DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Page 2180 of 5267

REAR BUMPER

REMOVAL

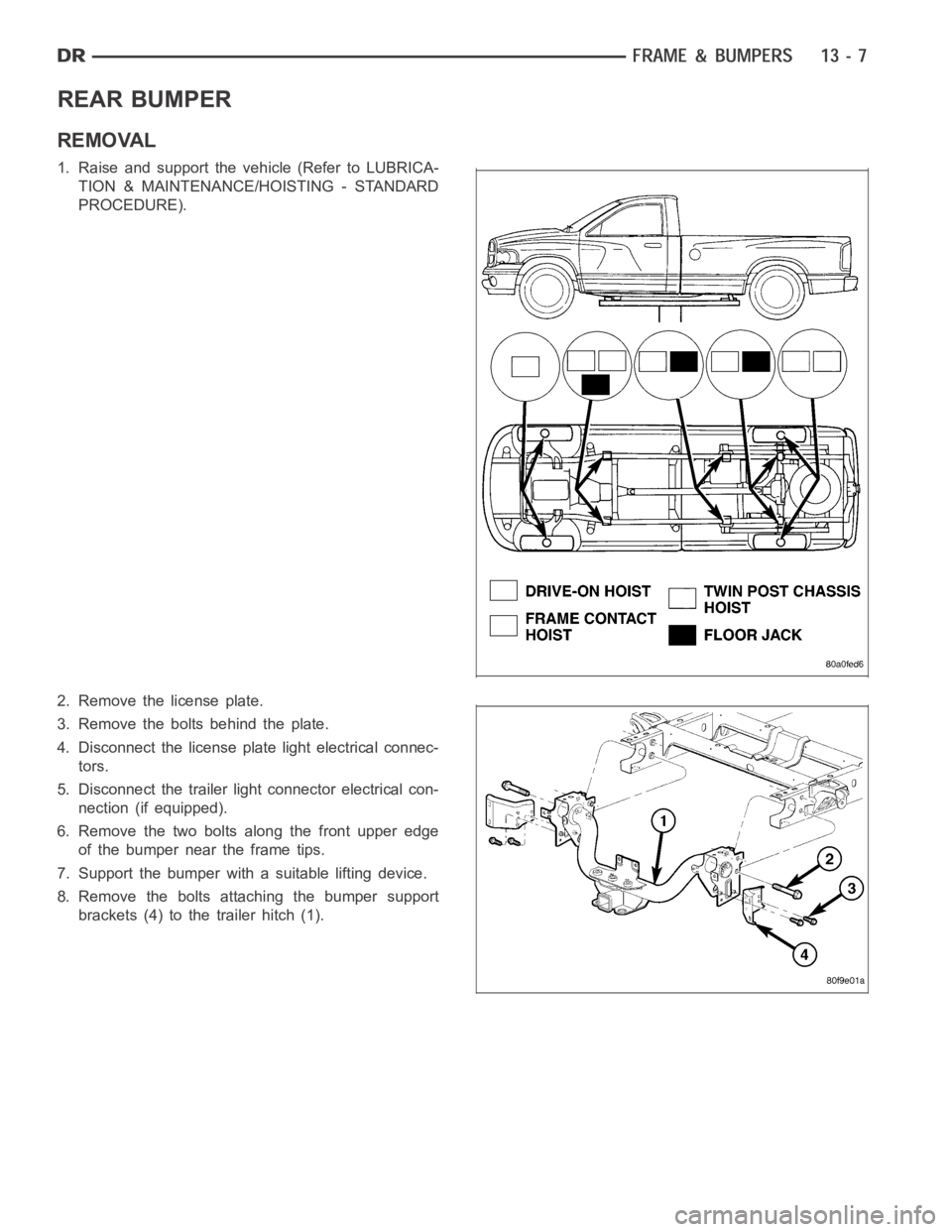

1. Raise and support the vehicle (Refer to LUBRICA-

TION & MAINTENANCE/HOISTING - STANDARD

PROCEDURE).

2. Remove the license plate.

3. Remove the bolts behind the plate.

4. Disconnect the license plate light electrical connec-

tors.

5. Disconnect the trailer light connector electrical con-

nection (if equipped).

6. Remove the two bolts along the front upper edge

of the bumper near the frame tips.

