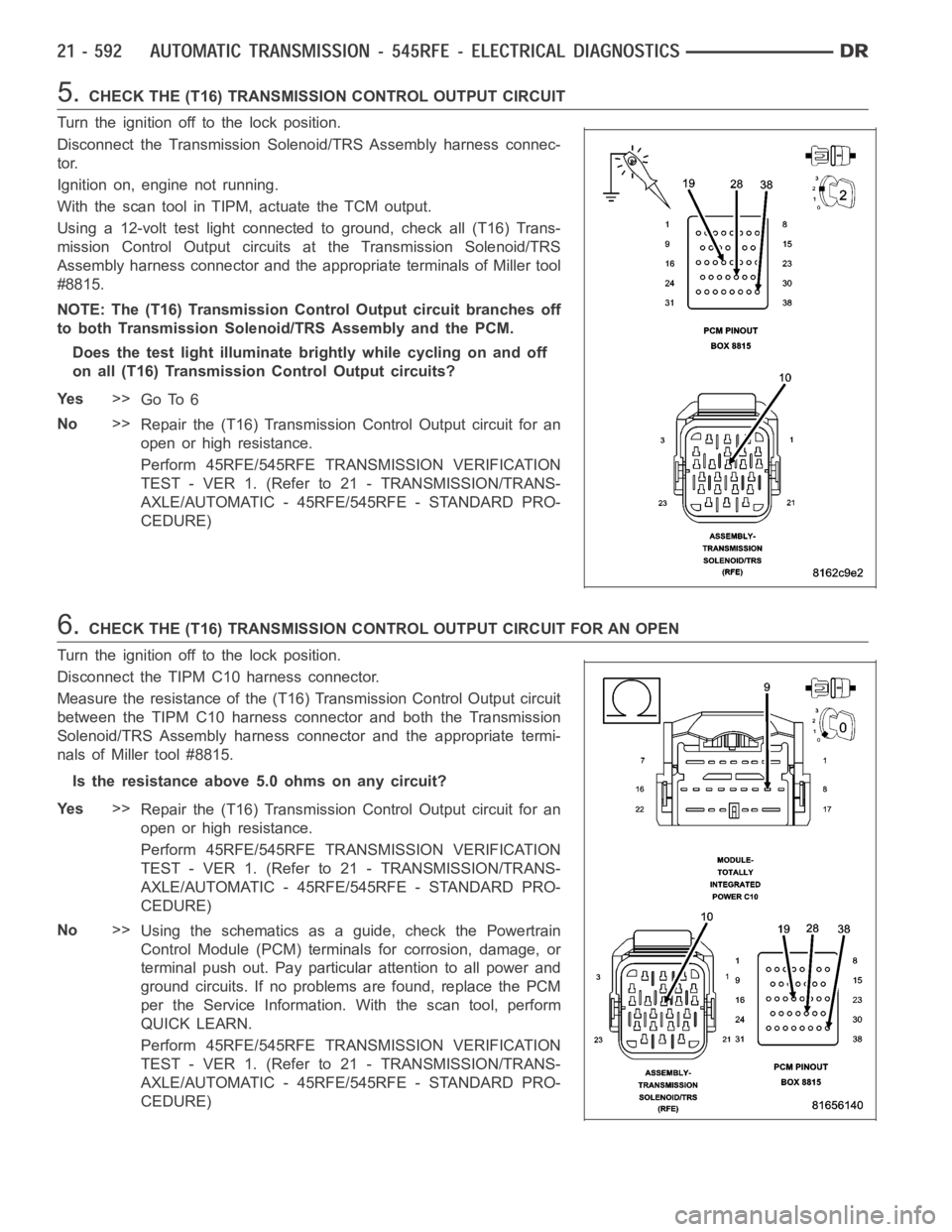

5.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/TRS Assembly harness connec-

tor.

Ignition on, engine not running.

With the scan tool in TIPM, actuate the TCM output.

Using a 12-volt test light connected to ground, check all (T16) Trans-

mission Control Output circuits at the Transmission Solenoid/TRS

Assembly harness connector and the appropriate terminals of Miller tool

#8815.

NOTE: The (T16) Transmission Control Output circuit branches off

to both Transmission Solenoid/TRS Assembly and the PCM.

Does the test light illuminate brightly while cycling on and off

on all (T16) Transmission Control Output circuits?