7. Support the bumper with a suitable lifting device.

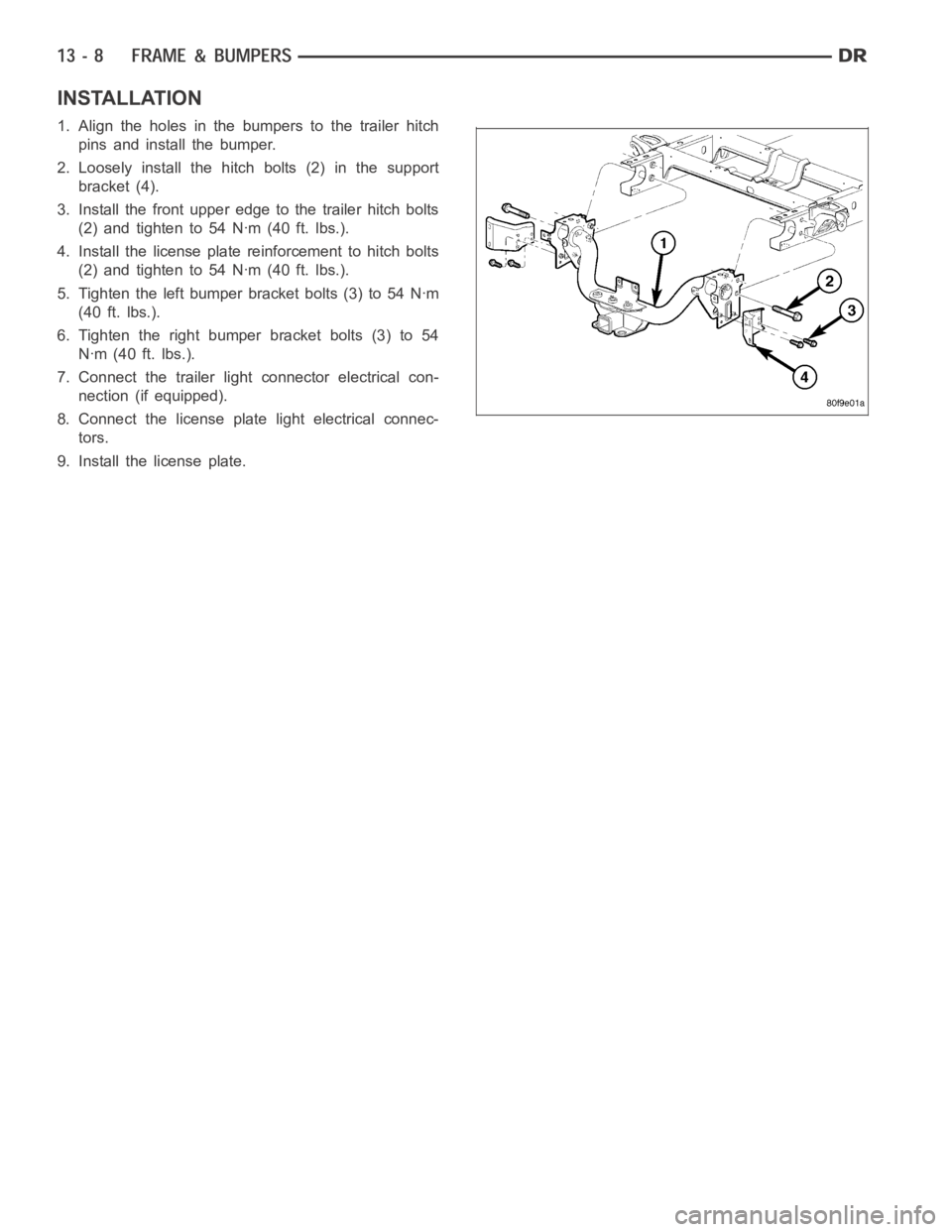

8. Remove the bolts attaching the bumper support

brackets (4) to the trailer hitch (1).

Page 2181 of 5267

INSTALLATION

1. Align the holes in the bumpers to the trailer hitch

pins and install the bumper.

2. Loosely install the hitch bolts (2) in the support

bracket (4).

3. Install the front upper edge to the trailer hitch bolts

(2)andtightento54Nꞏm(40ft.lbs.).

4. Install the license plate reinforcement to hitch bolts

(2)andtightento54Nꞏm(40ft.lbs.).

5. Tighten the left bumper bracket bolts (3) to 54 Nꞏm

(40 ft. lbs.).

6. Tighten the right bumper bracket bolts (3) to 54

Nꞏm (40 ft. lbs.).

7. Connect the trailer light connector electrical con-

nection (if equipped).

8. Connect the license plate light electrical connec-

tors.

9. Install the license plate.

Page 2194 of 5267

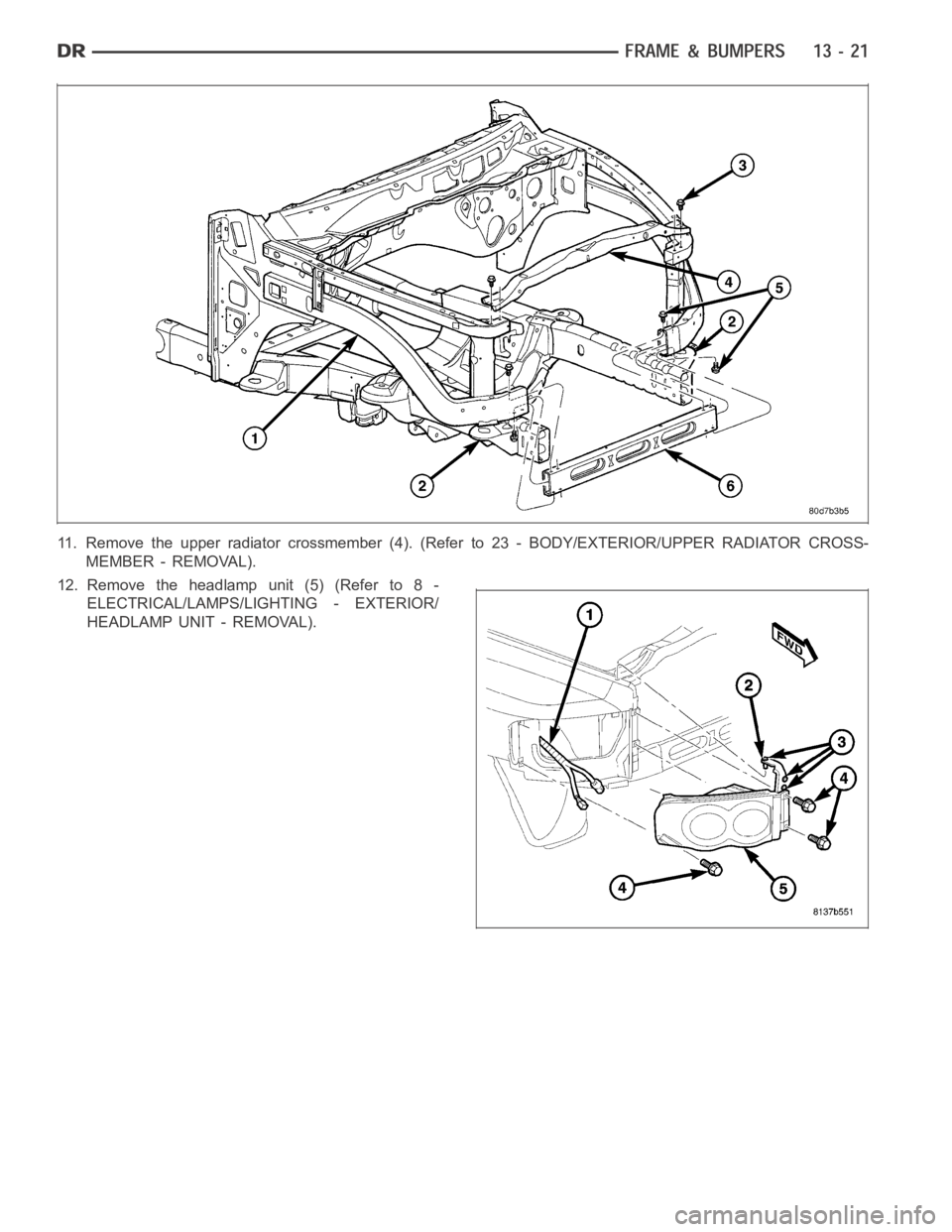

11. Remove the upper radiator crossmember (4). (Refer to 23 - BODY/EXTERIOR/UPPER RADIATOR CROSS-

MEMBER - REMOVAL).

12. Remove the headlamp unit (5) (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL).

Page 2197 of 5267

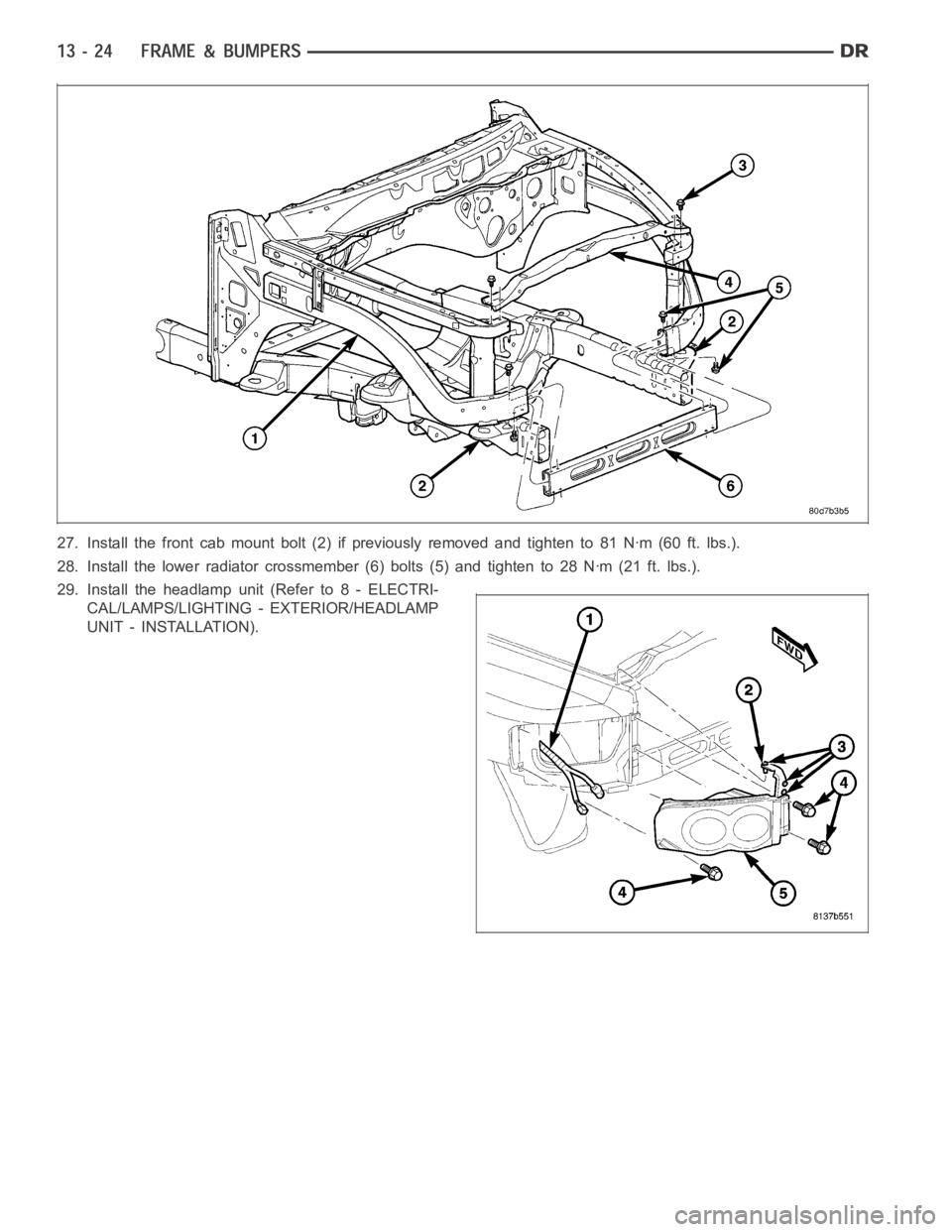

27. Install the front cab mount bolt (2) if previously removed and tighten to81Nꞏm(60ft.lbs.).

28. Install the lower radiator crossmember (6) bolts (5) and tighten to 28 Nꞏm ( 2 1 f t . l b s . ) .

29. Install the headlamp unit (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/HEADLAMP

UNIT - INSTALLATION).