Ye s>>

Go To 6

No>>

Repair the (T16) Transmission Control Output circuit for an

open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

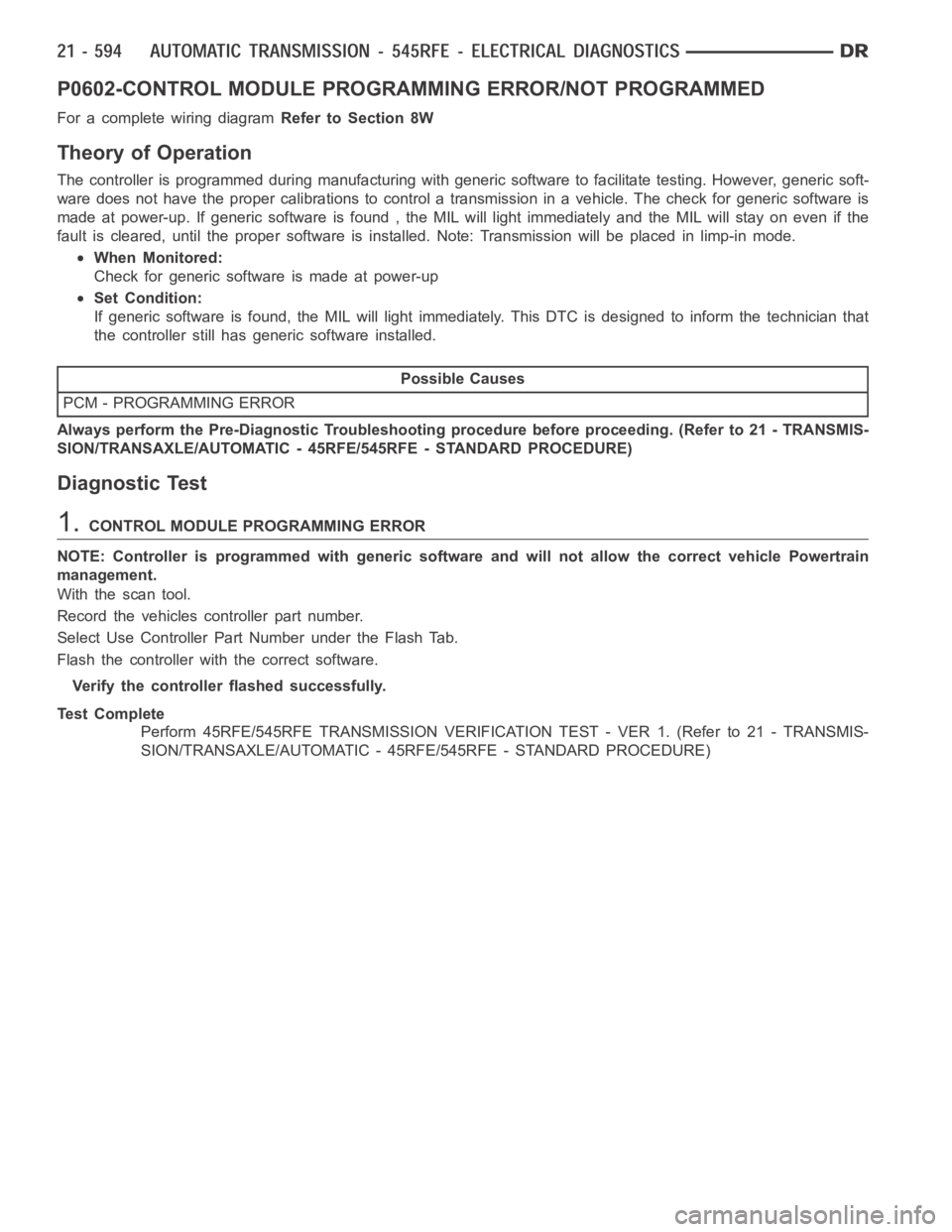

6.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C10 harness connector.

Measure the resistance of the (T16) Transmission Control Output circuit

between the TIPM C10 harness connector and both the Transmission

Solenoid/TRS Assembly harness connector and the appropriate termi-

nals of Miller tool #8815.

Is the resistance above 5.0 ohms on any circuit?

Ye s>>

Repair the (T16) Transmission Control Output circuit for an

open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

Page 3115 of 5267

P0602-CONTROL MODULE PROGRAMMING ERROR/NOT PROGRAMMED

For a complete wiring diagramRefer to Section 8W

Theory of Operation

The controller is programmed during manufacturing with generic softwareto facilitate testing. However, generic soft-

ware does not have the proper calibrations to control a transmission in a vehicle. The check for generic software is

made at power-up. If generic software is found , the MIL will light immediately and the MIL will stay on even if the

fault is cleared, until the proper software is installed. Note: Transmission will be placed in limp-in mode.

When Monitored:

Check for generic software is made at power-up

Set Condition:

If generic software is found, the MIL will light immediately. This DTC is designed to inform the technician that

the controller still has generic software installed.

Possible Causes

PCM - PROGRAMMING ERROR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.CONTROL MODULE PROGRAMMING ERROR

NOTE: Controller is programmed with generic software and will not allow the correct vehicle Powertrain

management.

With the scan tool.

Record the vehicles controller part number.

Select Use Controller Part Number under the Flash Tab.

Flash the controller with the correct software.

Verify the controller flashed successfully.

Te s t C o m p l e t e

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)