Page 2218 of 5267

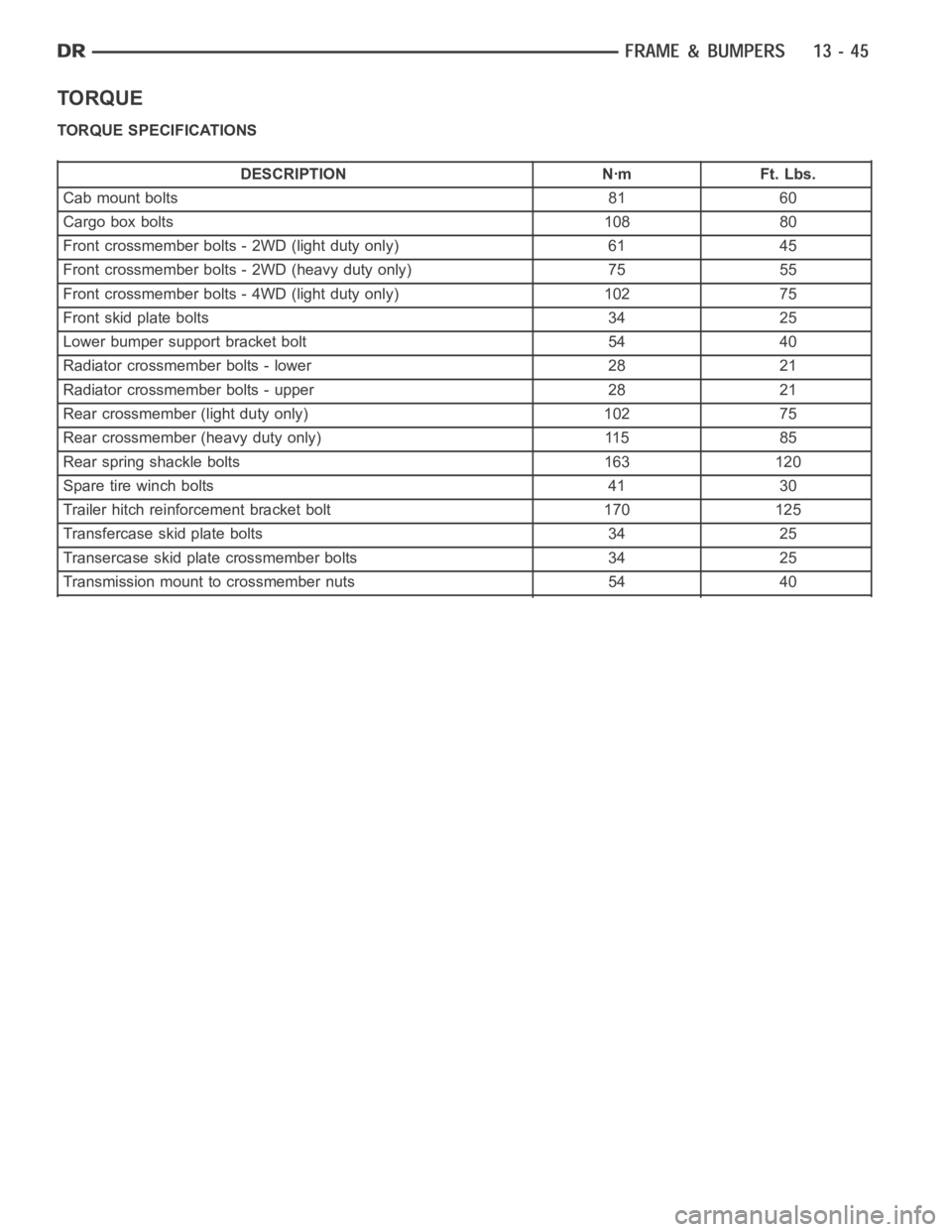

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs.

Cab mount bolts 81 60

Cargo box bolts 108 80

Front crossmember bolts - 2WD (light duty only) 61 45

Front crossmember bolts - 2WD (heavy duty only) 75 55

Front crossmember bolts - 4WD (light duty only) 102 75

Front skid plate bolts 34 25

Lower bumper support bracket bolt 54 40

Radiator crossmember bolts - lower 28 21

Radiator crossmember bolts - upper 28 21

Rear crossmember (light duty only) 102 75

Rear crossmember (heavy duty only) 115 85

Rear spring shackle bolts 163 120

Sparetirewinchbolts 41 30

Trailer hitch reinforcement bracket bolt 170 125

Transfercase skid plate bolts 34 25

Transercase skid plate crossmember bolts 34 25

Transmission mount to crossmember nuts 54 40

Page 2221 of 5267

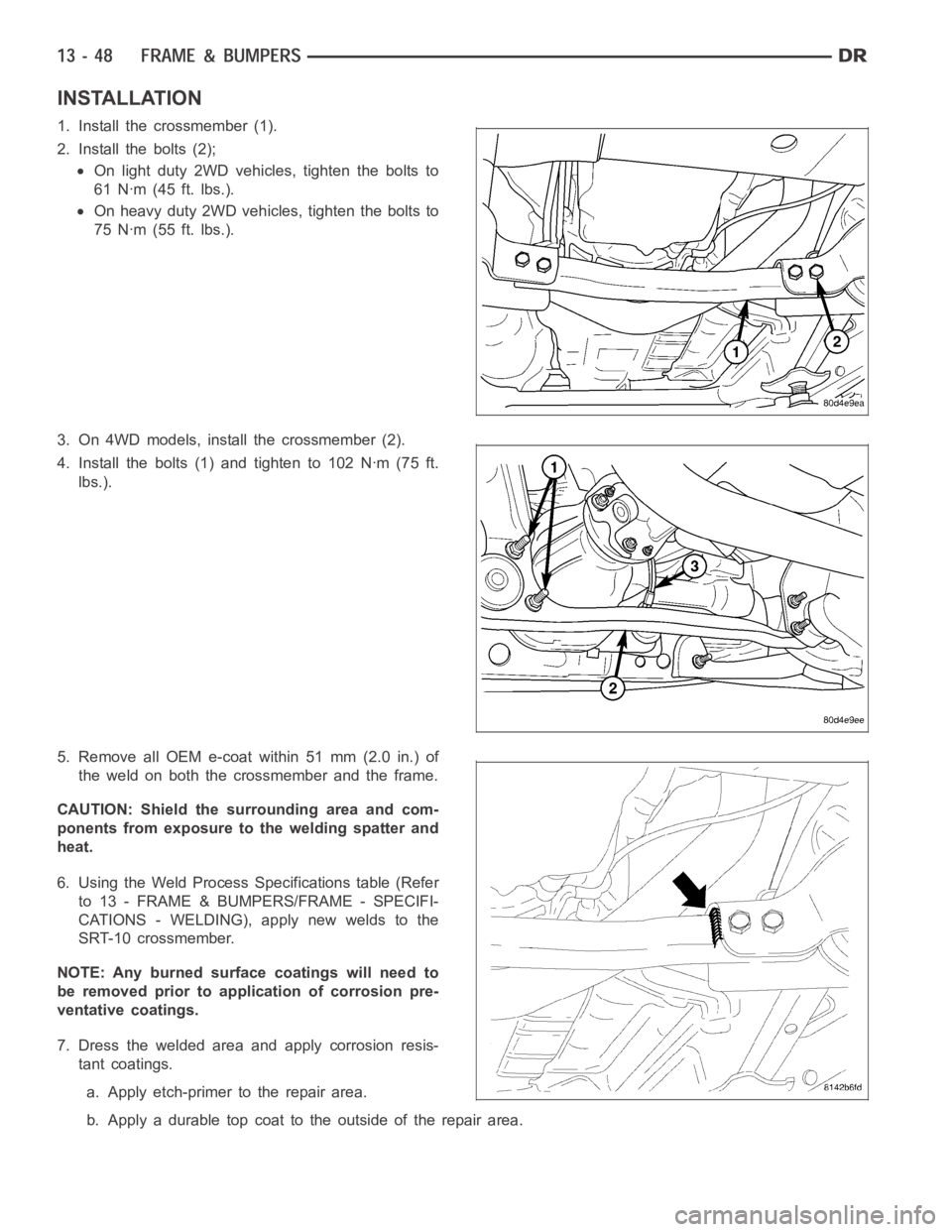

INSTALLATION

1. Install the crossmember (1).

2. Install the bolts (2);

On light duty 2WD vehicles, tighten the bolts to

61 Nꞏm (45 ft. lbs.).

On heavy duty 2WD vehicles, tighten the bolts to

75 Nꞏm (55 ft. lbs.).

3. On 4WD models, install the crossmember (2).

4. Install the bolts (1) and tighten to 102 Nꞏm (75 ft.

lbs.).

5. Remove all OEM e-coat within 51 mm (2.0 in.) of

the weld on both the crossmember and the frame.

CAUTION: Shield the surrounding area and com-

ponents from exposure to the welding spatter and

heat.

6. Using the Weld Process Specifications table (Refer

to 13 - FRAME & BUMPERS/FRAME - SPECIFI-

CATIONS - WELDING), apply new welds to the

SRT-10 crossmember.

NOTE: Any burned surface coatings will need to

be removed prior to application of corrosion pre-

ventative coatings.

7. Dress the welded area and apply corrosion resis-

tant coatings.

a. Apply etch-primer to the repair area.

b. Apply a durable top coat to the outside of the repair area.

Page 2229 of 5267

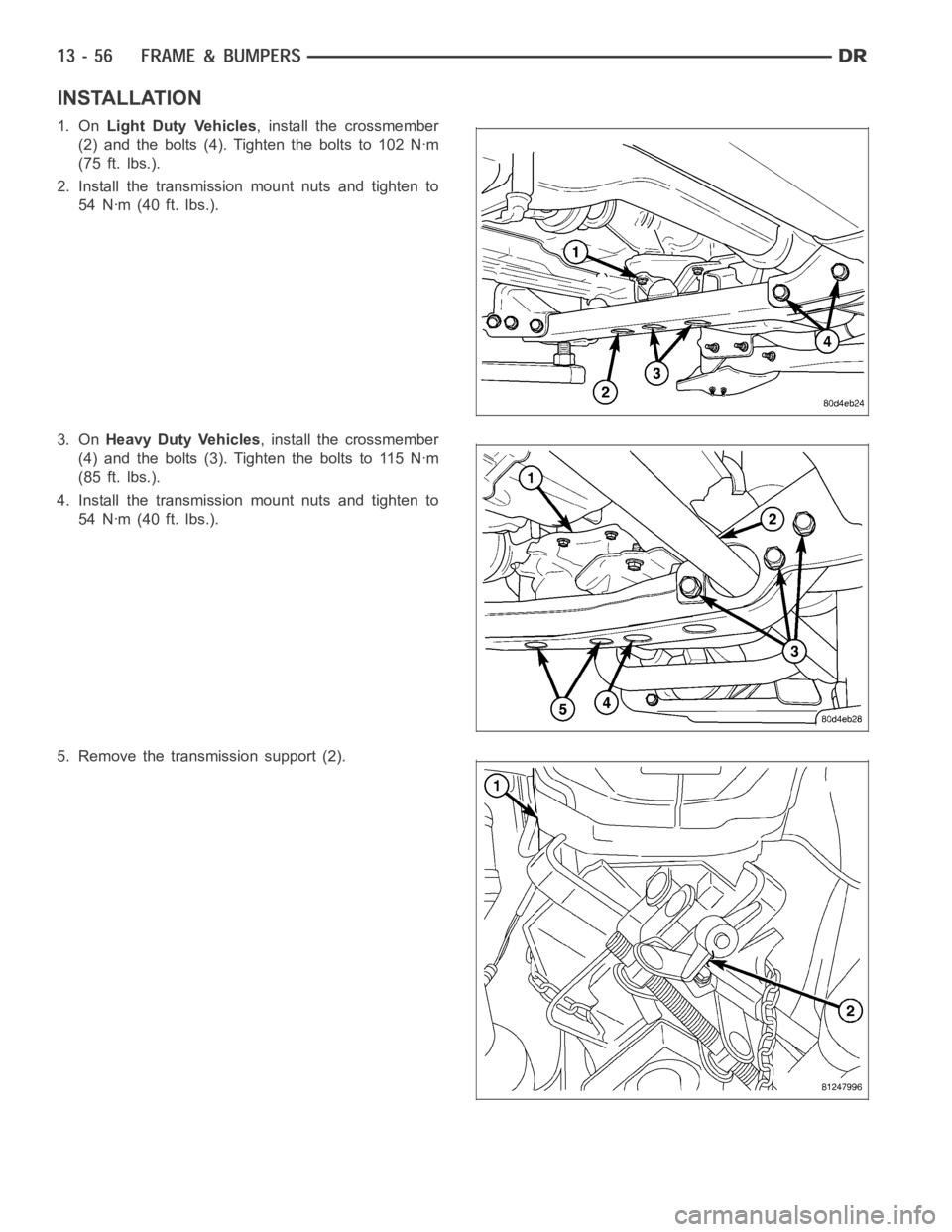

INSTALLATION

1. OnLight Duty Vehicles, install the crossmember

(2) and the bolts (4). Tighten the bolts to 102 Nꞏm

(75 ft. lbs.).

2. Install the transmission mount nuts and tighten to

54 Nꞏm (40 ft. lbs.).

3. OnHeavy Duty Vehicles, install the crossmember

(4) and the bolts (3). Tighten the bolts to 115 Nꞏm

(85 ft. lbs.).

4. Install the transmission mount nuts and tighten to

54 Nꞏm (40 ft. lbs.).

5. Remove the transmission support (2).

Page 2231 of 5267

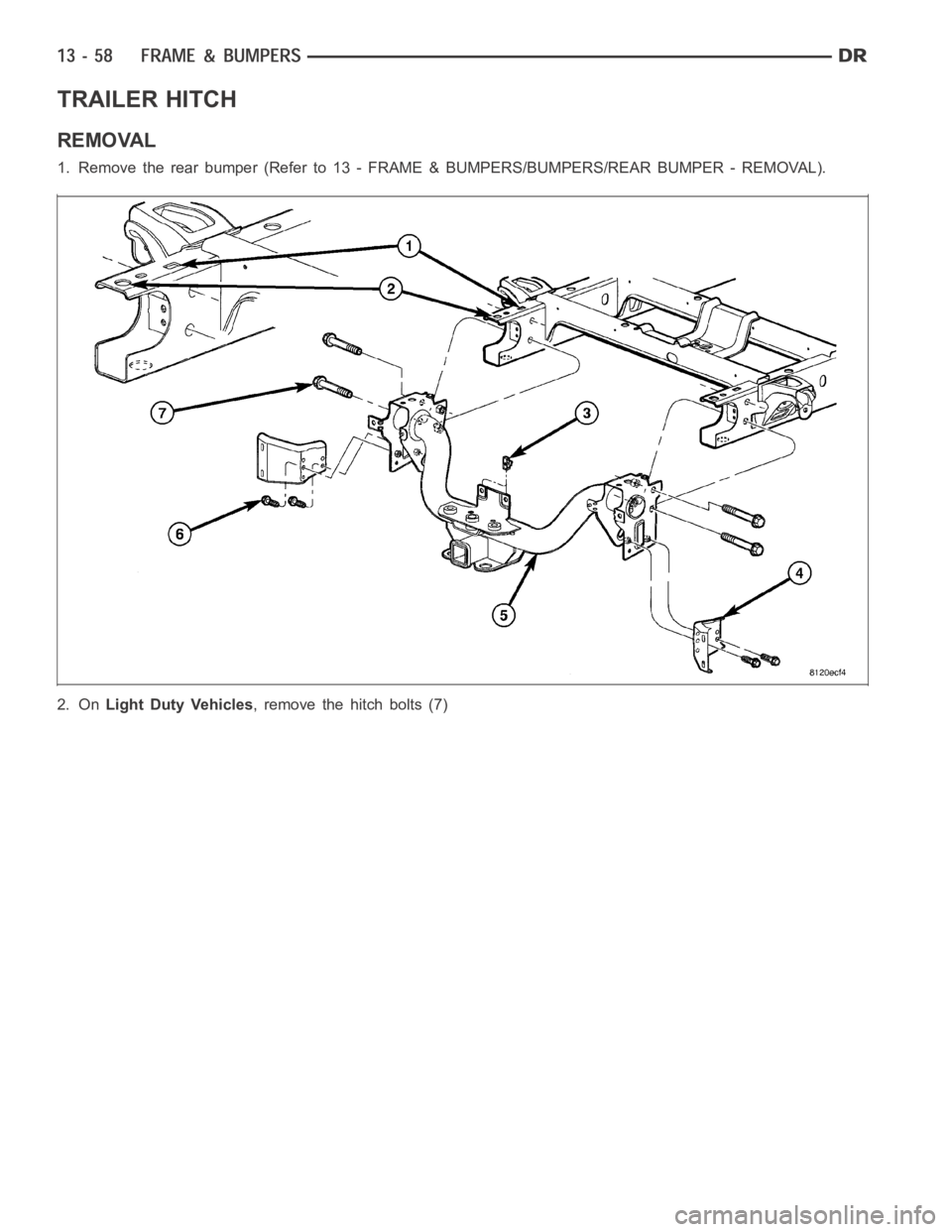

TRAILER HITCH

REMOVAL

1. Remove the rear bumper (Refer to 13 -FRAME & BUMPERS/BUMPERS/REAR BUMPER-REMOVAL).

2. OnLight Duty Vehicles, remove the hitch bolts (7)

Page 2233 of 5267

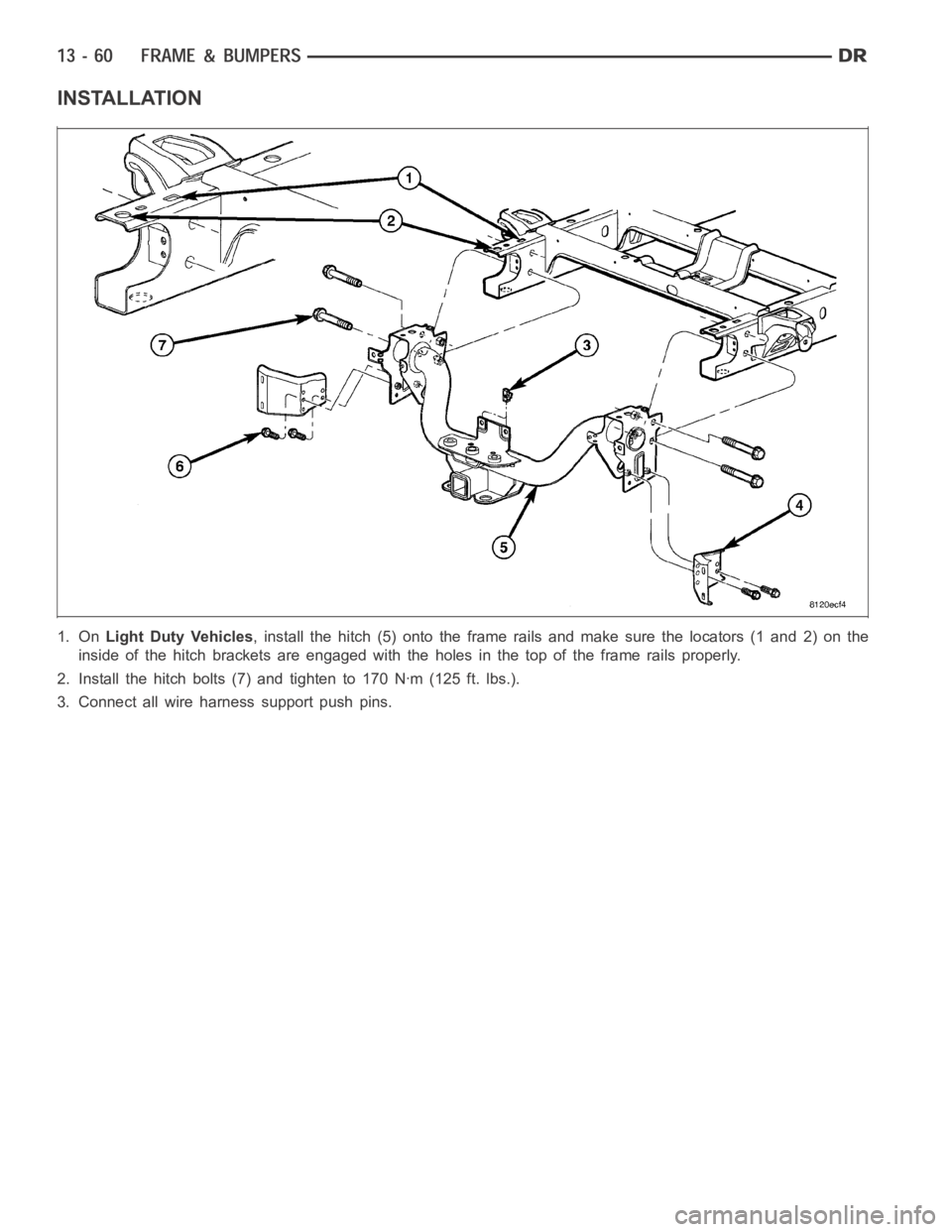

INSTALLATION

1. OnLight Duty Vehicles, install the hitch (5) onto the frame rails and make sure the locators (1 and2) on the

inside of the hitch brackets are engaged with the holes in the top of the frame rails properly.

2. Install the hitch bolts (7) and tighten to 170 Nꞏm (125 ft. lbs.).

3. Connect all wire harness support push pins.

Page 2257 of 5267

MODULE - FUEL PUMP

DESCRIPTION

The fuel pump module assembly is located on the top of the fuel tank. The complete assembly contains the fol-

lowing components:

A combination fuel filter/fuel pressure regulator

A separate fuel pick-up, or inlet filter

An electric fuel pump

Alockringtoretainpumpmoduletotank

A soft gasket between tank flange and module

A fuel gauge sending unit (fuel level sensor)

Fuel line connection

The fuel gauge sending unit may be serviced separately. If the electrical fuel pump, primary inlet filter, fuel filter or

fuel pressure regulator require service, the fuel pump module must be replaced.

OPERATION

Refer to Fuel Pump, Inlet Filter, Fuel Filter / Fuel Pressure Regulator andFuel Gauge Sending Unit.

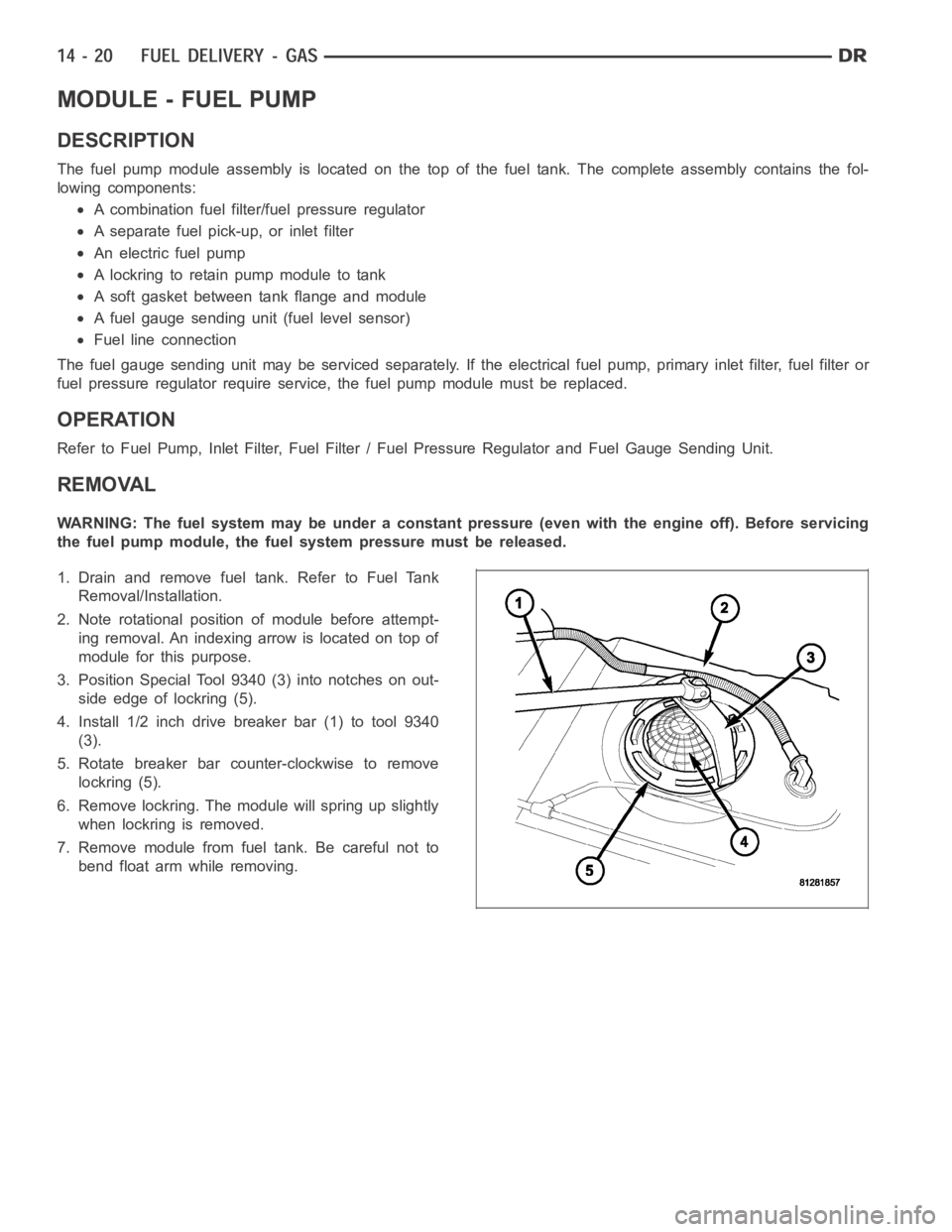

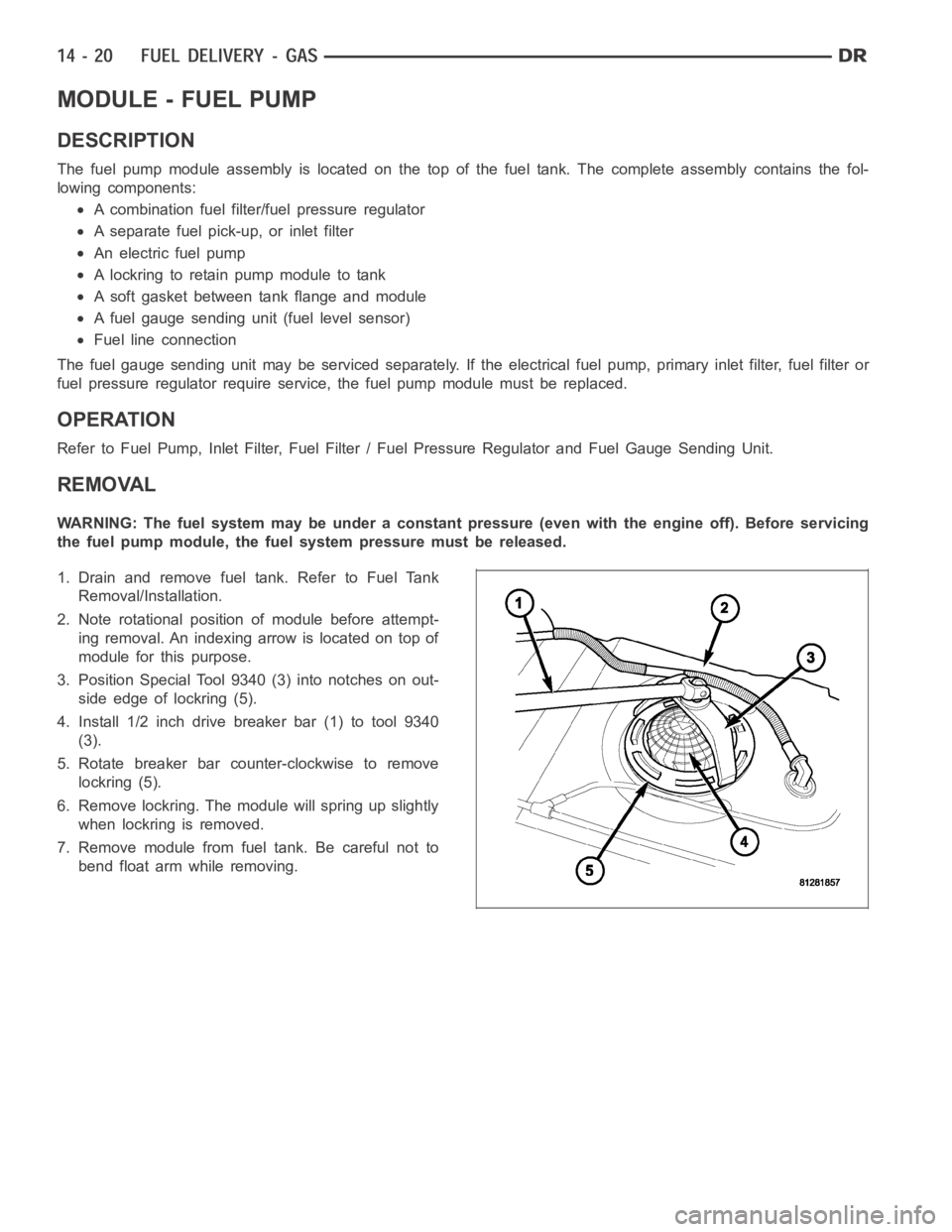

REMOVAL

WARNING: The fuel system may be under a constant pressure (even with the engine off). Before servicing

the fuel pump module, the fuel system pressure must be released.

1. Drain and remove fuel tank. Refer to Fuel Tank

Removal/Installation.

2. Note rotational position of module before attempt-

ing removal. An indexing arrow is located on top of

module for this purpose.

3. Position Special Tool 9340 (3) into notches on out-

side edge of lockring (5).

4. Install 1/2 inch drive breaker bar (1) to tool 9340

(3).

5. Rotate breaker bar counter-clockwise to remove

lockring (5).

6. Remove lockring. The module will spring up slightly

when lockring is removed.

7. Remove module from fuel tank. Be careful not to

bend float arm while removing.